Patents

Literature

67results about How to "Eliminate anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

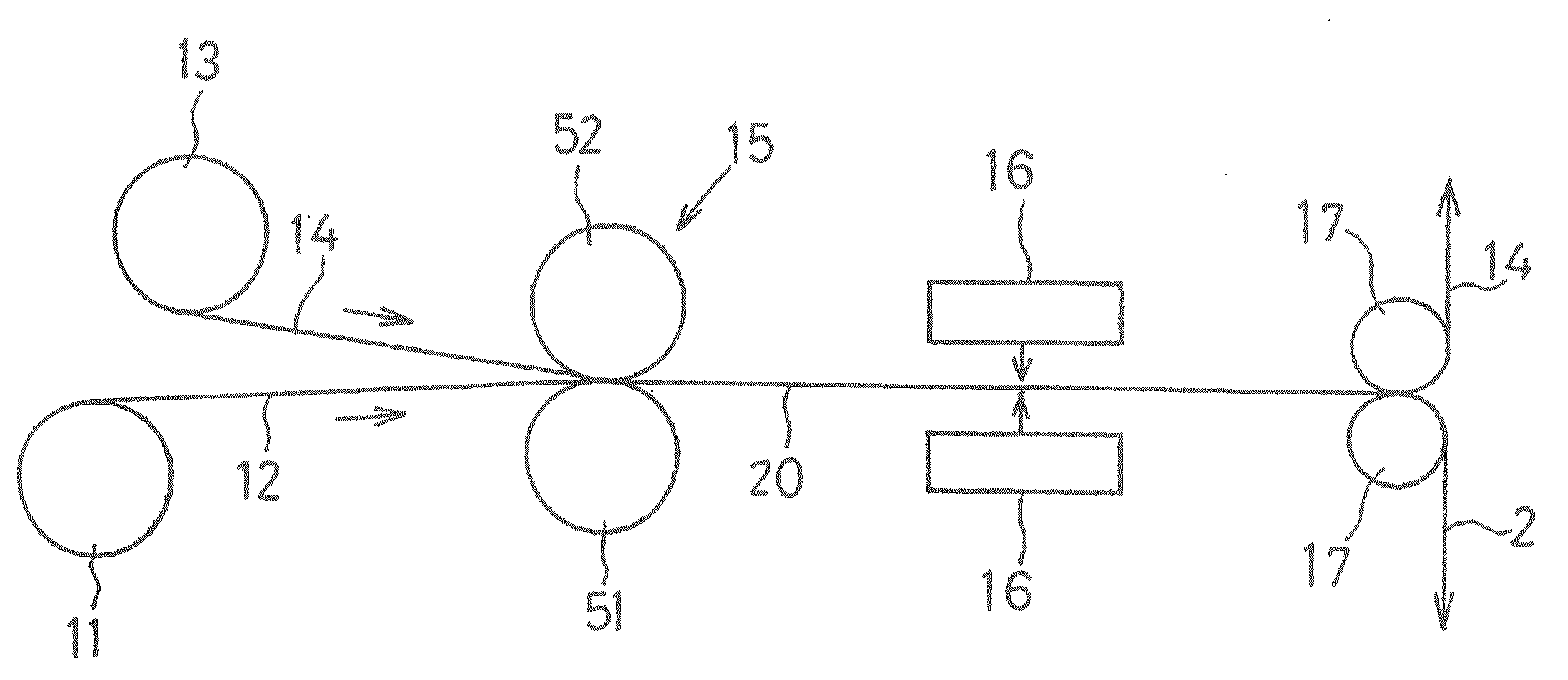

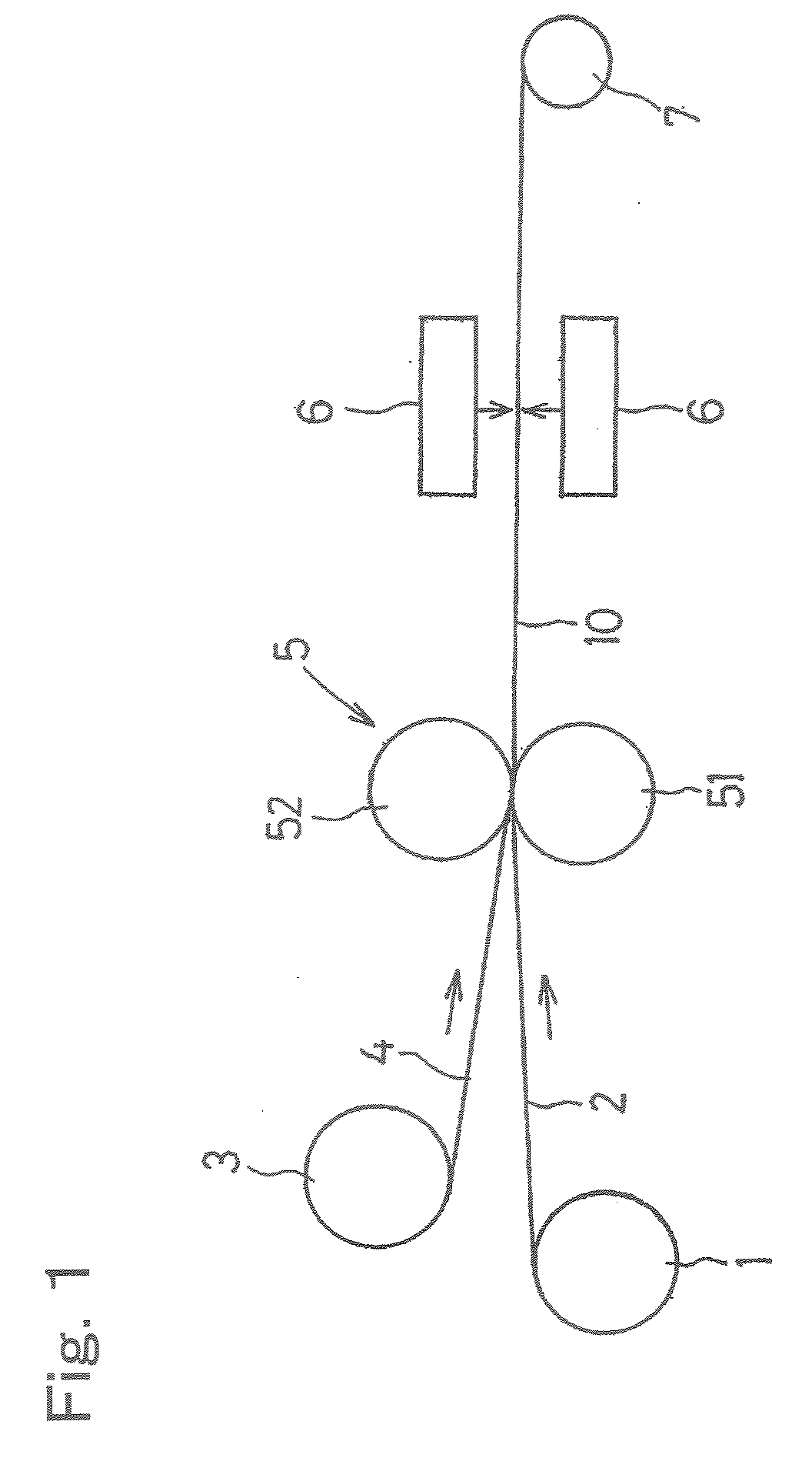

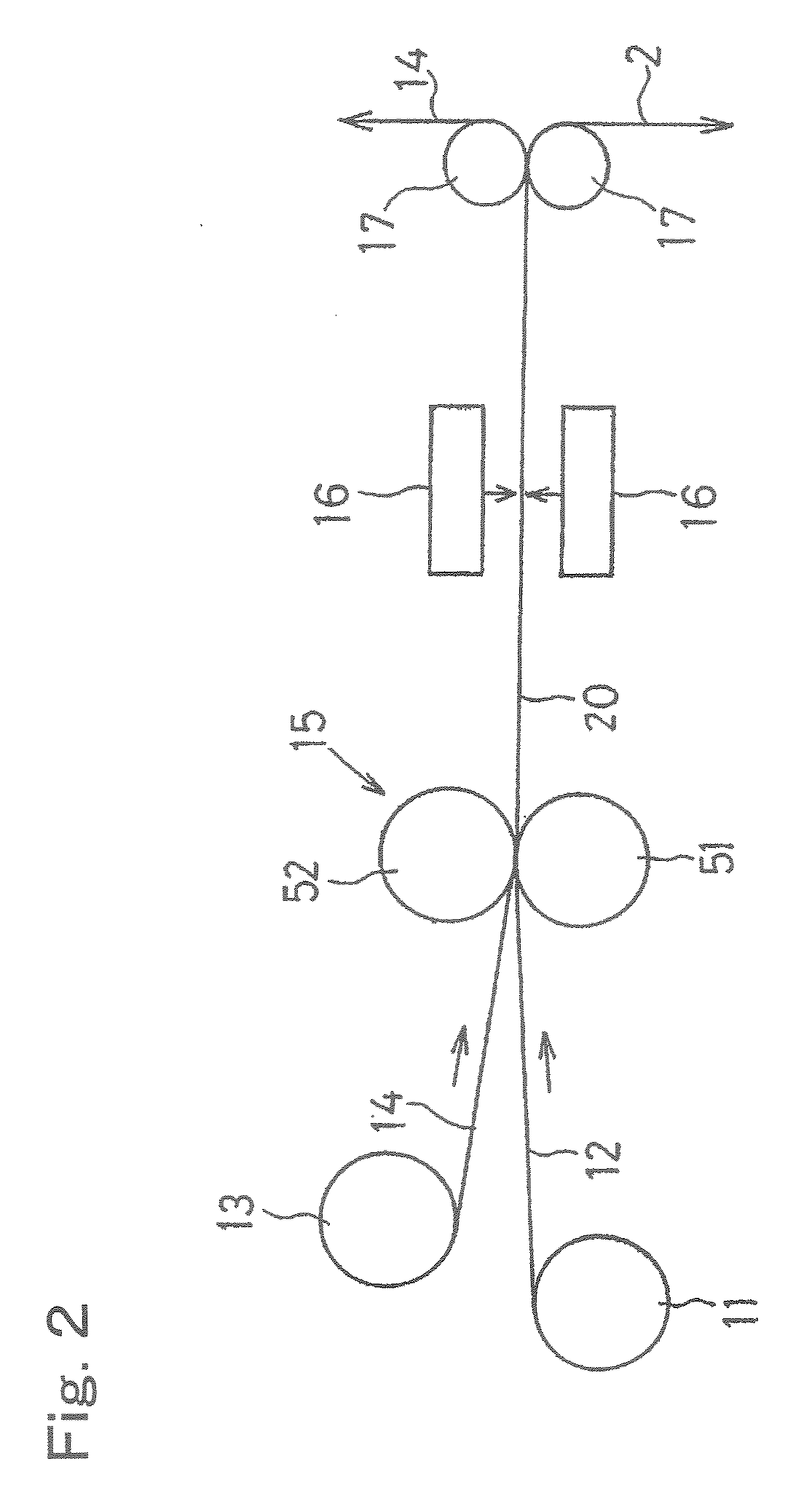

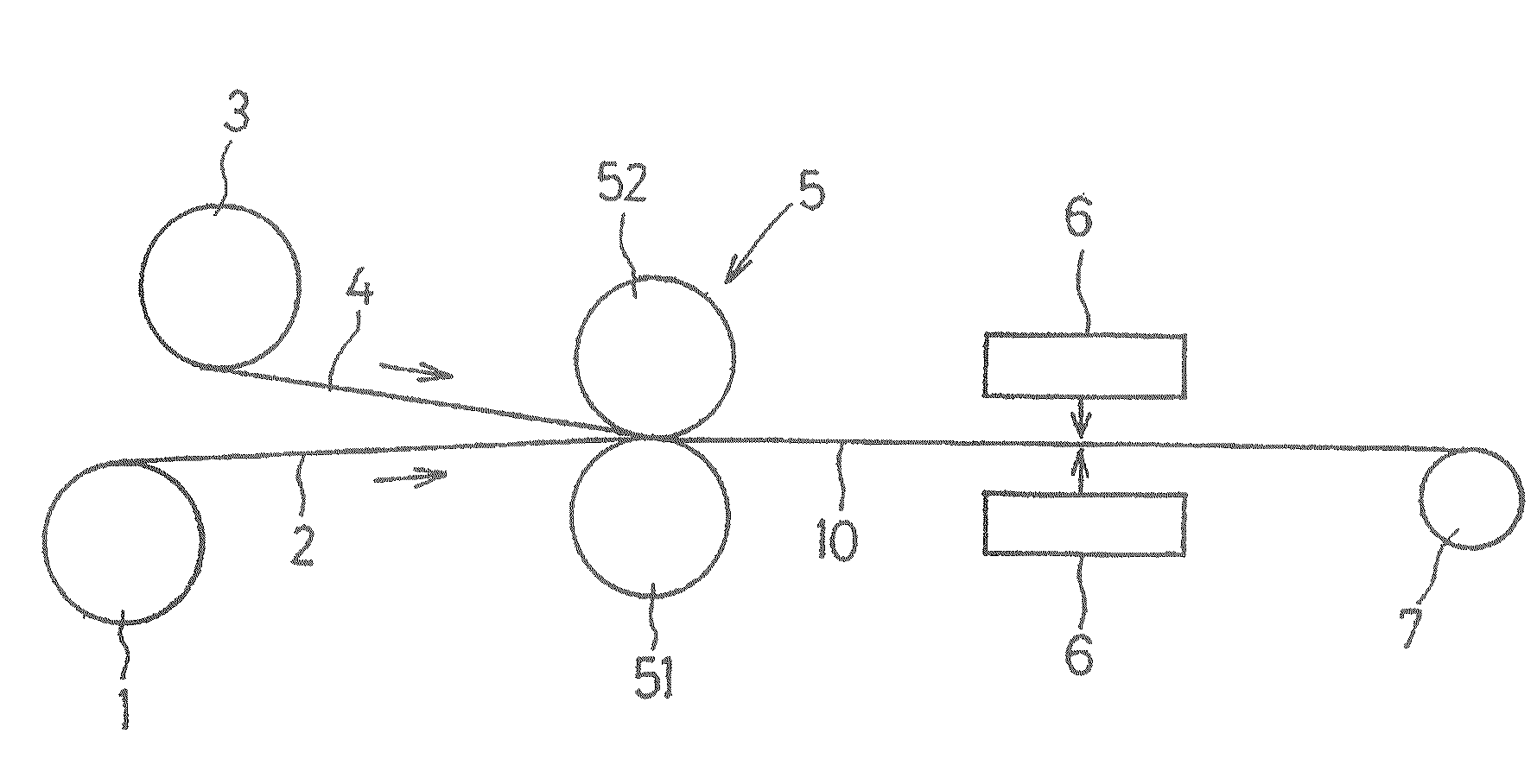

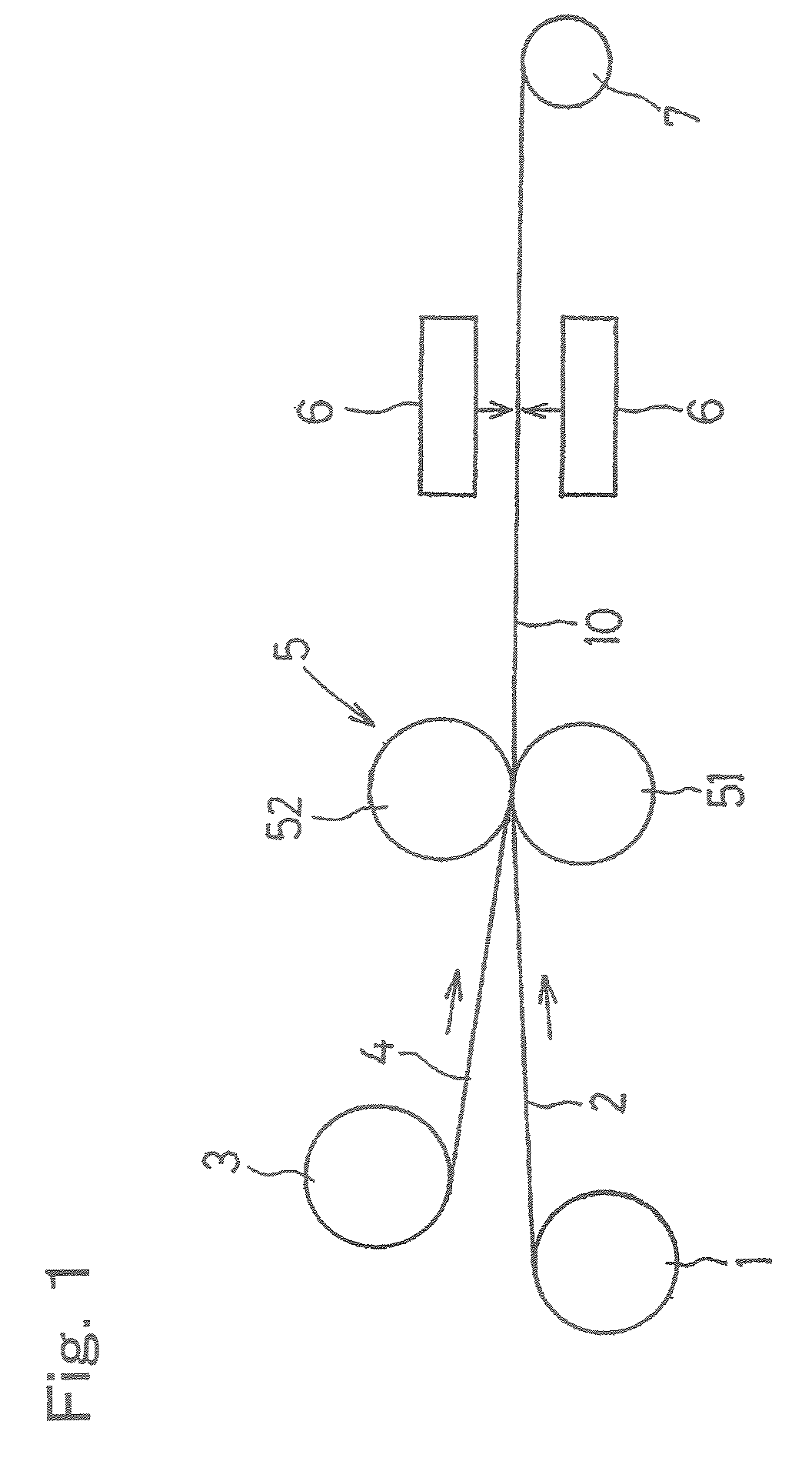

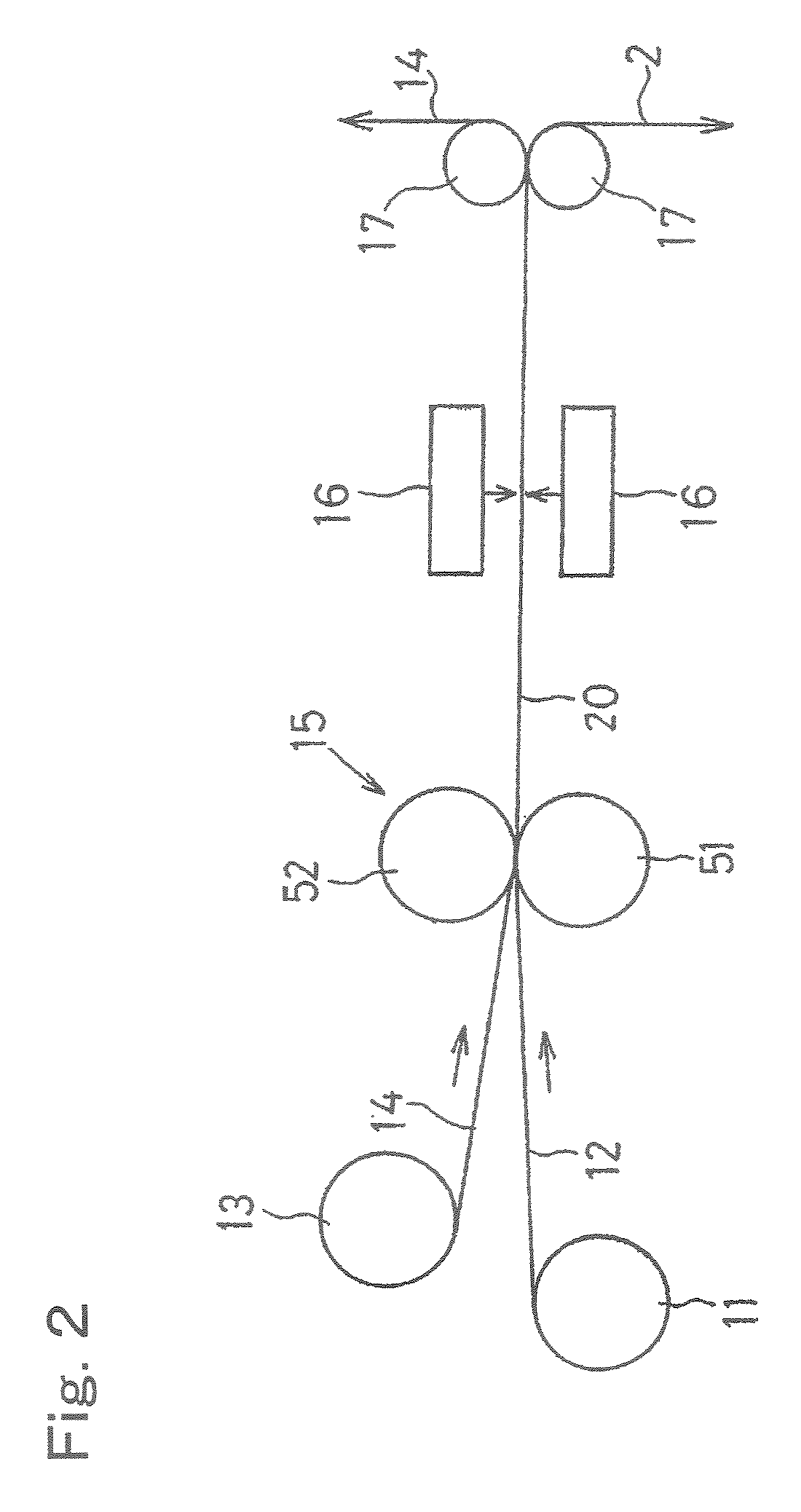

Metal-Clad Laminate And Method For Production Thereof

ActiveUS20080107833A1Good dimensional stabilityImprove isotropyLiquid crystal compositionsAdhesive processesThermal expansionMetal sheet

A metal-clad laminate excellent in isotropy, appearance, bondability between a TLC polymer film and a metallic sheet, and dimensional stability is provided less costly with a first step of thermally compressing the film with the metallic sheet by passing them through a nipping region between heating rolls, and a second step of heat-treating the resultant metal-clad laminate at a temperature not higher than the melting point of the film, wherein the film has thermal expansion coefficient αL satisfying αL=βT+γ with thickness T, thickness coefficient β and anisotropy coefficient γ of the film; wherein the coefficient β is within the range of −0.08 to −0.01; the coefficient γ is within the range of αM+6≦γ≦αM+10 with thermal expansion coefficient αM of the metallic sheet; and thermal expansion coefficient αT of the film is within αM−2≦αT≦αM+3 with the coefficient αM.

Owner:KURARAY CO LTD

Environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor

ActiveCN105133813AImprove wear resistanceStrong environmental protectionNon-macromolecular adhesive additivesLaminationPolyesterFiber

The invention discloses an environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor, and relates to the technical field of wood-plastic floor production. The environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor comprises a base material layer and a decorative layer. The base material layer is made from the following raw materials, by mass, 50 to 55 parts of straw powder, 35 to 40 parts of hard resin, 12 to 15 parts of amino resin, 10 to 13 parts of modified bamboo powder, 5 to 8 parts of calcium carbonate, 4 to 6 parts of chlorinated paraffin, 3 to 5 parts of polyvinyl alcohol, 3 to 4 parts of polyester fiber, 2 to 4 parts of magnesium hydroxide, 2 to 3 parts of nanometer sponge, 1 to 2 parts of triethanolamine, 8 to 11 parts of glycerol and 10 to 13 parts of ethanol. The decorative layer is made through steps of immersing color or texture decorative paper in an adhesive, and paving the dried and solidified decorative paper on the base material layer, wherein the adhesive is made from the following raw material by mass. The environmental friendly, wear resistant and sound-absorbing double-layer-structure waterproof wood-plastic floor has a double-layer structure which is a structure of a novel wood-plastic floor, the surface of the decorative layer is flat and smooth, so the wood-plastic floor is easy to maintain and clean, good in wear resistance and corrosion resistance. The base material layer can stop moisture, so defects that a present floor easily bents, deforms, shrinks in dry conditions and expands in wet conditions.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

