Patents

Literature

74results about How to "Dilute oxygen concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

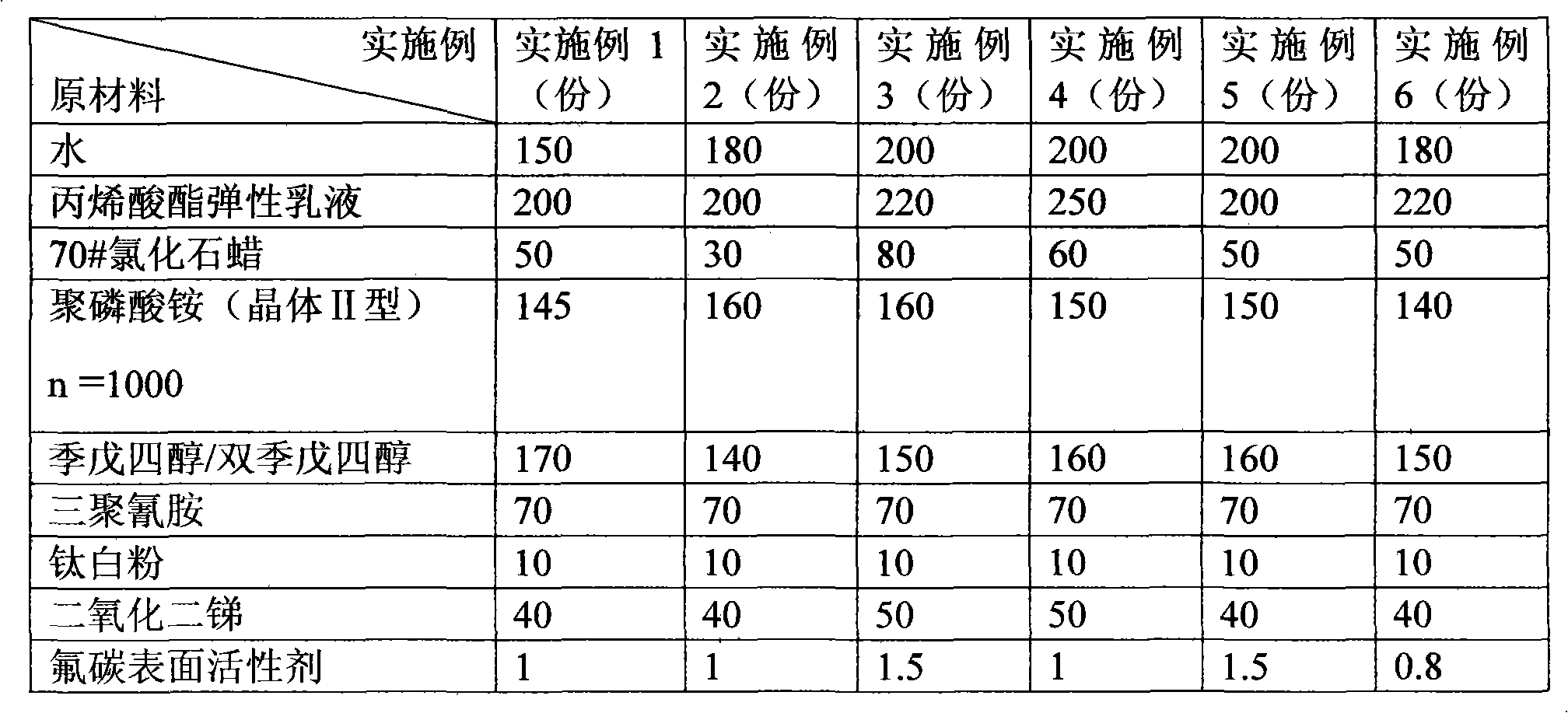

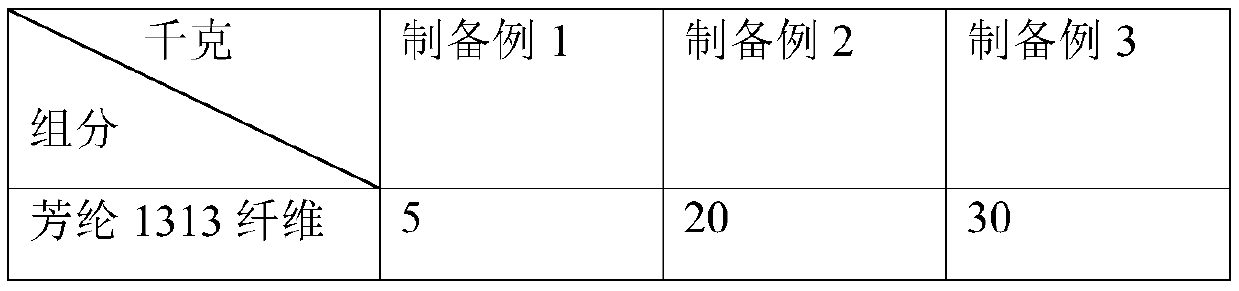

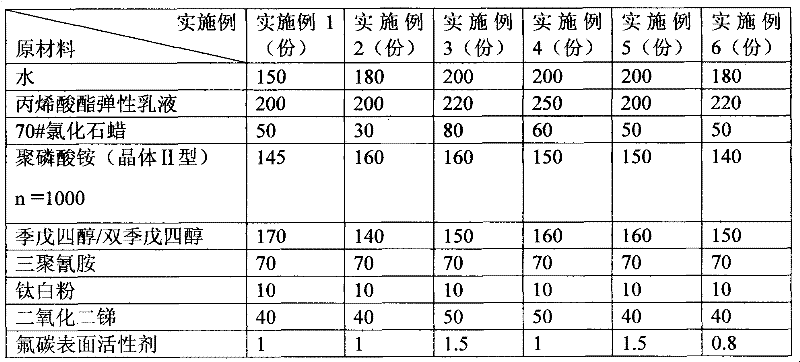

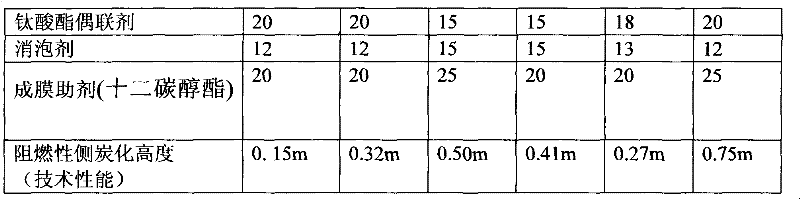

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

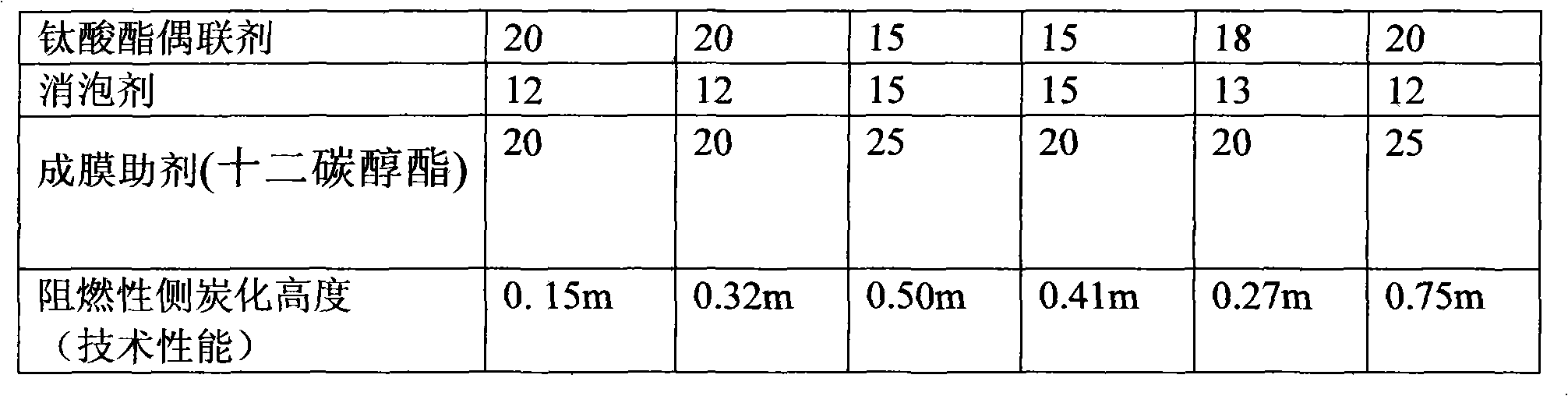

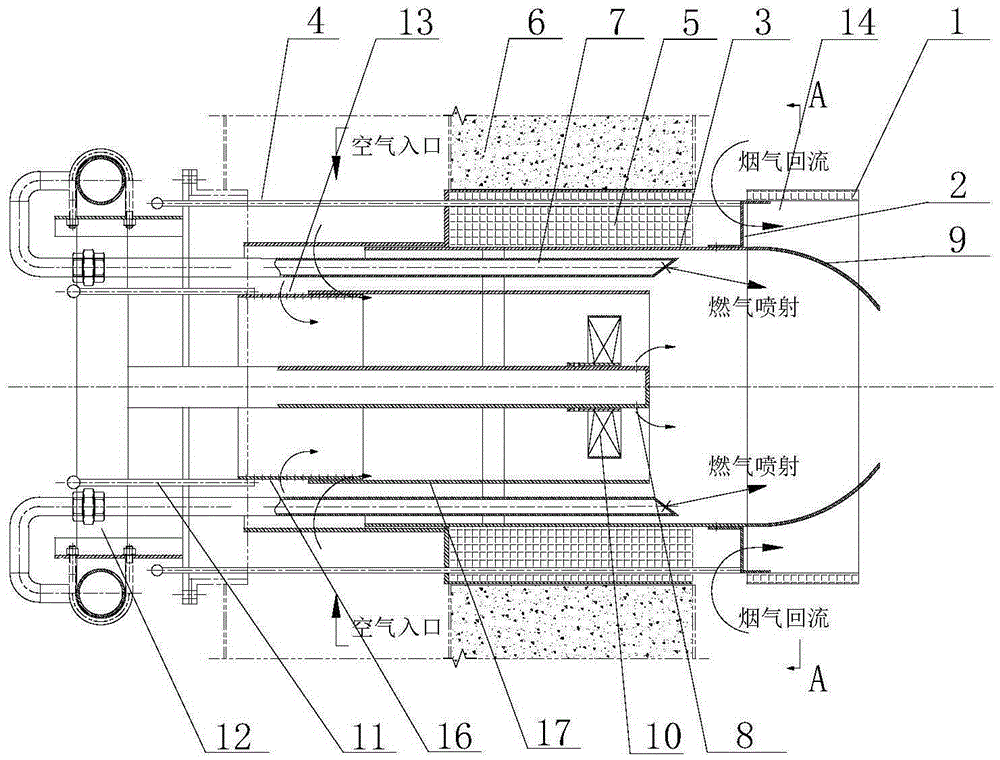

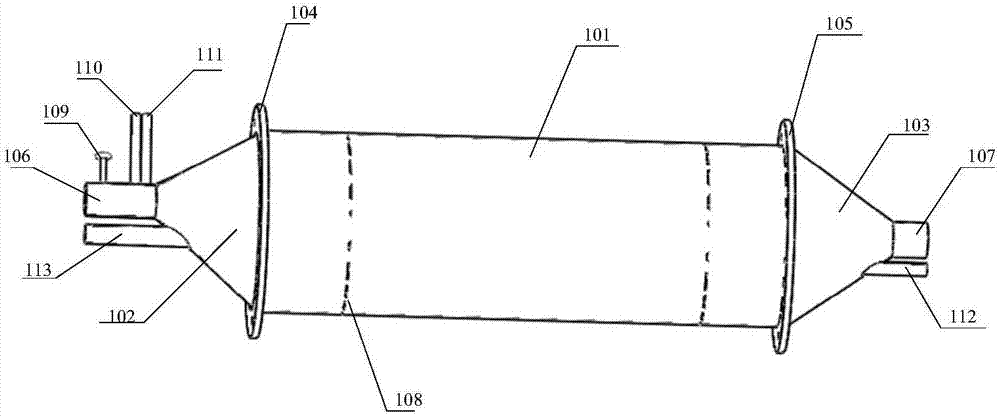

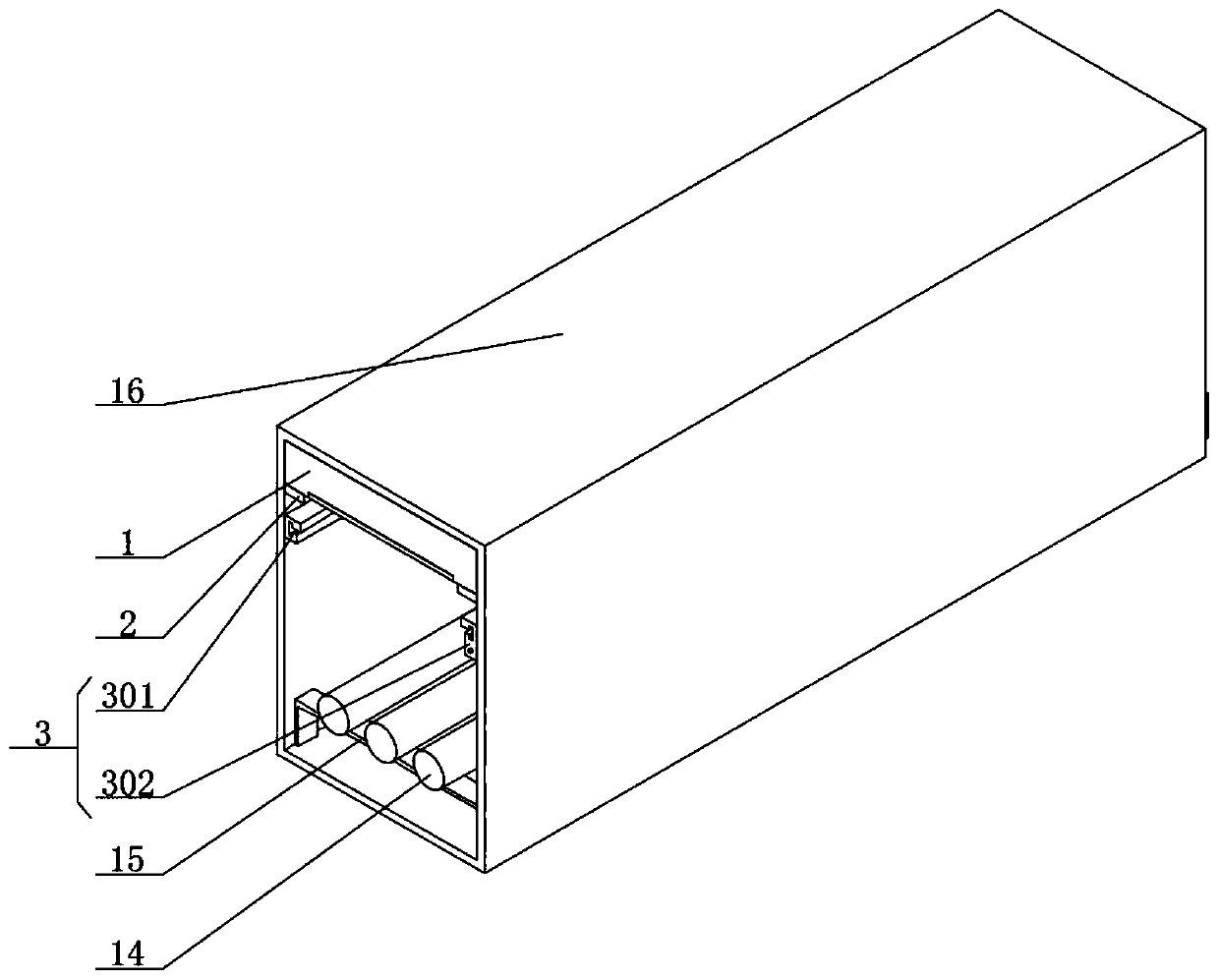

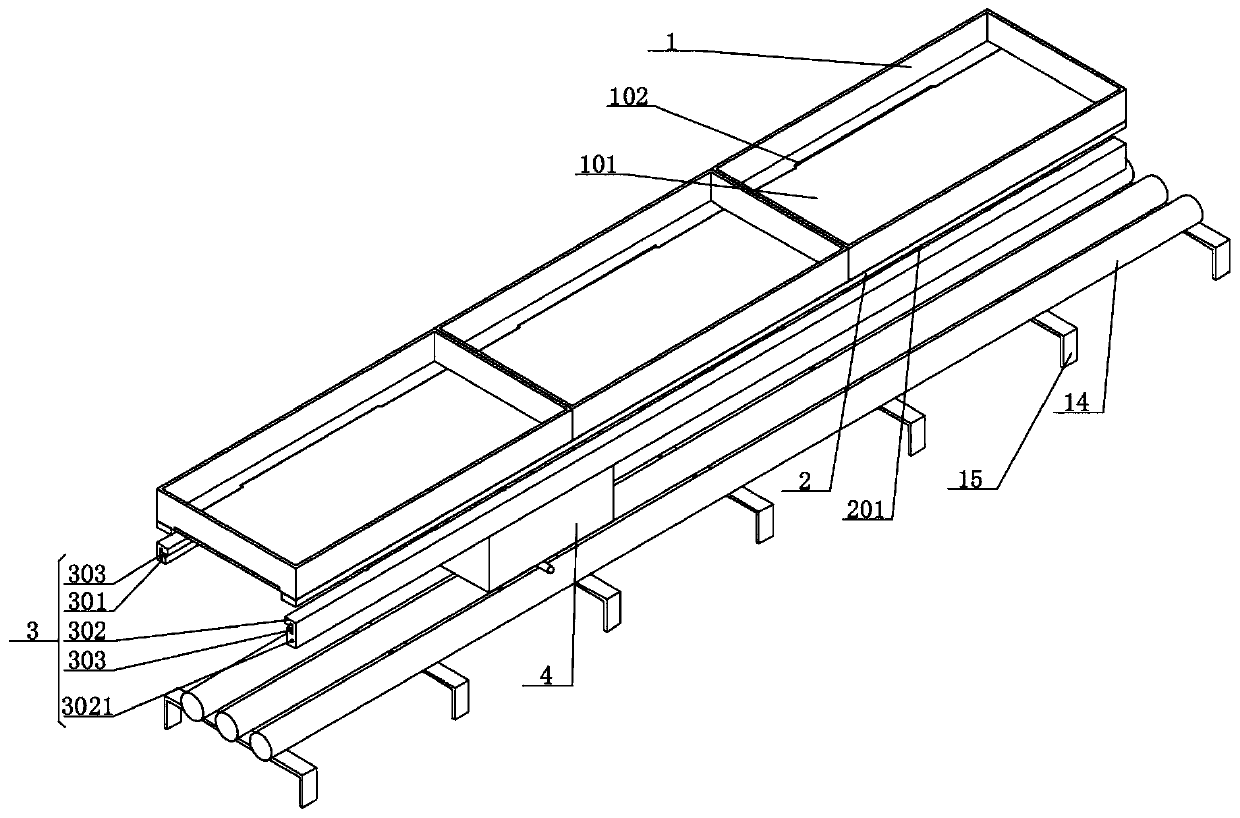

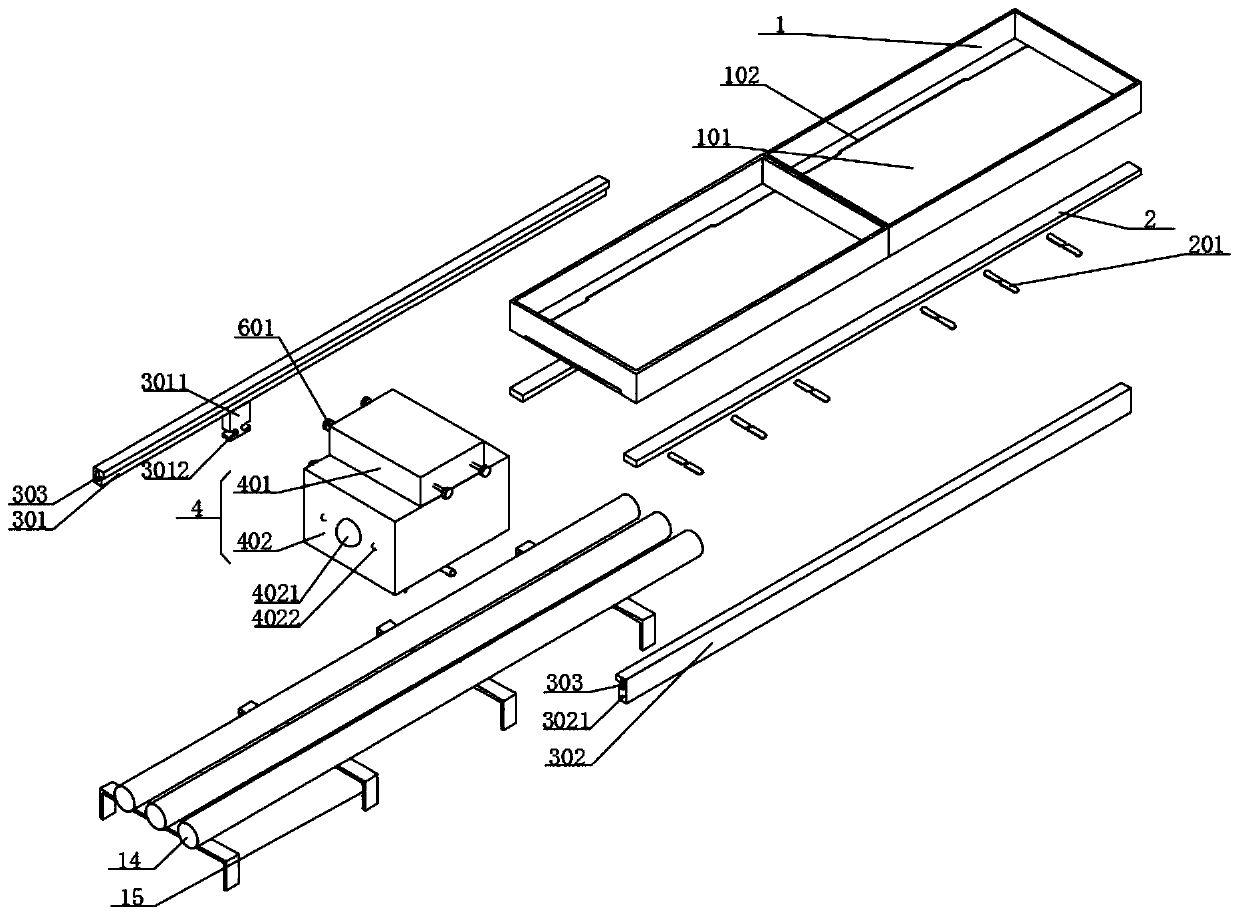

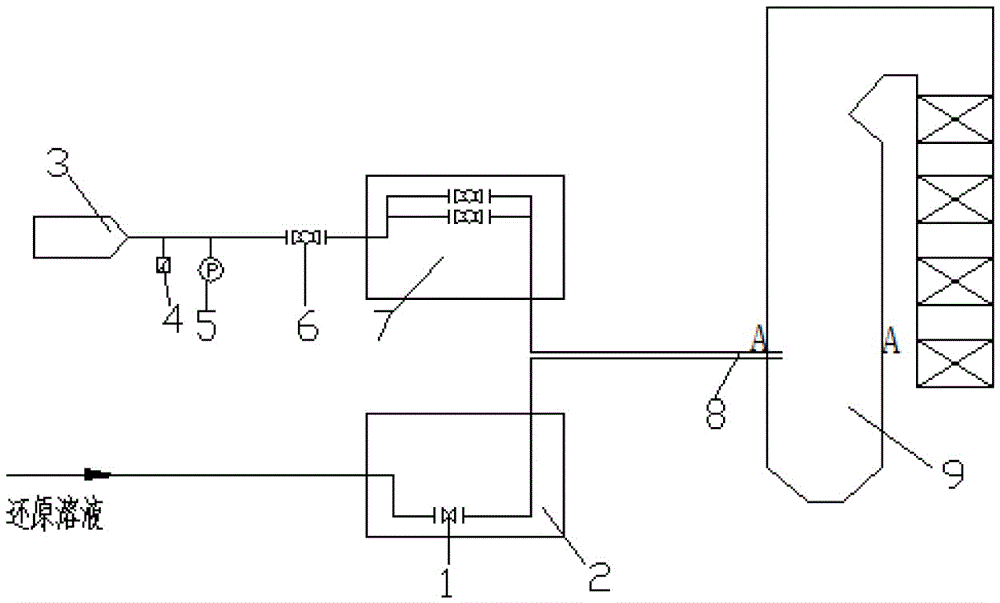

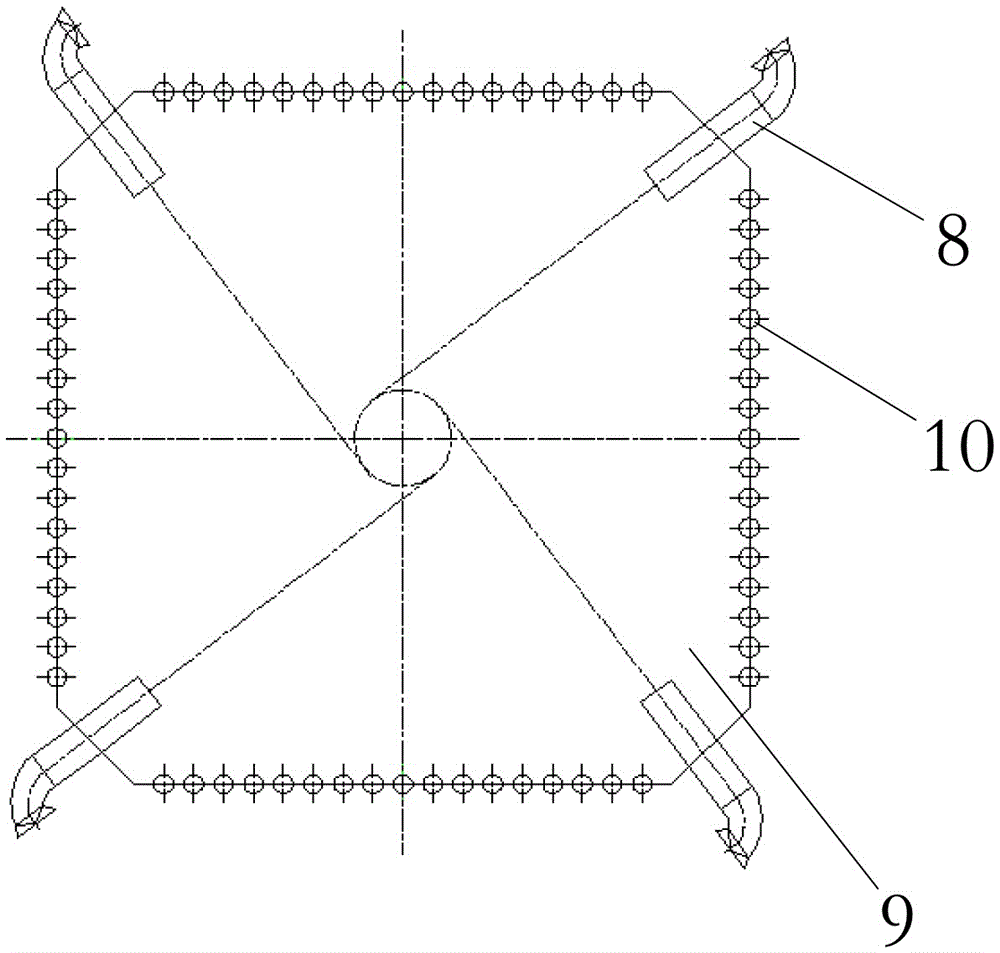

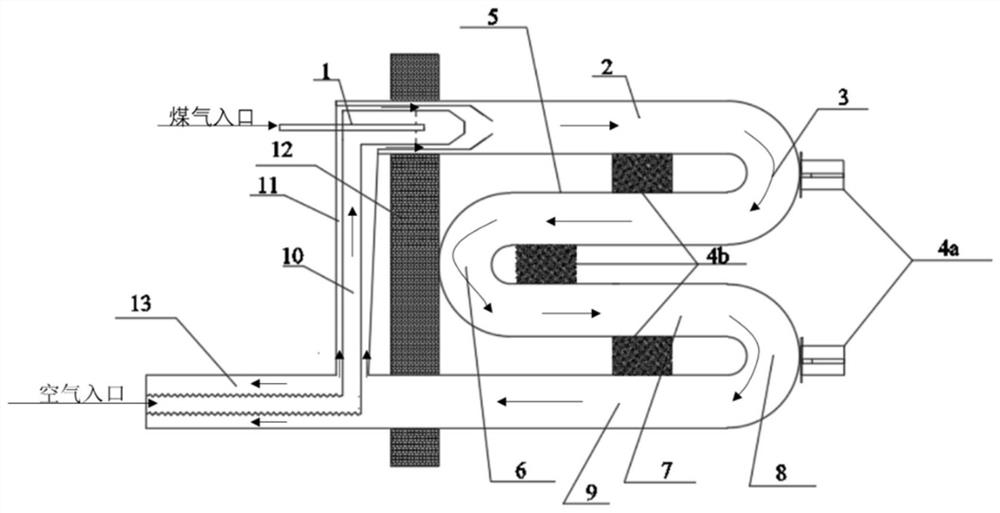

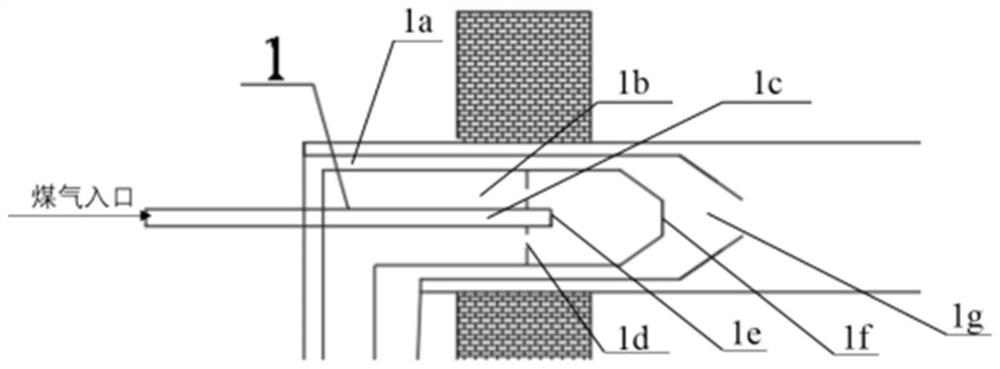

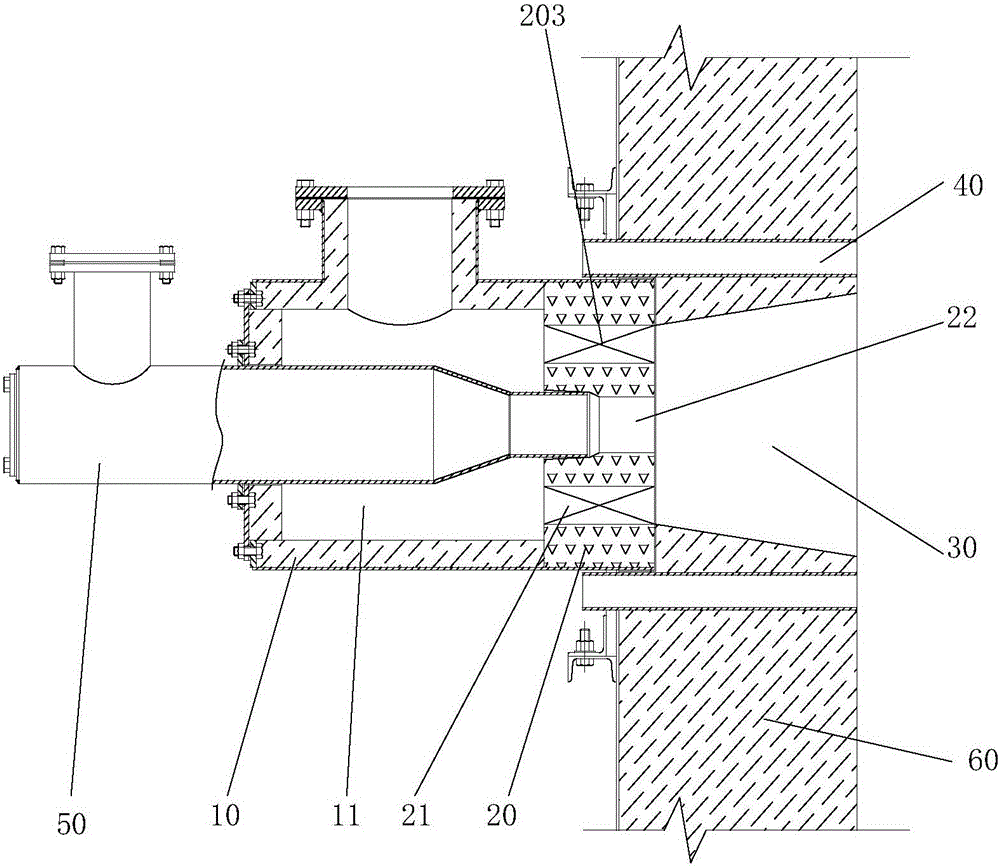

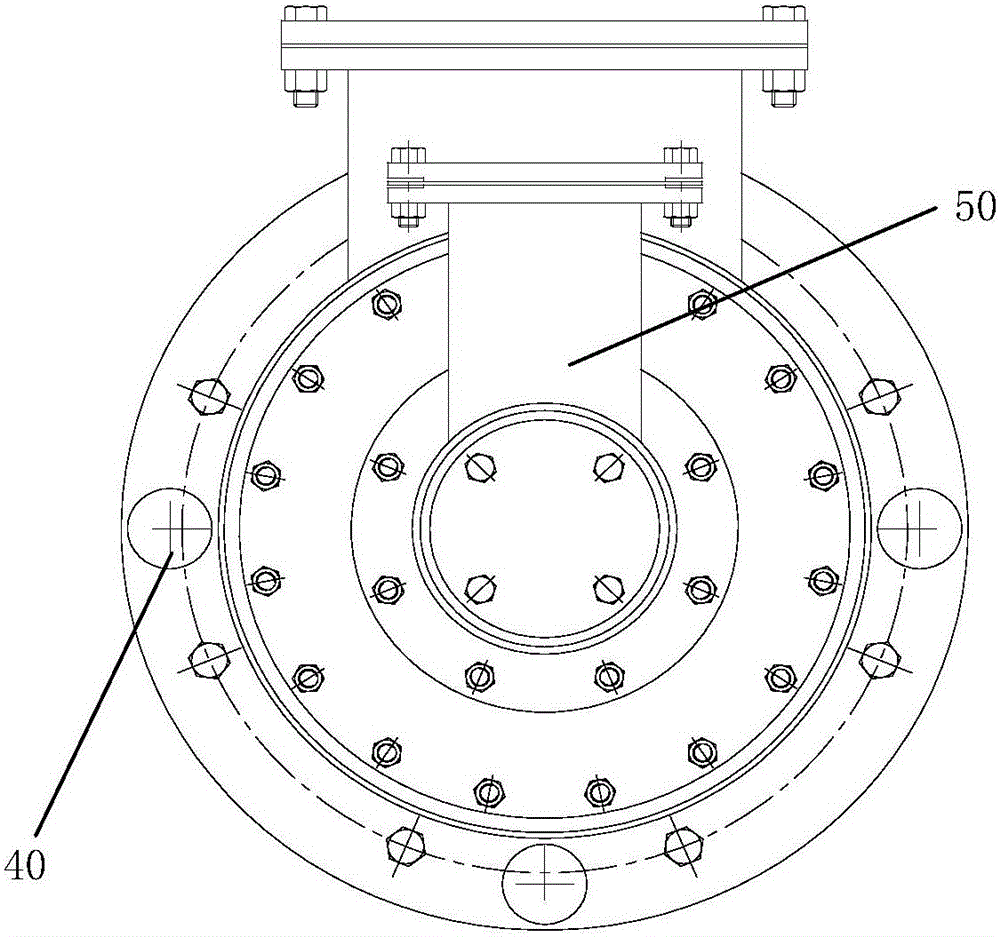

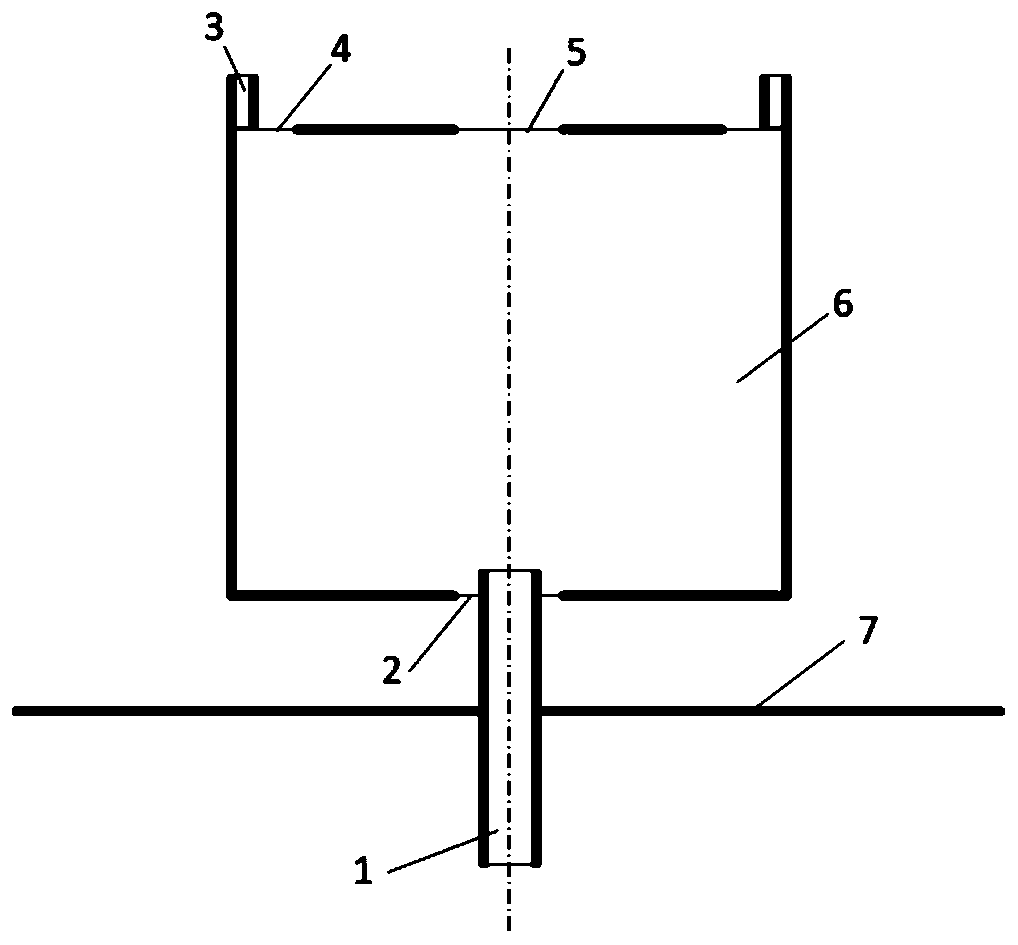

Smoke internal circulation low-nitrogen combustor

InactiveCN105299651ADilute oxygen concentrationExtended burn timeGaseous fuel burnerCombustorLow nitrogen

The invention discloses a smoke internal circulation low-nitrogen combustor which comprises an outer barrel. An inner barrel is arranged in the outer barrel. Main gas spray guns are arranged in a clearance between the outer barrel and the inner barrel. A center gas spray gun is arranged in the inner barrel. A mixed gas outlet flow guide shrinkage cover is fixedly connected with the end of the outer barrel and sleeved with a smoke backflow cover. The smoke backflow cover can slide front and back along the axis of the outer barrel. A smoke backflow channel is arranged between the mixed gas outlet flow guide shrinkage cover and the smoke backflow cover. According to the scheme, smoke in a hearth can flow into a flame area of a combustor outlet through the smoke backflow channel, and therefore the oxygen concentration in mixed gas is diluted, the combustion time of fuel is prolonged, the combustion strength is lowered, high-temperature areas are avoided, and finally the aim of reducing NOx emission is achieved. By means of the structure, no circulating smoke pipeline or circulating fan needs to be additionally arranged, and therefore the investment cost is low.

