C/C composite material surface carbide derived carbon/rhenium/iridium coating layer and preparation method thereof

A carbide-derived carbon and composite material technology, applied in the field of high-temperature materials, can solve the problems of lowering the service temperature of the coating system, insufficient high-temperature thermal shock resistance, inability to overcome coating cracking, etc., and achieves good bonding and thermal expansion mitigation and elimination. Anisotropy, the effect of relieving thermal stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

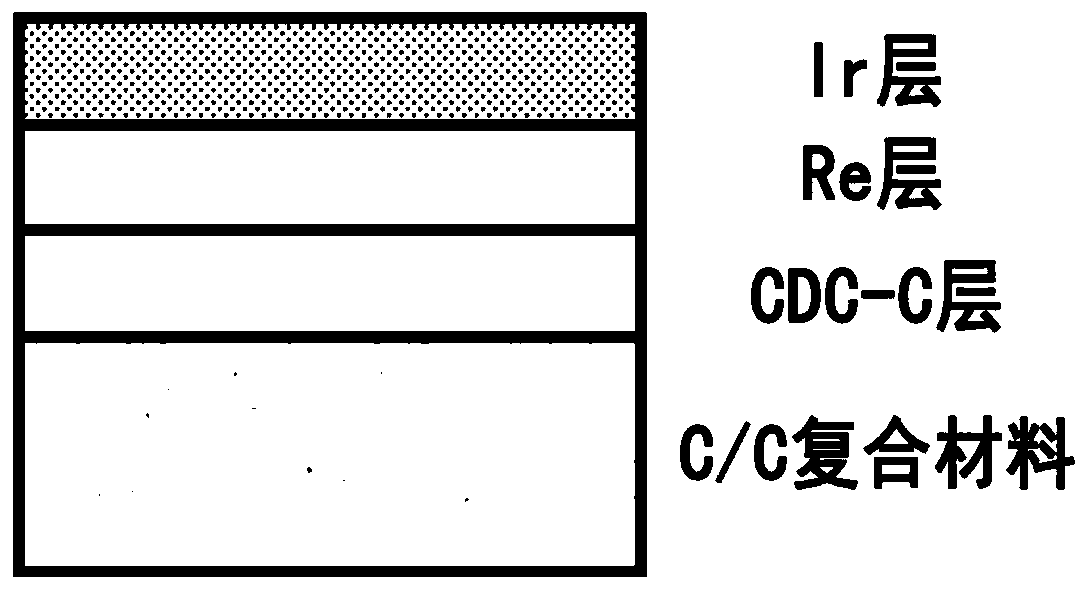

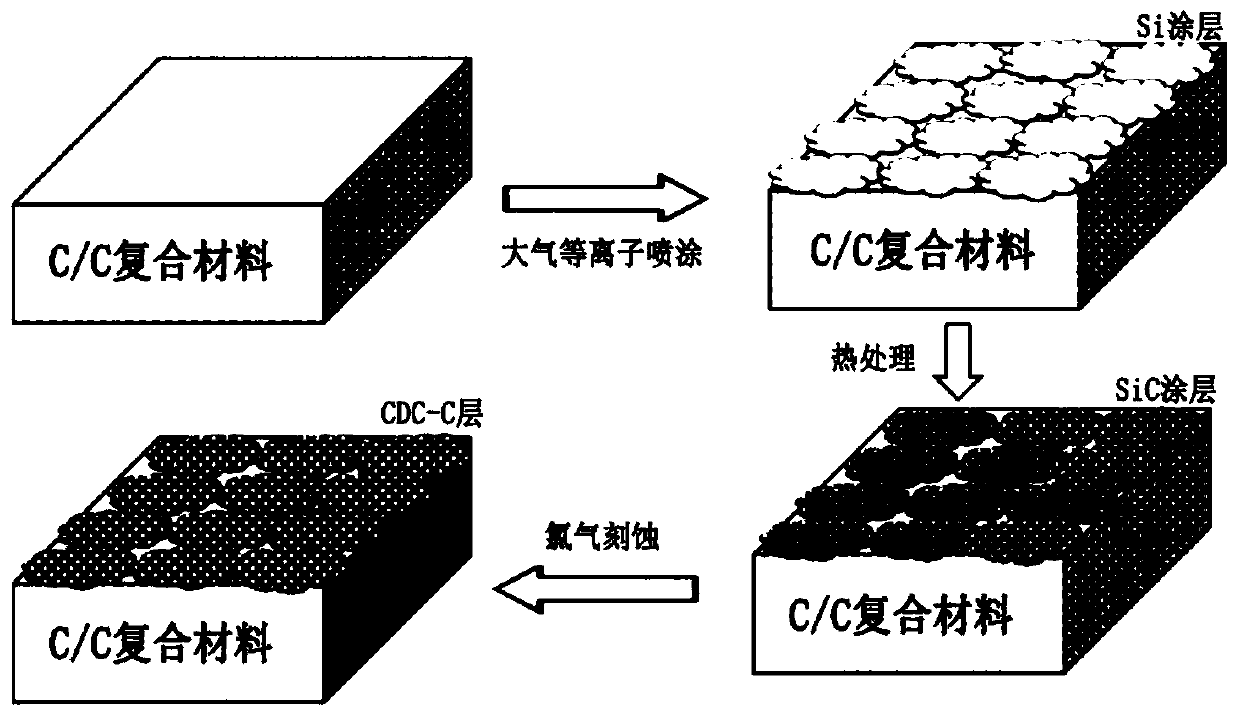

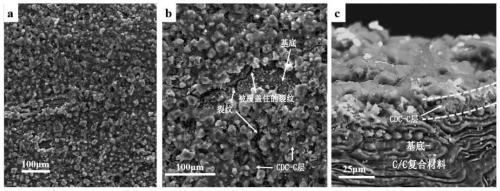

[0039] A kind of C / C composite material surface carbide derivative carbon / rhenium / iridium coating of the present invention, i.e. CDC-C / Re / Ir coating, such as figure 1 As shown, the C / C composite material is used as the base, and the surface of the C / C composite material is provided with a carbide-derived carbon layer, a rhenium coating, and an iridium coating in sequence from bottom to top. The carbide-derived carbon layer is formed on the C / C composite The thermal expansion transition layer is generated in situ on the surface of the material, and the rhenium coating is the bonding layer between the carbide-derived carbon layer and the iridium coating.

[0040] In this embodiment, the thickness of the carbide-derived carbon layer is about 20 μm, the thickness of the rhenium coating is 60 μm, and the thickness of the iridium coating is 50 μm.

[0041] A method for preparing the carbide-derived carbon / rhenium / iridium coating on the surface of the C / C composite material of this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com