Patents

Literature

75 results about "Neutral atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing hot-rolled ferritic stainless steel strip steel

InactiveCN101245435AFree from common surface defectsNo surface defectsRoll mill control devicesHeat treatment process controlSurface finishChemical composition

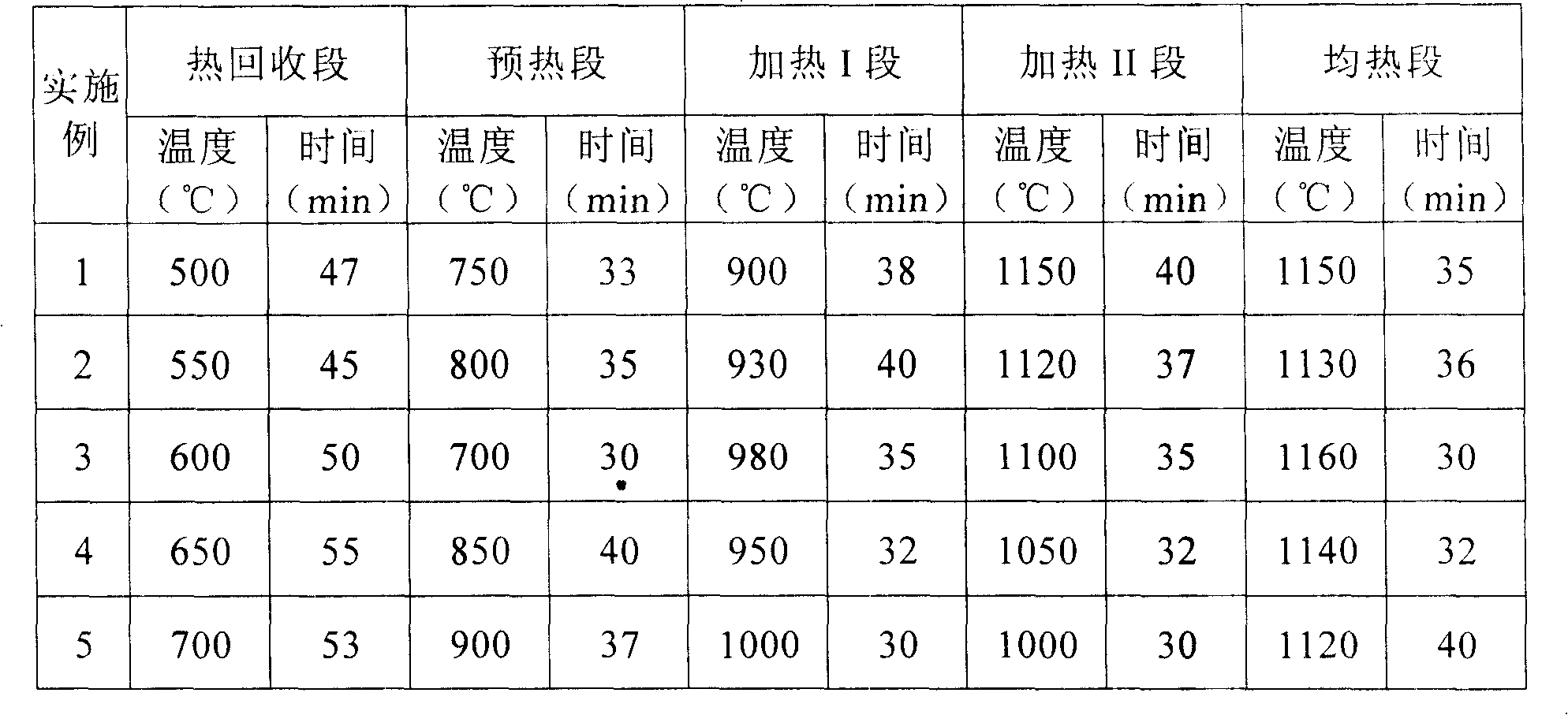

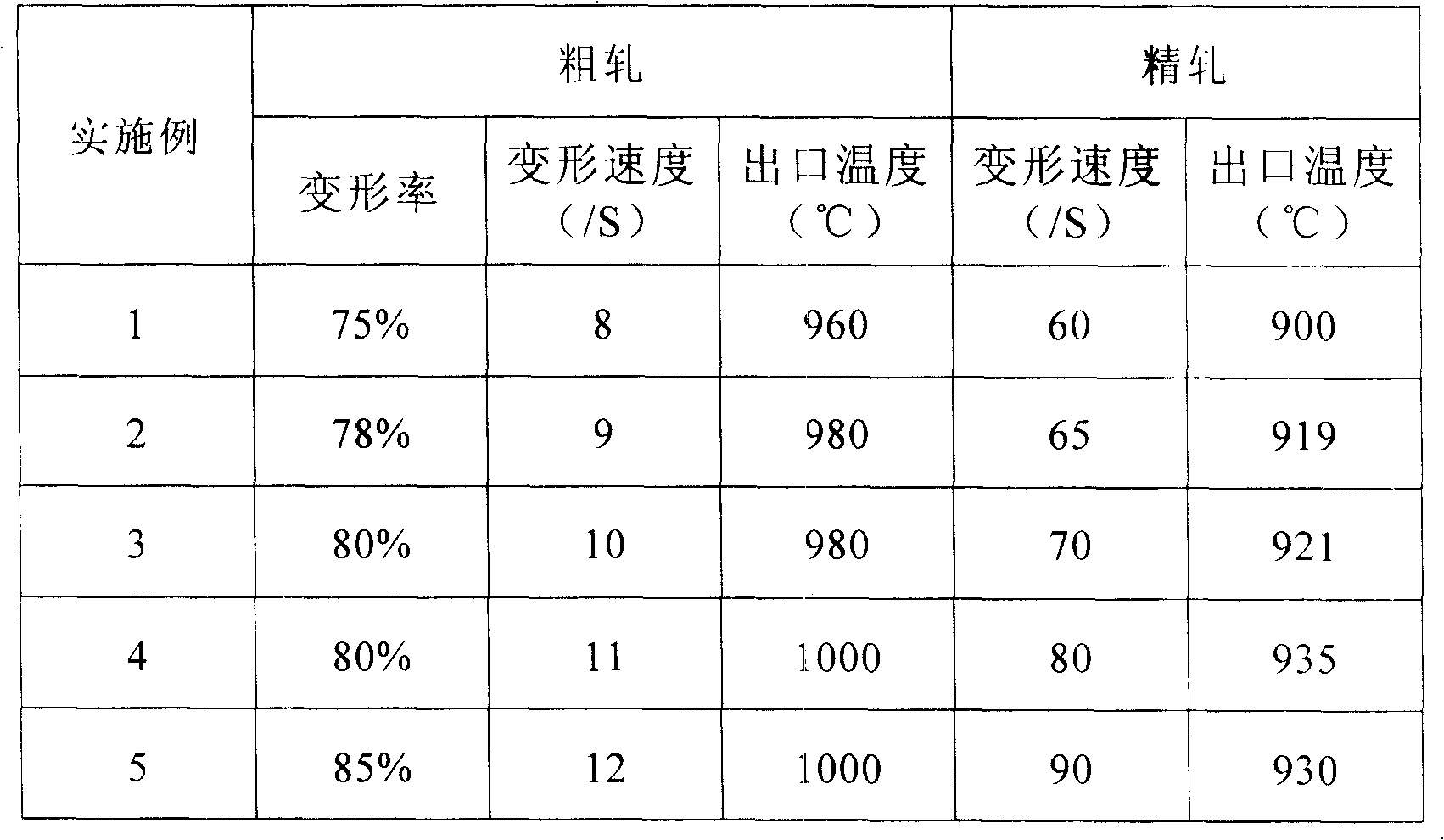

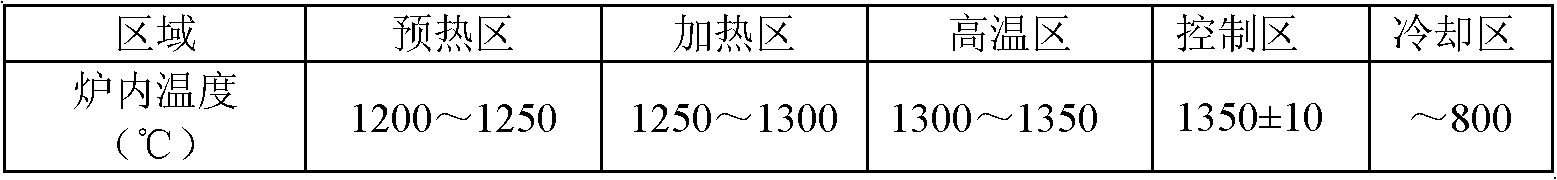

The invention discloses a method for producing a hot-rolled ferrite stainless strip steel, which comprises the following steps: 1) the chemical components by weight percentage are: 0.025-0.04 percent of C, less than or equal to 1.00 percent of Si, 0.25-0.4 percent of Mn, less than or equal to 0.030 percent of S, less than or equal to 0.035 of P, 12-12.5 percent of Cr and the rest is Fe; 2) a billet is formed by smelting and casting; 3) heating: the heating temperature zone for heating are divided into a heat recovery section, a preheating section, a I heating section, a II heating section and a holding section; furnace gas is controlled to be neutral atmosphere of non-oxidizing atmosphere; 4) when in heat rolling and rough rolling, the rolling temperature is 1,120 DEG C-1,160 DEG C, and the deforming speed during rolling is 10 / s-12 / s; 5) finish rolling: the deforming speed of the last pass rolling is 60 / s-90 / s, and the outlet temperature of the finish rolling is more than 900 DEG C; 6) cooling is carried out after rolling, and then reeling is carried out. The method of the invention has the advantages that the method guarantees not only the edge quality of the hot-rolled strip steel but also the stamping property of the cold-rolled strip steel, improves the surface finish quality and lowers the production cost, and has high production efficiency and rolling yield, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

