Ru/Al2O3 catalytic ozone oxidation catalyst and its microwave synthesis method

A technology of ozone oxidation and microwave synthesis, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as poor results, achieve energy saving, Broad application prospects, promotion and application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

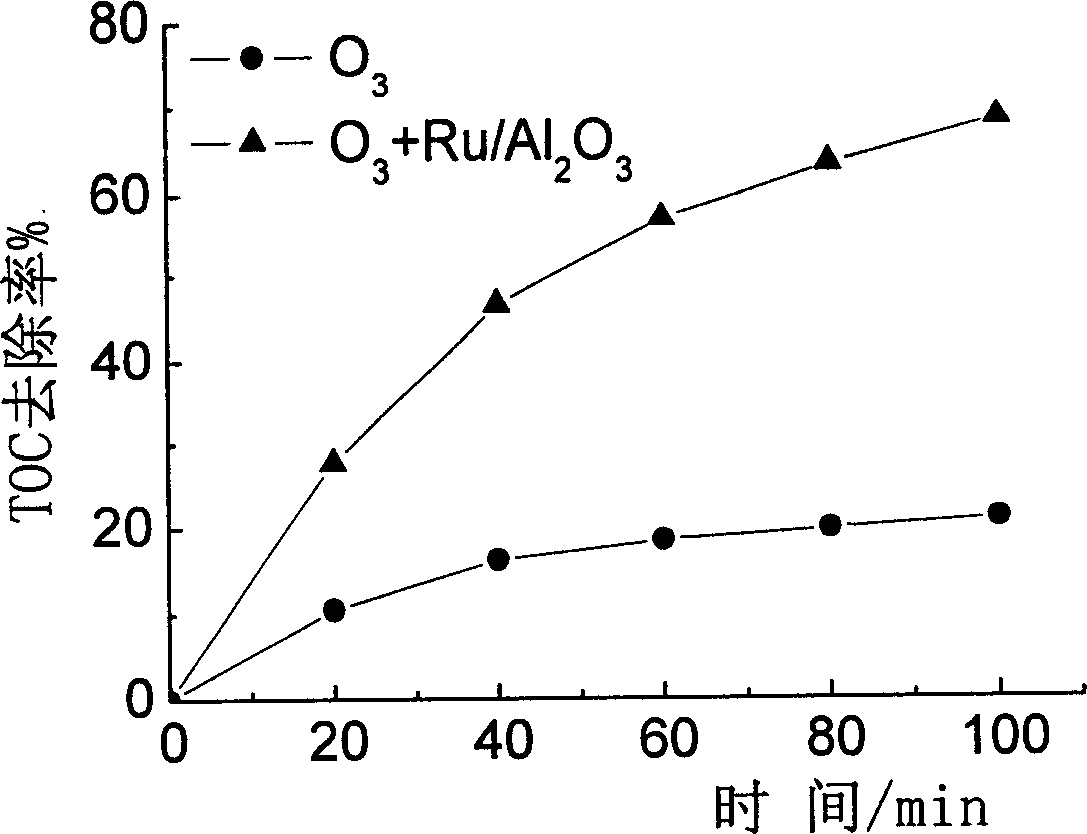

[0024] Embodiment 1: Ru / Al 2 o 3 Catalyst preparation and its effect on the oxidation and mineralization of dimethyl phthalate by ozone

[0025] Using equal volume impregnation method, 1g / L RuCl 3 solution and Al 2 o 3 Carriers are mixed in equal volumes (this concentration of RuCl 3 The Ru loading of the prepared catalyst is 0.1wt.%), and soaked in a shaker at 100-160rmp for 2 hours at 10-30°C. Then dry in an air-atmosphere oven for 2 hours, the drying temperature is 105°C, the water content of the catalyst obtained at this time is about 33%, and finally microwave heating in a microwave reactor to obtain the finished catalyst, wherein the frequency of microwave heating is 2450MHz, The power is 300W, the microwave heating time is 3min, and the diameter of the microwave-treated reactor is 4cm.

[0026] In a 1L cylindrical bubbling semi-continuous reactor, the above Ru / Al 2 o 3 Catalytic ozone oxidation of dimethyl phthalate, catalyst dosage is 20g / L, catalyst particle s...

