Patents

Literature

41results about How to "Short investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

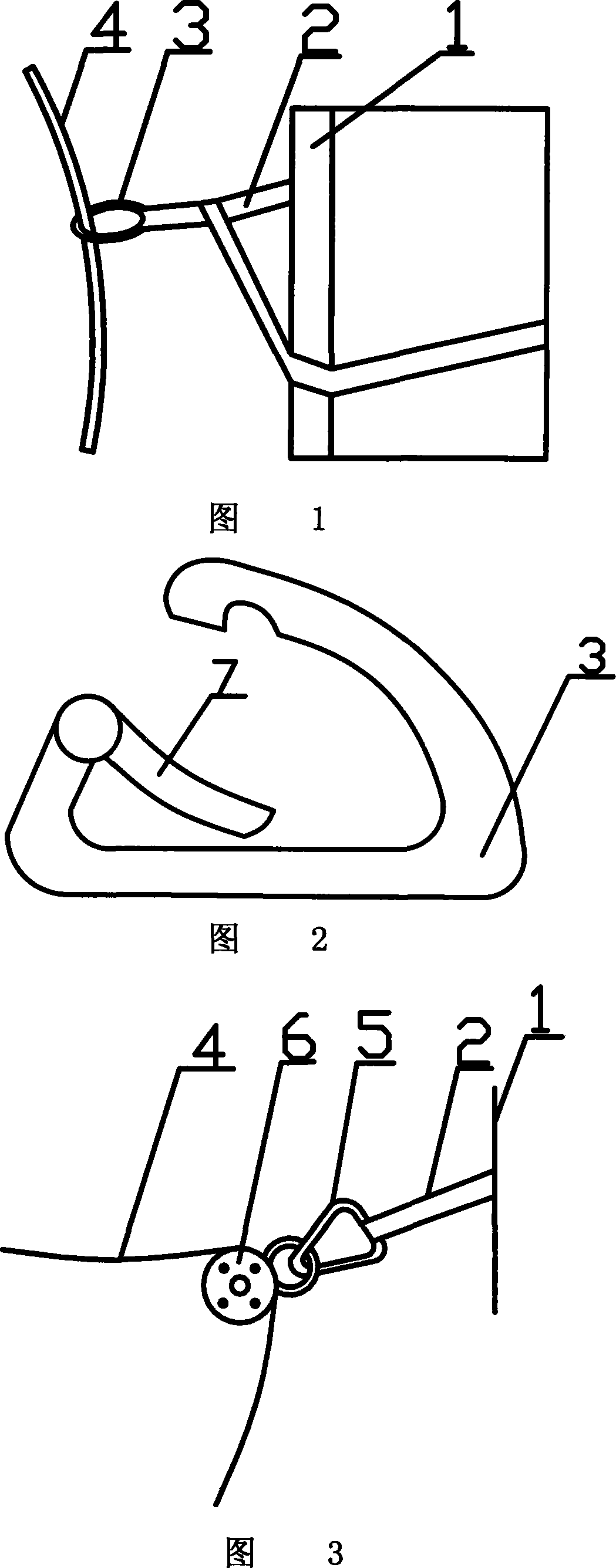

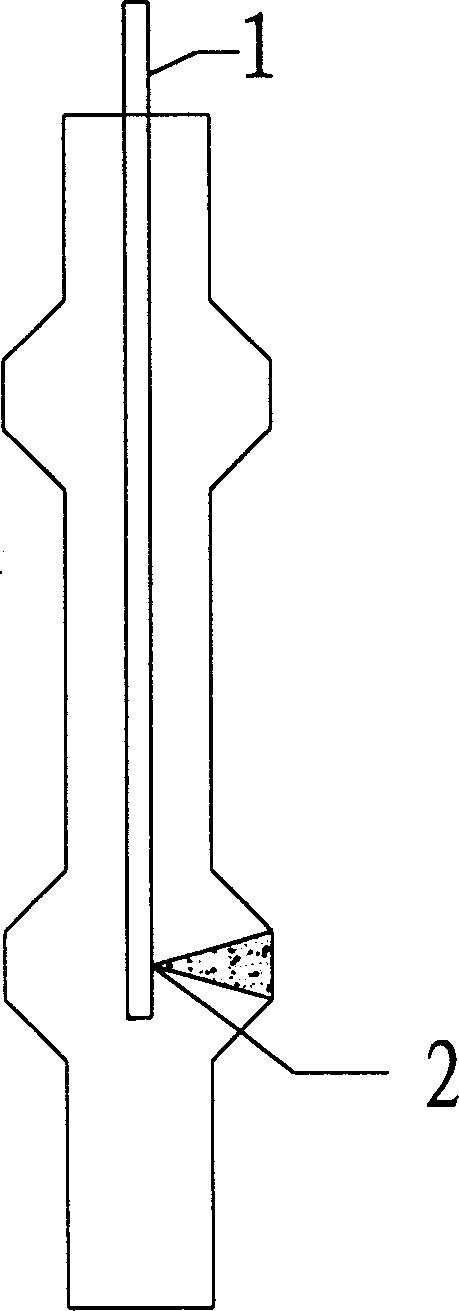

Anti-drop method for climbing iron tower of power transmission line

The present invention relates to a fall protection device used in the process of climbing steel tower of power transmission line. Said full protection device includes the following several portions: large hanger, small hanger, endless rope, delta wire-lock fastener, pear-shaped fastener, small tackle and safety hook. Said invention also provides a fall protection method by using said fall protection device and its concrete operation steps.

