A kind of forging method of superalloy gh4099

A technology of GH4099 and high-temperature alloy, which is applied in the field of high-temperature alloy forging, can solve the problems of uneven heating of steel ingots, reduce hot-working plasticity, deformation cracking, etc., improve the distribution of carbides and grains, improve process performance and serviceability , Improve the effect of forging yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A batch of GH4099 steel ingots was homogenized for 48 hours at a temperature of 1150 °C, and the forging furnace was heated at the same time. When the temperature in the forging furnace was 480 °C, the steel ingots were placed in the forging furnace for forging heating, and the burning natural gas was guaranteed to be Neutral, then slowly heat up to 900°C for 5h, and keep for 2h; slowly heat again for 3h to 1150°C, and keep for 1.5h; then forge the heated ingot, with a deformation amount of 10% per fire, and then put it into forging After the furnace is kept for a period of time, forging is performed again until the forging of all the ingots in the batch is completed, and the ingots are placed in the preheated hot furnace to be air-cooled to room temperature.

[0036] The yield of this batch of ingots is 60%.

Embodiment 2

[0038] A batch of GH4099 steel ingots was homogenized for 48 hours at a temperature of 1150 °C, and the forging furnace was heated at the same time. When the temperature in the forging furnace was 450 °C, the steel ingots were placed in the forging furnace for forging heating, and the burning natural gas was guaranteed to be Neutral, then slowly heated for 4.6h to 910°C, and kept for 1.5h; then slowly heated again for 2.5h to 1140, and kept for 1.5h; then the heated ingot was forged, the deformation amount per fire was 12%, and then After being placed in the forging furnace for a period of time, forging is carried out again until the forging of all the ingots in the batch is completed, and the ingots are placed in the preheated hot furnace to be air-cooled to room temperature.

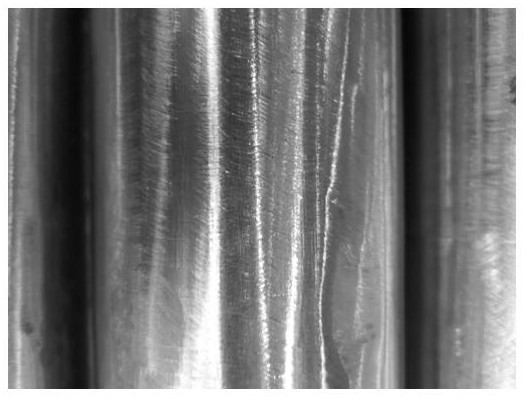

[0039] The yield of this batch of ingots is 60.5%. Forged steel ingots such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com