Environment-friendly cable insulation material, preparation method thereof, and cable sheath

A cable insulation and environment-friendly technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of flame spread, impassability, life and property, fire rescue hazards, etc., and achieve high flame retardancy and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

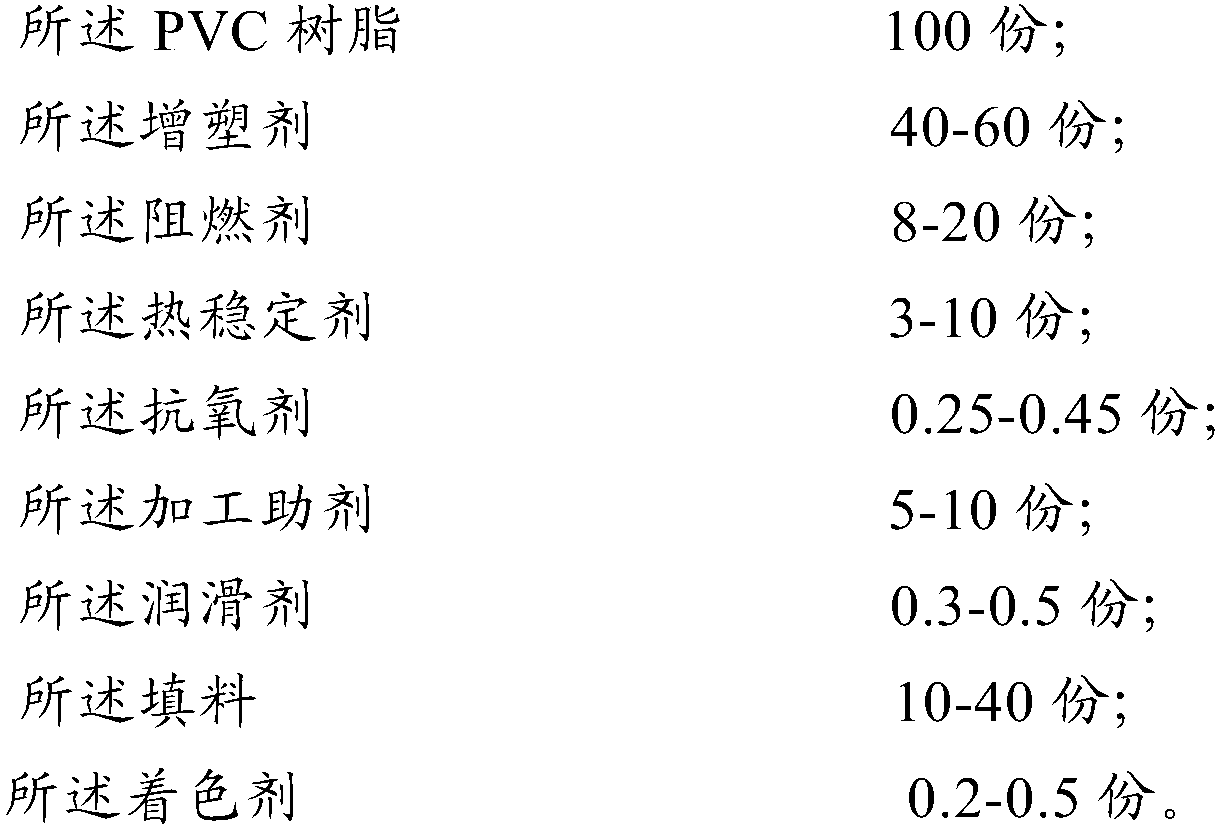

[0052] This embodiment provides an environment-friendly cable insulation material. The raw material formula of the cable insulation material includes:

[0053] PVC resin;

[0054] plasticizer;

[0055] Flame retardants, including melamine-coated ammonium polyphosphate;

[0056] Heat stabilizers, heat stabilizers include organic calcium zinc rare earth composite stabilizers and hydrotalcites;

[0057] Antioxidant;

[0058] Processing aids;

[0059] lubricant;

[0060] filler;

[0061] Colorant.

