Method for preparing environmental-friendly flame-retardant silicone adhesive

A silicone adhesive, environmentally friendly technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of flame retardant performance not reaching the flame retardant grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

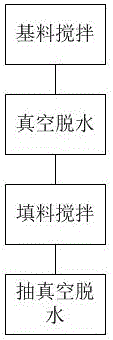

[0034] Such as figure 1 Shown, a kind of preparation method of environment-friendly type flame retardant silicone glue, comprises the steps:

[0035] (1) Add 107 base rubber, 201 methyl silicone oil, antimony trioxide flame retardant, and fumed silica into a vacuum kneader, heat and stir, vacuumize and dehydrate, remove air bubbles, and discharge to prepare the base material;

[0036] (2) Use the base material after grinding, add cross-linking agent, coupling agent, waterproofing agent, and catalyst in a double-planetary dispersing mixer in proportion, stir and mix evenly, vacuumize and dehydrate to obtain a sample, and put it into a plastic bottle.

[0037] The mass fraction of described 107 base glue is 100 parts, the mass fraction of 201 methyl silicone oil is 1-30 parts, the mass fraction of antimony trioxide flame retardant is 15-75 parts, the mass fraction of fumed silica is 5-150 parts, the mass fraction of the crosslinking agent is 1-15 parts, the mass fraction of the...

Embodiment 2

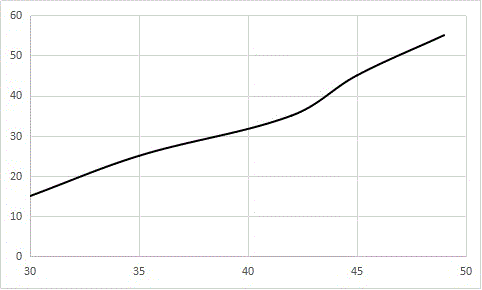

[0046] Such as figure 2 As shown, the same as in Example 1, the main difference is that the relationship between the fraction of the antimony trioxide flame retardant contained in the 107 base rubber per 100 parts and the oxygen index satisfies:

[0047] Z=2O 2 -45, 25≥O 2 ≥15;

[0048] Z=-0.02O 2 2 +1.9O 2 , 45≥O 2 ≥25;

[0049] Z=2.5O 2 -67.5, 49≥O 2 ≥45;

[0050] Wherein Z is the fraction of antimony trioxide flame retardant contained in every 100 parts of 107 base rubber, O 2 is the oxygen index in percentage.

[0051] Through the simulation analysis of NWCHEM software and Digimat software, it is found that when the relationship of the above ratio is satisfied, as the fraction of antimony trioxide flame retardant increases, the oxygen index increases significantly. The corresponding mass fraction of antimony trioxide flame retardant can be selected for addition.

[0052] Finally, the inventor conducted an experiment, using 100 parts by mass of 107 base rubber a...

Embodiment 3

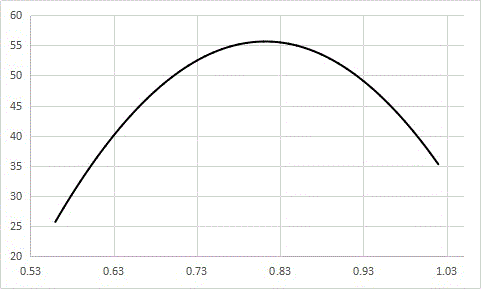

[0057] Such as image 3 As shown, the same as in Example 1, the main difference is that the relationship between the fraction of the antimony trioxide flame retardant contained in the 107 base rubber per 100 parts and the tensile bond strength satisfies:

[0058] Z=-471P 2 +765P-255,0.56Mpa≥P≥0.96Mpa,

[0059] P is the tensile bond strength.

[0060] Through the simulation analysis, it can be seen that with the increase of the antimony trioxide flame retardant fraction per 100 parts of 107 base rubber, the tensile bond strength first increases and then decreases, so the tensile bond strength within a certain range is required For environmentally friendly flame retardant silicone glue, you can choose the corresponding fraction of flame retardants to add to make.

[0061] In the specific experiment, different mass parts of flame-retardant silicone glue were prepared, and tensile bonded specimens were prepared according to the GB / T13477.8-2002 standard. Cured for 21 days unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com