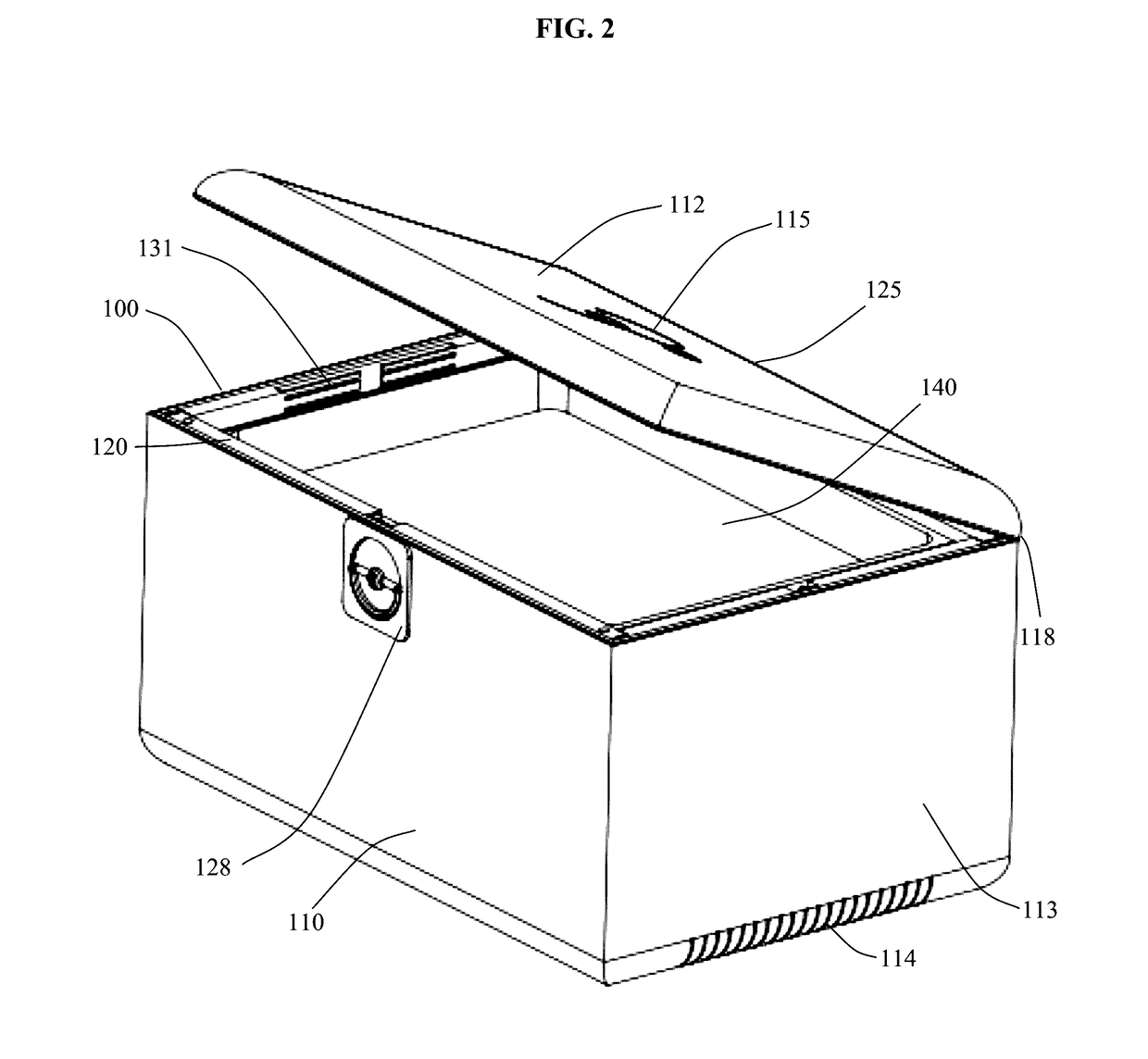

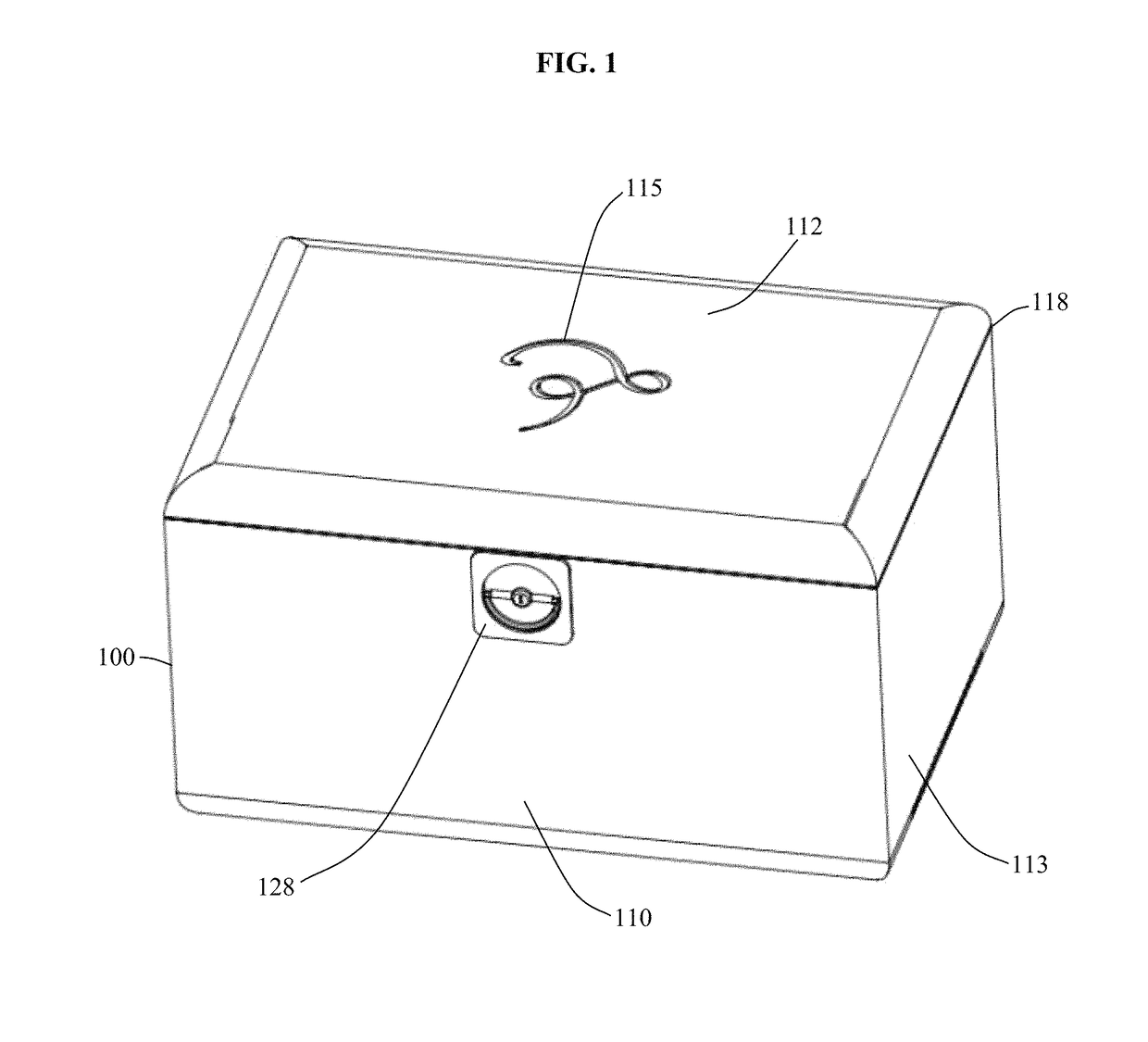

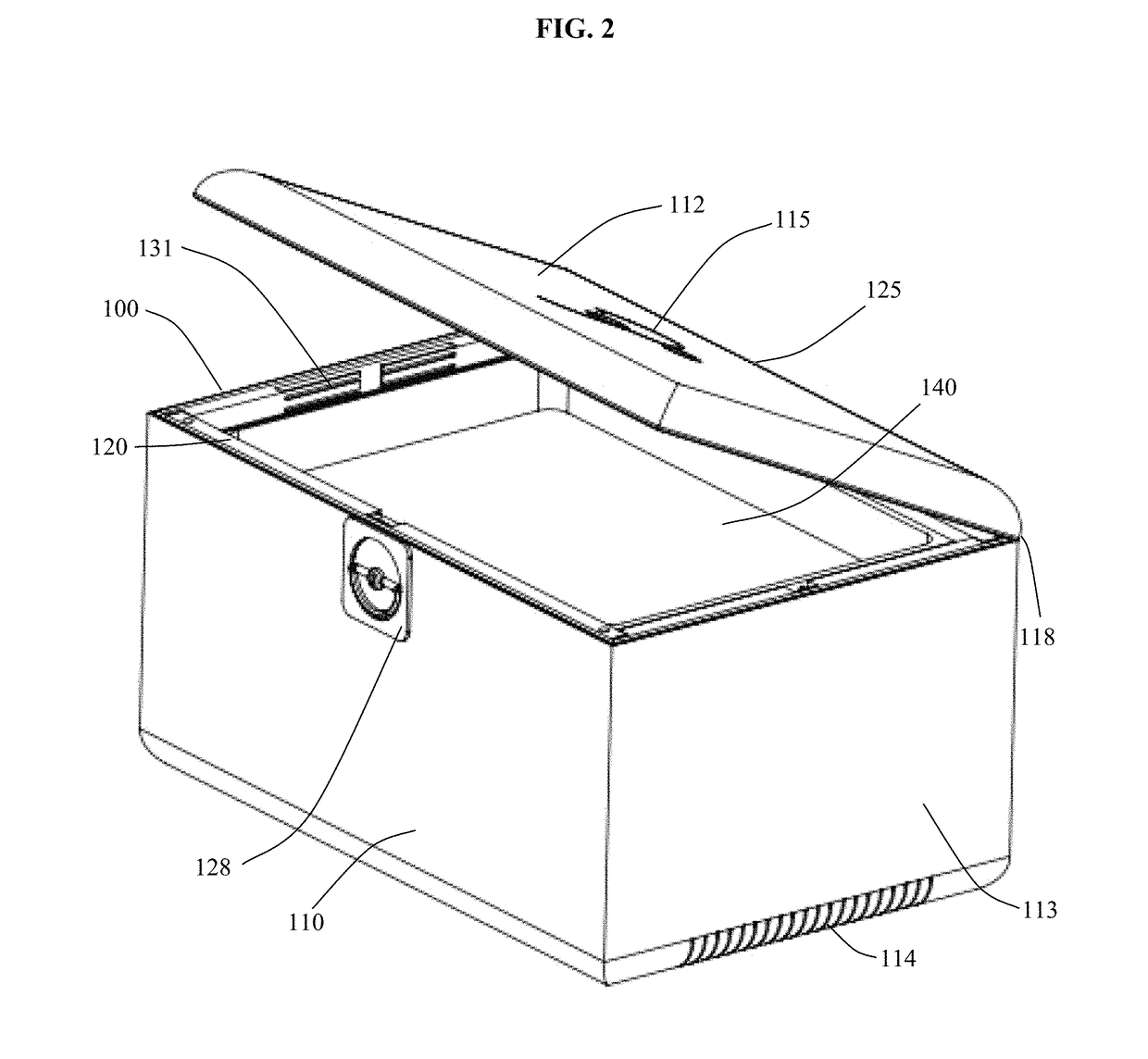

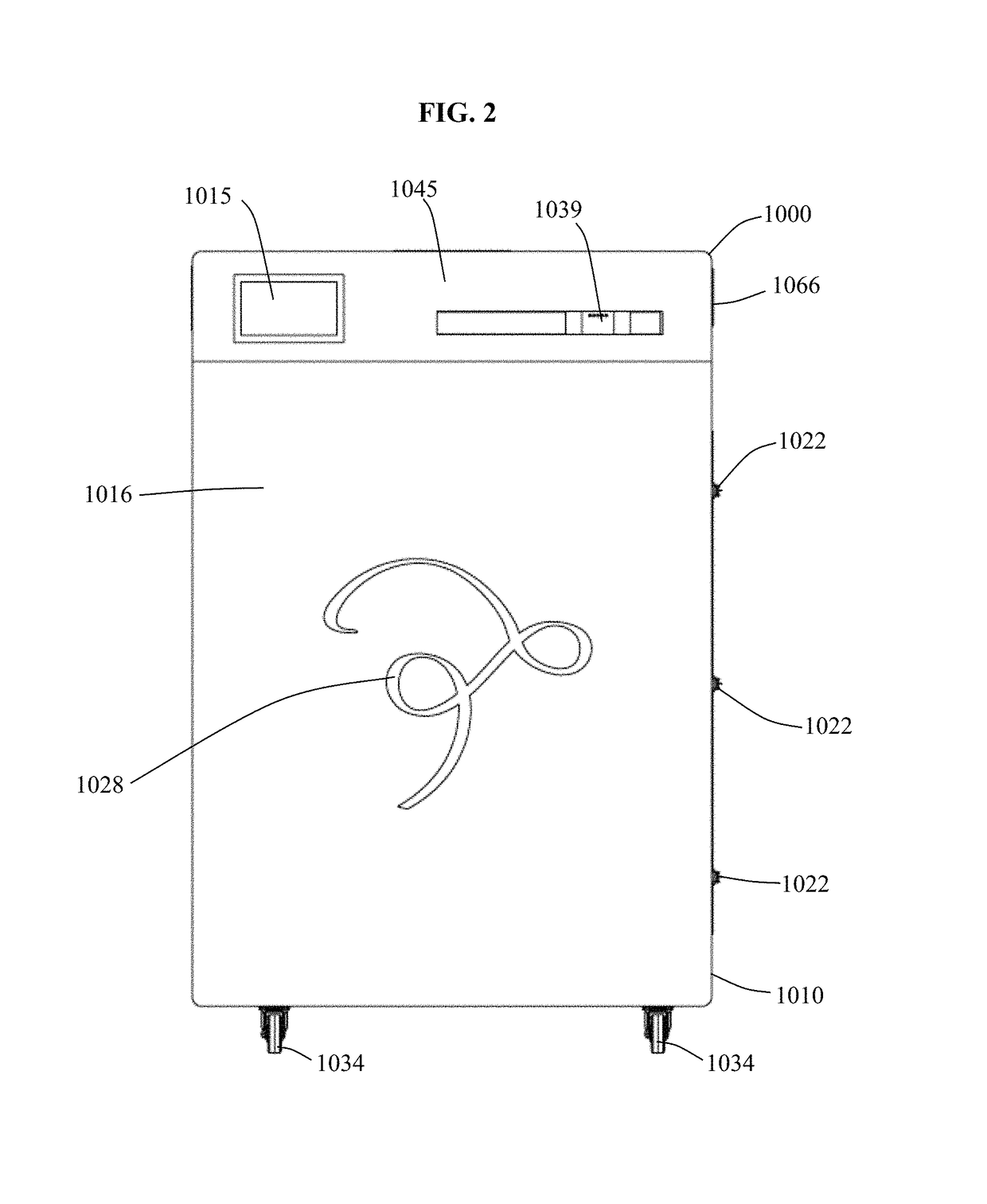

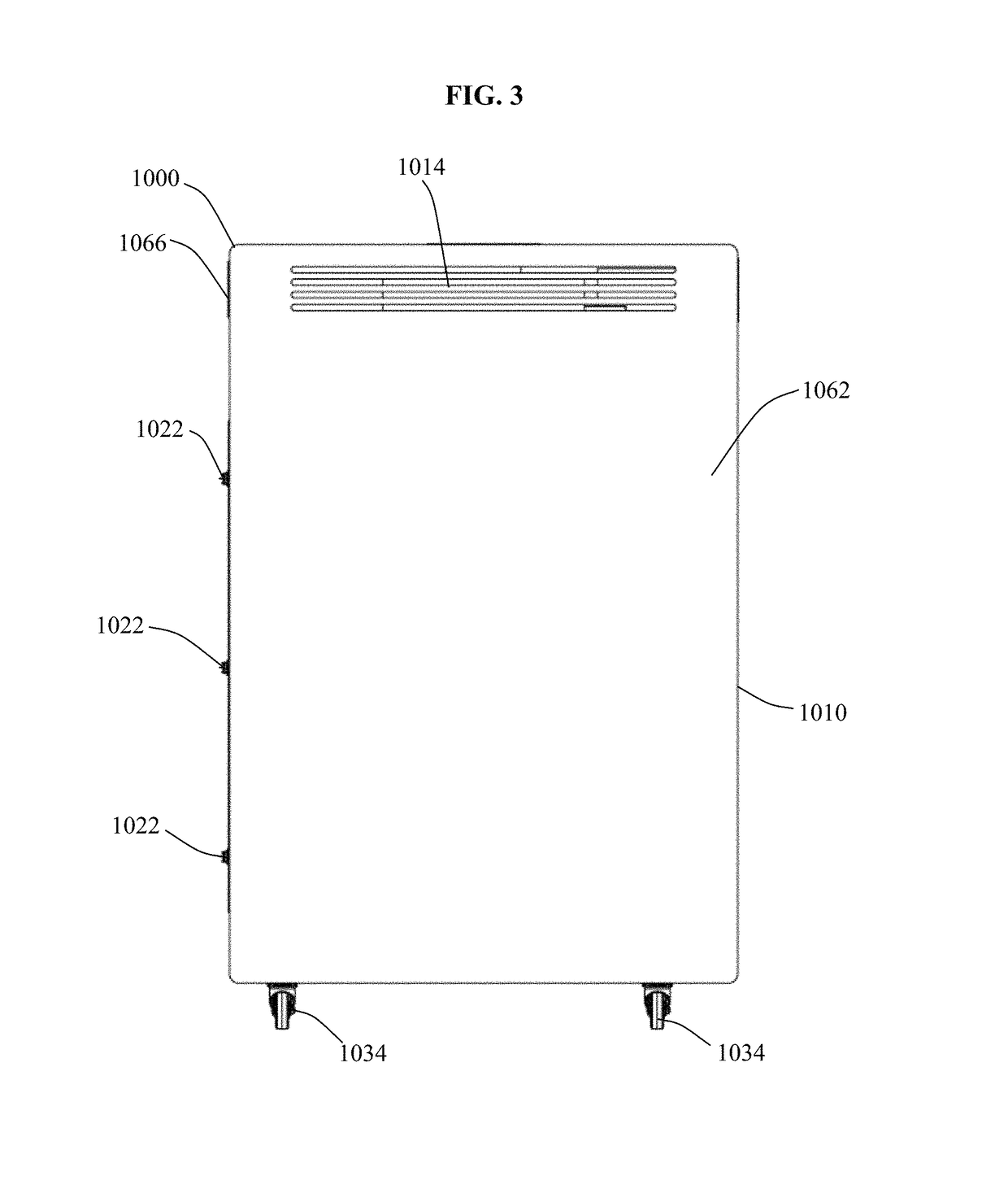

Neutral Atmosphere and Sanitization Storage Apparatus, Method and System

ActiveUS20170096279A1High saturationMaintain qualityLiving organism packagingNetwork topologiesWeb applicationNeutral atmosphere

Disclosed herein are an apparatus, method and system for storing perishable items that degrade in the presence of oxygen and / or humidity and that are frequently accessed by a consumer. The apparatus comprises an openable vessel, which becomes airtight when closed, and an UV light source and fan within the airtight enclosure, which converts ambient oxygen trapped within the airtight enclosure into ozone by circulating the enclosed volume of air around the UV light source after the vessel is opened and then closed. The apparatus is network connected to allow for remote control and monitoring and sends alerts to web applications or mobile applications when monitored parameters substantially vary from their settings.

Owner:CAMPALANS ALFONSO +1

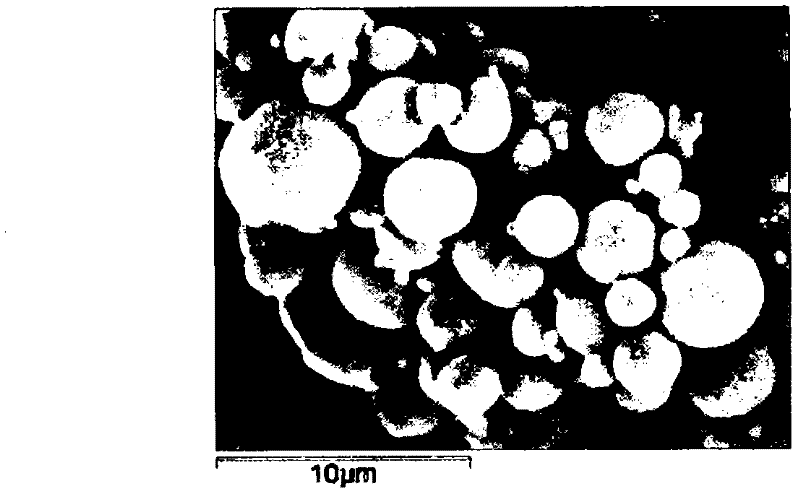

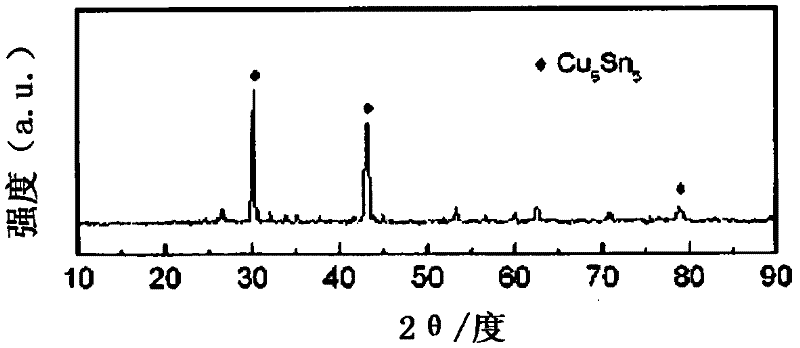

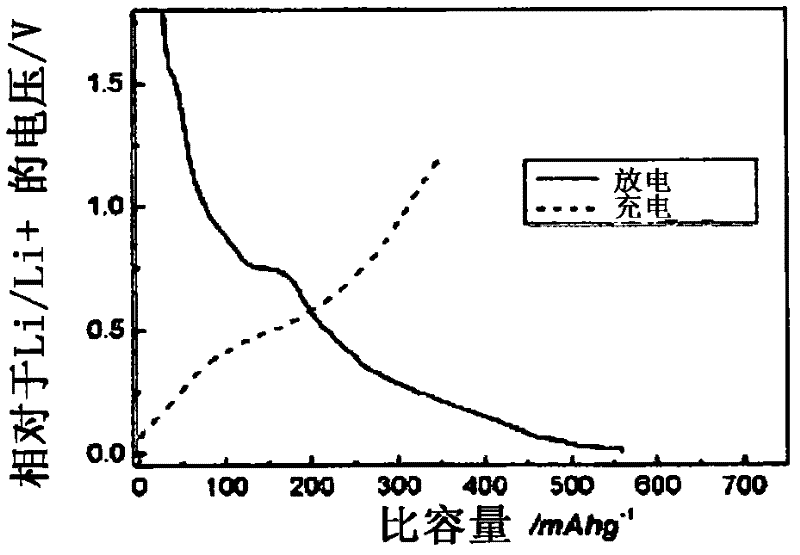

Process for preparing alloy composite negative electrode material for lithium ion batteries

InactiveCN102484241AImprove electrochemical performanceLow costElectrode manufacturing processesNeutral atmosphereAlloy composite

The present invention relates to a process for preparing an alloy composite negative electrode material having a spherical carbon matrix structure for lithium ion batteries by spray-drying carbothermal reduction. The invention covers a process for preparing a negative electrode material for a lithium ion battery with a general formula A-M / Carbon, wherein A is a metal selected from the group consisting of Si, Sn, Sb, Ge and Al; and wherein M is different from A and is at least one element selected from the group consisting of B, Cr, Nb, Cu, Zr, Ag, Ni, Zn, Fe, Co, Mn, Sb, Zn, Ca, Mg, V, Ti, In, Al, Ge; and comprising the steps of: - providing a solution comprising an organic polymer and either chemically reducible nanometric A- and M-precursor compounds, or nanometric Si and a chemically reducible M-precursor compound, when said metal A is Si; - spray-drying said solution whereby a A- and M-precursor bearing polymer powder is obtained, and - calcining said powder in a neutral atmosphere at a temperature between 500 and 1000 DEG C for 3 to 10 hours whereby, in this carbothermal reduction, a carbon matrix is obtained bearing homogeneously distributed A-M alloy particles.

Owner:UMICORE AG & CO KG +1

High purity metallurgical silicon and method for preparing same

InactiveUS20050053539A1Lower iron levelsEasy to operateSiliconFinal product manufactureForming gasNeutral atmosphere

The invention concerns a silicon designed in particular for making solar cells containing a total of impurities ranging between 100 and 400 ppm, a boron content ranging between 0.5 and 3 ppm, a phosphorus / boron content ratio ranging between 1 and 3, and a content of metal elements ranging between 30 and 300 ppm. The invention also concerns a method for making such a silicon from an oxygen- or chorine-refined metallurgical silicon containing at least 500 ppm of metal elements, and comprising: refusion under neutral atmosphere of the refined silicon, in an electric furnace equipped with a hot crucible; transferring the molten silicon, to provide a plasma refining, in an electric furnace equipped with a hot crucible; plasma refining with as plasma-forming gas a mixture of argon and of at least a gas belonging the group consisting of chlorine, fluorine, HCI and HF; casting under controlled atmosphere in an ingot mould wherein is produced segregated solidification.

Owner:CENT NAT DE LA RECHERCHE SCI +1

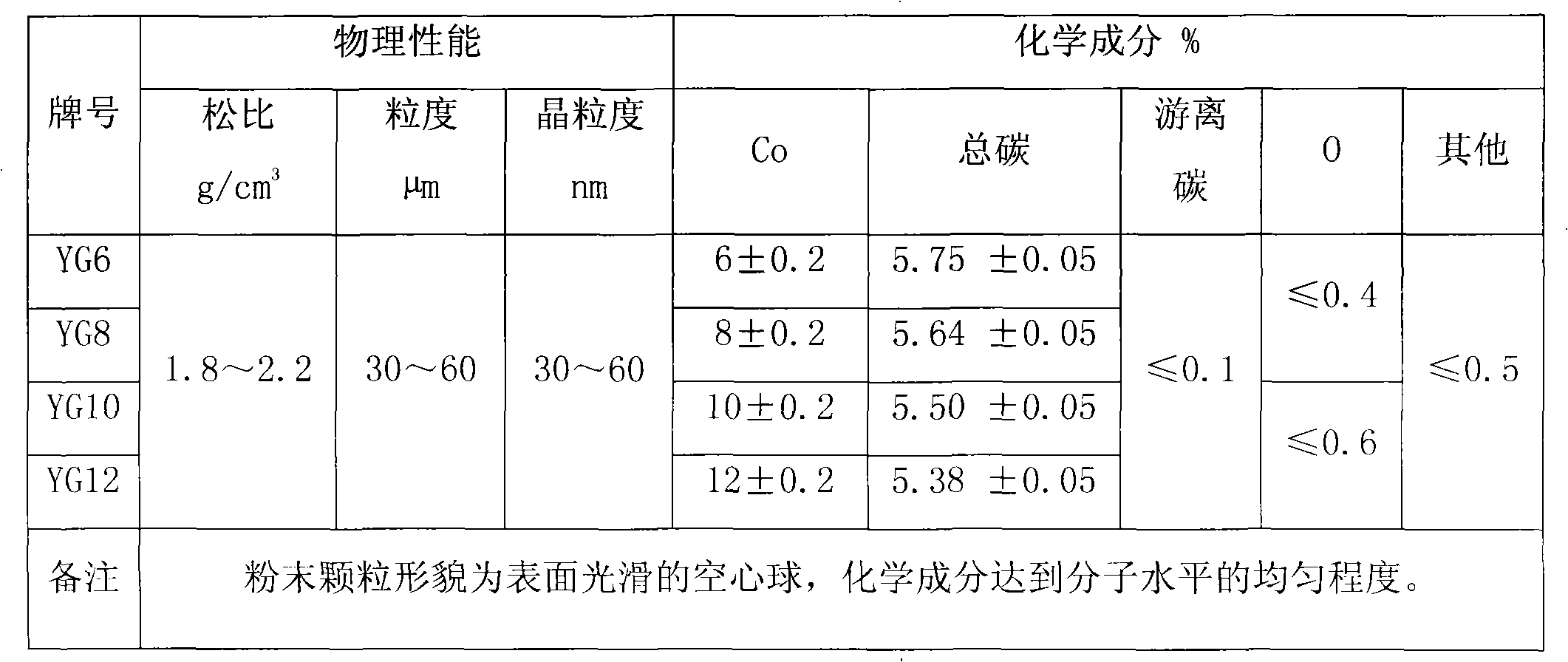

Preparation method of nanometer WC-Co composite powder

The invention discloses a preparation method of nanometer WC-Co composite powder. In the formula, soluble carbon source is directly added, carbon content is accurately controlled by regulating the hydrogen-carbon ratio of mixed gas in the carbonization and carbon regulation procedures. The specific steps are as follows: (1) according to the main ingredients of the WC-Co composite powder, calculating and weighing tungsten salt, cobalt salt and carbon source, dissolving the ingredients in water, evenly stirring, and preparing precursor solution; (2) preparing precursor pre-composite powder by spraying and drying mixed solution; (3) under the protection of neutral atmosphere, roasting the prepared precursor pre-composite powder to prepare original composite powder; (4) under the protection of hydrogen-carbon mixed gas, further carbonizing and regulating carbon for original composite powder at high temperature to prepare the nanometer WC-Co composite powder. The carbon element of the composite powder of the method has reasonable addition mode, easily precise control of carbon content, even chemical component, simple manufacturing technology and easy realization of industrial production.