Owner:SHANGHAI QIYAO THERMAL ENERGY ENG CO LTD +1

High-fire-retardancy aminoresin nano-complex-function tanning agent

The invention discloses a tanning agent with high flame-resistance amino-resin nano-composite function, which is prepared by the method as follows: firstly, melamine, dicyandiamide, formaldehyde and acidic components are used as raw material to prepare flame-resistance amino-resin prepolymer; secondly, montmorillonite or organic montmorillonite are modified by tetrakis hydroxymethyl phosphonium and silane coupling agents to obtain modified montmorillonite or modified organic montmorillonite; finally, the prepared flame-resistance amino-resin prepolymer and the obtained modified montmorillonite or the modified organic montmorillonite are processed through in-situ intercalation compounding reaction. The tanning agent not only has better tanning performance and retanning filling performance, but also brings good flame-resistance and washable migration resistance to leather goods, and the addition quantity is less, and the flame retardant efficiency is high.

Owner:SICHUAN UNIV

Branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on triazine ring structure and preparation method of copolyester

ActiveCN104710604AIncrease melt viscosityImprove flame retardant performanceNitrogenNetwork structure

The invention discloses branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester based on a triazine ring structure. The copolyester is prepared by conducting random copolymerization on structure units expressed as formulae I, II and III or structure units expressed as formulae I, II, III and IV according to a conventional method. The intrinsic viscosity [eta] of the prepared branching, cross-linking, expanded, melt-dropping-resistant and flame-retardant copolyester is 0.41-1.10 dL / g; the extreme oxygen index is 24.5-38.0%; the vertical combustion grade is between V-2 and V-0; the peak heat release rate p-HRR in a cone heat test is 247-643 kW / m<2>. According to the copolyester, a modified monomer of the triazine ring structure is introduced, and then copolymerized with polyester to form a unique ternary branched cross-linking network structure; the modified monomer of the triazine ring structure contains the flame-retardant element nitrogen, so that the melt viscosity of the copolyester in combustion can be improved; the copolyester is capable of releasing nitrogen and quickly forming an expanded char layer with excellent heat and oxygen insulation effects; especially, a phosphorus-nitrogen synergism effect can be generated when the copolyester is used together with the conventional phosphorus-containing flame-retardant agent; the flame-retardant performance and the melt-dropping-resistant effects can be more excellent; the selected monomer is low in price; the preparation process is mature; the operation is simple and convenient; the industrialized large-scale production is liable to implement.

Owner:SICHUAN UNIV

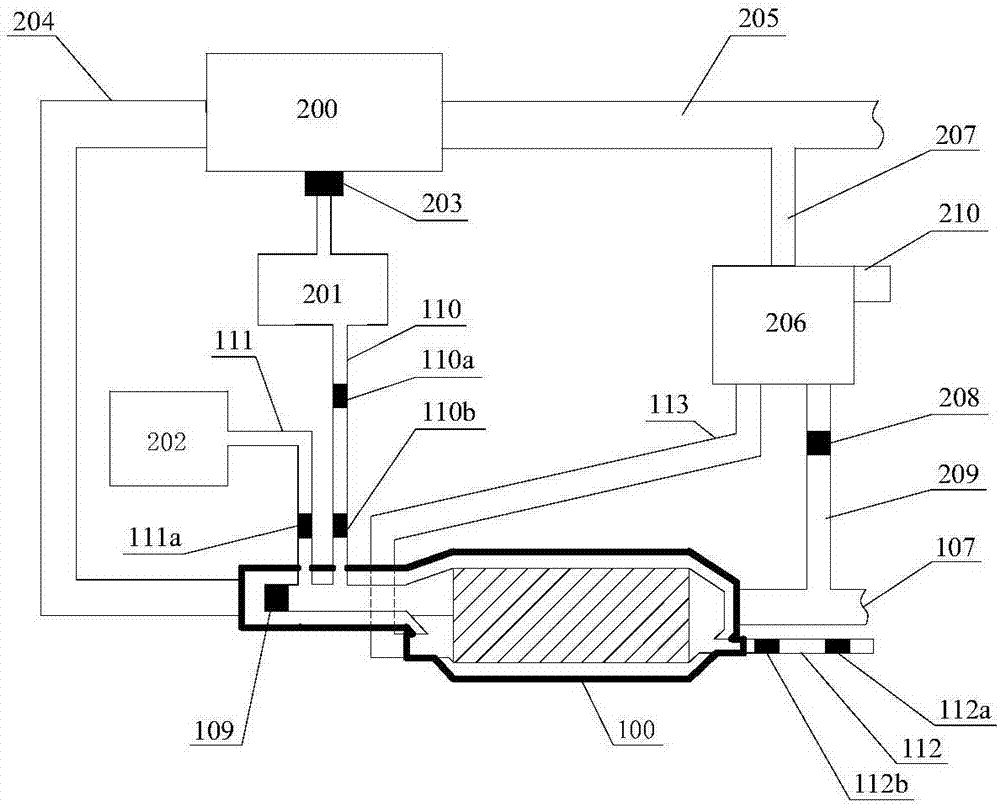

Waste gas-fuel reforming and recycling natural gas engine system and control method

ActiveCN107061053ARealize online preparationAvoid offeringInternal combustion piston enginesFuel supply apparatusWater vaporIntercooler

The invention discloses a waste gas-fuel reforming and recycling natural gas engine system and a control method. The waste gas-fuel reforming and recycling natural gas engine system comprises an engine, a fuel supply device, a gas tank used for supplying to the fuel supply device, a reformer and an intercooler. Engine fuel is directly subjected to a multiple reforming reaction with O2 and water vapor, so that reformed gas which is rich in H2 and CO is generated, and H2 production efficiency is high; online production of hydrogen is achieved, an extra fuel storage device or an extra hydrogen storage tank does not need to be provided, the safety is improved, and the size of the whole system is reduced; two pass tubes are adopted, so that the heat transfer coefficient is increased, and the reforming efficiency is improved accordingly; the reformed gas contains a large quantity of H2, the in-cylinder combustion speed is increased, and the lean burning extreme is widened; the oxygen concentration in a gas inlet pipe can be decreased through circulating waste gas, the specific heat capacity of working media is improved, and the in-cylinder combustion temperature is decreased; and by combining the reformed gas with the circulating waste gas, stable low-temperature lean burning of the natural gas engine can be achieved, and meanwhile, the HC concentration, the CO concentration and the NOx concentration can be decreased.

Owner:WUHAN UNIV OF TECH

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

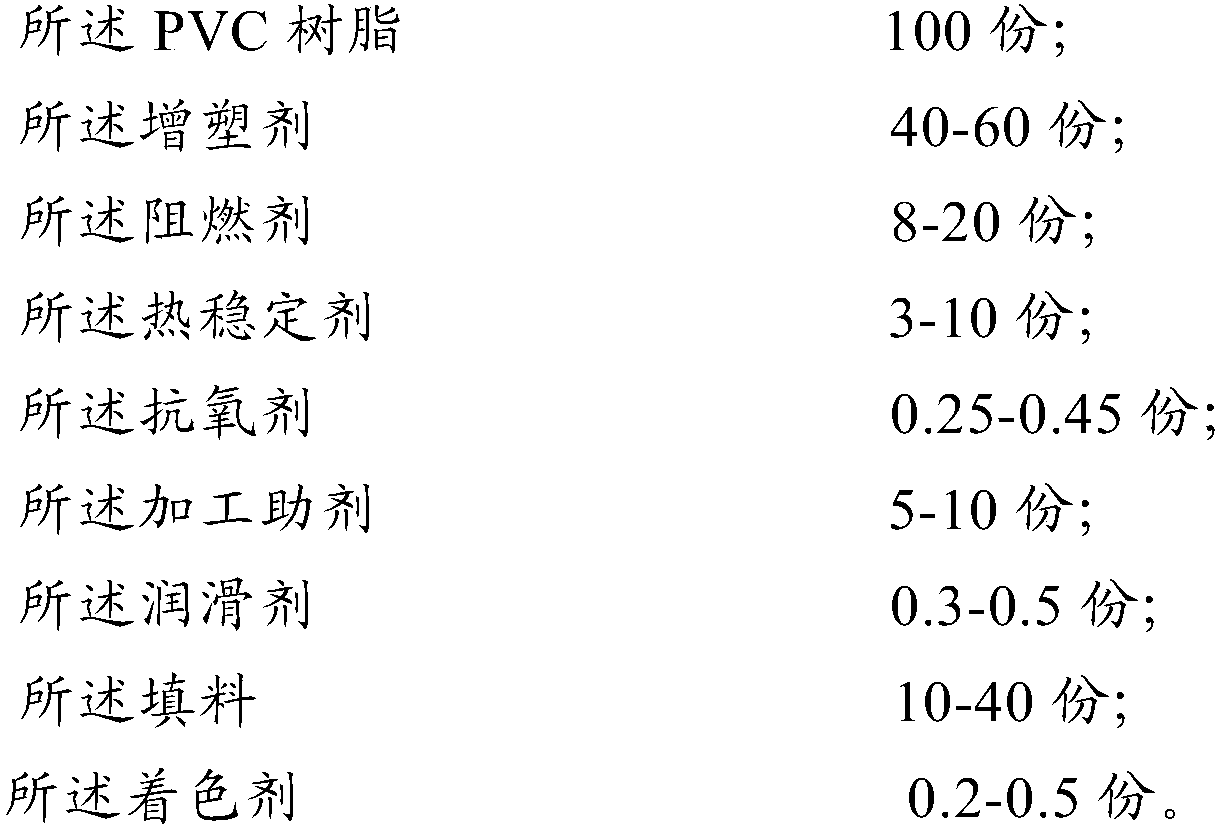

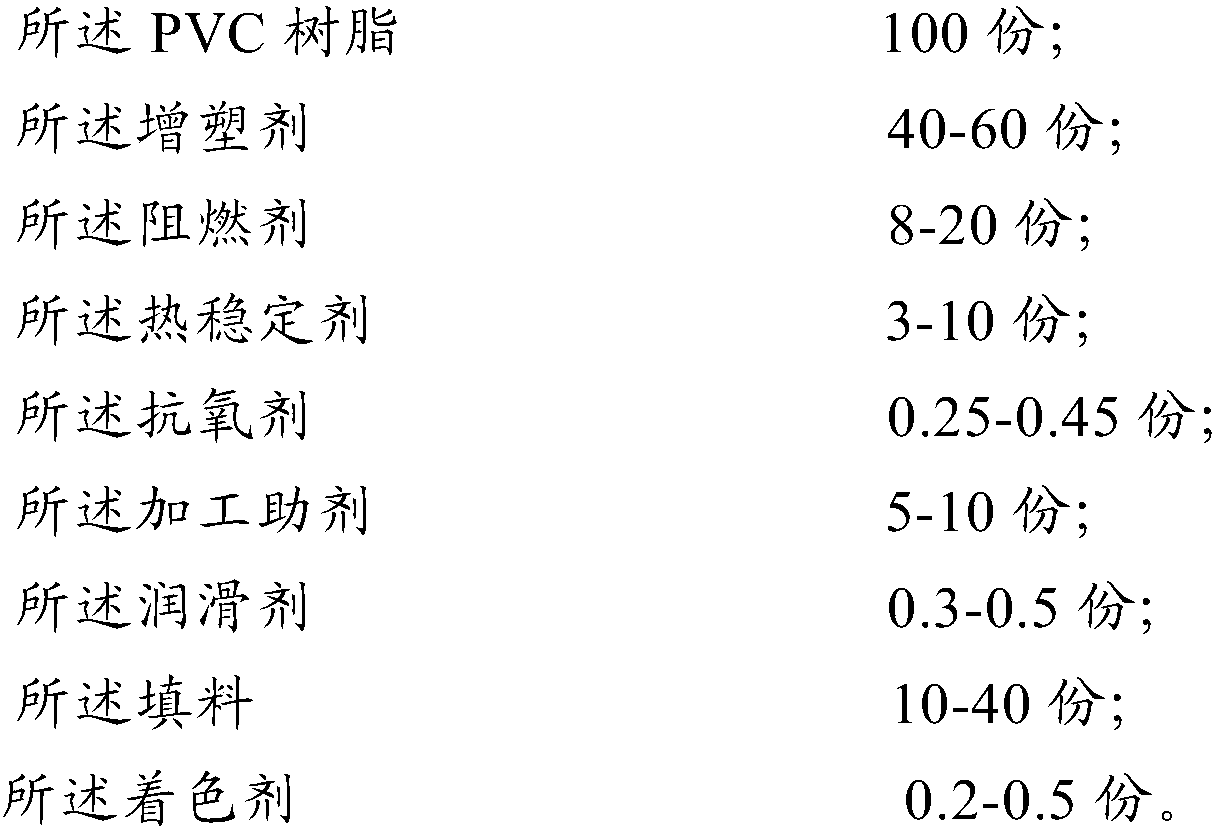

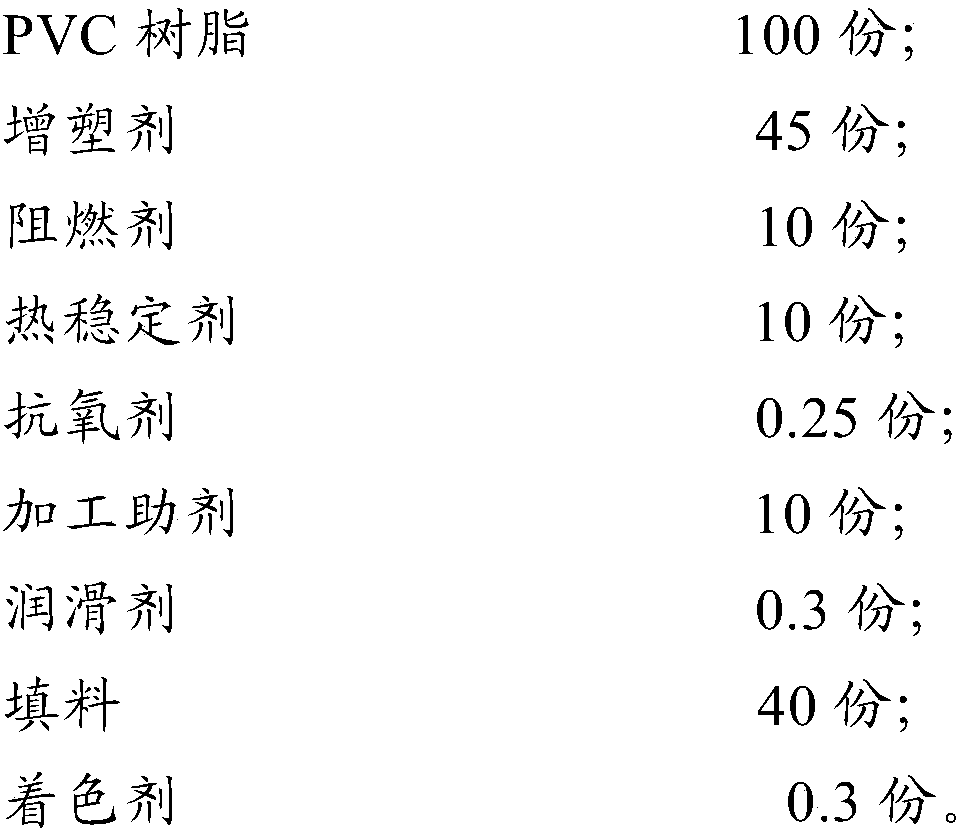

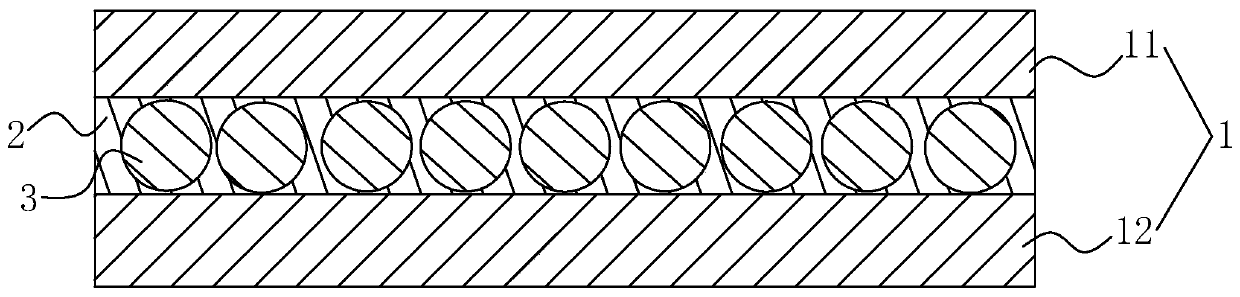

Environment-friendly cable insulation material, preparation method thereof, and cable sheath

InactiveCN107722488ABlock deliveryReduce the temperaturePlastic/resin/waxes insulatorsInsulated cablesProcedure AgentsAntioxidant

The invention discloses an environment-friendly cable insulation material, a preparation method thereof, and a cable sheath. The cable insulation material is prepared from the following raw materials:a PVC resin, a plasticizer, a flame retardant which comprises zinc borate-coated antimony trioxide and / or melamine-coated ammonium polyphosphate, a thermal stabilizer which comprises one or more of an organic calcium zinc complex stabilizer, an organic calcium zinc rare earth complex stabilizer, hydrotalcite, and methyltin dilaurate, an antioxidant, a processing aid, a lubricant, a filler, and acolorant. The environment-friendly cable insulation material provided by the invention is a thermoplastic cable material, which can achieve the functions of preventing burning or retarding combustionin case of fire and extinguishing away from fire, the oxygen index of the cable insulation material is more than or equal to 35, the environmental protection performance of the cable insulation material is better than the RoHS instruction requirement, and the heavy metal content of the cable insulation material provided by the invention is reduced by 10% on the basis of the RoHS instruction requirement. The cable insulation material provided by the invention is suitable for use in workplaces with high fire safety requirements.

Owner:TEBIAN ELECTRIC APP CO LTD +1

Production method of fireproof and flame-retardant type medium-density fiber wood floor

InactiveCN109366680AAlleviate the contradiction between supply and demandImprove fire and flame retardant performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberMedium density

The invention discloses a production method of a fireproof and flame-retardant type medium-density fiber wood floor. The production method comprises the steps of (1) pretreatment of raw materials; (2)screening; (3) stewing softening operation; (4) grinding operation; (5) glue application and drying; (6) pre-pressing operation; (7) hot-pressing operation; (8) sawing and sanding; (9) glue coating and veneering hot-pressing operation; and (10) preservation and grooving, so that the finished product is obtained. According to the production method, the eucalyptus bark, branches and waste leftovermaterials which remain after board manufacturing is accomplished are used as main raw materials, then other miscellaneous trees are added, the waste is turned into the wealth, and therefore the sufficient and effective utilization of timber resources can be achieved; and due to the fact that modified paraffin and flame-retardant urea-formaldehyde resin adhesives are added, the fireproof and flame-retardant performance of the wood floor can be greatly improved, and the produced medium-density fiber wood floor is excellent in fireproof and flame-retardant performance, good in water resistance and low in formaldehyde content, and is a safe, environmentally friendly and durable wood floor.

Owner:广西横州丽冠环保材料有限公司

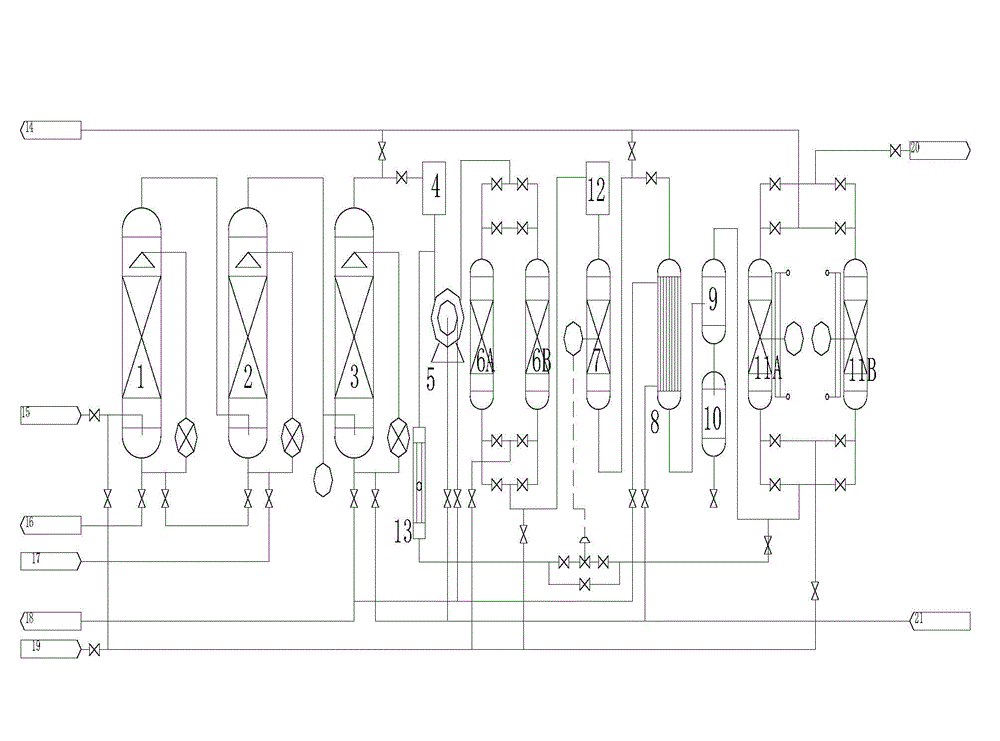

Device and method used for recycling hydrogen from chlor-alkali industry vented tail gas and preparing high purity hydrogen

The invention provides a device and a method used for recycling hydrogen from chlor-alkali industry vented tail gas and preparing high purity hydrogen. The method comprises following steps: two times of alkaline washing, one time of water washing, adsorption deep dechlorination, water ring compressor pressurizing, catalytic deoxidation, water cooling, terminal purification, oxygen dilution with countercurrent flow hydrogen, and explosion precaution. Production hydrogen purity of the method is as high as 99.9 to 99.999999%, and recovery rate is as high as 98%. Chlorine content and oxygen content in residual impurities can be as low as 1*10<-8> respectively, and flexible adjustment can be realized based on product purity requirements. The method is especially suitable to separate and recycle hydrogen from vented tail gas in chlor-alkali production, and possesses excellent economic benefits and environmental protection benefits.