Owner:贵州送变电有限责任公司

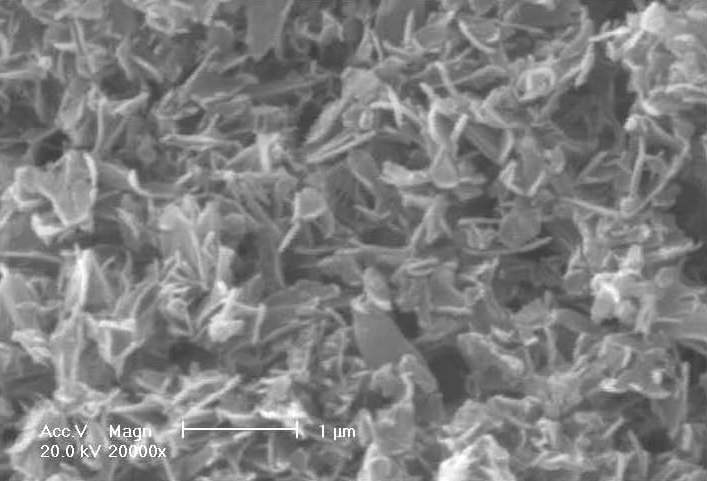

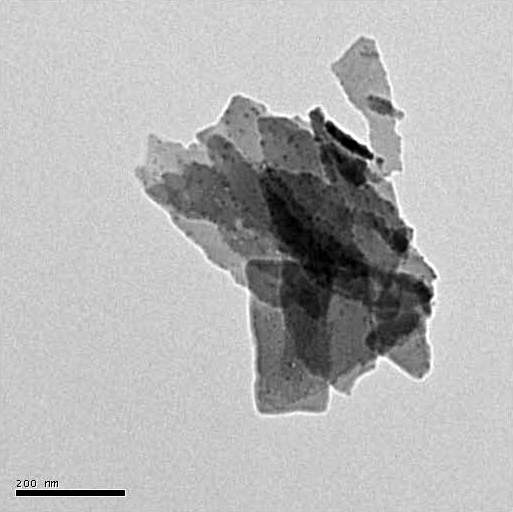

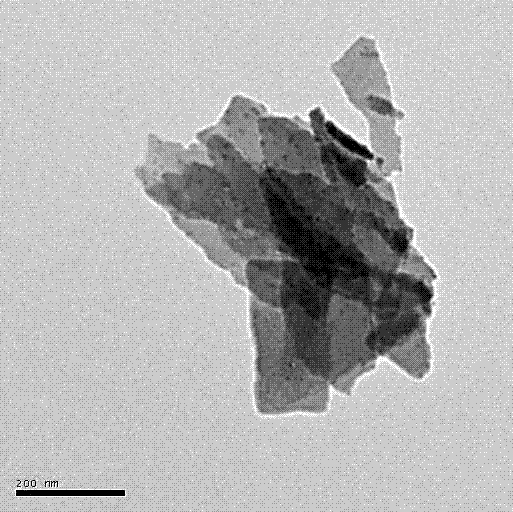

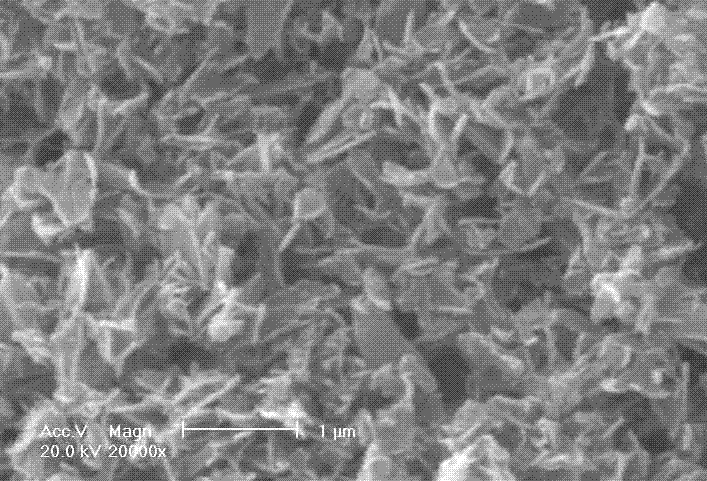

Method for preparing flaky nano copper powder

The invention discloses a method for preparing flaky nano copper powder, comprising the following steps: compounding a copper salt aqueous solution with a surfactant to obtain a mixed solution A, wherein the water in the copper salt aqueous solution and the surfactant form a surfactant compound system; (2) compounding a reducing agent aqueous solution with the surfactant which is the same as that used in step (1) to obtain a mixed solution B, wherein the water in the reducing agent aqueous solution and the surfactant form the surfactant compound system; (3) mixing the mixed solution B obtained in step (2) and the mixed solution A obtained in step (1) by stirring at the temperature of 20 DEG C to 80 DEG C, and reacting completely with stirring; and (4) carrying out solid and liquid separation on the product, washing the solid, and carrying out vacuum drying to obtain the flaky nano copper powder. The method of the invention has mild condition, simple process, short production period, low equipment investment and low preparation cost, and is easy to realize industrial production. The prepared flaky nano copper powder has consistent appearance, uniform size and good dispersibility.

Owner:尊领科技集团有限公司 +1

Instant agent of donkey-hide gelatin and preparation method

ActiveCN1600320AEasy to produceProduct quality is easy to controlPowder deliveryUnknown materialsGelatinChemistry

Owner:FUJIAO GROUP CORP SHANDONG

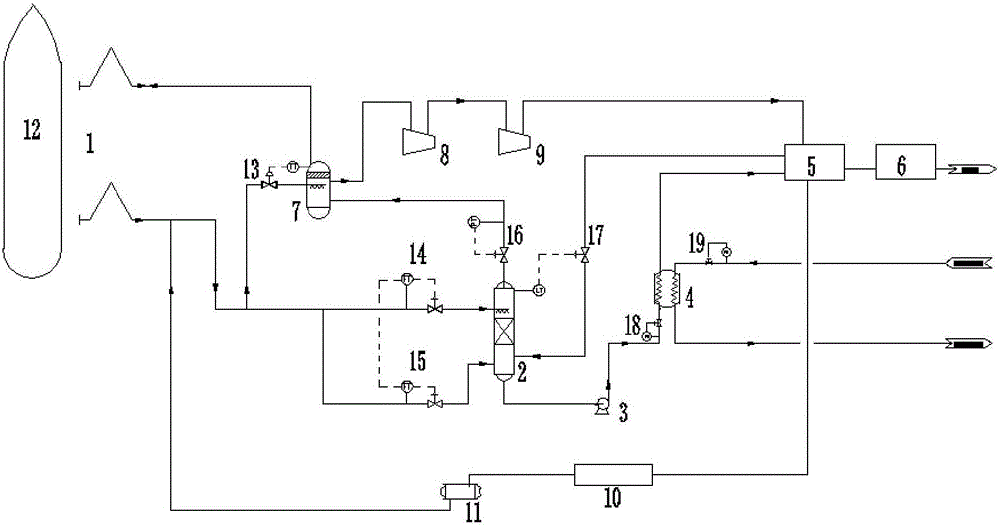

Process for recycling copper through electrodeposition by treating scrap copper materials by adopting cyclone electrolysis technology

ActiveCN102534656ATo achieve the purpose of high efficiency and environmental protectionImprove leaching efficiencyPhotography auxillary processesProcess efficiency improvementHigh current densityCyclone

The invention provides a process for recycling copper through electrodeposition by treating scrap copper materials by adopting a cyclone electrolysis technology, belonging to the technical field of recycling copper from wastes containing copper. The process is characterized by taking various purchased wastes containing copper as raw materials, preliminarily screening and grinding the wastes, adding the materials to a dissolved copper leaching bath device to undergo continuous copper dissolving to obtain a copper sulfate solution, then filtering the solution with precision filter equipment, decoppering the obtained filtrate through cyclone electrolysis, scalding an obtained copper pipe with weak acid and then feeding the copper pipe into a product processing unit to process a standard copper plate. The process has the following beneficial effects: through portable or module assembly, the cyclone electrolysis bath and support equipment are convenient to install, dismantle and move; the solution circulates in a closed loop, thus avoiding emission of harmful gases; electrolytic deposition is carried out on the metals selectively and the copper can be better purified by applying the cyclone electrolysis technology; higher current density and current efficiency are ensured, fewer reagents are consumed, the production cost is lowered and the enterprise revenue is improved; and high efficiency and high purity electrolytic extraction is carried out on the solution, the recycled copper is the standard cathode copper and the total recycling rate is above 96%.

Owner:浙江科菲科技股份有限公司

Offshore LNG receiving system and method

ActiveCN106287213AShort processReduce construction costsWaterborne vesselsContainer filling methodsShoreLiquefied natural gas