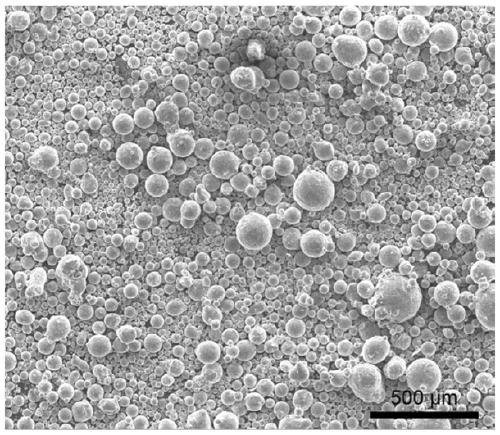

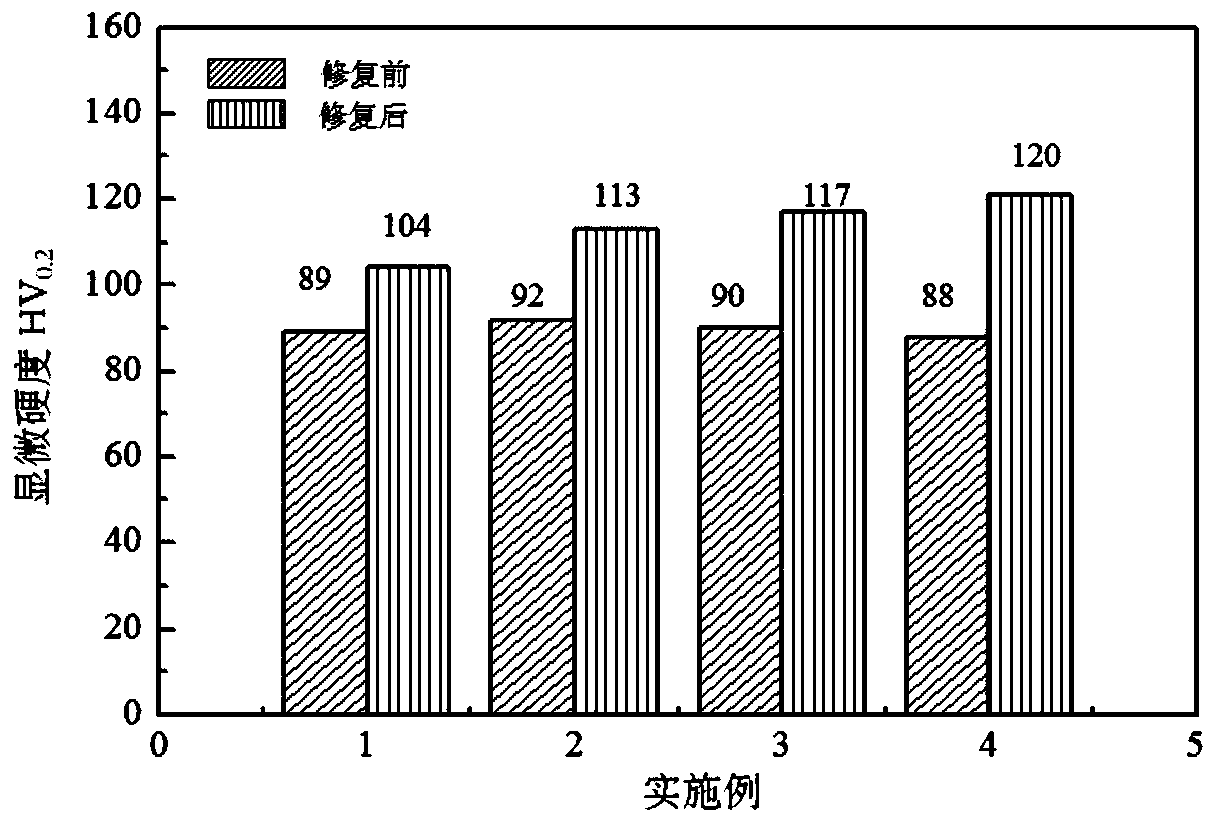

Aluminum alloy powder for laser coaxial powder feeding additive manufacturing and application of aluminum alloy powder in repairing 5-series aluminum alloy

ActiveCN111593238AEliminate anisotropyIncrease contentAdditive manufacturing apparatusMetallic material coating processesSi elementAluminium alloy

The invention discloses aluminum alloy powder for laser coaxial powder feeding additive manufacturing and application of the aluminum alloy powder in repairing 5-series aluminum alloy. The aluminum alloy powder is composed of the following components in percentage by mass: 0.4-1.5 wt% of Si, 0.5-5.0 wt% of Mg, 0.15-0.8 wt% of Cu, 0.05-0.9 wt% of Mn, 0.15-0.7 wt% of Zn, 0.01-1.0 wt% of Cr, 0.2-1.2wt% of Ti, 0.1-2.0 wt% of Fe, 0.2-2.1 wt% of Zr, 0.2-2.1 wt% of Sc, 0.15-0.65 wt% of Ni, 0.2-2.5 wt% of TiB2, 0.1-0.9 wt% of Ce, and the balance of Al. The beneficial elements including Zn, Cr, Ti, Fe, Ni, TiB2 and Ce are added on the basis of the 5-series aluminum alloy, second phases such as a long-range ordered phase and a twin crystal phase are formed to form synergistic reinforcement of the elements, so that the anisotropy of the material is eliminated, meanwhile, the content of Si element is increased, then a eutectic structure is formed in the later period of laser cladding solidification, and the eutectic structure is used for supplementing hot crack pores caused by rapid solidification.

Owner:CENT SOUTH UNIV +1

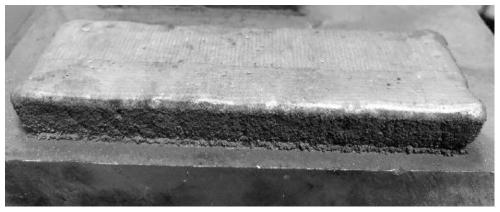

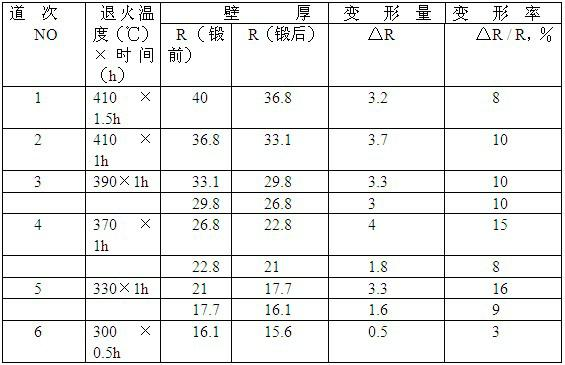

Radial forging process of cast-state magnesium alloy tube

InactiveCN102632175AReduce manufacturing costImprove mechanical propertiesMetal-working apparatusMetalworkingSurface roughness

The invention relates to a radial forging process of a cast-state magnesium alloy tube, belonging to non-ferrous metal processing. The process comprises the following steps of firstly carrying out homogenizing annealing, forging, finishing and finally carrying out surface machining. By using the process, two problems for limiting the development of seamless magnesium alloy tubes, namely difficult hot piercing and low yield, are fundamentally solved, so that the yield of the magnesium alloy tube is raised from 45-55% currently at home and abroad to above 90%, the production cost of tubes is reduced by above 40% and leapfrog development is realized in the production of the magnesium alloy seamless tubes. The processed product has the advantages of excellent mechanical property, high production efficiency, high material utilization ratio, high precision of forging member and low surface roughness.

