Patents

Literature

39results about How to "Reduce heat stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

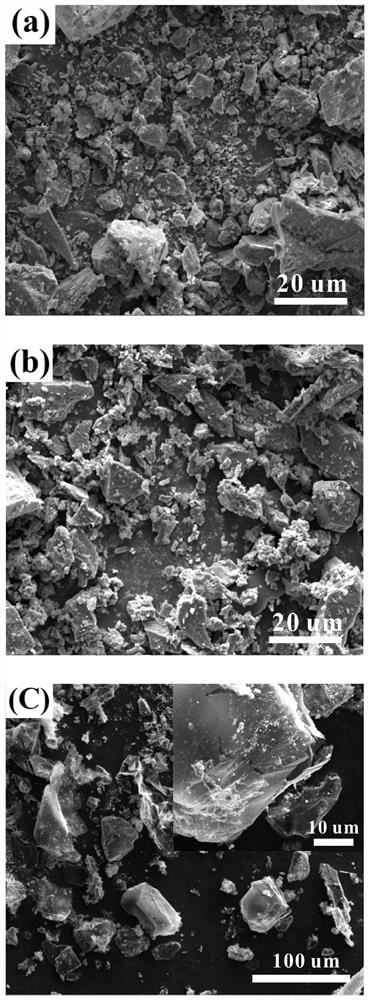

Method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition

ActiveCN110449581ATurn up the plasticityControl the preheating temperatureAdditive manufacturing apparatusTransportation and packagingStress concentrationLaser additive manufacturing

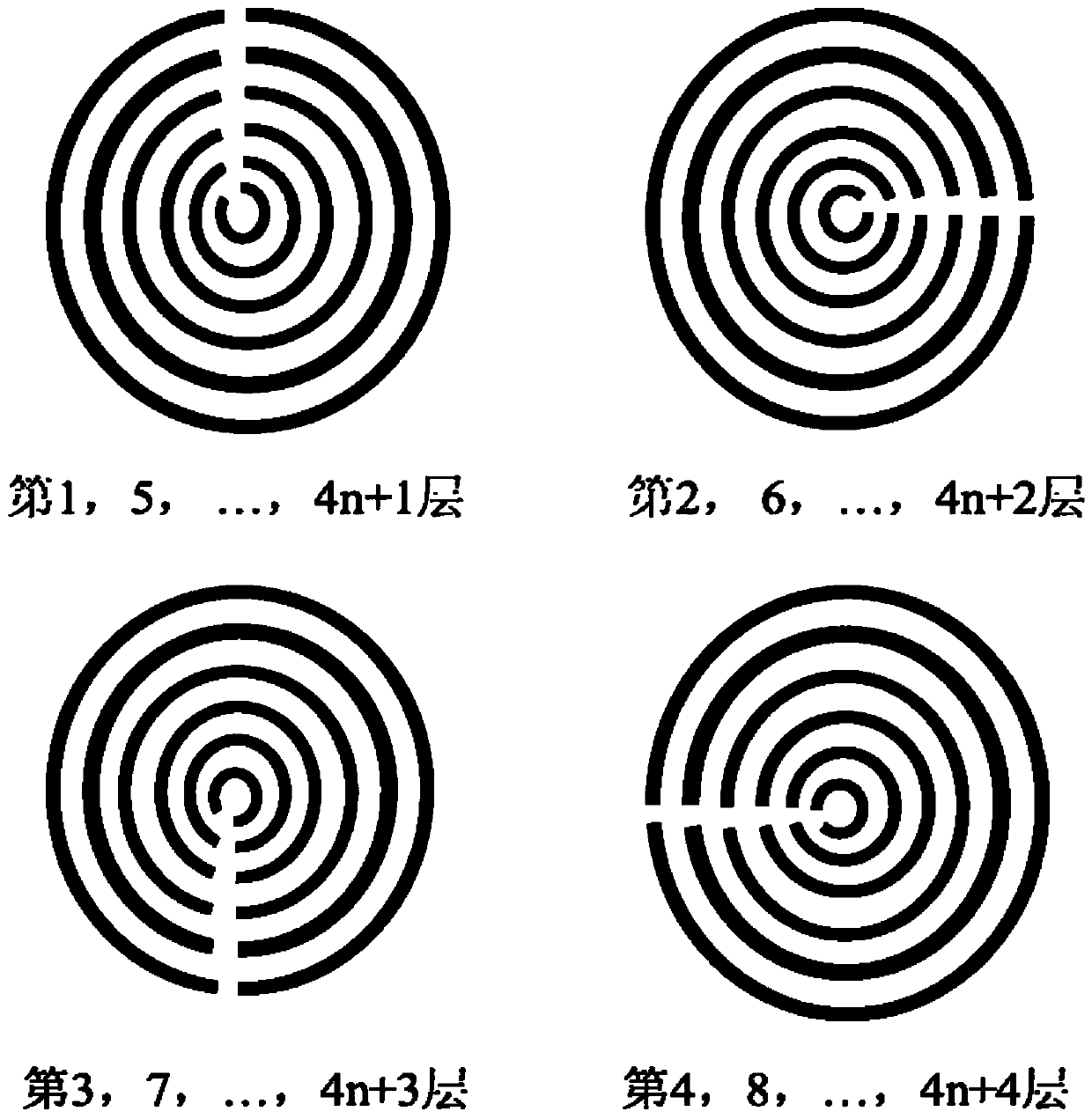

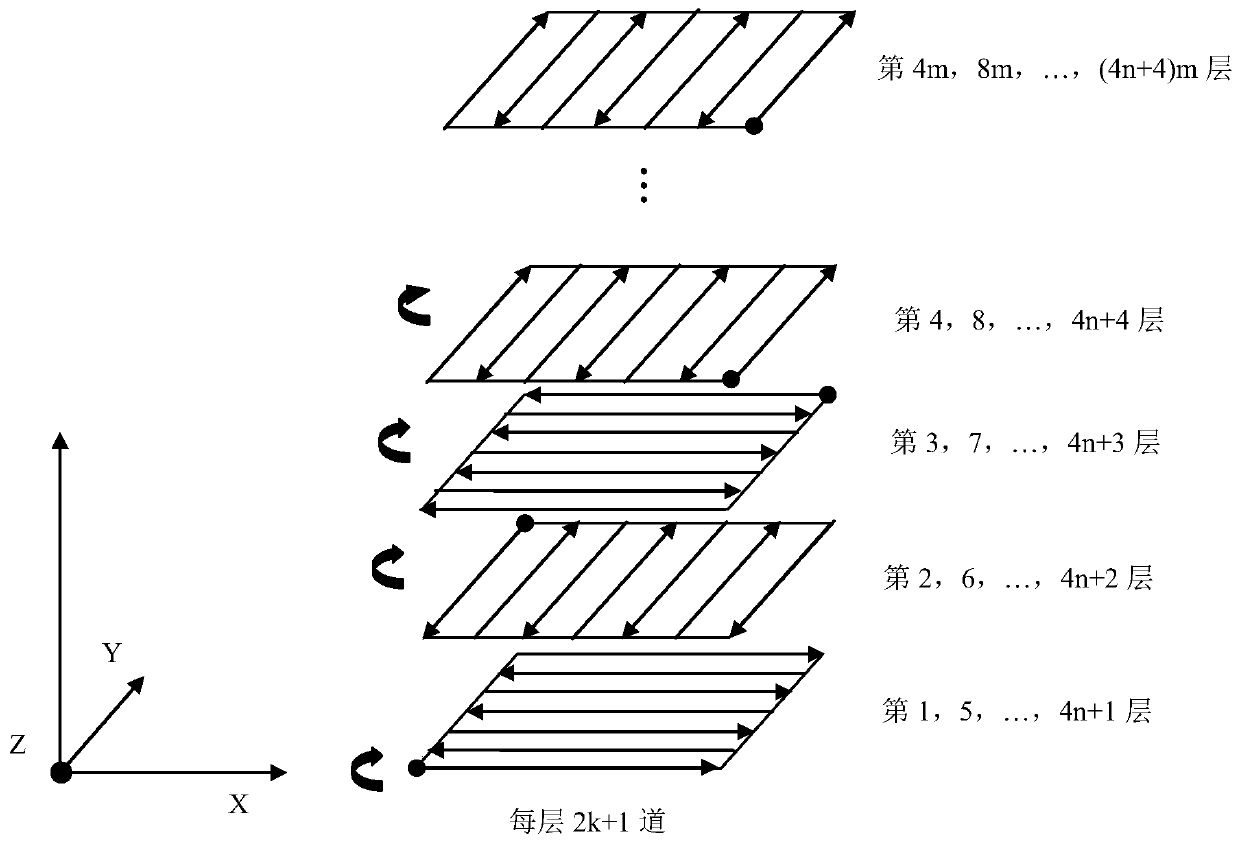

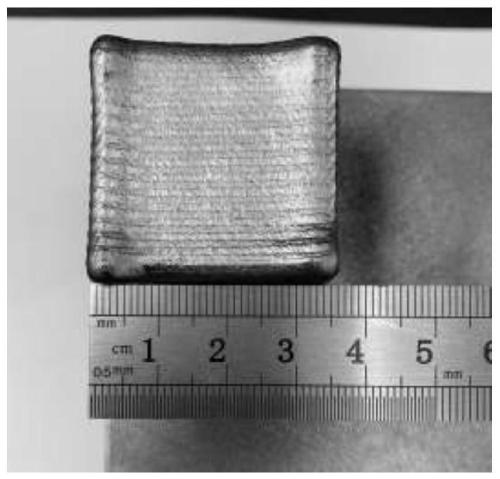

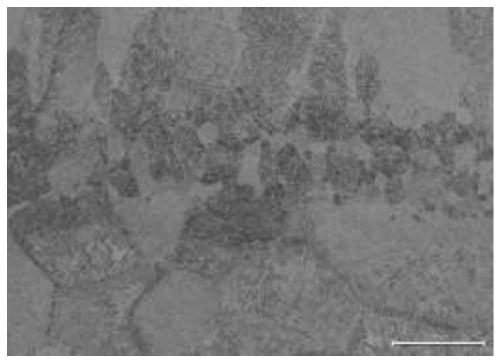

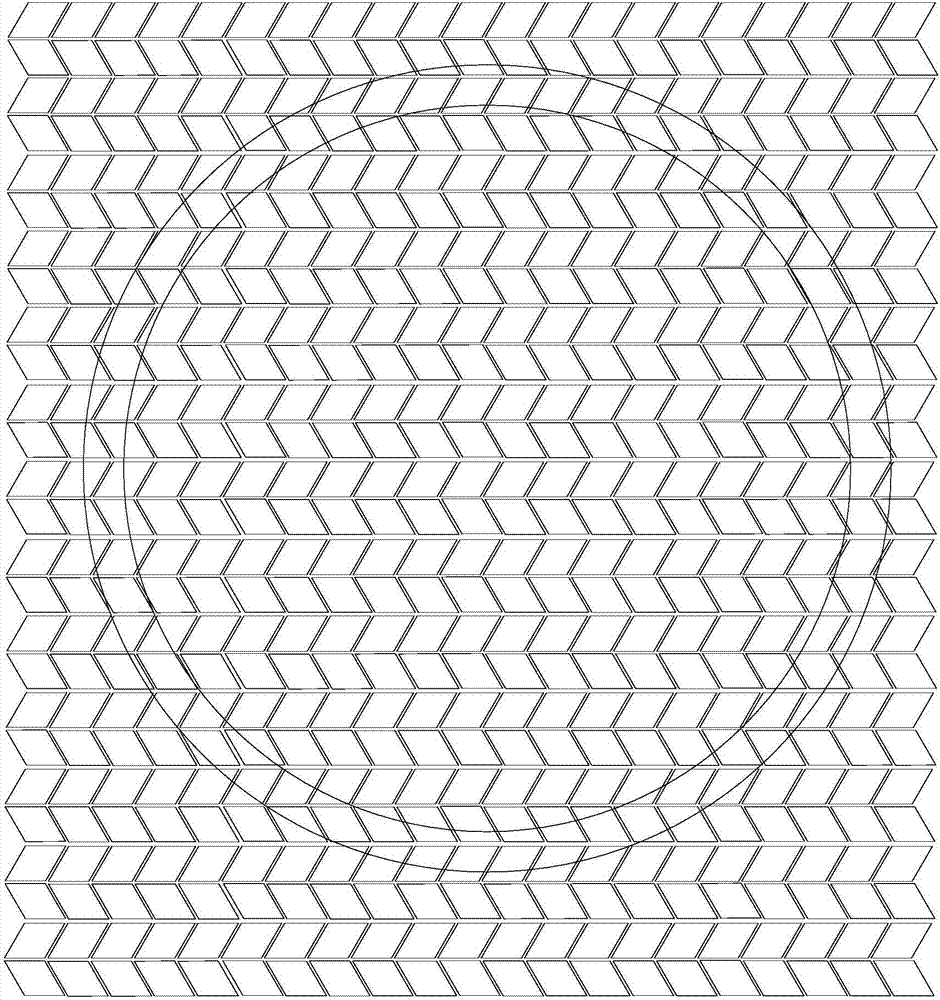

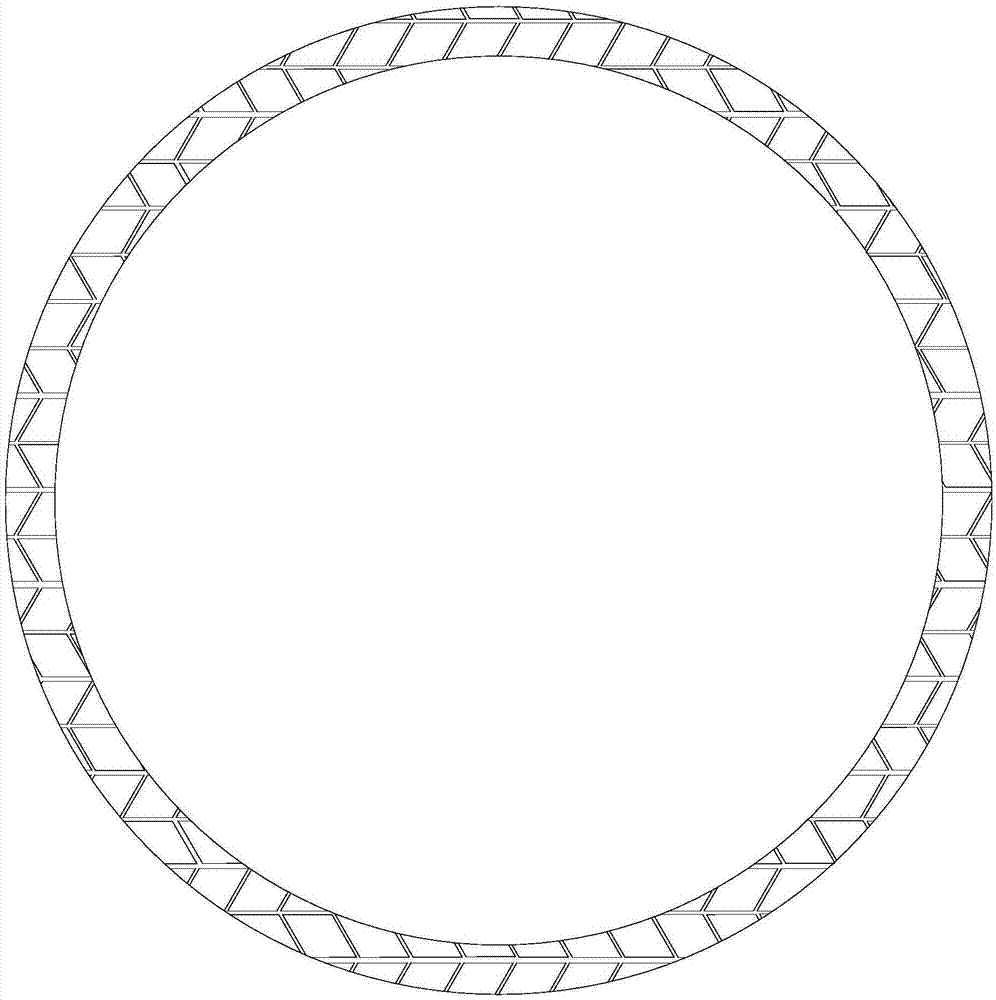

The invention belongs to the technical field of laser added material manufacturing, and relates to a method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition. The laser melting deposition method is adopted to form the TiAl+Ti2AlNb composite materials; and the feeding quantity of Ti2AlNb is adjusted to achieve a pinning effect in composite material structures to improve overall plasticity of the materials. Meanwhile, circular samples are formed, and scanning paths are changed to concentric arcs to prevent the tensile stress of linear scanning paths of rectangular samples; and concentric circle openings on each layer are converted by 60-90 degrees, that is, the positions of scanning initial points on each layer are changed, so that the thermal stress concentration isreduced to prevent cracks. The heat input quantity in the forming process is controlled, and the substrate preheating temperature in the forming process is adjusted to slow down the formed metal solidification speed and cooling speed, so that the stress is released for a longer time.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Laser additive repair method for titanium alloy valve rod

InactiveCN111451500AEasy to implementLow costAdditive manufacturing apparatusIncreasing energy efficiencySurface cleaningTest sample

The invention discloses a laser additive repair method for a titanium alloy valve rod. The laser additive repair method for the titanium alloy valve rod comprises the following steps: optimizing parameters and carrying out a multi-pass multi-layer laser additive experiment through an earlier-stage single-pass laser additive process experiment for a titanium alloy powder, and carrying out metallographic observation on a cladding layer to obtain the optimal process parameters; carrying out laser additive manufacturing printing for a performance test sample piece of the titanium alloy on a titanium alloy substrate, completing a performance test, evaluating a test result, and determining a repair process; carrying out photographing recording on an area to be repaired, and completing surface cleaning; carrying out accurate clamping on the titanium alloy valve rod, and locking the end part by a center; reserving machining allowance in an additive repair damage area carrying out coaxial powder feeding through laser, setting a scanning path to be spiral forward, enabling the left end and the right end of a starting point position to be alternating and rotate clockwise with time difference,and controlling temperature rise of the workpiece; and adopting fluorescence detection, machining according to the requirement of a drawing to restore a size, and delivering and using. According to the laser additive repair method for the titanium alloy valve rod, the requirement of safe use for the titanium alloy valve rod in a life cycle is guaranteed by optimizing the laser additive process parameters and a scanning path strategy.

Owner:航发优材(镇江)增材制造有限公司

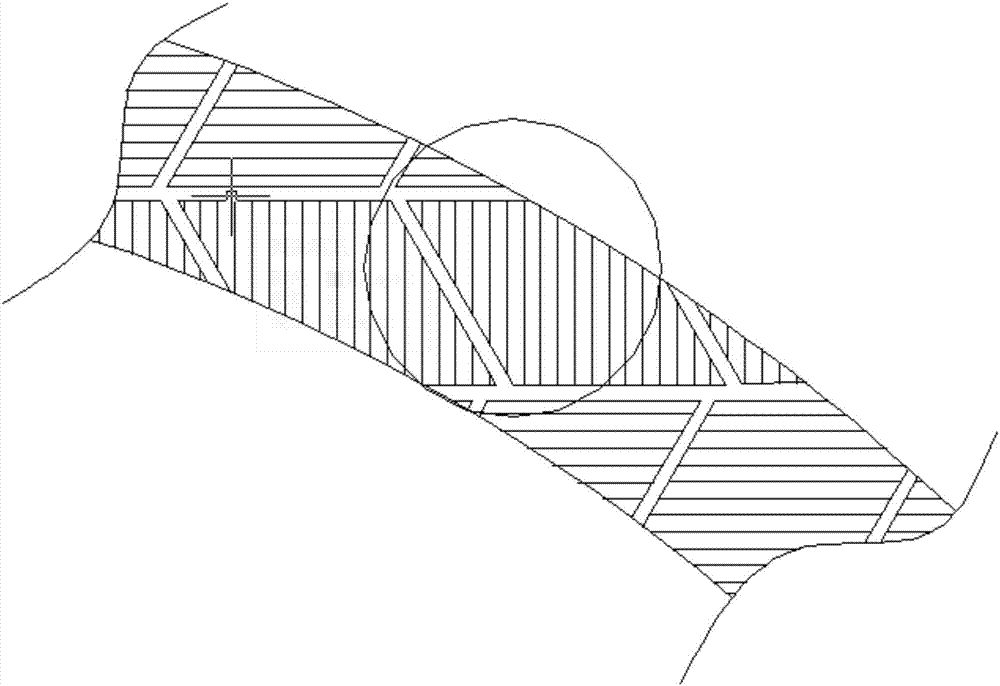

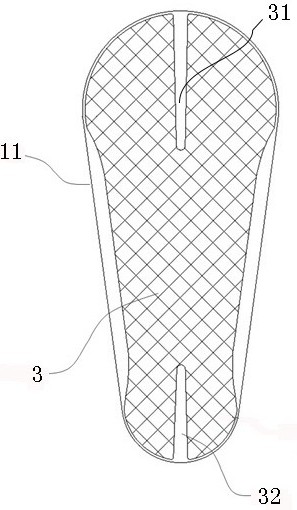

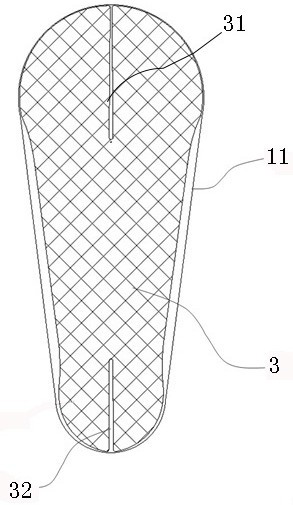

Laser sintering scanning method

InactiveCN107876766AReduce heat stress concentrationConsider scanning efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyThin walledLaser scanning

The invention belongs to the technical field of metal additive manufacturing and particularly relates to a laser sintering scanning method mainly comprising division of the section of a workpiece, planning of the scanning direction, the first time of scanning, division after scanning according to temperatures, scanning according to temperature areas and other steps. According to the laser sintering scanning method, parallelogram division is conducted on the laser scanning section of the workpiece, then the temperature image of the sintering layer obtained after laser scanning is collected in real time through a thermal infrared imager, the outlines of the different temperature areas are extracted, adaptive scanning intervals are adopted for the low temperature areas and the high temperature areas in real time to form a scanning path, the problems that a large temperature gradient is formed due to temperature concentration of a certain area of a large-size thin-wall part, and residual stress is high are solved, the scanning efficiency is improved, and compactness and precision of the workpiece are ensured.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing LaB6/Si-Mo gradient high-temperature anti-oxidation coating

The invention relates to a method for preparing a LaB6 / Si-Mo gradient high-temperature anti-oxidation coating. According to the method, a SiC internal coating is prepared on the surface of a C / C composite material to relieve the problem of concentrated thermal stress caused by thermal expansion coefficient difference between a matrix and the coating; the intermediate layer is a SiC-MoSi2 transition coating and serves as a transition layer of internal and external coatings, cracks, pores and other defects of the external coating generated under a high-temperature condition can be effectively reduced, the excellent high-temperature oxidation resistance of the coating can be achieved, and the resistance adaptability of the C / C composite material under high-temperature aerobic relieving condition is further improved; the LaB6 / Si-Mo coating is prepared by utilizing a plasma spraying method, so that the thickness of the coating can be accurately controlled, and the problem of uneven thickness of the coating is solved. Gradient is sequentially formed among the coatings, so that generation of thermal stress is reduced, and the binding force among the coatings is improved. Advantages of the plasma spraying method and an embedding method are combined, so that the high-temperature oxidation resistance of the coating can be greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Laser vibration deposition device and laser vibration deposition method under condition of integral heat insulation

The invention discloses a laser vibration deposition device and a laser vibration deposition method under the condition of integral heat insulation. A spring piece is arranged on a vibration table of the laser vibration deposition device; a temperature control heater band is fixed below the spring piece and is connected with a temperature controller; a vibration generator is connected with the spring piece through a vibration arm and a vibration head; the spring piece is in a flat shape; and a to-be-deposited metal plate is fixed on the spring piece. The method comprises the following steps that: required powder is coated on the to-be-deposited metal plate, and the to-be-deposited metal plate is arranged on a vibration workbench; the temperature control heater band is arranged below a to-be-deposited workpiece, so that the integral workpiece is at the temperature of between 80 and 420 DEG C; the workpiece is driven to vibrate by starting the vibration device in the vibration frequency of between 20 and 200 Hz; and the scanning is performed by using a CO2 laser to perform laser deposition under the condition of vibration. The laser vibration deposition device and the laser vibration deposition method inhibit air holes and cracks from being formed in the conventional laser deposition technology effectively, and can improve deposition layers and interface tissue and improve the performance of wear resistance, corrosion resistance, heat-temperature resistance and the like of the deposition layers.