Owner:DALIAN ZHONGDING CHEM

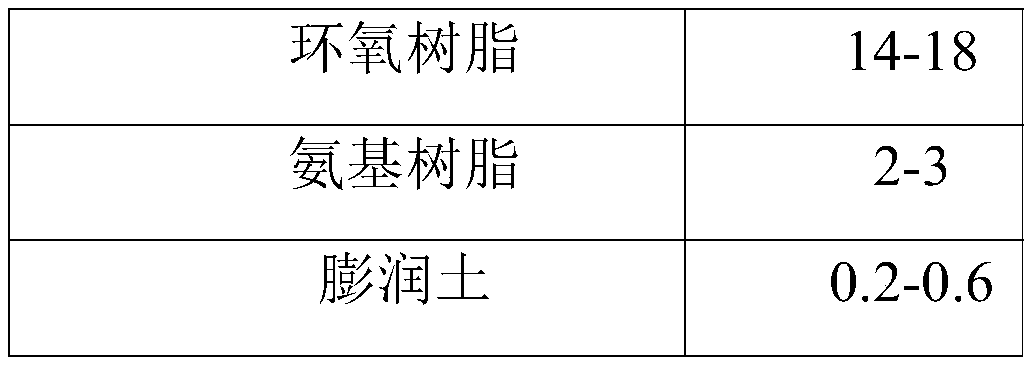

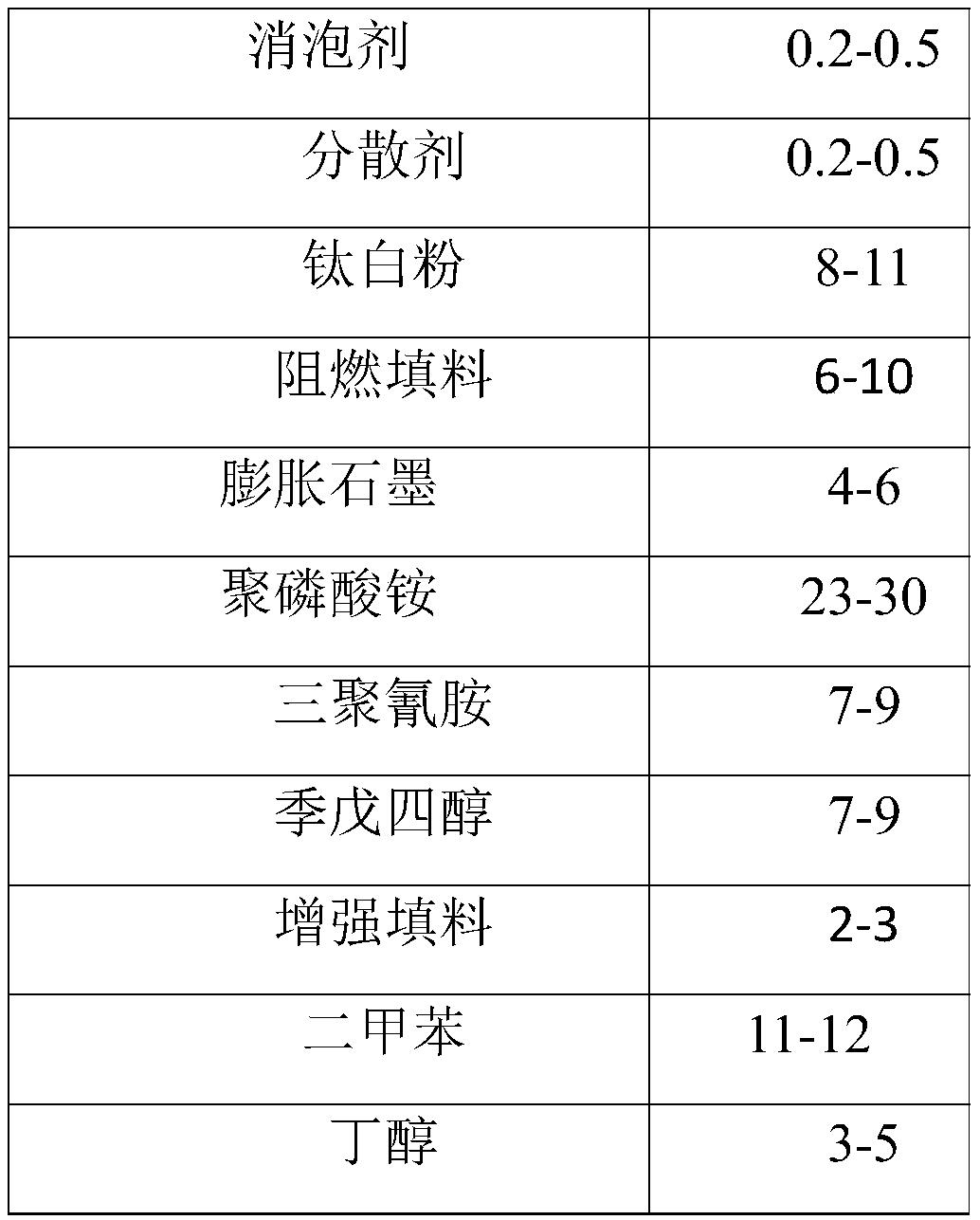

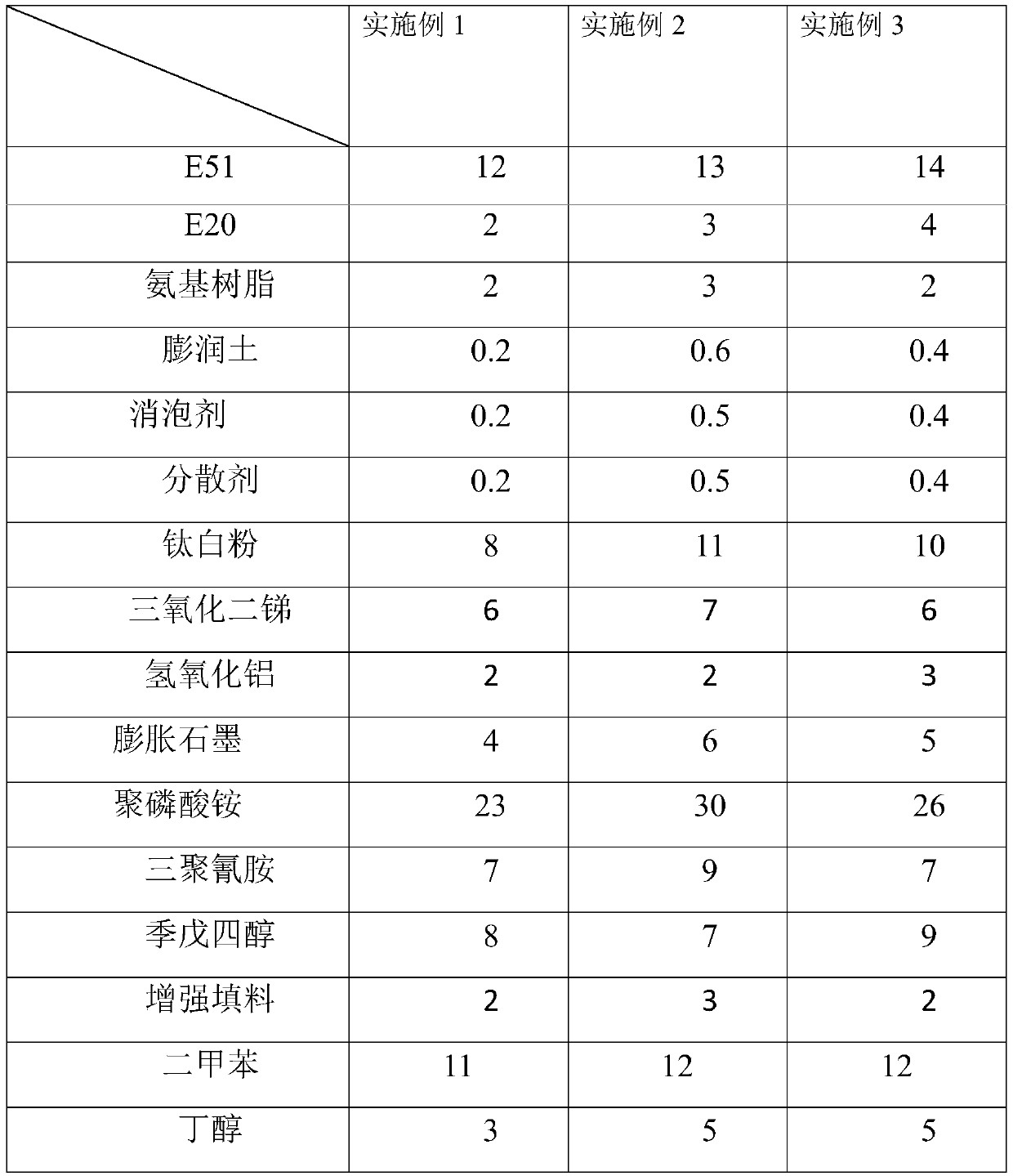

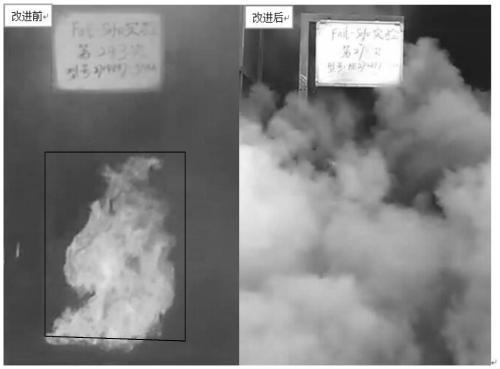

Double-component expansion type fireproof coating and preparation method thereof

InactiveCN110591502AStrong adhesionImprove cohesionFireproof paintsEpoxy resin coatingsEpoxyDefoaming Agents

The invention discloses a double-component expansion type fireproof coating which consists of a component A and a component B, wherein the component A consists of the following raw materials in partsby weight: 14-18 parts of an epoxy resin, 2-3 parts of an amino resin, 0.2-0.6 part of bentonite, 0.2-0.5 part of a defoaming agent, 0.2-0.5 part of a dispersant, 8-11 parts of titanium dioxide, 6-10parts of flame-retardant filler, 4-6 parts of expanded graphite, 20-30 parts of Ammonium Polyphosphate, 5-9 parts of melamine, 5-9 parts of pentaerythritol, 2-3 parts of reinforcing filler, 11-12 parts of xylene and 3-5 parts of butanol; and the component B is a modified polyamide epoxy curing agent. The fireproof coating is excellent in flame retardancy, high in mechanical strength and excellentin water resistance.