Owner:江苏诚德钢管股份有限公司

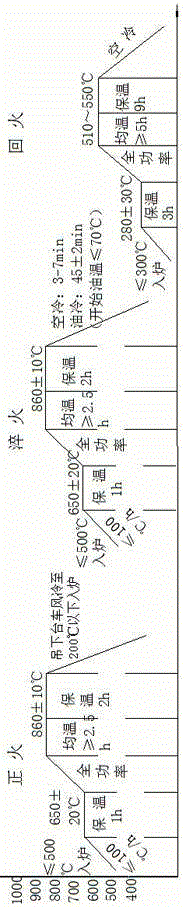

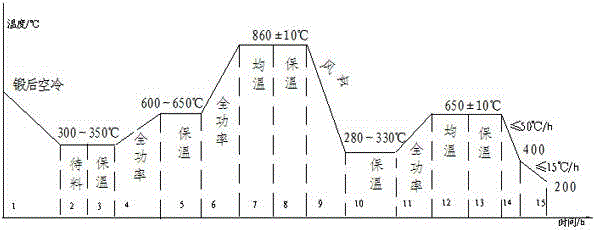

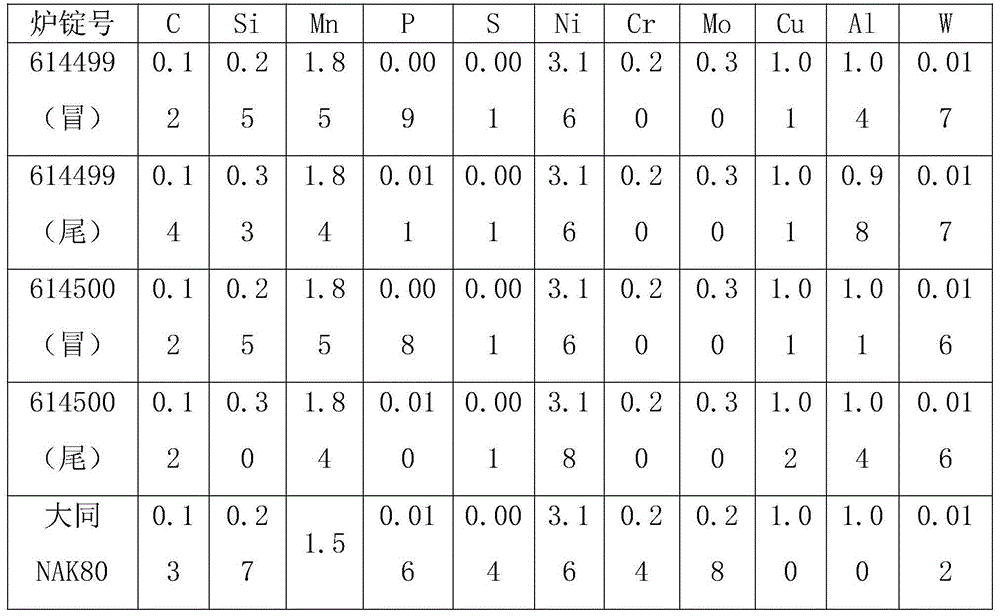

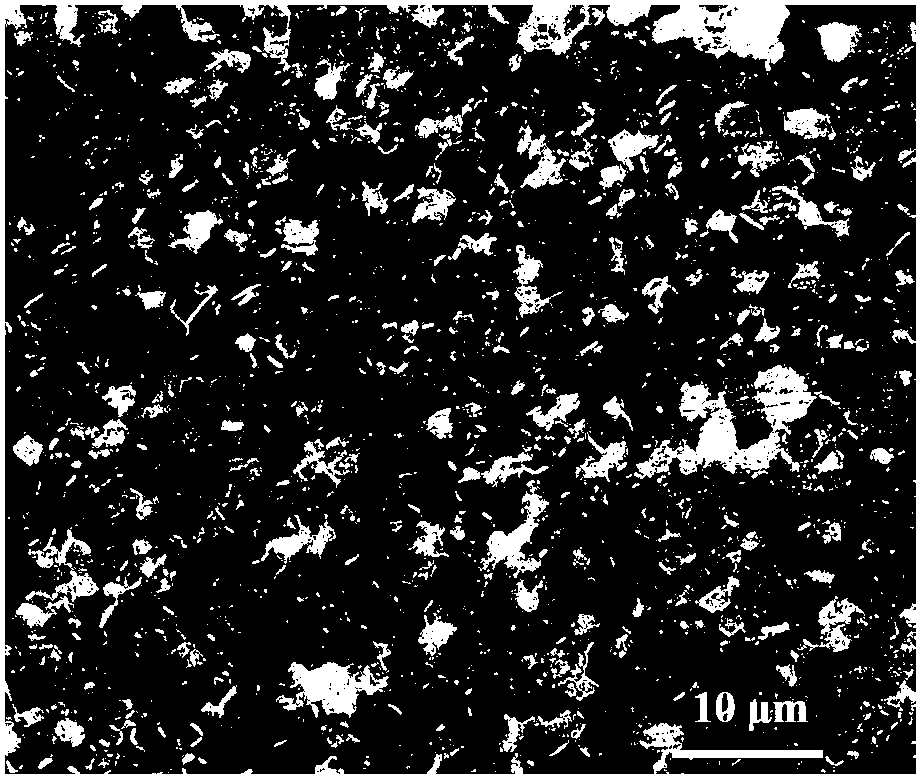

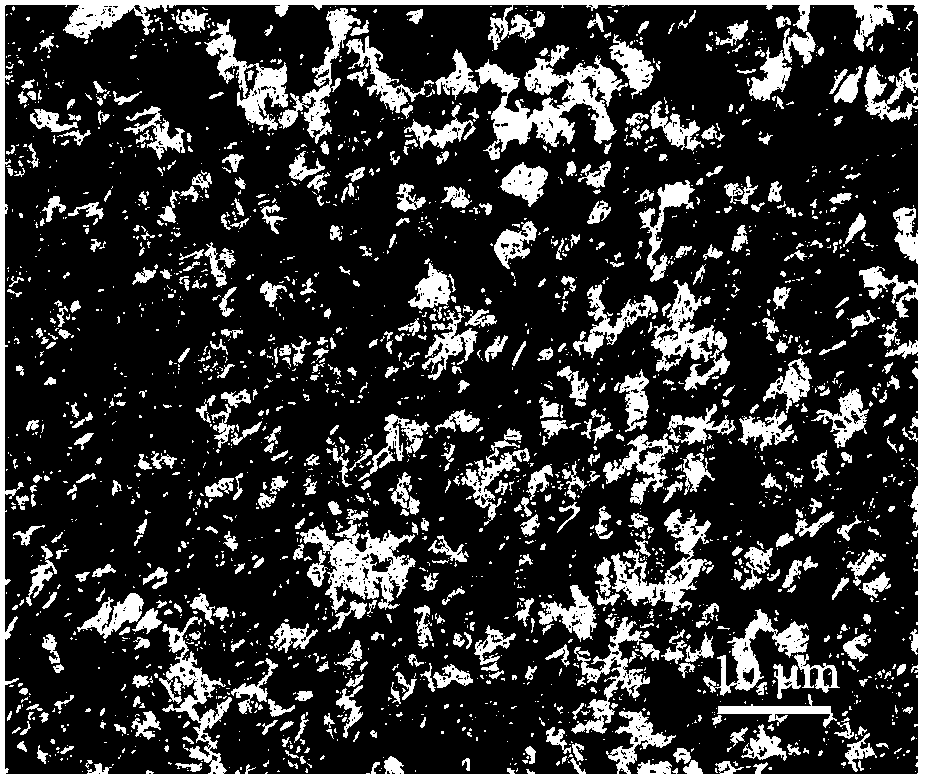

Production method of NAK80 high-grade mirror surface plastic rubber mold material for mobile phone mold

ActiveCN104611642AEliminate tail segregationEliminate riser shrinkage defectsProcess efficiency improvementElectric furnaceMicrostructureMaterials processing

The invention relates to a production method of an NAK80 high-grade mirror surface plastic rubber mold material for a mobile phone mold. The method includes the steps of: batching, electric furnace smelting, vacuum refining, vacuum pouring, electrode billet forging, electroslag remelting, square steel forging, normalizing and hydrogen diffusion annealing, and pre-hardening heat treatment. The method provided by the invention overcomes the disadvantages that the processability, polishing performance and use performance of domestic NAK80 plastic rubber mold materials cannot meet the requirement of an A2 level mirror surface for the mobile phone mold, and provides the production method of the NAK80 high-grade mirror surface plastic rubber mold material for the mobile phone mold. The produced mold material has a pure inside and uniform microstructure, and processing and polishing verification prove that the processability, polishing performance and use performance of the mold material all meet the A2 level mirror surface requirement.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

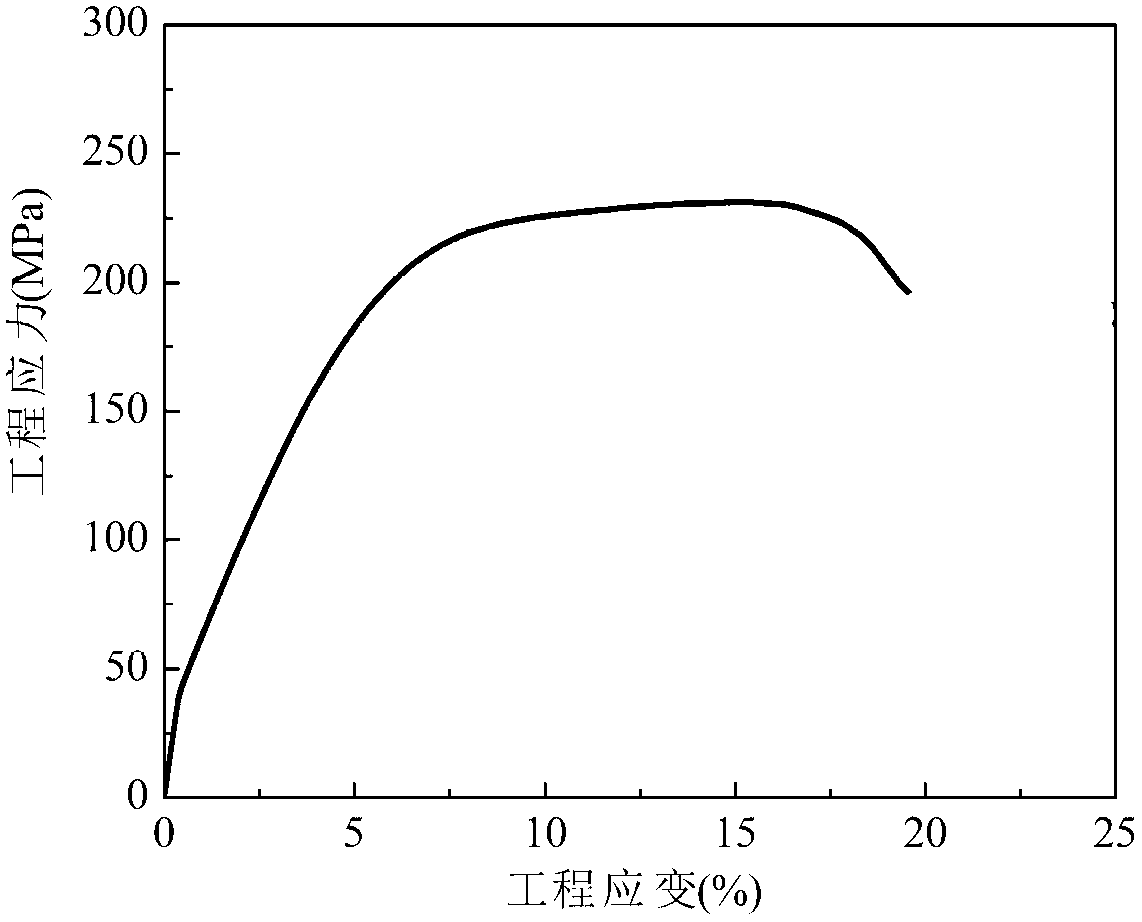

Magnesium alloy sheet with high toughness at low temperature

The invention relates to a magnesium alloy sheet with high toughness at a low temperature. The magnesium alloy sheet comprises the following chemical components: Mg, xM and yN, wherein x and y represent mass percent; x is greater than or equal to 0.2% and less than or equal to 0.5%; y is greater than or equal to 0.5% and less than or equal to 0.8%; M contains barium, calcium and manganese; N contains one or two of lead, bismuth, indium and rare earth elements; when the N contains the two elements, the content of the two elements are equal; and the rare earth elements mainly include samarium, gadolinium and lutetium. After an alloy ingot is smelted, the alloy ingot on which a solid solution treatment is carried out is rolled to form the alloy sheet at the room temperature by utilizing an asynchronous rolling method. The alloy sheet manufactured by utilizing the method is small in crystallite dimension, good in ductility and low in anisotropy. The ductility of the alloy sheet at the room temperature reaches 15% to 25%.

Owner:YANSHAN UNIV

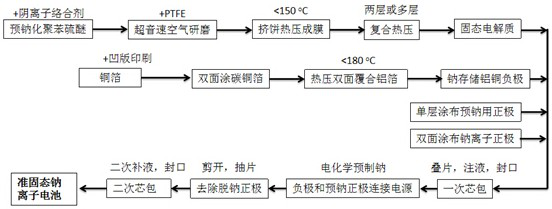

Manufacturing method of high-energy-density quasi-solid-state sodium ion battery

ActiveCN112290081AImprove thermal stabilityNon-flammableSolid electrolytesFinal product manufactureSolid state electrolyteElectrolytic agent

The invention relates to the field of new energy and discloses a manufacturing method of a high-energy-density quasi-solid-state sodium ion battery, and the method comprises two main technological processes of pre-preparing sodium and removing secondary packaging of a positive electrode for pre-preparing sodium. According to the pre-preparing sodium process, under the action of an electric field,a positive electrode for sodium prefabrication is subjected to single-layer coating, and uniform sodium plating is formed on the surface of a porous aluminum foil by compounding a sodium ion polyethylene and polyphenylene sulfide-based composite solid electrolyte, so that nucleation and growth of metal sodium are uniform, and dendritic crystal generation is inhibited. The sodium-ion polyethylene polyphenylene sulfide-based composite solid electrolyte can be tightly adhered to a sodium storage aluminum-copper negative electrode after sodium is prefabricated, and can be easily separated from a single-layer coated positive electrode for pre-sodium, the positive electrode for pre-sodium after sodium removal is taken out, the internal damage of a battery cell cannot be caused, and secondary vacuumizing and sealing are performed. The battery manufactured by the method has good flame retardant property and good thermal stability, the electrolyte injection amount is reduced, combustibles in the battery are also reduced, and the safety performance of the battery is improved.