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

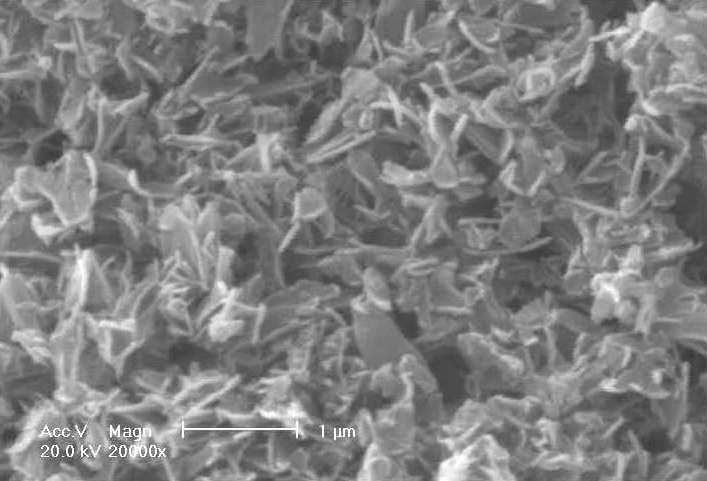

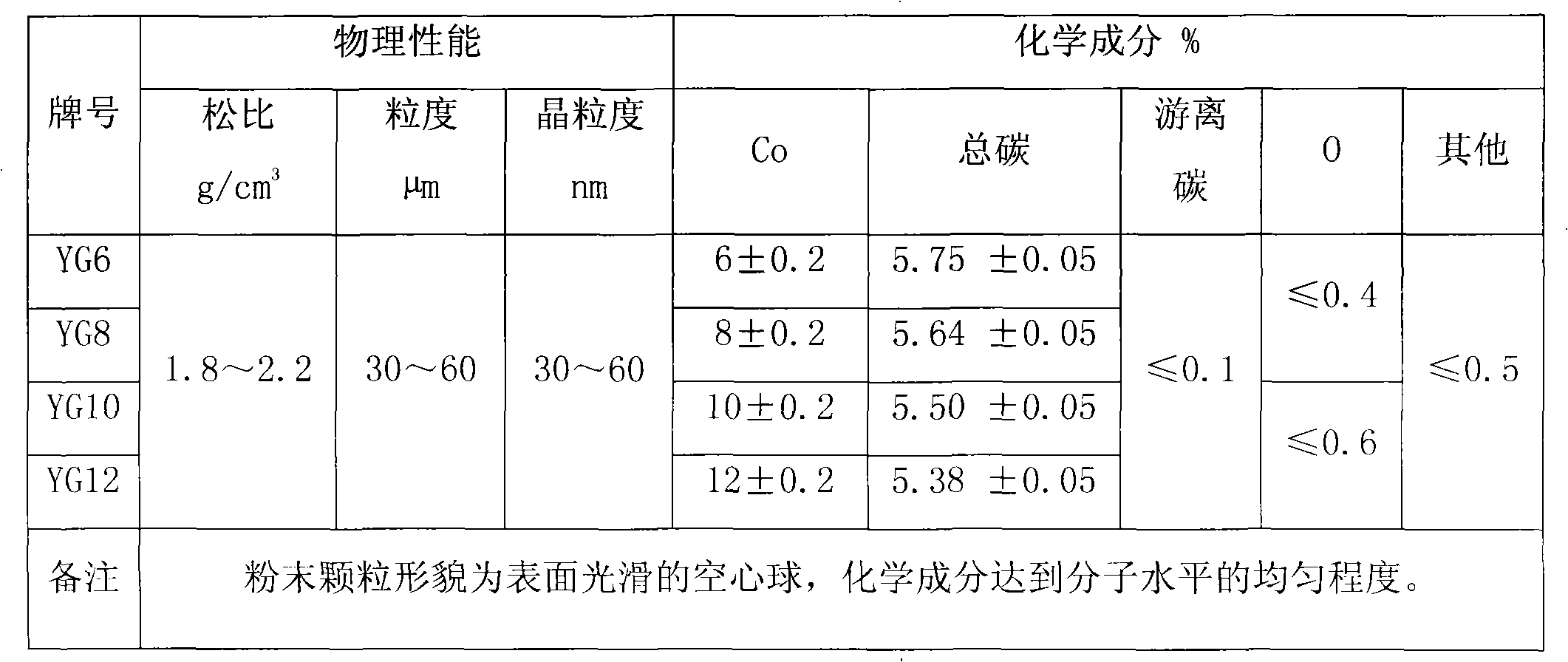

Preparation method of nanometer WC-Co composite powder

The invention discloses a preparation method of nanometer WC-Co composite powder. In the formula, soluble carbon source is directly added, carbon content is accurately controlled by regulating the hydrogen-carbon ratio of mixed gas in the carbonization and carbon regulation procedures. The specific steps are as follows: (1) according to the main ingredients of the WC-Co composite powder, calculating and weighing tungsten salt, cobalt salt and carbon source, dissolving the ingredients in water, evenly stirring, and preparing precursor solution; (2) preparing precursor pre-composite powder by spraying and drying mixed solution; (3) under the protection of neutral atmosphere, roasting the prepared precursor pre-composite powder to prepare original composite powder; (4) under the protection of hydrogen-carbon mixed gas, further carbonizing and regulating carbon for original composite powder at high temperature to prepare the nanometer WC-Co composite powder. The carbon element of the composite powder of the method has reasonable addition mode, easily precise control of carbon content, even chemical component, simple manufacturing technology and easy realization of industrial production.

Owner:FUJIAN JINXIN TUNGSTEN

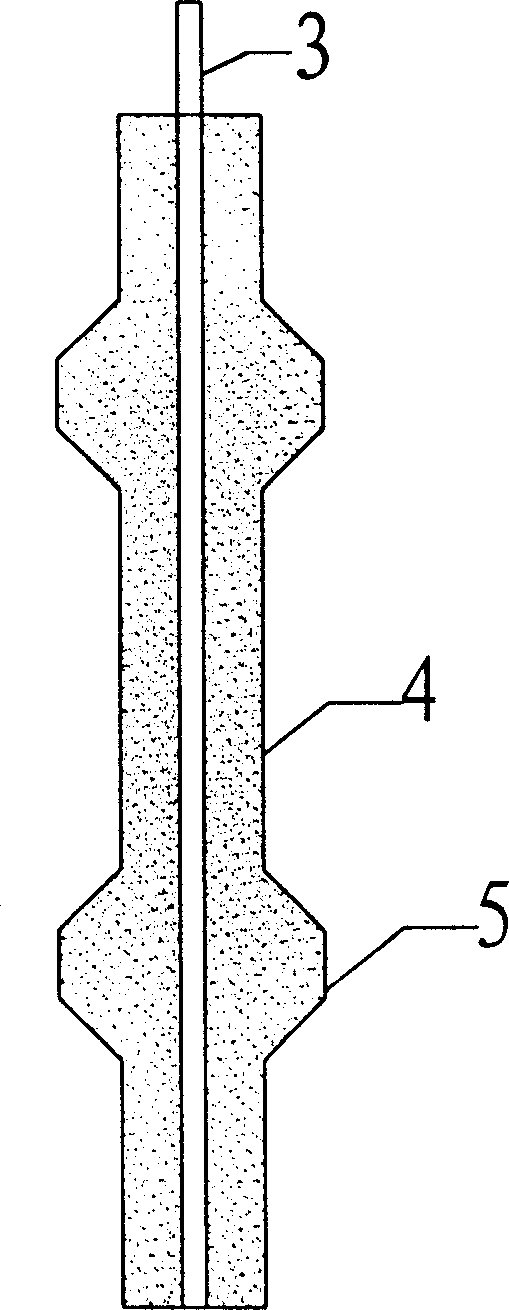

Section bar inserting and high-pressure rotary jetting method for forming pile with expanded plates in sink area

InactiveCN1844588AReduce occupancyImprove vertical bearing capacityBulkheads/pilesLand resourcesEconomic benefits

The invention discloses a method for molding the high-pressure rotational spray expansion post in sink area. Wherein, forming a trapezium expansion disc on the post formed by rotational spraying slurry injection according to the segment pressure or the injection time; inserting section steel as anti-drawing material into the post. The invention can increase the upright bearing ability and improve the horizontal bearing ability; especially at the interface of soil, it can eliminate the effect of horizontal displacement, with lower cost, short time, easy construction, lower soil occupied and saved land resource. The invention can be used to strengthen the foundation in large distortion condition, to reduce cost and improve economic benefit, with wider application.

Owner:CHINA UNIV OF MINING & TECH

Method for treating acid waste water containing copper and iron

InactiveCN102531271ANo secondary pollutionFast formingMultistage water/sewage treatmentBiological water/sewage treatmentCopperMetal

The invention discloses a method for treating acid waste water containing copper and iron. The method comprises the steps of: firstly, carrying out metathesis on copper in wastewater by using iron powder and filtering; secondly, activating and culturing strains preserved in a unit by using a solution obtained through the metathesis, and carrying out domestication; thirdly, oxidizing the solution obtained through the metathesis by using domesticated bacteria under the stirring or aerating condition; and fourthly, generating polyferric sulfate by using an oxidized Fe<3+> solution. The method has the advantages of short process flow, simple equipment structure, less investment, low cost, environment friendliness because of no generation of externally-emitted matters, and capability of recycling valued metals so that economic benefit is increased.

Owner:厦门紫金矿冶技术有限公司

Method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red

InactiveCN102674480AReduce consumptionNo emissionsFerric oxidesIron sulfatesSludgeAmmonium Hydrogen Carbonate

The invention discloses a method for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red and relates to a technological method for chemical extraction and separation. The method is an organic solvent effect crystallization process for extracting and separating iron from industrial waste iron sludge and preparing ferrous sulfate and iron oxide red, consists of four technical processes and realizes the chemical goal of extracting and separating iron and preparing ferrous sulfate and iron oxide red. The four technical processes are respectively as follows: 1) a diluted sulfuric acid leaching process of industrial waste iron sludge; 2) an iron crystallization and separation process under the effect of monobasic alcohol serving as organic solvent; 3) an iron oxide red preparation process through reaction between ferrous sulfate solution and ammonium hydrogen carbonate and oxidizing roasting of sediment; and 4) an ammonium sulfate preparation process through evaporative crystallization of sedimentation solution. The method is suitable for extracting and separating iron element from all kinds of iron-containing minerals and industrial waste residues, valuable components are comprehensively utilized and the environmental pollution and the resource wastage are reduced.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

