Ageing-free washing-free printing technique of diverse dyes

A printing process and disperse dye technology, applied in the field of textile printing processing, can solve the problems of improper process control, easy occurrence of defective products, affecting printing color and color stability, etc., and achieve the effect of good anti-wrinkle performance and good anti-wrinkle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

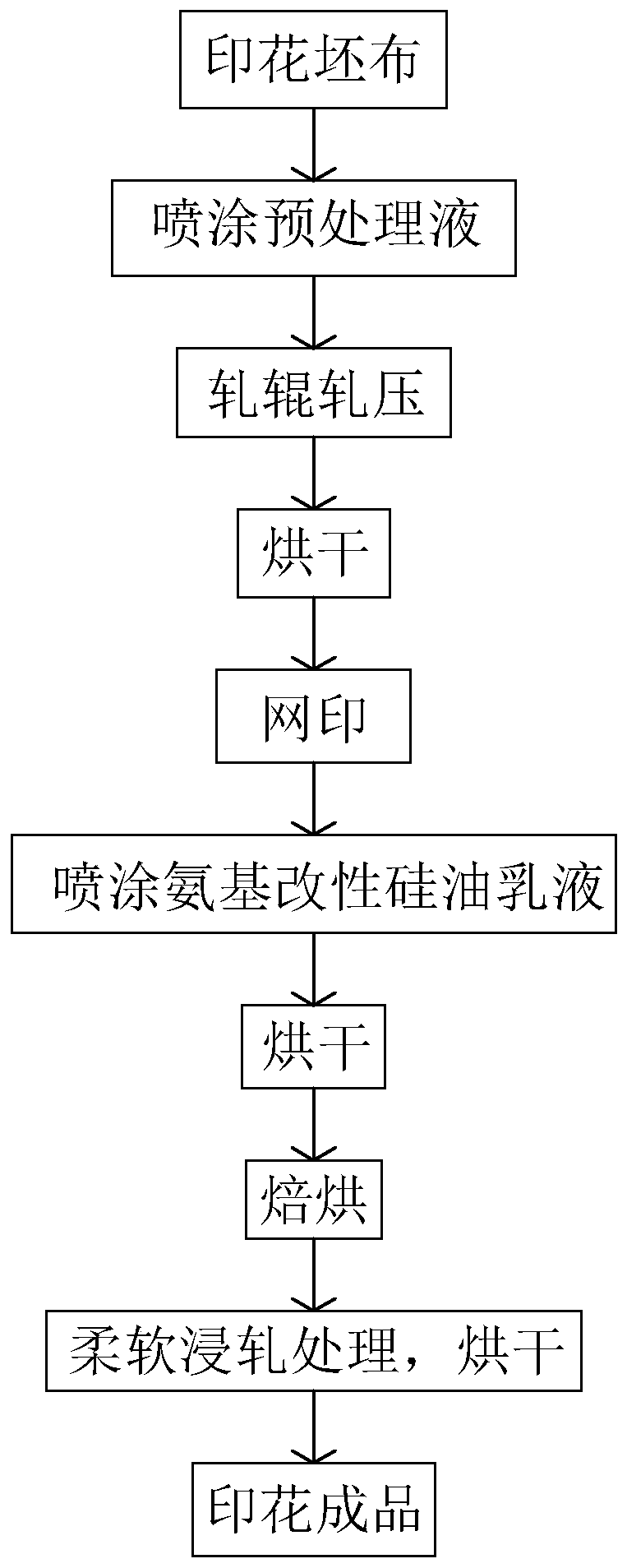

[0057] A kind of disperse dye non-steaming washing printing process, with reference to figure 1 , which includes the following steps:

[0058] A preprocessing

[0059] Prepare the pretreatment solution according to the following formula,

[0060] N-maleyl chitosan 5wt%

[0061] Polyglycolic acid 1wt%

[0062] N-Methylpyrrolidone 1wt%

[0063] Penetrant JFC 0.5wt%

[0064] NP-50 emulsifier 0.5wt%

[0065] Deionized water balance.

[0066] After the pretreatment solution is prepared, it is applied to the printing surface of the printed gray cloth by spraying, and the application amount of the control pretreatment solution is 50g / m 2 . Then, an infrared pre-drying device is used to dry the printed gray cloth sprayed with the pre-treatment liquid. In this embodiment, the pure polyester woven fabric with a grammage of 200 g is selected as the printed gray fabric, and it has been pre-treated in advance. The deionized water used can also be replaced by softened water.

[0...

Embodiment 2

[0087] A kind of disperse dye non-steaming washing printing process, with reference to figure 1 , which includes the following steps:

[0088] A preprocessing

[0089] Prepare the pretreatment solution according to the following formula,

[0090] N-maleyl chitosan 7wt%

[0091] Polyglycolic acid 2.5wt%

[0092] N-Methylpyrrolidone 1.5wt%

[0093] Penetrant JFC 0.8wt%

[0094] NP-50 emulsifier 0.8wt%

[0095] Deionized water balance.

[0096] After the pretreatment solution is prepared, it is applied to the printing surface of the printed gray cloth by spraying, and the application amount of the control pretreatment solution is 40g / m 2 . Then, an infrared pre-drying device is used to dry the printed gray cloth sprayed with the pre-treatment liquid. In this embodiment, the pure polyester woven fabric with a grammage of 200 g is selected as the printed gray fabric, and it has been pre-treated in advance. The deionized water used can also be replaced by softened water. ...

Embodiment 3

[0112] A kind of disperse dye non-steaming washing printing process, with reference to figure 1 , which includes the following steps:

[0113] A preprocessing

[0114] Prepare the pretreatment solution according to the following formula,

[0115] N-maleyl chitosan 10wt%

[0116] Polyglycolic acid 5wt%

[0117] N-Methylpyrrolidone 3wt%

[0118] Penetrant JFC 1wt%

[0119] NP-50 emulsifier 1wt%

[0120] Deionized water balance.

[0121] After the pretreatment solution is prepared, it is applied to the printing surface of the printed gray cloth by spraying, and the application amount of the pretreatment solution is controlled to be 30g / m 2 . Then, an infrared pre-drying device is used to dry the printed gray cloth sprayed with the pre-treatment liquid. In this embodiment, the pure polyester woven fabric with a grammage of 200 g is selected as the printed gray fabric, and it has been pre-treated in advance. The deionized water used can also be replaced by softened water. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com