Owner:FUJIAN JINXIN TUNGSTEN

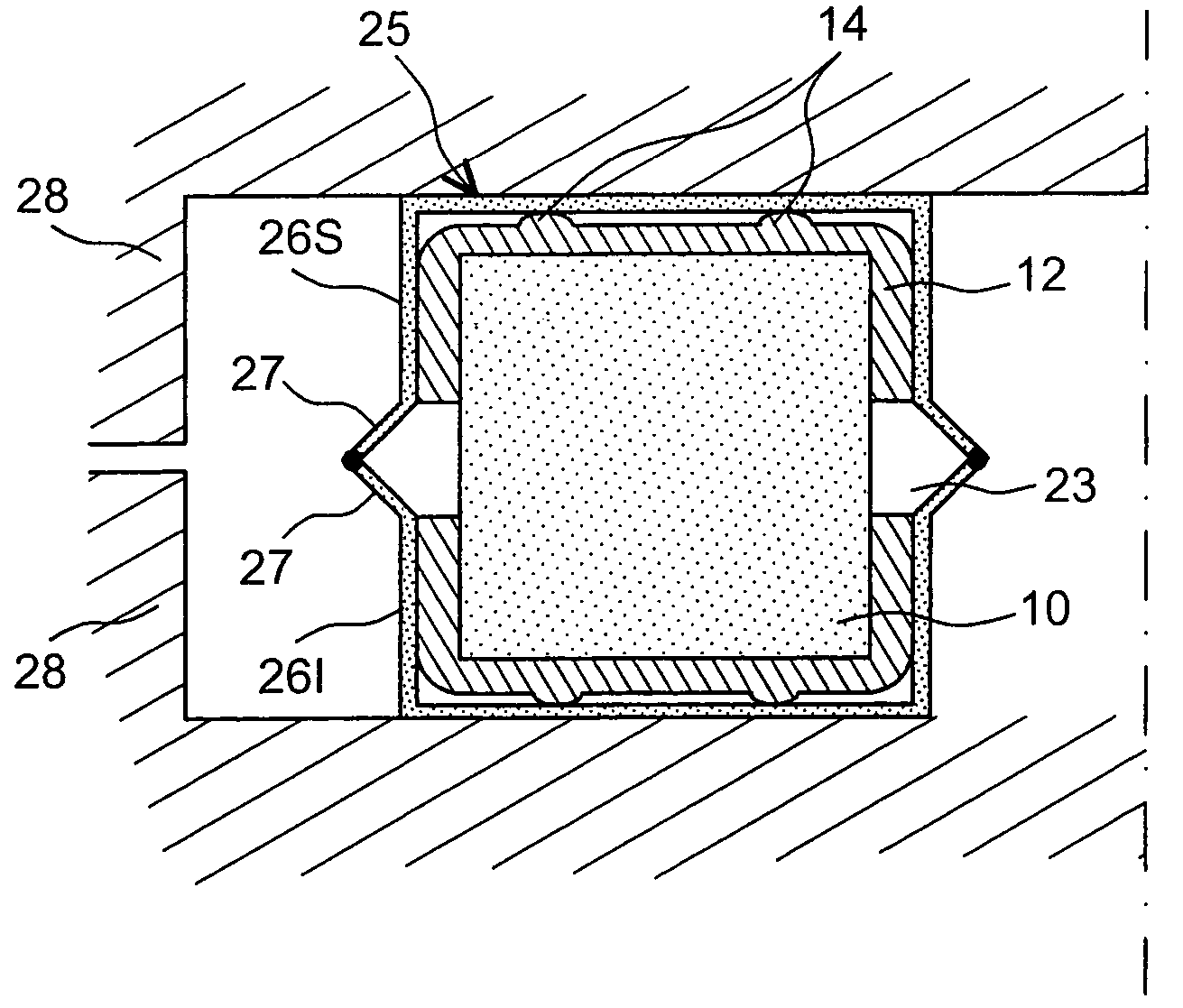

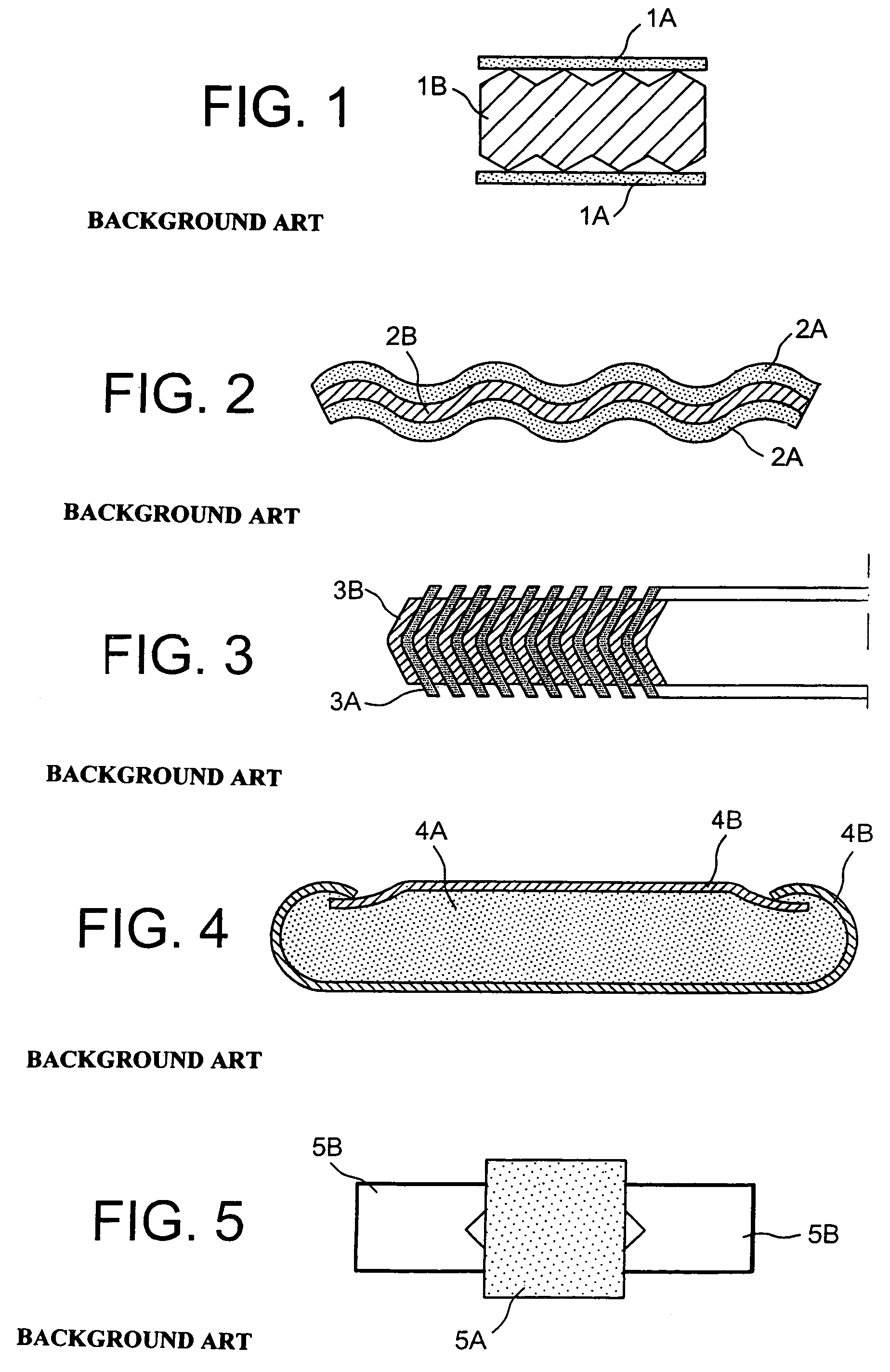

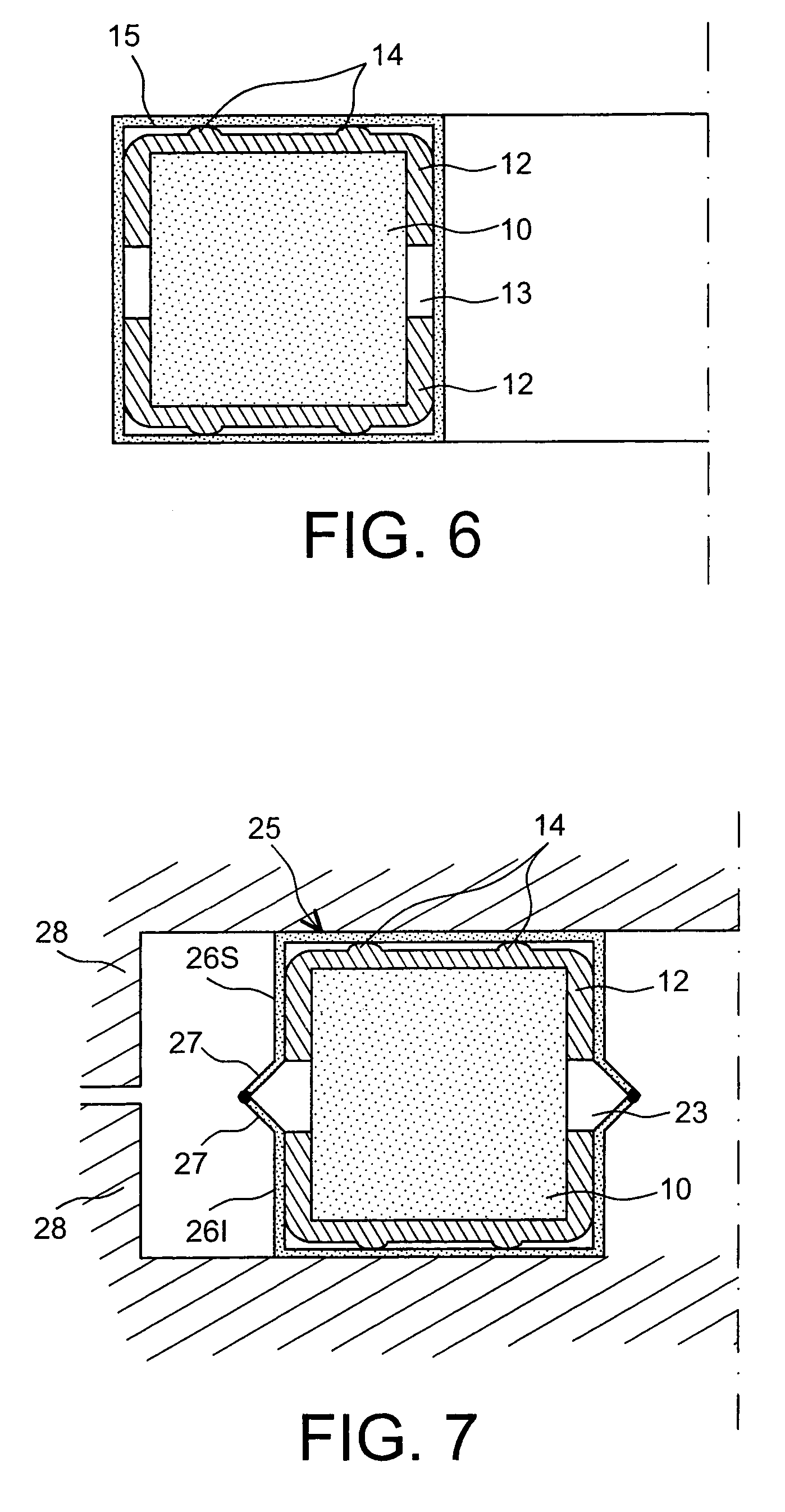

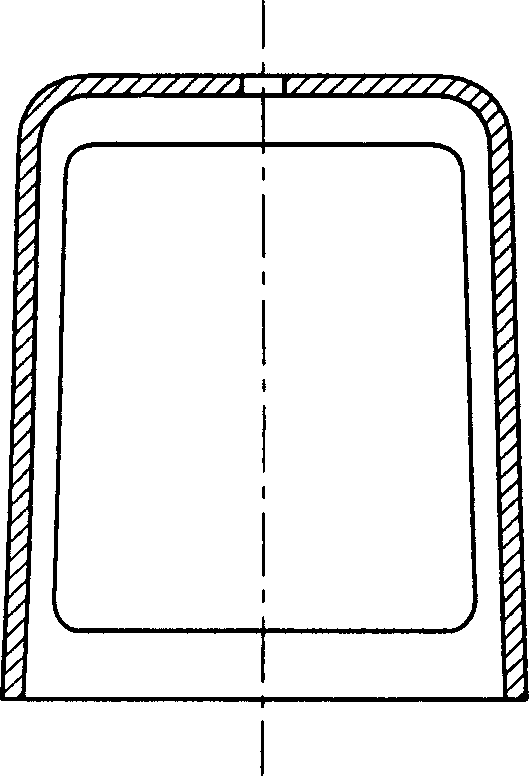

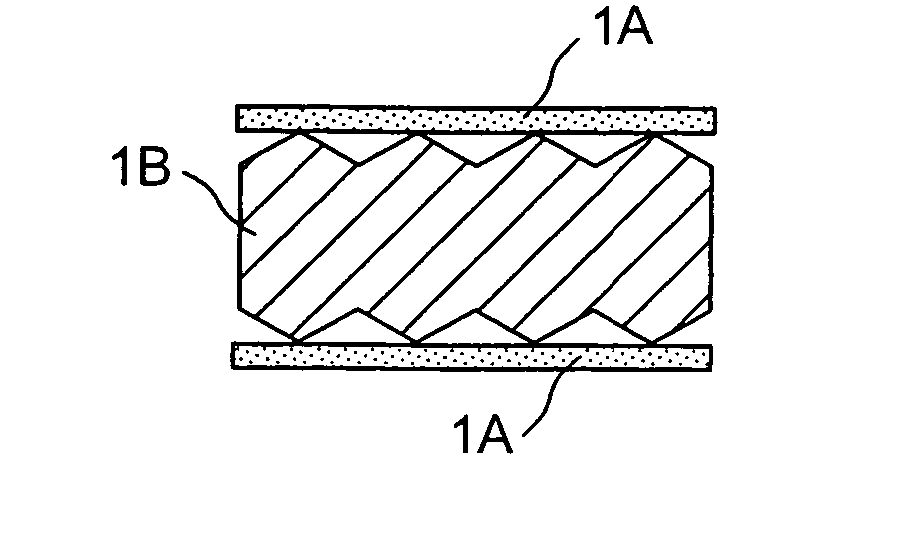

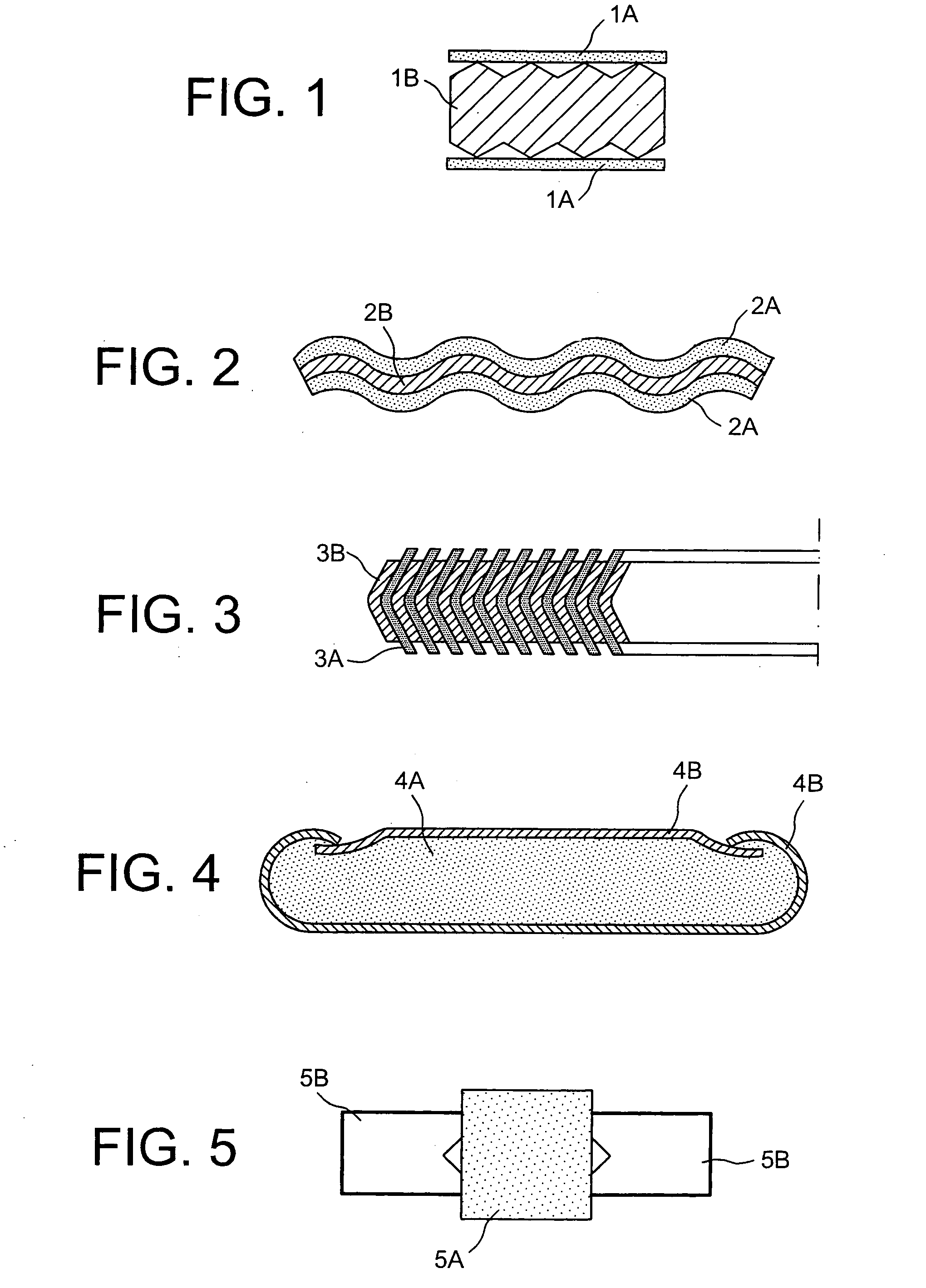

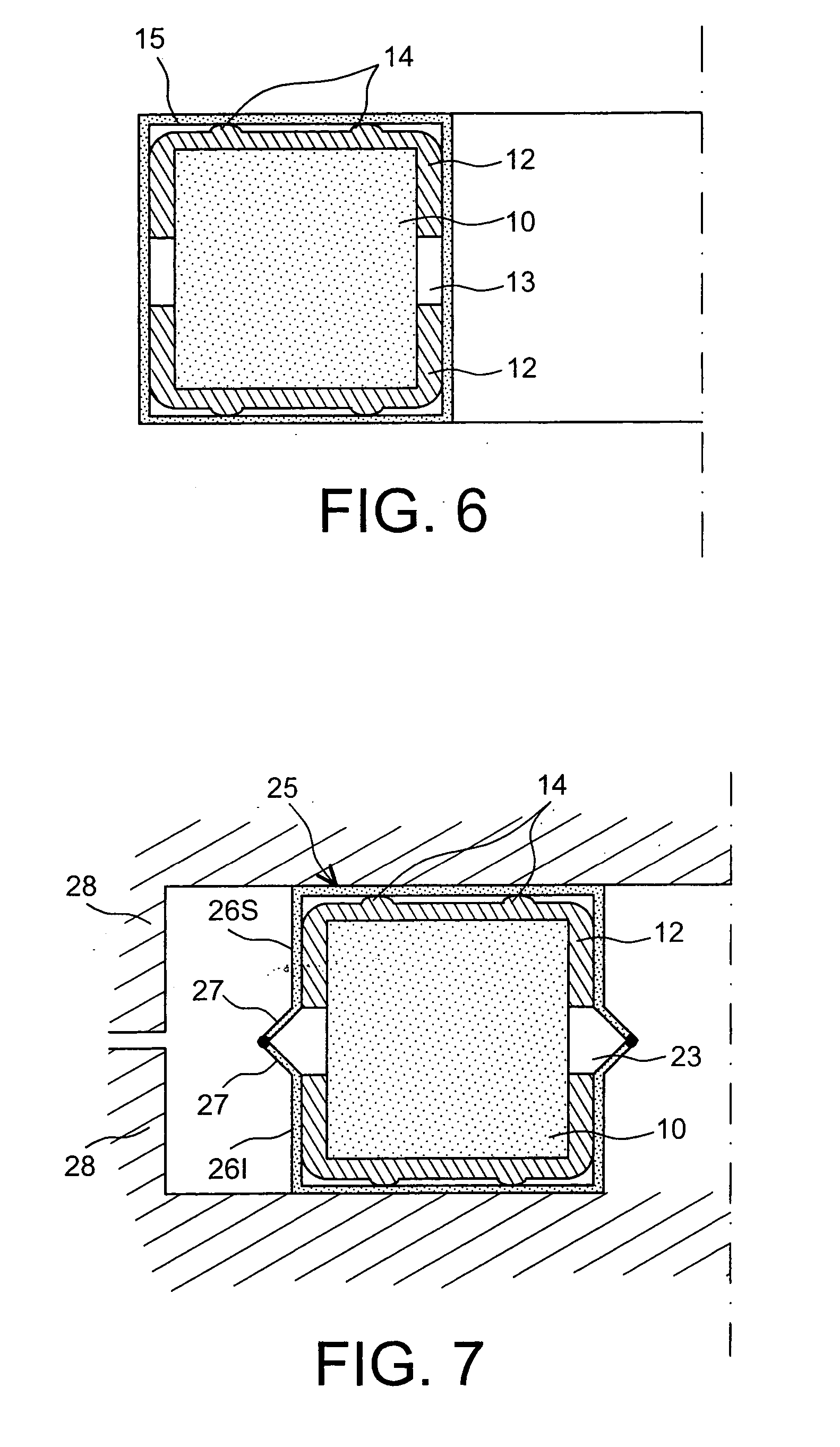

Flexible graphite sealing joint with metal jacket for high temperature

The seal can be used at high temperature. It is composed of a central flexible graphite core (10) maintained in its shape by two metal cups (12) that do not touch. It is all surrounded by a tight sheath (15) enabling the flexible core (10) to be maintained in a neutral atmosphere such as a partial vacuum or a neutral gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