Owner:SOUTH CHINA UNIV OF TECH

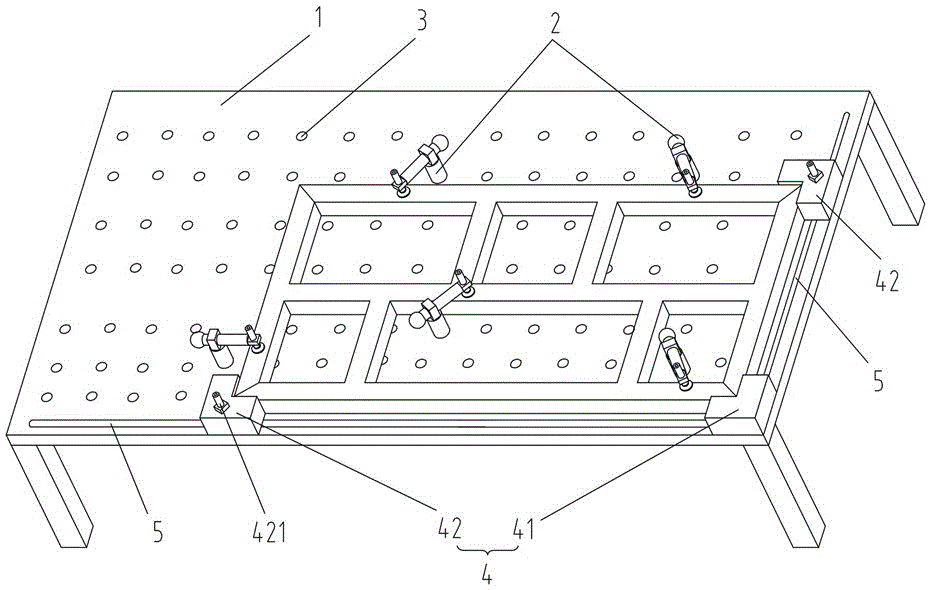

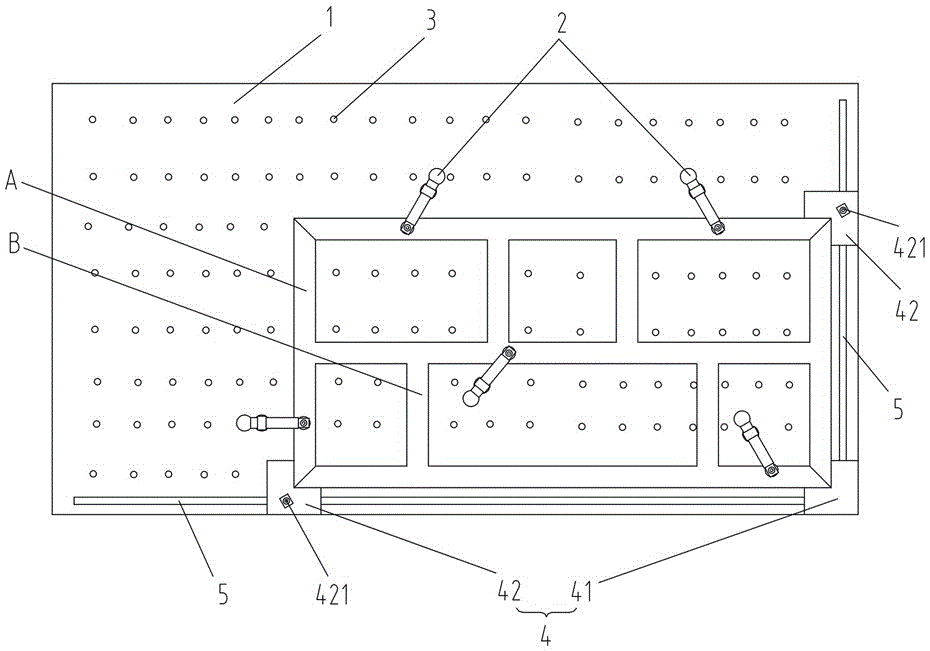

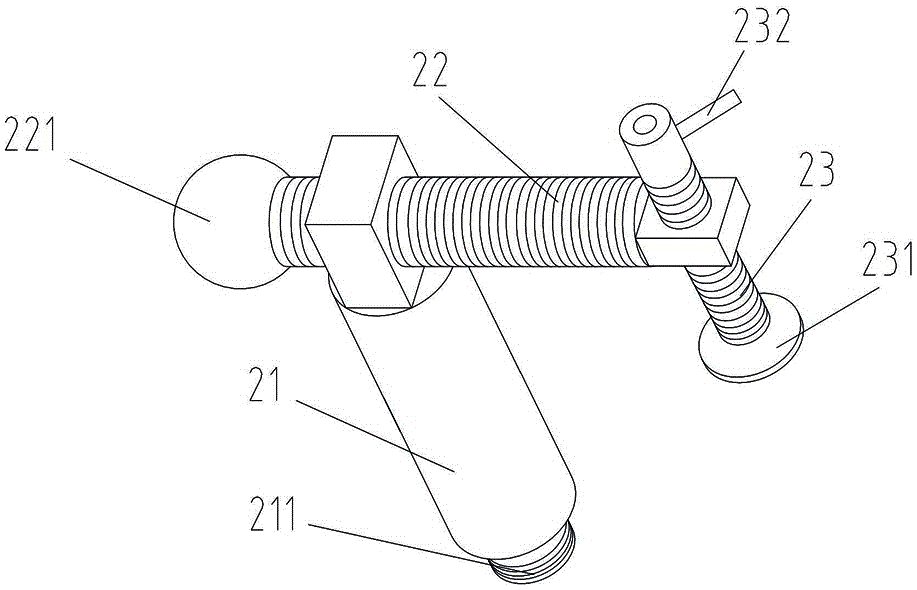

Welding platform used for welding photovoltaic equipment multifunctional cart frame

InactiveCN106541238ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringWelding deformation

The invention discloses a welding platform used for welding a photovoltaic equipment multifunctional cart frame. The welding platform comprises a platform body used for holding a to-be-welded part. The platform body is provided with a plurality of detachable vertical pressing devices used for pressing the to-be-welded part. Each vertical pressing device comprises a fixing rod, a transverse adjusting rod and a longitudinal adjusting rod. The lower end of the fixing rod is used for being fixed to the platform body. The transverse adjusting rod is horizontally mounted at the upper end of the fixing rod. One end of the transverse adjusting rod is provided with the longitudinal adjusting rod in a penetrated mode. The longitudinal adjusting rod and the transverse adjusting rod are in threaded connection and used for rotatably adjusting the horizontal height of the longitudinal adjusting rod, so that the longitudinal adjusting rod presses and fixes the to-be-welded part to the platform body, and then welding operation is conducted. The welding platform has the advantages of being reasonable in structure design, low in manufacturing cost, convenient and rapid to operate, small in welding deformation and capable of improving working efficiency.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

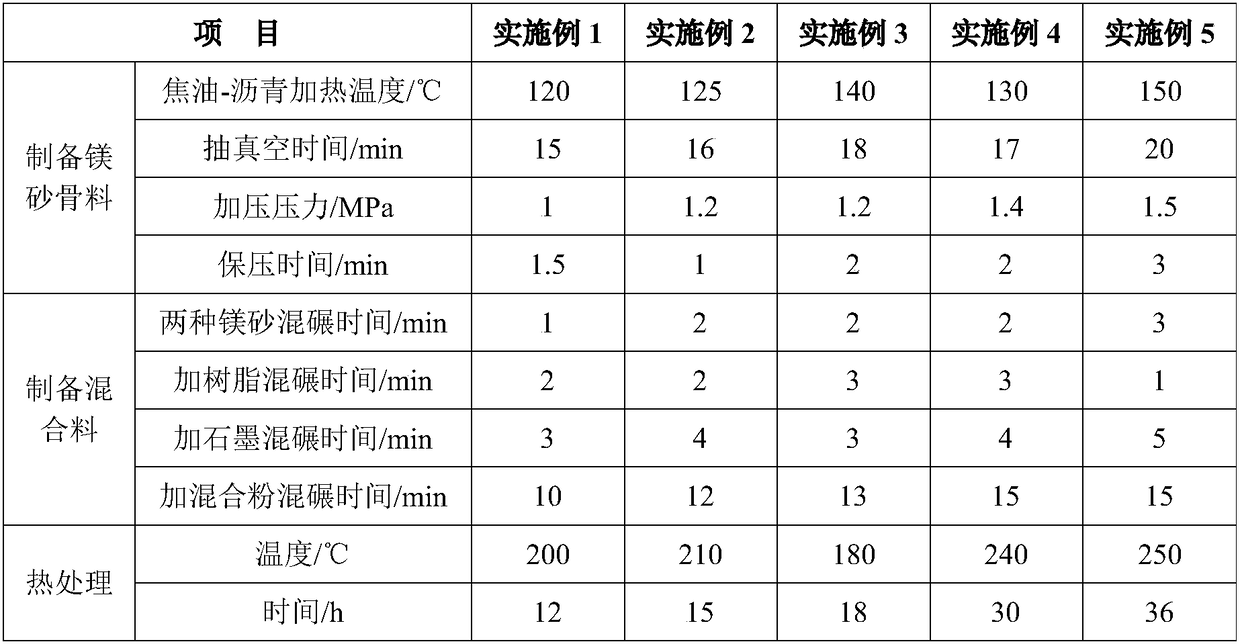

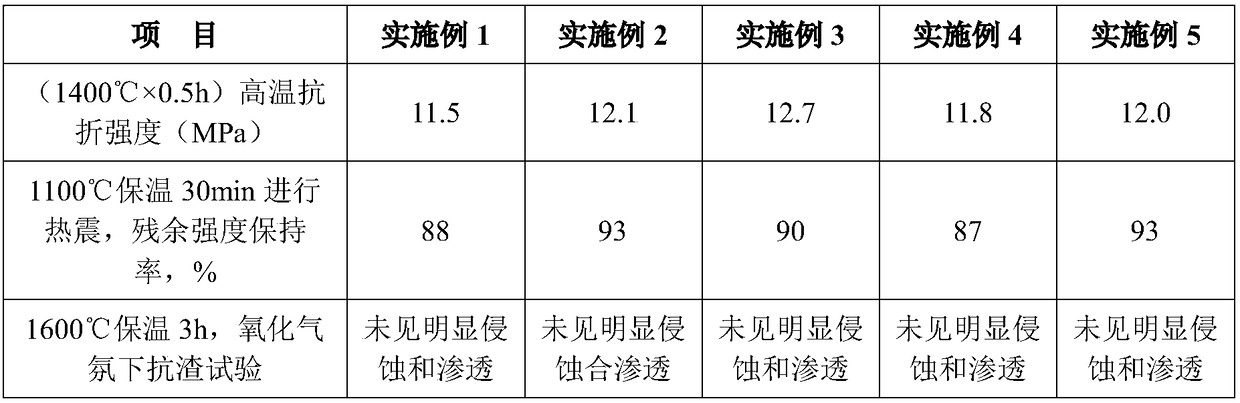

Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as aggregate and preparation method thereof

The invention discloses a Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as an aggregate and a preparation method thereof. The low-carbon magnesia carbon brick comprisesthe following components by weight: 45 to 55% of a magnesia aggregate impregnated by tar and asphalt, 35 to 45% of unimpregnated magnesia, 3 to 5% of graphite, 0.5 to 1.5% of high-temperature asphalt, 2 to 3% of an antioxidant and 2.5 to 3.5% of a binder. The preparation method comprises the following steps: 1) carrying out impregnating so as to obtain the magnesia aggregate impregnated by tar and asphalt; 2) weighing the components with the desired weight; 3) premixing unimpregnated magnesia powder, high-temperature asphalt and the antioxidant to obtain mixed powder; 4) subjecting the magnesia aggregate and the unimpregnated magnesia powder to dry mixing in a mixing and grinding machine, then successively adding the binder, graphite and the mixed powder, and carrying out mixing and grinding to form a mixture; and 5) carrying out briquetting, molding and heat treatment so as to obtain the low-carbon magnesia carbon brick with the magnesia impregnated by tar and asphalt as the aggregate. The low-carbon magnesia carbon brick has the advantages of good thermal shock resistance, good resistance to slag erosion and great high-temperature strength, and is significantly prolonged in service life.

Owner:WUGANG REFRACTORY CO LTD

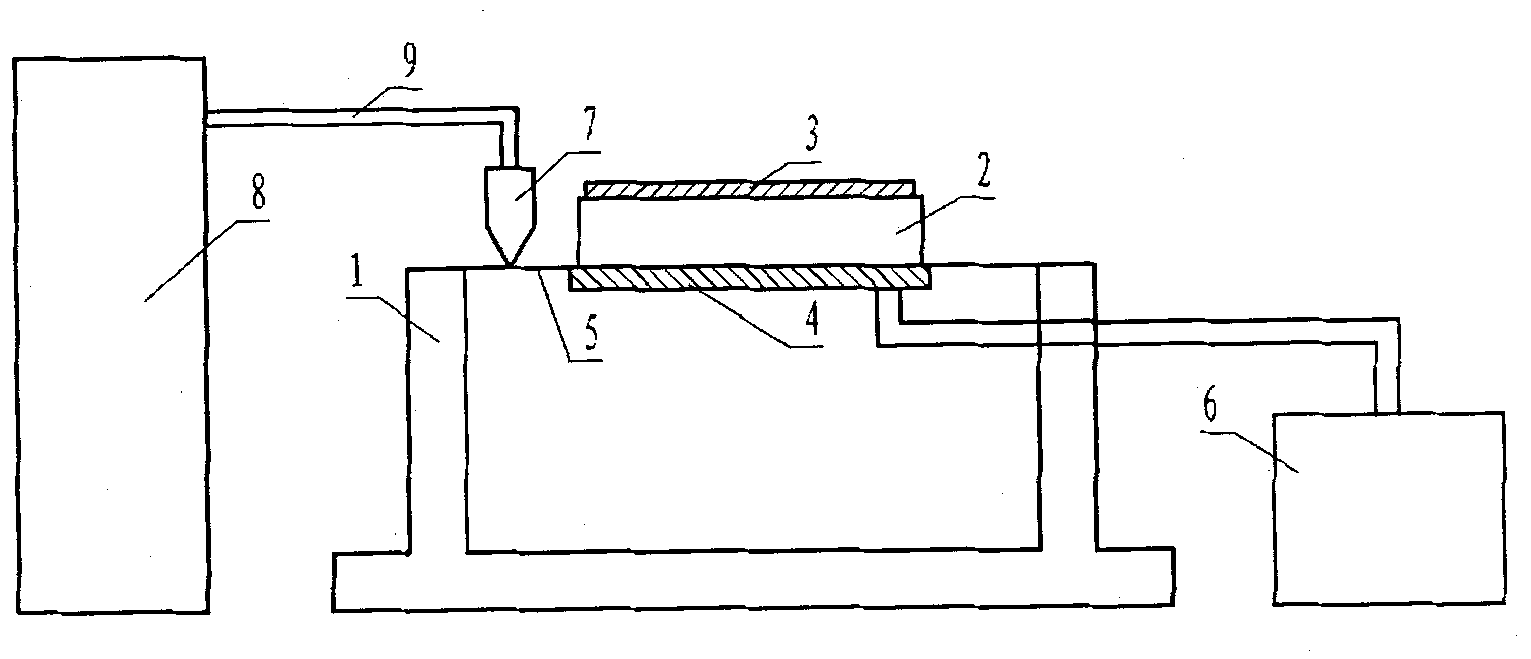

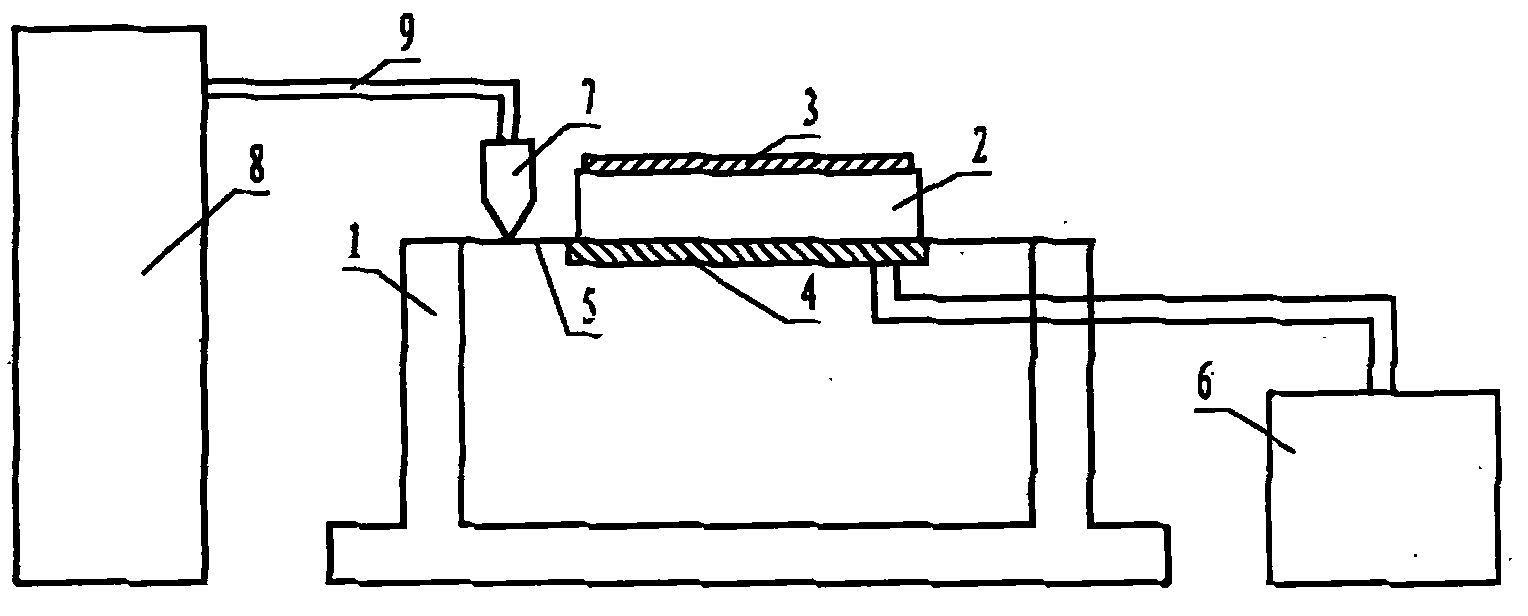

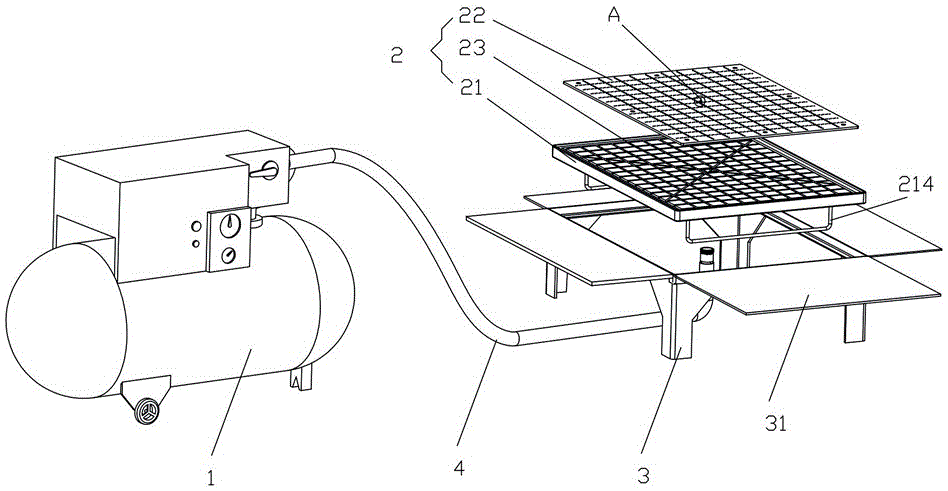

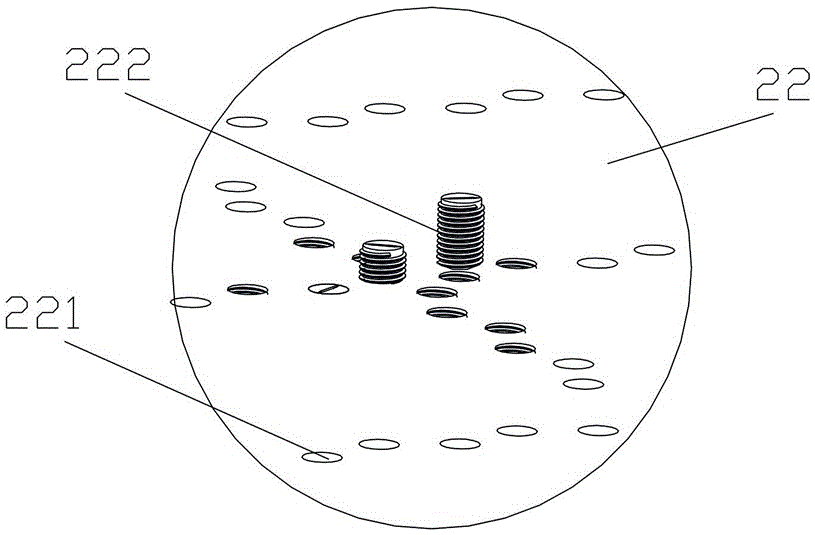

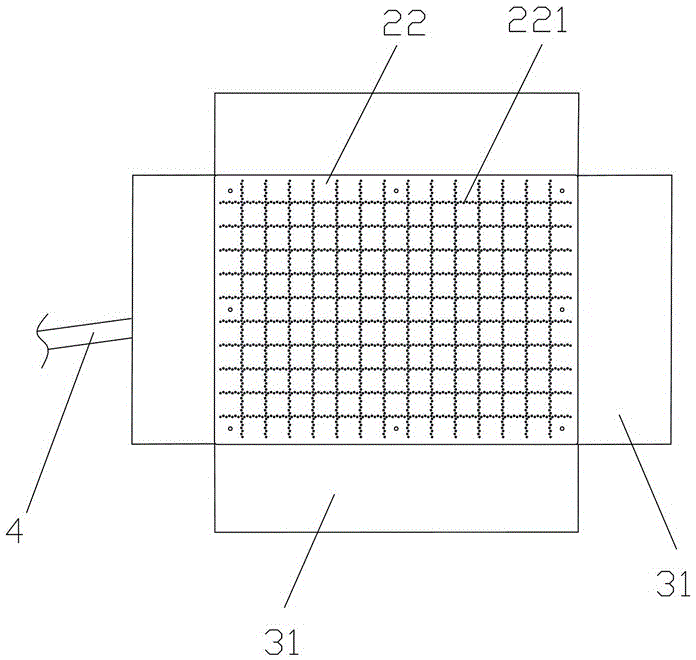

Negative-pressure adsorption welding device and negative-pressure adsorption welding method

InactiveCN106141519ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a negative-pressure adsorption welding device which comprises a negative-pressure producing assembly and negative-pressure adsorption plate assemblies; the negative-pressure adsorption plate assemblies comprise a bottom negative-pressure adsorption plate assembly and a top negative-pressure adsorption plate assembly; negative-pressure adsorption chambers are formed between the negative-pressure plate assemblies and the adsorption plate assemblies; the negative-pressure production assembly communicates with the negative-pressure adsorption chambers for extracting air in the negative-pressure adsorption chambers to form vacuum negative pressure; a plurality of negative-pressure adsorption holes are formed in the adsorption plate assemblies for fixing to-be-welded parts onto the adsorption plate assemblies in a negative-pressure adsorption manner to carry out welding operation when vacuum negative pressure is formed in the negative-pressure adsorption chambers. The invention further discloses a negative-pressure adsorption welding method. The negative-pressure adsorption welding device is reasonable in design, is convenient and quick to operate, is small in welding deformation and is capable of reducing working cost and improving working efficiency.