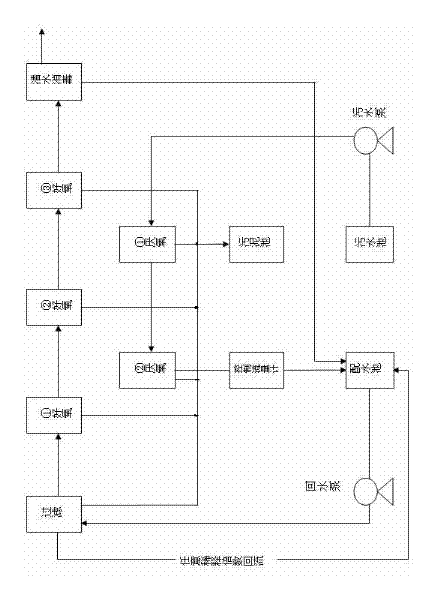

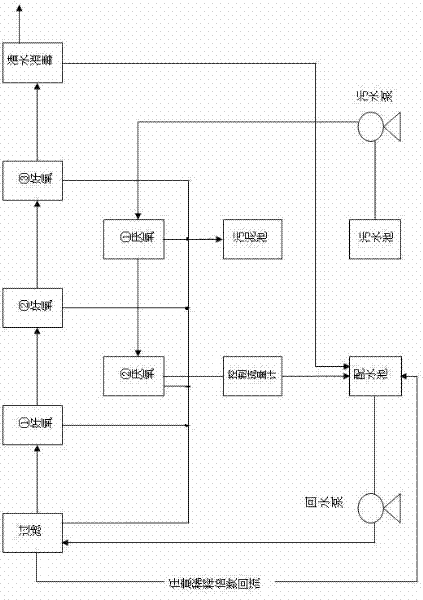

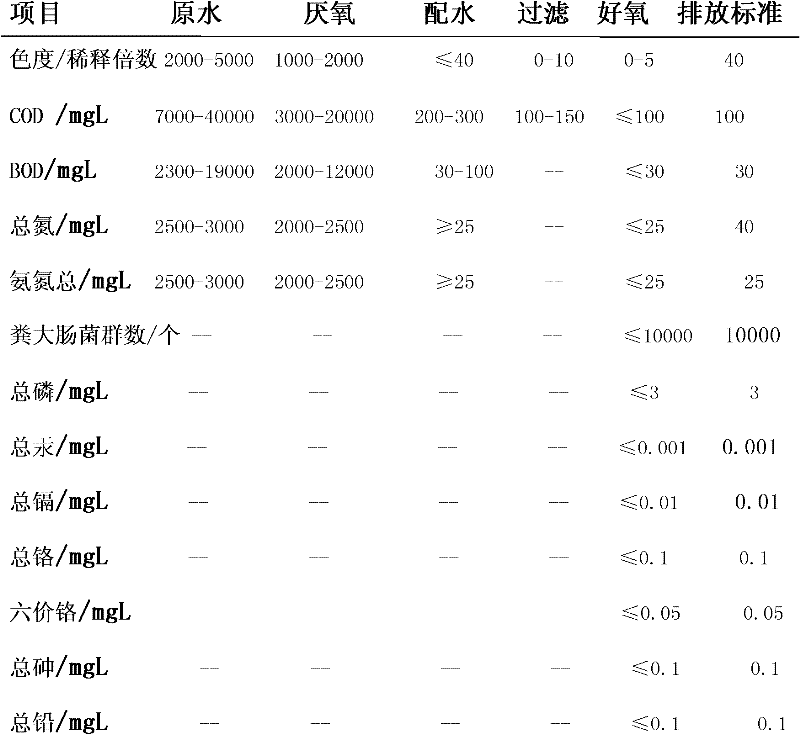

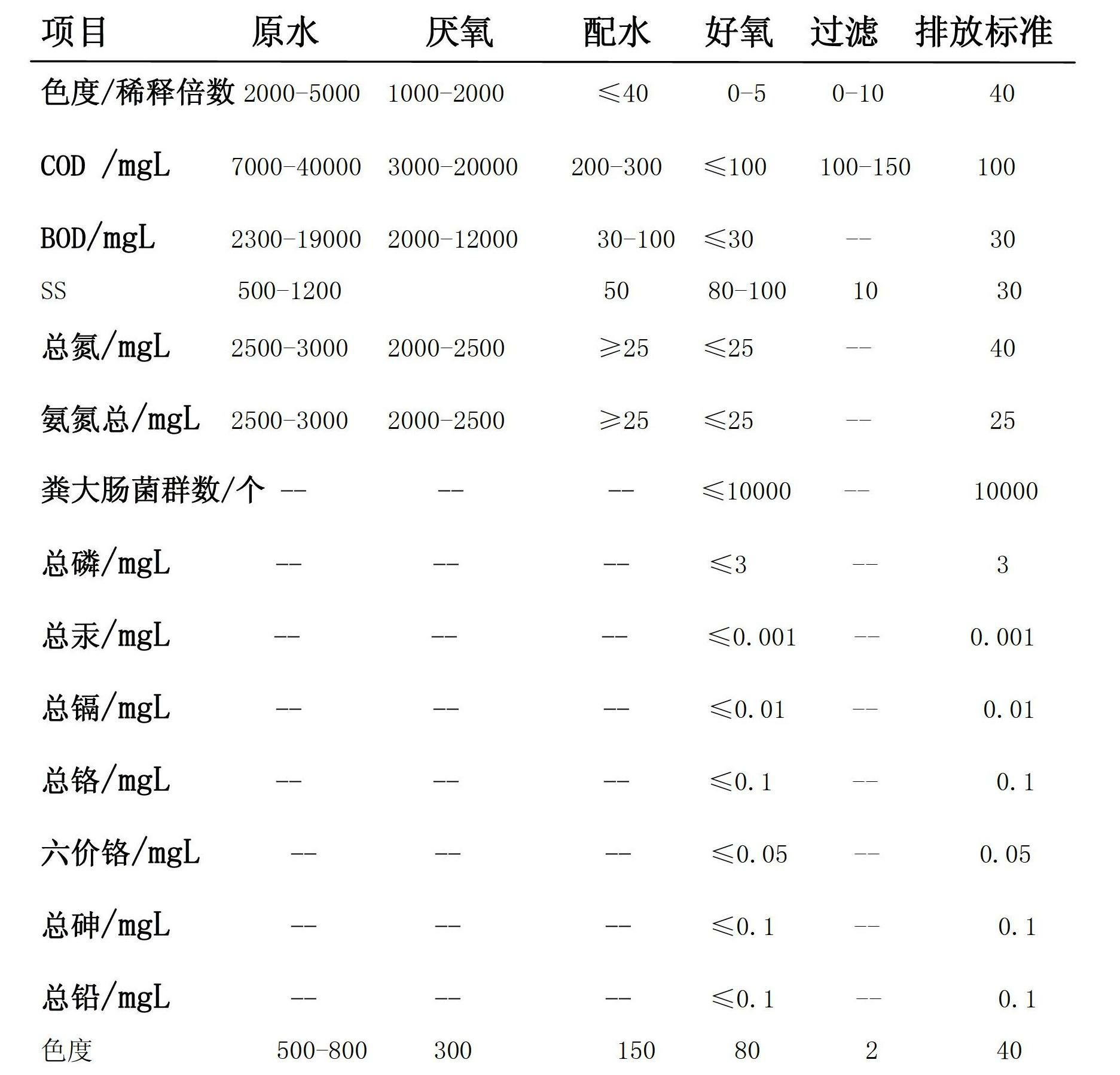

Technology for treating high-concentration and high-chromaticity wastewater

InactiveCN102303937ASmall footprintShort stayMultistage water/sewage treatmentDyeingHigh concentration

The invention discloses a technology for treating high-concentration and high-chromaticity wastewater. The technology realizes wastewater treatment by the following steps: treating by a two-stage anaerobic tank, a water distribution tank, a filter tank and a one-to-three-stage aerobic biological tank; disinfecting in a clear water tank; and recycling the water reaching the standard in the water distribution tank. The treatment technology is suitable for treating various types of high-concentration and high-chromaticity wastewater, such as garbage percolate, dye mother liquor, dyeing and finishing wastewater, cane mill alcohol waste mash, DDNP (diazodinitrophenol) waste liquor, soy sauce water, traditional Chinese medicine wastewater, electrophoretic paint wastewater and the like. According to the technology, various types of high-concentration and high-chromaticity wastewater can reach the nationally specified discharge standard after treatment. In addition, the complicated high-concentration and high-chromaticity wastewater treatment is simplified, thereby greatly lowering the cost for treating the type of wastewater.