[0062] The flame retardant melamine-coated ammonium polyphosphate absorbs heat and forces dehydration to form a non-combustible simple carbon layer, which blocks heat and oxygen transfer, prevents the generation of CO, releases nitrogen and ammonia, dilutes the effect of oxygen concentration, and simultaneously decomposes the generated PO· Free radicals, which can combine with H free radicals in the flame area, play a role in suppressing the flame.

[0063] The environment-friend...

Embodiment 2

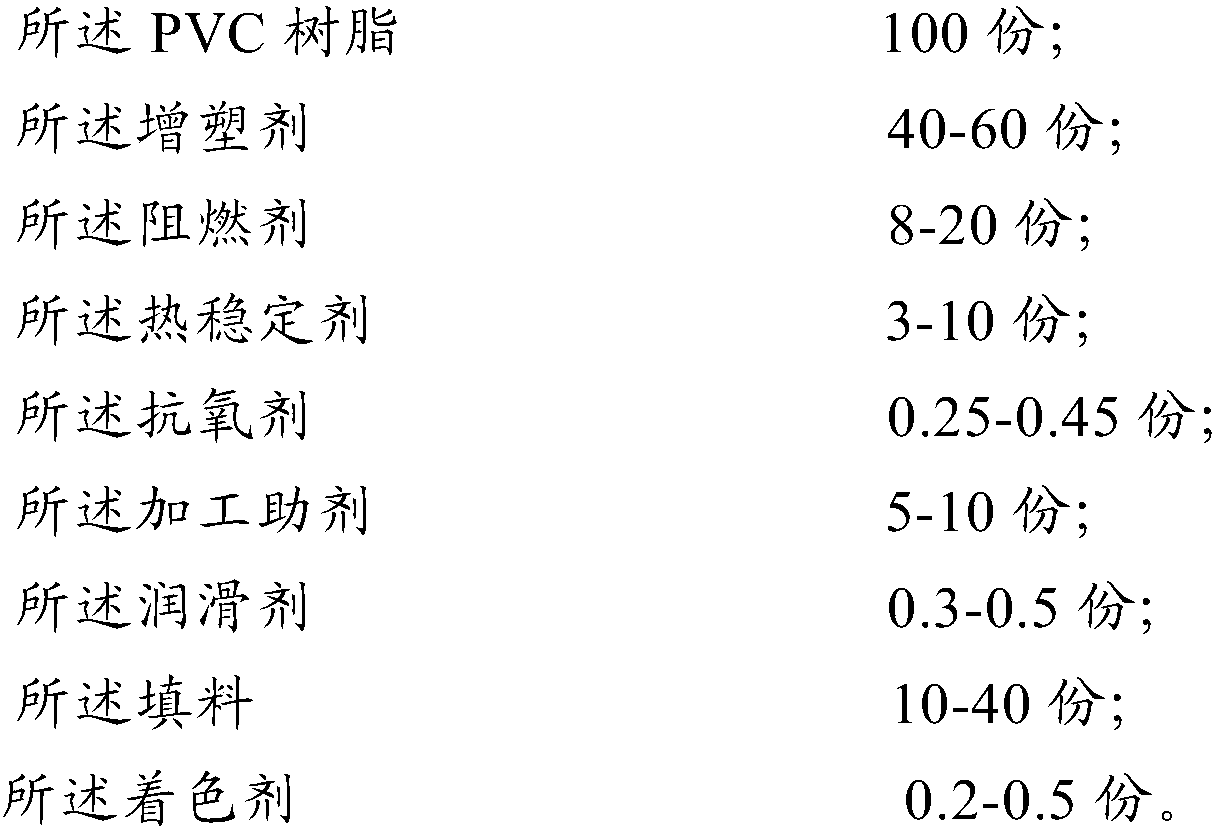

[0065] This embodiment provides an environment-friendly cable insulation material. The raw material formula of the cable insulation material includes:

[0066] PVC resin;

[0067] plasticizer;

[0068] Flame retardants, including antimony trioxide coated with zinc borate;

[0069] Heat stabilizers, heat stabilizers include organic calcium zinc rare earth composite stabilizers;

[0070] Antioxidant;

[0071] Processing aids;

[0072] lubricant;

[0073] filler;

[0074] Colorant.