Embodiment 2

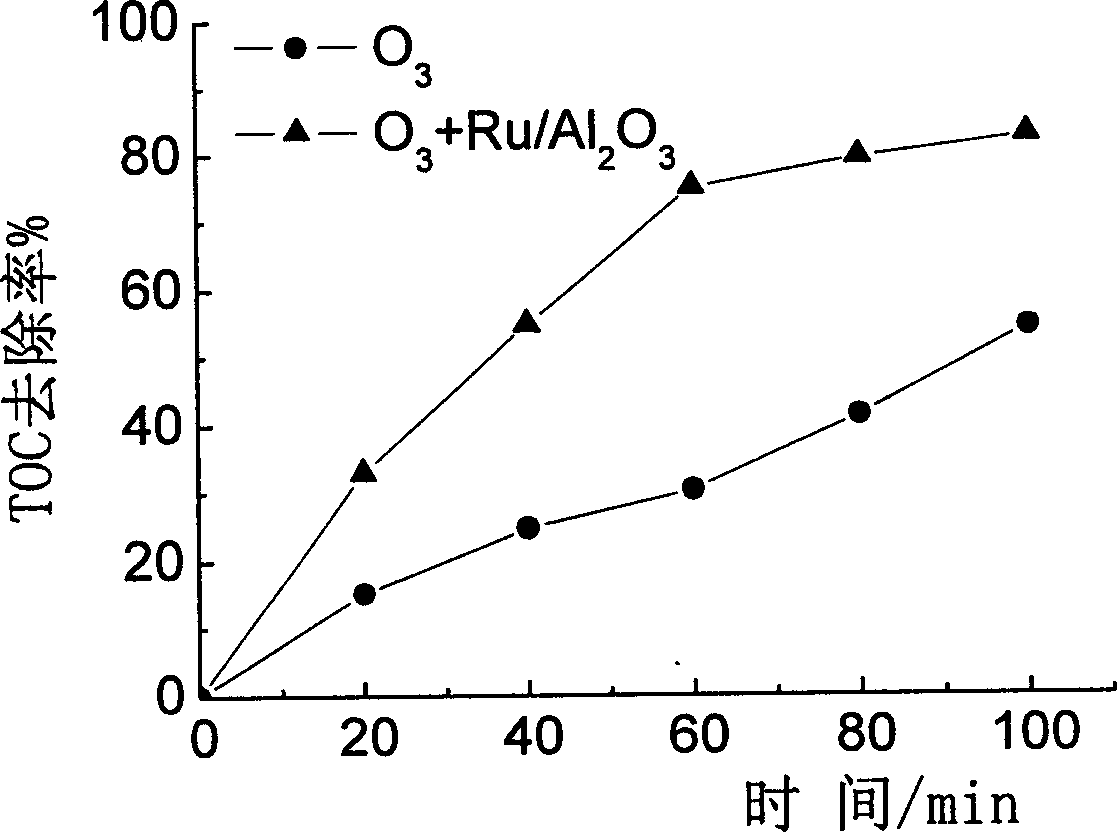

[0028] Embodiment two: Ru / Al 2 o 3 Catalyst preparation and its effect on the oxidation of mineralized phenol by ozone

[0029] Using equal volume impregnation method, 20g / L RuCl 3 solution and Al 2 o 3 Carriers are mixed in equal volumes (this concentration of RuCl 3 The Ru loading of the prepared catalyst is 2.0wt.%), and soaked in a shaker at 100-160rmp for 2 hours at 10-30°C. Then dry in an air-atmosphere oven for 2 hours, the drying temperature is 105°C, the water content of the catalyst obtained at this time is about 33%, and finally microwave heating in a microwave reactor to obtain the finished catalyst, wherein the frequency of microwave heating is 2450MHz, The power is 700W, the microwave heating time is 10min, and the diameter of the microwave-treated reactor is 4cm.

[0030]In a 1L cylindrical bubbling semi-continuous reactor with Ru / Al 2 o 3 Catalytic ozone oxidation of phenol, catalyst dosage is 20g / L, catalyst particle size is 2-3mm, initial concentratio...