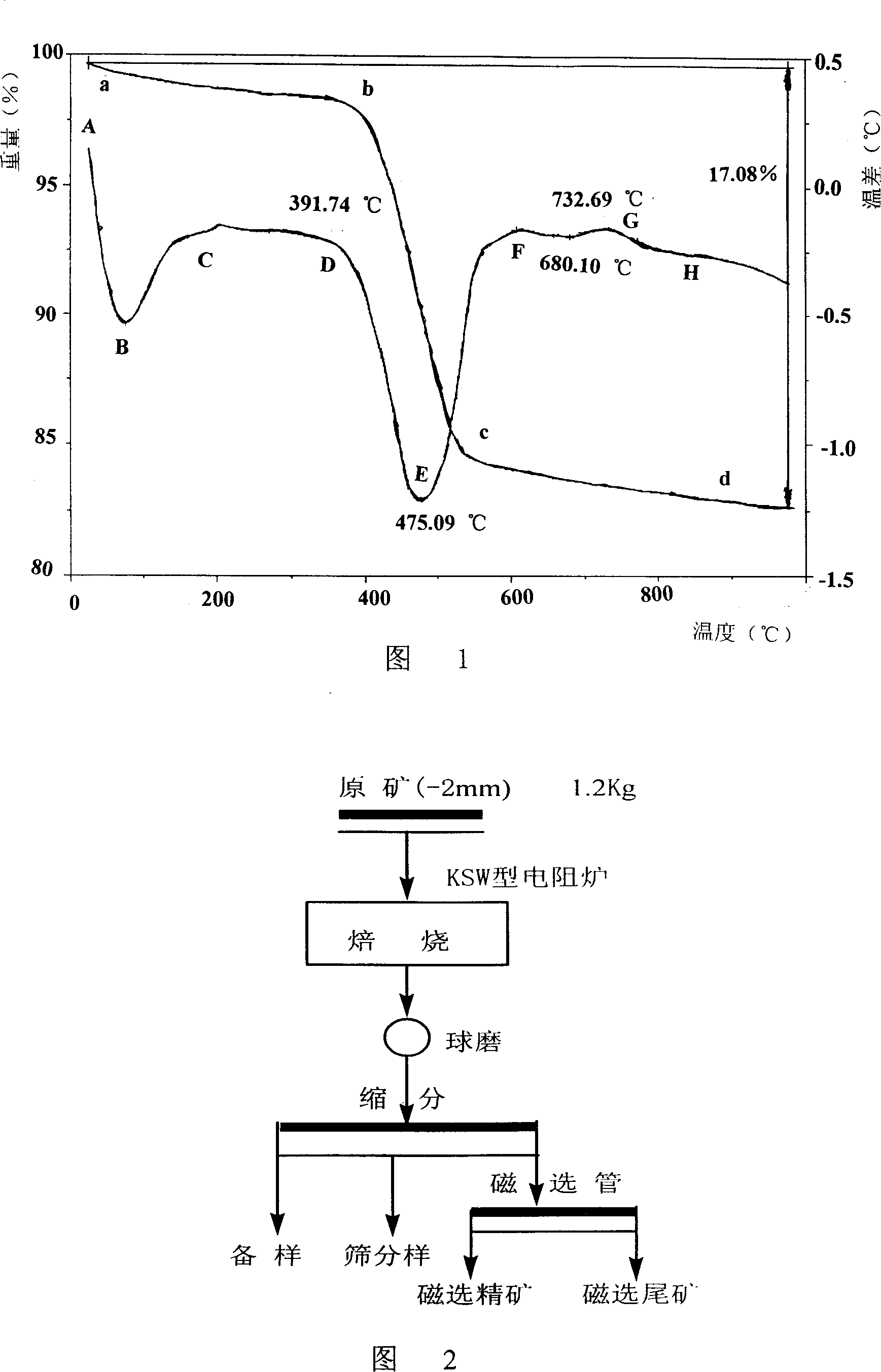

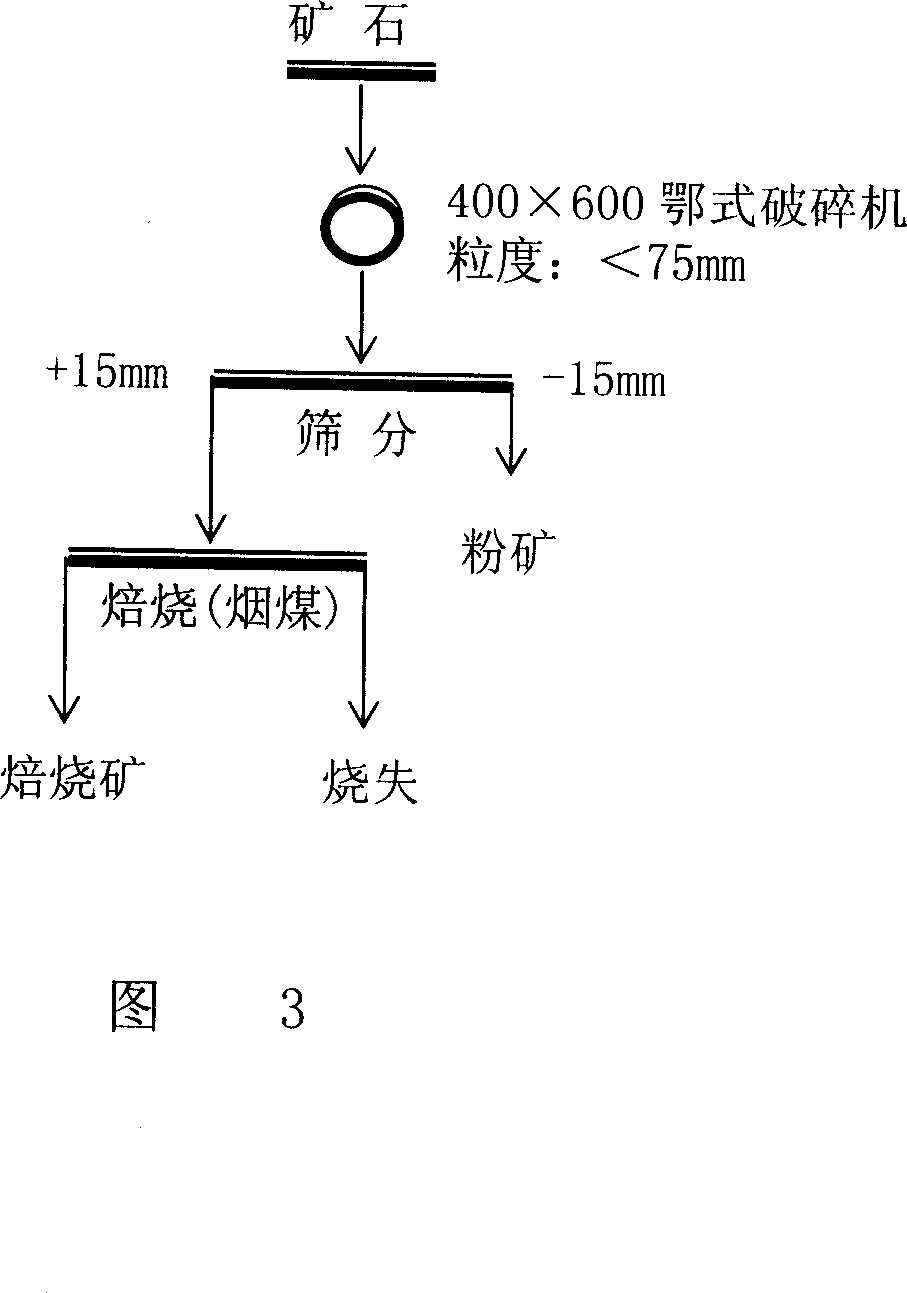

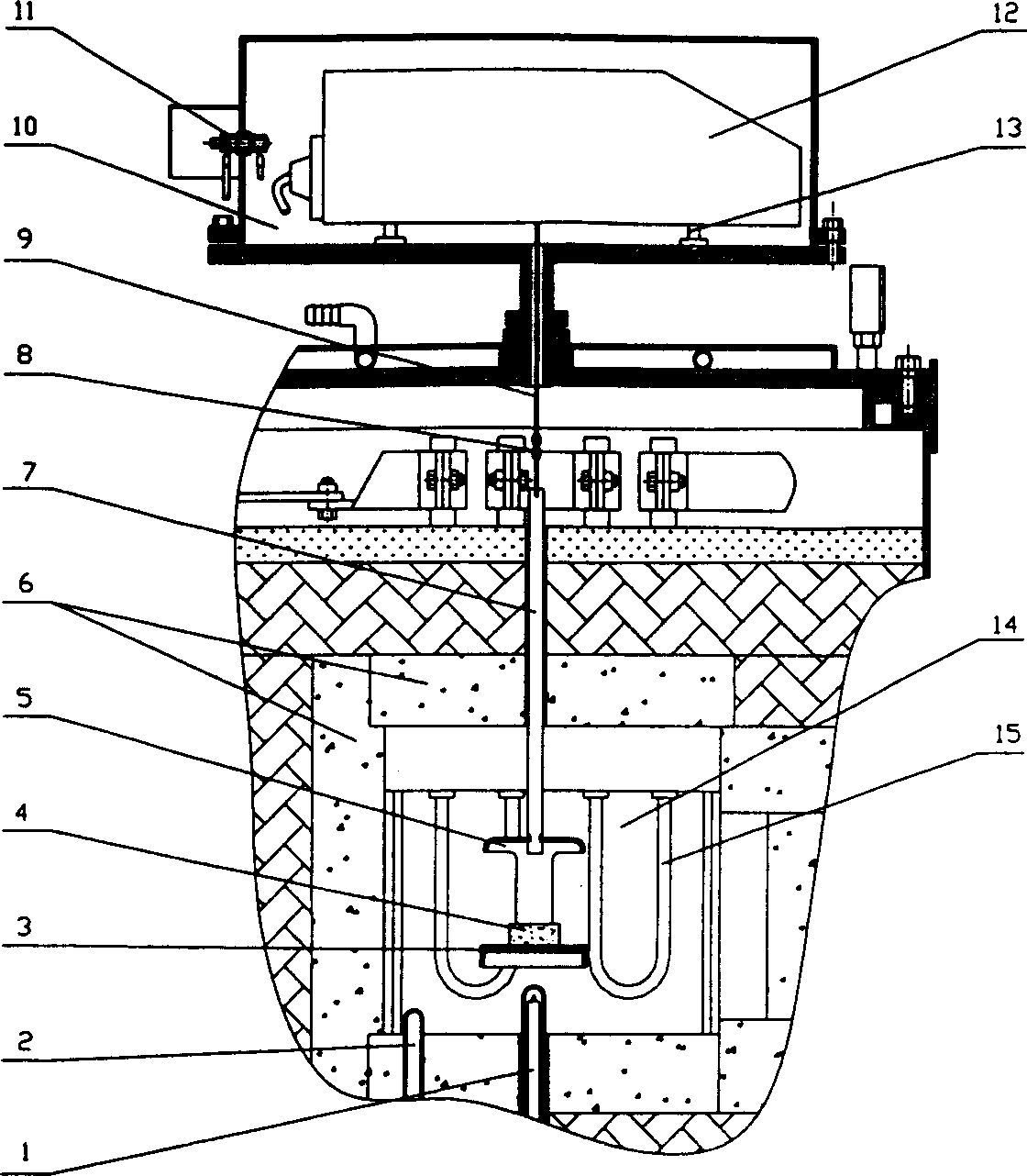

Iron ore roasting technique

The invention discloses an iron ore calcinations process, which comprises (1) detecting and regulating the weight proportions of siderite (FeCO3) and hematite (Fe2O3) in the iron ore, if the content of siderite (FeCO3) in the iron ore is low, the siderite (FeCO3) is added to allow the weight ratio of siderite to hematite is larger than or equal to 0.725; (2) crushing iron ore or a mixture of iron ore and siderite, sieving, and collecting ore particles with a grain size of 10-75mm; and (3) calcining at a temperature ranging from 720 DEG C to 900 DEG C under a negative pressure larger than 100mm water column. The inventive iron ore calcinations process has the advantages that the magnetic roasting of siderite is completed in a neutral atmosphere without using reducers and the CO gas with reducing capacity is released and serves as a reducer for the magnetic roasting of hematite; and the procedure of adding reducer is omitted, so that the consumption of reducer such as powdered coal is reduced and the calcinations cost is saved. The invention can better utilize the siderite (limonite)-siderite mixed iron ore, provide a basis for developing the iron ore in Qijiang technically and theoretically.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

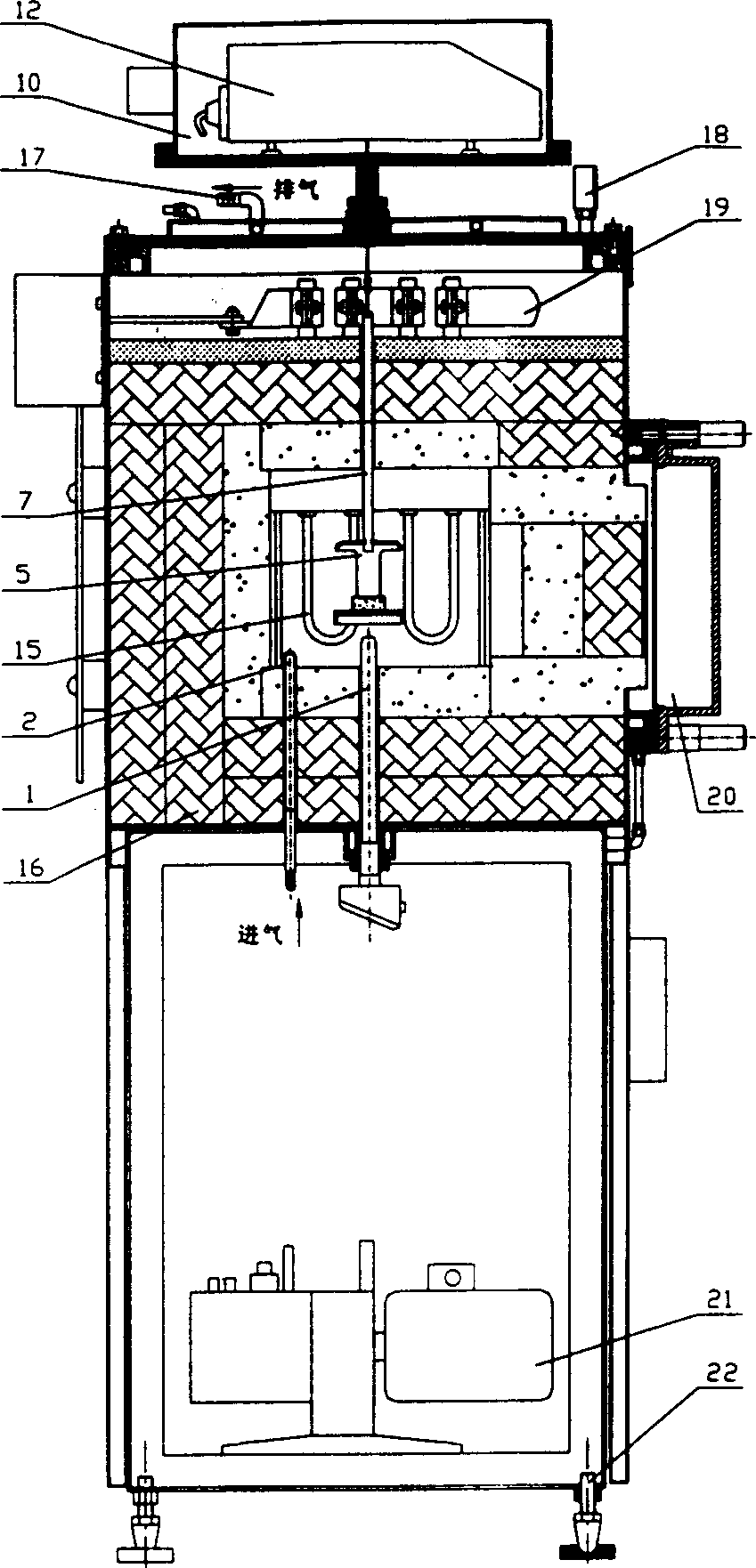

Large test sample fireproof material high temperature thermogravimetric analyzer

InactiveCN1664552ALarge mass dynamic measurementIn line with the actual production applicationMaterial weighingNeutral atmosphereImage resolution

The invention relates to a device for measuring the quality change of the fireproof material in the high temperature and different atmosphere, which comprises a vacuum furnace and a quality measuring system, wherein the measuring system comprises a quality sensor connected with the fire resistant basket which is fitted in the vacuum, the lower of the quality sensor is connected with the heatproof thread, the lower of the thread is connected with the binding rod, the fire resistant basket is connected with the binding rod and a fire resistant bank is set on the basket. Said invention can measure the relations of the quality and temperature in the heating up process or in a certain temperature, and the measuring range is from normal temperature to 1700 deg, the measuring atmosphere maybe oxidation, reduction,neutral atmosphere and inert atmosphere, the quality range is 20-5000g, the distinguishability is 0.1-100mg.

Owner:洛阳精达检测仪器有限公司 +1

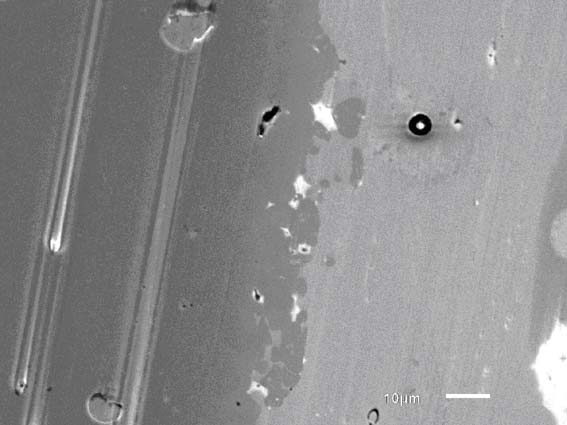

Double phase cast iron cylinder liner produced through centrifugal casting, and processing technology thereof

ActiveCN103352163AHigh strengthImprove wear resistanceProcess efficiency improvementQuenching agentsThermal fatigueDouble phase

The invention discloses a double phase cast iron cylinder liner produced through centrifugal casting. The double phase cast iron cylinder liner comprises, by weight, 3.80-3.90% of C, 2.2-2.8% of Si, less than 0.1% of P, 0.02-0.03% of S, 0.2-0.25% of Mn, 1.2-1.3% of Cu, 0.04-0.05% of Sn, 0.01-0.03% of residual Mg, 0.02-0.03% of Ce, and the balance of Fe. According to the present invention, the cylinder liner is subjected to neutral atmosphere heating and isothermal salt bath quenching, such that the inner wall structure of the cylinder liner is ausferrite and vermicular graphite, the outer wall structure of the cylinder liner is ausferrite and spheroidal graphite, the whole performance strength achieves 950 MPa, and a hardness is greater than 320 HB. In addition, the cylinder liner of the present invention has advantages of high strength, good wear resistance, good abrasion resistance, and good thermal fatigue resistance compared with the conventional gray cast iron cylinder liner.

Owner:ZYNP GRP

Preparation method of nodular cast iron-bronze composite material for cylinder body of plunger pump

The invention relates to a preparation method of a nodular cast iron-bronze composite material for a cylinder body of a plunger pump, relating to a preparation method of a metal composite material. The preparation method comprises the following steps of: plating a nickel layer on the surface of a nodular cast iron through a plating method, and then pressing a powdery bronze layer on the surface of the nickel-plated surface of the nodular cast iron to obtain a composite blank; and sintering the composite blank in a reducing or neutral atmosphere to obtain a sintered composite material. The invention effectively solves the problems of lower solid solubility between the nodular cast iron and bronze, higher heat stress gradient during cooling, and the like, thereby greatly enhancing the combining performance of an interface of the composite material.

Owner:无锡市汉力士液压泵制品有限公司 +1

Method for preparing Longquan celadon glaze and products thereof prepared from coloring element-containing soluble salt

InactiveCN102001863AAddress technical bias against direct preparation of glazesEvenly dispersedTO-18Neutral atmosphere

The invention relates to a method for preparing Longquan celadon glaze and products thereof prepared from coloring element-containing soluble salt. Natural mineral raw materials and industrial chemical raw materials are adopted, and parent glaze and a dyeing assistant comprise the following components in percentage by weight: 62 to 73 percent of SiO2, 10 to 18 percent of Al2O3, 1 to 4 percent of K2O, 0 to 3 percent of Na2O, 10 to 20 percent of CaO, 0 to 2 percent of MgO, and 0 to 2 percent of ZnO. The method comprises the following steps of: adding 2 to 10 weight percent of coloring element-containing soluble salt in different modes, glazing and drying the conventional Longquan celadon body, trimming and drying, putting into a kiln, and sintering in reducing atmosphere or neutral atmosphere at the temperature of between 1,260 and 1,320 DEG C to obtain the Longquan celadon glaze products. The coloring substance exists in the glaze in the form of ions, is uniformly dispersed and can be accurately measured, so the Longquan celadon glaze with stable fineness can be prepared by the method.