Owner:株洲天瑞精密钣金有限公司

Cooling structure for high-temperature rotating wheel disc

ActiveCN104454025AReduce weightProlonged heat fatigueBlade accessoriesMachines/enginesDynamic balanceCooling effect

The invention relates to a cooling structure for a high-temperature rotating wheel disc. The cooling structure can be used for the rotating wheel disc of a ground fuel gas turbine, an aircraft engine and other turbine motors in the high-temperature working environment. Both the front end face and / or the rear end face of the rotating wheel disc are / is provided with a plurality of rows of heat exchanging elements distributed in the radial direction. Each row comprises a plurality of the heat exchanging elements evenly distributed along the axis of the wheel disc in the peripheral direction. The heat exchanging elements in every adjacent rows of the heat exchanging elements are distributed in a staggered mode or in an aligned mode in columns in the radial direction. By means of the heat exchanging elements, the turbulence intensity of an end face flow field of the high-temperature rotating wheel disc can be improved, and the temperature of the surface of the disc body can be further lowered through the reattachment feature that the cooling air flow bypasses the tails of the heat exchanging elements. Compared with a traditional wheel disc structure, the wheel disc cooling mode is simple in structure and easy to implement, the cooling effect of the surface of the wheel disc can be greatly improved by just additionally arranging a heat exchanging rib plate on the surface of the disc body, the wheel disc surface temperature is lowered, and the heat exchanging elements can also be used as dynamic balancing bosses of the rotating wheel disc.