Owner:喻明生

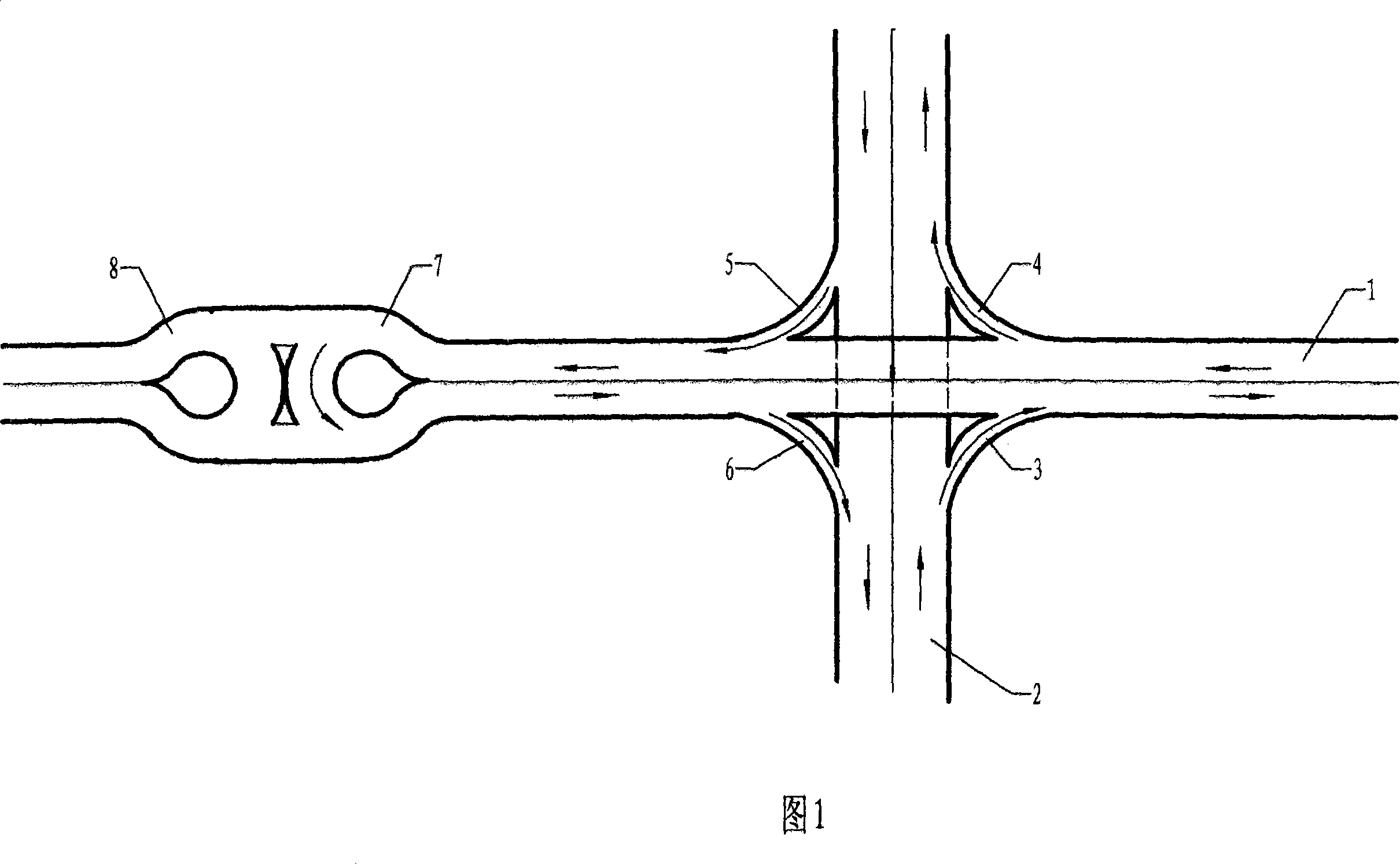

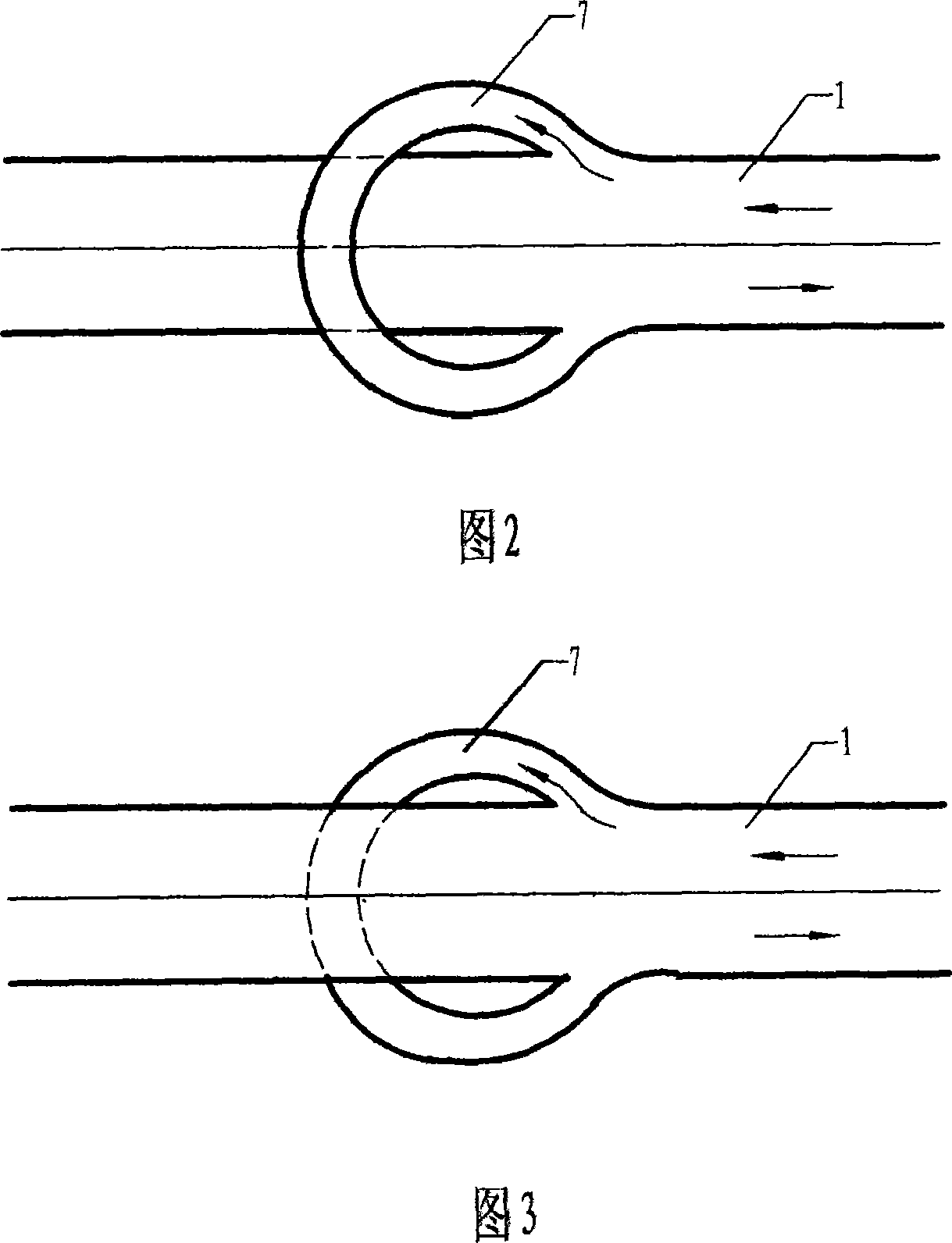

Gyration expedite viaduct

The invention relates to a rotating smooth type crossroad, comprising a cross right bridge. The cross right bridge is provided with four inner arc right hand bending channels; the four extending directions of the main artery on the cross right bridge are respectively provided with a left rotating channel which is an arc bending channel left rotating 360 degrees. The invention not only solves the vehicle smooth problem at the crossroad without red and green light control, but also has the advantages of simple structure, few layers, low height, short approaching bridge and investment saving, which is beneficial for popularizing and use.

Owner:陈崧

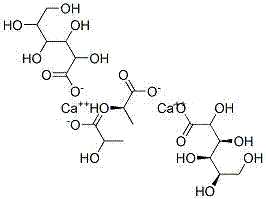

Chemical dust suppressing agent for mines

InactiveCN107384319AEasy to prepareLess investment in equipmentOther chemical processesChemistryAlkylphenol

The invention relates to a chemical dust suppressing agent for mines. The chemical dust suppressing agent is characterized by being prepared from the following raw materials in parts by weight: 15 to 25 parts of alkylphenol ethoxylate, 15 to 25 parts of alpha-olefin sulfonate, 15 to 25 parts of alkyl amide propyl betaine, 3 to 10 parts of tetra-polylysine, 0.5 to 1 part of water glass, 0.5 to 1 part of calcium chloride, 0.5 to 1 part of compound of calcium lactate and calcium gluconate, 2 to 8 parts of epoxy resin, 0.05 to 0.1 part of 2-methyl sodium isocitrate, 1 to 5 parts of 1,2-propanediol and 100 parts of water. The chemical dust suppressing agent has the advantages that a surfactant and a complexing product are poisonless, and can be easily dissolved into water; the obtaining is easy, the cost is low and economical, and the surface tension is lower; a produced foam film has certain viscosity and elasticity, and the secondary pollution can be avoided.

Owner:ANSTEEL GRP MINING CO LTD

Cyclone treatment technique of nickel-containing electroplating wastewater

InactiveCN104724864AIncrease current densityIncrease workloadPhotography auxillary processesWater contaminantsElectroplating wastewaterImpurity

The invention discloses a cyclone treatment technique of nickel-containing electroplating wastewater. By adopting a cyclone technique which is completely different from the traditional technique for electrodepositing nickel, the current efficiency can reach 90% above which is much higher than 75% in the traditional nickel electrodeposition. The current density is 600-800 A / m<2> which is more than twice higher than that of the traditional technique. Besides, the nickel product produced by the technique has the advantages of stable quality and low requirements for impurity content in the catholyte. The technique can decrease civil engineering investment, and has the advantages of low production cost, high degree of mechanization, low workshop labor requirement, low worker labor intensity and the like.