Owner:JINGDEZHEN CERAMIC INSTITUTE +1

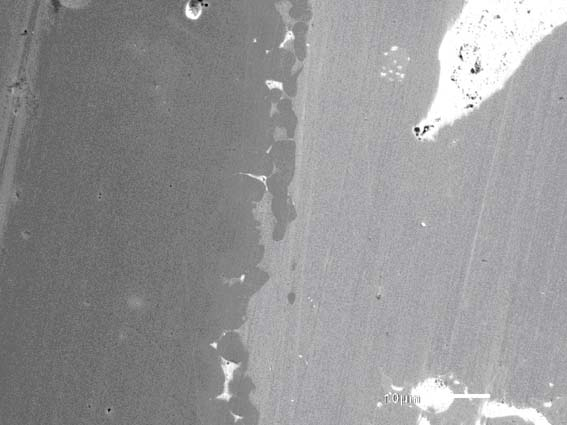

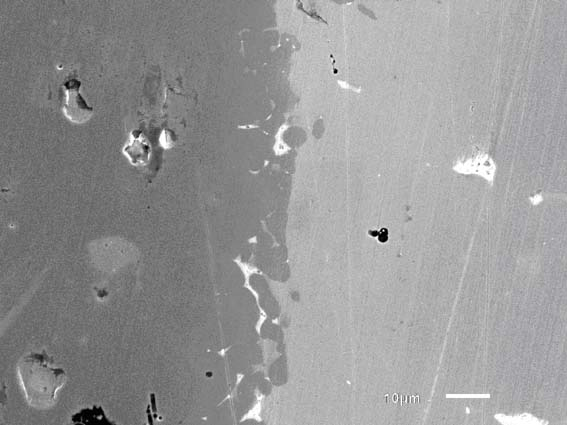

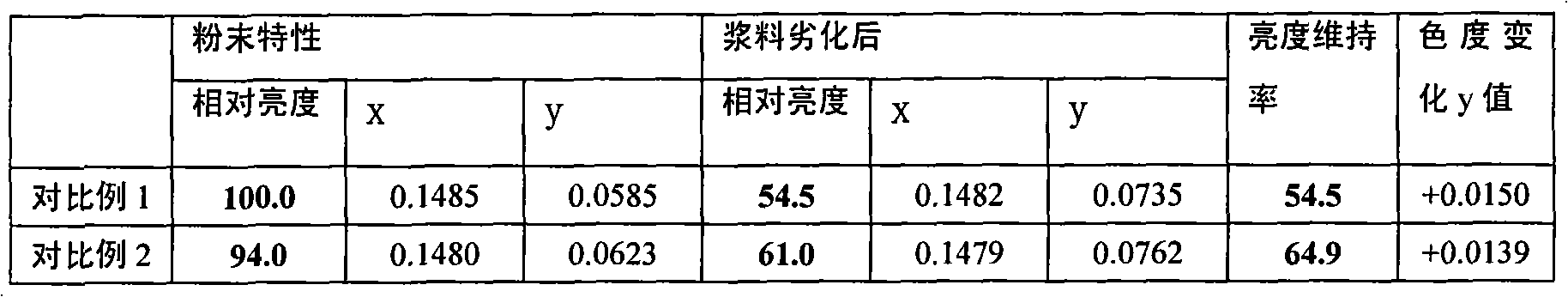

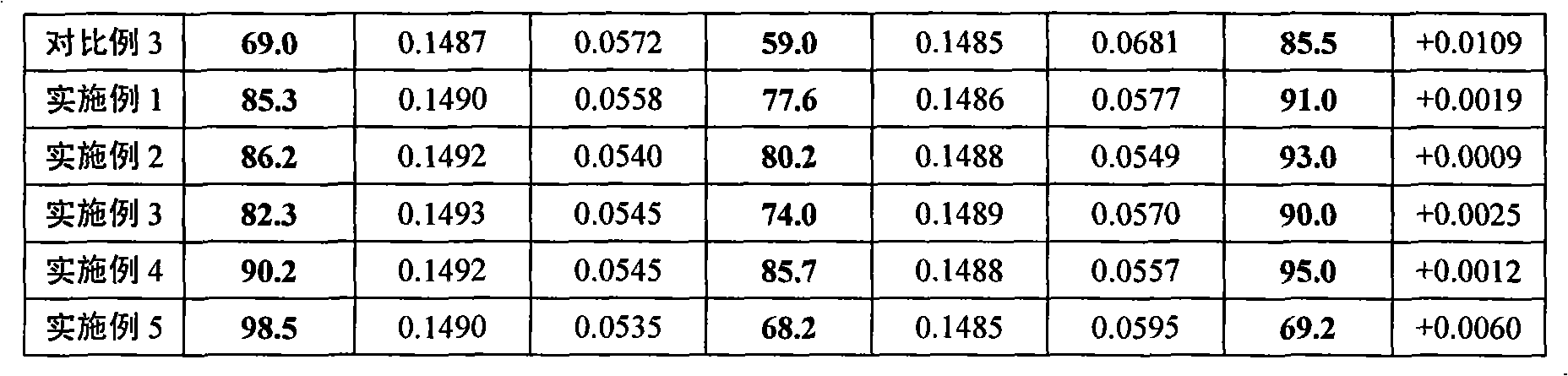

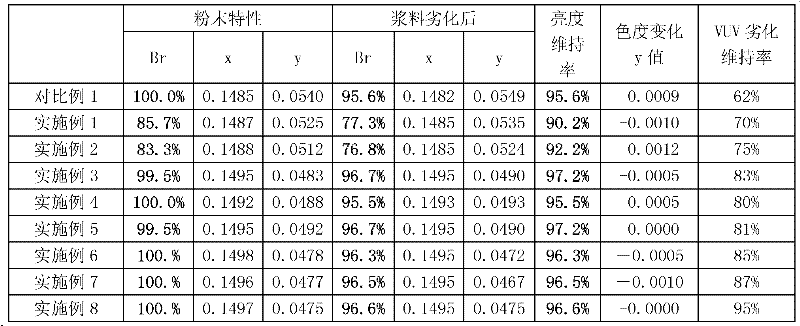

Method for manufacturing BAM blue phosphor for PDP

InactiveCN101586026AImprove luminous efficiencyIncrease heat treatment processSolid cathode detailsLuminescent compositionsAluminateNeutral atmosphere

The invention discloses a method for manufacturing BAM blue phosphor for PDP. The method comprises: (1) evenly mixing alumina, barium carbonate, magnesium oxide and europium oxide to obtain a pre-mixture, adding fluxing agent flux to the pre-mixture and mixing the two well to obtain a mixture; (2) putting the mixture into a high-purity alumina crucible, firing the mixture at least once in a reducing atmosphere of nitrogen and hydrogen and obtaining a sintered substance; (3) grinding, sifting, scattering, water-sieving, washing, drying and resifting the sintered substance to obtain a BAM phosphor semi-finished product; and (4) thermally treating the BAM phosphor semi-finished product in a neutral atmosphere or an extremely weak reducing atmosphere, cooling and sifting the obtained product and obtaining a BAM phosphor finished product. The invention provides a method for manufacturing blue phosphor barium-magnesium-europium aluminate for plasma display parts (PDP). On the basis of the prior conventional BAM blue powder, the method adds an atmosphere heat treatment process by optimizing a sintering process and a post-treatment process. The obtained BAM blue powder has the advantages of high luminescent efficiency, good thermal degradation performance, good vacuum ultraviolet degradation resistance and suitability for PDP.

Owner:CAIHONG GRP ELECTRONICS CO LTD

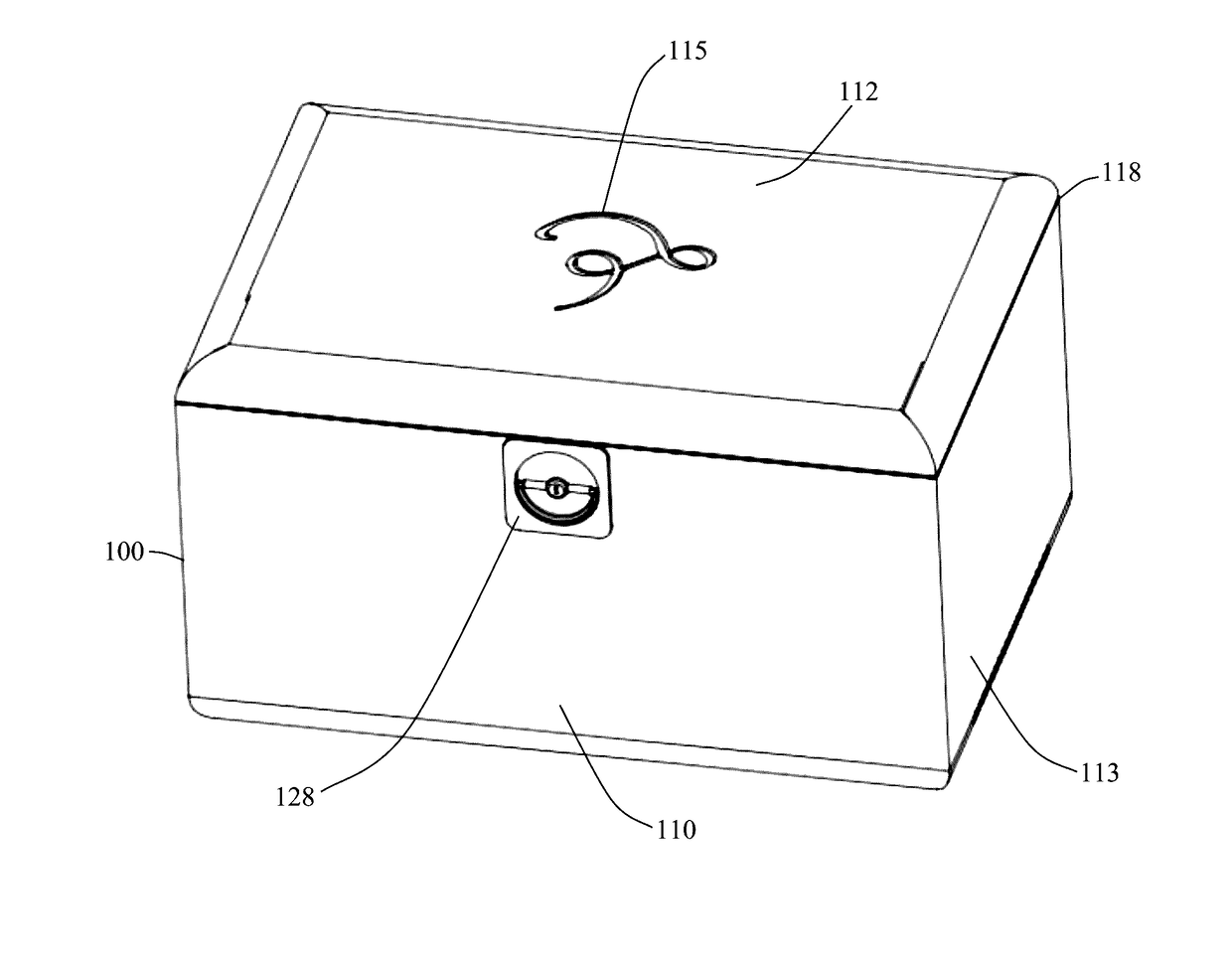

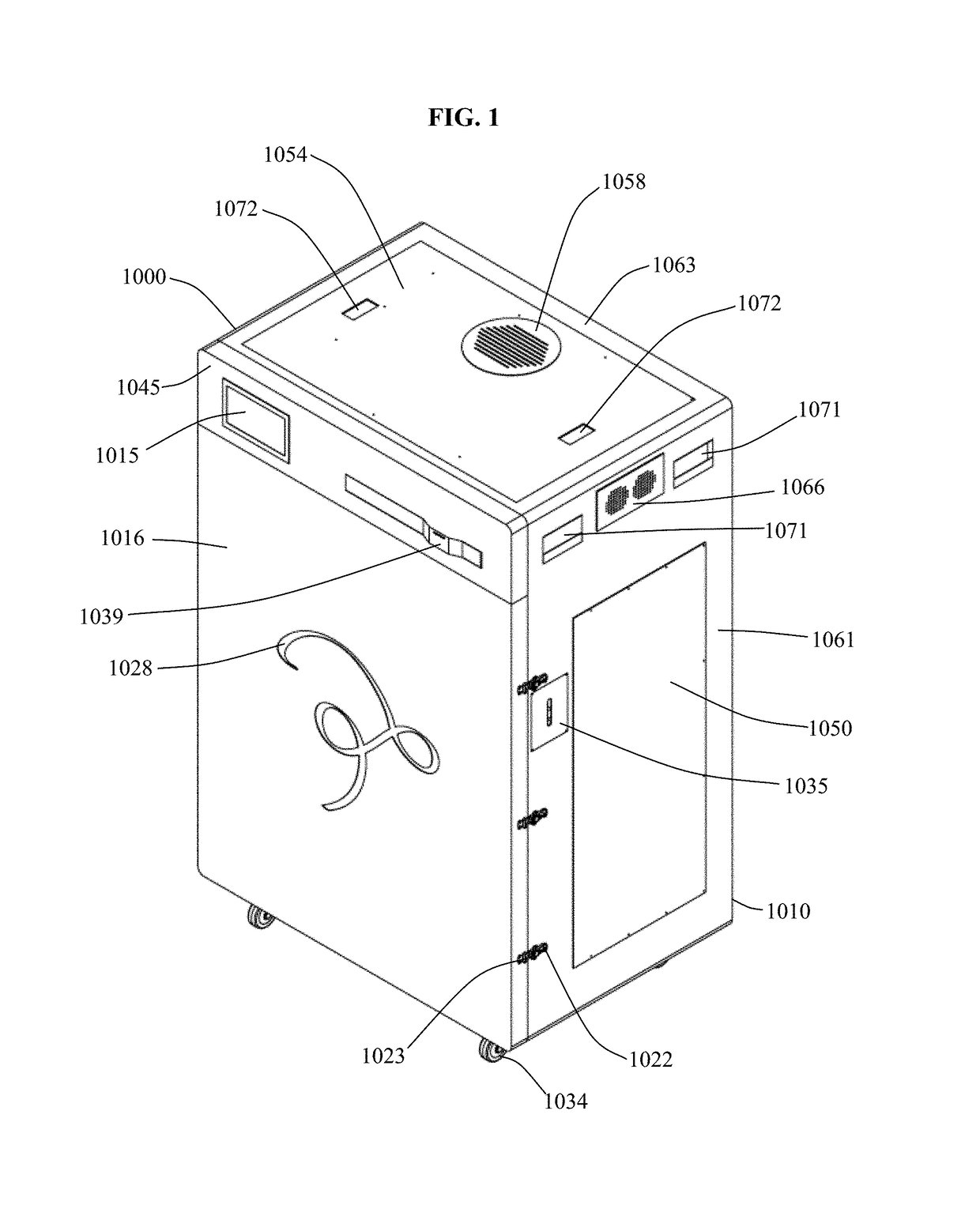

Neutral atmosphere and sanitization storage apparatus, method and system

ActiveUS9792748B2Promote degradationQuality improvementPackaging under vacuum/special atmosphereContainers preventing decayWeb applicationRemote control

Disclosed herein are an apparatus, method and system for storing perishable items that degrade in the presence of oxygen and / or humidity and that are frequently accessed by a consumer. The apparatus comprises an openable vessel, which becomes airtight when closed, and an UV light source and fan within the airtight enclosure, which converts ambient oxygen trapped within the airtight enclosure into ozone by circulating the enclosed volume of air around the UV light source after the vessel is opened and then closed. The apparatus is network connected to allow for remote control and monitoring and sends alerts to web applications or mobile applications when monitored parameters substantially vary from their settings.

Owner:CAMPALANS ALFONSO +1

Ceramic based high temperature heat storage material and preparation method thereof

InactiveCN107266050AAdjust high temperature reactivityHigh heat storage densityNeutral atmosphereThermal shock

The invention relates to a ceramic based high temperature heat storage material and a preparation method thereof. The preparation method is as follows: mixing a silicon-containing material, an aluminum salt, a stabilizer and a complexing agent and grinding to obtain a ground material; mixing the aluminum salt, an inorganic salt, iron powder, manganese powder and aluminum powder, pressing under 50-100MPa for molding, thermally treating in a neutral atmosphere at 600-800 DEG C, ball-milling, drying and sieving to obtain a sieved material A with the size of 0.088-1mm and a sieved material B with the size less than 0.088mm; mixing 0-50wt% of the ground material, 10-30wt% the sieved material A, 20-40wt% of the sieved material B and 5-10wt% of the inorganic salt, pressing under 10-30 MPa for molding, thermally treating in the neutral atmosphere at 700 to 900 DEG C to obtain the ceramic based high temperature heat storage material. The preparation method has the advantages of wide raw material sources, simple process and low production cost, and the ceramic based high temperature heat storage material product has high heat storage density, large thermal conductivity, high compressive strength and high thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH

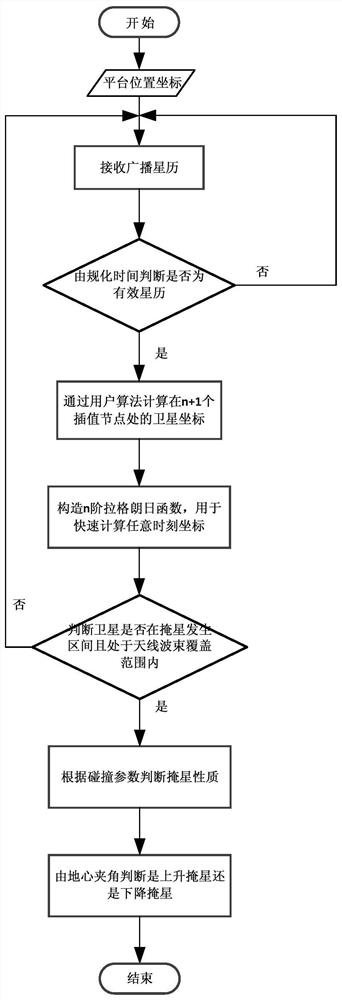

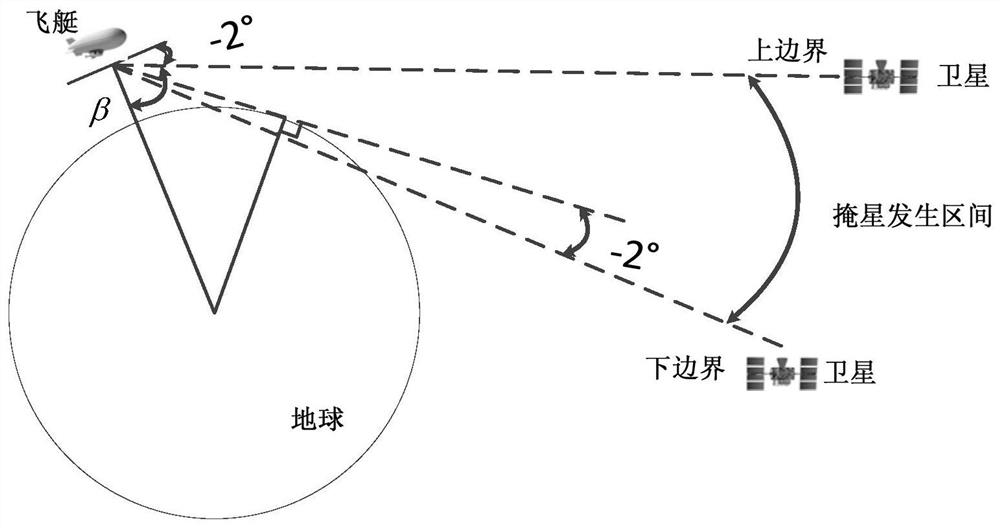

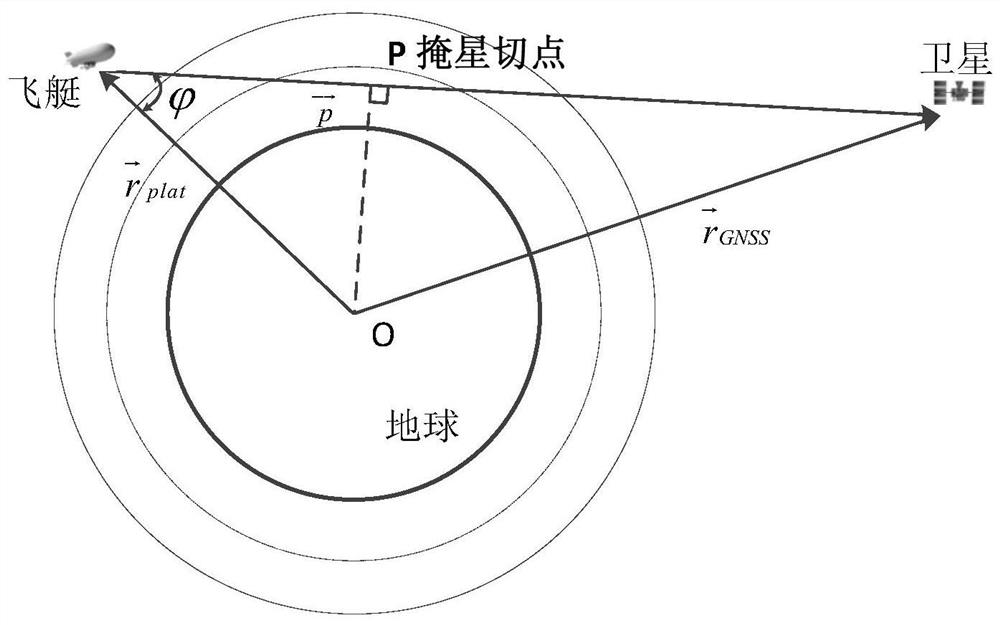

Efficient and rapid occultation forecasting method based on near space floating platform

