Variable-channel extrusion die and forming method

A technology of extrusion die and variable channel, applied in the direction of metal extrusion die, metal extrusion mandrel, etc., can solve the problems of cracks, uniform control, unsatisfactory stress state of deformed billets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

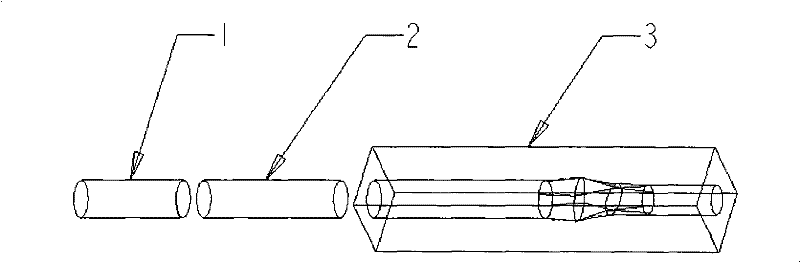

[0026] In this embodiment, a variable-channel extrusion die is used to extrude a prefabricated workpiece of Aermet100 high-nickel-cobalt secondary-hardening ultra-high-strength steel. The specification of the blank 2 for forming the prefabricated workpiece is 100mm×400mm, the prepared specifications are 80mm×625mm prefabricated workpiece. The extrusion process parameters are extrusion speed of 10mm / s, deformation temperature of 900-1000°C, and coefficient of friction between the billet 2 and the die 3 of 0.2-0.4.

[0027] The variable-channel extrusion die used in this embodiment mainly includes a punch 1 and a die 3 . Both punch 1 and die 3 are made of 5CrNiMo steel. The punch 1 is cylindrical, one end is the clamping and fixed end of the extrusion equipment, and the other end is the extrusion working end; the external dimensions of the working part of the punch 1 are the same as those of the billet 2.

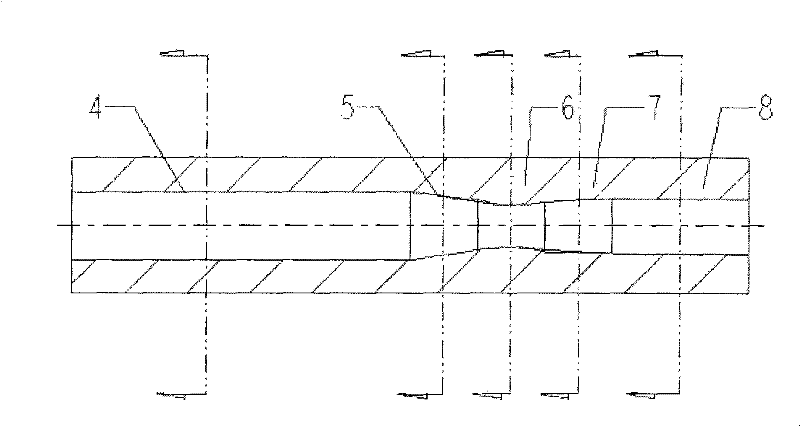

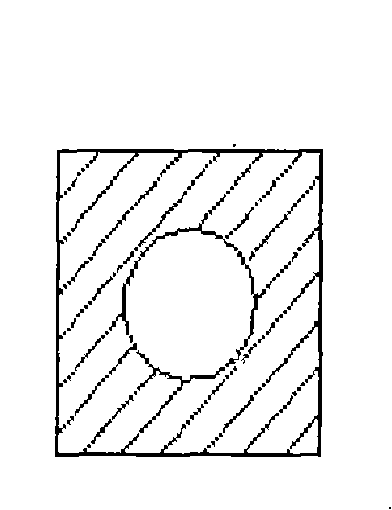

[0028] Such as figure 2 As shown, the die 3 is a hollow square c...

Embodiment 2

[0037] In this embodiment, a variable-channel extrusion die is used to extrude a prefabricated workpiece of Aermet100 high-nickel-cobalt secondary-hardening ultra-high-strength steel. The specification of the blank 2 for forming the prefabricated workpiece is 120mm×450mm, the prepared specifications are 100mm×648mm prefabricated workpiece. The extrusion process parameters are extrusion speed of 1mm / s, deformation temperature of 900-1000°C, and coefficient of friction between the billet 2 and the die 3 of 0.2-0.4.

[0038] The variable-channel extrusion die used in this embodiment mainly includes a punch 1 and a die 3, both of which are made of 5CrMnMo steel. The punch 1 is cylindrical, one end is the clamping and fixed end of the extrusion equipment, and the other end is the extrusion working end; the external dimensions of the working part of the punch 1 are the same as those of the billet 2.

[0039] The die 3 is hollow cylindrical, and its external dimensions must meet...

Embodiment 3

[0048] In this embodiment, a prefabricated workpiece of Ti-6Al-4V titanium alloy is extruded by a variable-channel extrusion die. The specification of the blank 2 for forming the prefabricated workpiece is 110mm×400mm, the prepared specifications are 85mm×670mm prefabricated workpiece. The extrusion process parameters are extrusion speed of 5mm / s, deformation temperature of 850-950°C, and coefficient of friction between the billet 2 and the die 3 of 0.2-0.4.

[0049] The variable-channel extrusion die used in this embodiment mainly includes a punch 1 and a die 3, both of which are made of 5CrNiMo steel. The punch 1 is cylindrical, one end is the clamping and fixed end of the extrusion equipment, and the other end is the extrusion working end; the external dimensions of the working part of the punch 1 are the same as those of the billet 2.

[0050] The die 3 is hollow cylindrical, and its external dimensions must meet the strength requirements of extrusion. The hollow par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com