Owner:石家庄市油漆厂

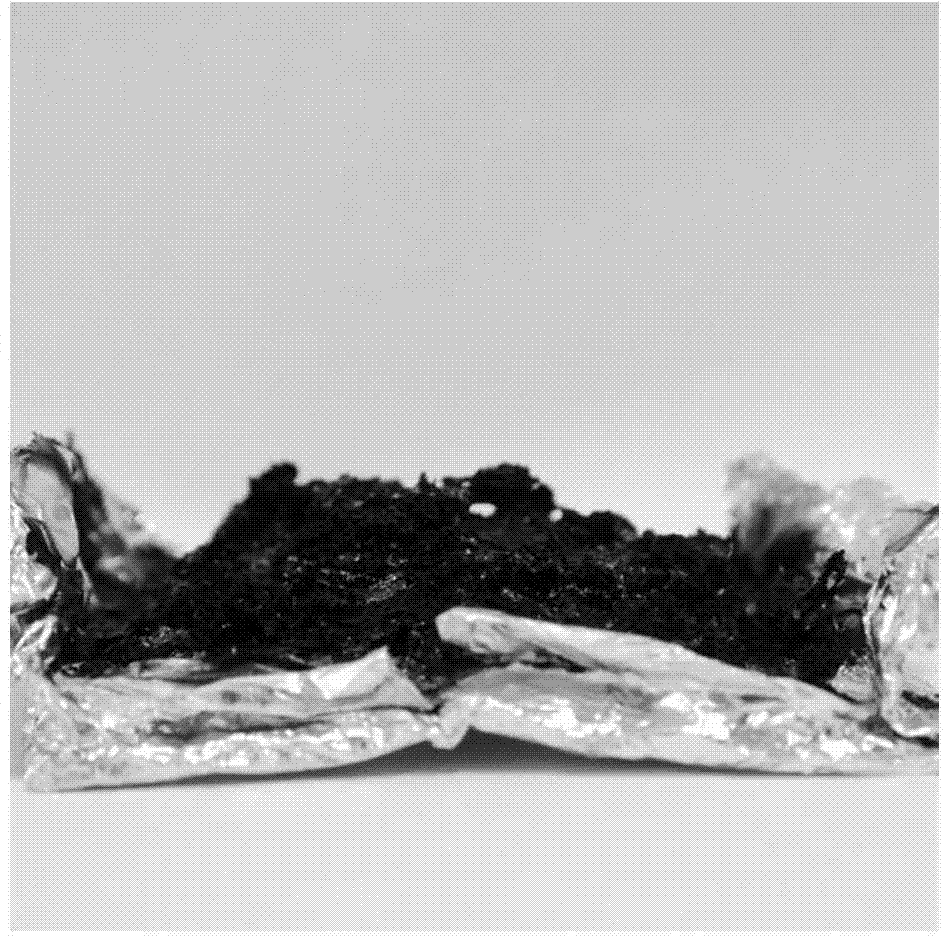

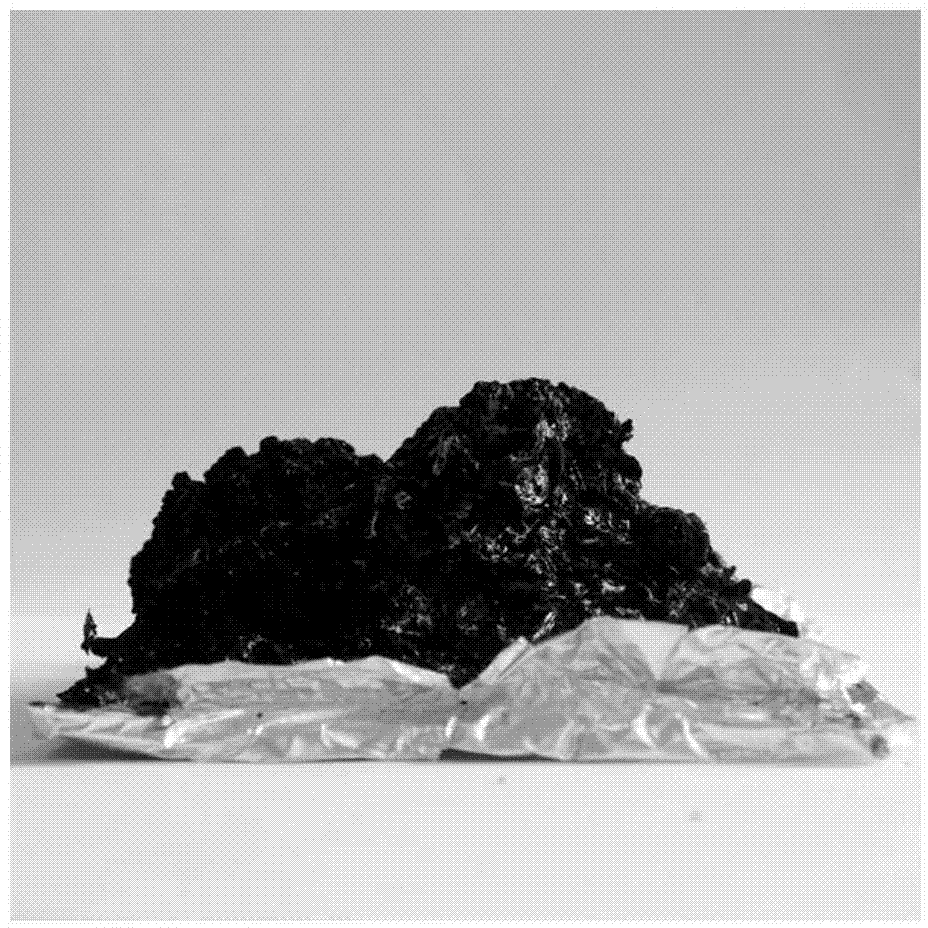

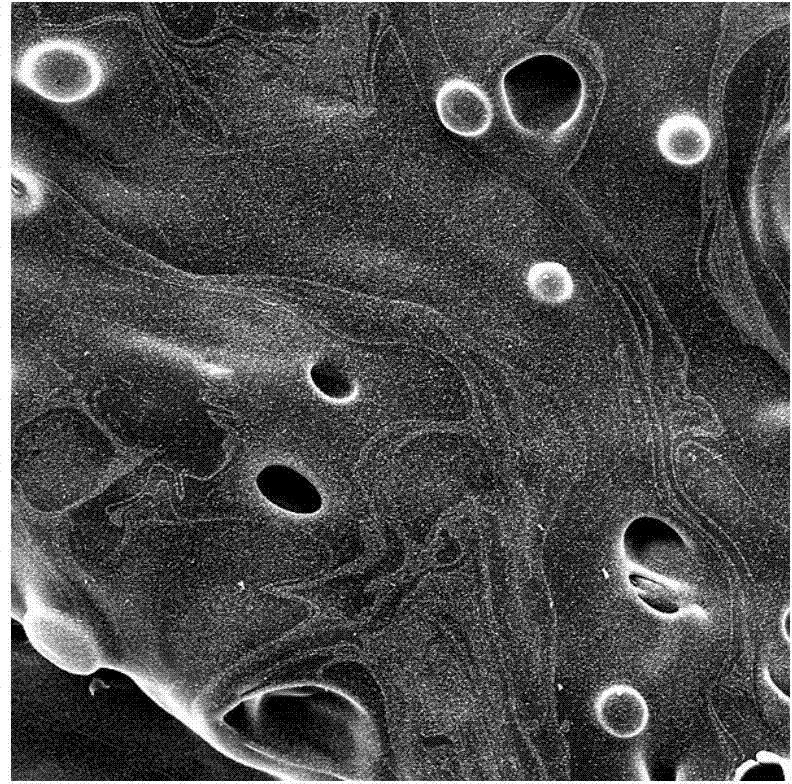

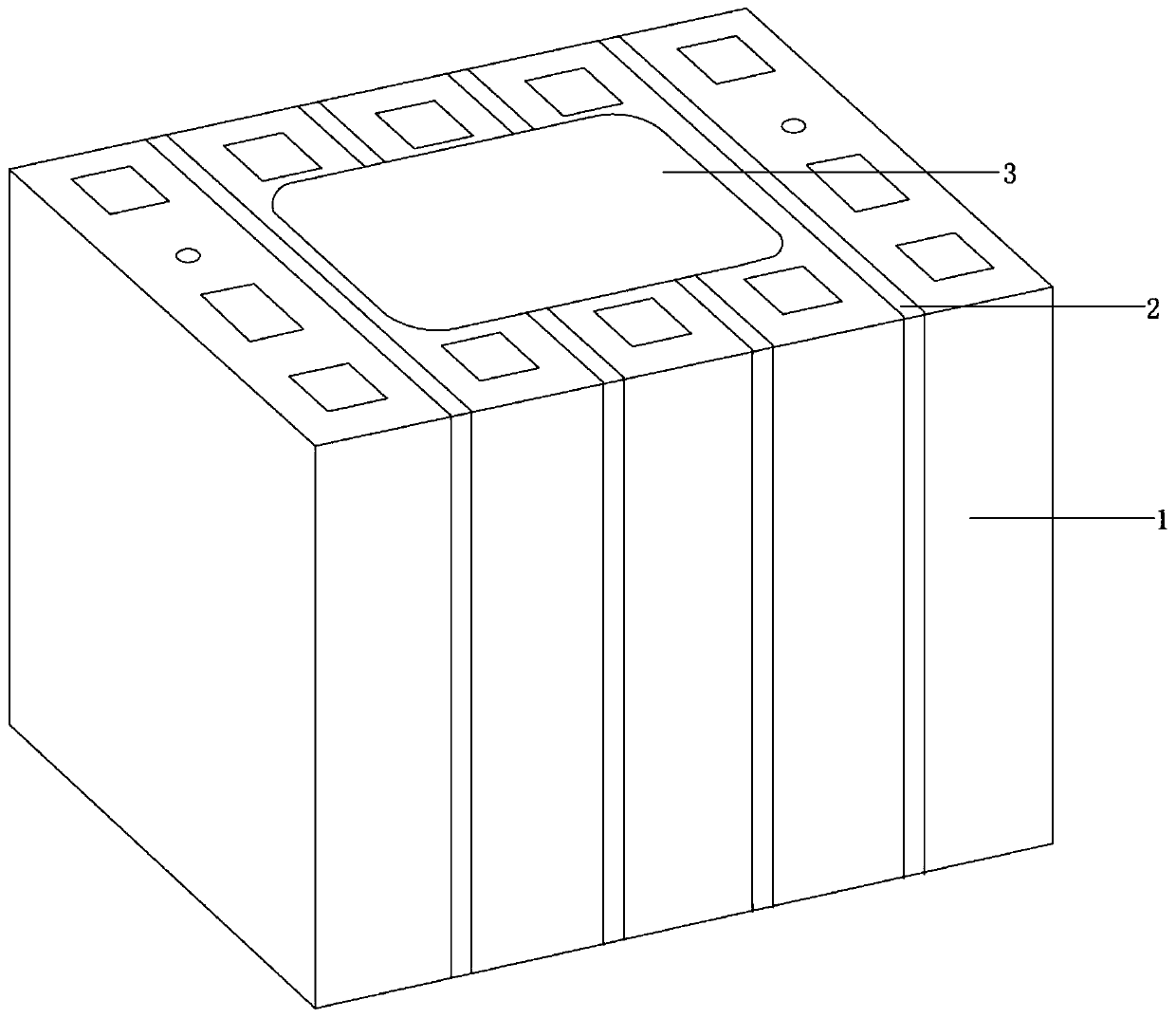

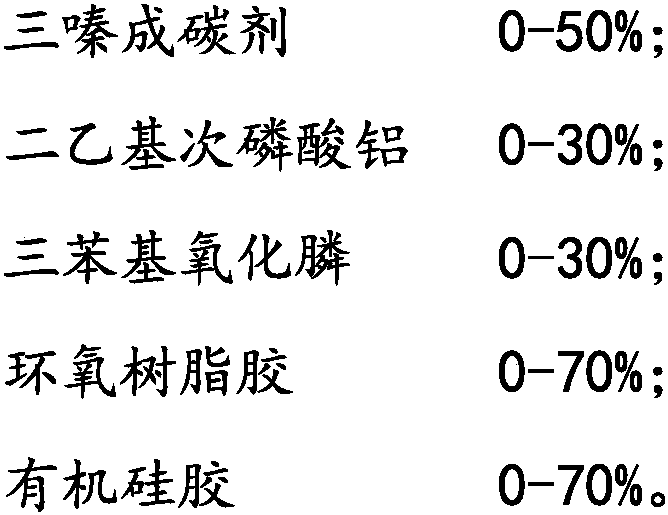

Flame retardant material of lithium battery module and preparation method of flame retardant material

The invention provides a flame retardant material of a lithium battery module. The flame retardant material is disposed on the top surface and / or the side surface of the lithium battery module, and comprises the following components: in percent by weight, 0-50% of a triazine carbon-forming agent, 0-30% of aluminum diethylphosphinate, 0-30% of triphenylphosphine oxide, 0-70% of an epoxy resin adhesive and 0-70% of organic silica gel. The invention also provides a preparation method of the flame retardant material for the lithium battery module. Through the flame retardant material, combustion can be slowed down and stopped, ignition of the lithium battery module is avoided, and the safety performance of lithium ion batteries is improved greatly.

Owner:SUZHOU YOULION BATTERY INC

High-temperature fire extinguishing device for high-voltage cable trench

ActiveCN111437546AReduce local temperatureLower oxygen levelsCable installations on groundFire rescueStructural engineeringElectric cables

The invention relates to a high-temperature fire extinguishing device for a high-voltage cable trench. The high-temperature fire extinguishing device comprises a guide rail system and an inspection device. The guide rail system comprises a left guide rail and a right guide rail which are fixed on the left side wall and the right side wall of the cable trench respectively, and the inspection deviceis arranged between the left guide rail and the right guide rail in a sliding mode. A fire extinguishing device is arranged in the inspection device and can perform fire extinguishing operation on afire source of the cable trench. The temperature inside the cable trench can be monitored in real time, and the cable can be automatically extinguished through a sandbox and the inspection device in time after being on fire.

Owner:山东和兑智能科技有限公司

Multi-point injected ammonia water atomization reduction method for reducing NOx discharge of gas-fired boiler

InactiveCN105536487AReduce generationEmission reductionGas treatmentDispersed particle separationOxygenNitrogen gas

The invention provides a multi-point injected ammonia water atomization reduction method for reducing NOx discharge of a gas-fired boiler, aims at solving the technical problem that gas fuel is directly burned for decrease and accordingly a large amount of NOx is generated and environmental pollution is caused and belongs to the technical field of reduction of nitrogen oxide discharge of the gas-fired boiler. The multi-point injected ammonia water atomization reduction method is characterized in that after ammonia water is subjected to compressed air atomization and is jet to a main burning area (fuel-rich area) with the temperature of above 1000 degrees of a gas-fired boiler area through spray gun spray nozzles symmetrically and evenly distributed in a layered multi-point mode, so that NH3 in atomized ammonia steam and hydroxyl and NOx of the main burning area produce chemical reduction reaction, and the NOx concentration is reduced. The low-temperature atomized ammonia water is jet to the high-temperature main burning area, and local burning temperature of the area can be reduced. In addition, the atomized ammonia water can dilute oxygen concentration, reduces binding probability of nitrogen, a nitrogen compound and oxygen and accordingly reduces NOx. The NOx concentration in exhaust gas is reduced.

Owner:SHANGHAI WISEBOND TECH

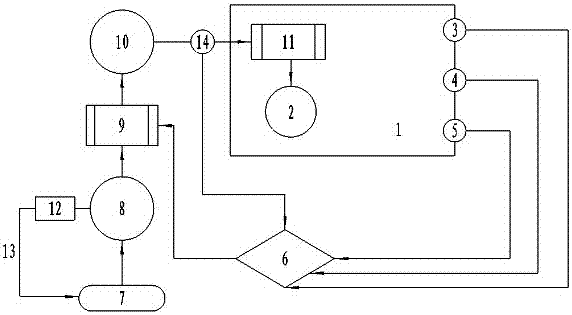

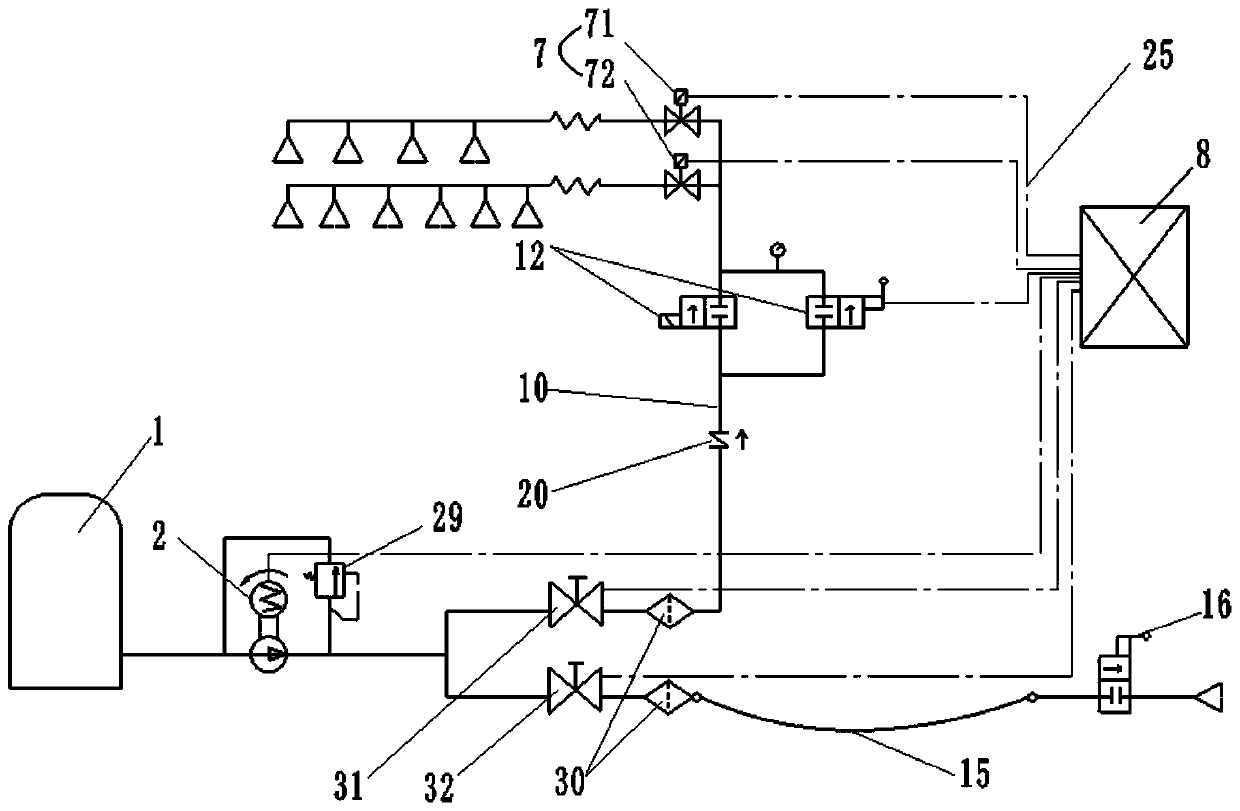

Water spray device capable of reducing NOx emission of dual-fuel engine of fishing boat

InactiveCN107304732AEasy to controlTo achieve the effect of moisturizingNon-fuel substance addition to fuelMachines/enginesCooling effectEngineering

The invention discloses a water spray device capable of reducing NOx emission of a dual-fuel engine of a fishing boat. The water spray device comprises a main body, namely, the dual-fuel engine; an exhaust temperature sensor, a rotating speed sensor and a crankshaft position sensor on the dual-fuel engine are electrically connected with an ECU (electronic control unit) through wires. The water spray device further comprises a pure water box; the pure water box is in series connection with a water pump, a water quantity control valve, a flowmeter and a plurality of spray nozzles sequentially; the water quantity control valve is electrically connected with the ECU through a wire; and positions of the spray nozzles correspond to those of air cylinders. The water pump sucks water from the pure water box, due to the action of a pressure maintaining valve, pressure of water flowing out of the water pump is stabilized at two barometric pressure, excess water flows back to the pure water box, and the ECU, according to the crankshaft position sensor, sprays the water into the air cylinders through the spray nozzles at the later stages of exhaust strokes of pistons. The ECU controls the water quantity control valve through the pulse width and a spray cycle and thus controls the water spray quantity, and receives and adjusts a numerical value of a water quantity sensor, thereby achieving the air humidifying and cooling effects.

Owner:NANTONG SHIPPING COLLEGE

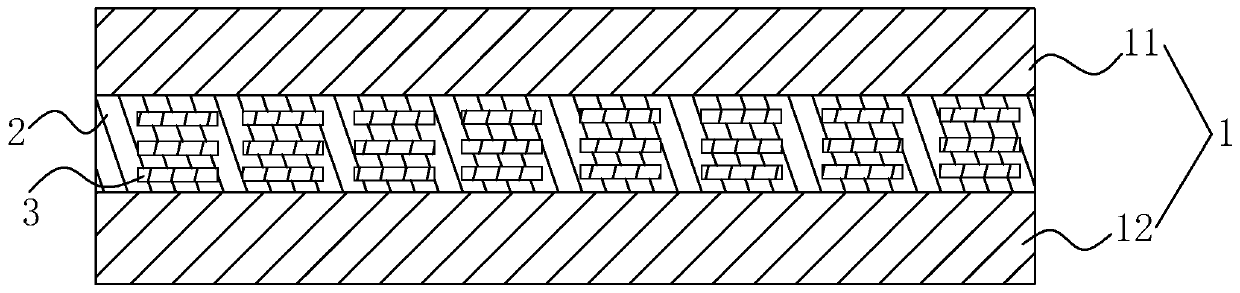

Wear-resistant flame-retardant conveying belt and preparation process thereof

The invention discloses a wear-resistant flame-retardant conveying belt and a preparation process thereof. The wear-resistant flame-retardant conveying belt comprises a cover glue, an adhesive intermediate glue and a framework material, wherein the cover glue comprises an upper cover glue and a lower cover glue; the framework material is a steel wire rope or a flame-retardant polyester fabric; thecover glue comprises the following components: a matrix rubber, sulfur, flame retardant, 10-15 parts of stearic acid, an anti-aging agent, a vulcanization accelerator, a reinforcing filler, paraffinwax, metal oxides, a wear-resistant filler and a dispersing agent. A preparation process of the wear-resistant flame-retardant conveying belt comprises the steps of S1, preparation of the cover glue:(1) preliminary plastication and (2) mixed granulation; S2, preparation of the adhesive intermediate glue: I, preliminary plastication; II, stirring and mixing; III, grinding and defoaming; S3, impregnation and plasticizing of an aggregate material; and S4, extrusion and gluing of the cover glue. The wear-resistant flame-retardant conveying belt disclosed by the invention has the advantages of good wear resistance and excellent flame-retardant effect; in addition, the preparation method disclosed by the invention has the advantages of simple process, low production cost and high work efficiency.

Owner:青岛环球输送带有限公司

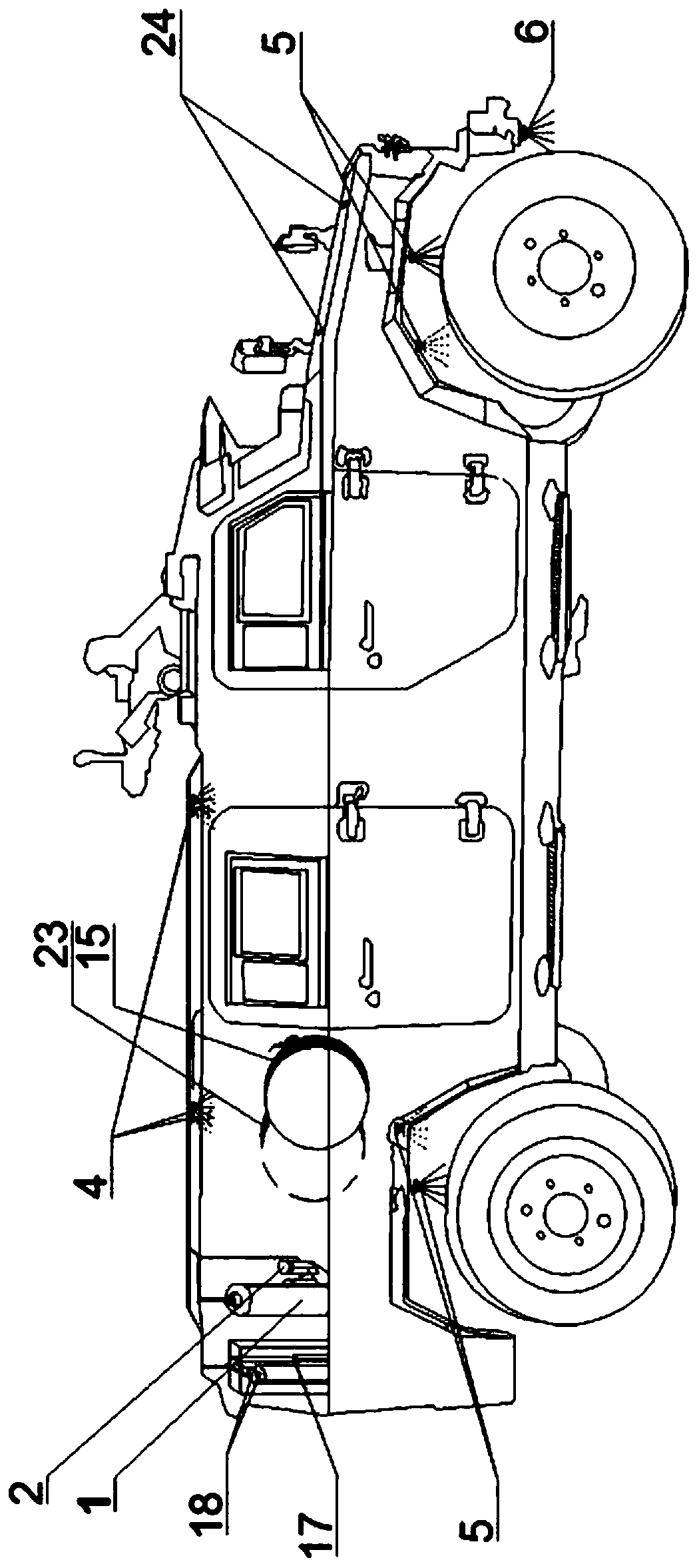

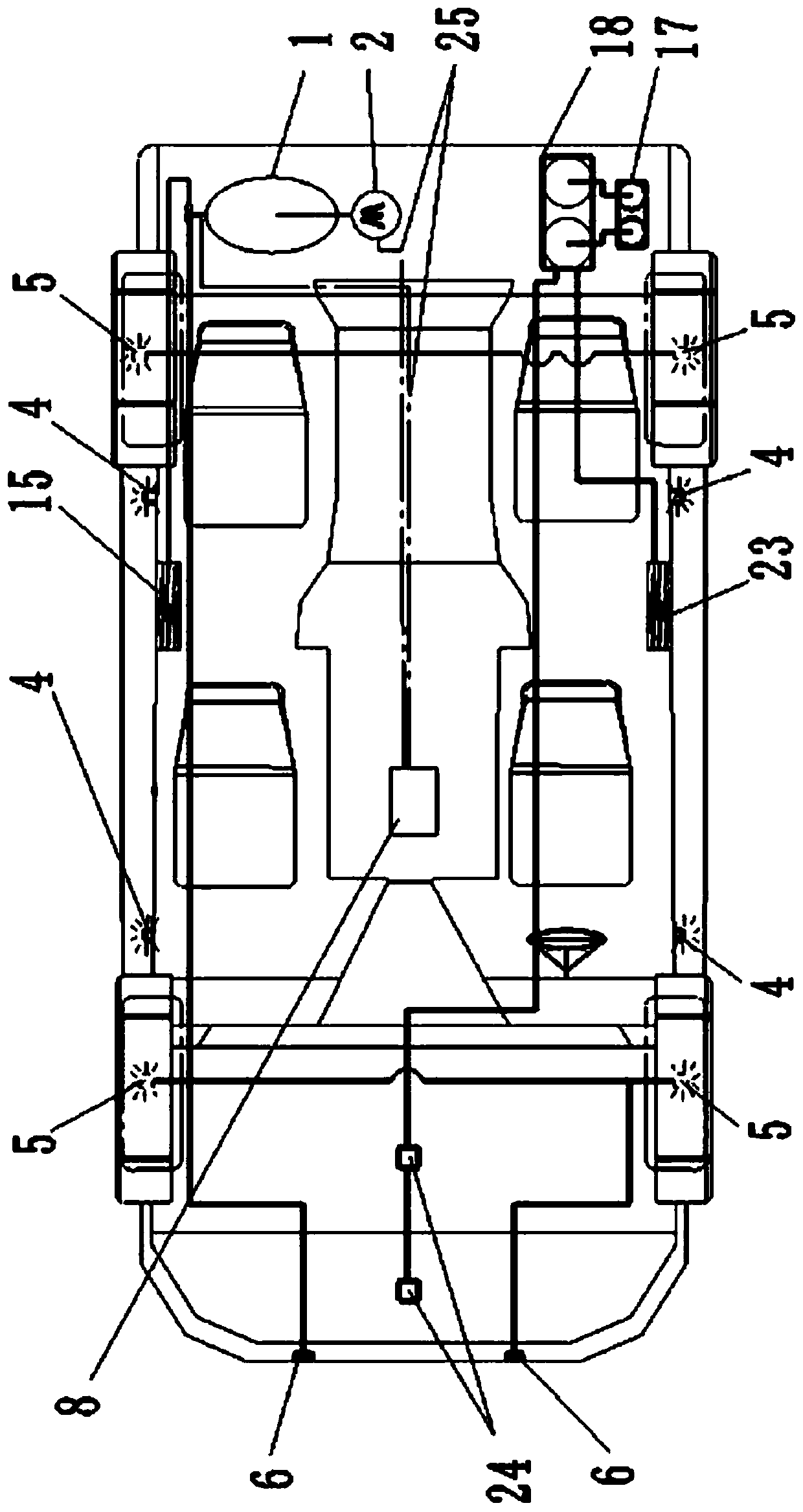

Vehicle-mounted protection fire extinguishing device for anti-riot armored vehicle

The invention discloses a vehicle-mounted protection fire extinguishing device for an anti-riot armored vehicle, and belongs to the technical field of fire extinguishing equipment. The device comprises a high-pressure water mist fire extinguishing system and a Novec 1230 gas fire extinguishing system, wherein the high-pressure water mist fire extinguishing system and the Novec 1230 gas fire extinguishing system are arranged inside and outside a carriage and are controlled by a function control panel in a cab. The high-pressure water mist is utilized to absorb heat and vaporize, thus the oxygenconcentration is diluted while the temperature of a fire scene is reduced; and meanwhile, the water quantity required for fire extinguishing is small, and the water stain residual quantity is small after fire extinguishing, so that the damage of a large amount of accumulated water to equipment and the environment can be effectively avoided; the requirement on space tightness is avoided, ventilation in a certain degree can be borne, and deep fire can be effectively inhibited; an Novec 1230 fire extinguishing agent of the Novec 1230 gas fire extinguishing system is vaporized and then forms a gaseous mixture with air, so that a large amount of heat can be absorbed to cool a combustion area; the temperature is reduced to be below the temperature point of flame extinguishment; the Novec 1230 gas fire extinguishing system has the characteristic of low toxicity, namely the minimum gas concentration required by fire extinguishment is less than the harmful concentration of a human body; the fire extinguishing efficiency is high, the universality is high, and the popularization and application are convenient.