PendingCN112346086AComputationally efficientQuick calculationSatellite radio beaconingComplex mathematical operationsNeutral atmosphereEngineering

An efficient and rapid occultation forecasting method based on a near space floating platform comprises the following steps that firstly, satellite coordinates at an interpolation time node are calculated through a broadcast ephemeris; secondly, a Lagrange interpolation function is constructed, and the coordinate value of a satellite at each moment within the effective time of the ephemeris is calculated; whether the satellite is located in an occultation generation interval is judged according to the spatial position, and whether the satellite is located in an occultation antenna beam coverage range is calculated; after it is determined that an occultation event happens to a certain satellite at the current moment, the occultation duration is calculated according to an interpolation polynomial; whether the occultation is neutral atmosphere occultation or ionospheric occultation is judged according to the collision parameters; finally, in the effective ephemeris time, the geocentric angle changes at the current moment and the next moment are calculated to judge whether the occultation is ascending or descending occultation; and all satellites in the constellation are traversed. According to the method, an occultation event is efficiently and quickly estimated, the problems of large data volume and long calculation time during traditional ephemeris calculation are solved, and the occultation event forecasting precision is improved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

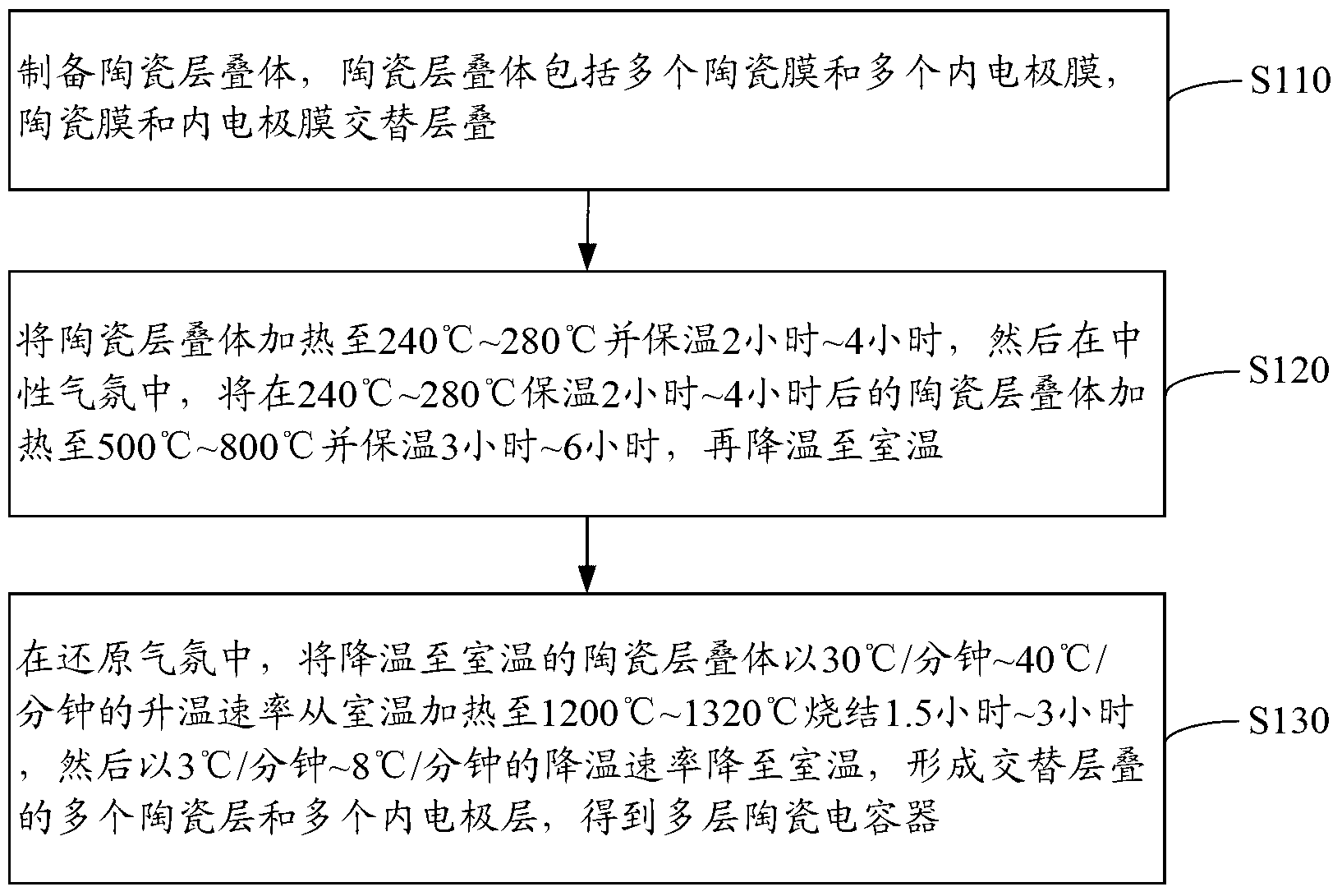

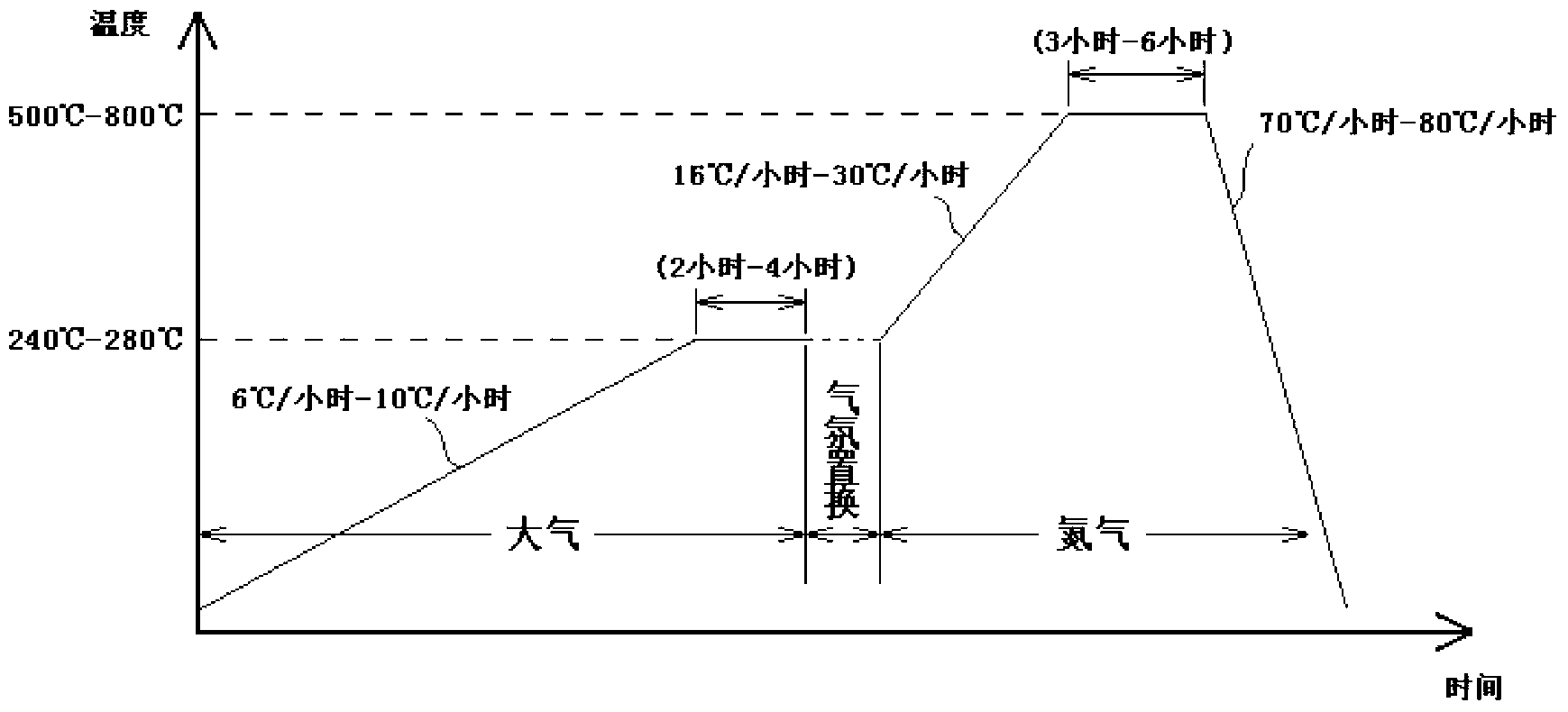

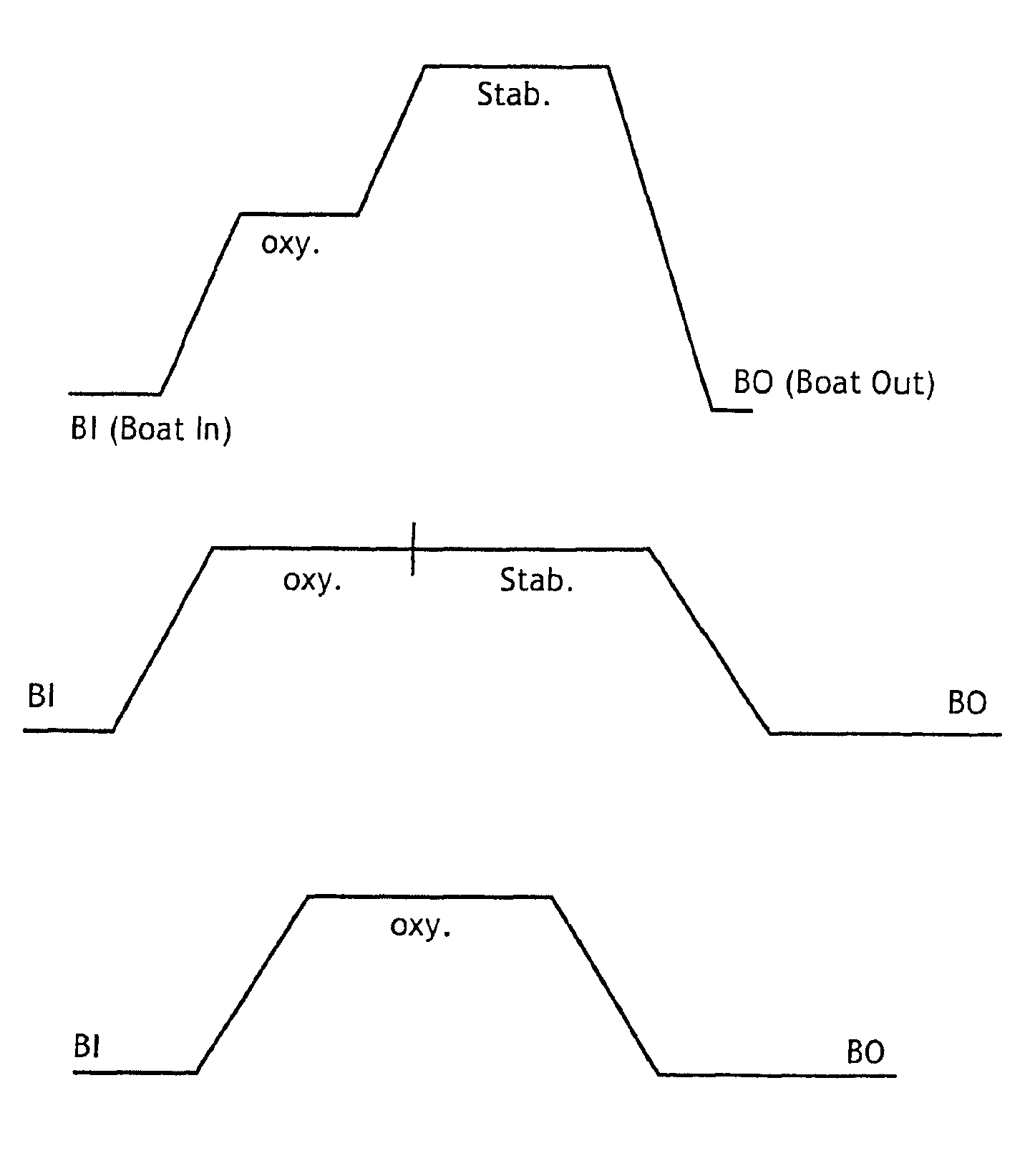

Manufacturing method for multi-layer ceramic capacitor

ActiveCN103295780AHigh capacitanceImproved performance characteristicsStacked capacitorsNeutral atmosphereCeramic capacitor

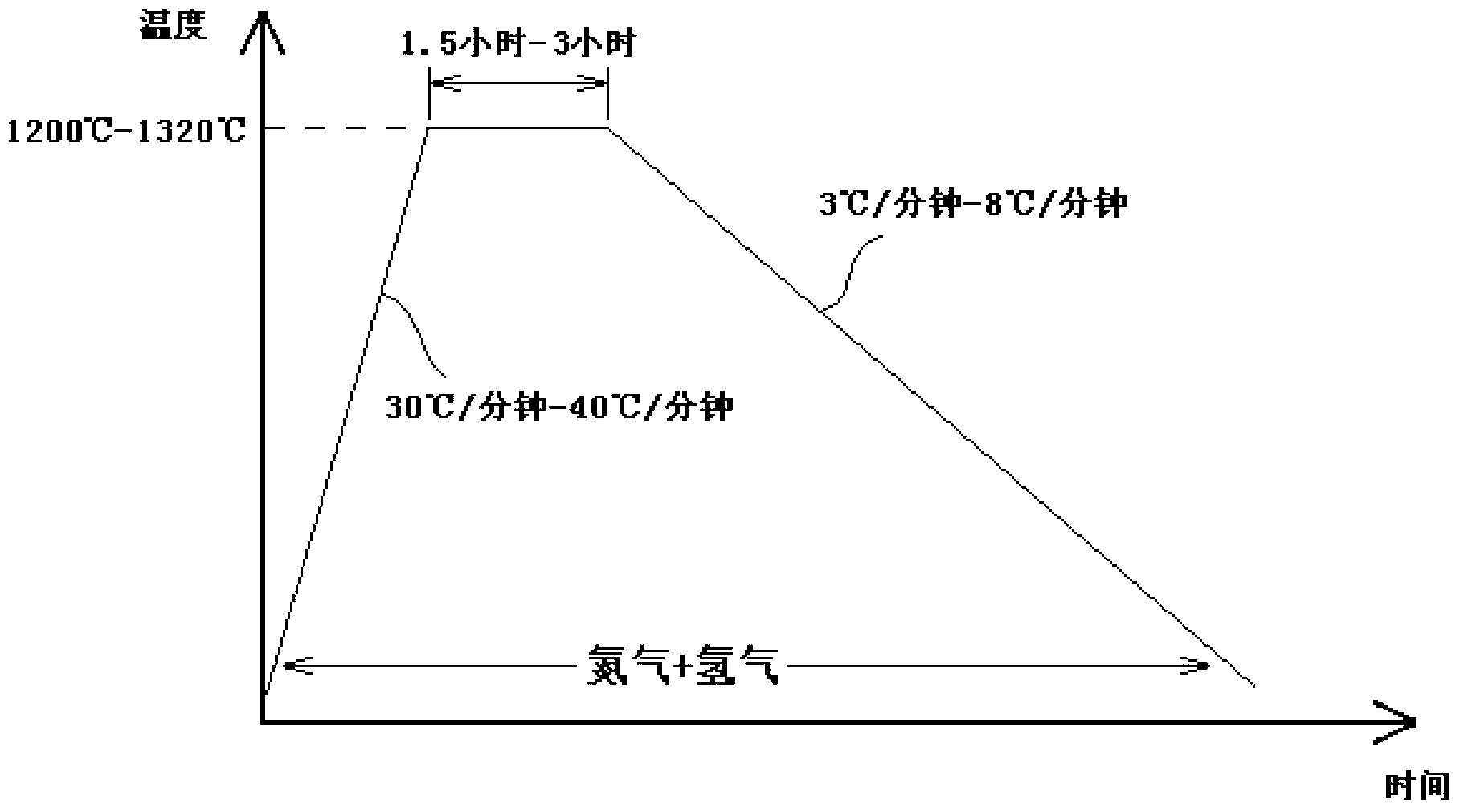

The invention relates to a manufacturing method for a multi-layer ceramic capacitor. The manufacturing method includes: manufacturing a ceramic stacking body comprising a plurality of ceramic films and a plurality of inner electrode films, wherein the ceramic films and the inner electrode films are stacked alternatively; heating the ceramic stacking body to 240-280 DEG C, keeping the temperature for 2-4 hours, heating the ceramic stacking body to 500-800 DEG C after the temperature of 240-280 DEG C of the ceramic stacking body is kept for 2-4 hours in an neutral atmosphere, keeping the temperature for 3-6 hours, cooling the ceramic stacking body to the room temperature; in a reduction atmosphere, heating the ceramic stacking body which is cooled to the room temperature to 1200-1320 DEG C with the temperature rising rate as 30-40 DEG C / minute, sintering for 1.5-3 hours, cooling the ceramic stacking body to the room temperature with the temperature dropping rate as 3-8 DEG C / minute to form the plurality of ceramic layers and the plurality of inner electrode layers which are stacked alternatively to form the multi-layer ceramic capacitor. By means of the manufacturing method, the inner electrode layers which are even and continuous can be formed.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