Owner:东莞奥创能源科技有限公司

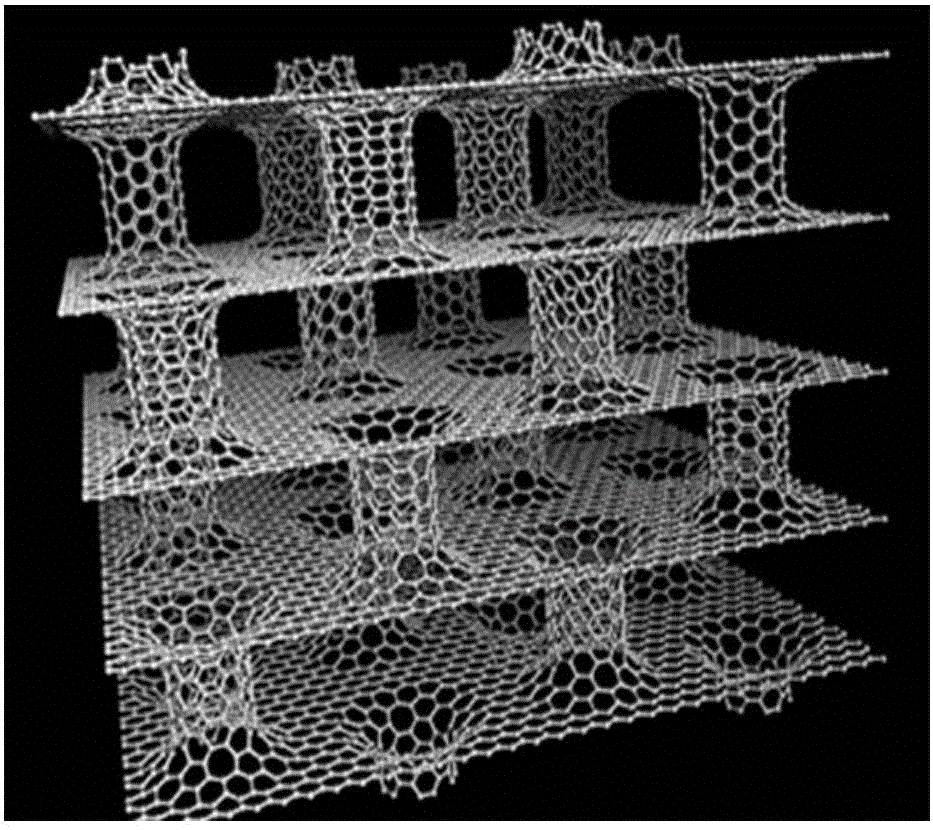

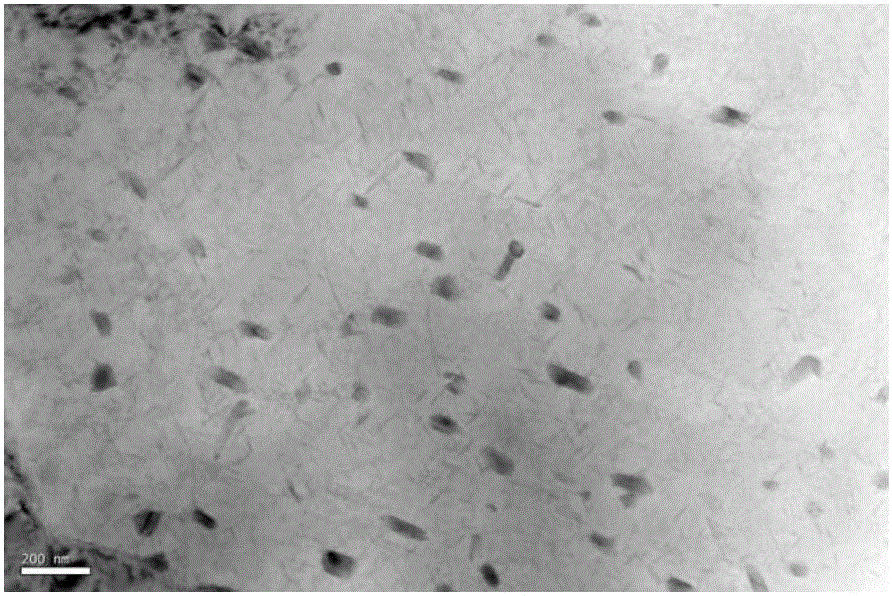

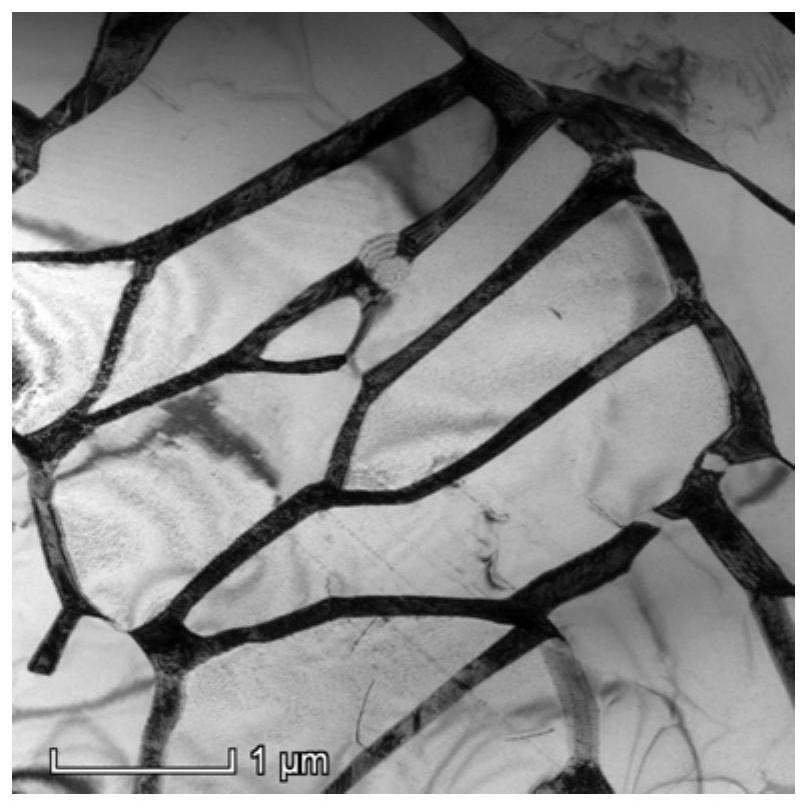

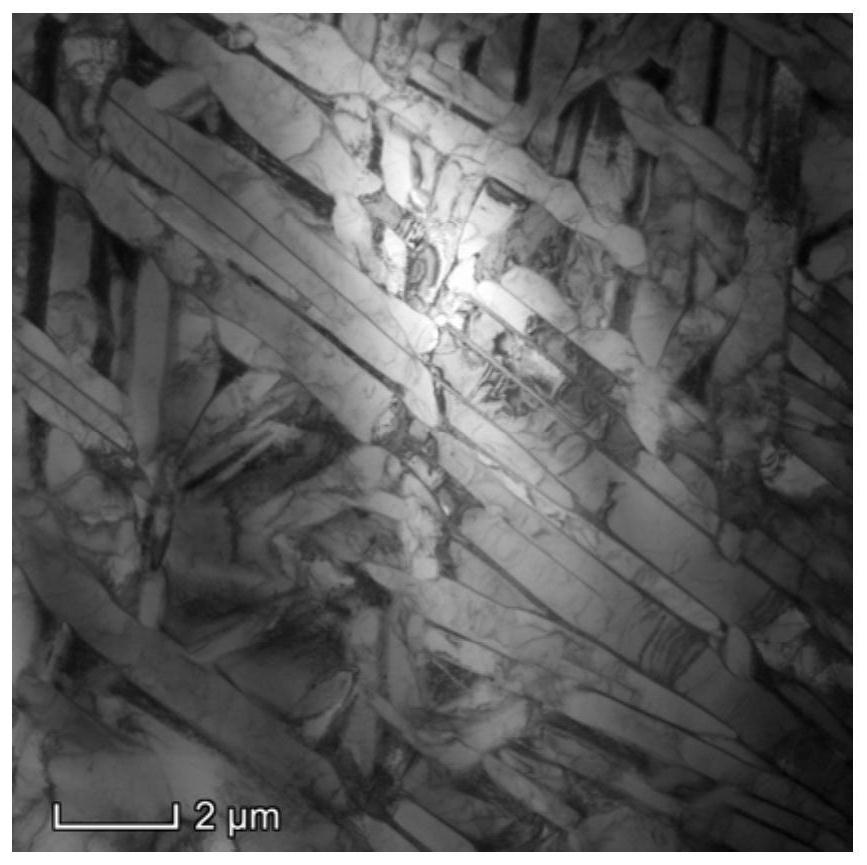

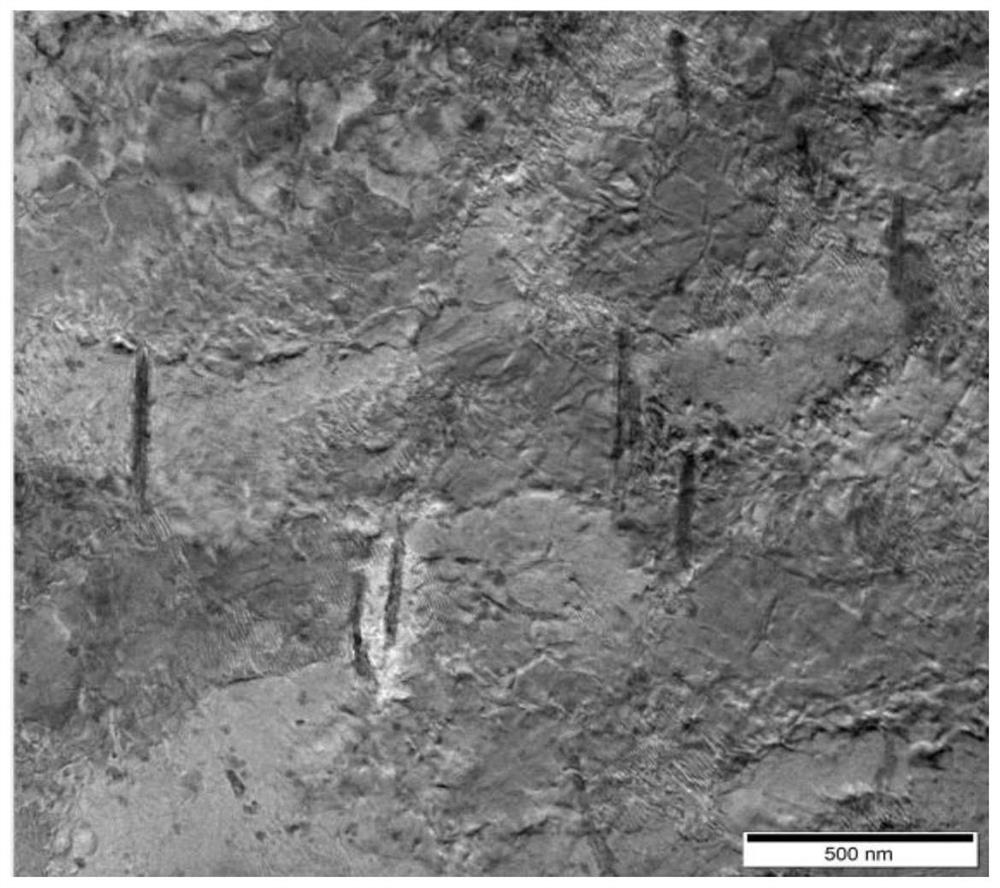

Preparation method of graphene hybrid carbon nanotube

InactiveCN105819420AEliminate anisotropyImprove mechanical propertiesMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsGas phaseActive component

The invention relates to a method for preparing graphene hybrid carbon nanotubes. The hybrid is composed of carbon nanotubes and layered carbon materials, and the carbon nanotubes are distributed between sheets of the layered carbon materials; The precursor of the layered carbon material is made into a homogeneous solution, and the layered carbon material carrier is impregnated in the homogeneous solution, and the active component is dispersed and intercalated between the sheets of the layered carbon material by high pressure or ultrasonic method, and then heated at 200 to 600 Calcining at ℃ to form a catalyst with such a structure that the metal active components are distributed between the carrier sheets; the catalyst is placed in the reactor, and carbon nanotubes or carbon nanotubes are deposited on the surface of the catalyst through a chemical vapor deposition process Graphene. The invention can obtain graphene hybrid carbon nanomaterials with a special structure in large quantities; the carriers, catalyst precursors and carbon sources involved in various precursors used in the method are cheap and easy to obtain, and are convenient for engineering enlargement and mass production.

Owner:TIANJIN XITENG SCI & TECH CO LTD

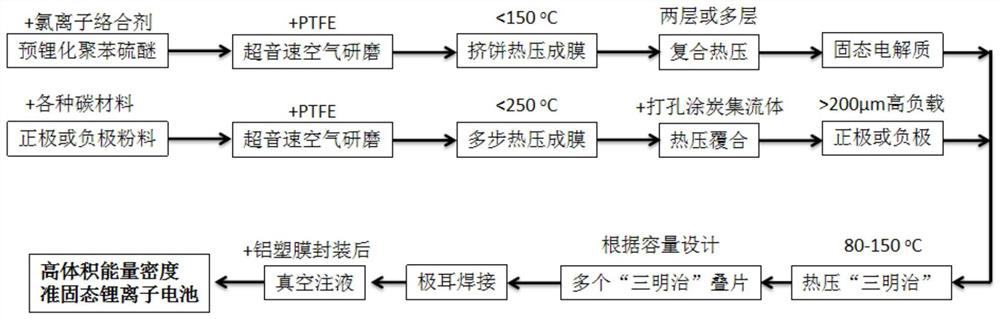

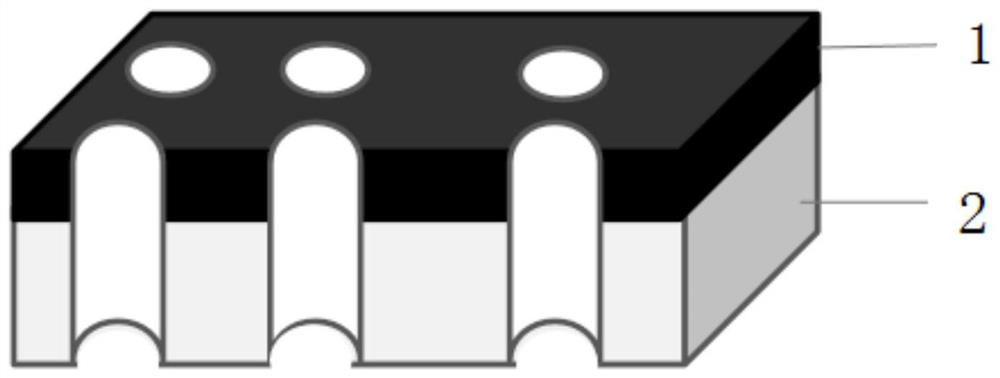

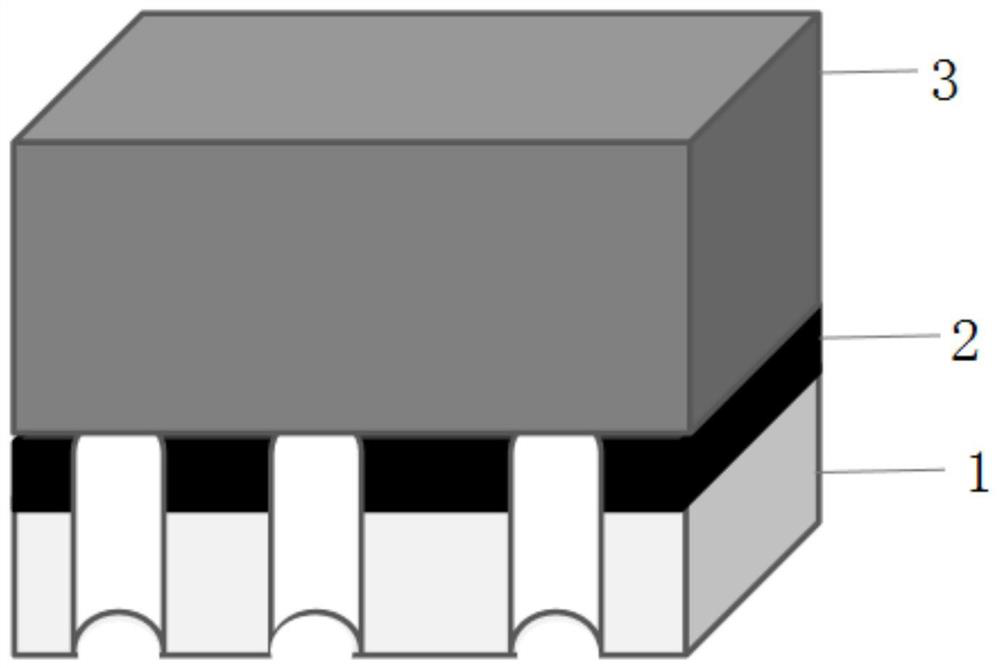

High-safety high-volume-energy-density quasi-solid-state lithium-ion battery and manufacturing method thereof

ActiveCN111864272AEasy to operateNo pollution in the processFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteElectrolytic agent

The invention provides a high-safety high-volume-energy-density quasi-solid-state lithium-ion battery and a manufacturing method thereof. The manufacturing method comprises three steps of preparing isotropic polyphenylene sulfide solid electrolyte by adopting a solvent-independent method, manufacturing a high-load battery pole piece and assembling the quasi-solid-state lithium-ion battery. The volume ratio of the active substance load is increased to 30%-50%; the polyphenylene sulfide solid electrolyte has good flame retardant property and good thermal stability, the electrolyte injection amount is reduced, the electrolyte dosage is greatly reduced, combustibles in the battery are also reduced, and the safety performance of the battery is improved. The solid electrolyte contains lithium, and the content of toxic fluorine-containing lithium salt in the electrolyte is also greatly reduced. The battery pole piece and the solid electrolyte are bonded into a whole after hot pressing, are not easy to shift under repeated bending, can be used as an ultrathin flexible quasi-solid battery, and are used in wearable electronic equipment.