Owner:江苏地一环保科技有限公司

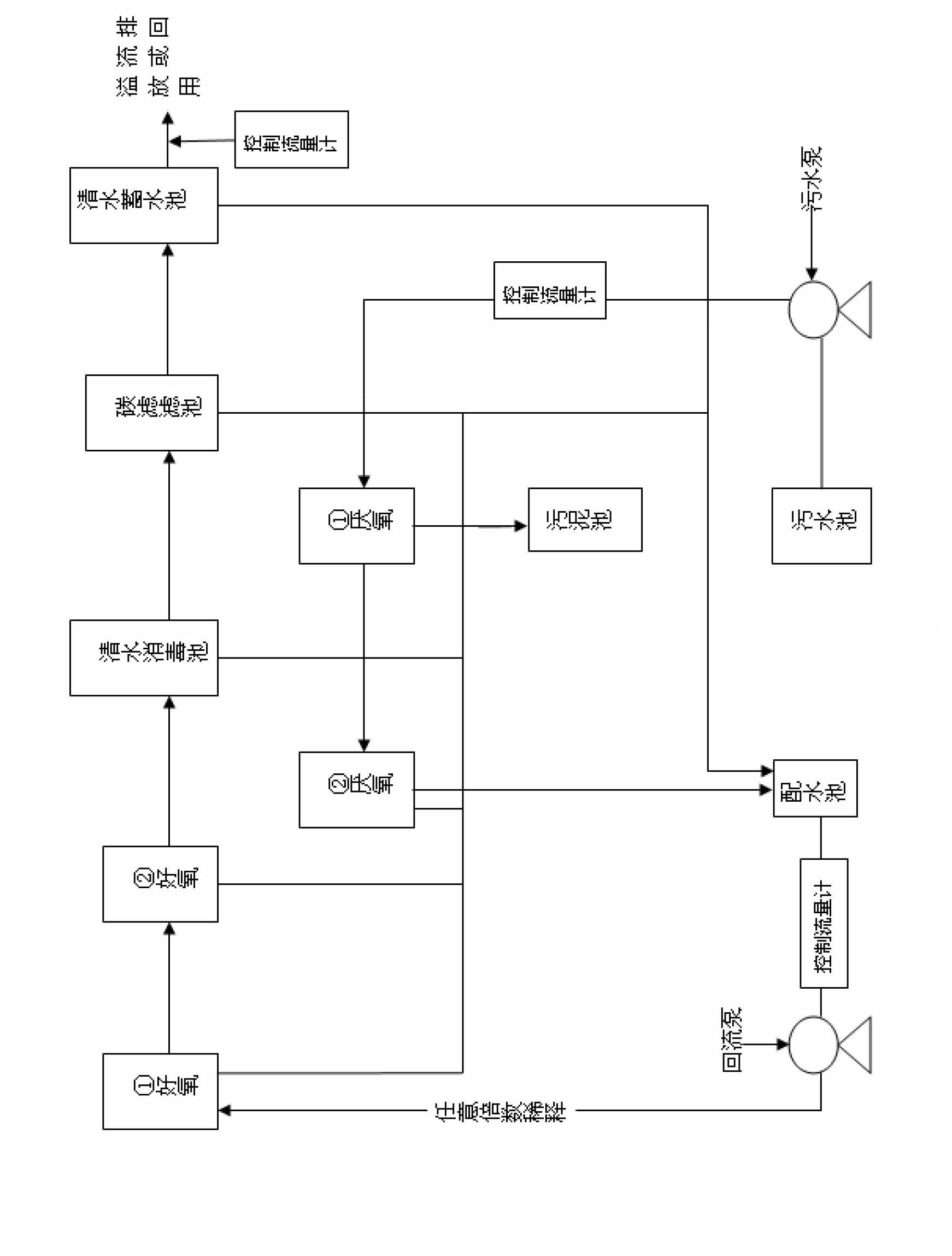

High-concentration high-chroma wastewater treatment technique

ActiveCN102642994AReduce processing stepsSmall footprintMultistage water/sewage treatmentHigh concentrationFiltration

The invention discloses a high-concentration high-chroma wastewater treatment technique which comprises steps as follows: wastewater is treated through primary and secondary anaerobic tanks, a distribution reservoir, primary, secondary and tertiary aerobic biological tanks; the qualified water degraded by aerobes naturally flows into a clear water disinfection tank; the disinfected water naturally flows into a filter tank, thereby removing suspended substances and residual color by adsorption and filtration; the qualified filtered water flows back to the distribution reservoir to dilute the circulating water, and excess water enters a clear water reservoir; and the water outlet of the clear water reservoir is provided with a flow controller for controlling the balance between the overflow discharge water flow and the raw wastewater water inflow of the sewage pump. The treatment technique disclosed by the invention is suitable for treating multiple types of high-concentration high-chroma wastewater, such as garbage leachate, dye mother liquor, dyeing and finishing wastewater, alcohol waste fermented liquor in cane mills, DDNP waste liquor, soy sauce liquor, traditional Chinese medicine wastewater, electrophoretic paint wastewater, slaughter wastewater, aquacultural wastewater and the like. The invention not only can treat multiple types of high-concentration high-chroma wastewater to achieve or exceed the discharge standard specified by China, but also can simplify the complex high-concentration high-chroma wastewater treatment, thereby greatly lowering the wastewater treatment cost.

Owner:喻明生

Method for separating and recovering silver and palladium from silver-palladium alloy scrap

InactiveCN112501438AInhibit electrolysisEffects of recycling processes such as avoidor restoreProcess efficiency improvementWater chlorinationAlloy

The invention discloses a method for separating and recovering silver and palladium from silver-palladium alloy scrap. The comprises the following steps of dissolving and leaching high-silver low-palladium alloy scrap by using nitric acid; conducting selective palladium precipitation on the leachate by adding a first palladium precipitation agent, and filtering to obtain silver-rich filtrate and palladium-rich salt; preparing high-purity silver powder from the silver-rich filtrate by adopting a reduction method; and after palladium-rich salt oxidation acid leaching, adding a second palladium precipitation agent for further purification and recovery. By adopting the recovery method to recover palladium, the problem of entrainment loss of precious metal ions caused by a traditional chlorination precipitation method is optimized, the tedious step of repeatedly washing silver chloride precipitates to recover the precious metal ions is avoided, the recovery process of the palladium is greatly shortened, the recovery rate and purity of the palladium are remarkably improved, meanwhile, the influence of the palladium on recovery of the high-purity silver powder is avoided, the energy consumption can be effectively reduced, the difficulty in wastewater treatment is reduced, and the method is environment-friendly.

Owner:FIRST RARE MATERIALS CO LTD

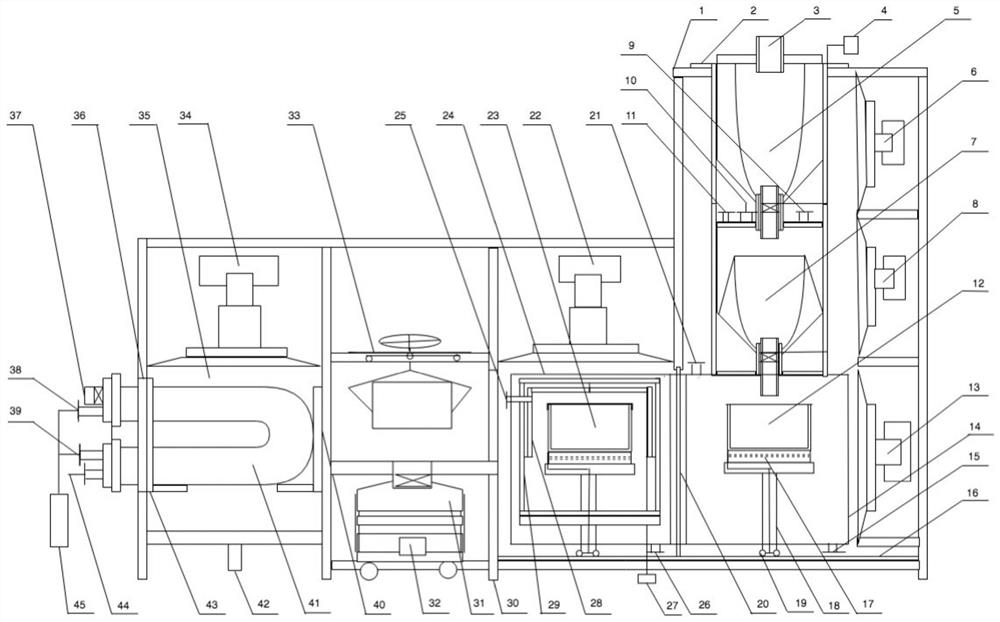

Method and device for preparing 6N polycrystalline silicon by vacuum microwave refining of industrial silicon

ActiveCN112624122AConducive to technology upgradesAvoid pollutionFinal product manufactureSilicon compoundsSingle crystalSolar cell

