Flame retardant material of lithium battery module and preparation method of flame retardant material

A flame retardant material, lithium battery technology, applied in fire retardant coatings, epoxy resin coatings, coatings, etc., can solve problems such as explosion, battery fire, loss of thermal insulation, etc., to improve safety performance and avoid fire effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

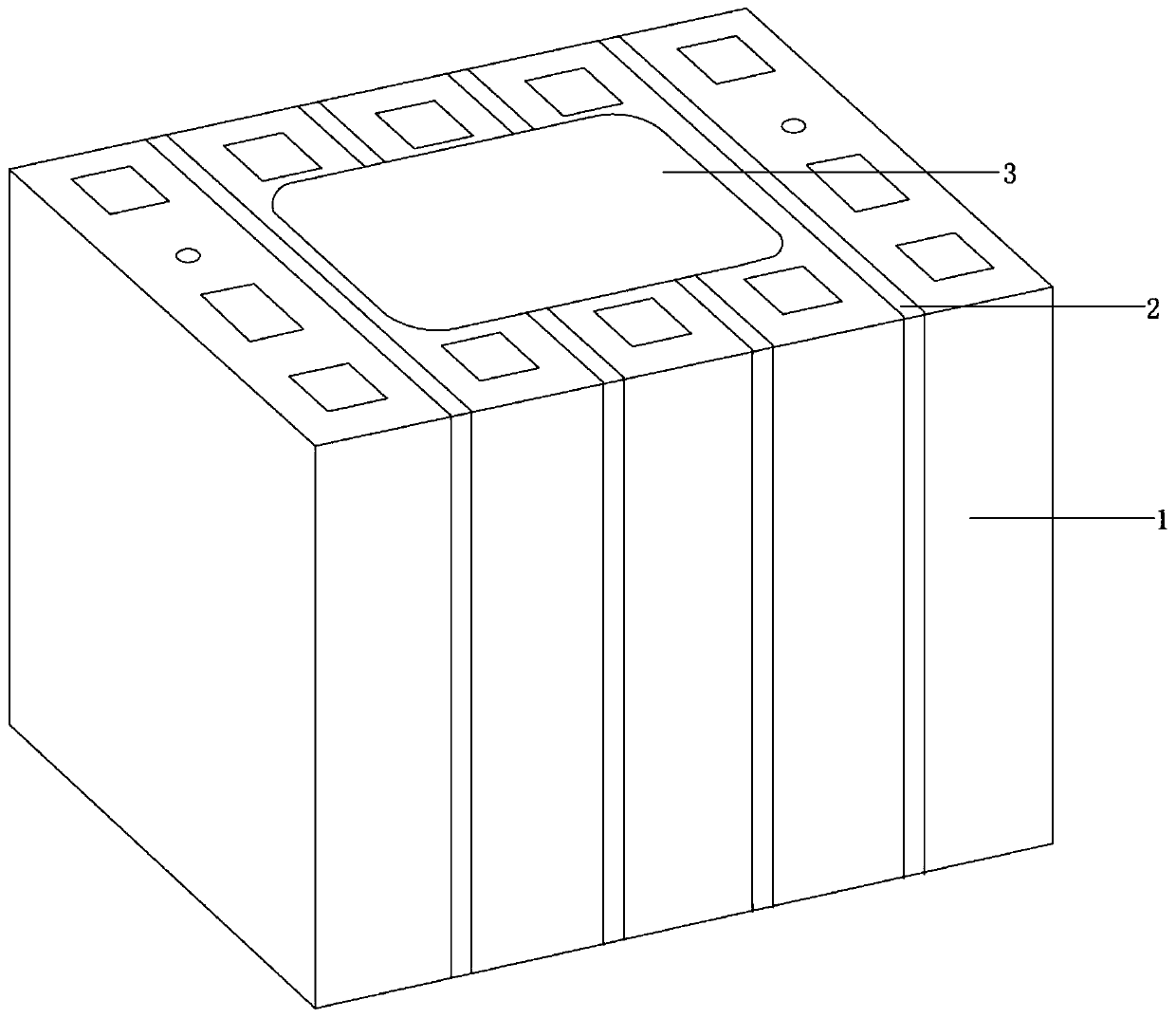

Image

Examples

specific Embodiment approach

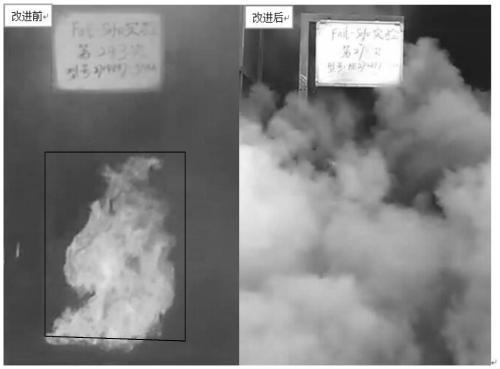

[0033] see figure 2 , the prepared battery module was used to test the thermal runaway of the simulated battery on the top of the acupuncture device designed by Yuliang Company. Specific implementation method: drop a 10kg discus from a height of 1m, hit a copper-plated steel needle with a length of 90mm and φ5mm perpendicular to the explosion-proof valve of the battery cell, the steel needle stays in the battery cell, and record the fire situation. The flame retardant material before improvement has obvious open flame ( figure 2 The middle black frame is the flame); the improved flame retardant material has no open flame when burning, only smoke, thus achieving the flame retardant effect.

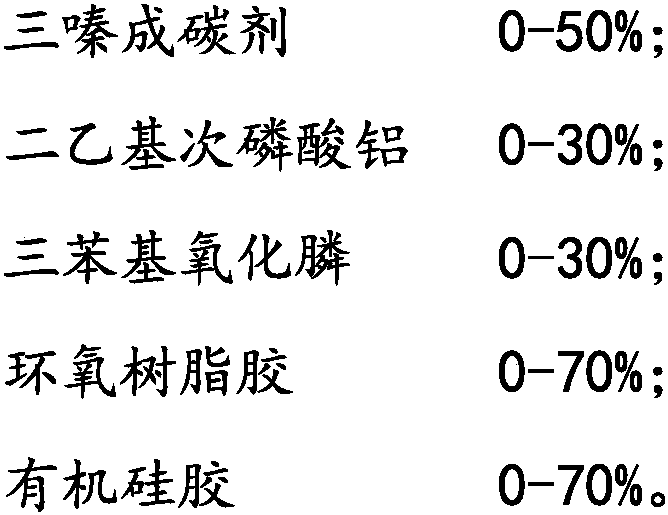

[0034] In the flame retardant material of a lithium battery module provided in the above embodiment and its preparation method, the flame retardant materials such as triazine carbon former, diethyl aluminum hypophosphite, triphenyl phosphine oxide and epoxy resin glue , organic silica g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com