[0075] Flame retardant zinc borate coating antimony trioxide to make full use of antimony trioxide combustion product SbCl 3 The covering effect of steam covering the surface of the combustion zone, zinc borate releases water to reduce the temperature of the combustion zone and forms a glass on the surface, which has a solid-phase flame-retardant effect of insulation, heat insulation and oxygen insulation, and at the same time captures the combustion factor HO in the gas phase, Vapor-phase fl...

Embodiment 3

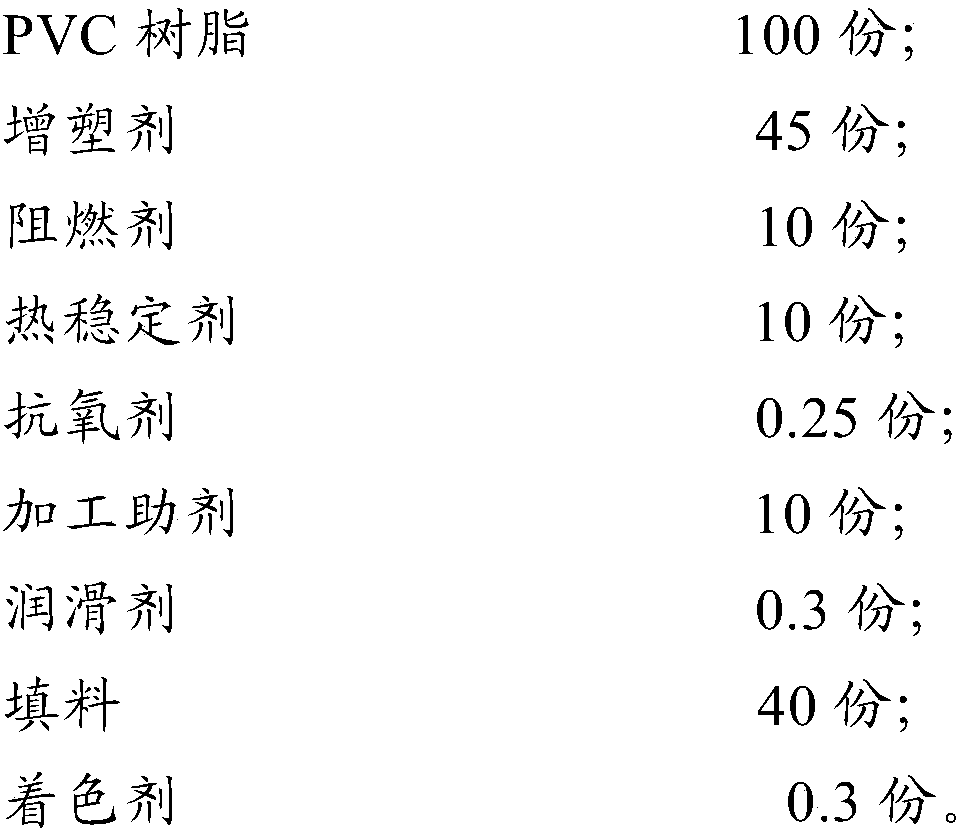

[0086] This embodiment provides an environment-friendly cable insulation material. The raw material formula of the cable insulation material includes the following weight components:

[0087]

[0088] The PVC resin includes PVC resin SG-3.

[0089] The flame retardant includes antimony trioxide coated with zinc borate, ammonium polyphosphate coated with melamine, and octametic anhydride (the weight ratio is 2:1:1).

[0090] The heat stabilizer includes organic calcium zinc composite stabilizer and hydrotalcite (weight ratio is 2:3).

[0091] The plasticizer includes chlorinated paraffin 52# and tricresyl phosphate (weight ratio is 1:1).

[0092] Described antioxidant comprises tetrakis [beta-(3,5-di-tert-butyl-4-hydroxyl phenyl) propionate] pentaerythritol ester and three [2.4-di-tert-butyl phenyl] phosphite (weight ratio is 2:1).

[0093] The processing aids include silicones.

[0094] The lubricant comprises ethylene bis stearic acid amide and stearic acid (weight r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com