Owner:中科航空动力(株洲)装备制造研究院有限公司

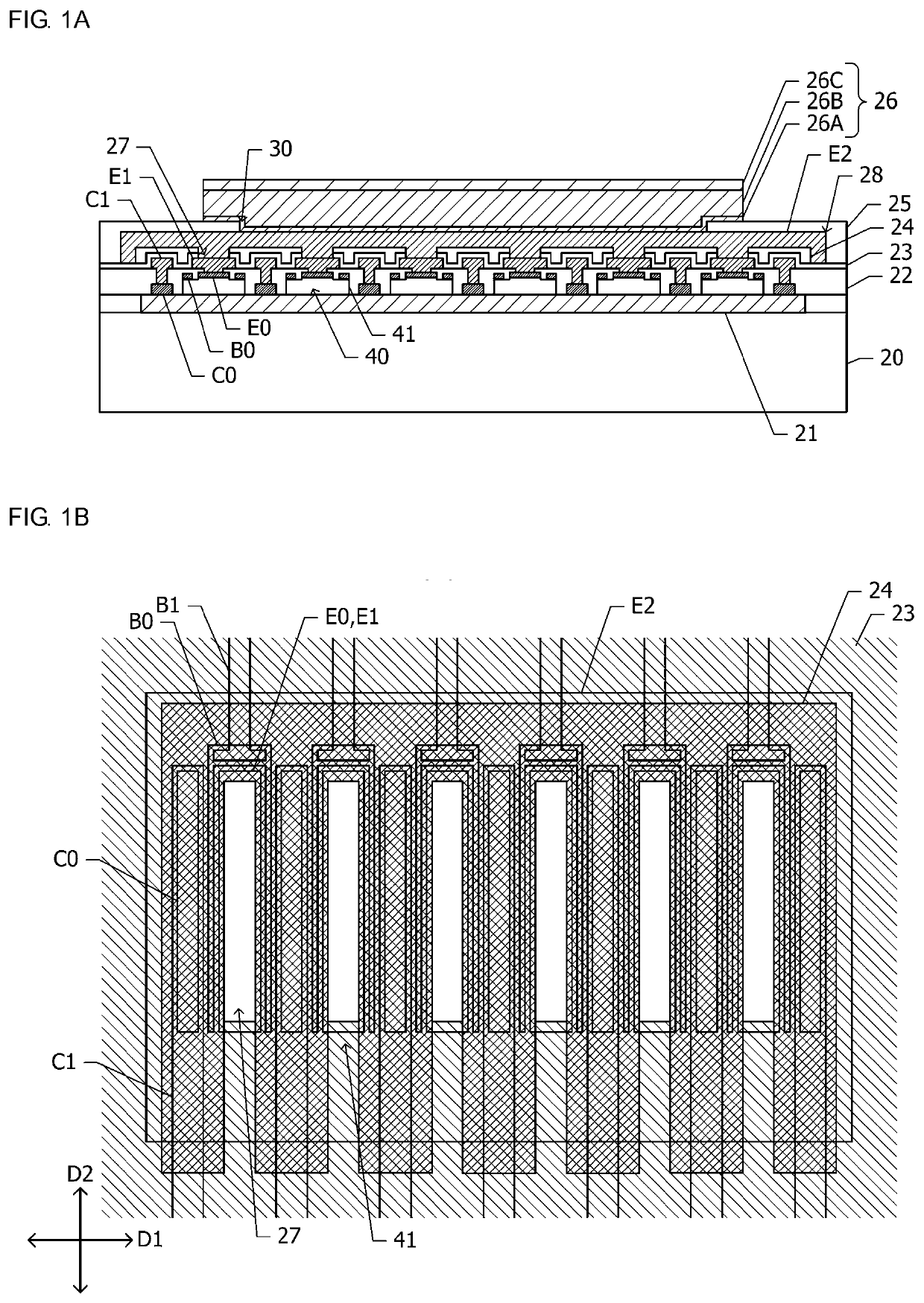

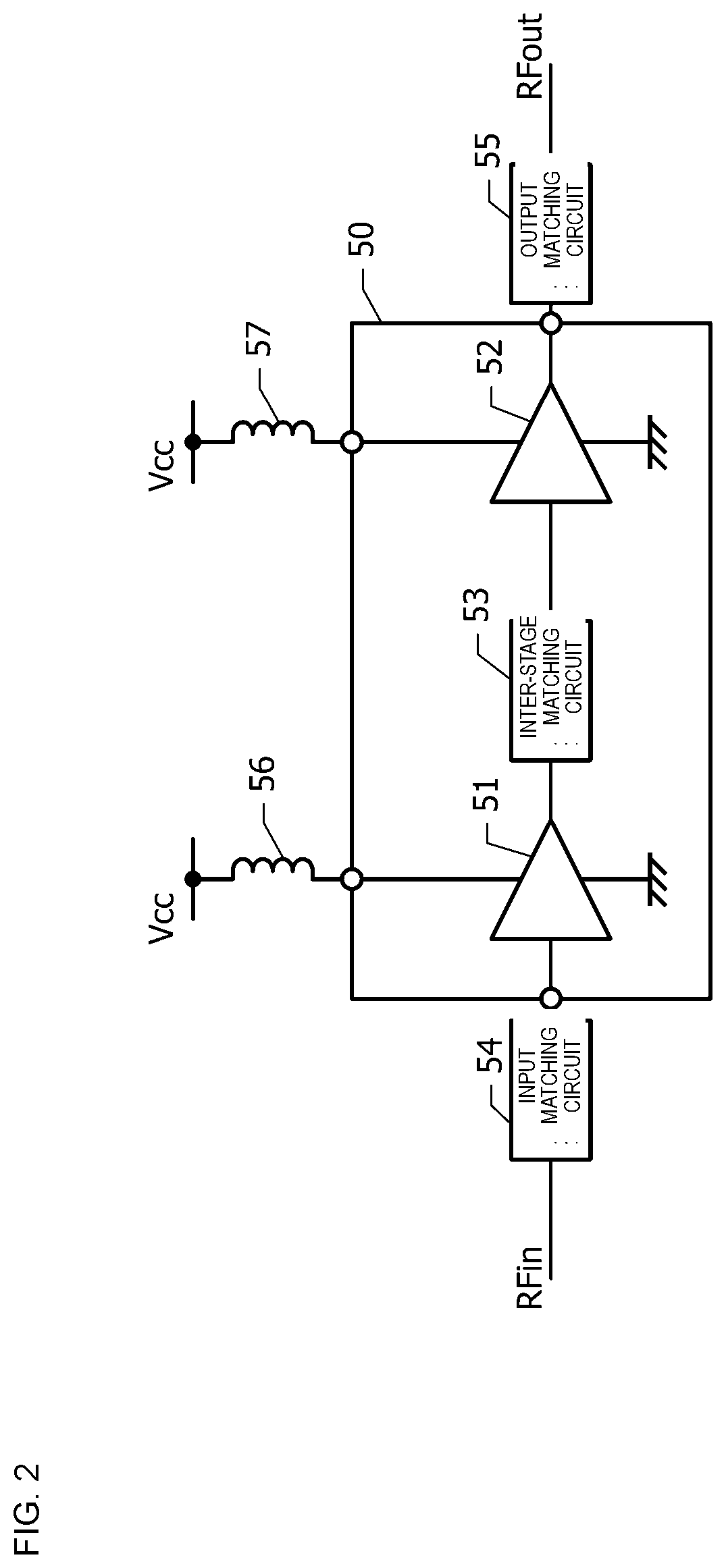

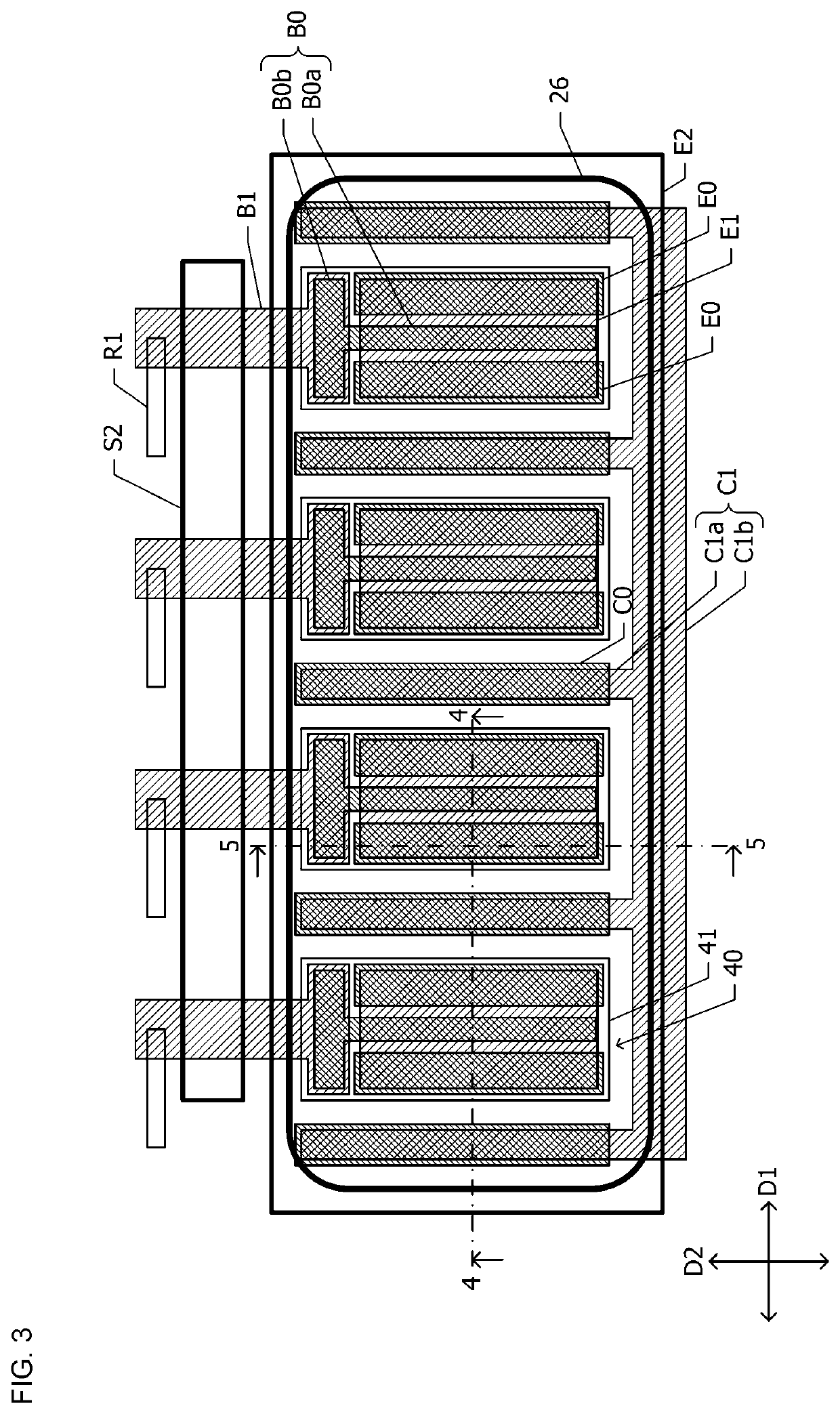

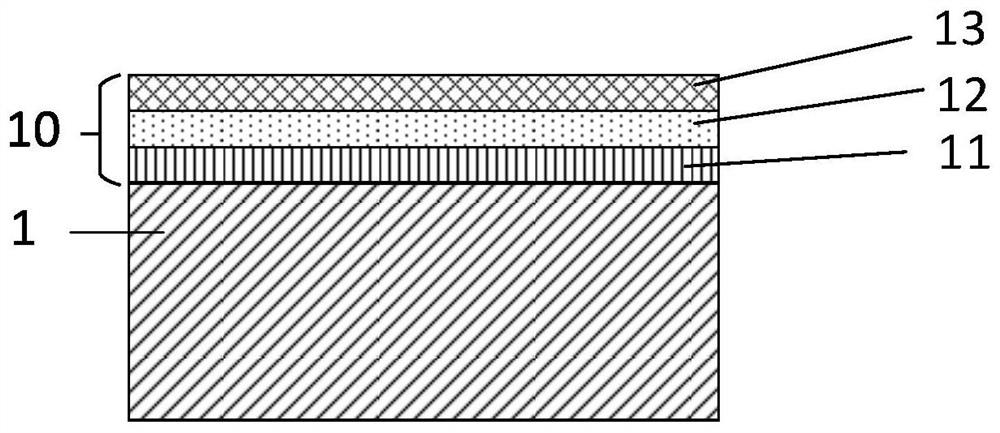

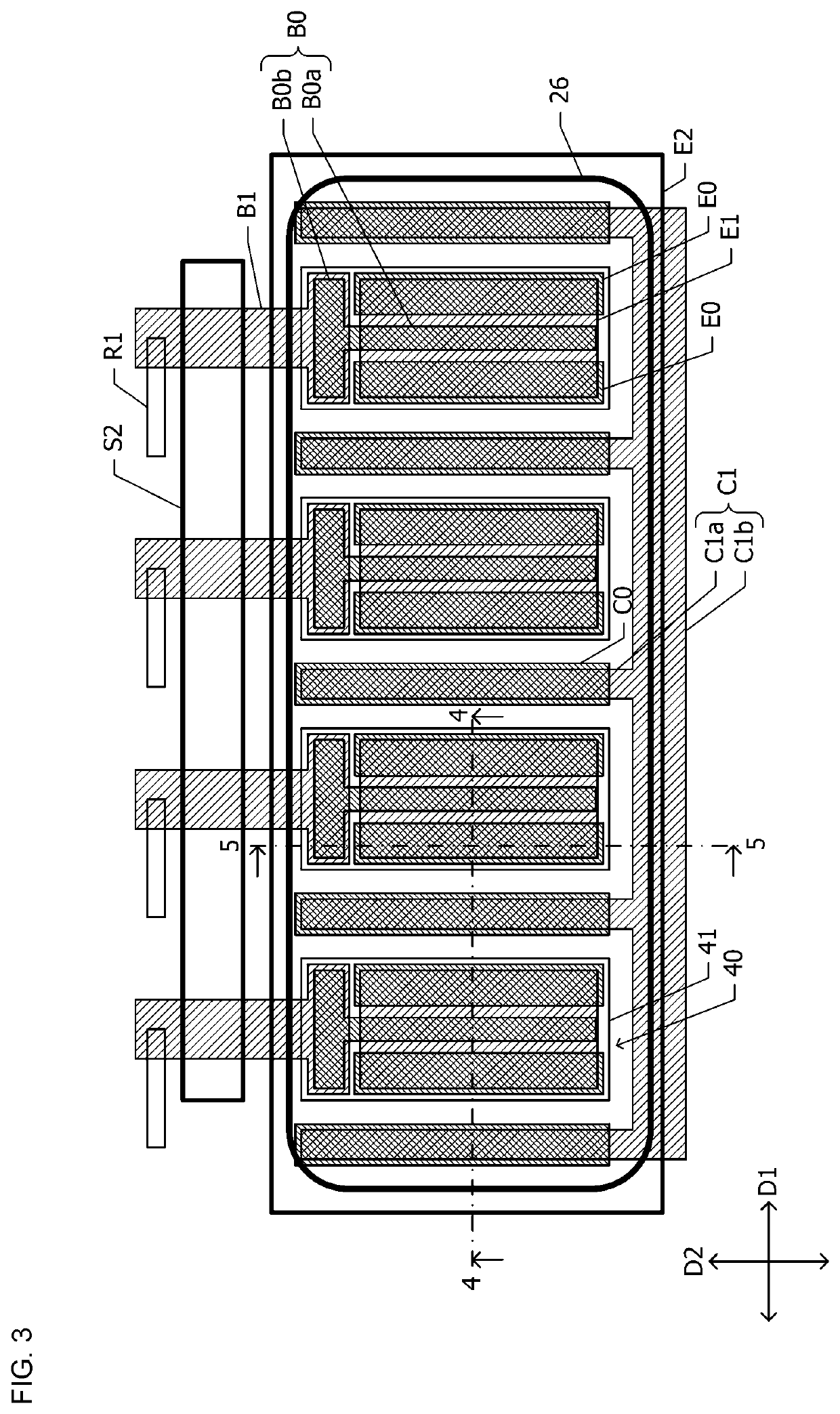

Semiconductor device and high-frequency module

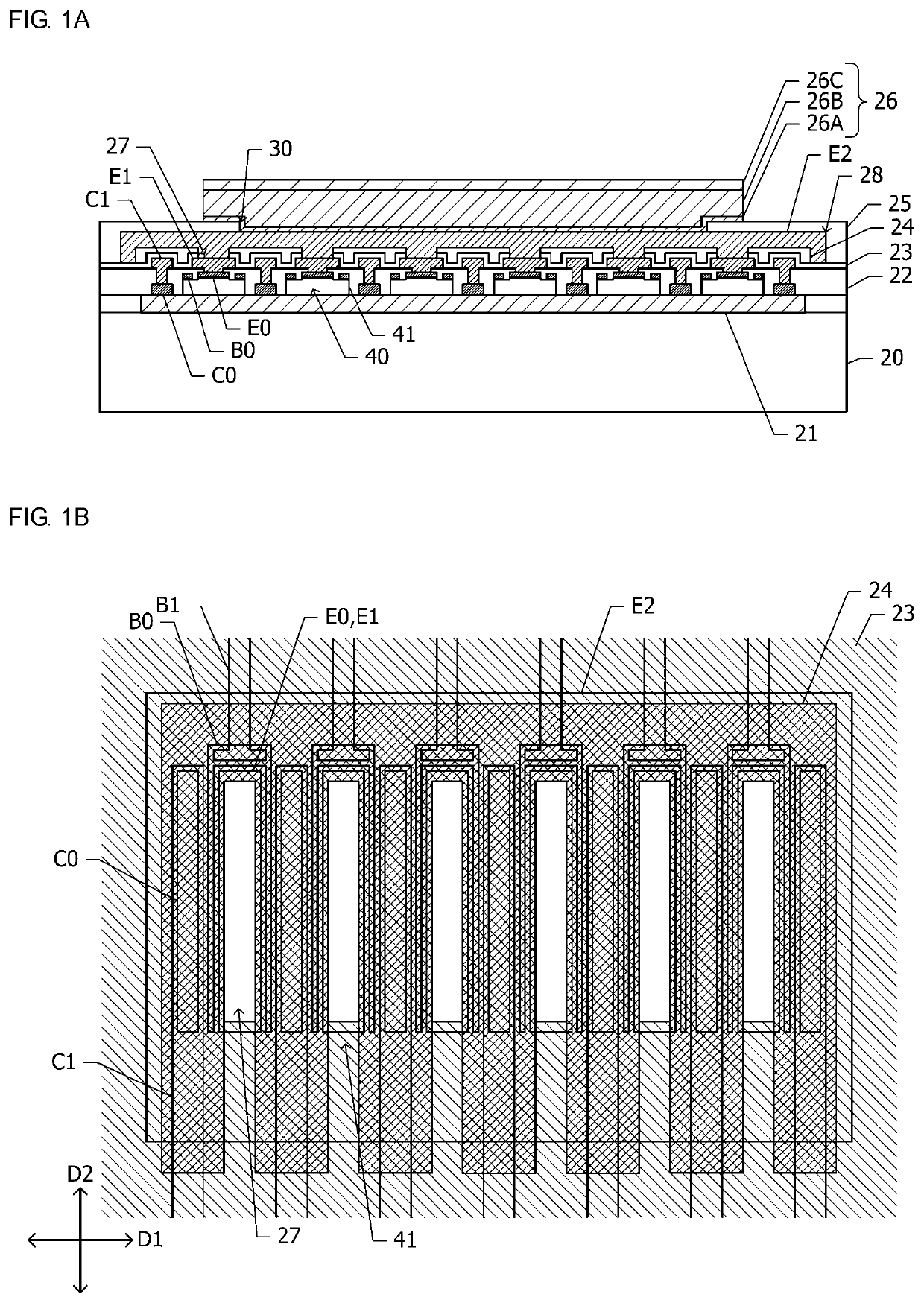

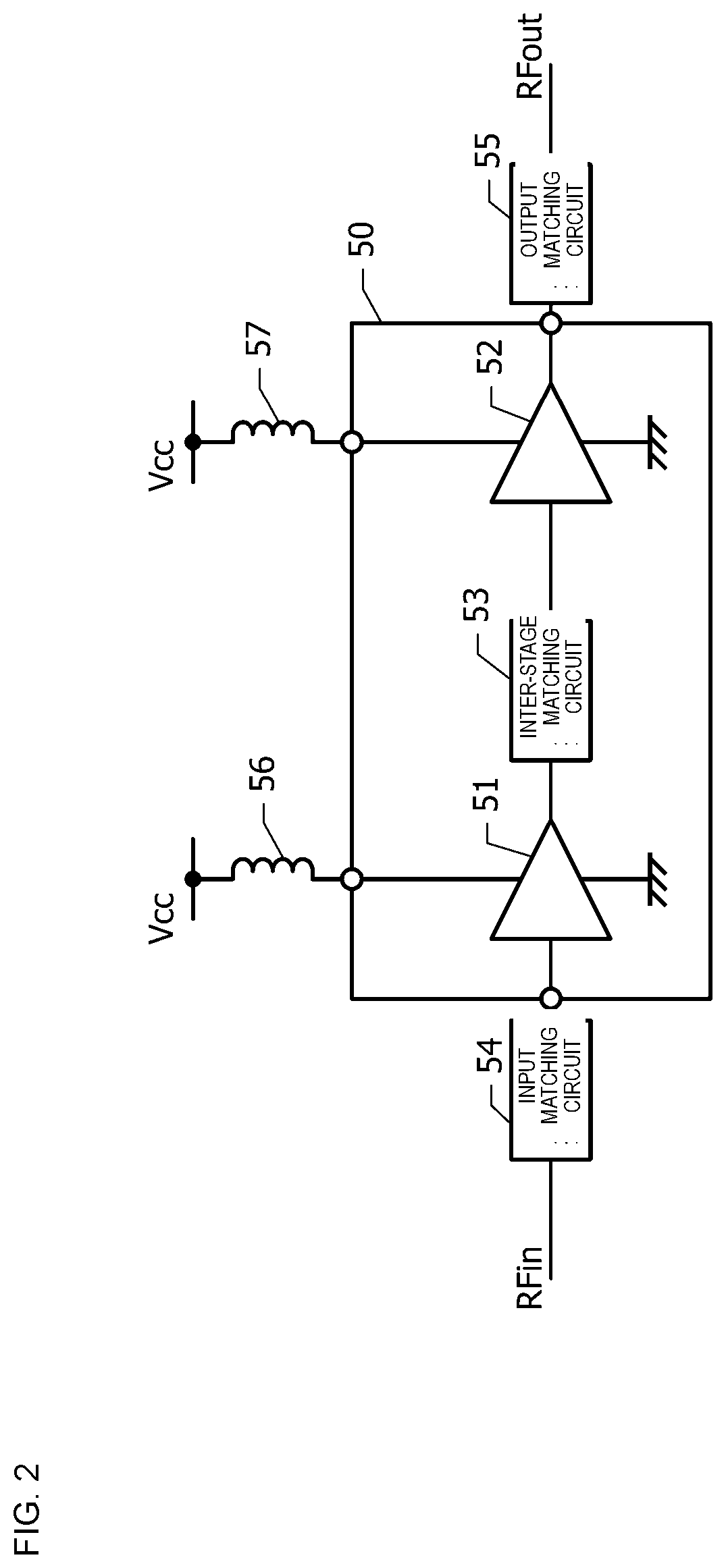

ActiveUS20210035922A1Reduce thermal stressImprove reliabilityTransistorSemiconductor/solid-state device detailsDevice materialElectric current flow

At least one unit transistor is arranged over a substrate. A first wiring as a path of current that flows to each unit transistor is arranged over the at least one unit transistor. An inorganic insulation film is arranged over the first wiring. At least one first opening overlapping a partial region of the first wiring in a plan view is provided in the inorganic insulation film. An organic insulation film is arranged over the inorganic insulation film. A second wiring coupled to the first wiring through the first opening is arranged over the organic insulation film and the inorganic insulation film. In a plan view, a region in which the organic insulation film is not arranged is provided outside a region in which the first wiring is arranged. The second wiring is in contact with the inorganic insulation film outside the region in which the first wiring is arranged.