Owner:中国人民警察大学

Flame-retardant moisture-absorbing fabric and preparation method thereof

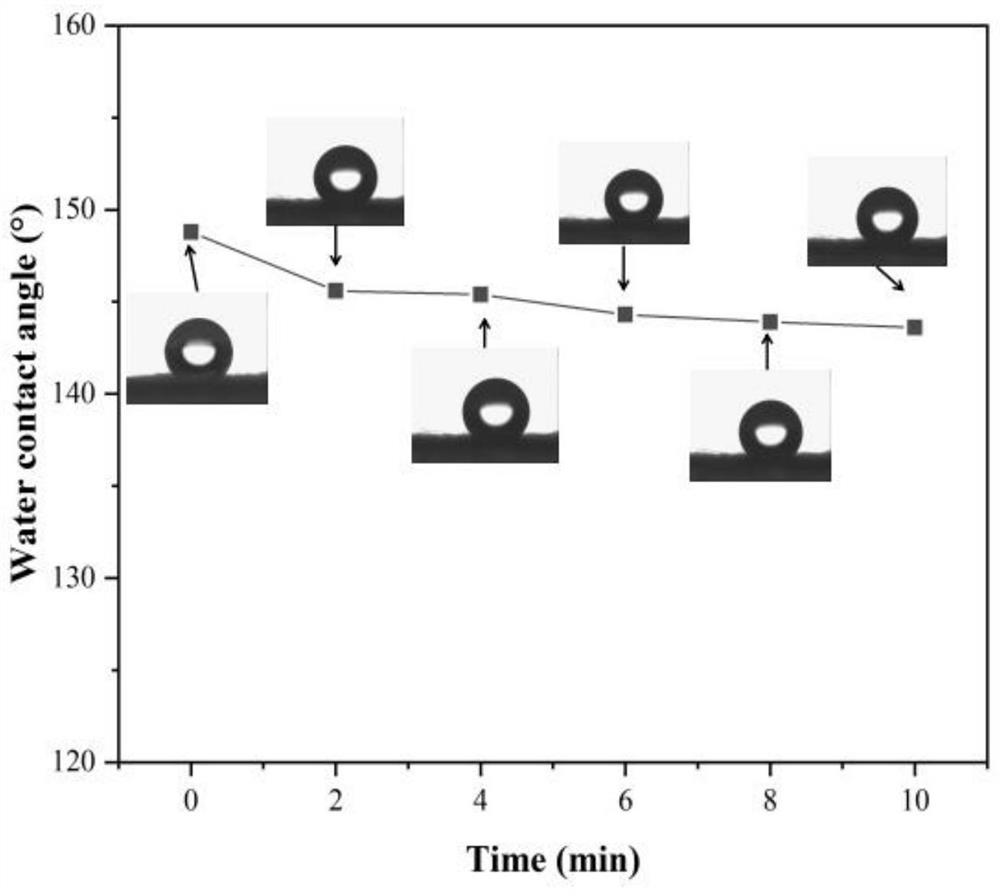

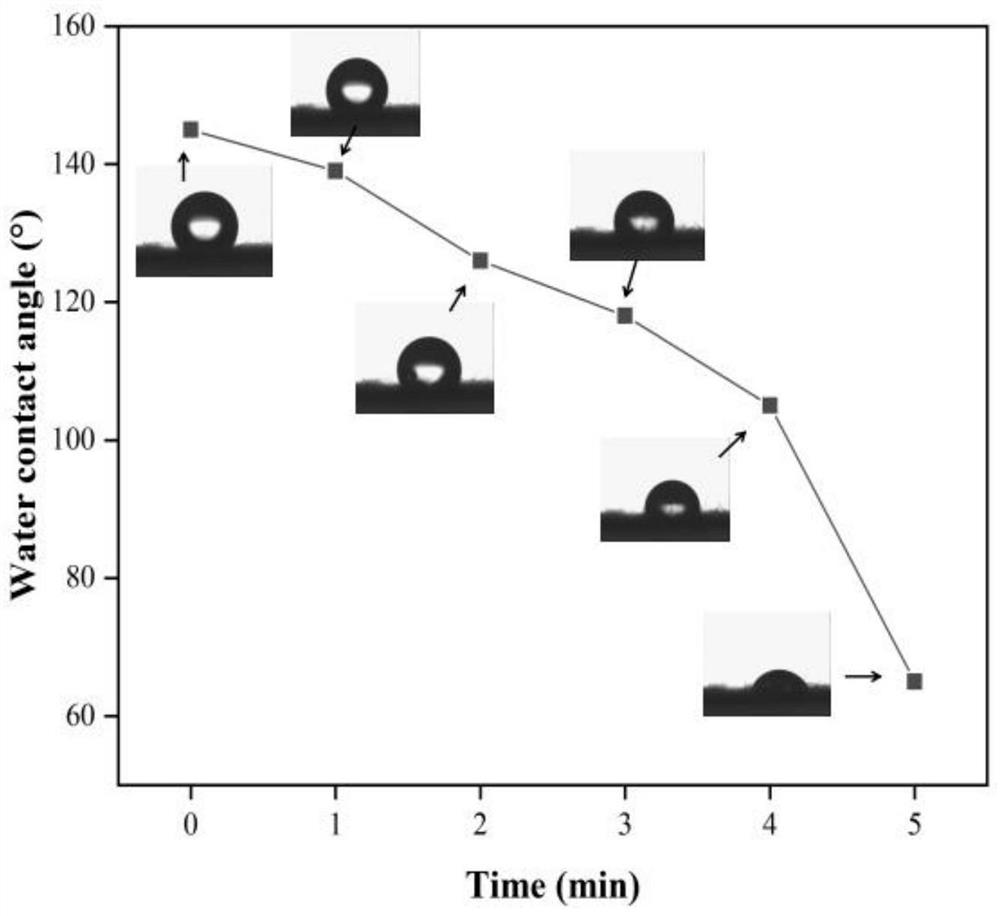

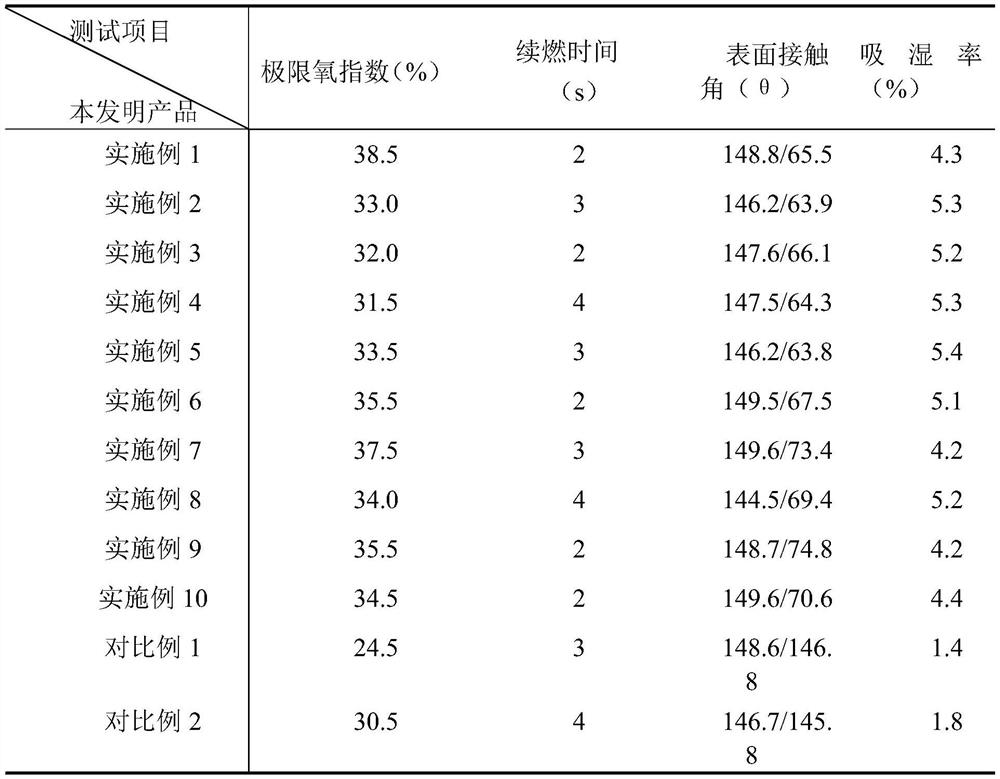

PendingCN112342788AEnhanced interface bindingHigh surface energyHeat resistant fibresLiquid repellent fibresPhysical chemistryMoisture absorption

The invention discloses a flame-retardant moisture-absorbing fabric and a preparation method thereof. The preparation method specifically comprises the following steps that a metal salt and an alkaline substance are fully dissolved in water, and then transferred into a hydrothermal kettle for a hydrothermal reaction to obtain a layered double hydroxide (LDH); the LDH is placed in a buffer solutionto be subjected to ultrasonic treatment to obtain a uniform and stable suspension system; and the fabric and dopamine hydrochloride are added into the suspension system for oscillation treatment, andfinally drying is carried out to obtain the modified fabric. According to the preparation method, dopamine and LDH are coordinated, so that a LDH flame retardant is firmly loaded on the surface of the fabric, and the stability of the modified layer is greatly improved. Meanwhile, dopamine can be self-polymerized at normal temperature, and the adhesion capacity is extremely high. The preparation method has the characteristics of mild reaction conditions, simplicity, feasibility and wide application range, and the flame retardance and moisture absorption performance of the modified fabric are remarkably improved.

Owner:ZHEJIANG SCI-TECH UNIV +1

Flame-retardant high-strength conveyor belt and preparation process thereof

InactiveCN109734975AHigh strengthHigh limiting oxygen indexNatural rubber adhesivesConveyorsPolyesterAdhesive

The invention discloses a flame-retardant high-strength conveyor belt and a preparation process thereof. The flame-retardant high-strength conveyor belt comprises a covering adhesive, a bonded intermediate adhesive and a framework material, wherein the covering adhesive comprises an upper covering adhesive and a lower covering adhesive, and the framework material is steel wire ropes or flame-retardant polyester fabrics. The preparation method includes the following steps: S1. preparing covering glue: (1) preliminarily plasticating; (2) mixing and granulating; S2. preparing the bonded intermediate adhesive: I. primary plastication; II. stirring and mixing; III. grinding and defoaming; S3. gum dipping and plasticizing of aggregate materials; S4. extruding and bonding the covering adhesive. The flame-retardant high-strength conveyor belt has the advantages of good flame retardant performance, safety, environmental protection and high mechanical strength; and in addition, the preparation method has the advantages of simple process, low production cost and high working efficiency.

Owner:青岛环球输送带有限公司

High-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material and preparation method thereof

InactiveCN104558867AGood flexibilityImprove solubilityRubber insulatorsPlastic/resin/waxes insulatorsPolymer scienceAntimony trioxide

The invention discloses a high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material which is prepared from the following raw materials in parts by weight: 48-54 parts of ethylene propylene diene monomer rubber, 28-34 parts of preformed fluorine-containing polymer, 20-23 parts of styrene-butadiene rubber, 10-12 parts of hard clay, 3-5 parts of monoalkoxy titanate coupling agent, 5-8 parts of aluminum hydroxide, 6-7 parts of red phosphorus master batch, 4-5 parts of antimony trioxide, 0.5-0.8 part of sulfur, 0.4-0.6 part of dicumyl peroxide, 1.1-1.4 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1.4-1.5 parts of trimethylolpropane trimethylacrylate, 1.6-2 parts of anti-aging agent H and 1.2-1.5 parts of anti-aging agent DFC-34. The invention also discloses a preparation method of the high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material. The high-elasticity high-strength weather-resistant flame-retardant ethylene propylene diene monomer cable material has the advantages of high elasticity, high strength, excellent flame retardancy, excellent wear resistance, excellent ozone erosion resistance and excellent weather resistance.

Owner:ANHUI SPECIAL CABLE GRP

Production method of dedicated fireproof flame-retardant medium-density fiber cabinet board

InactiveCN109366667AIncrease surface areaImprove adsorption capacityWood working apparatusFlat articlesEnvironmental resistanceFiber

The invention discloses a production method of a dedicated fireproof flame-retardant medium-density fiber cabinet board. The production method comprises the following steps: (1) raw material pretreatment; (2) sieving; (3) softening through stewing; (4) grinding; (5) gluing and drying; (6) prepressing; (7) hot-pressing; (8) sawing and sanding; (9) veneering hot-pressing; and (10) edge cutting, thereby obtaining the finished product. Eucalyptus bark, branches, and waste leftover materials left in plate manufacturing are used as main raw materials, and other weedtrees are added, so that waste isturned into wealth, and timber resources are sufficiently and effectively utilized; modified paraffin and a flame retardant urea resin adhesive are added, so that the fire resistance and the flame retardation performance are greatly improved, and the manufactured dedicated medium-density fiber cabinet board is high in fire resistance and the flame retardation performance, high in water resistance,and low in formaldehyde content, and is a safe and environmental-friendly dedicated cabinet board.

Owner:广西横州丽冠环保材料有限公司

Fireproof flame-retardant silicon rubber

The invention provides fireproof flame-retardant silicon rubber. The fireproof flame-retardant silicon rubber is prepared from the following components in parts by weight: 300 parts of silicone raw rubber, 30-70 parts of reinforced filler, 15-30 parts of anti-structuralization assistant, 40-90 parts of aluminum powder, 3-5 parts of releasing agent, 10-40 parts of special filler, and 4-10 parts ofvulcanizing agent. In high temperature or combustion environment, the aluminum powder is heated for decomposing and absorbing heat, and a temperature of the silicone rubber is reduced, secondly watermolecules are released by thermal decomposition by heating, an oxygen concentration can be diluted, so combustion is prevented from being continuously performed. The special filler is prepared from one or more of mica, aedelforsite, kaolin, powder-like glass, glass fibers, a boron-containing compound and zinc oxide. Three parties of aluminum oxide generated by the thermal decomposition by heating,silicon dioxide generated by the combustion of the silicon rubber and the reinforced filler are sintered to generate a ceramic-like structure which covers the surface of the silicone rubber, oxygen can be isolated by the ceramic-like structure, a combustion process is prevented from being continuously diffused to an internal structure, and an internal device is prevented from being directly exposed in the high temperature or combustion environment.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

