Preparation method of energy-efficient and environmentally-friendly disperse dye

A technology of disperse dyes, energy saving and environmental protection, applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of increasing the difficulty of wastewater treatment, economic loss, and difficulty in transferring dyes, to reduce the difficulty of treatment and improve the The effect of transferring crystal quality and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

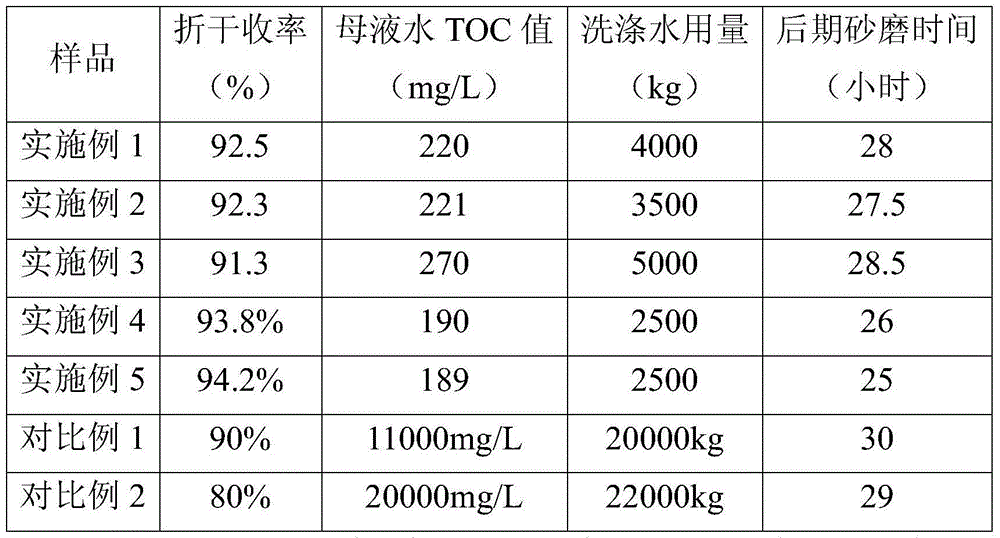

Examples

Embodiment 1

[0031] In the diazo kettle, 2000 kg of 98% sulfuric acid (mass percentage concentration) and 1972 kg of 28% nitrosyl sulfuric acid (mass percentage concentration, solvent is sulfuric acid) were successively dropped into the diazo kettle, stirred and cooled, and slowly dropped into 2,6-dibromo-p-nitro 1250kg of aniline, after adding, keep warm until the reaction is complete, and set aside;

[0032]Add 16,000kg of bottom water to the coupling kettle, add 30kg of Pingpingjia and 735kg of N-ethyl-N-cyanoethylaniline, after beating for 2 hours, dig out crushed ice to cool down, then add the above-mentioned diazonium solution, keep warm for 6 hours after adding, and detect the end point After qualified, start to add ammonia solution (mass percentage concentration is 10%) to adjust the pH value of the system to 4.5-5.5, then raise the temperature to 60-65 °C, stir for 1 hour, and after the dye is crystallized, enter the filter press to filter, Wash with water until neutral to obtain ...

Embodiment 2

[0035] In the diazo kettle, 1000kg of 98% sulfuric acid and 3150kg of nitrosylsulfuric acid of 28% are successively dropped into, stirred and lowered in temperature, slowly dropped into 900kg of p-nitroaniline, after adding, keep warm until the reaction is complete, and set aside;

[0036] Add 15,000kg of bottom water to the coupling kettle, add 25kg of Pingpingjia and 735kg of N, N-diacetoxyethyl-m-acetaniline, after beating for 2 hours, dig out crushed ice to cool down, then add the above-mentioned diazo solution, and keep warm for 6 hours after adding , after the detection end point is qualified, start to add ammonia solution (18% by mass percentage concentration) to adjust the pH value of the system to 6.0-7.0, then heat up to 65-70°C, stir and turn the crystal for 1 hour, and then enter the filter press after the dye turns crystal. Filter and wash with water until neutral to obtain 74 scarlet disperse dye filter cake, the mother liquor water is collected and used for the p...

Embodiment 3

[0039] Put 550kg of 98% sulfuric acid and 2100kg of 28% nitrosylsulfuric acid into the diazo kettle successively, stir and cool down, slowly put in 1200kg of 2,4-dinitro-6-bromoaniline, after adding, keep warm until the reaction is complete, and set aside ;

[0040] Add 20,000kg of bottom water to the coupling kettle, add 30kg of Pingpingjia and 945kg of N, N-diethyl-3-acetamidoaniline, after beating for 1 hour, dig out crushed ice to cool down, then add the above-mentioned diazonium solution, and keep warm for 7 hours after adding. After the detection end point is qualified, start to add sodium hydroxide solution (mass percentage concentration is 20%) to adjust the pH value of the system to 5.0-6.0, then raise the temperature to 60-65°C, stir for 1 hour and wait for the dye to crystallize before entering the filter press Press filter and wash with water until neutral to obtain 93 violet disperse dye filter cake, the mother liquor is collected and used for the preparation of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com