Preparation method of BAM (BaMgAl10O17) blue fluorescent powder for PDP (plasma display panel)

A technology of blue phosphor and compound, which is applied in chemical instruments and methods, luminescent materials, cold cathode tubes, etc., can solve the problems of not considering the change of BAM blue pink degree, the decrease of phosphor luminous efficiency, etc., and achieve good vacuum resistance UV degradation performance, good heat degradation performance, high luminous efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

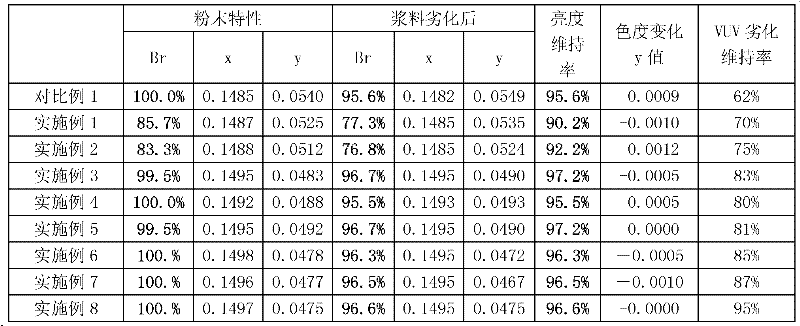

Examples

Embodiment 1

[0096] The raw material ingredients, high-temperature firing, and post-dispersion treatment are the same as those in Comparative Example 1. The sample is then heat-treated at 400°C for 30 minutes under atmospheric conditions. The obtained sample is subjected to the atmosphere heat treatment process in a tunnel furnace. The heat treatment temperature is within the temperature range of 900°C, and the heat treatment time in the highest temperature zone is 60 minutes. The entire heat treatment cycle is about 20 Hours, the nitrogen flow rate is 12.0m 3 / h.

Embodiment 2

[0098] The raw material ingredients, high-temperature firing, and post-dispersion treatment are the same as those in Comparative Example 1. The sample is then heat-treated at 800°C for 30 minutes under atmospheric conditions. The resulting sample completes the atmosphere heat treatment process in a tunnel furnace. The heat treatment temperature is within the range of 900°C, and the heat treatment time in the highest temperature zone is 60 minutes. The entire heat treatment cycle is about 20 Hours, the nitrogen flow rate is 12.0m 3 / h.

Embodiment 3

[0100] The raw material ingredients, high-temperature firing, and post-dispersion treatment are the same as those in Comparative Example 1. The sample is then subjected to atmospheric heat treatment in a tunnel furnace. The heat treatment temperature is 900°C. The heat treatment time in the highest temperature zone is 60 minutes. The entire heat treatment cycle is about 20 hours. The heating zone is filled with air and the air flow rate is 6.0m. 3 / h, the total flow of nitrogen in the second half is 8.0m 3 / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com