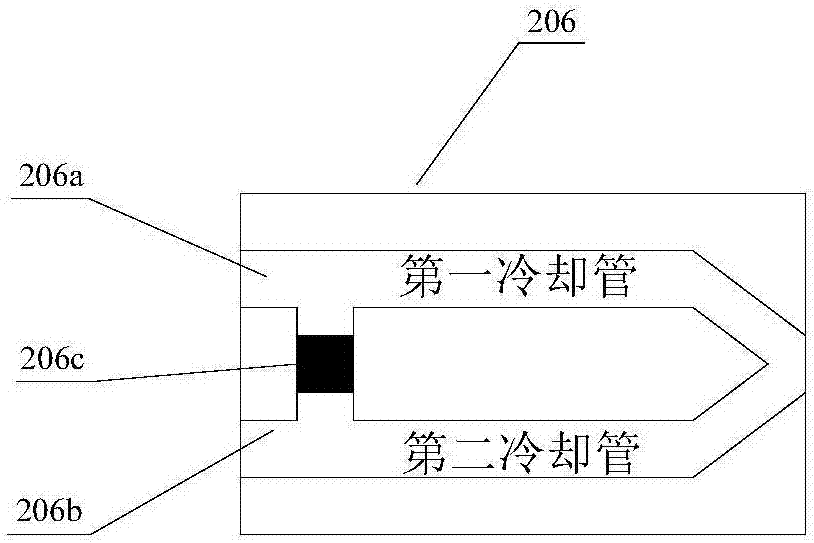

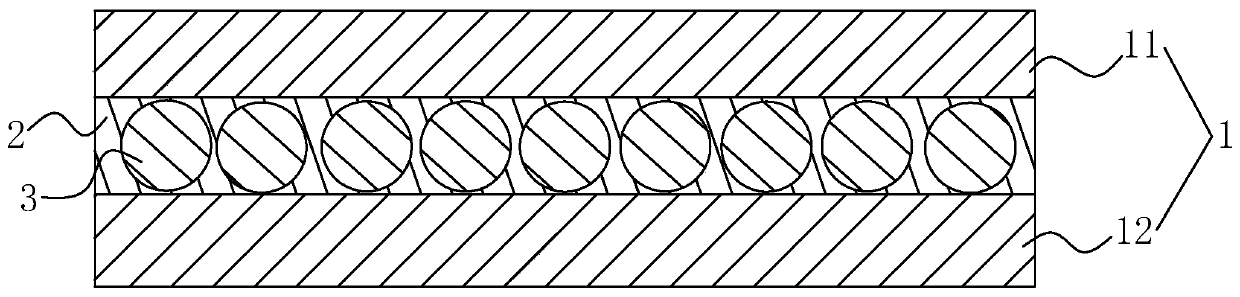

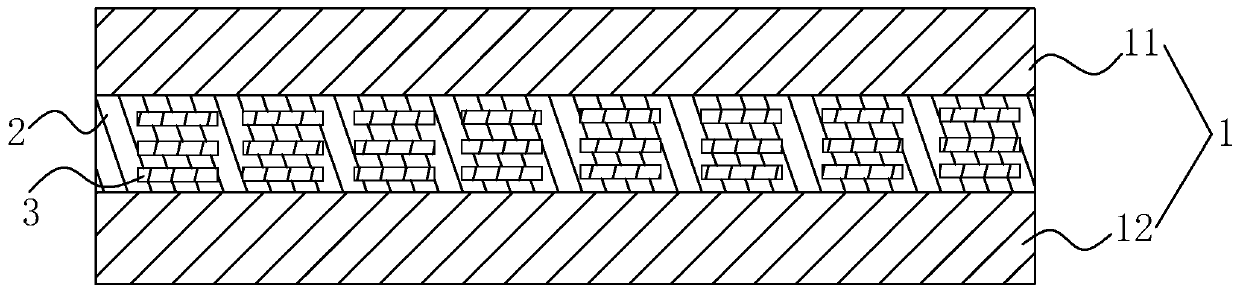

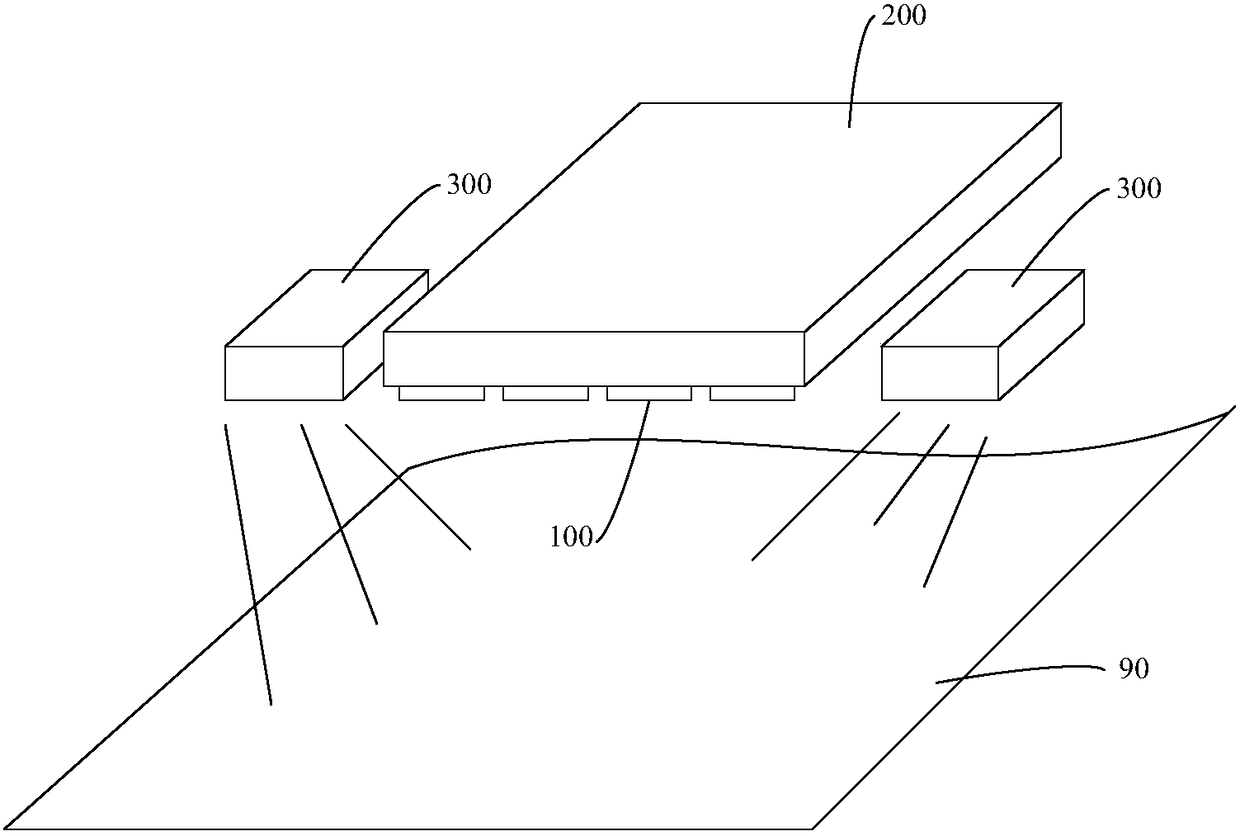

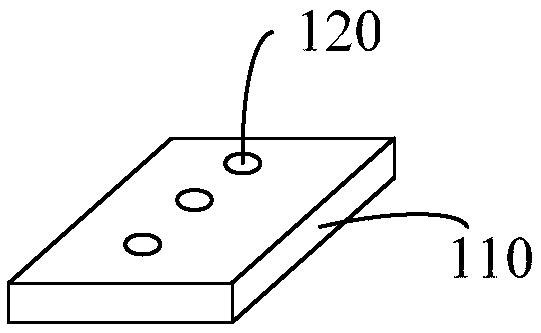

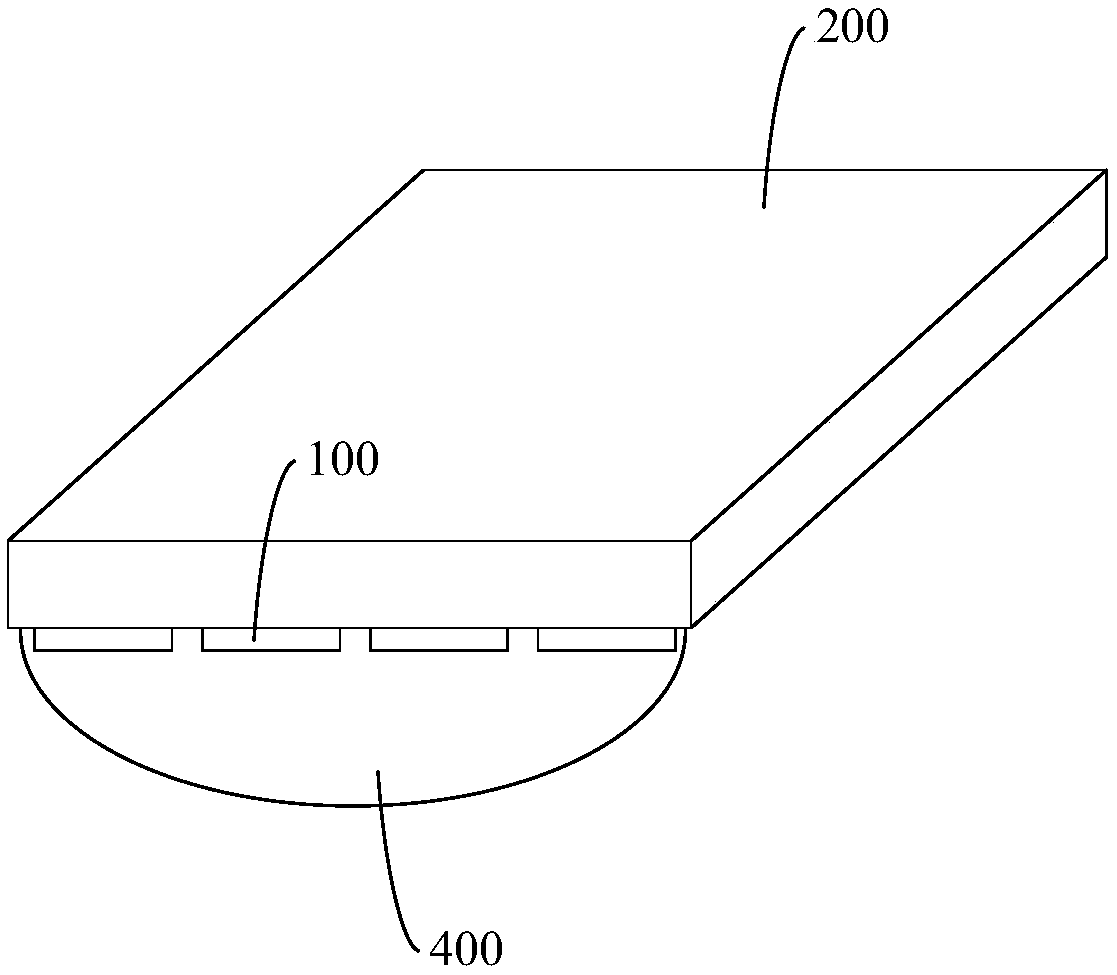

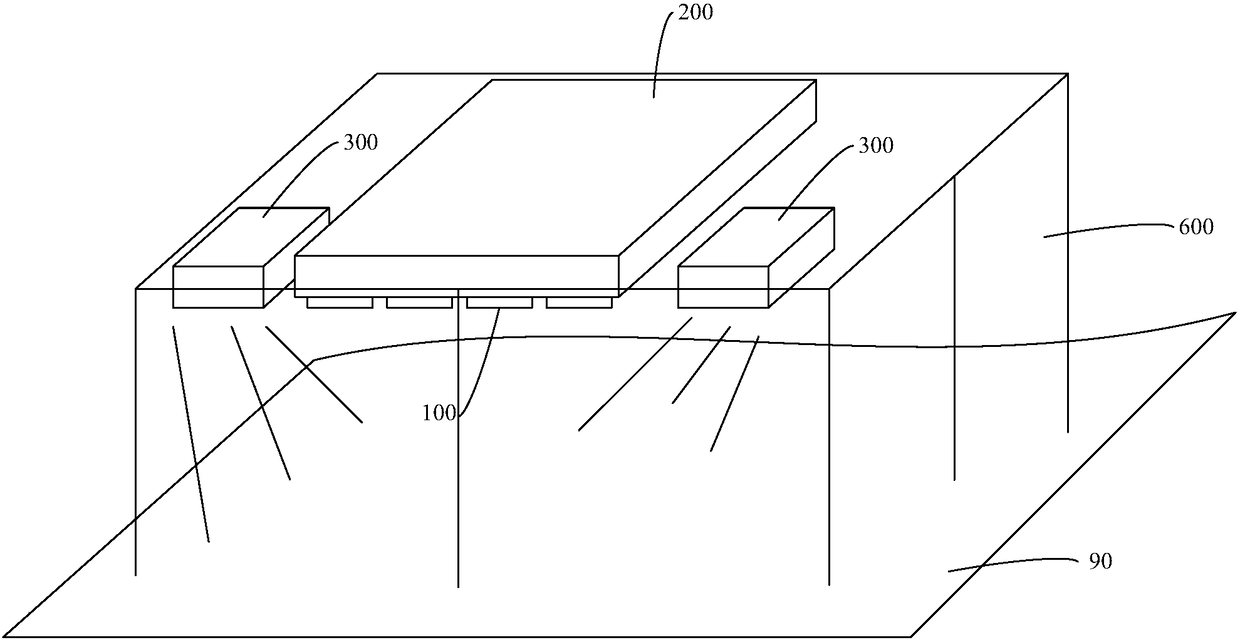

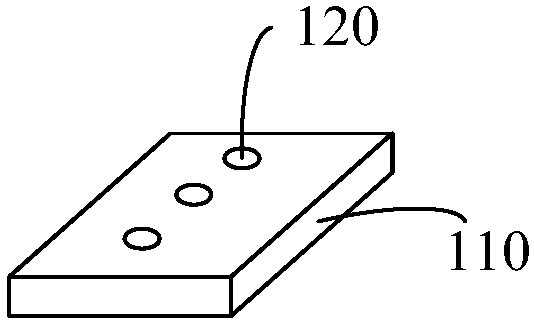

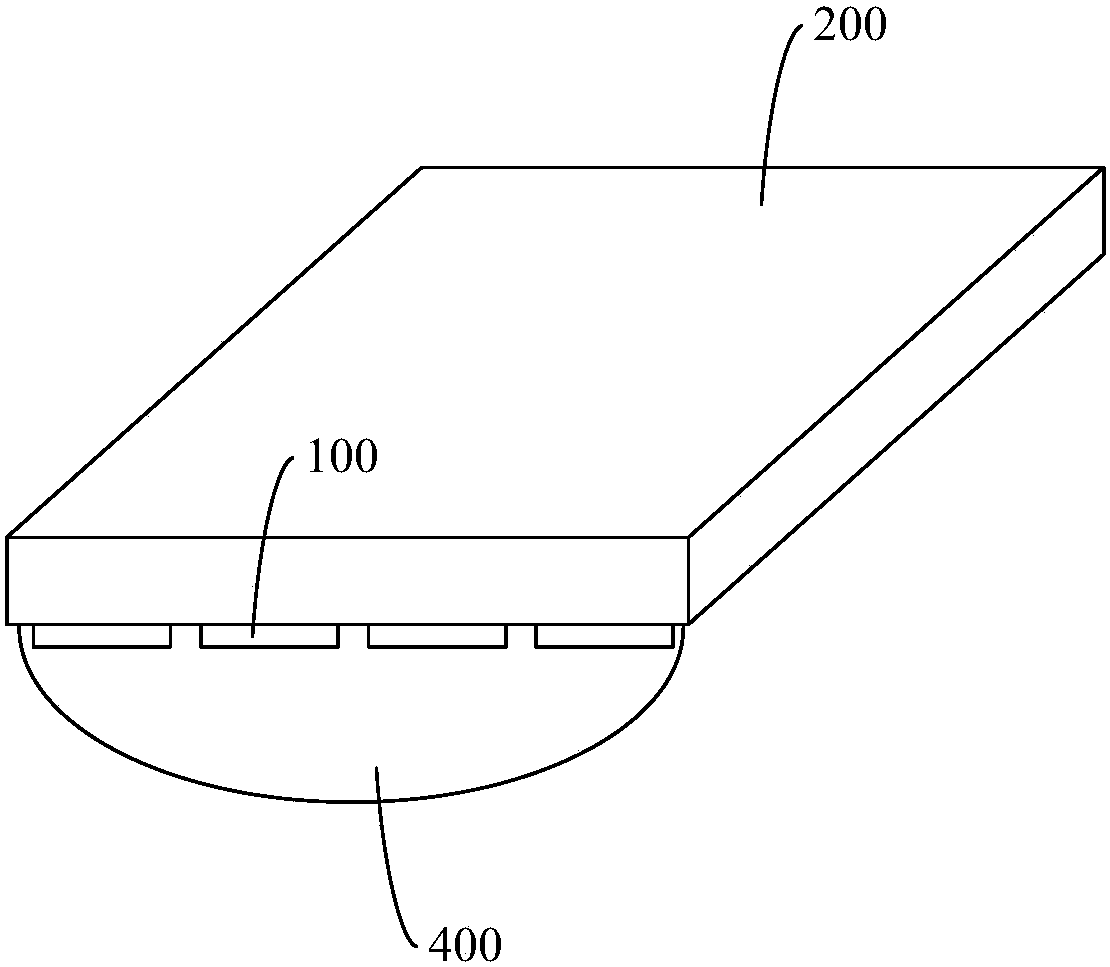

An ultraviolet light LED light source device

PendingCN108361561AGood linear spotDilute oxygen concentrationLighting heating/cooling arrangementsLight fasteningsUltraviolet lightsOxygen

The invention relates to an ultraviolet light LED light source device including a LED light source module and a heat radiation module. The LED light source module includes a substrate and LED light source units arranged in an array on the substrate. The substrate is installed on the heat radiation module and the ultraviolet light LED light source device also includes an oxygen-free gas source. Theoxygen-free gas source is used to blow oxygen-free gas on the irradiation surface of the LED light source module and to create an oxygen-free environment on the irradiation surface of the LED light source module. The above ultraviolet light LED light source device is equipped with the oxygen-free gas source, the oxygen-free gas source blow the oxygen-free gas to the irradiation surface during theultraviolet irradiation, the oxygen concentration in the upper space of the irradiation surface can be diluted, the oxygen concentration can be reduced to a lower degree through the continuous blowing, thus the oxygen-free environment is formed. Due to a fact that no ozone may be generated in an oxygen-free environment when ultraviolet rays irradiate on the irradiation surface, so that the quality of the ultraviolet ray irradiation solidification is ensured.

Owner:深圳市优绿源科技有限公司

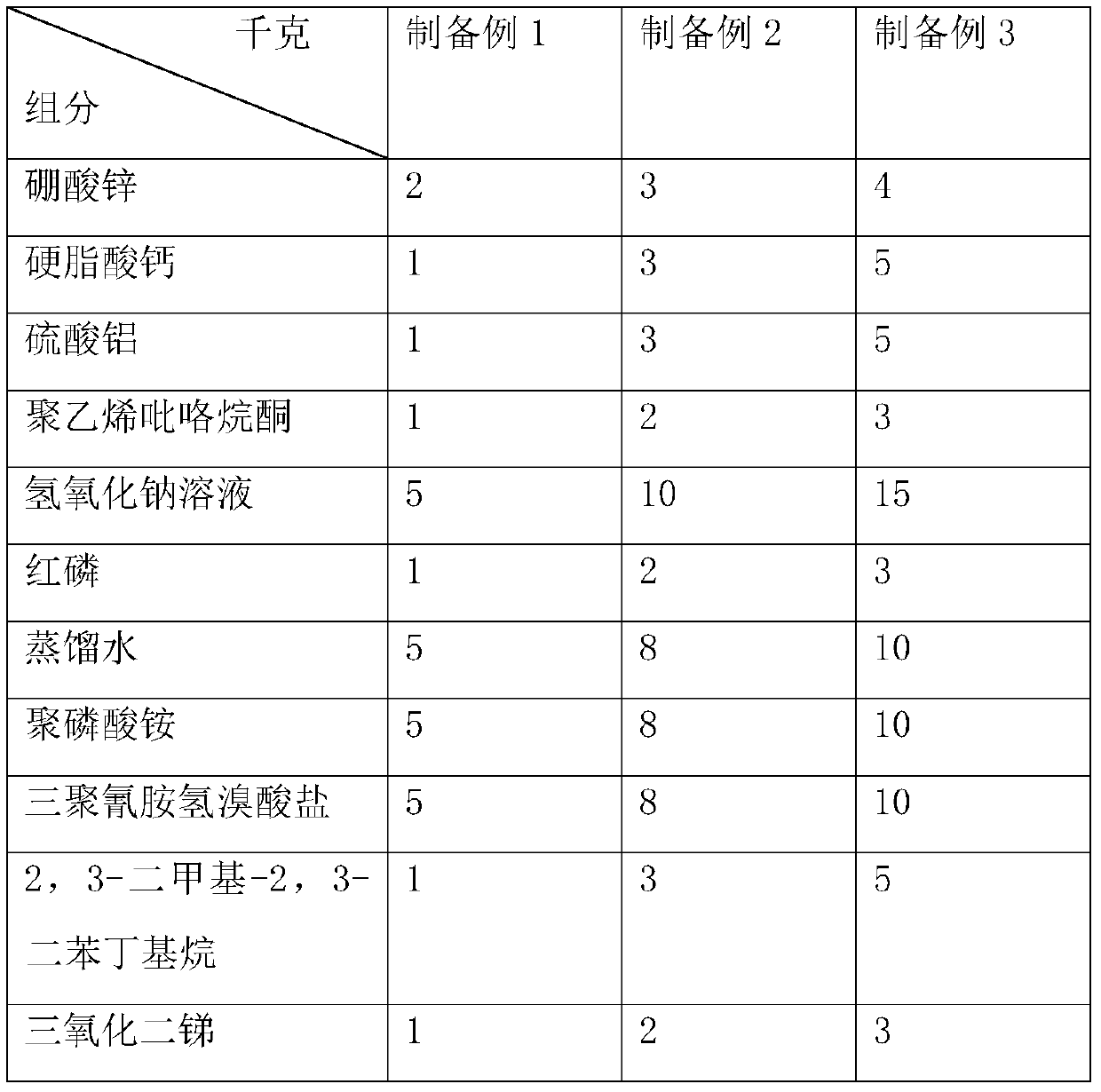

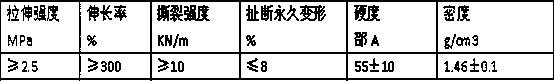

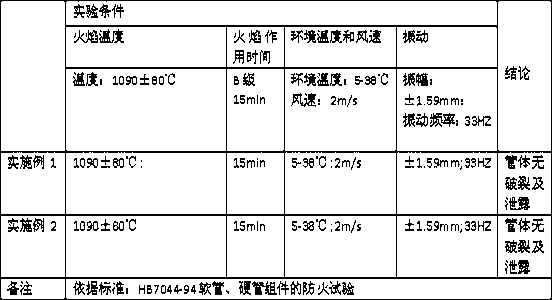

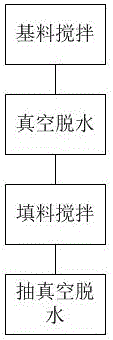

Method for preparing environmental-friendly flame-retardant silicone adhesive

InactiveCN106800910ADilute oxygen concentrationLower combustion temperatureNon-macromolecular adhesive additivesChemistryTest sample

The invention relates to the technical field of building material preparation, and particularly relates to a method for preparing an environmental-friendly flame-retardant silicone adhesive which is relatively good in flame retardancy and extrusion property. The method for preparing the environmental-friendly flame-retardant silicone adhesive comprises the following steps: (1) adding a 107 base adhesive, 201 methyl silicone oil, an antimonous oxide flame retardant and fumed silica into a vacuum kneading machine, heating and stirring, vacuuming to dehydrate and remove bubbles, and discharging so as to obtain a base material; (2) adding the grinded base material and a cross-linking agent, a coupling agent, a waterproof agent and a catalyst into a double-planet dispersion stirring machine in sequence in a ratio, uniformly stirring and mixing, vacuuming to dehydrate so as to obtain a test sample, and putting the test sample into an adhesive bottle. In the early combustion period, antimonous oxide is firstly molten, then a protection membrane can be formed on the surface of the material to isolate air, and through internal heat absorption reaction, the combustion temperature can be reduced. At a high-temperature state, the antimonous oxide is gasified, and the concentration of oxygen in the air can be diluted, therefore, a flame retardancy function can be achieved.