The invention discloses a method and a device for preparing 6N polycrystalline silicon by vacuum microwave refining of industrial silicon, wherein the method comprises the following steps: flowing industrial silicon melt into a primary oxidation refining furnace, introducing mixed gas I, adding SiO2 powder to perform primary oxidation refining, flowing into a secondary oxidation refining furnace, vacuumizing the system, and introducing mixed gas II; then adding SiO2 powder to perform secondary oxidation refining, enabling the mixture to flow into a directional solidification crucible to be subjected to primary vacuum evaporation and directional solidification refining, and heating the materials to be subjected to secondary vacuum evaporation refining; cooling and taking out the silicon ingot, removing the head, tail and edge portions, and crushing and screening the product; then feeding the product into a reactor and vacuumizing the equipment, feeding argon and mixed gas III, and carrying out microwave plasma vacuum evaporation and oxidizing volatilization refining to prepare polycrystalline silicon of which the purity is not less than 6N, the content of metal impurities such as boron, phosphorus, iron and the like is less than 0.1 ppm, the resistivity is about 2.5 ohm.cm. According to the invention, the quality requirement of the polycrystalline silicon solar cell material is met, and the high-quality and high-efficiency monocrystalline silicon solar cell material can be obtained through subsequent casting or single crystal drawing.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting and dyeing reddish-brown natural dye of oil-tea camellia shells

InactiveCN102153882AMeet needsNo allergic reactionNatural dyesDyeing processEcological environmentCamellia oleifera

The invention discloses a method for extracting and dyeing reddish-brown natural dye of oil-tea camellia shells. After cleaned and air-dried, the oil-tea camellia shell is smashed and leached with taking sodium carbonate aqueous solution as solvent. Filtered filter residues are repeatedly leached with the sodium carbonate aqueous solution. Filtrate is combined to obtain natural dye concentrate of the oil-tea camellia shell by pressure reduction, distillation and concentration. The obtained concentrate is subjected to pectin removal, filtration, pressure reduction, distillation, concentration, spray and drying to obtain the powder natural dye of the oil-tea camellia shell. Pretreated pure cotton fabric can be dyed with the natural dye of the oil-tea camellia shell to obtain fabric which is uniform in gloss. The method for extracting and dyeing the natural dye of the oil-tea camellia shell is safe and environment-friendly by taking the oil-tea camellia shell as a raw material so as to effectively utilize natural waste. The fabric dyed by the method can be made into clothing that is safe, free of carcinogenic and deforming action or causing skin sensibility, good in compatibility with ecological environment and available for biodegradation.