Owner:MURATA MFG CO LTD

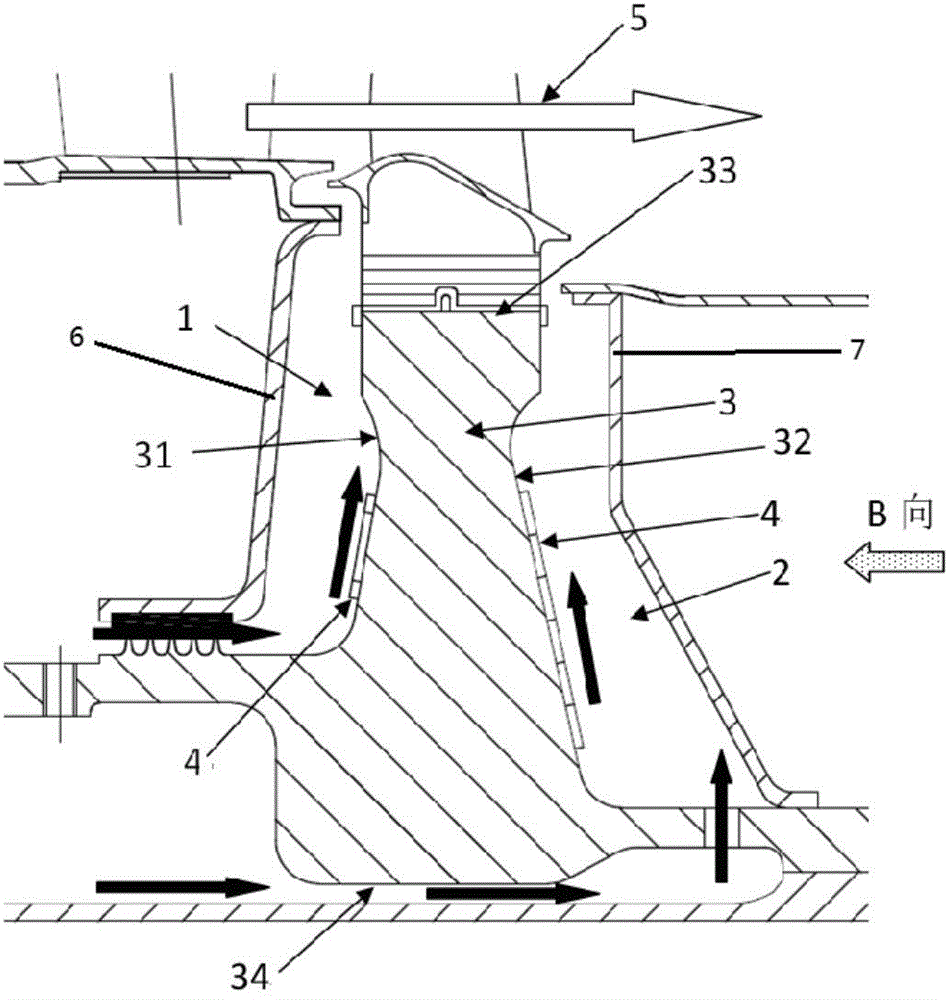

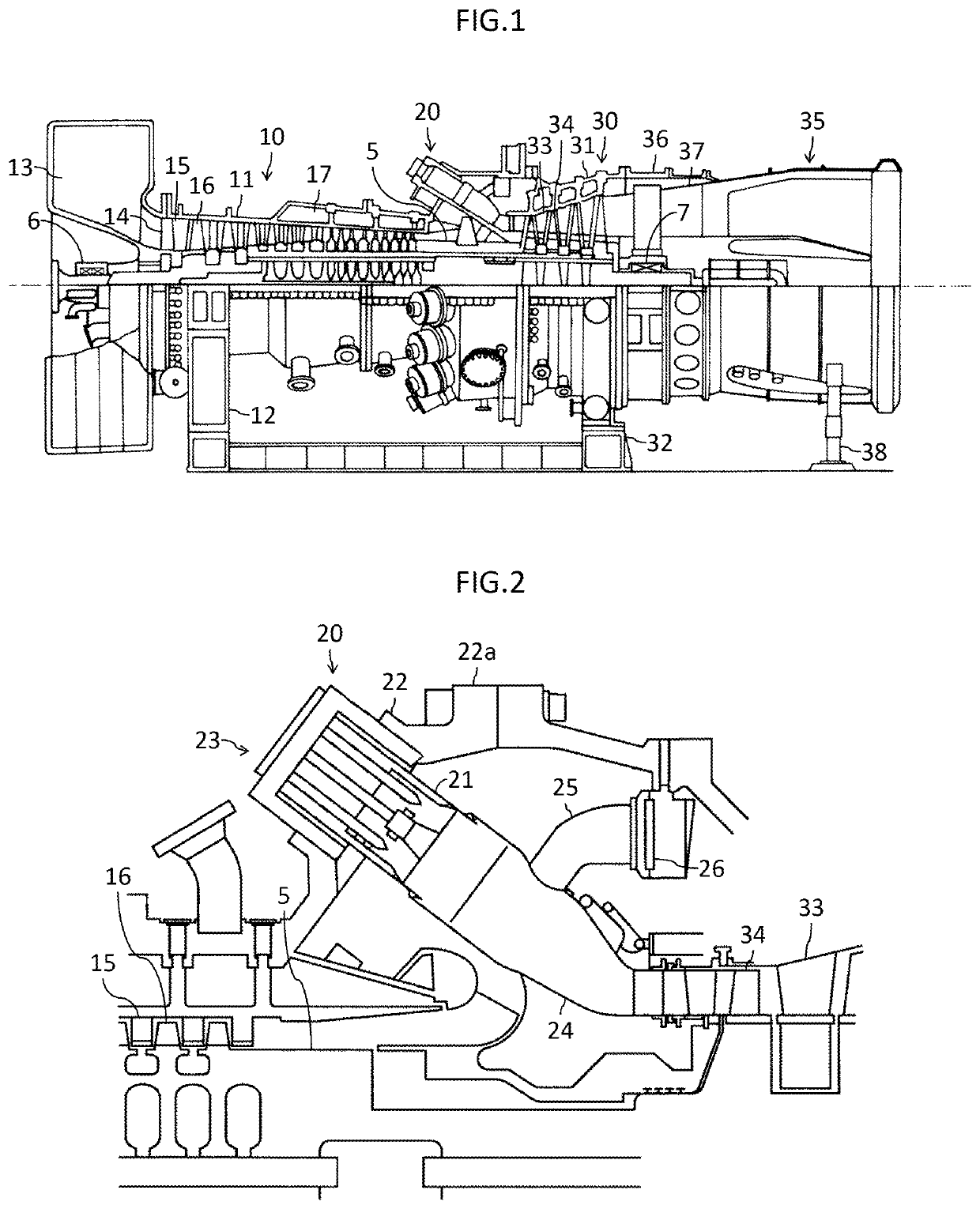

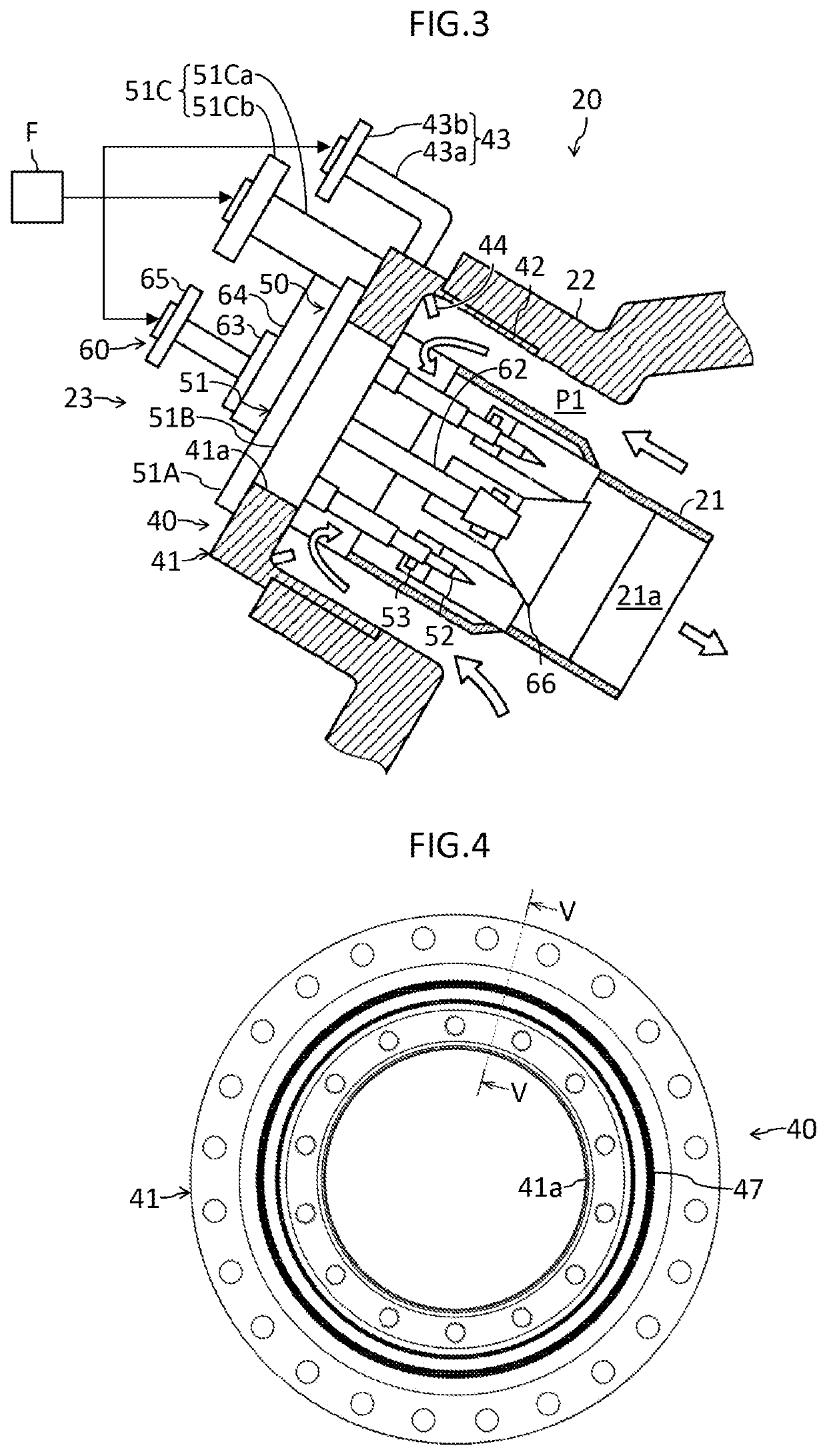

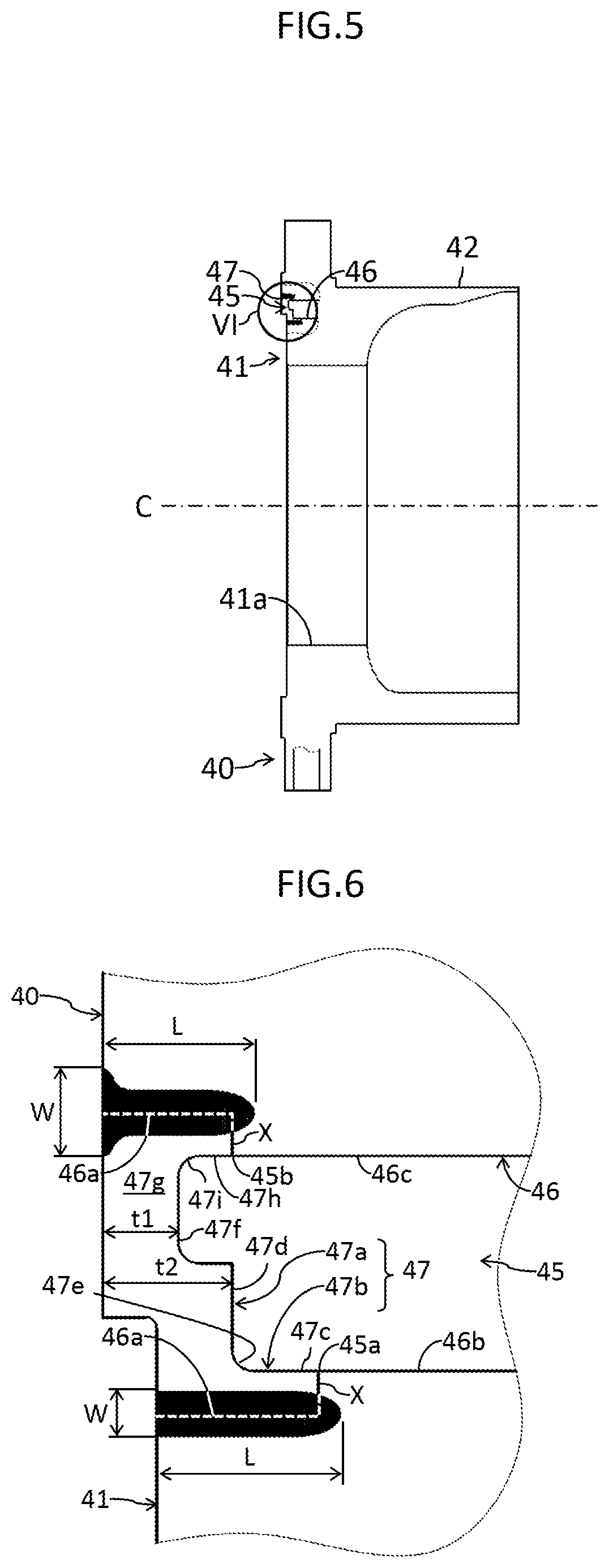

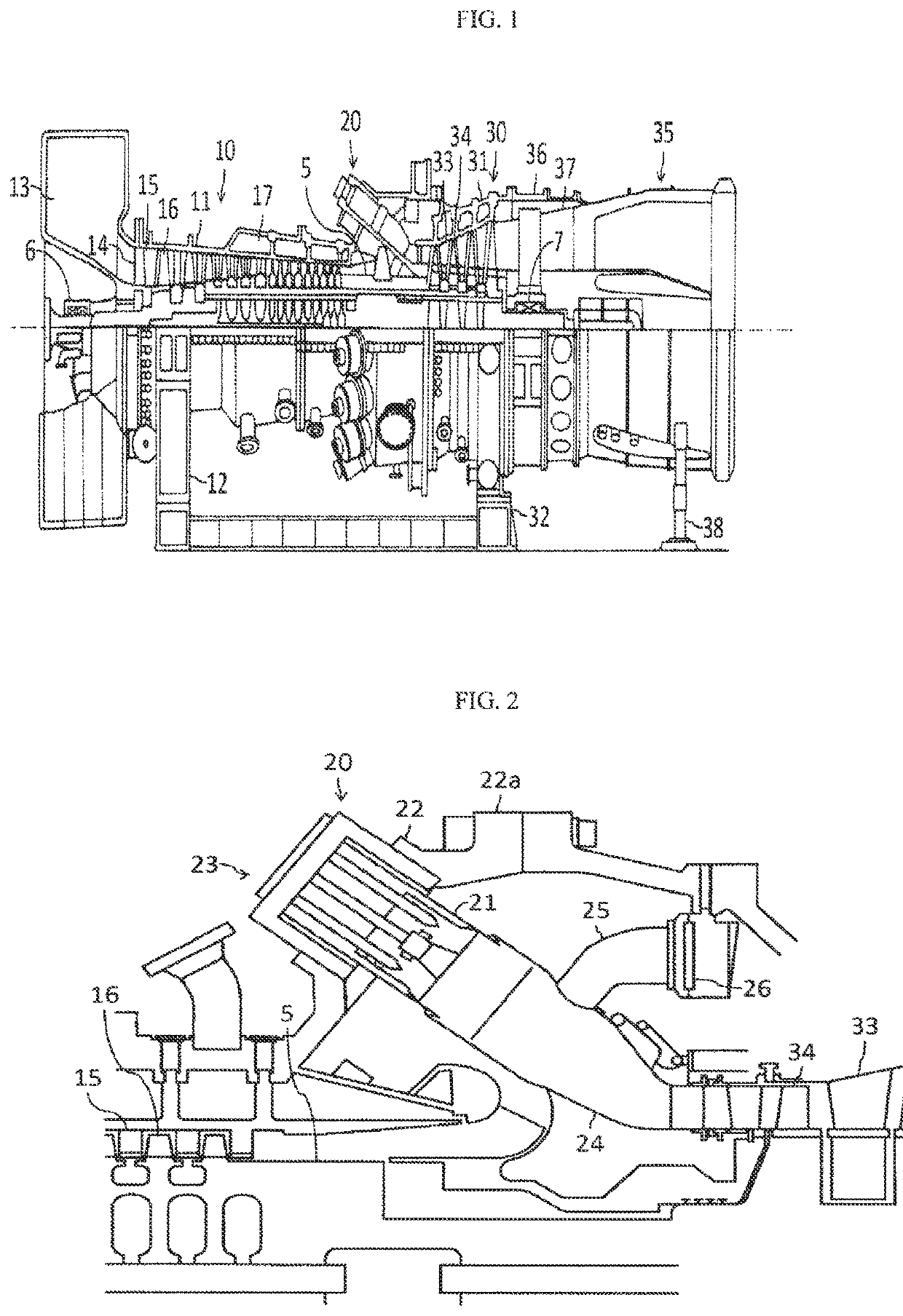

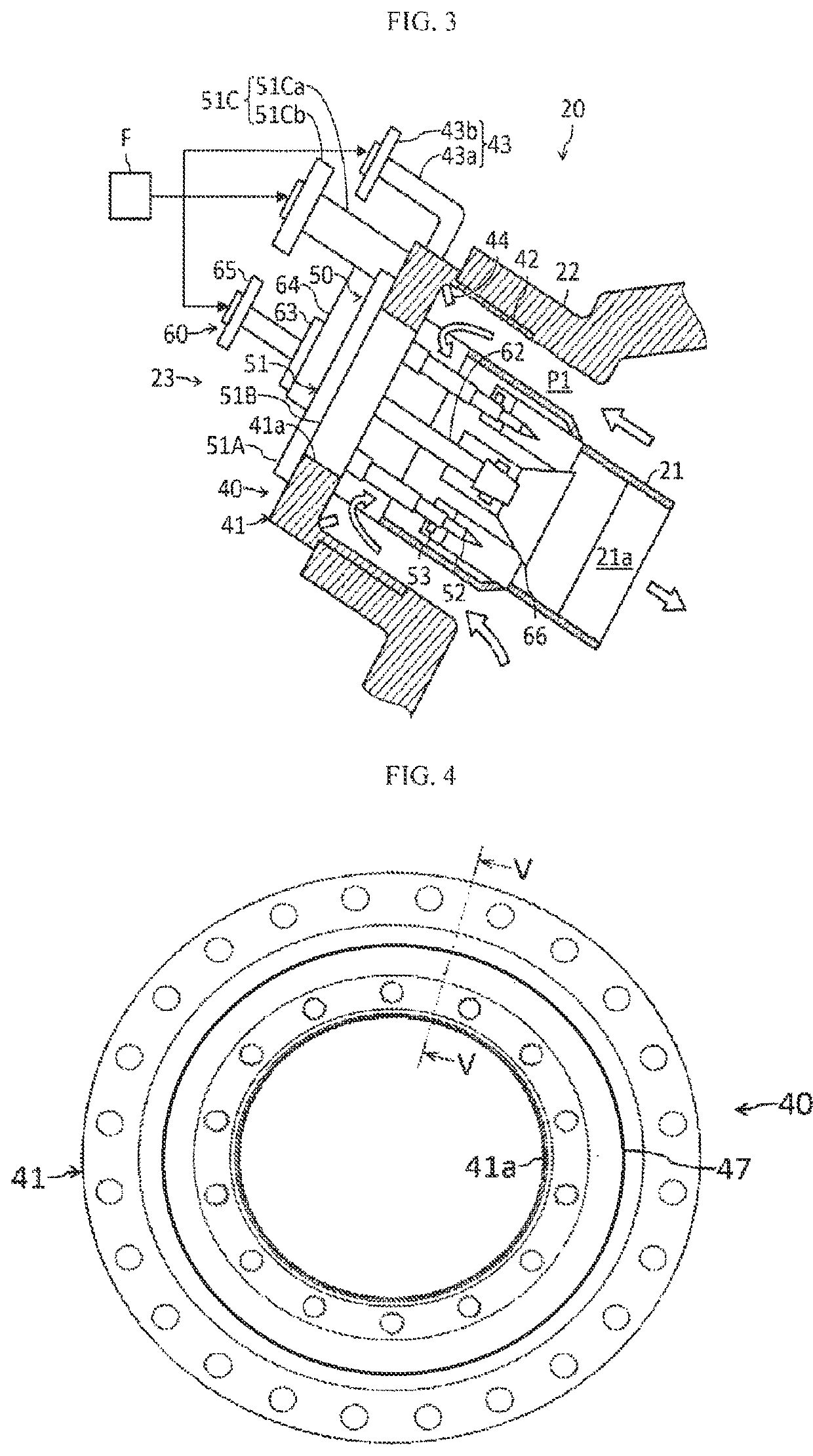

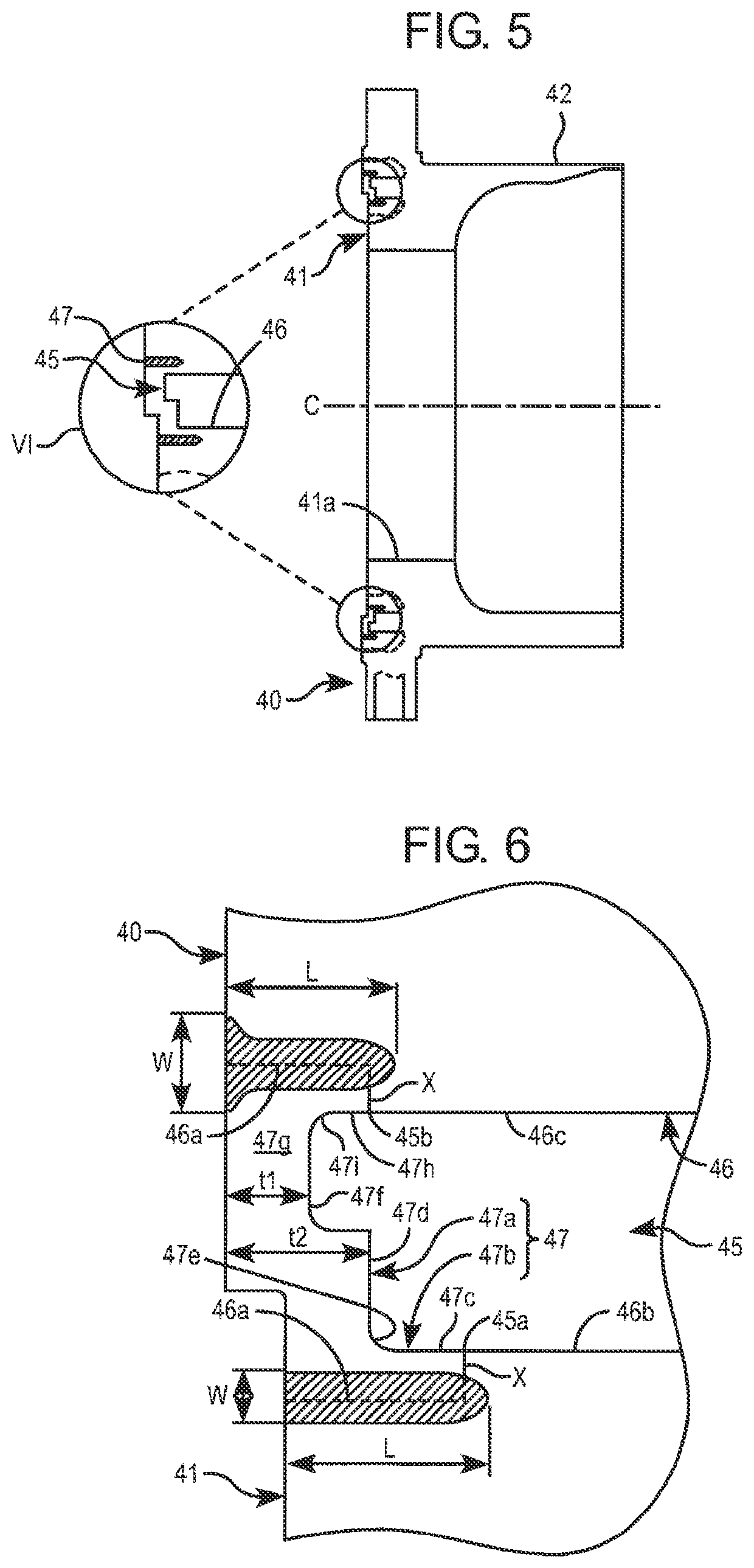

Gas Turbine Combustor and Gas Turbine

ActiveUS20200271322A1Reduce heat stress concentrationReduce thermal stressBurnersContinuous combustion chamberCombustorCombustion chamber

The present invention reduces the concentration of thermal stress on a burner. A gas turbine combustor receiving compressed air from a compressor, mixing the compressed air with a fuel, burning the mixture to generate a combustion gas, and supplying the combustion gas to a turbine. The combustor includes: an inner cylinder internally forming a combustion chamber; an outer cylinder covering the inner cylinder and forming a cylindrical outer circumferential flow path between the inner and outer cylinders to allow the compressed air to flow; and a burner mounted on an end of the outer cylinder, which is positioned on an opposite side to a turbine side, and facing the combustion chamber. The burner includes a cylindrical base frame including a cavity distributing the fuel, and fuel nozzles circularly arranged as viewed from the combustion chamber and connected to the cavity. When viewed from the combustion chamber, slits extending radially are formed in the base frame such that each separate the circumferentially adjacent fuel nozzles from each other.

Owner:MITSUBISHI POWER LTD

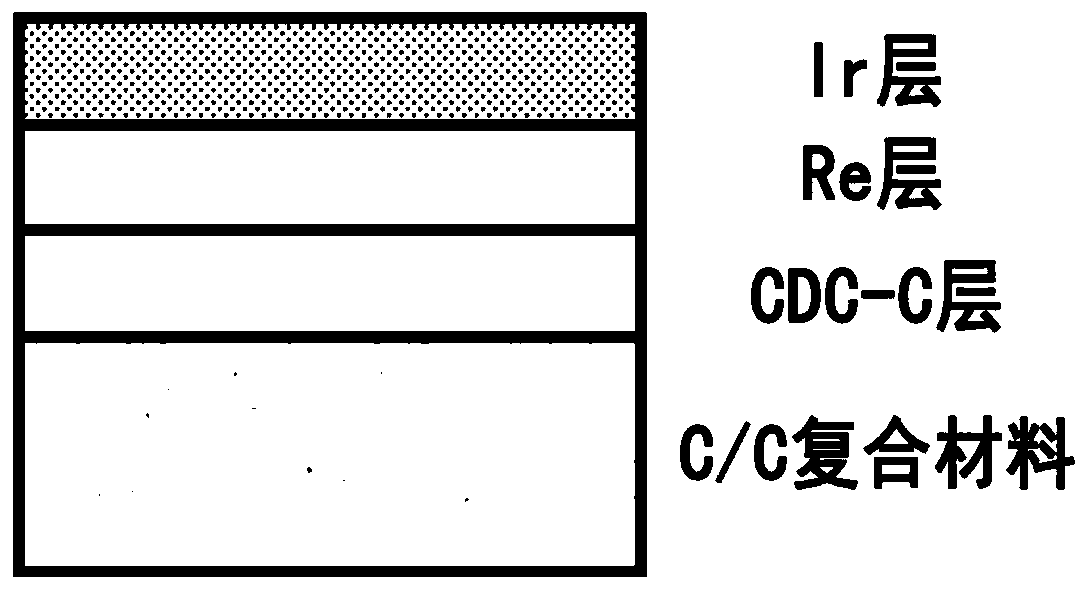

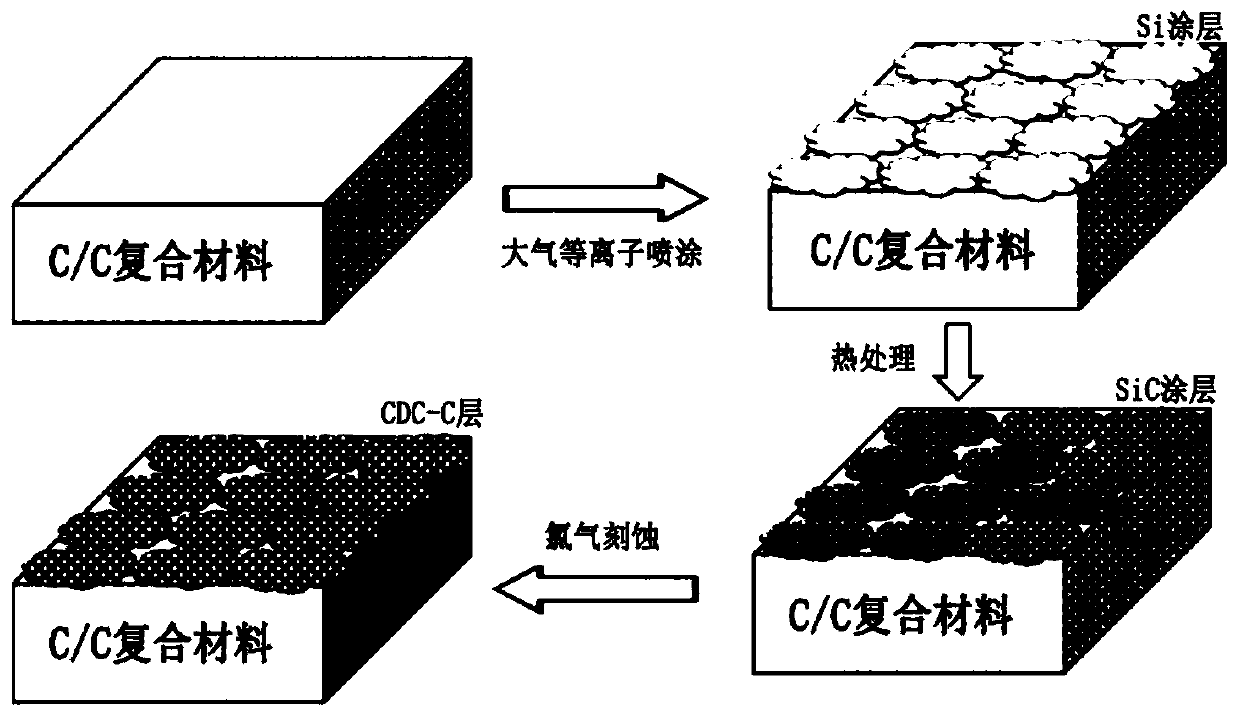

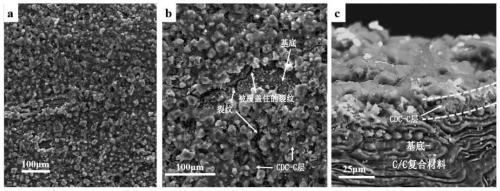

C/C composite material surface carbide derived carbon/rhenium/iridium coating layer and preparation method thereof

The invention discloses a C / C composite material surface carbide derived carbon / rhenium / iridium coating layer and a preparation method thereof. The coating layer takes a C / C composite material as a matrix; a carbide-derived carbon layer, a rhenium coating layer and an iridium coating layer are sequentially arranged on the surface of the C / C composite material from bottom to top. The preparation method comprises the steps: preparing a pure Si layer on the C / C composite material matrix, carrying out heat treatment to obtain an SiC layer, carrying out chlorine etching to form the carbide-derivedcarbon layer, and sequentially depositing the rhenium coating layer and the iridium coating layer on the carbide-derived carbon layer. The carbide-derived carbon / rhenium / iridium coating layer can perfectly consider coating layer combination, coating layer matrix thermal mismatch alleviation and coating layer system high-temperature thermochemical compatibility, and has a wide application prospect.

Owner:NAT UNIV OF DEFENSE TECH

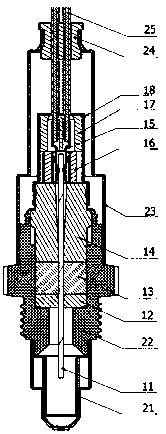

Compressive sealing method for vehicle oxygen sensor

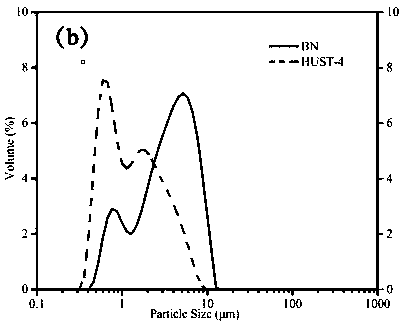

InactiveCN108519419AImprove air tightnessHigh bonding strengthMaterial analysis by electric/magnetic meansStress concentrationGlass composites

The invention relates to the technical field of vehicle oxygen sensors, in particular to a compressive sealing method for a vehicle oxygen sensor. A sealing material used in the compressive sealing method for the vehicle oxygen sensor is prepared from h-BN or a complex of the h-BN or glass powder by molding, assembling, pressing and heating with alcohol serving as a solvent. According to the compressive sealing method for the vehicle oxygen sensor, the novel h-BN-based sealing material which can meet the usage requirements of a high-accuracy oxygen sensor on the aspects of sealing performanceand high-temperature structural stability is adopted, and the laminated structure of the h-BN and a flexible B2O3 liquid film can effectively reduce thermal stress concentration generated in a thermalcirculation process, so that the performance stability of the sealing material is improved. The h-BN-glass composite sealing material can effectively improve the airtightness, bonding strength and impact resistance of the sealing position of the oxygen sensor.

Owner:CHANGZHOU LAMBDA ELECTRONICS

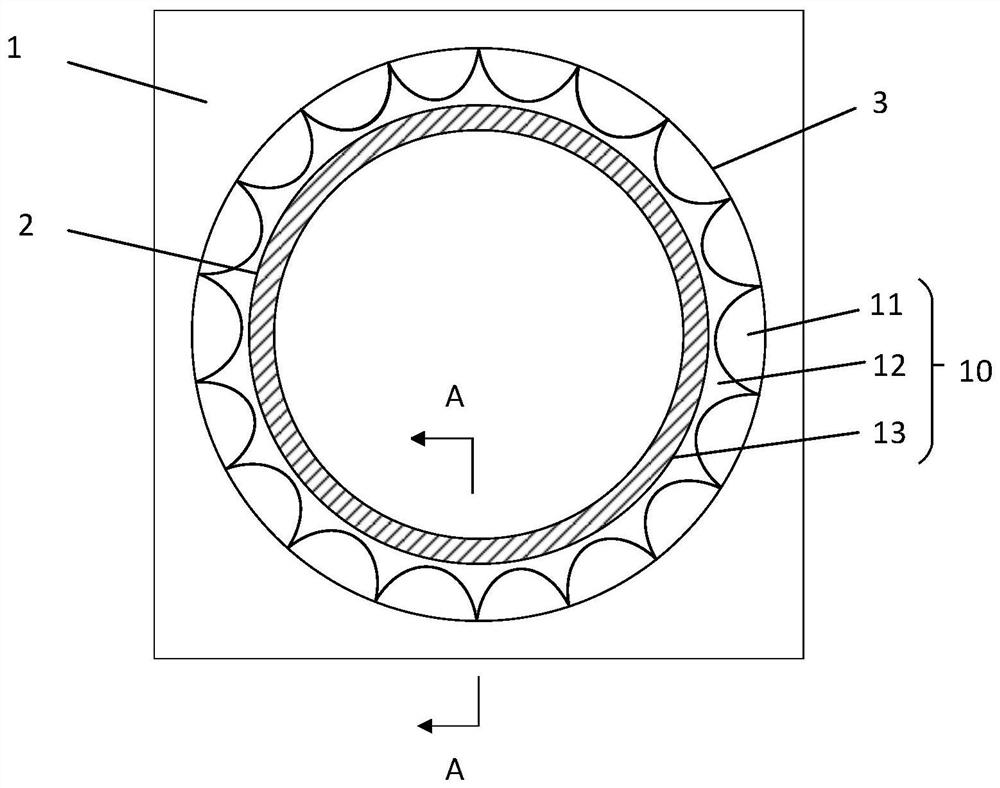

Display screen and cutting method thereof

InactiveCN111823419AImprove impact resistanceHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

The invention discloses a display screen and a cutting method thereof. The display screen is provided with a protecting structure along a cutting area edge of the display screen; the protecting structure covers the side wall of the cutting area edge, is a multi-layer structure and can effectively protect a trepanning area edge and a grooving area edge of the display screen, thus the stress is hierarchically buffered and dispersed, impact force is neutralized stage by stage, the anti-collision capacity of a trepanning area and a grooving area of the display screen is improved, and the overall strength of the display screen is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

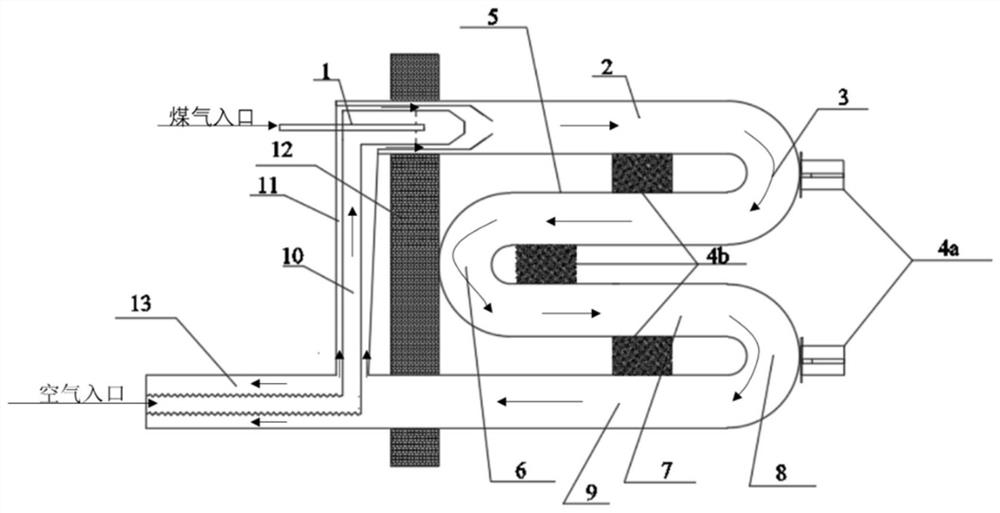

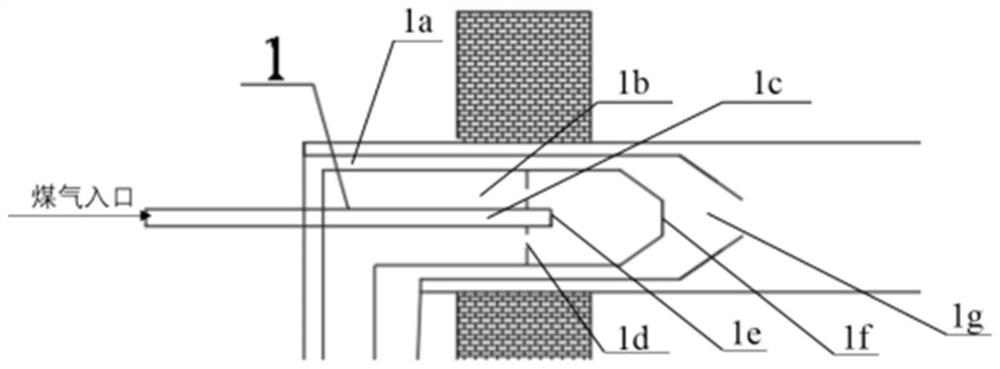

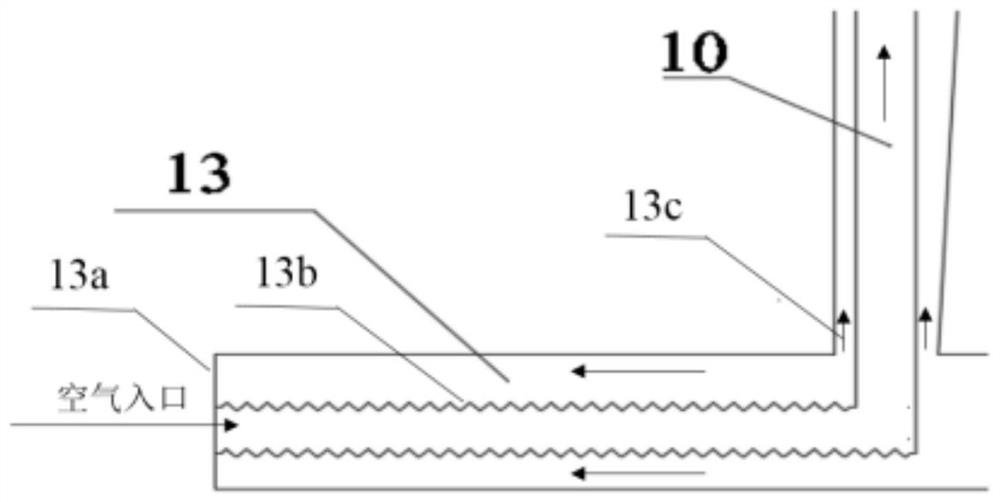

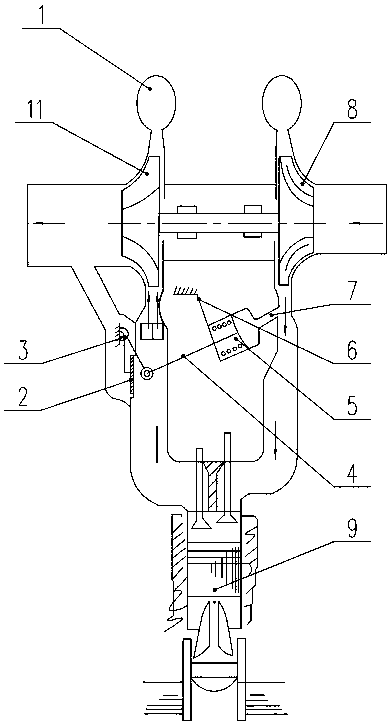

Radiant tube heating device with self-preheating type flue gas recirculation

PendingCN114087608AIncrease flow rateReduce heat stress concentrationIndirect carbon-dioxide mitigationGaseous fuel burnerExhaust gasCombustion chamber

