Stepping continuous extrusion device and method for metal severe plastic deformation

A technology of plastic deformation and extrusion equipment, applied in the direction of metal extrusion dies, etc., to achieve the effects of eliminating tissue defects, eliminating large lengths, and eliminating large deformation loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

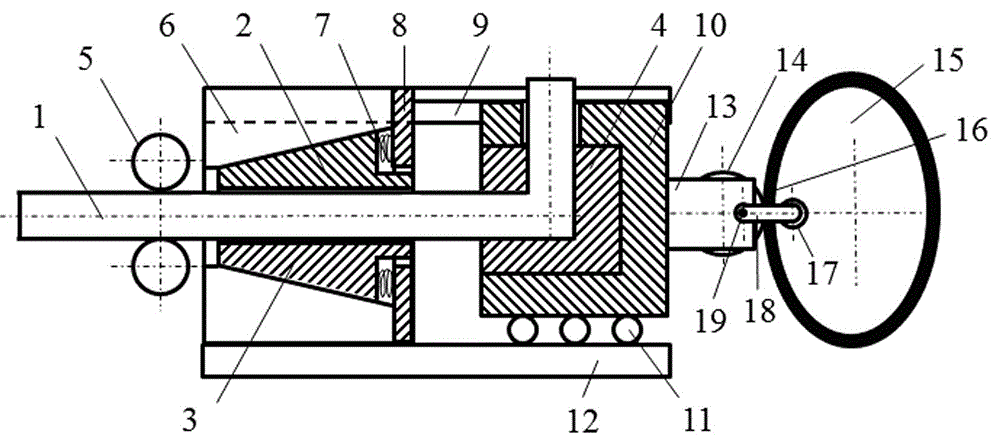

[0052] Step-by-step continuous extrusion devices for severe plastic deformation of metals such as figure 1 As shown, it includes the mold part and the fixture part; the fixture part is composed of the upper fixture 2, the lower fixture 3, the fixture seat 6, the fixing plate 8 and the spring 7, the upper fixture 2 and the lower fixture 3 are wedge-shaped fixtures, the upper and lower fixtures The space between constitutes the channel of the deformed part; wherein the height of the outlet end of the upper clamp 2 is greater than the height of the inlet end, and the height of the outlet end of the lower clamp 3 is greater than the height of the inlet end; Sliding connection, a fixing plate 8 is installed on the fixture seat 6, and the fixing plate 8 is located on the side of the outlet end of the deformation member channel, and two springs 7 are also fixed on the fixing plate 8 to connect with the upper fixture 2 and the lower fixture 3 respectively;

[0053] The mold part is co...

Embodiment 2

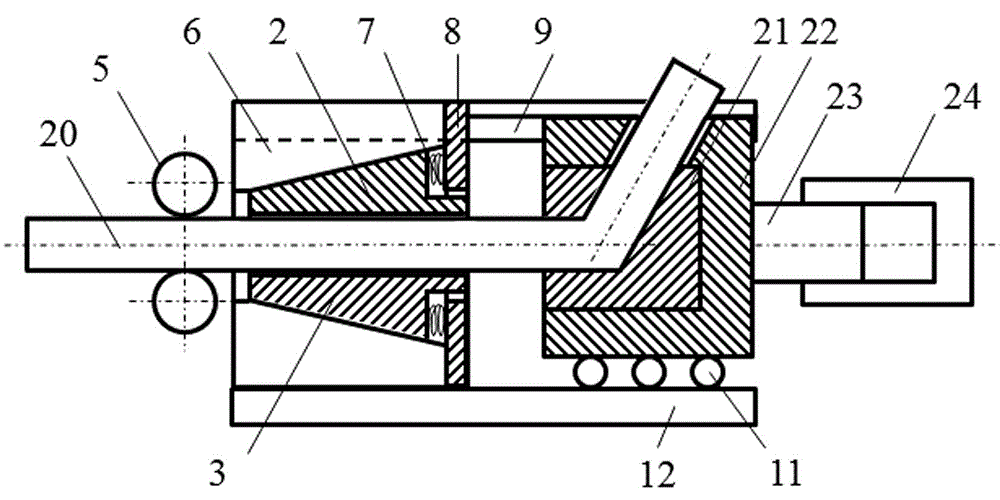

[0107] The structure of the step-by-step continuous extrusion device for severe plastic deformation of metals is as follows: figure 2 As shown, the mold driving device is a hydraulic driving device, which mainly includes a hydraulic cylinder 24 and a piston 23; the mold is a 120° channel mold 21, the mold seat is a 120° channel mold seat 22, and the piston 23 and the 120° channel mold seat 22 are fixed together , the angle between the axis of the front passage of the corner passage and the axis of the rear passage is 120o; the length of the front passage is 20mm; the rest are the same as in embodiment 1;

[0108] The semi-continuous casting 6061 aluminum alloy is used as the deformed part, the size is 5 mm × 30 mm × 100 mm, the structure is a rose-shaped grain structure, and the average grain size is 150 μm; the method of extrusion deformation is the same as that of Example 1, the difference is: ( 1) Set the height of the channel of the deformed part to be 99% of the thicknes...

Embodiment 3

[0112] The structure of the step-by-step continuous extrusion device for severe plastic deformation of metal is the same as that of Embodiment 1, except that the angle between the slope outside the fixture and the channel axis of the deformed part is 11o;

[0113] Pure aluminum is used as the deformed part, the size is 5mm × 50mm × 380mm, and the average grain size is 120μm; the method of extrusion deformation is the same as that of Example 1, the difference is: (1) the height of the channel of the deformed part is set to be the thickness of the deformed part 97%; (2) After 8 times of extrusion deformation, the deformed part obtained ultra-fine-grained aluminum with an average grain size of 255nm; annealing at 160°C for 6 minutes stabilized the microstructure; (3) The deformation of the deformed part during extrusion deformation The maximum deformation load is 18.2T, the deformation amount in a single pass is 0.9, and the deformation rate is 14.4s -1 ;

[0114] The deformatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com