Full-natural automatic-control granary ventilation and drying device

A ventilation and drying technology with natural energy, which is applied in the field of ventilation and drying of granaries, can solve the problems of affecting the food quality and economic value of rice processing, increasing the crack rate of rice, and large drying energy consumption, so as to achieve controllable dry humidity of the intake and exhaust, and save Energy, effect of improving ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

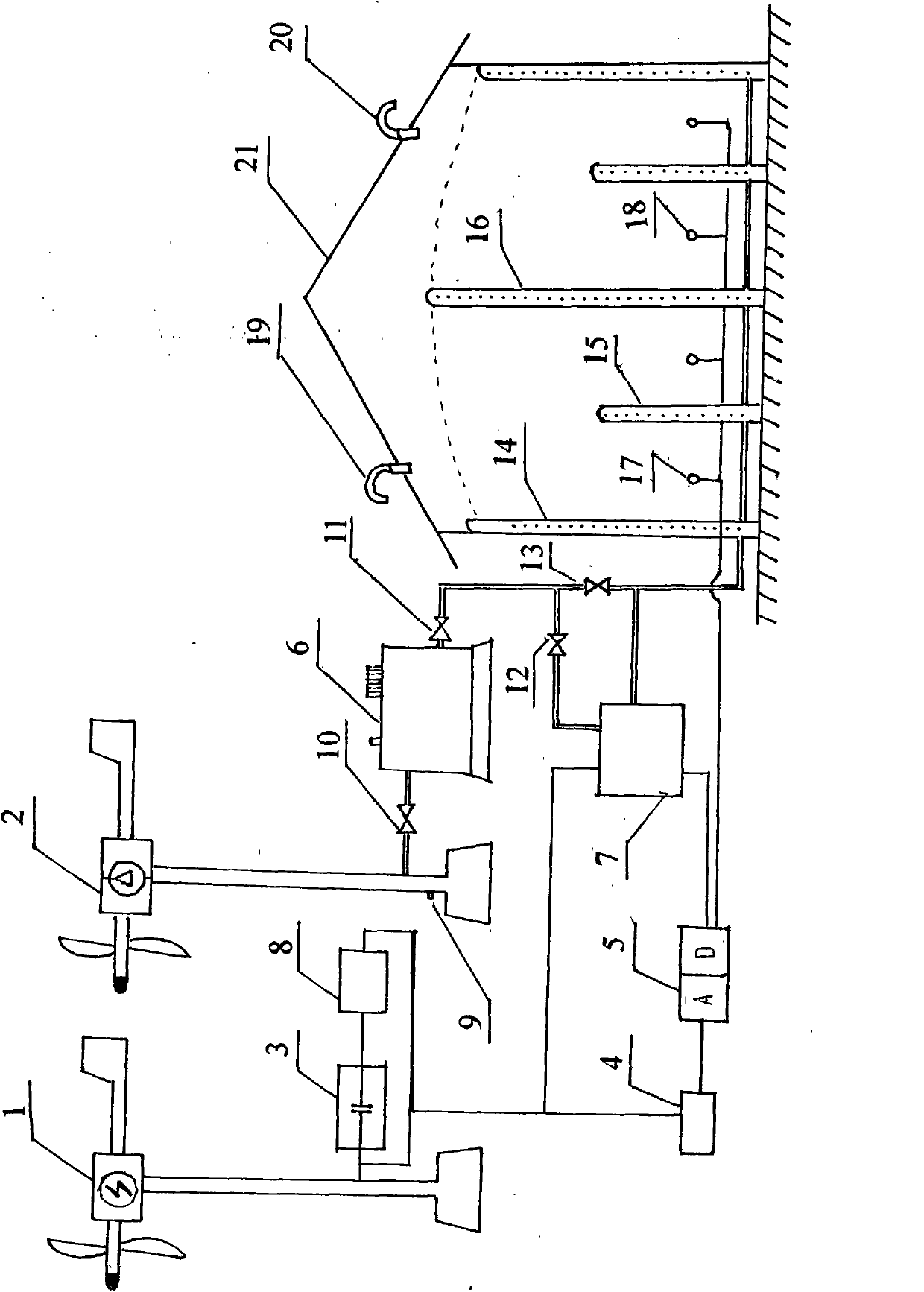

[0023] a. Install wind generators: set up 2000W wind generators 1, battery packs 3, and inverters 8 at a ventilated high place on the seashore to provide power and electric energy for the single-chip microcomputer 4 and auxiliary heat source 7;

[0024] b. Install the wind-force air compressor: install the wind-force air compressor 2 and set the pneumatic valve 10 on the pipeline of the wind-force air compressor to control the output of compressed gas. gas;

[0025] C. Set GBM gas booster: GBM gas booster 6 is connected to the output pipe of wind-powered air compressor 2, and the pressure of the high-pressure air source generated by boosting can reach 7-8 kg / cm2, providing power for the pneumatic pump , a pressure reducing valve 11 is installed at the air source outlet of the supercharger, so that the air source pressure required by the workplace can be adjusted through the pressure reducing valve 11;

[0026] d, single-chip microcomputer: set single-chip microcomputer 4, A / D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com