The invention discloses a radiant tube heating device with self-preheating type flue gas recirculation. The device comprises a radiant tube main body device, a combustion-supporting air preheating pipeline, a contraction opening and a formed flue gas circulation pipeline. In order to enhance heat exchange between flue gas and combustion-supporting air, a non-smooth air preheating pipeline is arranged at the tail part of the radiation pipe, so that the problems of high exhaust gas temperature and low heat efficiency of the device are solved; the gas circulation pipeline can enable a certain amount of flue gas to flow back to a combustion chamber to participate in re-combustion; the oxygen content of a combustion area is reduced by the backflow flue gas, so that the flame temperature is reduced, the stress concentration of the radiant tube is relieved while the generation of NOx is reduced, and the service life of the radiant tube is prolonged; the average flow rate of flue gas in the radiant tube is improved through jet flow generated by the shrinkage opening, so that the temperature gradient in the radiant tube is reduced, and the temperature distribution uniformity of the radiant tube is enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

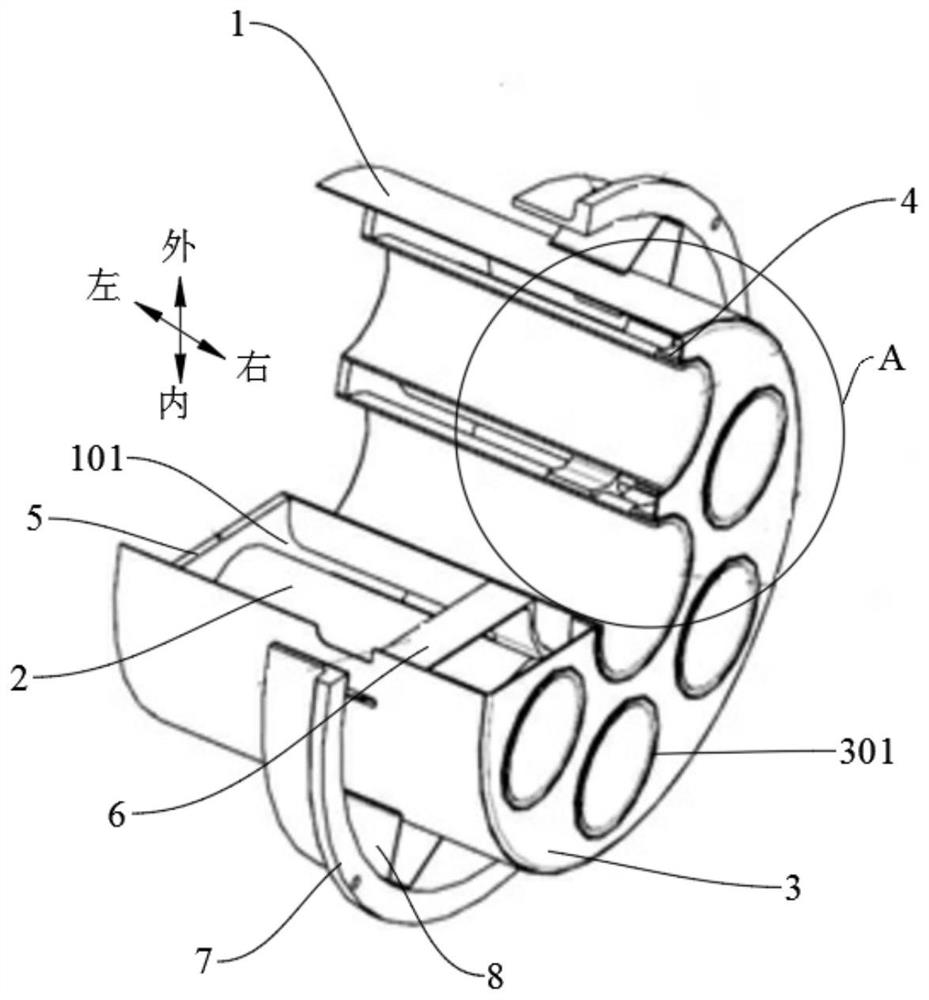

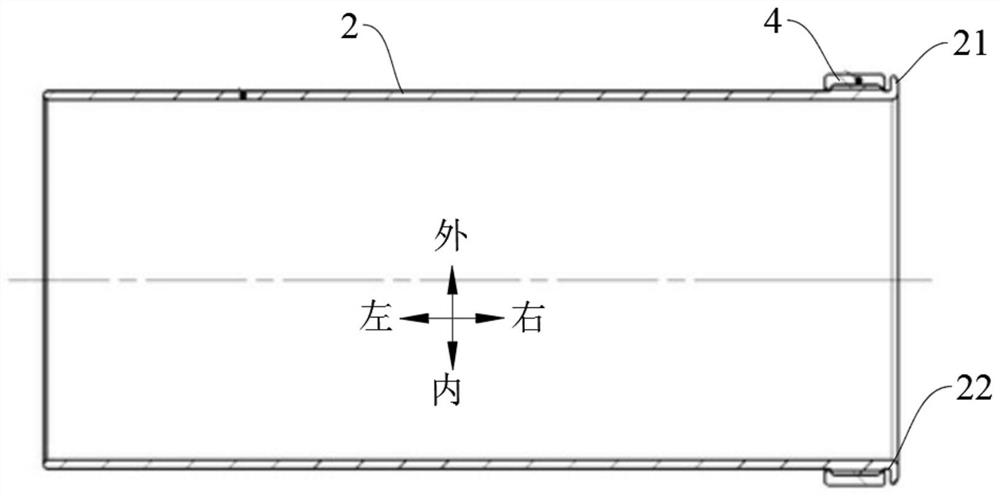

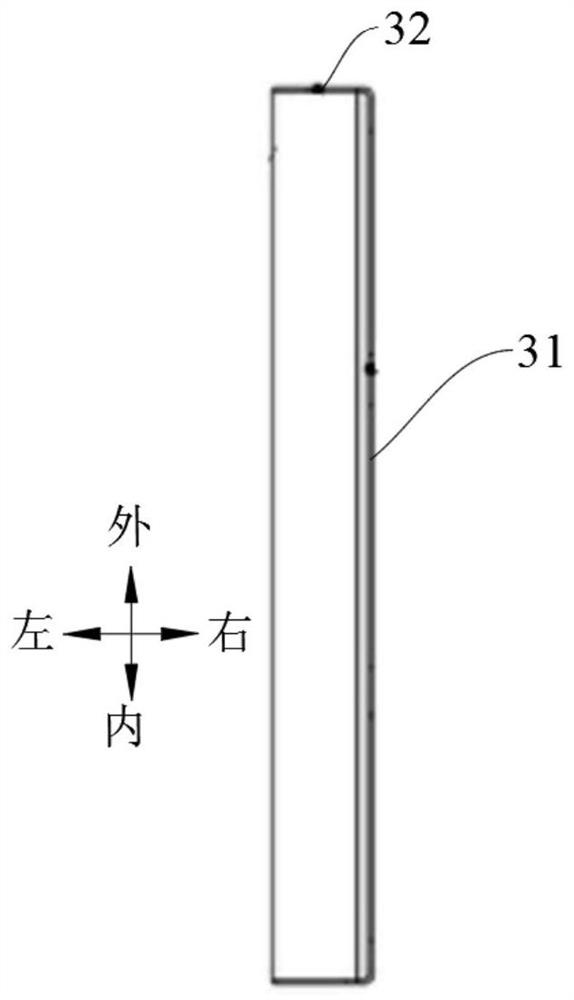

Burning chamber cover cap and gas turbine with same

PendingCN113669758AReduce heat stress concentrationExtended service lifeContinuous combustion chamberGas turbinesCombustion chamber

The invention discloses a burning chamber cover cap and a gas turbine with the same. The burning chamber cover cap comprises an outer cylinder, a nozzle cover cylinder, a diffusion panel and a fixing ring, wherein a containing cavity is formed in the outer cylinder; the nozzle cover cylinder is arranged in the containing cavity; heat dissipation holes are formed in the diffusion panel; the nozzle cover cylinder is connected with the diffusion panel; one end of the nozzle cover cylinder penetrates through the heat dissipation holes so that one end of the nozzle cover cylinder can be communicated with the outside; the fixing ring is arranged in the containing cavity; and the fixing ring is arranged on the nozzle cover cylinder in a sleeving mode so that the nozzle sleeve can be fixed to the diffusion panel. According to the burning chamber cover cap, thermal stress concentration of the diffusion panel can be reduced, and the service life of the diffusion panel is prolonged.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

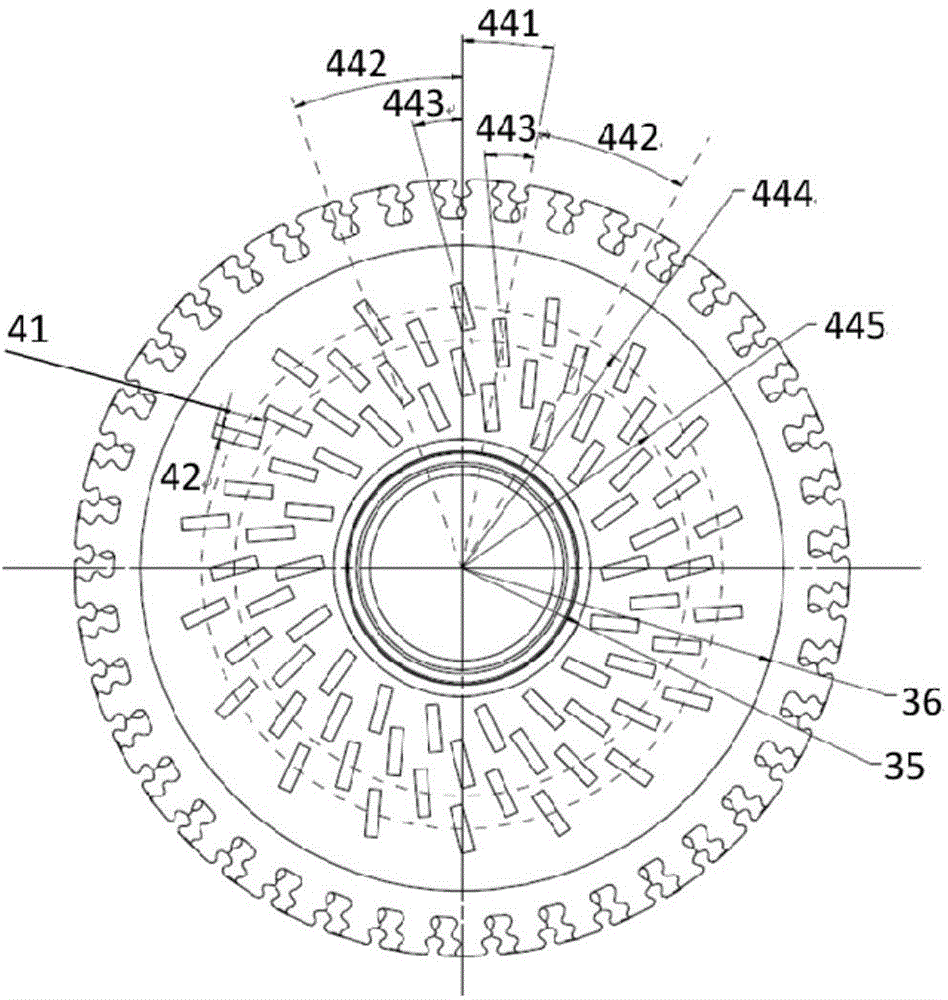

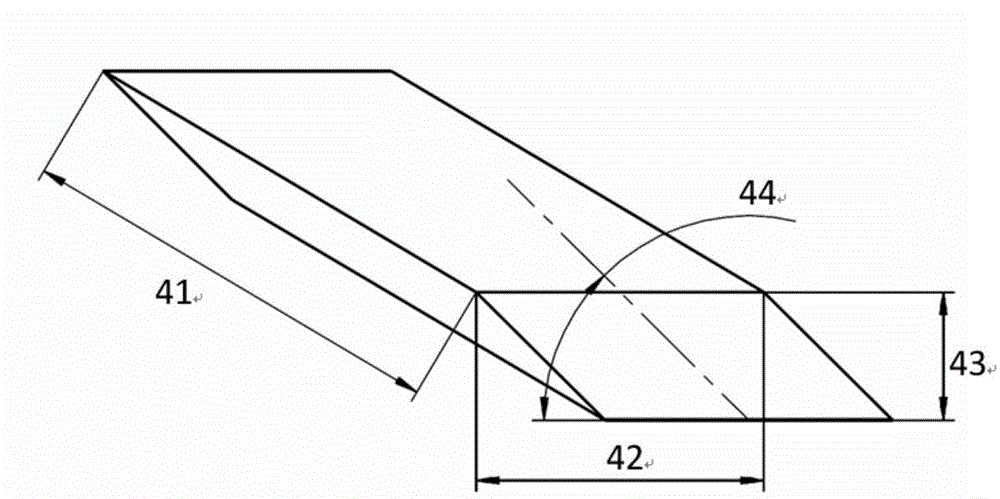

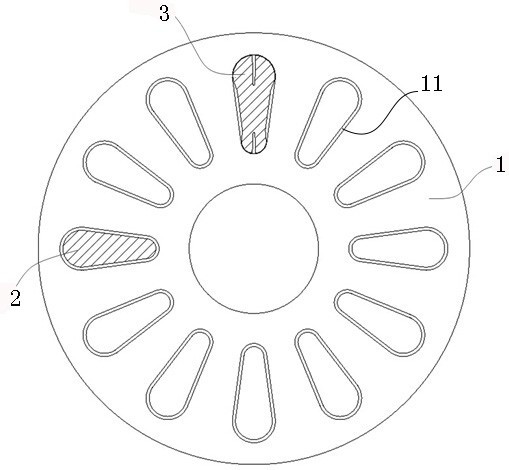

Induction motor rotor conducting strip and preparation method thereof

PendingCN112510874AEasy to enterAvoid imbalanceMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

The invention relates to the technical field of rotor conducting strips, particularly to an induction motor rotor conducting strip and a preparation method thereof. According to the induction motor rotor conducting strip, part of the contour of the conducting strip is the same as the nominal contour of an iron core groove, a gap exists between part of the contour of the conducting strip and the nominal contour of the iron core groove, and a deformation coping structure allowing the conducting strip to deform when driven into the iron core groove is arranged. The preparation method of the induction motor rotor conducting strip comprises the following steps: S01, designing the section shape of a conducting strip, so that a part of the contour of the conducting strip is the same as the nominal contour of an iron core groove, a gap exists between the other part of the contour of the conducting bar and the nominal contour of the iron core groove, and a deformation coping structure allowingthe conducting bar to deform when the conducting bar is punched into the iron core groove is arranged; S02, designing a conducting strip preparation mold according to the section shape of the conducting strip; and S03, extruding and forming the conducting strip material into the required conducting strip through the conducting strip preparation mold. According to the invention, the conducting strip and the iron core groove are convenient to drive in and moderate in tightness; and the preparation method of the conducting strip is very simple and convenient to operate, low in cost and suitable for mass production of the conducting bar.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

Energy-saving steel ladle working lining castable and preparation method thereof

The invention discloses an energy-saving type steel ladle working lining castable, and the castable is prepared through the following steps: taking 60-75 parts by mass of low-thermal-conductivity sintered corundum particles as aggregate and 8-15 parts by mass of low-thermal-conductivity sintered corundum fine powder, 2-8 parts by mass of fused magnesite fine powder, 8-15 parts by mass of alpha-Al2O3 micro powder and 3-7 parts by mass of pure calcium aluminate cement as matrix materials; uniformly premixing the matrix material, adding the matrix material into the aggregate, uniformly mixing, additionally adding water accounting for 3-6wt% of the raw materials, uniformly stirring, carrying out vibration molding, maintaining at room temperature for 12-24h, and finally carrying out heat preservation at 110-200 DEG C for 12-36h to prepare the energy-saving steel ladle working lining castable. The energy-saving steel ladle working lining castable prepared by the invention has the characteristics of low heat conductivity, good thermal shock resistance and long service life.

Owner:WUHAN UNIV OF SCI & TECH

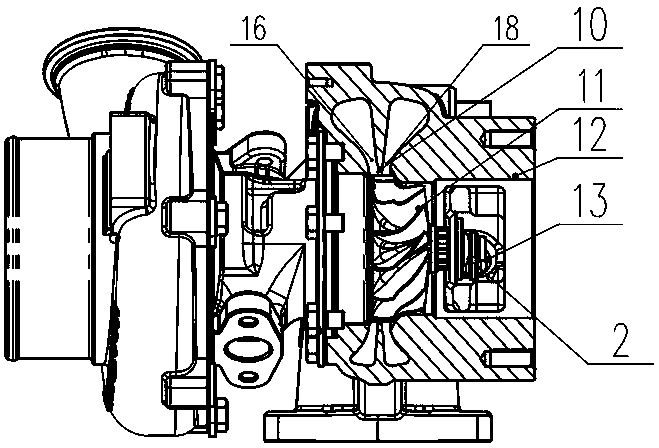

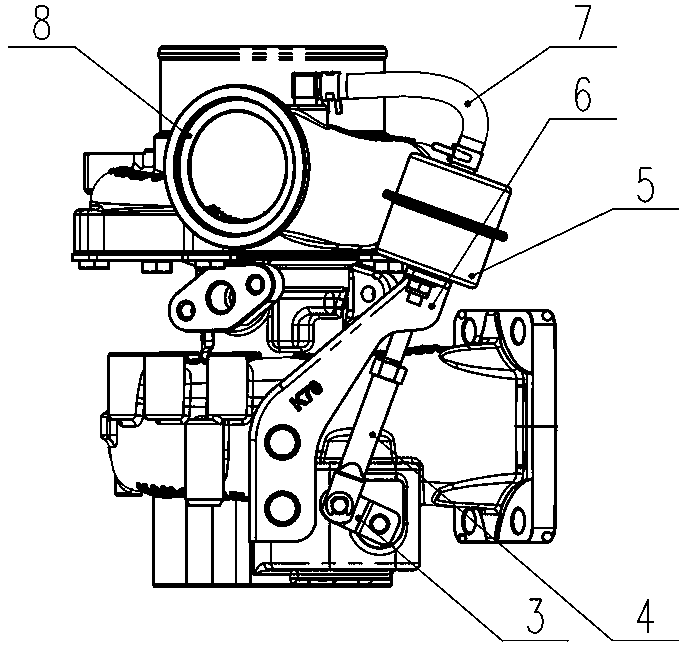

Exhaust gas bypass turbine machine with turbine end being provided with gas inlet mixing device

InactiveCN108757049AReduce BPF noiseGuaranteed flow characteristicsStatorsMachines/enginesStress concentrationTurbine blade

The invention discloses an exhaust gas bypass turbine machine with the turbine end being provided with a throat gas inlet mixing device. The exhaust gas bypass turbine machine comprises a turbine anda turbine shell, and a first throat, a second throat and a non-blade nozzle are arranged on the turbine shell. Before entering the turbine, turbine exhaust gas is mixed in the non-blade nozzle firstlyand then enters the turbine to work, thus the exhaust gas entering the turbine is even, and simultaneous impact on blades of the turbine is reduced. According to the exhaust gas bypass turbine machine with the turbine end being provided with the throat gas inlet mixing device, by designing different gas inlet mixing schemes on the turbine machine, under the situation that the through-flow characteristic of the turbine machine is guaranteed, airflow impact to the turbine blades is reduced, the reliability of the turbine and the turbine shell and the turbine machine efficiency are improved, andBPF noise of the turbine and thermal stress concentration of the shell are further lowered.

