Compressive sealing method for vehicle oxygen sensor

A vehicle oxygen sensor, oxygen sensor technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of interface leakage, aggravation, ceramic induction chip fracture, etc., to reduce thermal stress concentration, improve performance stability, improve The effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

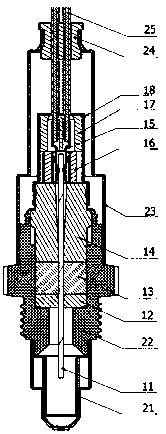

[0025] The invention provides a novel h-BN-based sealing material sealing material that can meet the requirements of a high-precision oxygen sensor in terms of sealing performance and high-temperature structural stability, and provides a compression sealing method for an oxygen sensor used in a vehicle.

[0026] The sealing material is h-BN or h-BN and glass powder composite, and the solvent is alcohol. Compression sealing methods include:

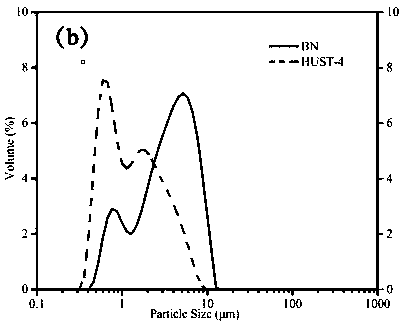

[0027] The first step, forming: use ball milling method to uniformly mix h-BN, or h-BN and glass powder composite, the solvent is alcohol, put the sealing material in the ball mill jar, in h-BN or ZrO 2 Ball milling is carried out under the collision and extrusion of the balls, dispersed into the organic solution to form a uniform suspension, and then dried to form uniformly distributed h-BN powder, or h-BN and glass powder;

[0028] The second step, assembly: place the zirconium core of the chip oxygen sensor in the middle of the alloy ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com