Owner:ZHEJIANG TIME NEW MATERIAL

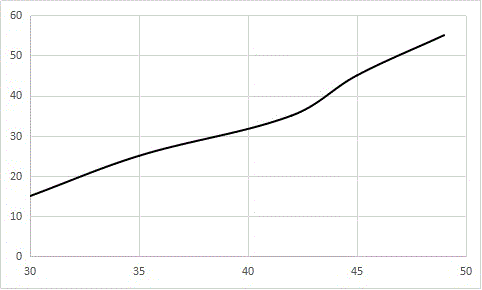

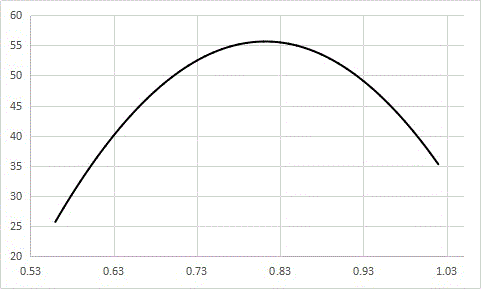

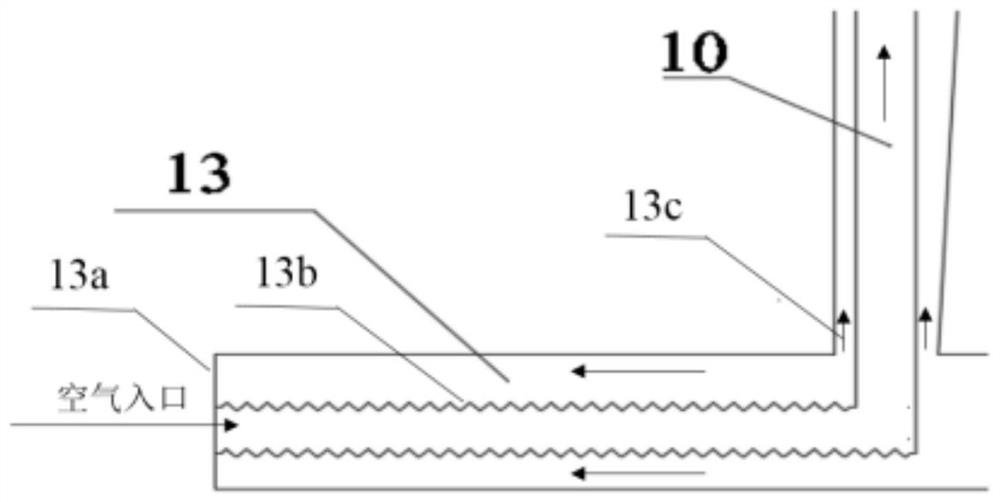

Radiant tube heating device with self-preheating type flue gas recirculation

PendingCN114087608AIncrease flow rateReduce heat stress concentrationIndirect carbon-dioxide mitigationGaseous fuel burnerExhaust gasCombustion chamber

The invention discloses a radiant tube heating device with self-preheating type flue gas recirculation. The device comprises a radiant tube main body device, a combustion-supporting air preheating pipeline, a contraction opening and a formed flue gas circulation pipeline. In order to enhance heat exchange between flue gas and combustion-supporting air, a non-smooth air preheating pipeline is arranged at the tail part of the radiation pipe, so that the problems of high exhaust gas temperature and low heat efficiency of the device are solved; the gas circulation pipeline can enable a certain amount of flue gas to flow back to a combustion chamber to participate in re-combustion; the oxygen content of a combustion area is reduced by the backflow flue gas, so that the flame temperature is reduced, the stress concentration of the radiant tube is relieved while the generation of NOx is reduced, and the service life of the radiant tube is prolonged; the average flow rate of flue gas in the radiant tube is improved through jet flow generated by the shrinkage opening, so that the temperature gradient in the radiant tube is reduced, and the temperature distribution uniformity of the radiant tube is enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for producing fireproof flame-retarding medium-density fiber plate special for office table

InactiveCN109397463AAlleviate the contradiction between supply and demandLow costWood veneer joiningDomestic articlesScrapSizing

The invention discloses a method for producing a fireproof flame-retarding medium-density fiber plate special for an office table. The method comprises the steps of (1) raw material treatment, (2) screening, (3) steaming and softening, (4) grinding, (5) sizing and drying, (6) pre-pressing, (7) hot pressing, (8) sawing and sanding, (9) facing hot pressing and (10) edge cutting. According to the method, eucalyptus bark, branches and scraps left after plate manufacturing are adopted as main raw materials, other miscellaneous trees are added, waste is turned into wealth, and full and effective utilization of timber resources can be achieved. Modified paraffin and an inflaming retarding urea-formaldehyde resin adhesive are added, so that the fireproof flame retarding performance is greatly improved; and the manufactured medium-density fiber plate special for the office table is good in fireproof and flame retarding performance, good in water resistance, low in formaldehyde content, safe andenvironment-friendly.

Owner:广西横州丽冠环保材料有限公司

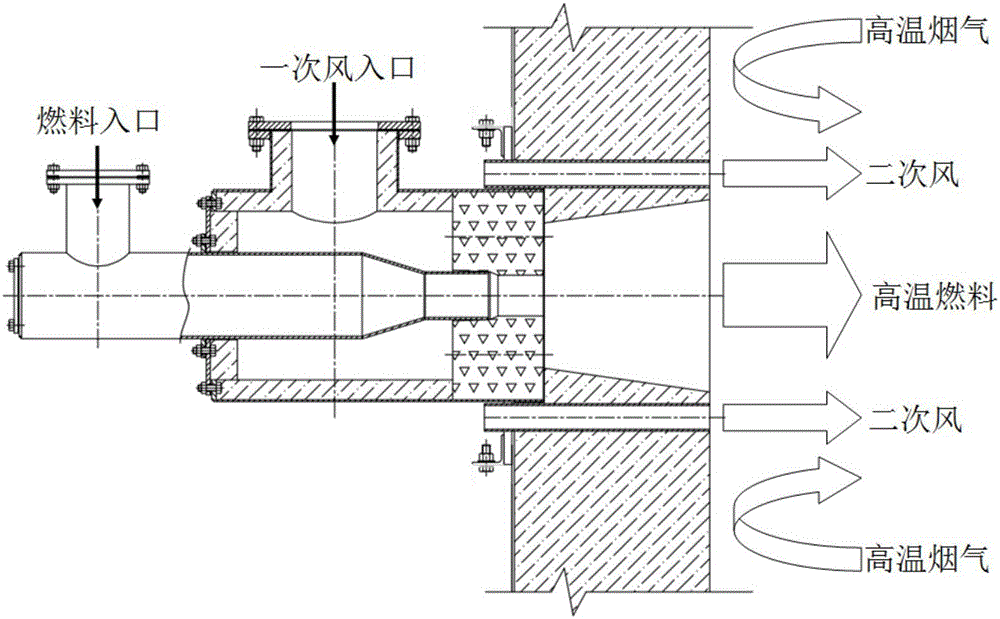

Staged oxygen-enriched flameless combustion gas burner and its control method

ActiveCN104235849BUnlimited calorific valueEfficient use ofIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHeating furnace

The invention discloses a grading oxygen-enriched flameless combustion gas burner which comprises a burner shell, an air distribution plate, a pre-combustion chamber, secondary air spray pipes and a fuel spray pipe. The wall of a heating furnace is provided with a channel penetrating through the wall, the burner shell is arranged on one side of the channel, the pre-combustion chamber is formed in space in the channel, the burner shell is provided with a combustion-supporting air channel, the fuel spray pipe is provided with a fuel channel, the air distribution plate is provided with a primary air inlet and a fuel inlet, the secondary air spray pipes are arranged and provided with secondary air channels used for introducing oxygen-enriched air or air into a hearth of the heating furnace, the secondary air spray pipes penetrate through the wall of the heating furnace, and the secondary air channels are communicated with the hearth of the heating furnace. The grading oxygen-enriched flameless combustion gas burner optimizes temperature distribution in the furnace and meanwhile reduces emission of NOx.

Owner:WISDRI WUHAN WIS IND FURNACE

High-strength anti-oxidation flame-retardant cable material

InactiveCN104194176AImprove flame retardant and heat resistanceImprove aging resistanceRubber insulatorsParaffin waxEpoxy

The invention discloses a high-strength anti-oxidation flame-retardant cable material. The high-strength anti-oxidation flame-retardant cable material is prepared from the following raw materials in parts by weight: 20-40 parts of chlorosulphonated polyethylene, 30-40 parts of chlorinated polyethylene, 20-25 parts of GNA type chloroprene rubber, 1-2.5 parts of epoxy fatty acid monoester, 5-8 parts of high abrasion resistance carbon black, 23-25 parts of talcum powder, 0.2-0.5 part of semi-refined paraffin wax, 2-2.5 parts of stabilizer, 20-40 parts of flame-retardant system, 0.15-0.34 part of antioxidant and 0.25-0.45 part of vulcanization system, wherein the vulcanization system comprises the following components in percentage by weight: 60-80wt% of dipentamethylene thiuram tetrasulfide and 20-40wt% of trimethylolpropane trimethylacrylate; the flame-retardant system comprises the following components in percentage by weight: 40-60wt% of magnesium hydroxide, 20-40wt% of diantimony trioxide and 5-20wt% of micro-encapsulated red phosphorus. The high-strength anti-oxidation flame-retardant cable material has excellent flame retardance, heat resistance and ageing resistance and good sealing property.

Owner:ANHUI MENTOR CABLE GROUP

Ultraviolet LED light source device

ActiveCN108662444AGood linear spotPromote rapid formationNon-electric lightingPoint-like light sourcePhysicsLight source

The invention discloses an ultraviolet LED light source device. The ultraviolet LED light source device comprises an LED light source module and a heat dissipation module; the LED light source modulecomprises a substrate and an LED light source unit, wherein the LED light source is arranged on the substrate and is arranged in an array mode, and the substrate is arranged on the heat dissipation module; and the device further comprises an oxygen-free gas source, wherein the oxygen-free gas source is used for blowing oxygen-free gas to the irradiation surface of the LED light source module, andan oxygen-free environment is manufactured on the irradiation surface of the LED light source module. According to the ultraviolet LED light source device, due to the fact that the oxygen-free gas source is arranged, when ultraviolet light is irradiated, the oxygen-free gas source blows oxygen-free gas to the irradiation surface, the oxygen concentration in the upper space of the irradiation surface can be diluted, the oxygen concentration can be reduced to a very low degree through continuous blowing, and therefore the oxygen-free environment can be formed; and due to the fact that ultraviolet rays irradiate on the irradiation surface, ozone cannot be generated in the oxygen-free environment, so that the quality of ultraviolet irradiation curing is guaranteed.

Owner:深圳市优绿源科技有限公司

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

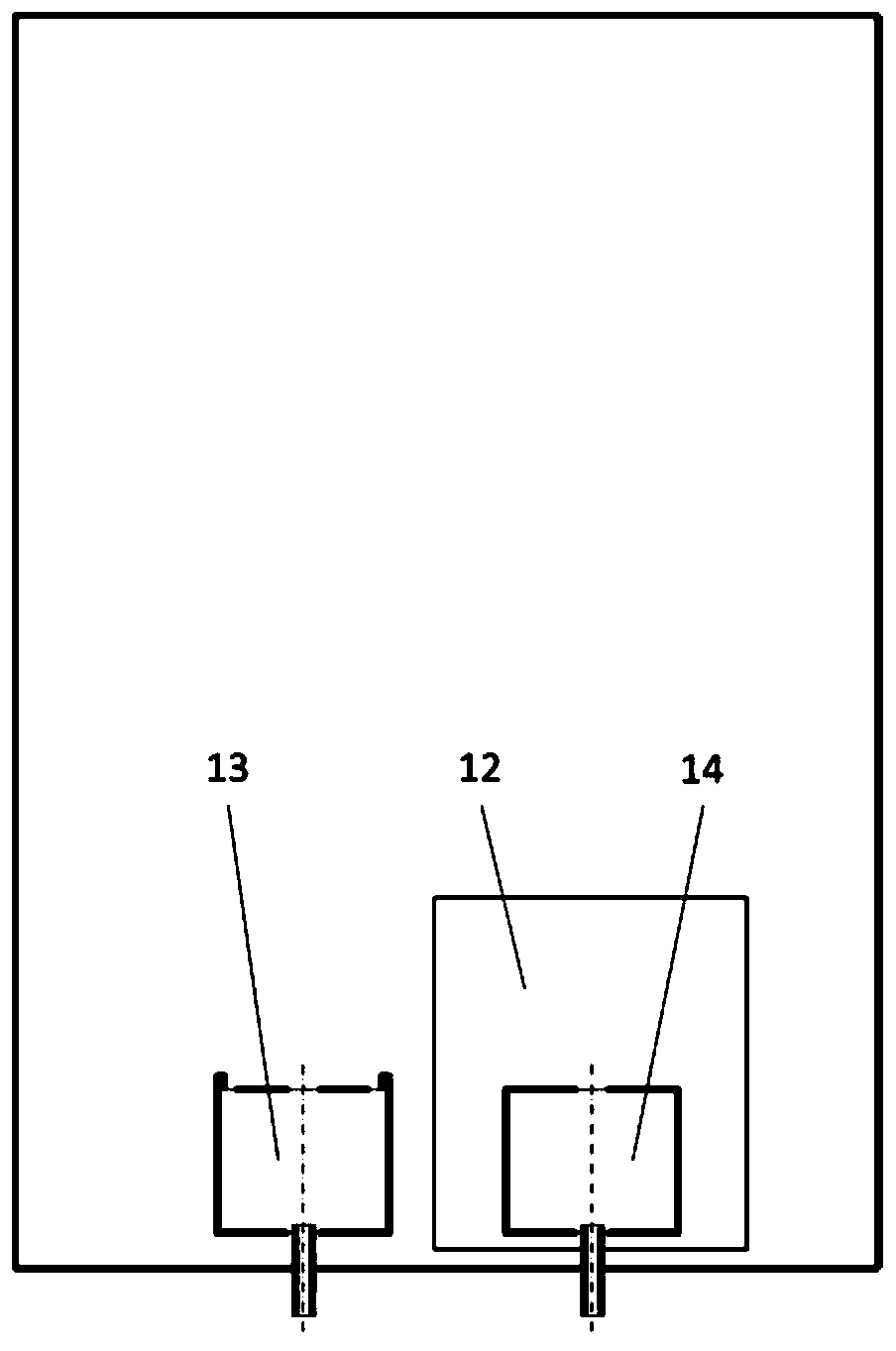

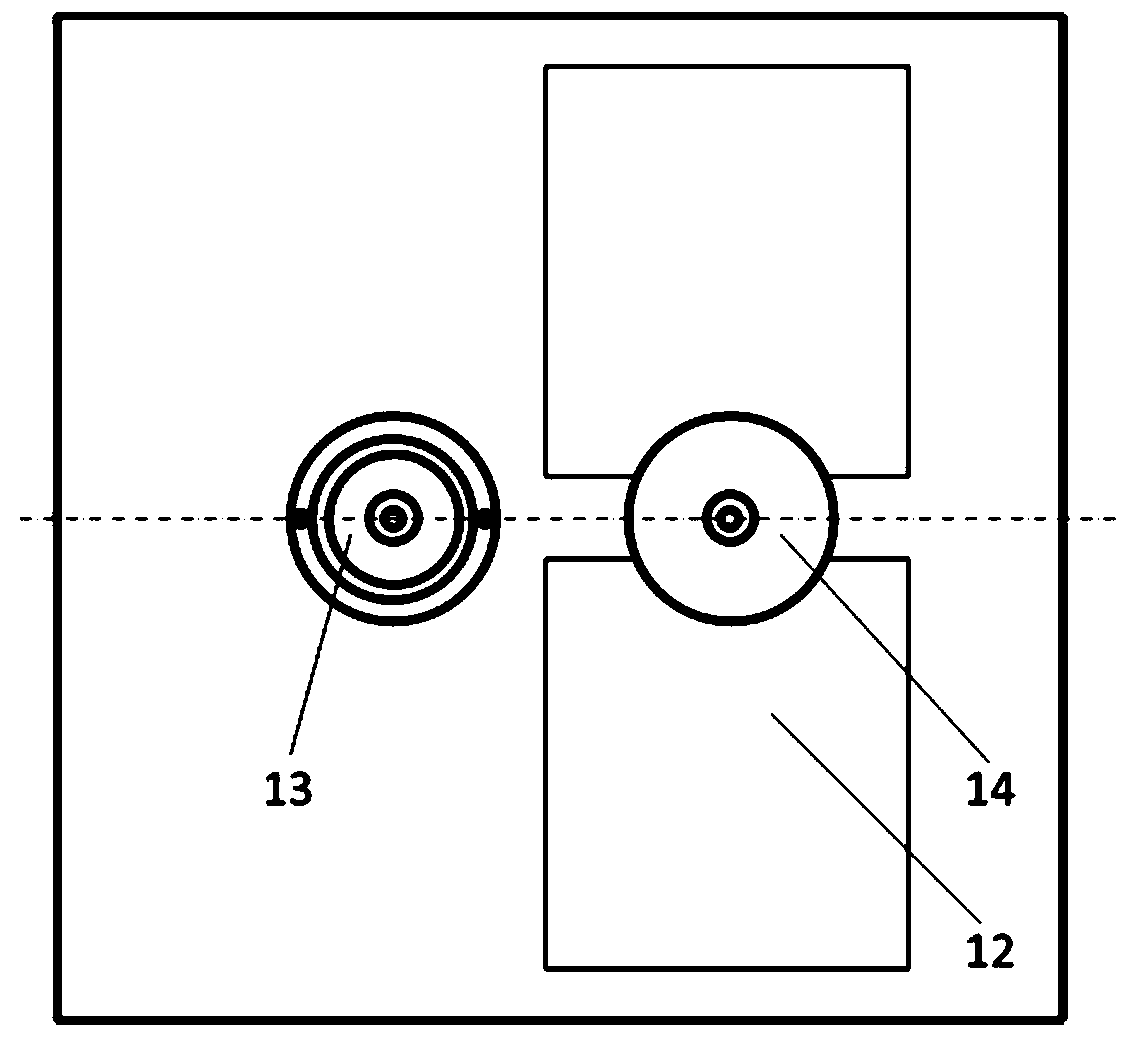

Flameless combustor without preheating and switching

ActiveCN110594739AUniform temperature distributionStable flameless combustionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorFlue gas

The invention belongs to the field of combustors, and particularly discloses a flameless combustor without preheating and switching. A fuel feeder comprises a fuel nozzle, auxiliary air nozzles and afirst backflow cavity, wherein the fuel nozzle vertically extends into the bottom of the first backflow cavity, and the auxiliary air nozzles are symmetrically arranged at the top edge of the first backflow cavity; the first backflow cavity is provided with a first annular entrainment port, a second annular entrainment port and a fuel outlet, and is used for entraining flue gas and providing a combustion space for flameless combustion of fuel; and an air feeder comprises an air nozzle and a second backflow cavity, wherein the air nozzle vertically extends into the bottom of the second backflowcavity, the second backflow cavity is provided with a third annular entrainment port and an air outlet, so that a large-scale circulation is formed in a hearth. According to the flameless combustor without preheating and switching, a vortex backflow area can be formed in the first backflow cavity, so that the temperature distribution in the first backflow cavity is ensured to be uniform, the fuelis stable in flameless combustion under the action of the flue gas, and the temperature distribution in the whole hearth can be ensured to be uniform.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com