Corrugated loading high-strength wallboard

A corrugated board and corrugated technology, applied in the field of high-strength combined wall panels, can solve the problems of high processing cost and poor versatility, and achieve the effects of low cost, light weight and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

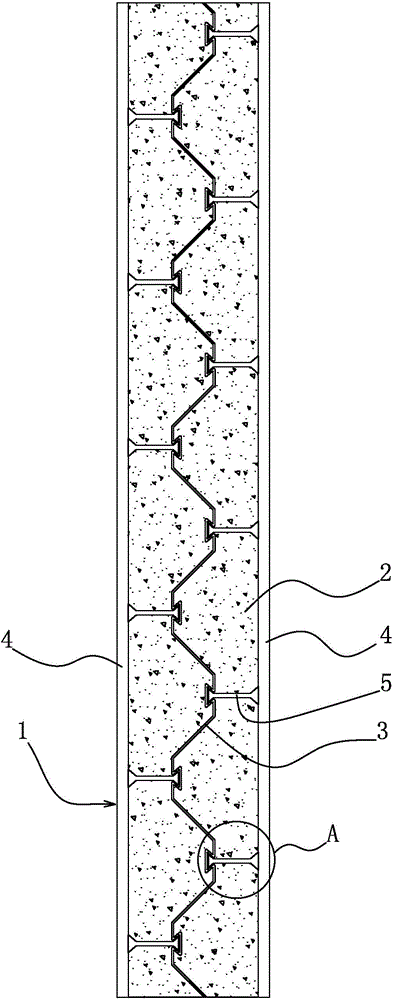

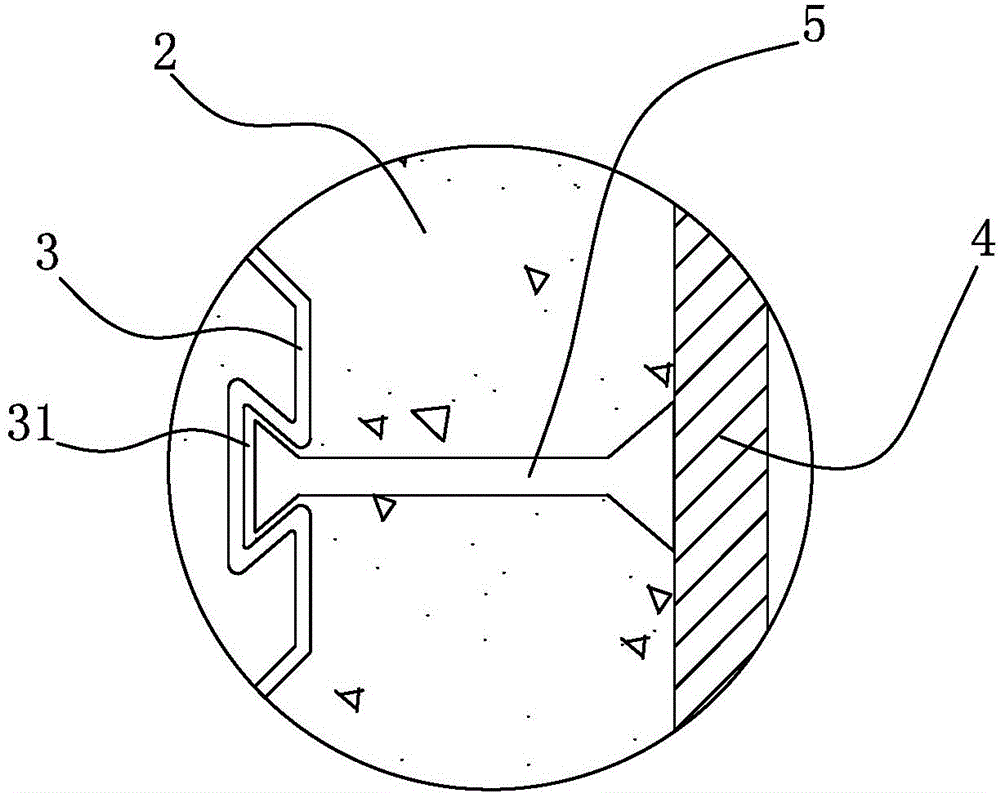

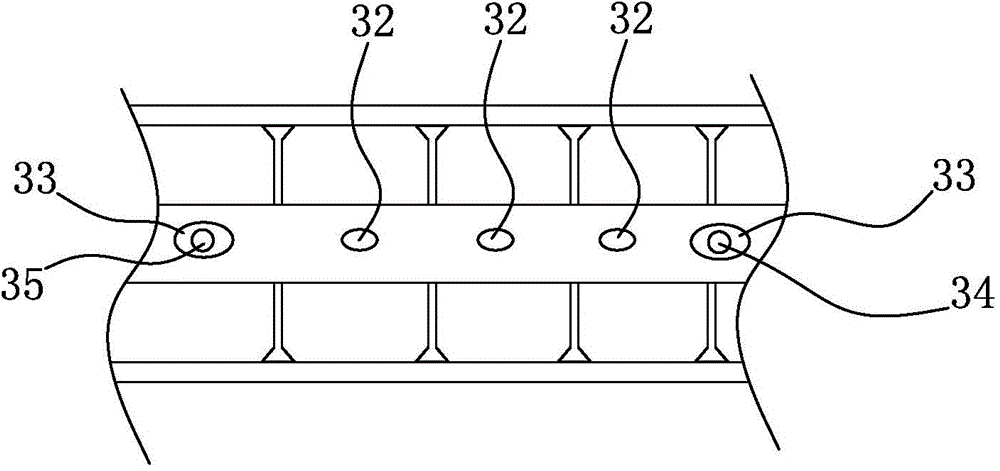

[0020] see figure 1 and figure 2 In the embodiment of a corrugated filling high-strength wallboard given in the present invention, it includes a high-strength keel 1 made of metal materials and a filling material 2, the keel 1 includes a corrugated board 3, and the corrugated board 3 The panels 4 on both sides and the thickness adjusting connector 5 connecting the corrugated board 3 and the panel 4 , the cavity formed by the corrugated board 3 , the panel 4 and the connector 5 is filled with the filling material 2 . The keel in the invention has higher strength, which is equivalent to or higher than that of traditional reinforced concrete wall panels, that is, the keel can meet the strength requirements of the wall panels. The thickness adjustment connector 5 means that the connector 5 has different length specifications, and according to the thickness requirements of the wallboard, the connector 5 of the corresponding length specification is used, so as to realize the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com