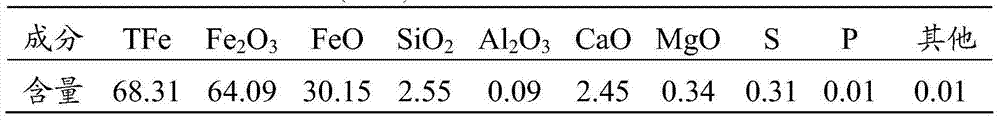

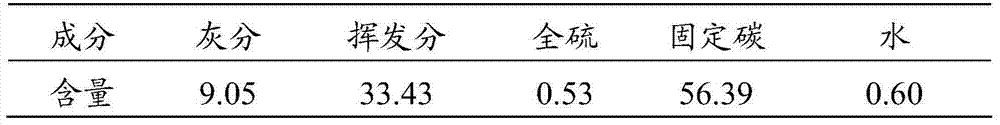

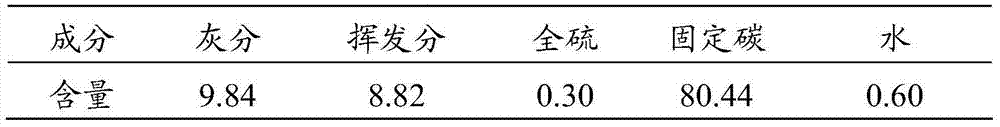

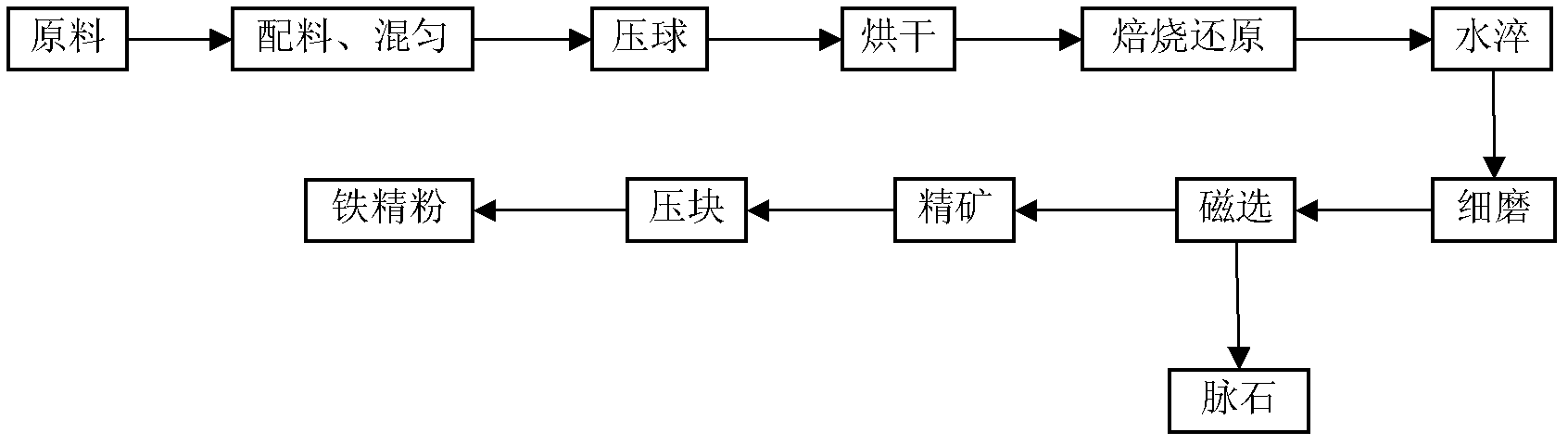

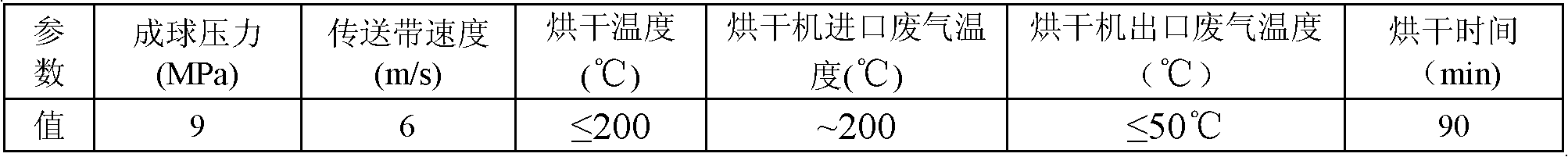

Preparation method of iron-ore hot-pressed carbon-containing pellet and iron-making raw material

The invention discloses a preparation method of an iron-ore hot-pressed carbon-containing pellet and an iron-making raw material. The preparation method comprises the following steps: uniformly mixing iron ore powder, coal dust and a solvent to obtain a first material, wherein the first material comprises 60 to 80wt% of iron ore powder, 20 to 40wt% of coal dust, and 0 to 10wt% of solvent; heating the first material to be 100 to 300 DEG C; performing hot pressing to form a pellet, so as to obtain a second material; feeding the second material into a tunnel kiln or a coal-based shaft furnace; then thermally processing for 4 to 6 hours at the temperature of 800 to 1100 DEG C under a neutral atmosphere or reducing atmosphere by a destructive distillation manner so as to obtain the iron-ore hot-pressed carbon-containing pellet. With the adoption of the preparation method, the energy consumption can be reduced, the process can be simplified, the production efficiency can be improved, and the requirements of steel and iron production on energy consumption, cost and environmental protection can be met; the preparation method has a wide industrial application prospect.

Owner:NORTHEASTERN UNIV

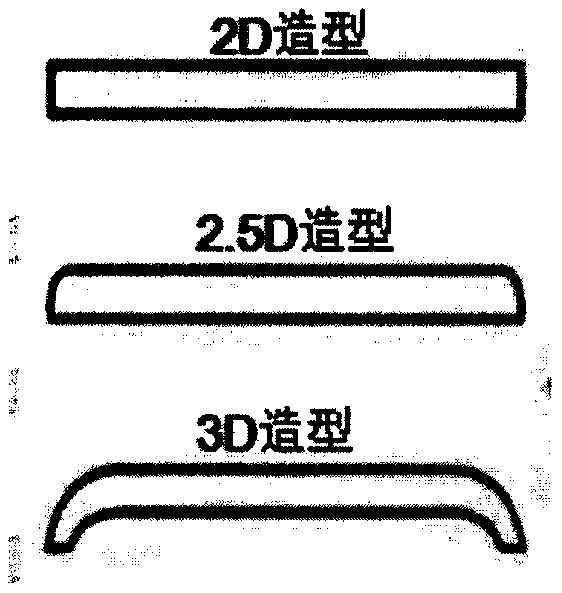

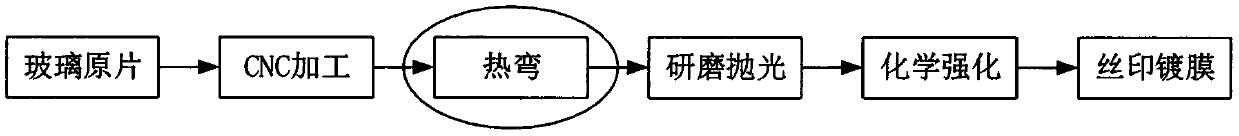

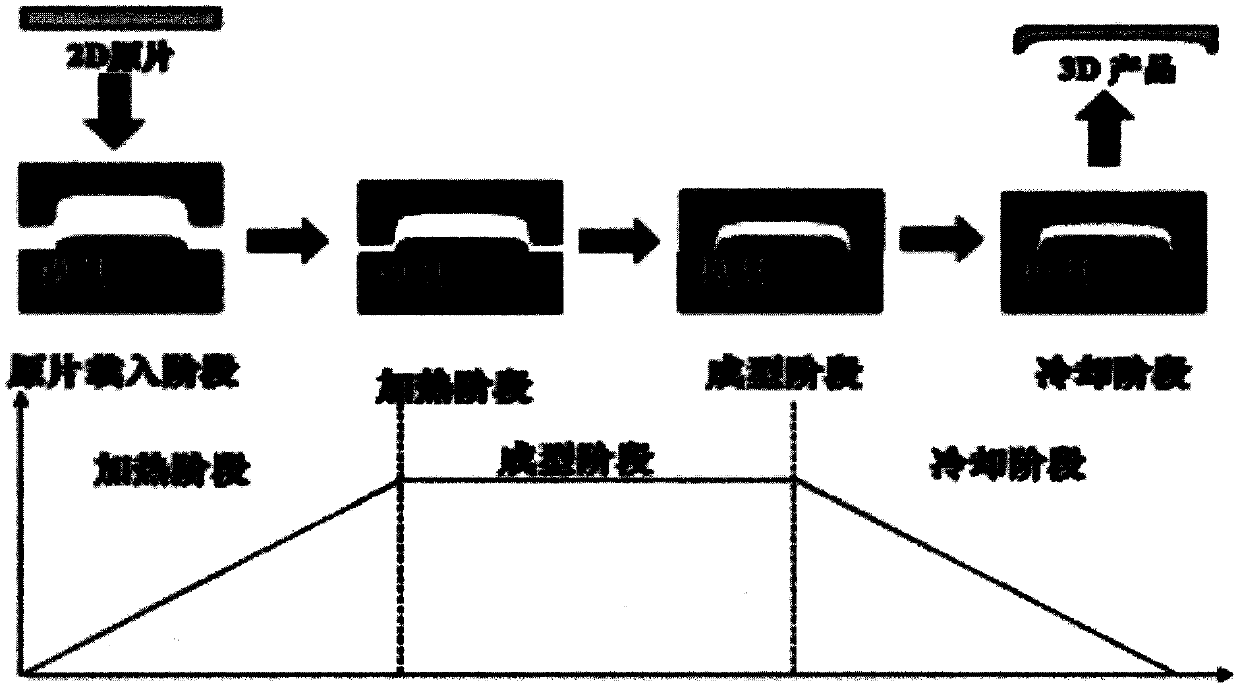

Method and device for strip-shaped glass feeding and mobile phone cover glass on-line 3D compression molding

InactiveCN110563318AGlass transportation apparatusGlass reforming apparatusNeutral atmosphereProtective glasses

The invention discloses a method and device for strip-shaped glass feeding and mobile phone cover glass on-line 3D compression molding, and belongs to the field of glass material preparation and machining. The device sequentially comprises a melting system, a feeding system, a heating system, a mold pressing system and a protective gas system; the device further comprises a traction system; the melting system comprises a glass melting furnace; the feeding system comprises a feeding channel, a slit feeder, a silicon carbon rod, a guide roller and a traction roller; the heating system comprisesa heating furnace and a heating element; the heating furnace comprises a shearing mechanism and the mold pressing system. A reducing atmosphere or a neutral atmosphere in the heating furnace is achieved through the protective gas system in a whole process. According to the method and the device, alkali aluminosilicate glass melt can be directly pressed and formed into the mobile phone cover protective glass with the thickness of 0.6-1.5 mm in one step, so that the accurate modeling of the mobile phone cover protective glass is maintained, the surface precision of the glass is ensured, and thegrinding and polishing workload of the surface of the compression-molded glass is reduced to a maximum extent.

Owner:XIANNING NANBO PHOTOELECTRIC GLASS CO LTD

Micro-wave sintering method for foam glass

InactiveCN101265018AEvenly sinteredReduce the temperature difference between inside and outsideGlass shaping apparatusGlass productionNeutral atmosphereRoom temperature

A microwave sintering method of foam glass comprises the following steps of: placing a foam glass blank into a microwave sintering device with oxidizing atmosphere or neutral atmosphere and microwave frequency of 300MHz-300GHz, heating up to 300-350 DEG C in 5 min, keeping at the temperature for 10 min, heating up to 750-820 DEG C in 20-45 min, keeping at the temperature for 15-40 min, turning off microwave source, rapidly cooling to 600 DEC G in 5 min, keeping at the temperature for 20 min, cooling to room temperature, and taking out. In the inventive method, the heat for microwave sintering is originated from inside, the foam glass blank is self-sintered by absorbing microwave, the internal and external temperature difference of the foam glass blank is small during sintering process, so as to uniformly sinter the foam glass blank, reduce sintering temperature, shorten sintering time, and improve sintering quality. The used temperature is 5-150 DEG C lower than conventional sintering temperature.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of phosphoric acid modified titanium dioxide photocatalyst

The invention discloses a preparation method of a phosphoric acid modified titanium dioxide photocatalyst. The preparation method is characterized in that the visible light absorption rate of titanium dioxide is improved by adopting phosphoric acid. The preparation method mainly comprises the following steps: (a) preparing titanium dioxide powder, slowly and dropwise adding an organic compound of titanium to an ice-bath, sufficiently stirring and uniformly mixing to generate a white precipitate, wherein the volume ratio of the organic compound of titanium to water is 1: 0.1-5, the organic compound of titanium is a mixture of tetrabutyl titanate, tetraisopropyl titanate and tetraethyl titanate mixed at a proportion of 1: 1: 1; then adjusting the pH value of the mixture to be between 5 and 9 by using ammonia water after stirring, and filtering the obtained white precipitate; (b) adding the titanium dioxide powder to a phosphoric acid solution with the concentration of 0.1-0.3 mol / l, then sufficiently stirring mixed liquid and heating so that the mixed liquid is boiled and concentrated, drying for ashing to obtain loosened blocks; (c) grinding the loosened blocks into powder, putting in a neutral atmosphere at the temperature of 500-550 DEG C for roasting for 1-8 hours so as to obtain the phosphoric acid modified titanium dioxide photocatalyst. The catalyst prepared by the method is high in visible light absorption rate.

Owner:华玉叶

Ceramic based heat storage material using copper slag as raw material and preparation method thereof

InactiveCN107266035AAdjust high temperature reactivityHigh heat storage densityCeramic materials productionClaywaresNeutral atmosphereThermal shock

The invention relates to a ceramic based heat storage material using copper slag as a raw material and a preparation method thereof. The preparation method is as follows: mixing a copper slag and silicon-containing material, a copper salt, a stabilizer and a complexing agent and grinding to obtain a ground material; mixing the copper salt, an inorganic salt, copper powder, manganese powder and aluminum powder, pressing for molding, thermally treating in a neutral atmosphere at 400-600 DEG C, ball-milling, drying and sieving to obtain a sieved material A with the size of 0.088-1mm and a sieved material B with the size less than 0.088mm; mixing 0-50wt% of the ground material, 10-30wt% the sieved material A, 20-40wt% of the sieved material B and 5-10wt% of the inorganic salt, pressing for molding, thermally treating in the neutral atmosphere at 400 to 600 DEG C to obtain the ceramic based heat storage material using the copper slag as the raw material. The preparation method has the advantages of wide raw material sources, simple process and low production cost, and the ceramic based heat storage material using the copper slag as the raw material has high heat storage density, large thermal conductivity, high compressive strength and high thermal shock stability.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of BAM (BaMgAl10O17) blue fluorescent powder for PDP (plasma display panel)

ActiveCN102337126AImprove luminous efficiencyGood thermal deterioration performanceCold-cathode tubesLuminescent compositionsHydrogenNeutral atmosphere

The invention discloses a preparation method of BAM (BaMgAl10O17) blue fluorescent powder for PDP (plasma display panel). The method comprises the following steps: 1) mixing raw materials alumina, barium carbonate, magnesium oxide and europium oxide in a stoichiometric ratio according to Ba0.9MgAl10O17:Eu0.1, and additionally adding a fluxing agent and oxides of W and Mo (or other compounds) in the mixture for fully mixing; 2) putting the mixture finally obtained from the step 1) in a high-purity oxidation crucible, firing for at least once at the reduction atmosphere of nitrogen and hydrogen; 3) smashing the firing substance, then screening, dispersing, screening with a water sieve, washing, drying and screening to obtain the BAM blue fluorescent powder; and 4) carrying out thermal treatment on the BAM blue fluorescent powder at the neutral atmosphere or weak oxidation atmosphere, cooling and then screening to obtain the BAM blue fluorescent powder finished product. The BAM blue fluorescent powder obtained by using the method in the invention has high luminous efficiency, good heat degradation property and good vacuum-resisting ultraviolet degradation property, and is suitable for PDP devices.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

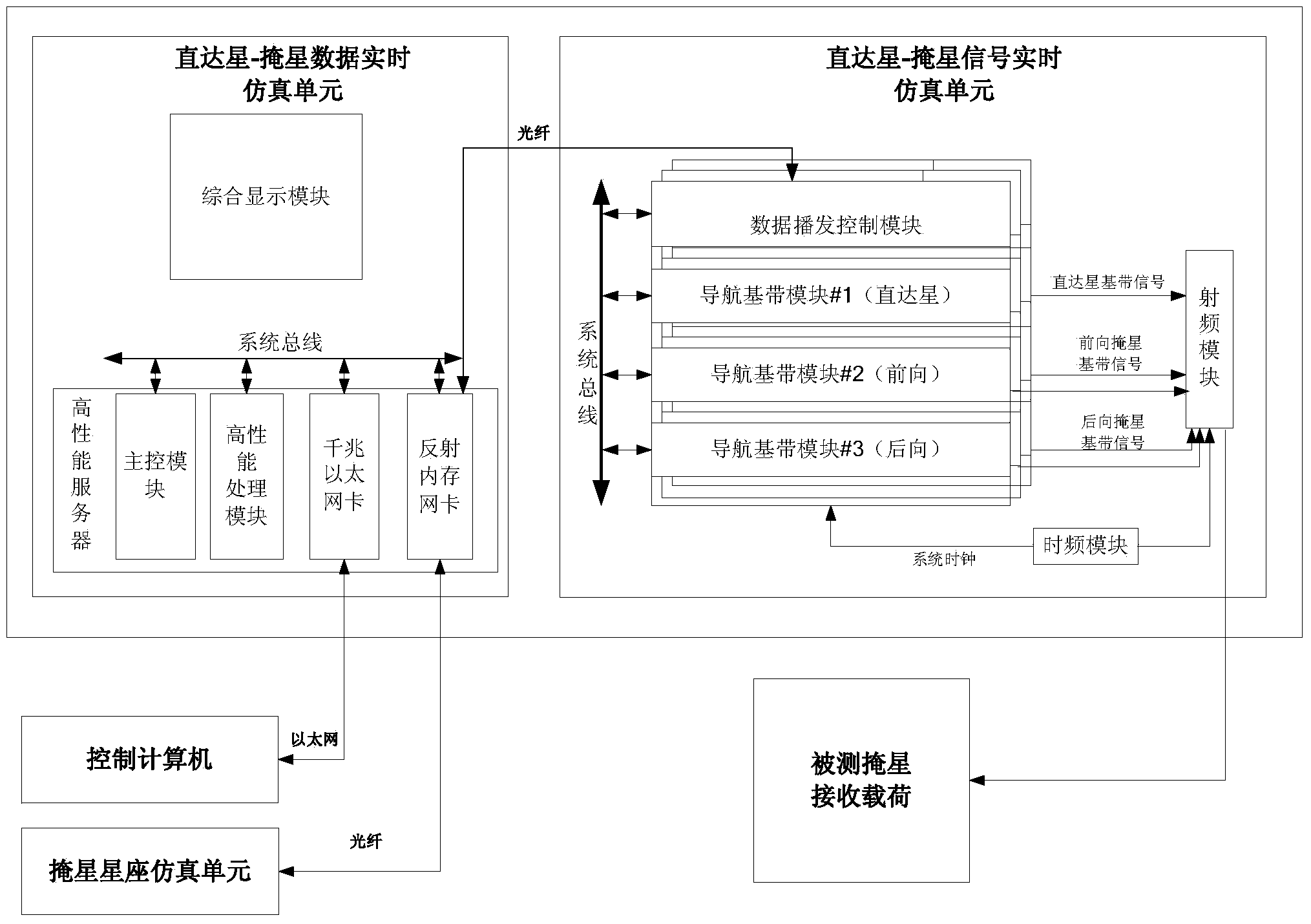

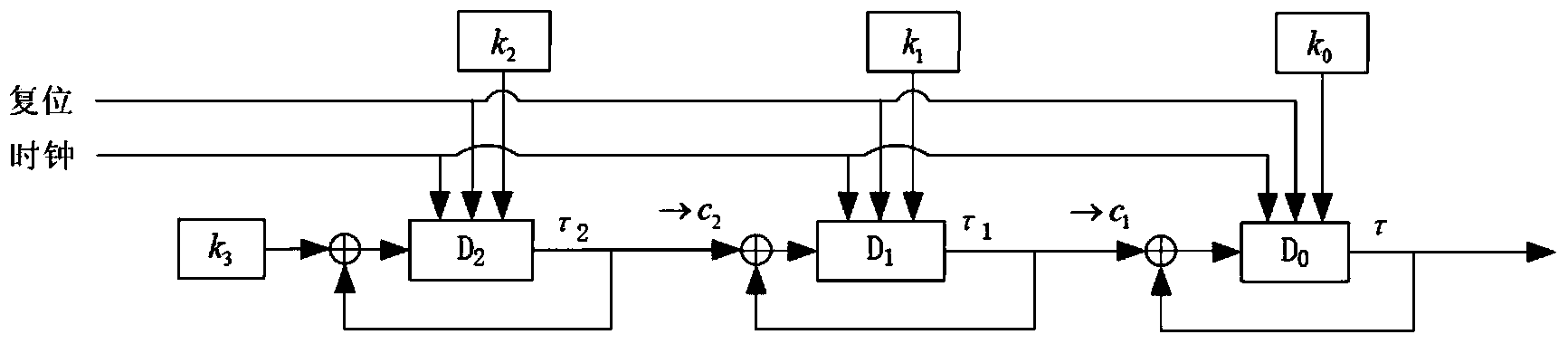

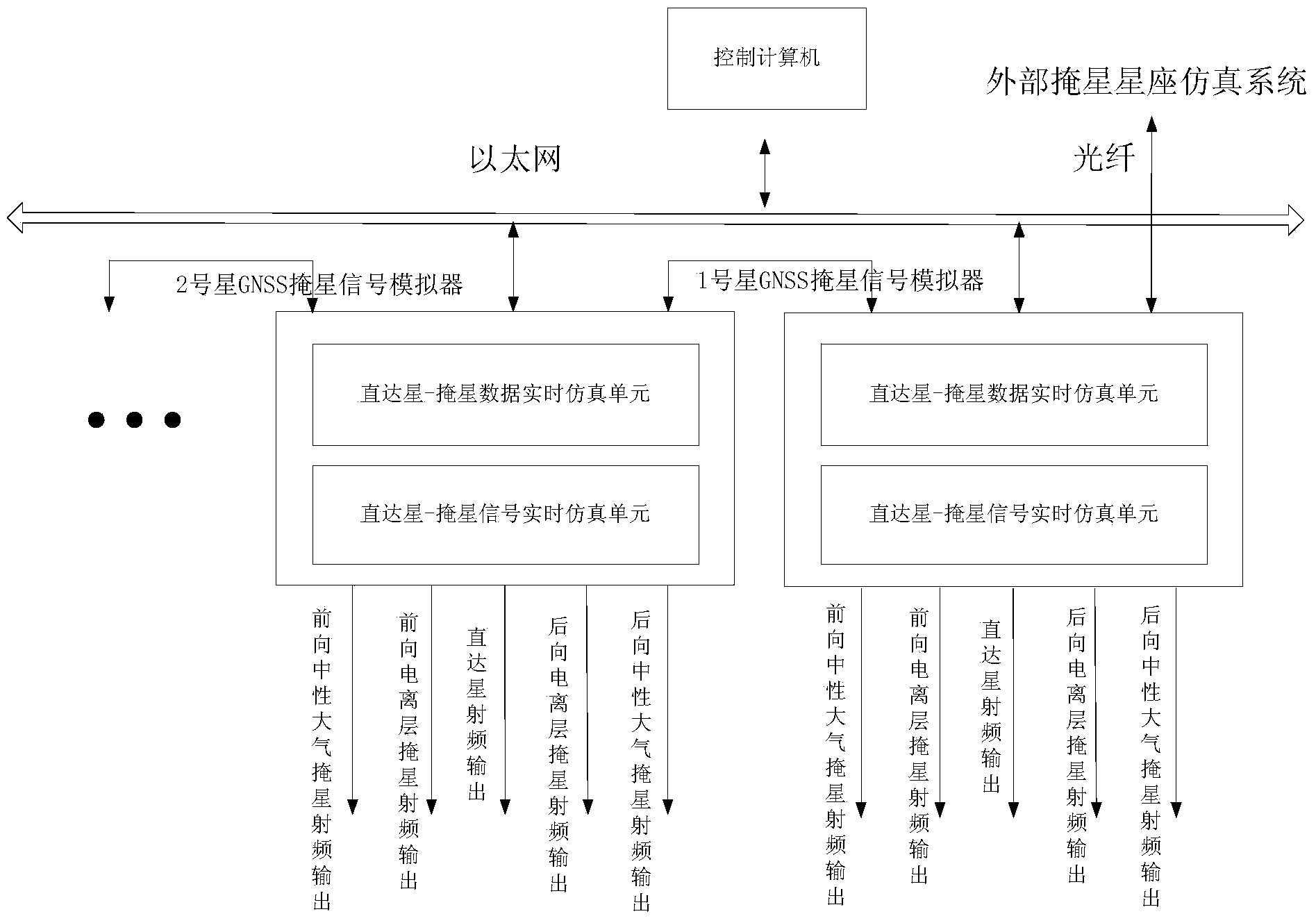

Single-carrier multiple-antenna occultation signal generation system

ActiveCN103675845AGuaranteed reliabilityGenerate accuratelySatellite radio beaconingNeutral atmosphereObservation data

