High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

A fire-resistant coating and weather resistance technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of fire-resistant performance attenuation, low construction efficiency, low solid content of coatings, etc., to improve fire-resistant durability, improve fire performance, and low thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in combination with specific embodiments.

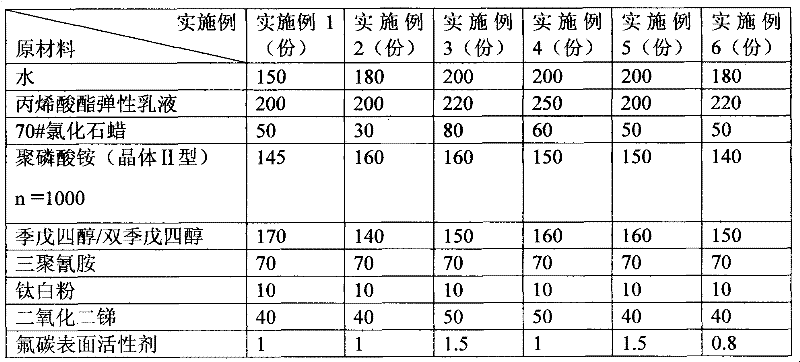

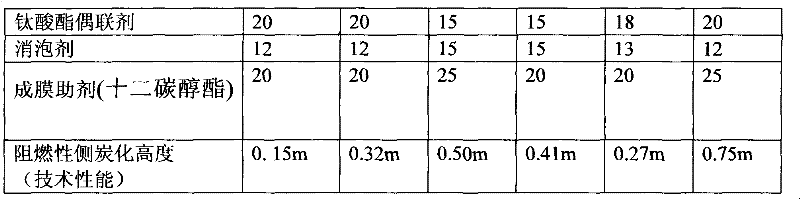

[0048] The formula of each embodiment of the environment-friendly water-based fireproof coating for cables with high weather resistance of the present invention is as follows:

[0049] Table 2

[0050]

[0051]

[0052] The preparation process of the above 6 embodiments is the same, and the concrete steps are as follows:

[0053]The first step is by the consumption of table 2, earlier with 50% water, acrylic acid ester elastic emulsion, titanate coupling agent, film-forming aid (dodecyl alcohol ester), fluorocarbon surfactant, 50% Add the antifoaming agent into the batching tank, stir at 400 rpm for 5 minutes through a dispersing mixer, then increase the stirring speed to 800 rpm, and then add 70# chlorinated paraffin in parts by weight as described in Table 2 , ammonium polyphosphate (type II crystal, n=1000), pentaerythritol, melamine, titanium dioxide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com