Owner:康跃科技(山东)有限公司

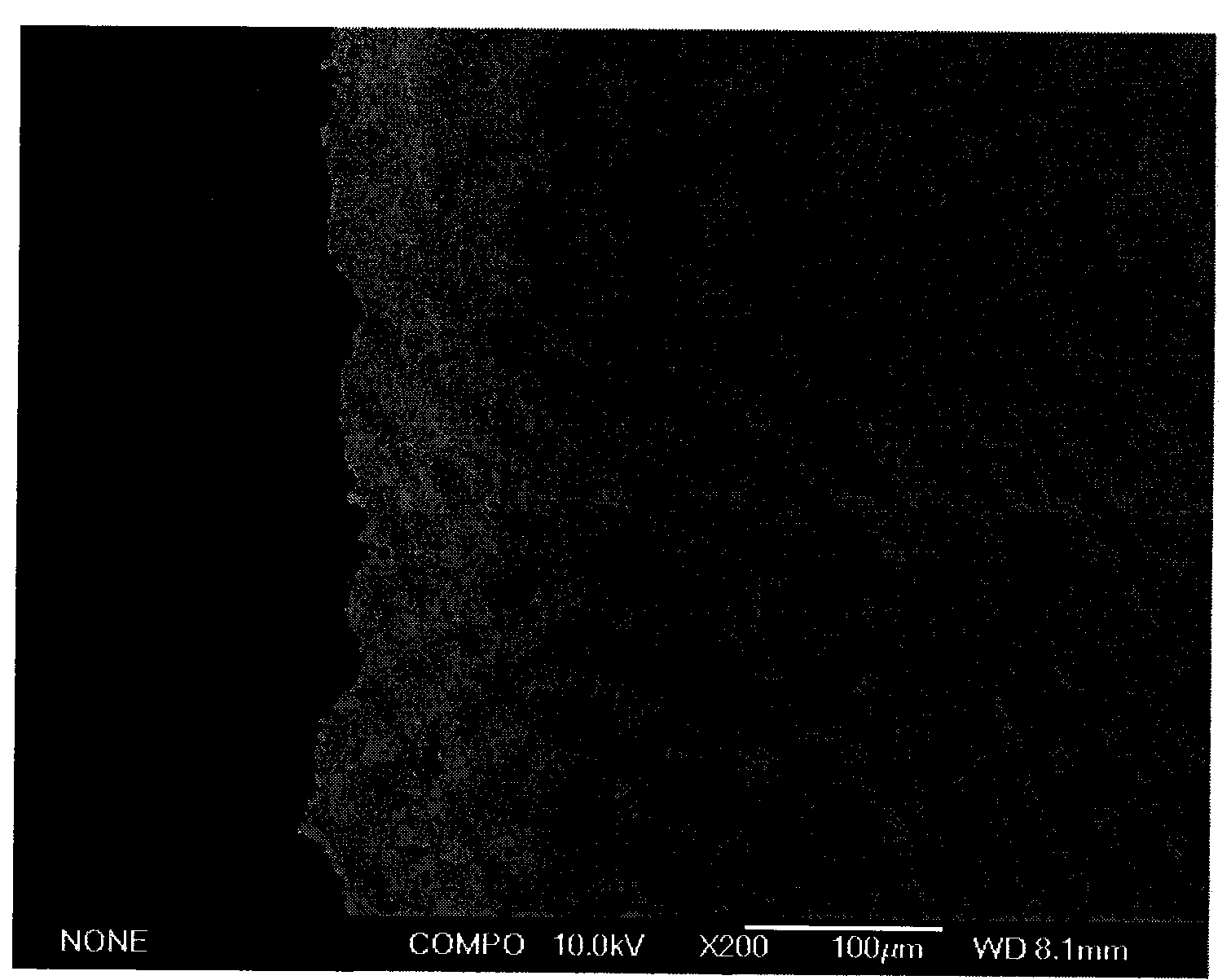

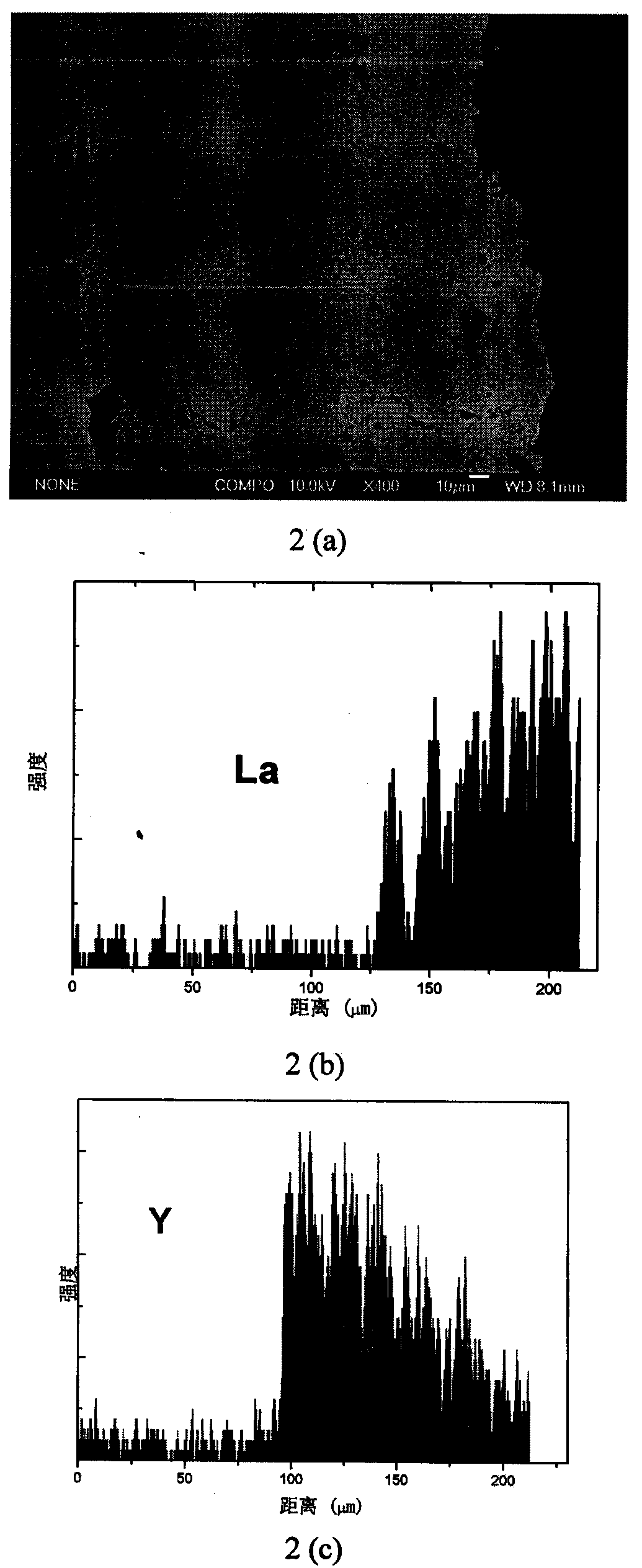

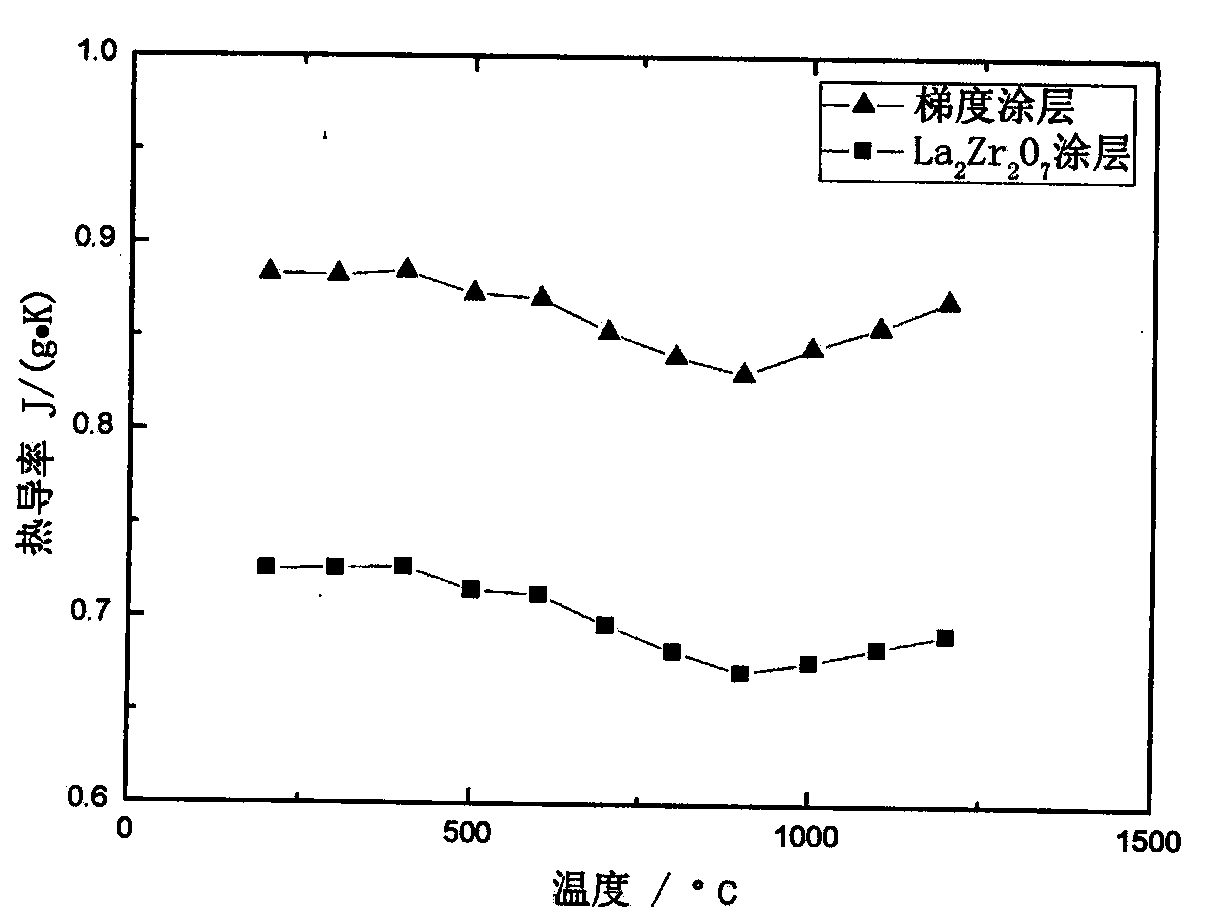

Thermal protection coating with component gradient change and preparation method

InactiveCN101768380BLow thermal conductivityUniform microstructureMolten spray coatingRare-earth elementInorganic materials