Owner:JIANGSU UNIV

Heat treatment method of high-strength high-toughness hot continuous rolling steel plate for engineering machine

InactiveCN101144142AEliminate internal stressEliminate anisotropyFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention belongs to a heat treatment method for a hot tandem rolling steel plate with high intensity and high toughness used for engineering machinery. The method solves the deficiencies that because of the releasing of the internal stress of the current hot tandem rolling steel plate, bulge or wave appears on the steel plate, thereby influencing the normal use of the steel plate. In order to solve the problems, the present invention provides the technical measures that the hot tandem rolling plate has the components and the weight percentages that C is 0.03 -0.06 percent, Si is 0.15 -0.35 percent, Mn is 1.65-1.75 percent, P is less than or equal to 0.02 percent, S is less than or equal to 0.006 percent, AlS is 0.02-0.05 percent, Ni is 0.3 -0.4 percent, Cr is 0.25-0.35 percent, Ti is 0.005-0.02 percent, Mo is 0.1-0.2 percent, Nb is 0.04-0.05 percent, and the residual is Fe and the inevitable impurity, and cross cutting is performed to the hot tandem rolling plate; 30-50 minute tempering processing is performed within the range of 530 to 620 DEG C; quality testing is performed to the hot tandem rolling steel plate after the tempering processing, and the hot tandem rolling steel plate is stand-by. The present invention can reduce or even eliminate the internal stress and the anisotropism of the hot tandem rolling steel plate, improve the toughness index, have good stability, and be uneasy to be distorted after cutting, thereby meeting the market request.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Forging process of high-strength heat-proof magnesium alloy pipe

InactiveCN105344742AImprove mechanical propertiesUniform tissueLubricant compositionHeat resistanceIngot

The invention provides a forging process of a high-strength heat-proof magnesium alloy pipe. According to the forging process, alloy components are subjected to ingot manufacturing, high-pressure extrusion, initial alloy ingot blank manufacturing, high-pressure extrusion, hollow ingot blank manufacturing with a cored extrusion cylinder, aluminium alloy pipe manufacturing and aging treatment to obtain the high-strength heat-proof magnesium alloy pipe. The magnesium alloy pipe has good mechanical properties. when the deformation is greater than 20%, the total cross section of the magnesium alloy pipe can obtain a uniform structure; as the accumulated deformation increases further, more uniform and finer crystals can be obtained in combination with a proper forging process, the average crystal size is lower than 10 mu m, anisotropy is basically eliminated, and the comprehensive mechanical properties are improved remarkably. Meanwhile, through twice pressure extrusion, the finally manufactured magnesium alloy pipe is precise in structure and suitable for working in a high-pressure environment and has high strength and heat resistance.

Owner:贵州航天风华精密设备有限公司

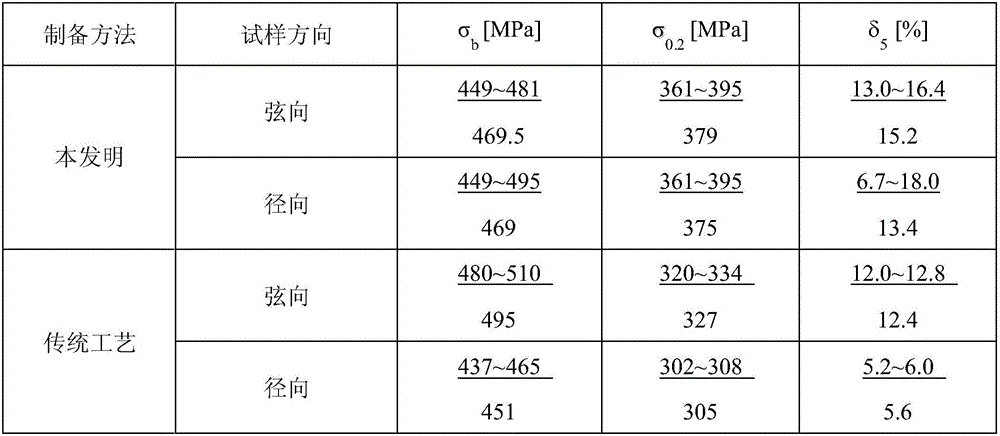

Low-stress manufacturing process for eliminating anisotropism of 2A12 aluminum alloy forging

The invention relates to a low-stress manufacturing process for eliminating anisotropism of a 2A12 aluminum alloy forging, and belongs to the field of metal material engineering. In the aerospace field, according to the use and stress environment of an aluminum alloy product, the requirement for lowering the anisotropism of a material is high, and especially the requirements of an airtight knuckle bearing type forging for the chordwise and radial strength and toughness of the product are higher. Especially the requirement of an airtight knuckle bearing for a space suit for the machining precision of the product is quite high. For an aluminum alloy capable of being subjected to heat treatment and strengthening, after the material is quenched, large internal quenching stress exists in the material, and for the product with the high requirement for machining precision, waste can be possibly caused by size tolerance after finish machining. According to the method, the anisotropism, in the chordwise direction and the radial direction, of the product can be effectively eliminated, especially the internal stress of the product is effectively eliminated, and the machining yield of the product is remarkably increased.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

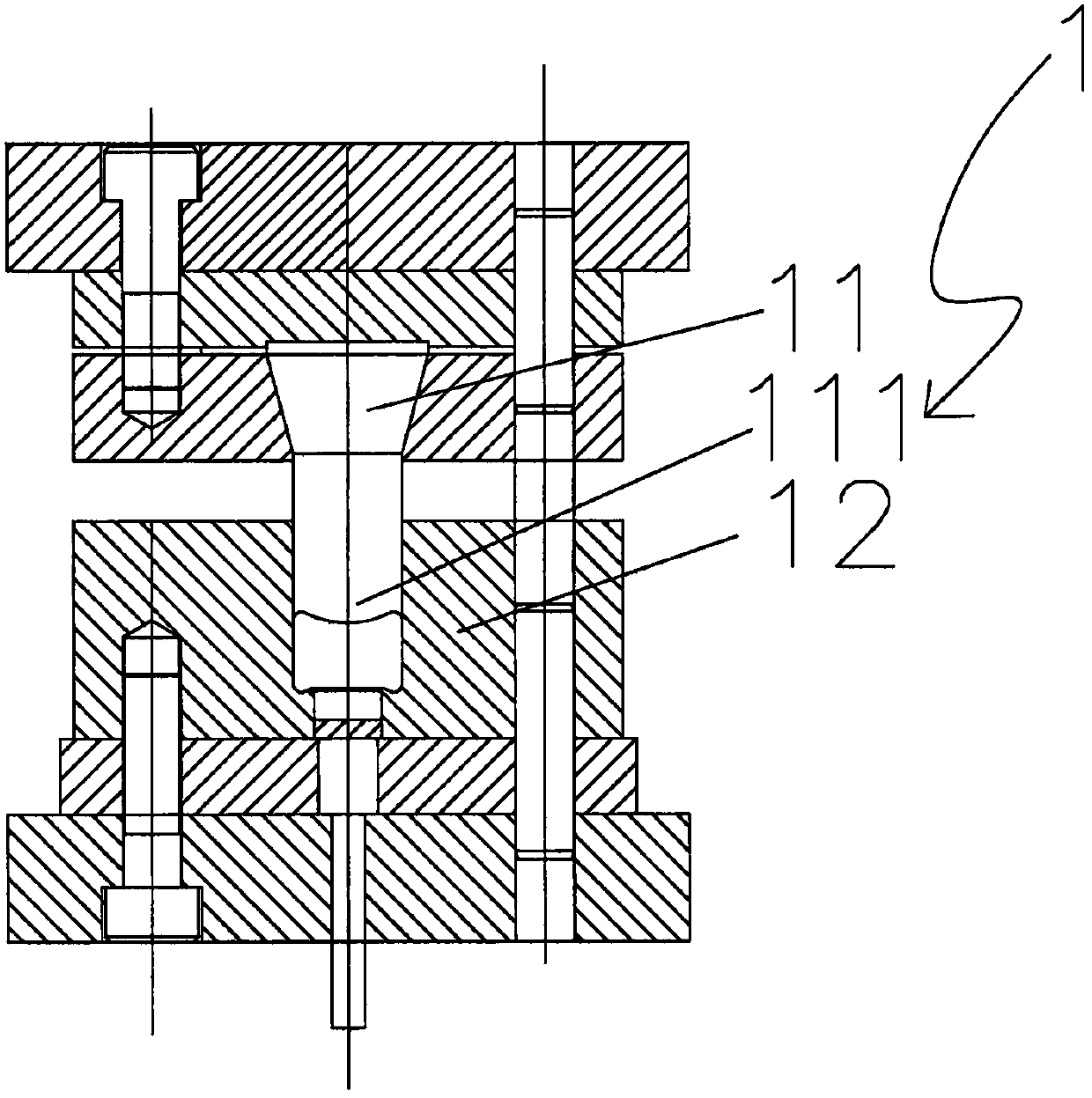

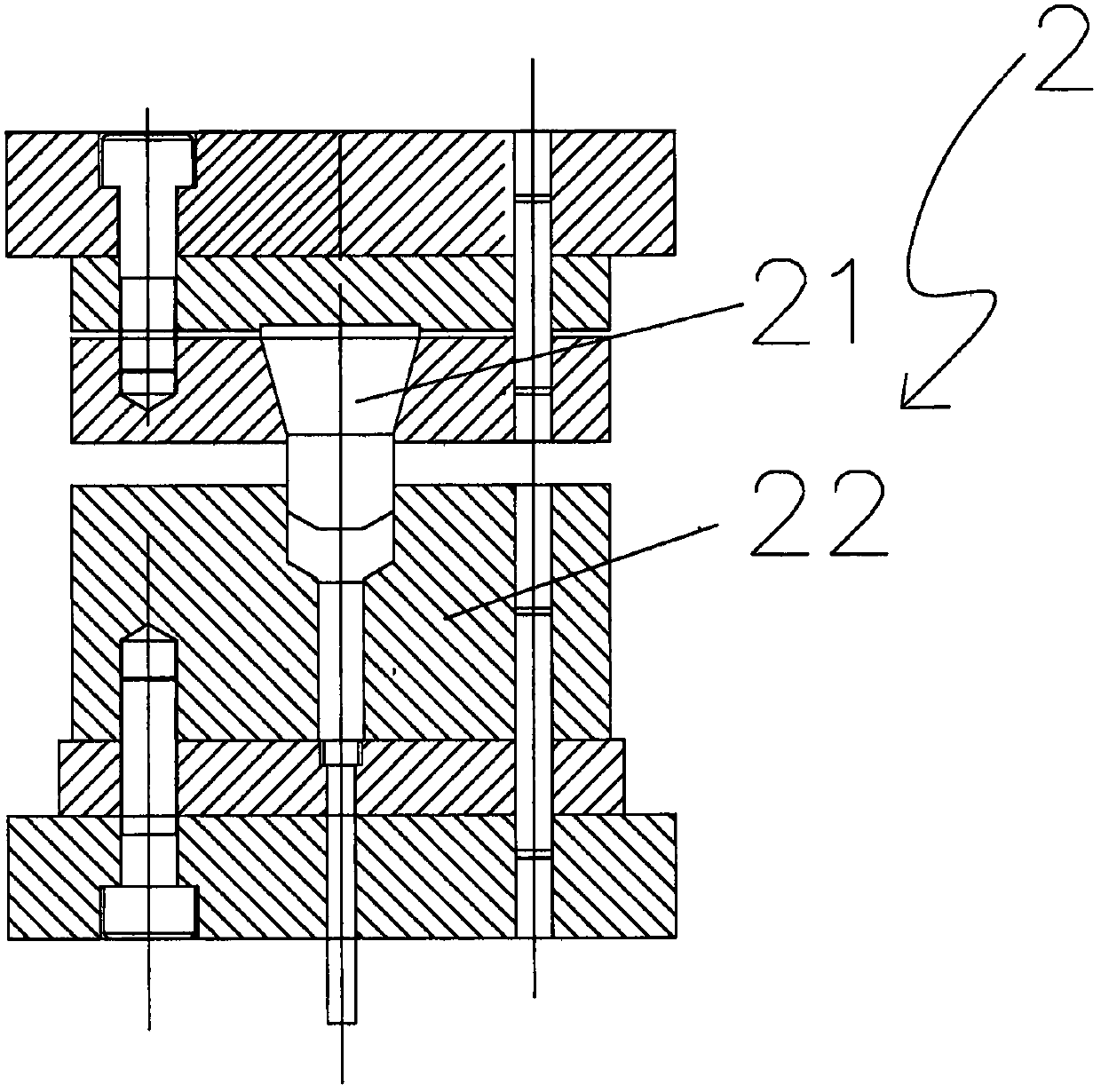

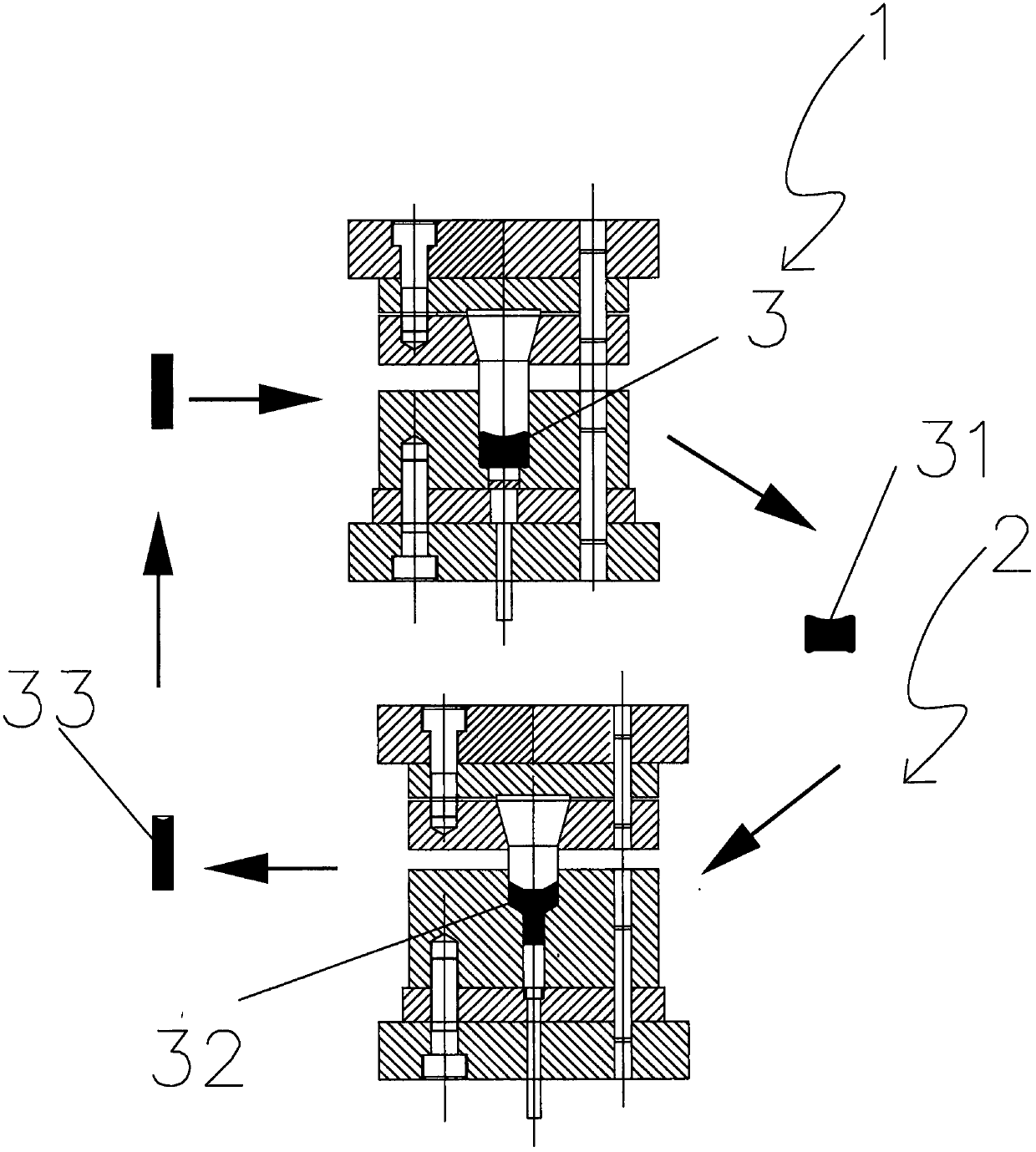

Large plastic shape and deformation blank-making method for eliminating anisotropy of magnesium alloy bar material with large height-diameter ratio

InactiveCN107649629AUniform deformationEnhanced deformation uniformityExtrusion diesForging/hammering/pressing machinesInvoluteDiameter ratio

The invention discloses a large plastic shape and deformation blank-making method for eliminating anisotropy of a magnesium alloy bar material with the large height-diameter ratio. The large plastic shape and deformation method comprises the steps that (1) an upsetting die is used and is formed by combining space curve faces which combine the symmetrical parabolain in the middle portion of the bottom end of an upsetting male die and the involute at the edge portion, the magnesium alloy bar material is placed in the closed upsetting die for upsetting machining, upsetting deformation is conducted on the magnesium alloy bar material under action of stress, and the alloy bar material is lengthened in the radial direction and is shortened in the axial direction; (2) the blank material after upsetting is put into an extruding die for being extruded and deformed, the blank material is shortened in the radial direction and is lengthened in the axial direction, and a bar-shaped blank material is formed; (3) then after the blank material is extruded, defects at the tail part of the blank material are cut off, the blank material with the defects at the tail parts being cut is put into the upsetting die for upsetting deformation again, and one-time upsetting and extruding process is finished; and (4) the workpiece after upsetting deformation is subjected to upsetting and extruding again, and upsetting and extruding process is repeated by three times. According to the large plastic shape and deformation blank-making method for eliminating anisotropy of the magnesium alloy bar material with large height-diameter ratio, uniform upsetting and blank-making of the large height-diameter ratio bar material without anisotropy is achieved by means of upsetting and extruding repeated circulation large deformation.