Embodiment 3

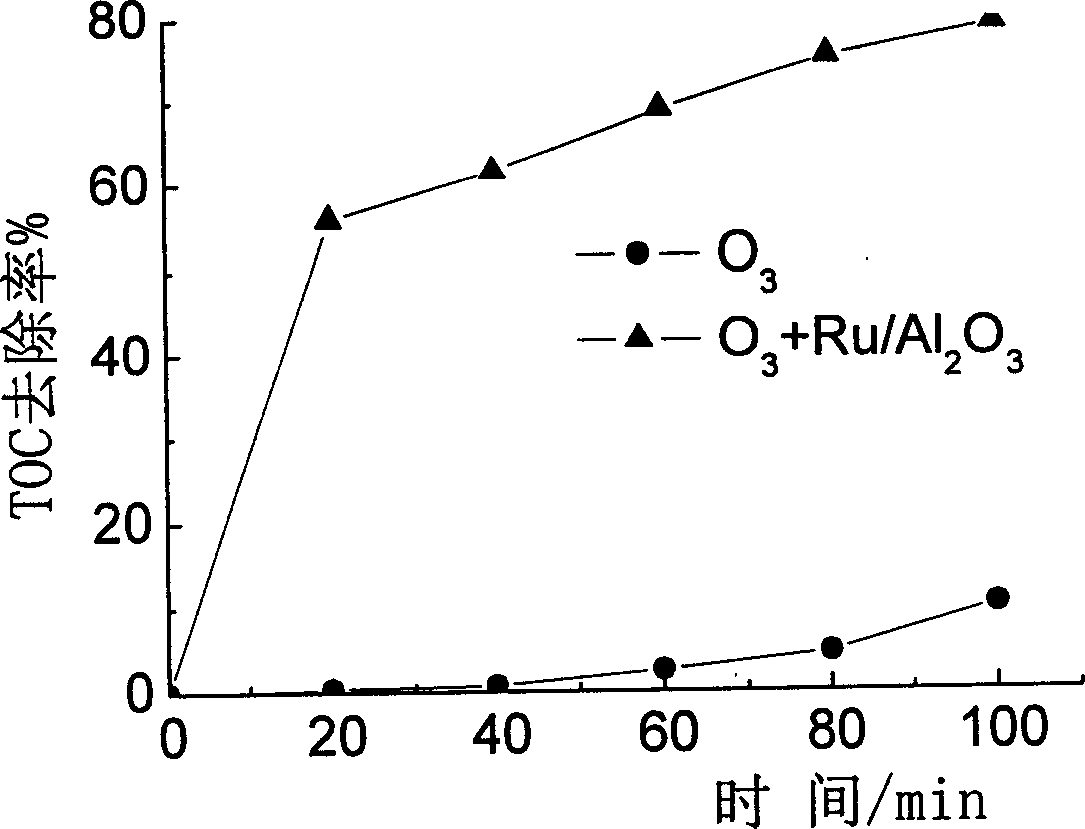

[0031] Embodiment three: Ru / Al 2 o 3 Catalyst preparation and its effect on the oxidation and mineralization of oxalic acid by ozone

[0032] Using equal volume impregnation method, 1g / L RuCl 3 solution and Al 2 o 3 Carriers are mixed in equal volumes (this concentration of RuCl 3 The Ru loading of the prepared catalyst is 0.1wt.%), and soaked in a shaker at 100-160rmp for 2 hours at 10-30°C. Then dry in an air-atmosphere oven for 12 hours, the drying temperature is 105°C, the water content of the catalyst obtained at this time is about 7.2%, and finally the finished catalyst is obtained by microwave heating in a microwave reactor, wherein the frequency of microwave heating is 2450MHz, The power is 300W, the microwave heating time is 20min, and the diameter of the microwave-treated reactor is 4cm.

[0033] In a 1L cylindrical bubbling semi-continuous reactor with Ru / Al 2 o 3 Catalytic ozone oxidation of oxalic acid, catalyst dosage is 20mg / L, catalyst particle size 2-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com