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

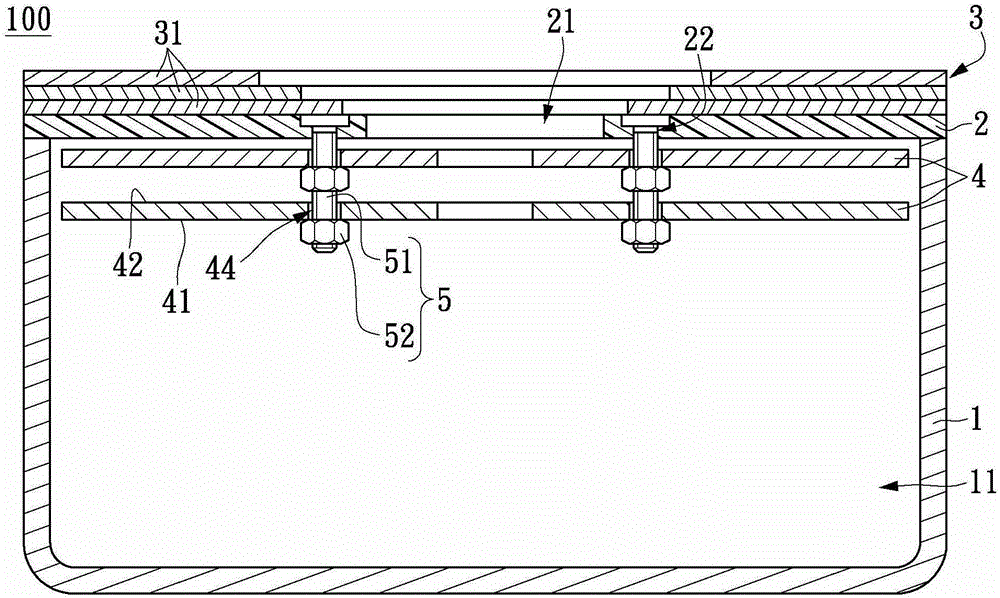

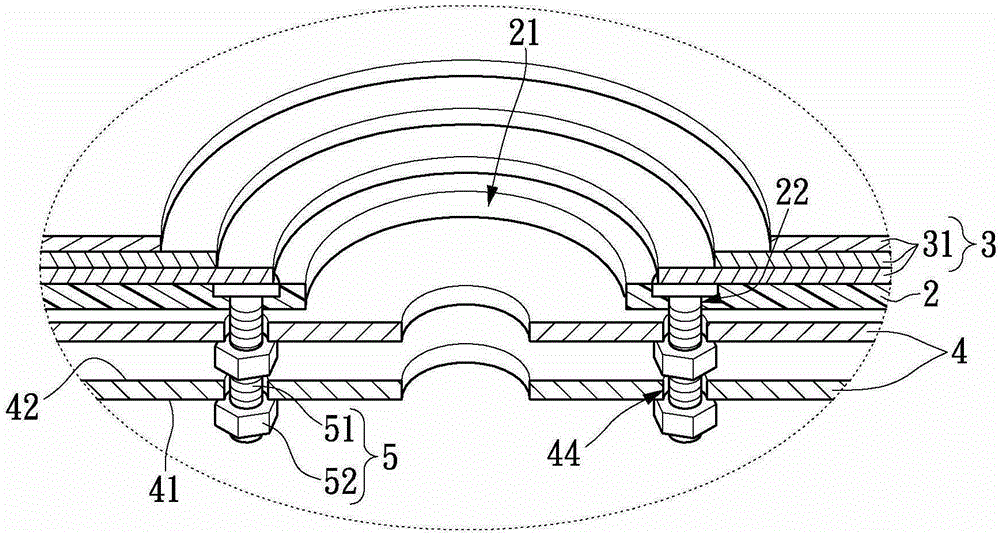

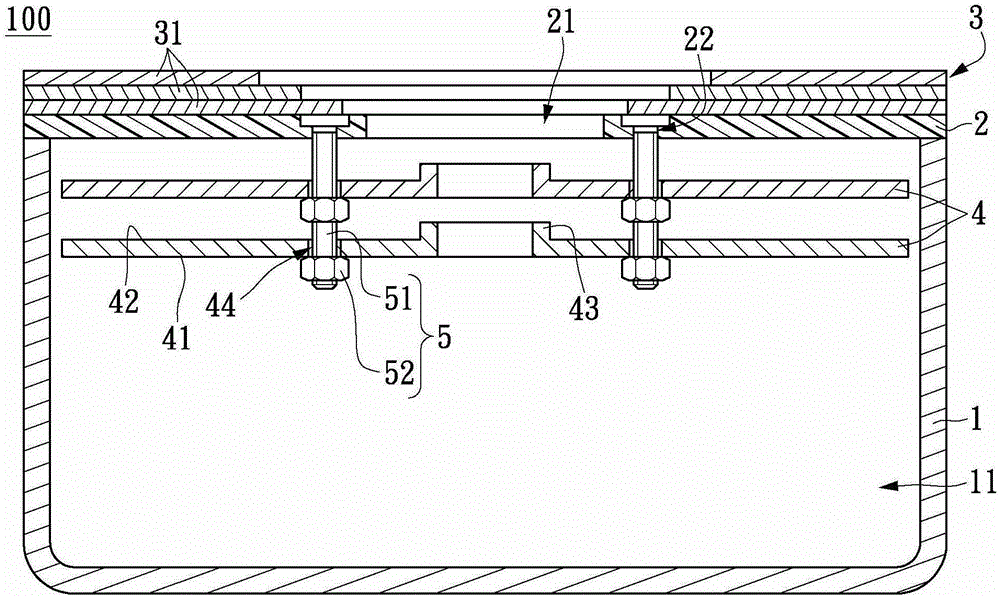

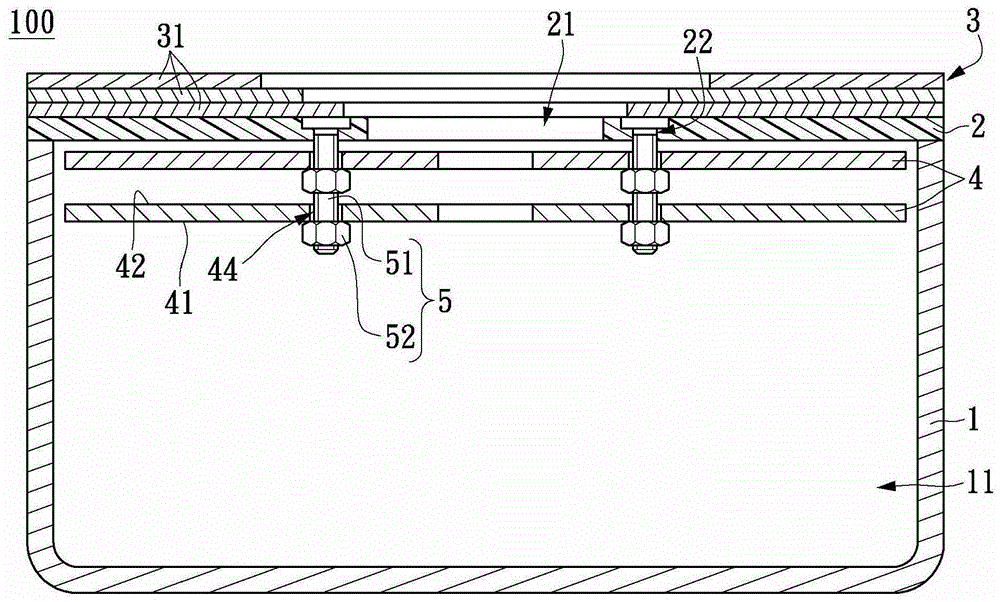

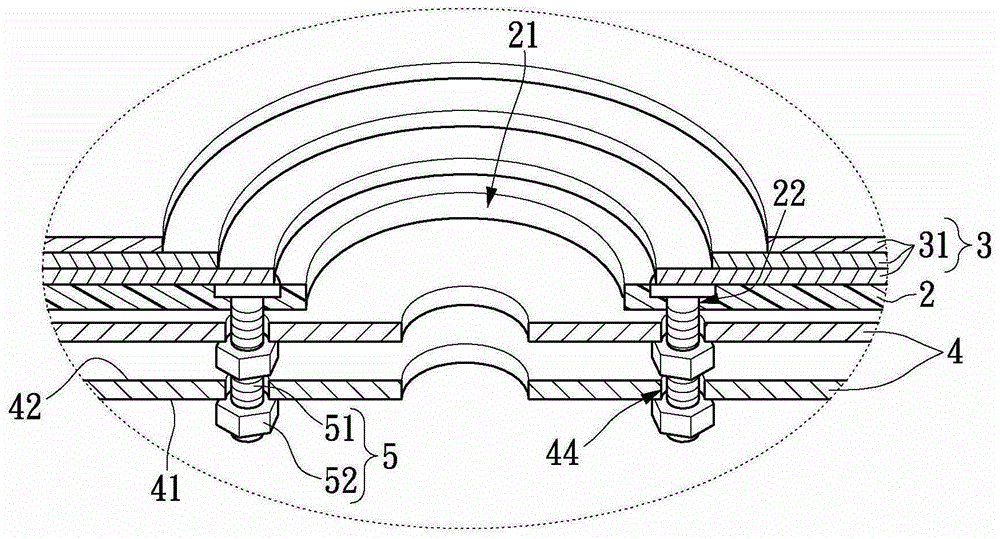

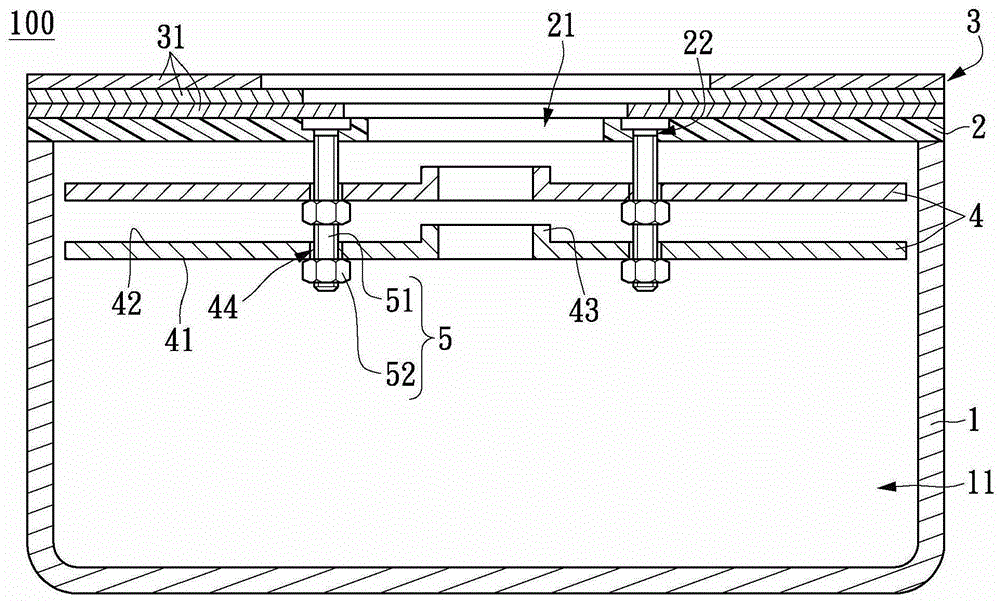

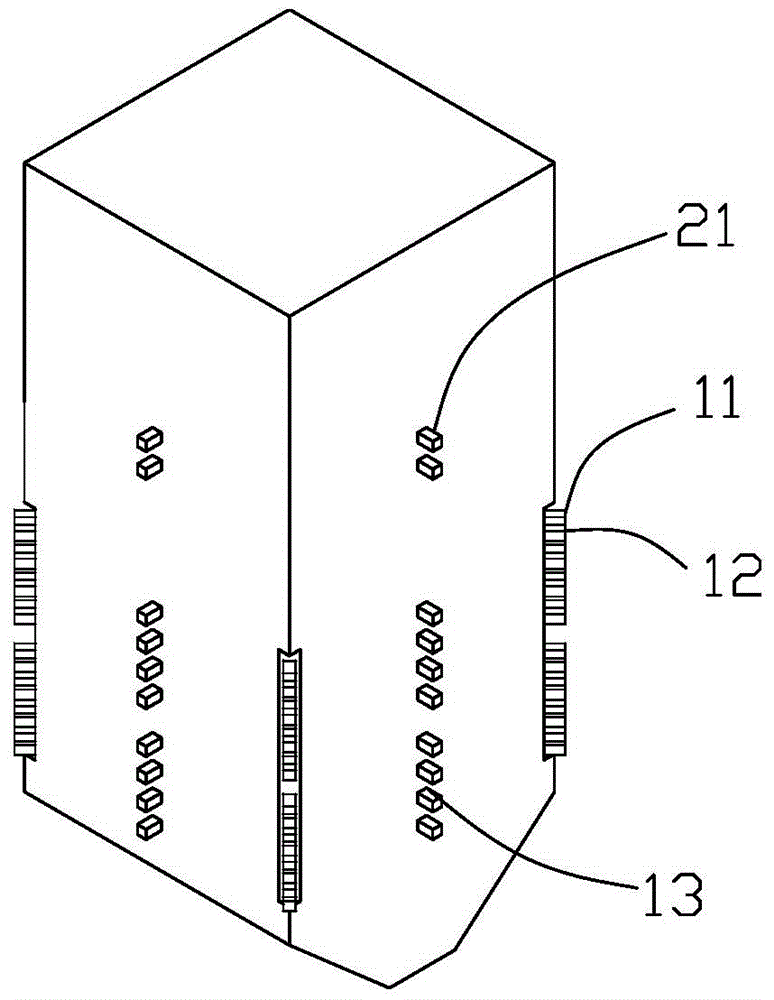

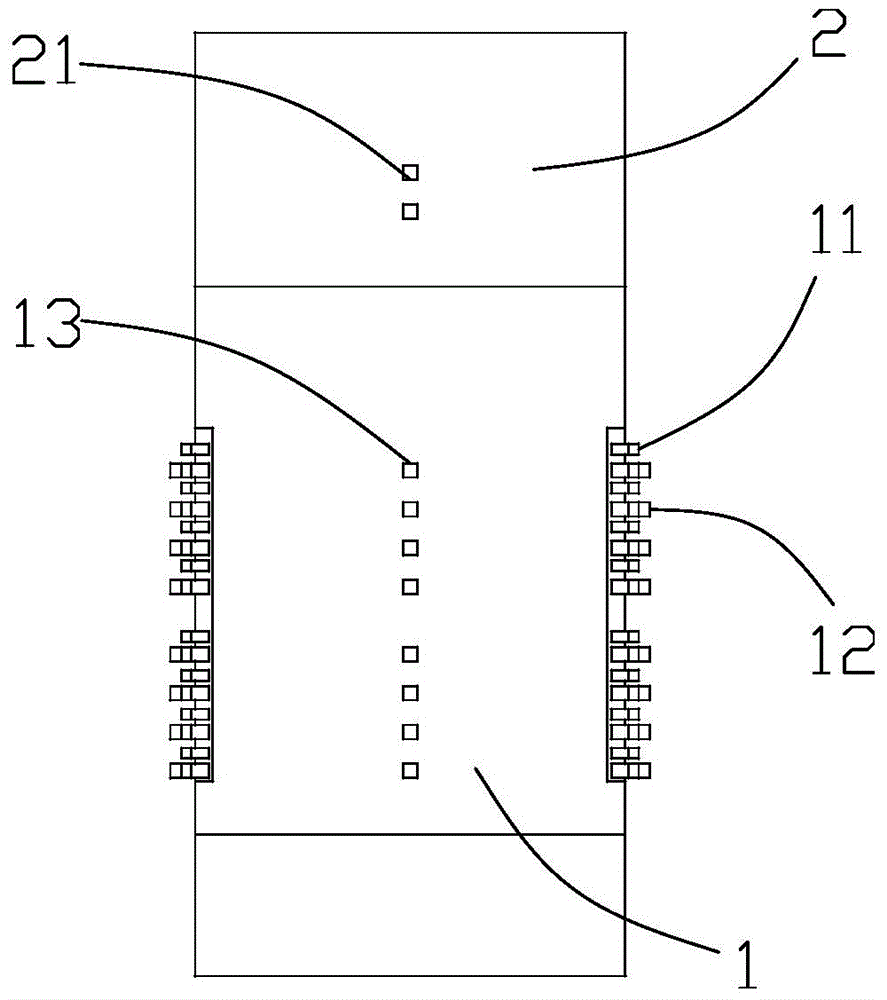

Crystal growth device and crystal manufacturing method

InactiveCN103911656AReduce heat stress concentrationImprove qualityPolycrystalline material growthUsing seed in meltEngineeringCrystal growth

A crystal growth device comprises a crucible, a crucible cover and a plurality of heat reflecting rings, wherein an opening is formed in the crucible cover which is mounted on the crucible, and the crucible cover and the crucible commonly surround to define accommodating space communicated with outside through the opening; the plurality of heat reflection rings are arranged in the accommodating space and suspended on the crucible cover; every two adjacent heat reflection rings are arranged at equidistant intervals; and a first angle is formed between each heat reflection ring and the crucible cover. The plurality of heat reflection rings can deform during the heating process of the crystal device, so that each first angle is changed into a second angle. Therefore, the crystal growth device can adjust temperature gradient distribution of molten liquid surface through the arrangement of the plurality of the heat reflection rings.

Owner:SINO AMERICAN SILICON PROD

Low-carbon magnesia carbon brick and preparation method thereof

The invention provides a high-performance low-carbon magnesia carbon brick and a preparation method thereof. The low-carbon magnesia carbon brick is obtained by mixing and molding a carbon-coated magnesium oxide raw material. The low-carbon magnesia carbon brick prepared by the method can be added with less or no graphite, has good thermal shock resistance and slag resistance, and can be widely applied to smelting of high-quality clean steel and ultra-low carbon steel.

Owner:WUHAN UNIV OF SCI & TECH +1

compound zro 2 ‑al 2 o 3 Preparation method of ceramic microfiltration membrane

ActiveCN104671750BNarrow pore size distributionModerate thicknessFiltration membraneSeparation coefficient

The invention discloses a preparation method of a composite ZrO2-Al2O3 ceramic micro-filtration membrane. The method comprises the following steps: (1) burdening zirconia powder and alumina powder, and carrying out ball-milling; (2) adding an additive lanthanum nitrate, and carrying out ball-milling; and (3) forming a film from the milled slurry, drying and sintering. The powder components of the composite membrane layer prepared by the preparation method gradually change; the pore size distribution of the membrane layer is relatively narrow; the thickness of the membrane layer is moderate, so that the micro-filtration membrane has relatively high permeation flux and separation coefficient; the particle size collocation of the powder of a transition membrane layer is reasonable; the surface roughness of the membrane layer is improved; relatively large membrane layer pollution is not easily caused in the actual separation process; zirconia with good chemical stability is utilized in the membrane layer; and the acid and alkali resistance of the membrane layer is improved. The price of the zirconia is higher than that of aluminum oxide, but the amount in preparation of the membrane layer is relatively small; meanwhile, the service life of an inorganic membrane can be prolonged; and the composite ZrO2-Al2O3 ceramic micro-filtration membrane is better than a simple aluminum oxide ceramic membrane or zirconia ceramic membrane in the market at present in performance.

Owner:安徽名创新材料科技有限公司

Semiconductor device and high-frequency module

ActiveUS11469187B2Reduce thermal stressHighly reliable semiconductor deviceTransistorSemiconductor/solid-state device detailsDevice materialElectric current flow

At least one unit transistor is arranged over a substrate. A first wiring as a path of current that flows to each unit transistor is arranged over the at least one unit transistor. An inorganic insulation film is arranged over the first wiring. At least one first opening overlapping a partial region of the first wiring in a plan view is provided in the inorganic insulation film. An organic insulation film is arranged over the inorganic insulation film. A second wiring coupled to the first wiring through the first opening is arranged over the organic insulation film and the inorganic insulation film. In a plan view, a region in which the organic insulation film is not arranged is provided outside a region in which the first wiring is arranged. The second wiring is in contact with the inorganic insulation film outside the region in which the first wiring is arranged.

Owner:MURATA MFG CO LTD

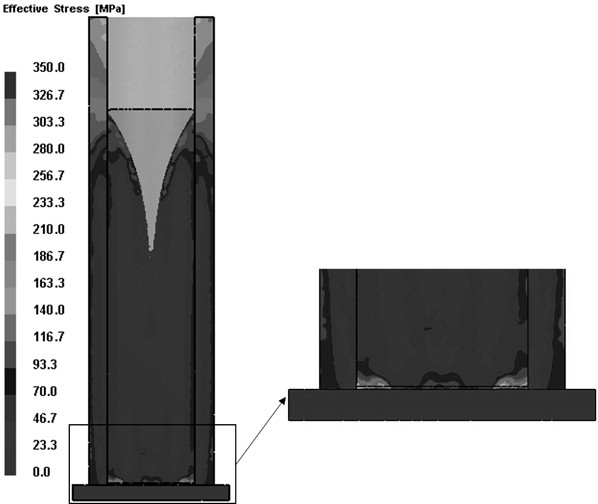

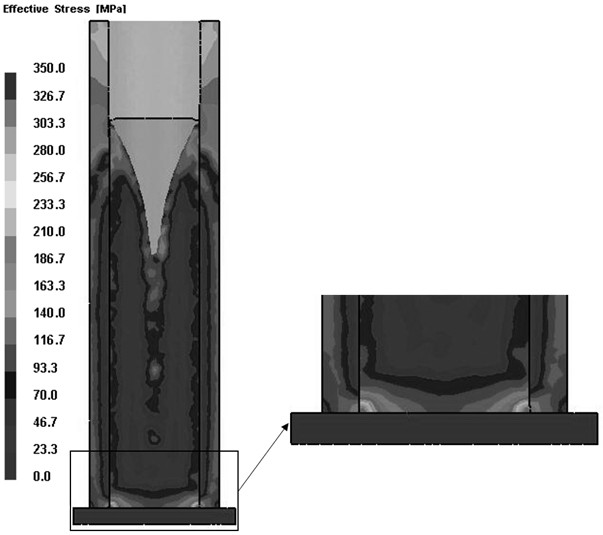

Ingot mould, smelting system and production method of large ingot type alloy ingot

ActiveCN112317705BReduce temperature gradientUniform distribution of temperature fieldStress concentrationIngot

The invention provides an ingot mold, a smelting system and a production method of a large ingot type alloy ingot. The ingot mold includes an ingot mold body and a metal bottom pad and a refractory lining arranged in the ingot mold body; the refractory bottom lining is arranged at the bottom of the ingot mold body, and the metal bottom pad is arranged on One side of the bottom of the ingot mold body. Smelting systems, including ingot moulds. The production method of large ingot-type alloy ingots includes: melting the high-temperature alloy to obtain alloy liquid, and then casting it into the ingot mold to obtain ingots. The ingot mold provided by this application is added with a metal bottom pad, which makes the temperature field distribution at the bottom of the ingot more uniform, reduces the stress concentration at the bottom of the ingot and reduces the sensitivity of cracks at the bottom; avoids the direct impact of the metal casting flow on the refractory lining The impact reduces the erosion of the refractory lining, and at the same time avoids the generation of bottom inclusions. The reduction in the number of bottom inclusions as a potential crack source also reduces the sensitivity to cracks at the bottom of the ingot.

Owner:UNIV OF SCI & TECH BEIJING +1

Crystal growing device and crystal manufacturing method

InactiveCN103911656BReduce heat stress concentrationImprove qualityPolycrystalline material growthUsing seed in meltEngineeringCrystal growth

A crystal growth device comprises a crucible, a crucible cover and a plurality of heat reflecting rings, wherein an opening is formed in the crucible cover which is mounted on the crucible, and the crucible cover and the crucible commonly surround to define accommodating space communicated with outside through the opening; the plurality of heat reflection rings are arranged in the accommodating space and suspended on the crucible cover; every two adjacent heat reflection rings are arranged at equidistant intervals; and a first angle is formed between each heat reflection ring and the crucible cover. The plurality of heat reflection rings can deform during the heating process of the crystal device, so that each first angle is changed into a second angle. Therefore, the crystal growth device can adjust temperature gradient distribution of molten liquid surface through the arrangement of the plurality of the heat reflection rings.

Owner:SINO AMERICAN SILICON PROD

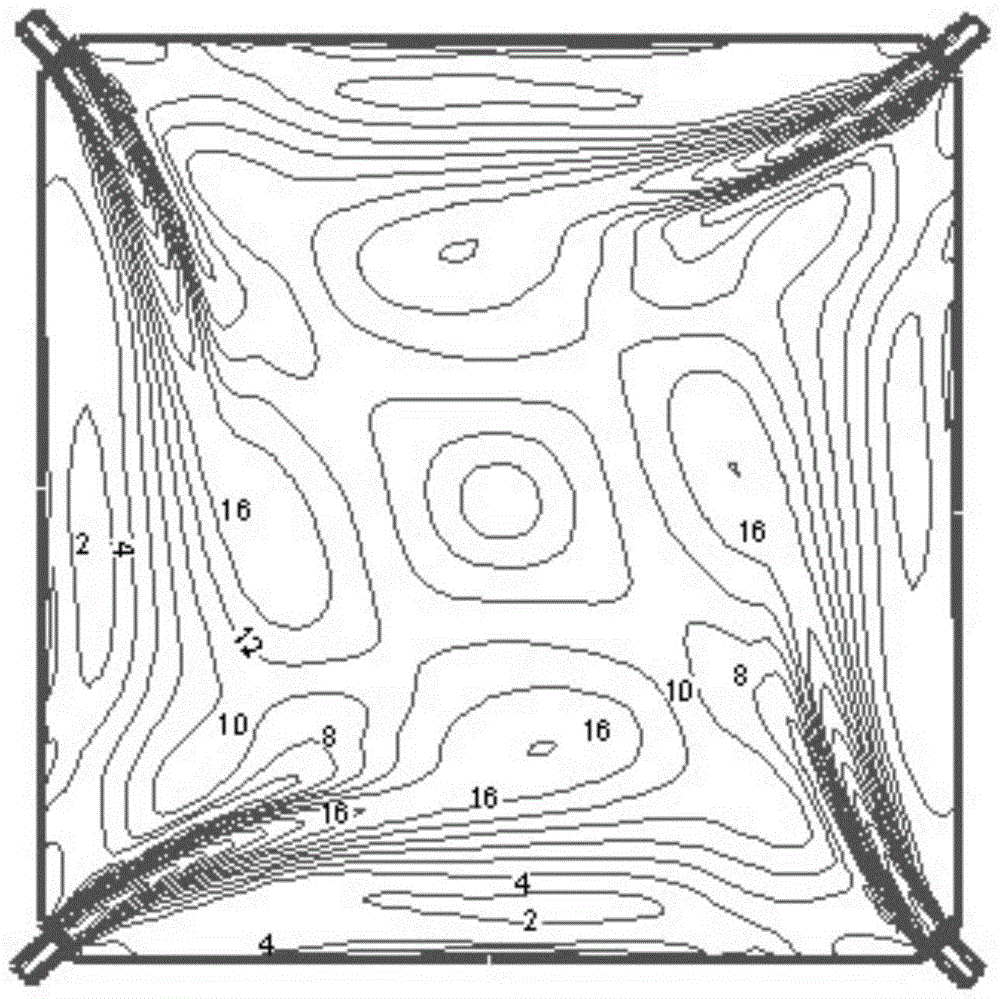

A boiler with controllable tangential combustion

ActiveCN103994423BAvoid coking tendencyIncrease turbulent mixing intensityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorNitric oxide

The invention provides a boiler with a controllable combustion tangent circle. The boiler comprises a hearth which is encircled by a plurality of walls, wherein the hearth comprises a main combustion area and a burnout area; the main combustion area and the burnout area are respectively provided with combustors which are connected with nozzles through pipelines; a plurality of corner-type primary air nozzles and corner-type secondary air nozzles which are vertically arrayed are respectively arranged at the corners of the adjacent walls of the main combustion area; a plurality of wall-type secondary air nozzles which are vertically arrayed are respectively arranged at the secondary air equal-height positions of all the walls of the main combustion area; each nozzle faces the interior of the boiler, and the jet flow direction can be adjusted. When the boiler with the corner-type secondary air nozzles and the wall-type secondary air nozzles works, combustion can be controlled by regulating the flow and the jet flow direction of the corner-type secondary air nozzles and the wall-type secondary air nozzles according to actual requirements. Therefore, the size of the combustion tangent circle of the hearth can be quite effectively controlled, generation of nitric oxides is effectively reduced, and coking of the hearth caused by combustion operation of the combustors close to the walls is avoided.

Owner:SHANGHAI JIAO TONG UNIV

Gas turbine combustor and gas turbine

ActiveUS11333359B2Reduce heat stress concentrationReduce thermal stressBurnersContinuous combustion chamberCombustorCombustion chamber

Owner:MITSUBISHI POWER LTD

Carbon nanotube toughened connection layer and method between inorganic composite material and nickel-based superalloy material

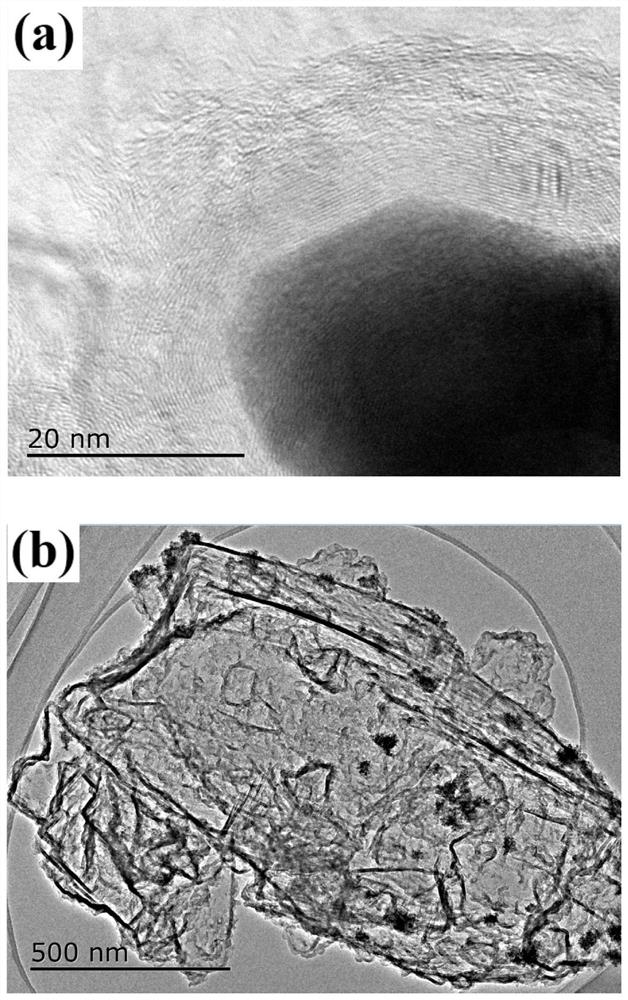

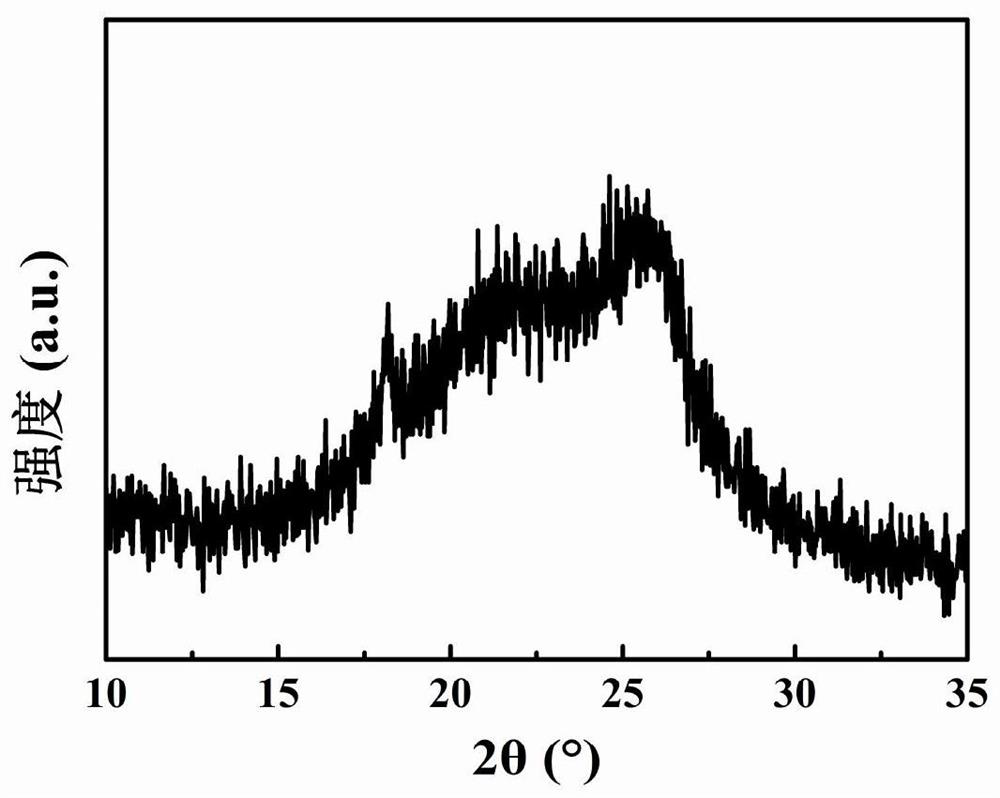

ActiveCN107150475BHigh bonding strengthReduce heat stress concentrationLaminationCarbon nanotubesStress concentrationSocial benefits

The invention relates to a carbon nanometer tube toughening connection layer between an inorganic composite material and a nickel-based high-temperature alloy material and a method. Firstly, carbon nanometer tubes with a nailing effect are generated in situ on the surface of a composite material; then, a Ti foil, a Ni foil and a Cu foil are used as middle layers for connecting the inorganic composite material and the nickel-based high-temperature alloy. Through the reaction between the middle layer and a mother material, a middle layer material is filled in nanometer tube pores; the nanometer tube toughening connection layer is obtained; the bonding intensity between interfaces of the composite material and the nickel-based high-temperature alloy can be enhanced; the problem of heat stress concentration due to great heat expansion coefficient differences between the mother material and the connection layer is solved; the strong combination between the inorganic composite material and the nickel-based high-temperature alloy is realized. The obtained nanometer tube toughening connection layer has high connection intensity. The method has great application potentials and has obvious economic and social benefits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production process for producing refractory brick by utilizing cordierite

InactiveCN112299834AIncrease resistance to contractionImprove thermal shock resistanceFire brickKaolin clay

The invention belongs to the technical field of refractory brick production, and particularly relates to a production process for producing refractory bricks by utilizing cordierite processing, whichsequentially comprises the following steps of: stirring raw materials, supplying the raw materials, automatically weighing, mixing and stirring, pressing by a pressing machine, carrying green bricks,inspecting the green bricks, tapping the green bricks, firing in a rotary kiln, cooling finished bricks and inspecting the finished bricks. The calcined kaolin is used for partially replacing raw clay, so that the shrinkage resistance and the thermal shock resistance of the refractory brick can be improved, zirconite powder can be decomposed into zirconium oxide in the firing process, so that thethermal shock stability of the refractory brick is improved, and the toughening effect is achieved, the kaolin powder, the talcum powder, the mullite powder and the zirconite are reasonably proportioned, so that the refractory brick has a stable structure, an ordered production process and a reasonable proportion are adopted, therefore, the effects of high production efficiency, uniform specification, stable proportioning structure and good quality are achieved.

Owner:苏木兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com