Owner:ZHONGBEI UNIV

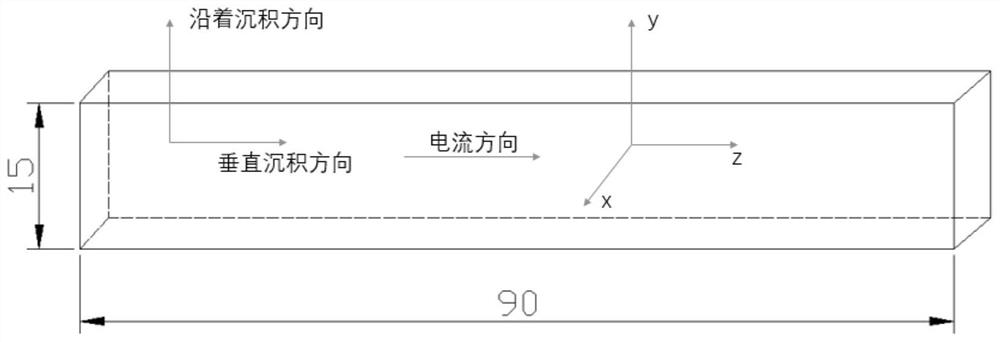

Method for improving anisotropy of additive manufacturing titanium alloy through pulse current

ActiveCN113249668AIncreased anisotropyEliminate anisotropyAdditive manufacturing apparatusIncreasing energy efficiencyHigh energySS - Stainless steel

The invention provides a method for improving anisotropy of an additive manufacturing titanium alloy through pulse current, and solves the problems of high energy consumption, high time consumption, difficulty in popularization and poor effect on large components in an existing post-treatment technology. The method comprises the following steps: (1) the surface of the additive manufacturing alloy component is cleaned; (2) the alloy is fixed through a clamp and then connected to the two ends of a pulse power source, and the clamp and the workpiece keep complete contact; (3) the clamped component is horizontally placed on a specific device, and is kept horizontal; (4) the voltage, the frequency and the action time are adjusted, and the additive manufacturing titanium alloy is treated through pulse current; and (5) the pulse power source is turned off, and the component is taken down after being cooled to the room temperature. The method has the advantages of being simple in process, rapid in implementation, capable of easily achieving batch production, capable of being applied to large workpiece treatment, wide in application range and the like, and can be applied to additive manufacturing of the titanium alloy, stainless steel, an aluminum alloy, a high-temperature alloy and the like and corresponding components.

Owner:HARBIN ENG UNIV

Preparation method of graphite crucible

The invention discloses a preparation method of a graphite crucible. The preparation method comprises the following steps: S1, raw material preparation: raw materials comprise graphite scraps, an Acheson furnace petroleum coke resistance material, an Acheson furnace petroleum coke thermal insulation material and medium-temperature coal pitch; s2, burdening: graphite is crushed and ground into graphite powder, then the graphite powder is mixed with the Acheson furnace petroleum coke resistance material, the Acheson furnace petroleum coke resistance material and the Acheson furnace petroleum coke heat preservation material according to the mass ratio of 3: 2: 5, the mixture is ground into mixed powder, the mixed powder is mixed with medium-temperature coal pitch, the mass percent of the mixed powder in the mixing process is 65%-85%, and the medium-temperature coal pitch is obtained; the mass percent of the medium-temperature coal pitch is 15%-35%; s3, mixing and kneading; s4, profiling is conducted; s5, roasting; and S6, processing. A hot-pressing cold-out one-time forming method is adopted, the obtained product is excellent in performance and shows good thermal shock resistance, ablation performance, leakage-proof performance and mechanical strength, and the preparation process has the advantages in the aspects of saving energy, protecting the environment, shortening the period and improving the aging efficiency.

Owner:吉林科工碳业有限公司

Linen fiber reinforced polypropylene automobile interior part injection molding method

InactiveCN107129632AImprove toughnessImprove sun resistanceBiochemical fibre treatmentLight resistant fibresFiberCellulose

The invention provides a linen fiber reinforced polypropylene automobile interior part injection molding method. According to the invention, the surface and pores of a linen fiber are filled with porous nano-scale silicon dioxide, titanium dioxide and nano crystalline cellulose, so that the toughness and light fastness of the linen fiber are improved; meanwhile, the polypropylene compatibility is improved, so that the material after injection molding has improved strength, improved durability, light fastness, antibacterial property and wear resistance, and is easy to clean; and the linen fiber and polypropylene are subjected to injection molding to obtain strips, and the strips are subjected to re-injection molding, so that the anisotropy of the linen fiber is eliminated, thereby improving the dimensional stability of the injection molding product.

Owner:岳西县同兴尼龙橡胶制品有限公司

Metal-clad laminate and method for production thereof

ActiveUS7811408B2Excellent in isotropy and appearance and adhesiveDimensional stabilityLiquid crystal compositionsAdhesive processesThin slabThermal expansion

A metal-clad laminate excellent in isotropy, appearance, bondability between a TLC polymer film and a metallic sheet, and dimensional stability is provided less costly with a first step of thermally compressing the film with the metallic sheet by passing them through a nipping region between heating rolls, and a second step of heat-treating the resultant metal-clad laminate at a temperature not higher than the melting point of the film, wherein the film has thermal expansion coefficient αL satisfying αL=βT+γ with thickness T, thickness coefficient β and anisotropy coefficient γ of the film; wherein the coefficient β is within the range of −0.08 to −0.01; the coefficient γ is within the range of αM+6≦γ≦αM+10 with thermal expansion coefficient αM of the metallic sheet; and thermal expansion coefficient αT of the film is within αM−2≦αT≦αM+3 with the coefficient αM.

Owner:KURARAY CO LTD

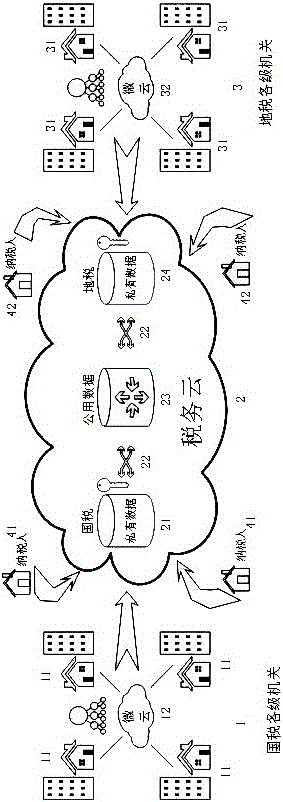

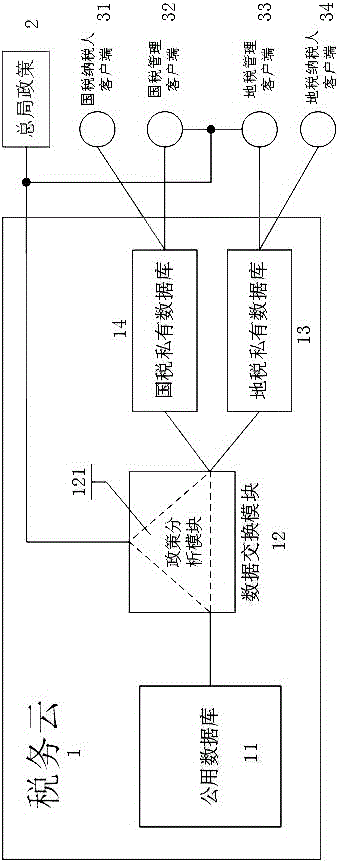

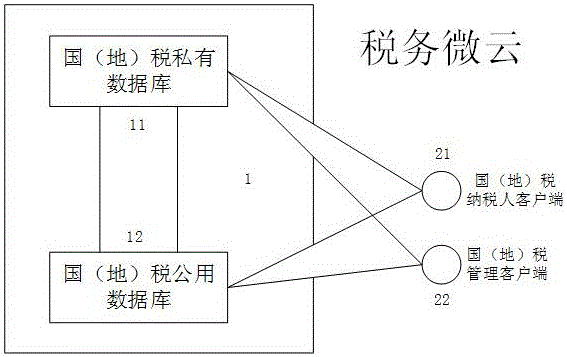

Cloud-based national and local joint tax dealing platform

The invention provides a cloud-based national and local joint tax dealing platform, and relates to the technology of the tax dealing platform. The platform is composed of a tax cloud, a tax micro cloud and client sides. The core part is the tax cloud which comprises a private database, a public database and a data exchange module. The tax micro cloud is connected with all levels of national and local tax authorities. The private part of the tax micro cloud is maintained by respective tax authority organizations, and the data of the public part are shared by all levels of national tax authorities or all levels of local tax authorities. Data collection and display are realized by the client sides, and the client sides are divided into a management client side and a taxpayer client side. The management client side is used by the tax authorities and the taxpayer client side is used by the taxpayers. Real-time data exchanging is performed between the public data and the private data of the tax cloud or the tax micro cloud so that the real-time performance of information can be guaranteed, national and local tax information sharing can be realized, the joint tax dealing efficiency can be enhanced and the tax dealing operation flow of the taxpayers can be reduced.

Owner:INSPUR QILU SOFTWARE IND

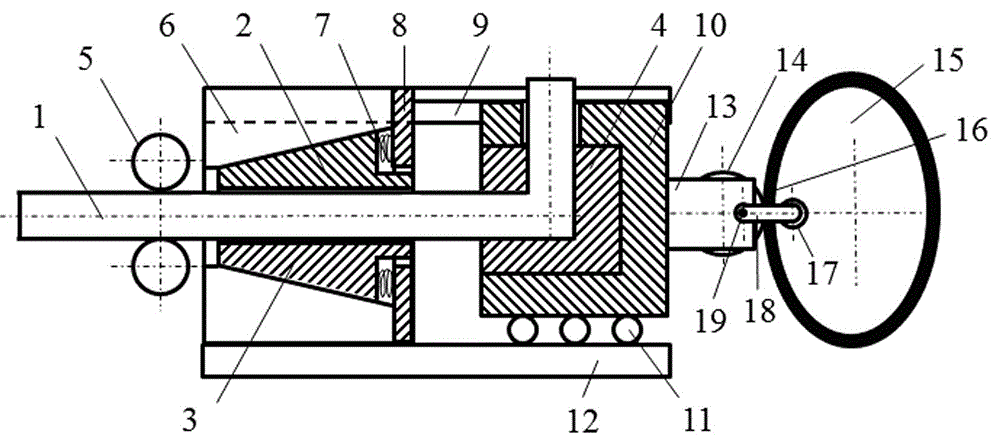

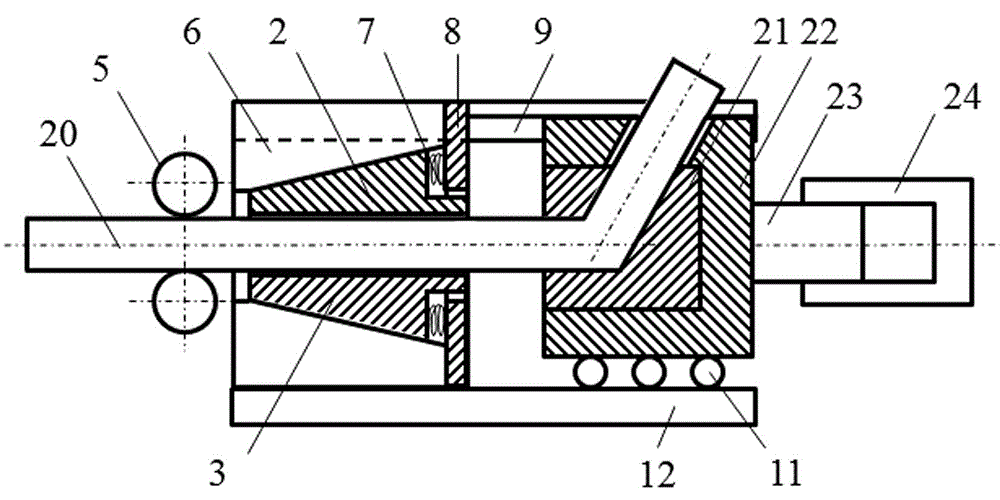

Stepping continuous extrusion device and method for metal severe plastic deformation

ActiveCN103331319AEliminate organizational defectsImprove tissue performanceExtrusion diesStart upPlastic property

The invention provides a stepping continuous extrusion device and method for metal severe plastic deformation. The device comprises a die part and a clamp part, wherein the clamp part comprises an upper clamp, a lower clamp, a clamp seat, a fixing plate and springs, the inclined planes on the outer sides of both the upper clamp and the lower clamp are connected with the inclined plane in the clamp seat, the fixing plate is mounted on the clamp seat, and the springs are fixed on the fixing plate and used for being connected with the upper clamp and the lower clamp respectively; the die part consists of a die, a die base and a die driving device, and the die is fixed on the die base connected with the die driving device. The method comprises the following steps: transmitting metal bar / plate strips to a deformable part channel as deformable parts through feeding rollers, and starting up the die driving device to enable the die to reciprocate so as to realize stepping continuous extrusion deformation of metal. By adopting the method, long superfine grained materials and materials subject to severe plastic deformation can be prepared, and the deformation load is reduced. The method has the advantages of simple process, energy saving, material saving and the like.

