Zero water consumption stainless energy-saving combined condenser

A condenser and water vapor technology, applied in evaporators/condensers, steam/steam condensers, refrigerators, etc., can solve the problems of energy consumption, water fouling, water consumption, etc., and achieve the effect of extending the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

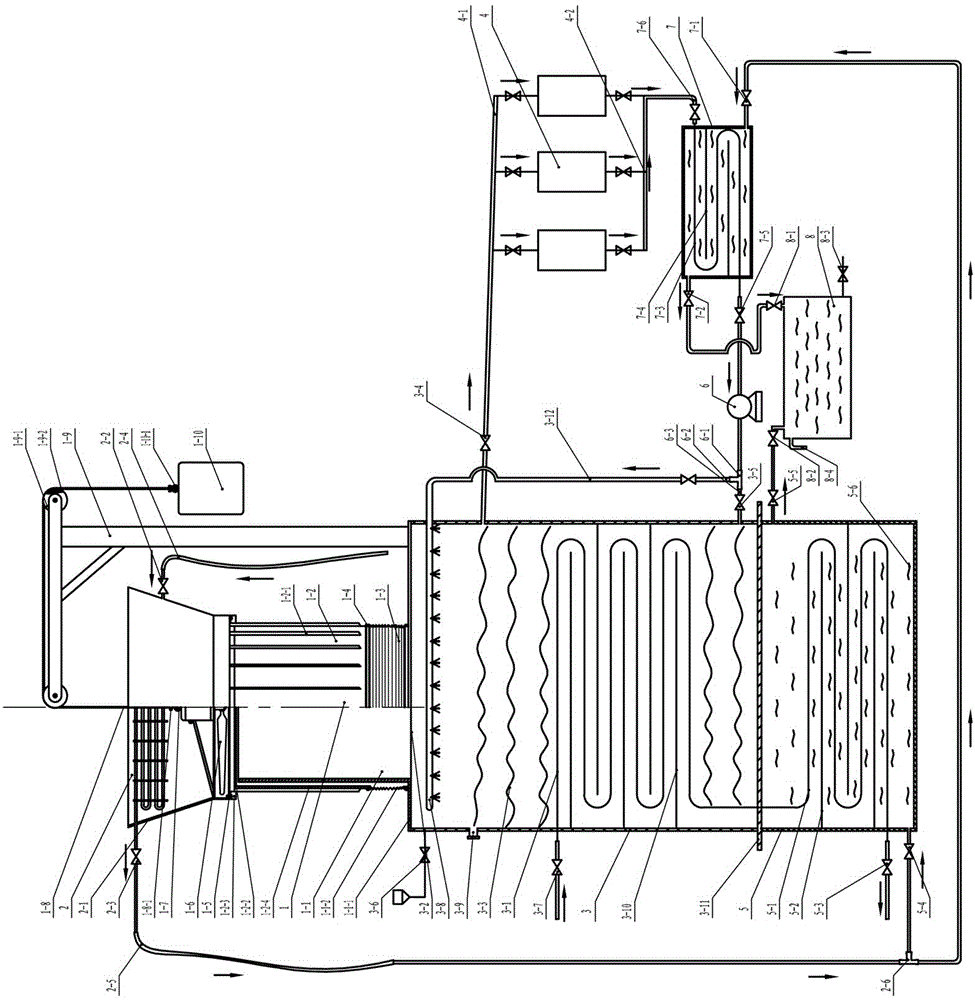

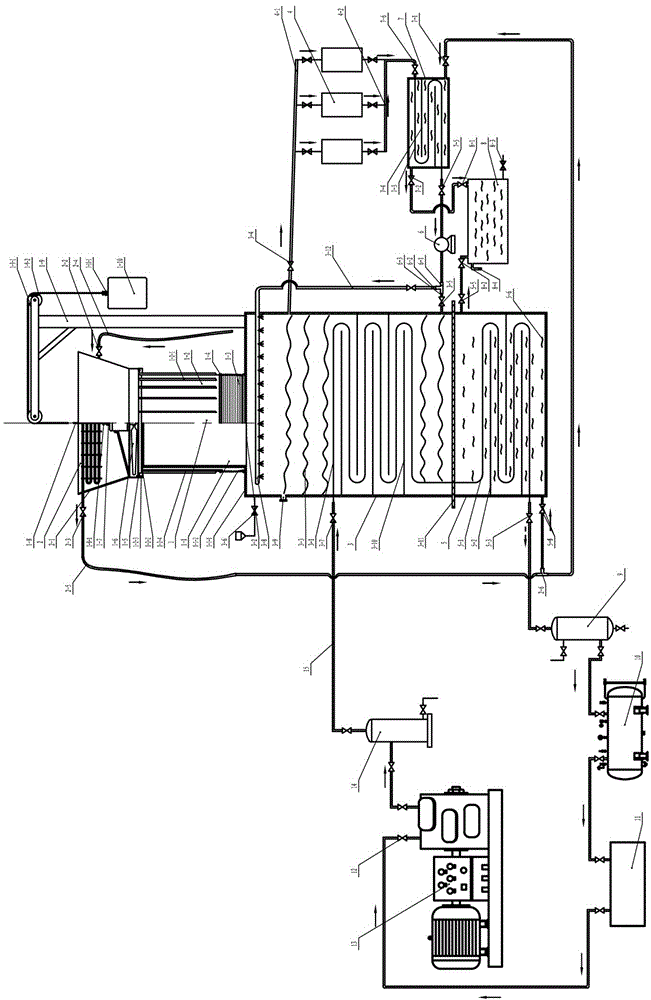

[0008] Such as figure 1 , figure 2 In the shown embodiment, after unscrewing the screw plug of the assembled horizontal nut screw plug assembly (3-9) of the present invention, the valves of the water inlet and the valve (3-6) and all related valves are all opened , add heat exchange water (3-3) to the normal pressure heat exchanger box (3), cooling fins (4), etc., and wait for the horizontal nut plug assembly (3-9) to flow out the heat exchange water (3- 3) Stop filling and close the water filling port and valve (3-4). Connect the tap water inlet hose (2-4) to the tap water pipe, and seal the gaseous refrigerant input main pipe and valve (3-7) with the gaseous refrigerant output pipe and valve (15). After the output main pipe and valve (5-3) are sealed and connected with the gas-liquid separator (9), then connect the gas-liquid separator (9), refrigerant liquid storage device (10), cold storage refrigeration evaporator (11), refrigerant Compressor assembly (13) and buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com