A single-carrier multiple-antenna occultation signal generation system includes a direct star - occultation data real-time generation unit and a direct star - occultation signal real-time generation unit. The direct star - occultation data real-time generation unit is used to generate an accumulative parameter and a power control code corresponding to direct star and occultation observation data; and the direct star - occultation signal real-time generation unit uses the inputted accumulative parameter and power control code to generate a five-way radio frequency signal output which respectively includes a direct star channel, a front neutral atmosphere channel, a front ionized layer channel, a rear neutral atmosphere channel, and a rear ionized layer channel. The single-carrier multiple-antenna occultation signal generation system can simulate a navigation positioning signal, an ionized layer occultation signal and a neutral atmosphere occultation signal, so that the single-carrier multiple-antenna occultation signal is truly realized; and the occultation signal source parallel with the simulation network can be formed to carry out the multi-star occultation signal simulation.

Owner:SPACE STAR TECH CO LTD

Ceramic-fiber heat-insulation material based on waste polyaluminum chloride residues and preparation method thereof

The invention relates to a ceramic-fiber heat-insulation material based on waste polyaluminum chloride residues and a preparation method thereof. According to a technical scheme in the invention, the preparation method comprises the following steps: mixing the waste polyaluminum chloride residues, an aluminum-containing raw material and an additive, adding water, carrying out stirring and then carrying out filtering so as to obtain a filter material; uniformly mixing the filter material, municipal sludge and a surfactant, carrying out molding and then successively carrying out heat treatment in a reducing atmosphere, grinding and screening so as to obtain a material A and a material B; uniformly mixing the material A, the material B, a silicon-containing raw material and an aluminum-containing raw material, carrying out heat treatment in a reducing atmosphere and then carrying out heat treatment in a neutral atmosphere so as to obtain a material C and a material D; uniformly mixing the material A, the material C, the material D, ceramic fibers, a binder, an inorganic thickening agent and an organic thickening agent, adding water and carrying out stirring and molding; and carrying out drying and heat treatment so as to prepare the ceramic-fiber heat-insulation material based on the waste polyaluminum chloride residues. The preparation method provided by the invention uses widely available raw materials and has low production cost; and the prepared ceramic-fiber heat-insulation material based on the waste polyaluminum chloride residues has small volume density and a low heat conduction coefficient.

Owner:河南瑞达净化材料有限公司

Neutral atmosphere and sanitization storage apparatus, method and system

InactiveUS10143763B2Promote degradationQuality improvementMechanical apparatusSpace heating and ventilation safety systemsOzone generatorWeb application

Disclosed herein are an apparatus, method and system for storing perishable items that degrade in the presence of oxygen and / or humidity and that are frequently accessed by a consumer. The apparatus comprises an openable insulated vessel with precisely controlled internal temperature and humidity, which becomes airtight when closed, and a corona ozone generator with an oxygen gas feed tank and fan within the insulated airtight enclosure, which converts ambient oxygen trapped within the airtight enclosure into ozone by circulating the enclosed volume of air through the corona ozone generator after the vessel is opened and then closed. Also disclosed is a refrigerated embodiment of the apparatus, which may be self-contained and transportable. The apparatus is network connected to allow for remote control and monitoring and sends alerts to web applications or mobile applications when monitored parameters substantially vary from their settings.

Owner:CAMPALANS ALFONSO +1

Method for improving iron content and reducing sulfur content by direct reduction of carbon-containing pellets in rotary hearth furnace

InactiveCN102605129ATo achieve the purpose of increasing iron and reducing sulfurMeet production requirementsFluidised-bed furnacesNeutral atmosphereSmelting process

The invention discloses a method for improving iron content and reducing sulfur content by direct reduction of carbon-containing pellets in a rotary hearth furnace. The method comprises the following steps of: uniformly mixing 64-84wt% of iron oxide scale, 19-25wt% of semi-coke, 4-10wt% of lime stone and 10wt% of composite binder; after pelletizing and drying, reducing at 1200-1400 DEG C in the rotary hearth furnace, wherein the atmosphere in the rotary hearth furnace is a neutral atmosphere or a weak reducing atmosphere, and the reduction time is 25-45 min; cooling a reduced product and then finely milling and magnetically separating so that metal iron grains are separated from gangues or slag rich in sulfur; and finally, briquetting the collected iron grains. The method disclosed by the invention is simple in process and lower in energy consumption; more than 75% of sulfur in the carbon-containing pellets can be removed, the grade of the iron grains is about 90% and the sulfur reduction burden in a subsequent smelting process is relived.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Space environment comprehensive monitoring system based on rail remaining tail sub-level

PendingCN114136366AHigh cost-effectiveIncrease the areaMeasurement devicesNeutral atmosphereLoad carrying

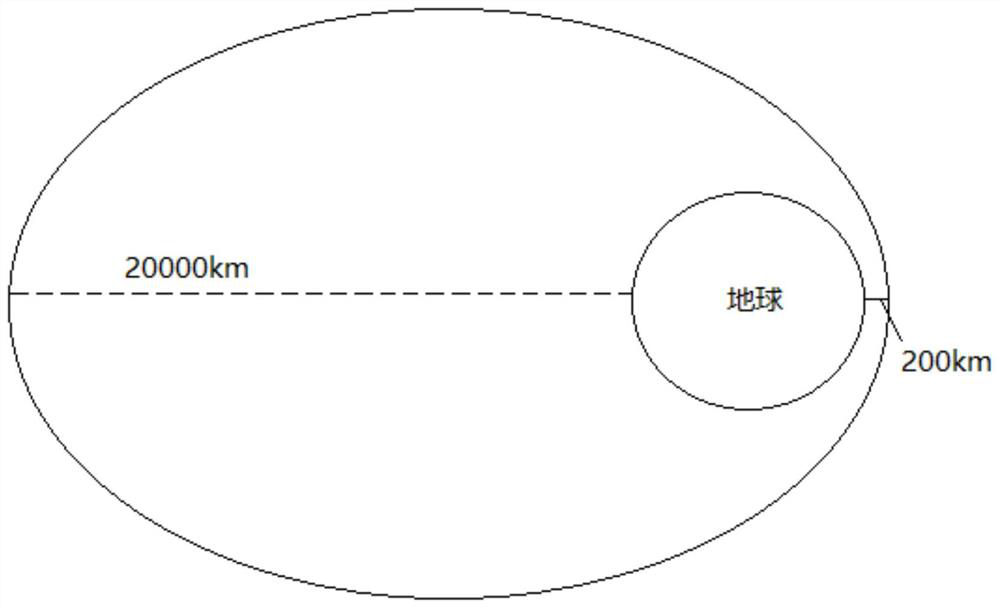

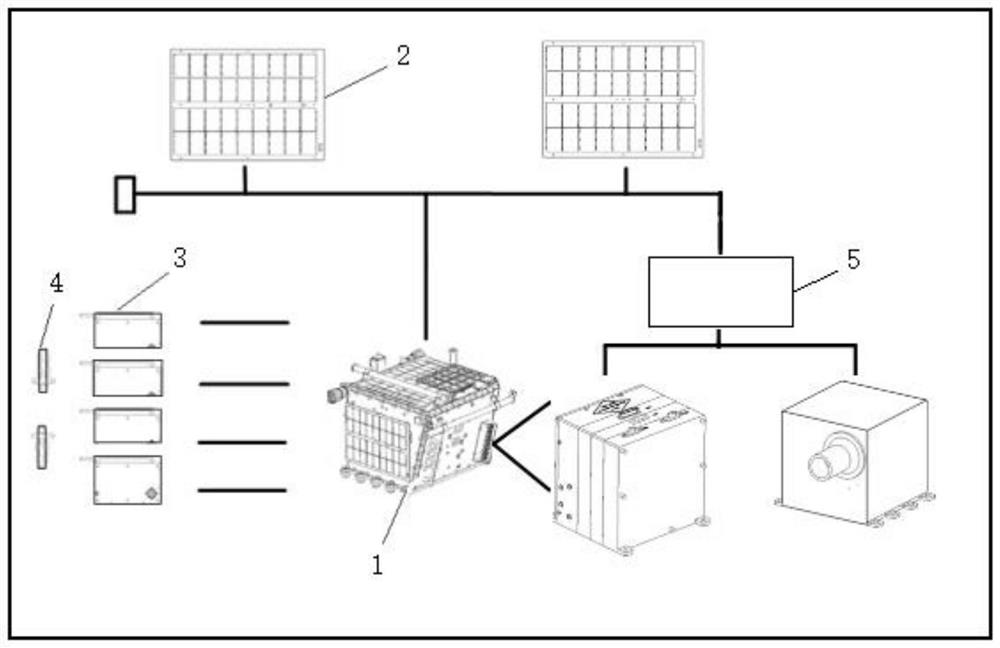

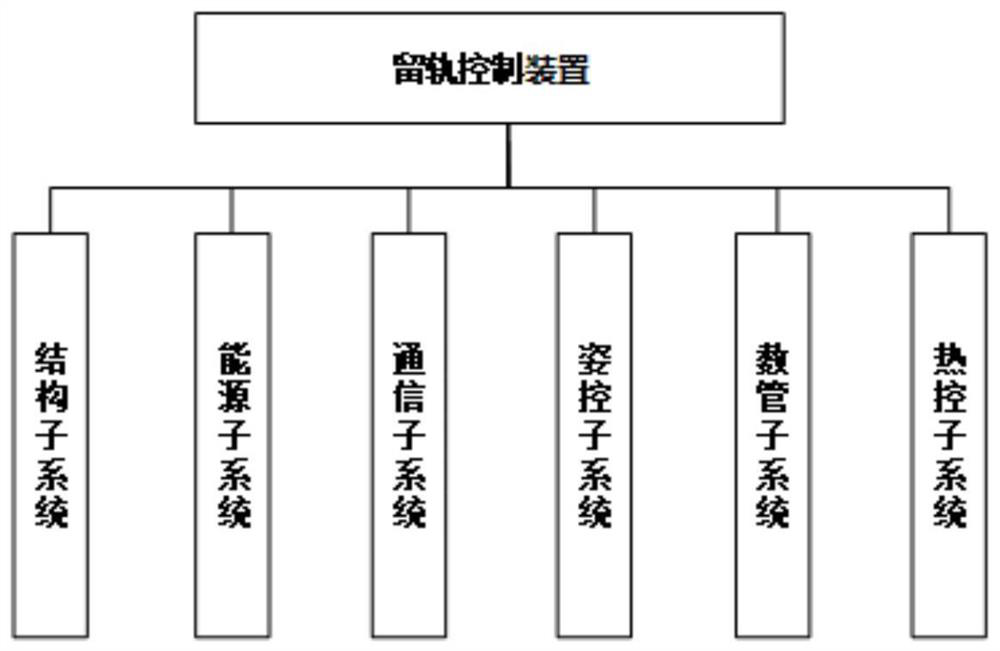

The invention discloses a space environment comprehensive monitoring system based on an orbit remaining tail sub-level, and aims to solve the problems of scarce opportunities, high cost and the like of space environment monitoring load carrying on a space environment research satellite and a general service satellite in the prior art. The method comprises the following steps of: monitoring a load by using a rail-leaving tail sub-stage of a preset rail-leaving control platform and a space environment loaded on the rail-leaving tail sub-stage based on a large elliptical rail formed after passivating and discharging the rail-leaving tail sub-stage; high-energy proton measurement, single event effect monitoring and radiation dose measurement of different orbit heights and earth neutral atmosphere density monitoring of which the perigee height of a large elliptical orbit is in a near space orbit range are carried out, and obtained monitoring data are used for fault analysis of a spacecraft and precise orbit forecasting of the spacecraft. The novel space environment comprehensive monitoring system is high in cost-effectiveness ratio, short in task period, wide in track coverage and distributed in bearing, and large-area, real-time, synchronous, multi-scale and multi-element space environment information can be obtained.

Owner:NO 63921 UNIT OF PLA

Flexible graphite sealing joint with metal jacket for high temperature

ActiveUS20050225038A1Increase temperatureEngine sealsFluid pressure sealed jointsNeutral atmosphereGraphite

The seal can be used at high temperature. It is composed of a central flexible graphite core (10) maintained in its shape by two metal cups (12) that do not touch. It is all surrounded by a tight sheath (15) enabling the flexible core (10) to be maintained in a neutral atmosphere such as a partial vacuum or a neutral gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

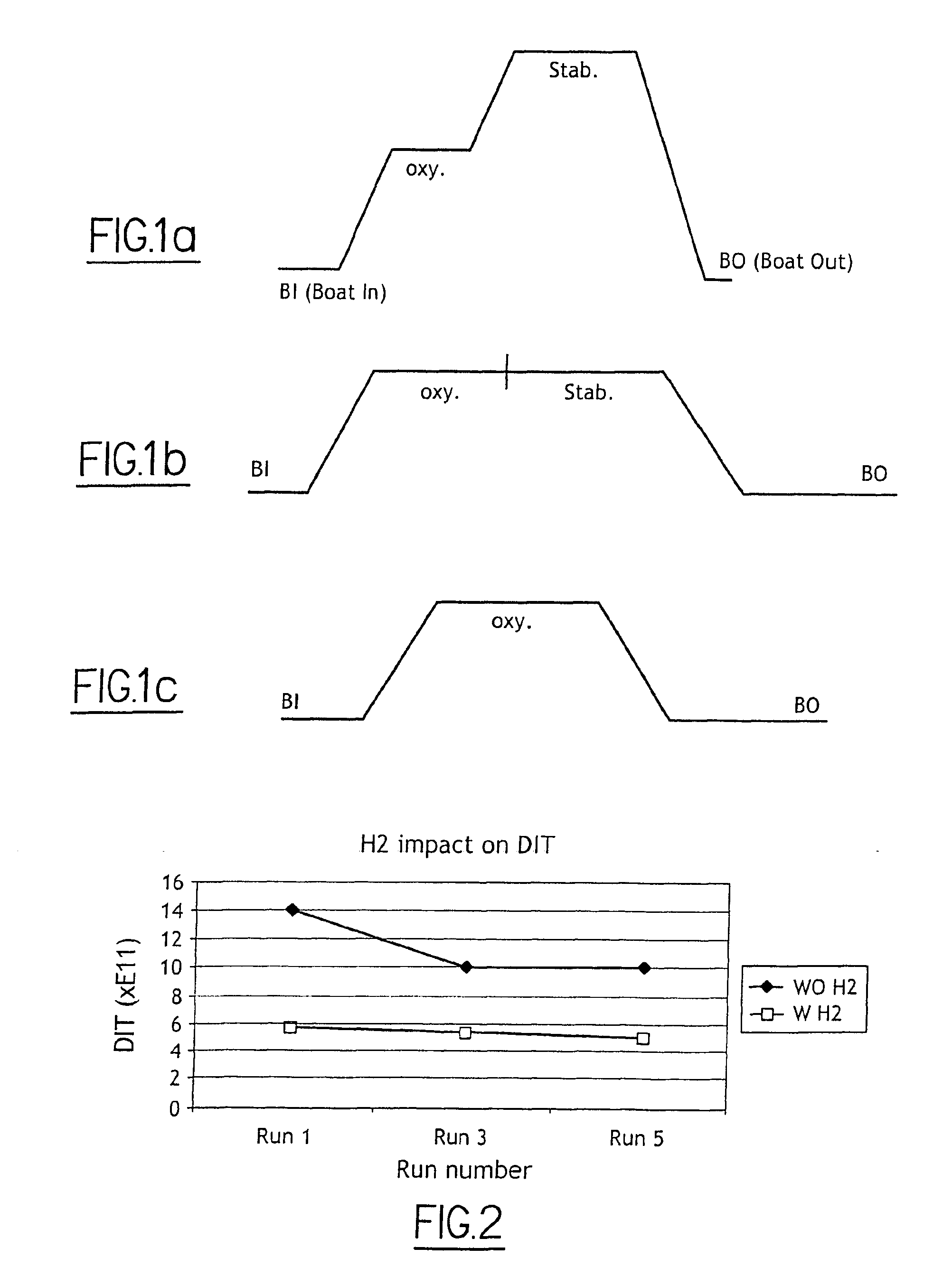

Method for reducing the trap density in a semiconductor wafer

ActiveUS20070020886A1Reduce trap densitySemiconductor/solid-state device manufacturingNeutral atmosphereEngineering

The invention provides methods for reducing trap densities at interfaces in a multilayer semiconductor wafer, specifically trap densities between an active layer and an insulating layer under the active layer. The methods comprise exposing wafers to high temperatures in a generally neutral atmosphere that also comprises one or more species that can, or whose ions can, migrate into the wafer down to the interface where reduction of the trap density is desired.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Ceramic-based heat-storage material based on iron tailings and preparation method of same

InactiveCN107286914AAdjust high temperature reactivityHigh heat storage densityHeat-exchange elementsNeutral atmosphereCobalt

The invention relates to a ceramic-based heat-storage material based on iron tailings and a preparation method of same. In a technical scheme, the method includes the steps of: 1) mixing the iron tailings, aluminum salt, a stabilizing agent and a complexing agent and grinding the mixture to obtain a ground material; 2) uniformly mixing the aluminum salt, an inorganic salt, cobalt powder, manganese powder and germanium powder, press-shaping the mixture, thermally treating the mixture in a neutral atmosphere at 400-600 DEG C, ball-milling the mixture, and drying and sieving the mixture to obtain a sieved material A with granularity being 0.088-1 mm and a sieved material B with granularity being less than 0.088 mm; 3) uniformly mixing 20-50 wt% of the ground material, 10-30 wt% of the sieved material A, 20-40 wt% of the sieved material B and 5-10 wt% of the inorganic salt, press-shaping the mixture, and thermally treating the mixture in a neutral atmosphere at 400-600 DEG C to produce the ceramic-based heat-storage material based on iron tailings. The preparation method has plenty sources of raw materials, is low in production cost and has simple process. The material is high in heat storage density and heat conductivity, and is excellent in compression strength and thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com