Owner:NORTHEASTERN UNIV

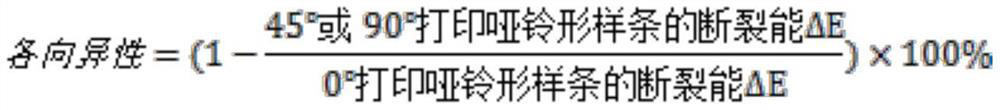

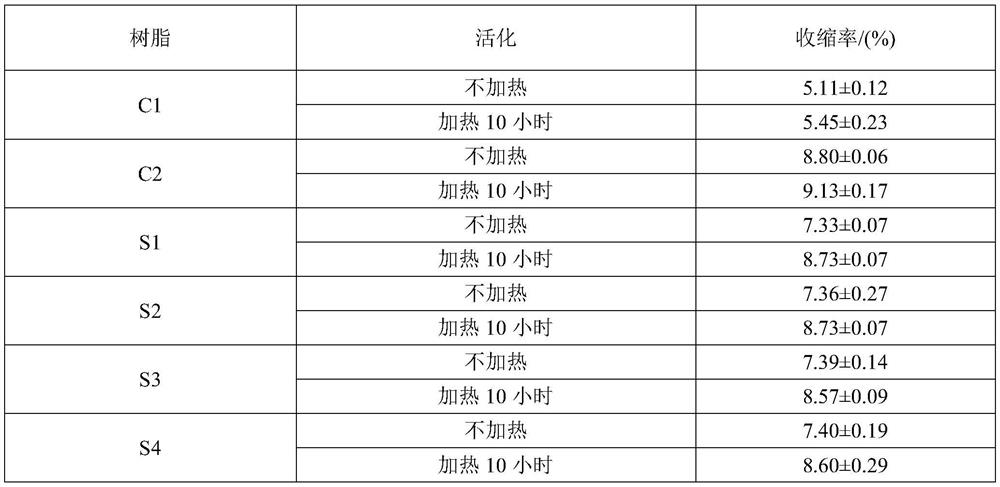

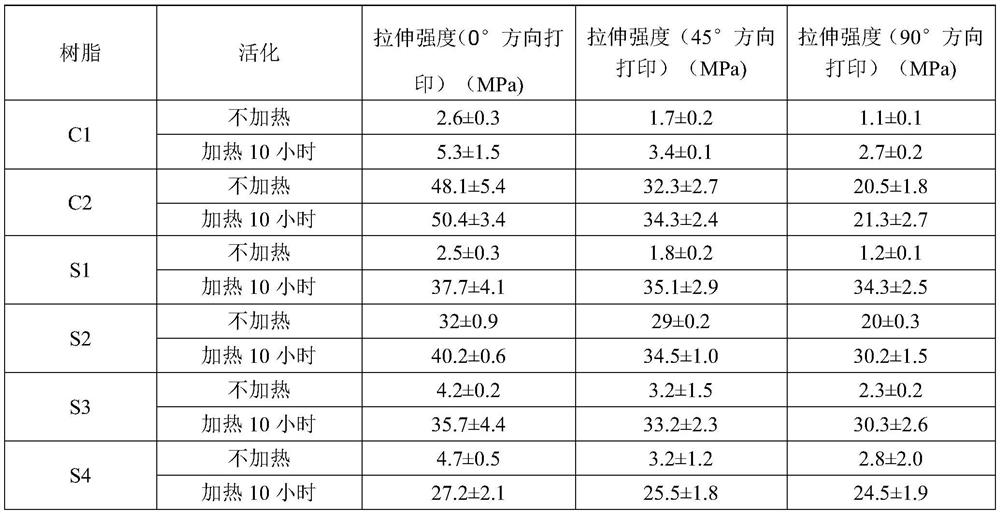

Photosensitive resin composition for photocuring 3D printing as well as preparation method and application of photosensitive resin composition

PendingCN113736085AImprove service performanceEliminate anisotropyAdditive manufacturing apparatusPhotoinitiatorPolymer chemistry

The invention discloses a photosensitive resin composition for photocuring 3D printing as well as a preparation method and application of the photosensitive resin composition. The photosensitive resin composition comprises the following components in parts by weight: 40-80 parts of a poly alkene monomer, 10-40 parts of a poly thiol monomer, 2-20 parts of allyl glycidyl ether, 1-6 parts of a free radical photoinitiator, 1-5 parts of a photobase generator, 0-2 parts of a sensitizer and 0-2 parts of a stabilizer. During photocuring 3D printing forming, a thiol monomer and an alkene monomer are subjected to a free polymerization reaction, and meanwhile, the photobase generator is cracked to generate organic strong base. A printed product is further heated and activated, and residual sulfydryl in the resin further reacts with an epoxy group in alkene glycidyl ether, so that the mechanical property anisotropy formed by 3D curing layer-by-layer curing molding is reduced, and the service performance of the resin is improved.

Owner:LINGNAN NORMAL UNIV

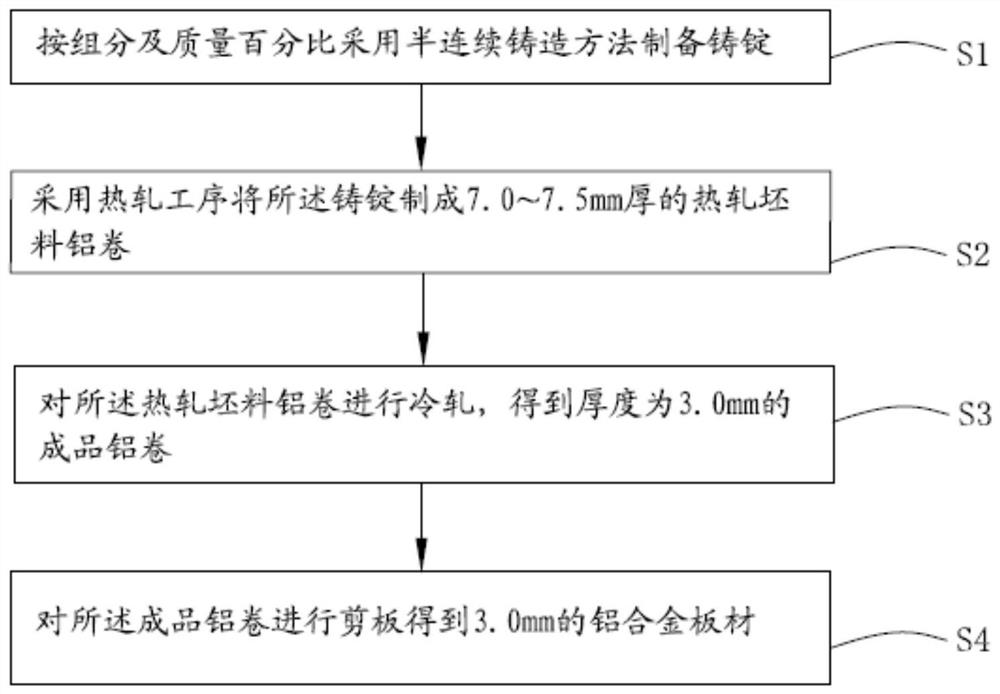

Aluminum alloy plate and preparation method thereof

PendingCN113046603AGood formabilityImprove edge qualityTelevision system detailsColor television detailsIngotMachining process

The invention discloses an aluminum alloy plate and a preparation method thereof. The aluminum alloy plate comprises, by mass, less than or equal to 0.16% of Si, less than or equal to 0.24% of Fe, less than or equal to 0.05% of Cu, 2.45%-2.65% of Mg, less than or equal to 0.05% of Mn, 0.21%-0.28% of Cr, less than or equal to 0.10% of Zn, less than or equal to 0.15% of Ti and the balance Al and inevitable impurities. Through cast ingot chemical component design, complete recrystallization annealing and stable annealing process design, the structure anisotropy is eliminated, and the plate forming performance is improved; and internal stress caused in the small-machining-rate cold machining process is eliminated, and the failure softening phenomenon caused by poor stability of a solid solution when the solid solution is placed in the natural environment for a long time is avoided. Compared with the prior art, the aluminum alloy plate prepared through the method is flat in plate shape, excellent in surface quality, high in strength, easy to machine and form and capable of being applied to a back plate of a flat panel television.

Owner:ZHEJIANG YONGJIE ALUMINUM CO LTD +1

Precision forging and cold pressing forming machining process and die for end tooth side inverted cone combined teeth

PendingCN110722081AIncrease productivityReduce manufacturing costForging/hammering/pressing machinesWheelsMachining processManufacturing engineering

The invention relates to the field of end face combined tooth production, and particularly relates to a precision forging and cold pressing forming machining process and die for end tooth side inverted cone combined teeth. The precision forging and cold pressing forming machining process comprises an end combined tooth pre-forming die forming procedure, an end combined tooth precision forging pre-forming procedure, an overall tooth shape cold pressing finishing tooth die forming procedure and an end tooth side inverted cone combined tooth cold pressing forming procedure. According to the precision forging and cold pressing forming machining process and the machining die for the end tooth side inverted cone combined teeth, the production efficiency of the end tooth side inverted cone combined teeth can be improved, the production cost of the end tooth side inverted cone combined teeth is reduced, and especially the cutter consumption in the production machining process is reduced; and meanwhile, the strength of the end tooth side inverted cone combined teeth is improved, and the service life of the end tooth side inverted cone combined teeth is prolonged as a whole.

Owner:洛阳福瑞可汽车零部件有限公司

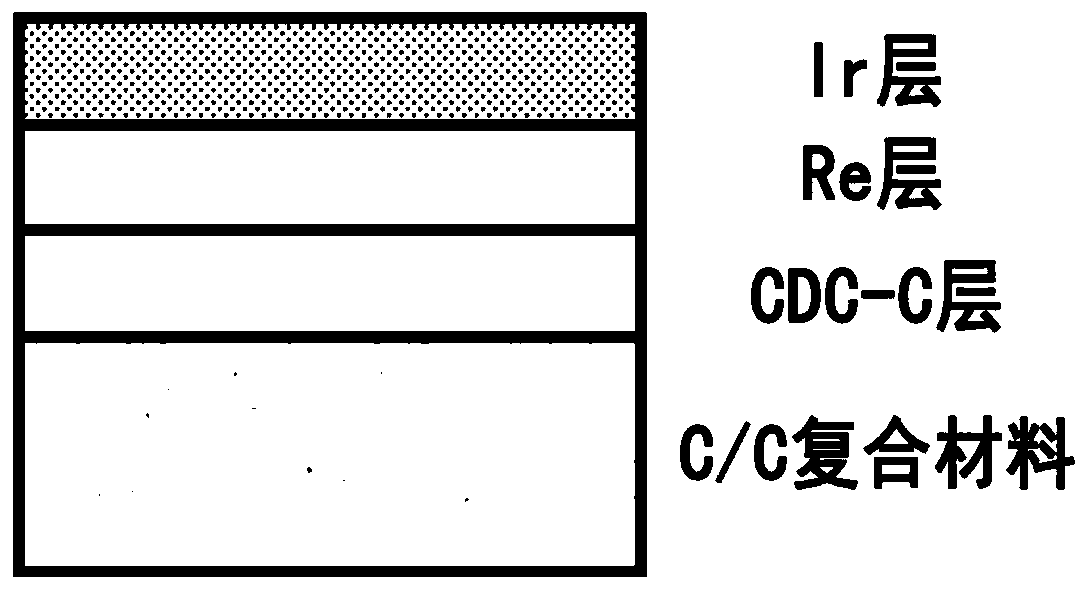

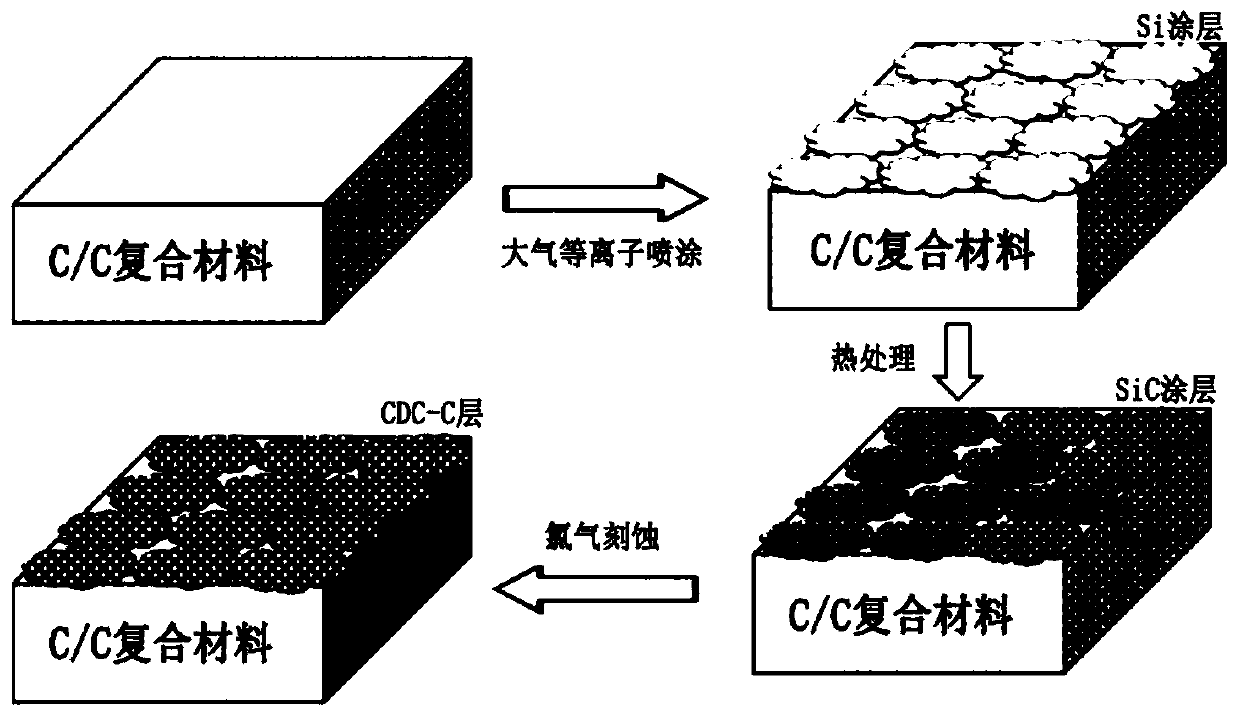

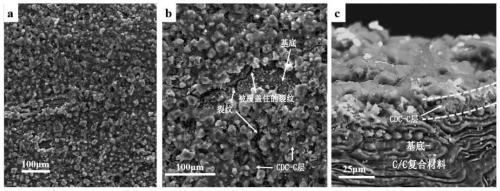

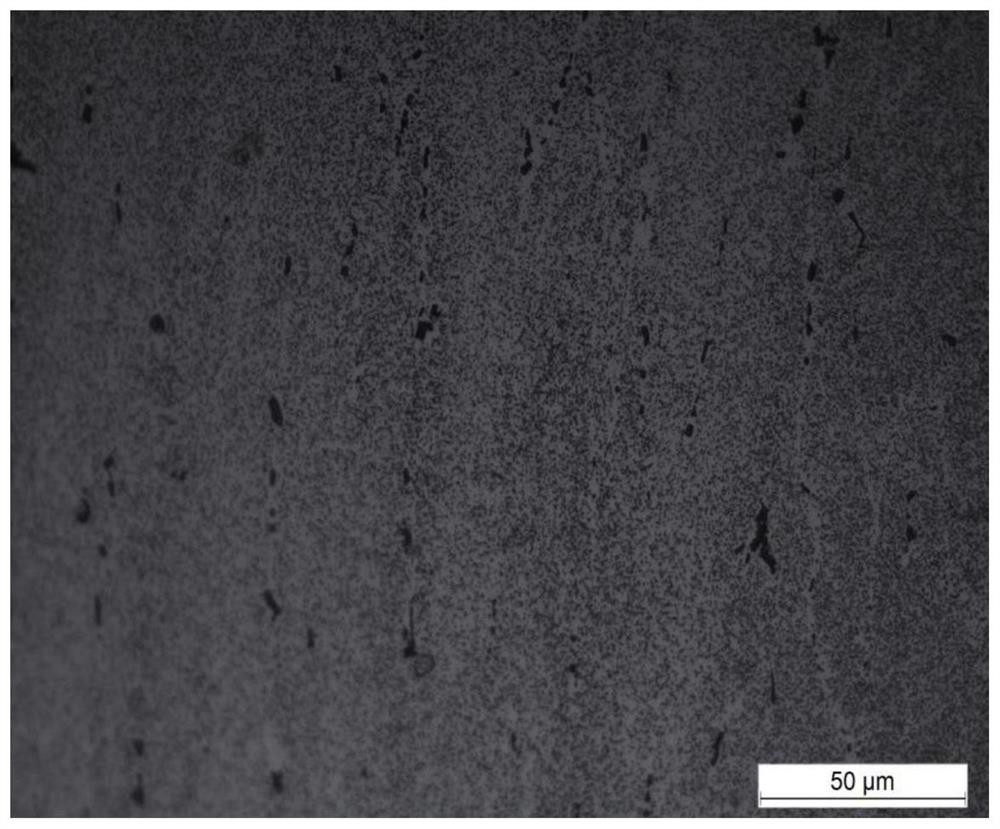

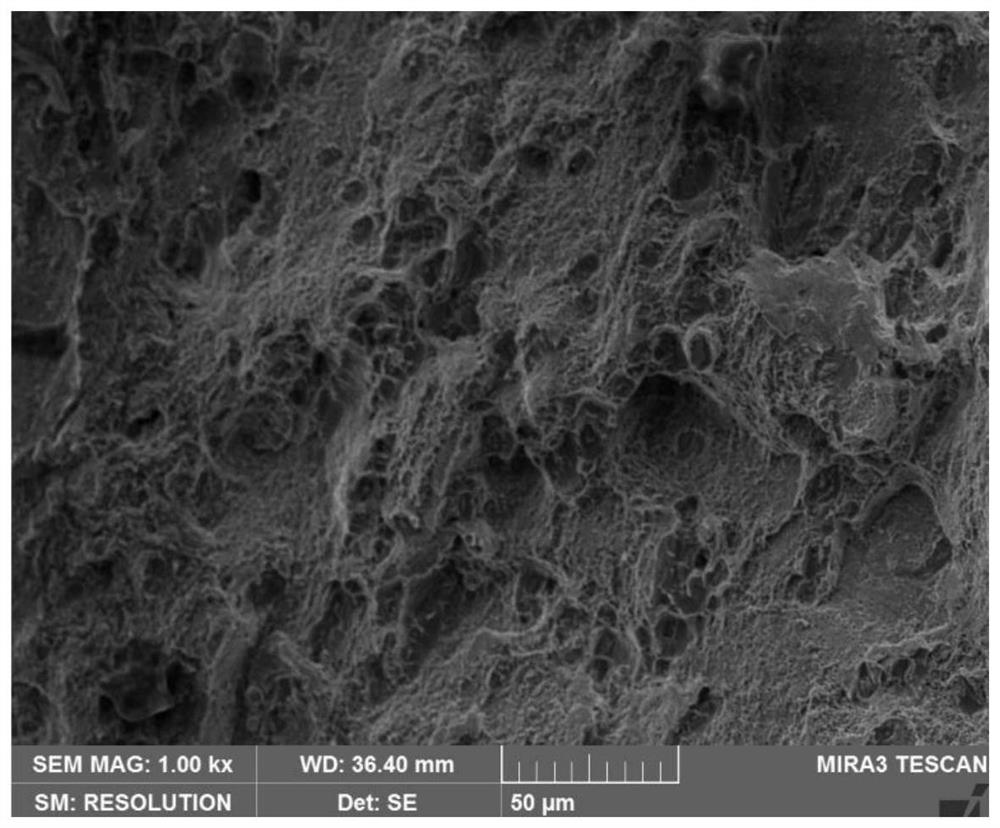

C/C composite material surface carbide derived carbon/rhenium/iridium coating layer and preparation method thereof

The invention discloses a C / C composite material surface carbide derived carbon / rhenium / iridium coating layer and a preparation method thereof. The coating layer takes a C / C composite material as a matrix; a carbide-derived carbon layer, a rhenium coating layer and an iridium coating layer are sequentially arranged on the surface of the C / C composite material from bottom to top. The preparation method comprises the steps: preparing a pure Si layer on the C / C composite material matrix, carrying out heat treatment to obtain an SiC layer, carrying out chlorine etching to form the carbide-derivedcarbon layer, and sequentially depositing the rhenium coating layer and the iridium coating layer on the carbide-derived carbon layer. The carbide-derived carbon / rhenium / iridium coating layer can perfectly consider coating layer combination, coating layer matrix thermal mismatch alleviation and coating layer system high-temperature thermochemical compatibility, and has a wide application prospect.

Owner:NAT UNIV OF DEFENSE TECH

Short-process preparation method of high-toughness aluminum-lithium alloy sheet

ActiveCN112981198ASolve oxidation burning lossSolve the suction problemFurnace typesMetal rolling arrangementsThin slabIngot

The invention discloses a short-process preparation method of a high-toughness aluminum-lithium alloy sheet, and belongs to the field of aluminum-lithium alloy rolling forming and deformation heat treatment. According to the method, a 2197 aluminum-lithium alloy cast ingot is prepared through smelting by adopting flux and argon protection and a common gravity casting method, and the high-strength and high-toughness sheet with the thickness of 1-1.5 mm is formed through three-pass rolling (the total rolling reduction is 75%) by adopting deformation, deep cooling and heat treatment regulation and control methods. According to the method, short-process preparation of small-pass and large-rolling-reduction rolling forming and structure property regulation and control is directly carried out on the aluminum-lithium alloy cast ingot, the technical problems that the aluminum-lithium alloy is poor in plasticity and toughness, serious in anisotropy, insufficient in strength and difficult in sheet forming are solved, and the defects that a conventional aluminum-lithium alloy plate thermal mechanical treatment is complex in process, long in production process, low in yield and high in manufacturing cost are overcome.

Owner:TAIYUAN UNIV OF TECH

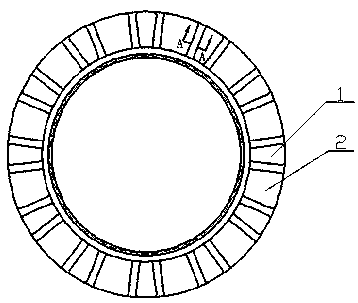

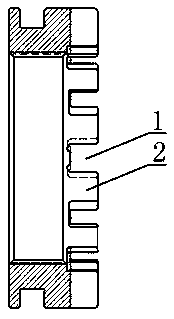

Forming method of annular voltage-sensitive resistor

The molding method of the ring varistor includes the following steps in sequence: (a) mixing: put the powder with binder and solvent in the kneader and mix evenly; (b) rough rolling: the above powder is mixed After training, the material is discharged to the rolling mill for the first rolling; (c) freezing: the mud obtained by rough rolling is sealed and refrigerated at 0-10°C; (d) finishing rolling: the mud obtained after refrigeration is subjected to the second rolling. Secondary rolling to make it uniform and compact; (e) Extrusion: place the finished mud in a vacuum extruder to extrude into a film belt with good uniformity, density and consistency; (f) drying; (g) stamping. The method can improve the uniformity and compactness of the green body and make the production efficiency higher.

Owner:广州新日电子有限公司

Production method of novel environment-friendly wood-plastic floor

InactiveCN107099161AFlat surfaceEasy to clean and maintainCoatingsPolyvinyl alcoholThermal insulation

The invention relates to a production method of a novel environment-friendly wood-plastic floor. The production method includes the steps of firstly, adding amino resin, polyvinyl alcohol, ethanol and a thermal stabilizer into a high-speed mixing machine, performing thermal-insulation mixing for a certain period of time, naturally cooling, adding a lubricating agent, adding the materials into a ball milling machine, and performing ball milling to obtain coating liquid; secondly, premixing a PVC plastic raw material, plasticizer, an acrylate impact modifier and straw powder to obtain a first mixture; thirdly, mixing the first mixture with modified bamboo powder, calcium carbonate, a titanate coupling agent and an anti-aging agent to obtain a second mixture; fourthly, using a double-screw extruder and a molding die to perform high-temperature extrusion molding on the second mixture, using the molding die for molding, and performing water cooling, traction and cutting to obtain a base plate; fifthly, coating the surface of the base plate with the coating liquid obtained in the first step to obtain the novel environment-friendly wood-plastic floor. The novel environment-friendly wood-plastic floor is high in wear resistance and corrosion resistance.

Owner:合肥易美特建材有限公司

A kind of processing method of tc4 titanium alloy sheet for superplastic forming

Owner:WESTERN TITANIUM TECH

Anode material for alkaline aluminum-air battery and preparation method of anode material

ActiveCN109338181AImprove effective utilizationImprove corrosion uniformityFuel and primary cellsCell electrodesEconomic benefitsImpurity

The invention relates to an anode material for an alkaline aluminum-air battery and a preparation method of the anode material, and belongs to the field of air batteries. The preparation method of theanode material for the alkaline aluminum-air battery is characterized in that the anode material is aluminum alloy, and the aluminum alloy consists of the following components in percentages by mass:0.05-0.20wt% of Sn, 0.05-0.15wt% of Ga, 0.2-1.0wt% of Mg, 0.1-0.5wt% of Mn, 0.1-0.3wt% of Zr, less than or equal to 0.30wt% of impurities and the balance of Al. The anode material is produced by a continuous cast rolling method, a production process is simple, the anode material is suitable for being produced in batches, defects of the anode material are reduced, the yield is increased, energy consumption is reduced, the production cost is lowered, and the economic benefit is good.

Owner:NORTHEASTERN UNIV

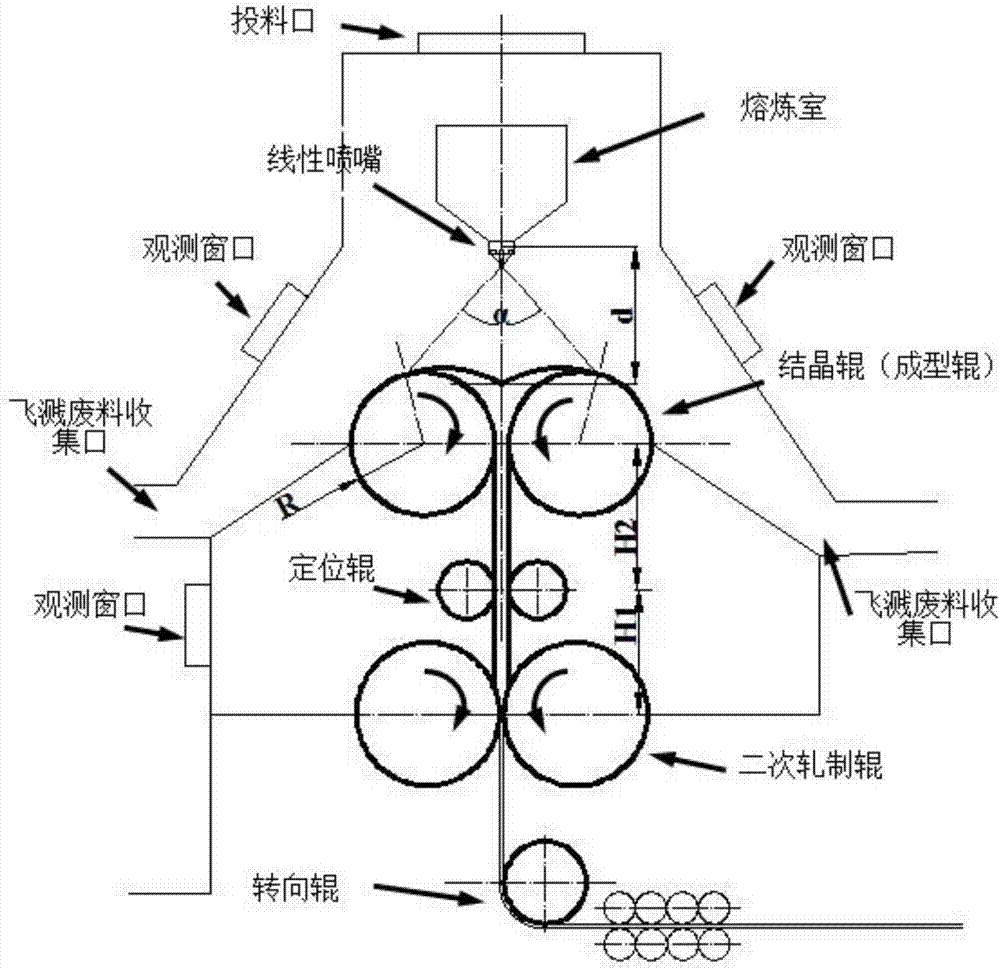

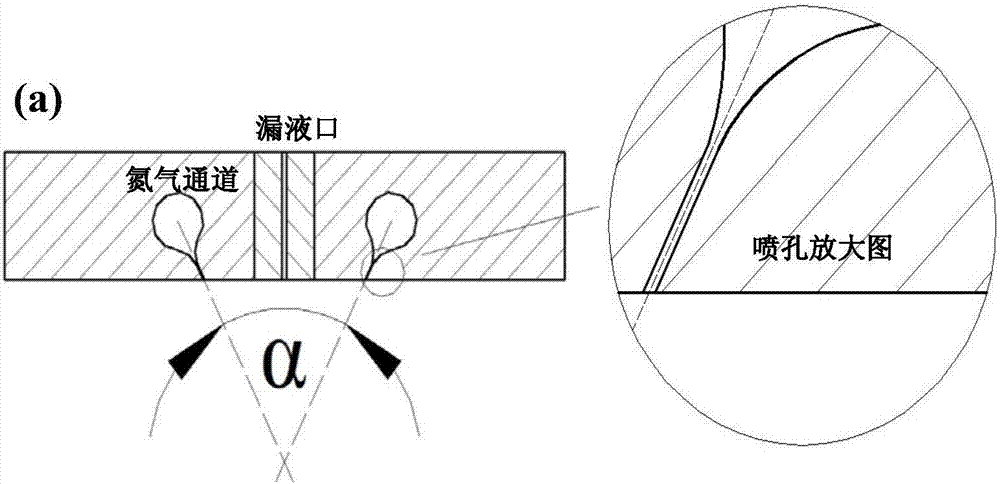

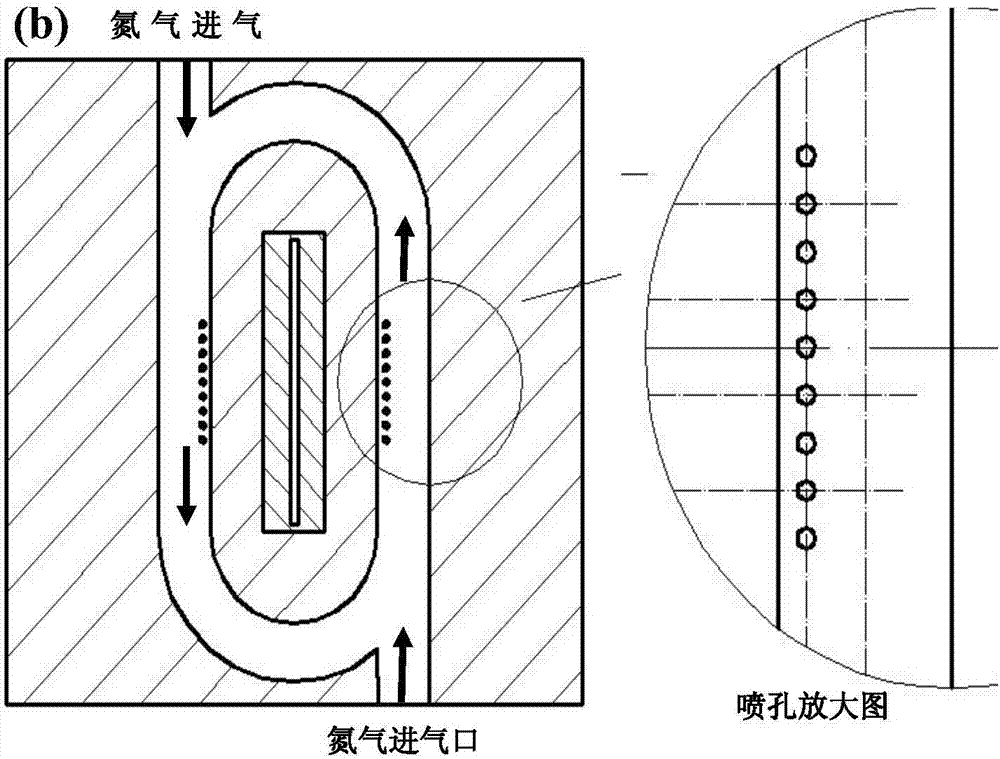

Jetting rolling equipment and method of application of jetting rolling equipment to aluminum alloy plate strip preparing process

The invention relates to jetting rolling equipment and a method of application of jetting rolling equipment to the aluminum alloy plate strip preparing process, and belongs to the development technical field of plate manufacturing equipment and application. The jetting rolling equipment is vertical jetting rolling equipment. The vertical jetting rolling equipment sequentially comprises a charging port, a smelting chamber, crystallization rollers, positioning rollers, secondary rolling rollers and a steering roller from top to bottom. A linear nozzle is arranged at the bottom of the smelting chamber and connected with the smelting chamber, and the linear nozzle is provided with a liquid leaking port and an air injection device. The liquid leaking port comprises a liquid inlet end and a liquid outlet end. The liquid outlet end is rectangular. The developed equipment and method are suitable for various series of aluminum alloys and particularly suitable for high-alloy-content aluminum alloys and belong to the aluminum alloy plate strip preparing and machining field.

Owner:长沙博朗思达金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com