Owner:CHANGZHOU UNIV +1

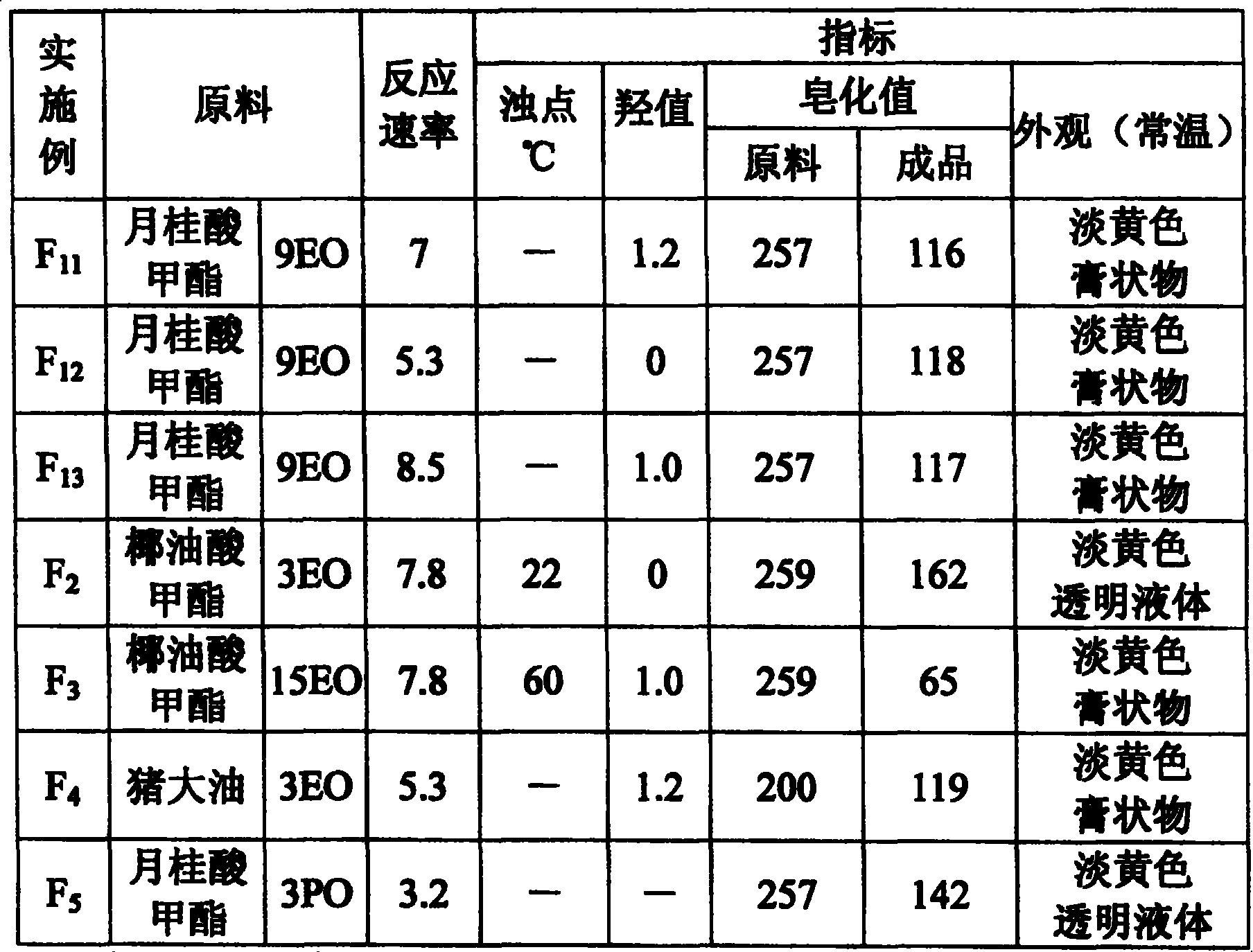

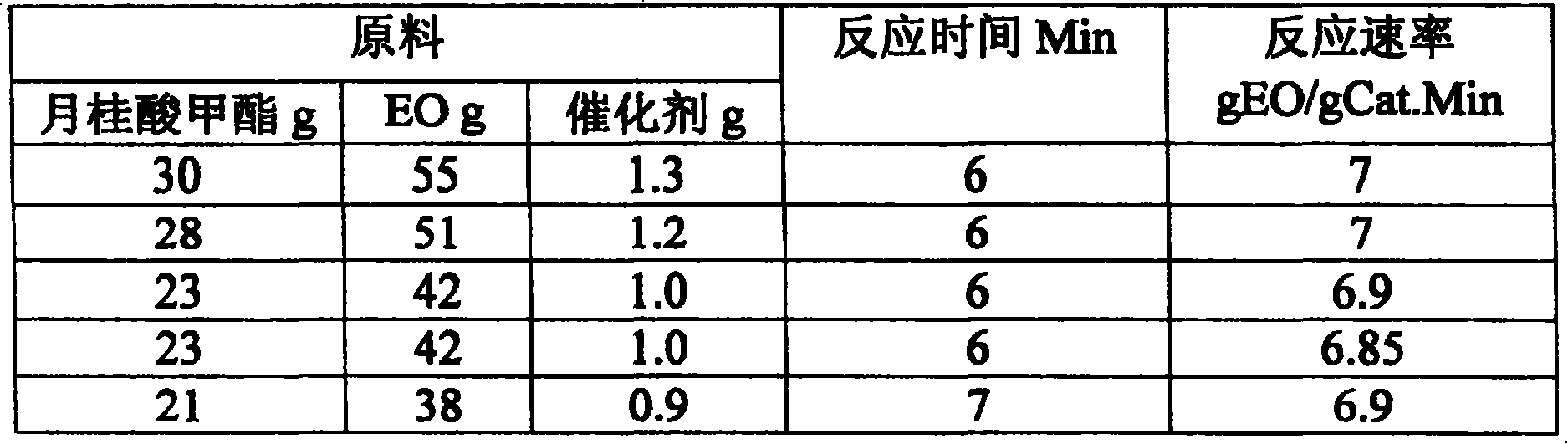

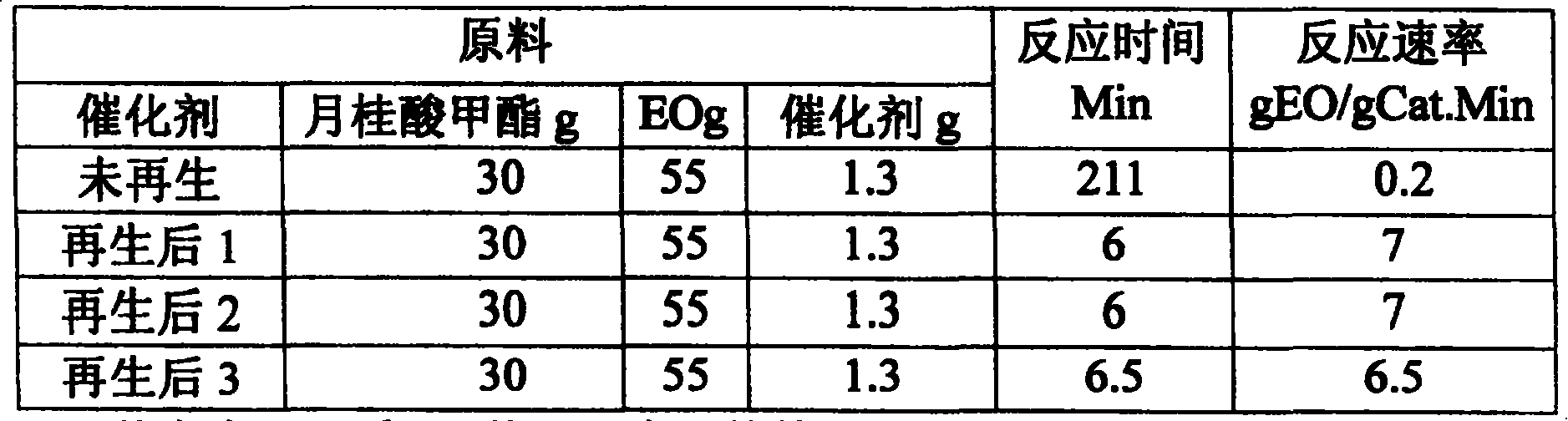

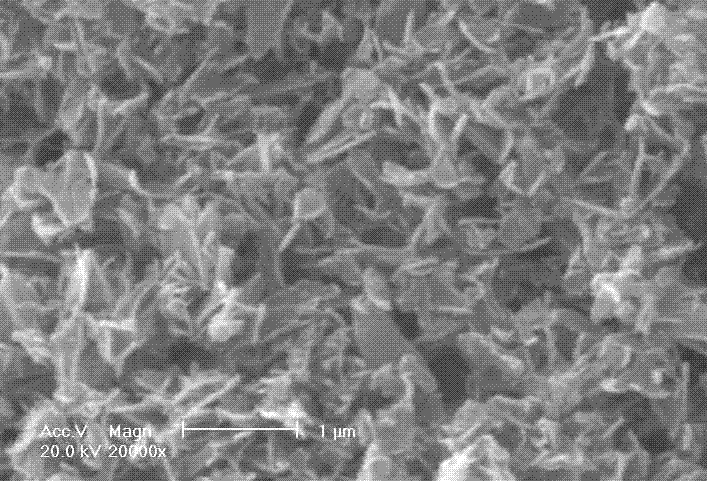

Fatty acid ester alkoxylating catalyst and its preparation method

ActiveCN100391597CHigh reactivityGood reaction selectivityPhysical/chemical process catalystsFunctional group formation/introductionSide reactionAlkoxylation

The present invention is fatty acid ester oxyalkylating catalyst and its preparation process, and provides one kind of catalyst with oxyalkylating activity on fatty acid ester. The catalyst consists of compound active aluminum-magnesium component and active clay in the weight ratio of 3-7, and is ring shaped. The preparation process includes the steps of adsorption, washing, stoving, mixing, extrusion to form, drying, showering and roasting. The catalyst of the present invention has excellent reaction activity and selectivity, and can inhibit side reaction during the production process. The product produced adopting the catalyst has no need of post-treatment and has less side products, and this results in simplified operation process.

Owner:LIAONING OXIRANCHEM INC

Method for preparing flaky nano copper powder

The invention discloses a method for preparing flaky nano copper powder, comprising the following steps: compounding a copper salt aqueous solution with a surfactant to obtain a mixed solution A, wherein the water in the copper salt aqueous solution and the surfactant form a surfactant compound system; (2) compounding a reducing agent aqueous solution with the surfactant which is the same as thatused in step (1) to obtain a mixed solution B, wherein the water in the reducing agent aqueous solution and the surfactant form the surfactant compound system; (3) mixing the mixed solution B obtained in step (2) and the mixed solution A obtained in step (1) by stirring at the temperature of 20 DEG C to 80 DEG C, and reacting completely with stirring; and (4) carrying out solid and liquid separation on the product, washing the solid, and carrying out vacuum drying to obtain the flaky nano copper powder. The method of the invention has mild condition, simple process, short production period, low equipment investment and low preparation cost, and is easy to realize industrial production. The prepared flaky nano copper powder has consistent appearance, uniform size and good dispersibility.

Owner:尊领科技集团有限公司 +1

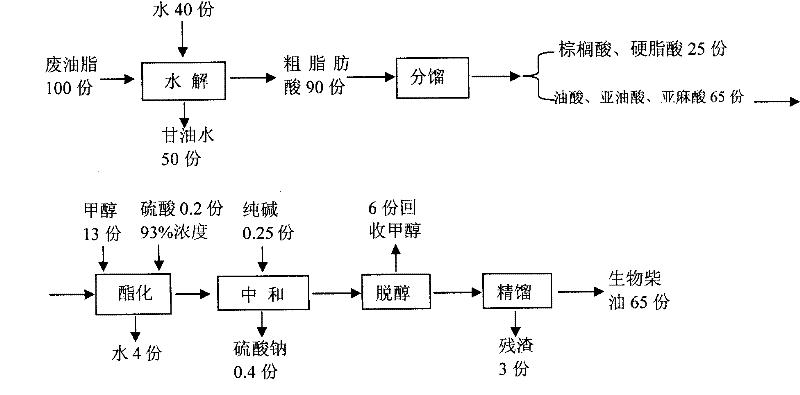

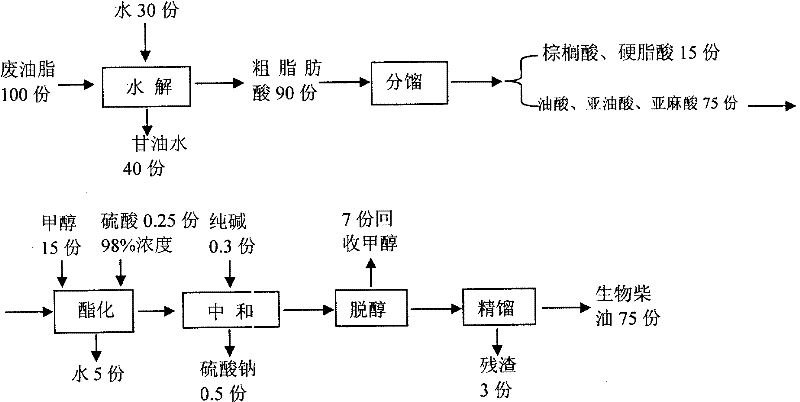

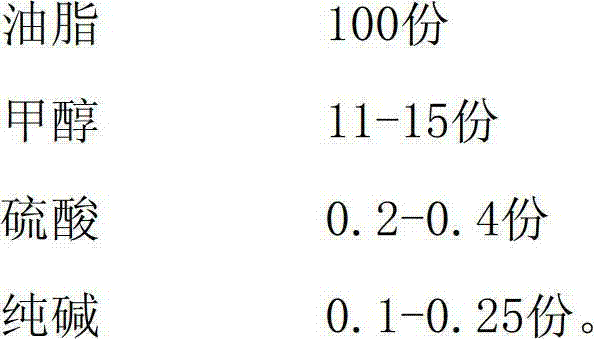

Method for preparing -20 DEC C biodiesel from waste lipid by distillation process

InactiveCN101440298BFunction increaseSimple preparation processBiofuelsLiquid hydrocarbon mixture productionBiodieselPtru catalyst

Owner:XIANGTAN ZHAOSHAN LIPID SCI & TECH

Composite dieselguhr coagulation aid used for garbage percolation sewage treatment

InactiveCN1868909AGood effectReduce usageWater/sewage treatment by flocculation/precipitationSewageSmall footprint

A composite diatomite coagulant with both coagulating and flocculating actions for treating the osmotic garbage sewage is prepared from the diatomite containing alumina (10-30%) or the diatomite plus the alumina leftover or bauxite through pulverizing and heating to 450-550 deg.C for dewatering.

Owner:张家彪 +2

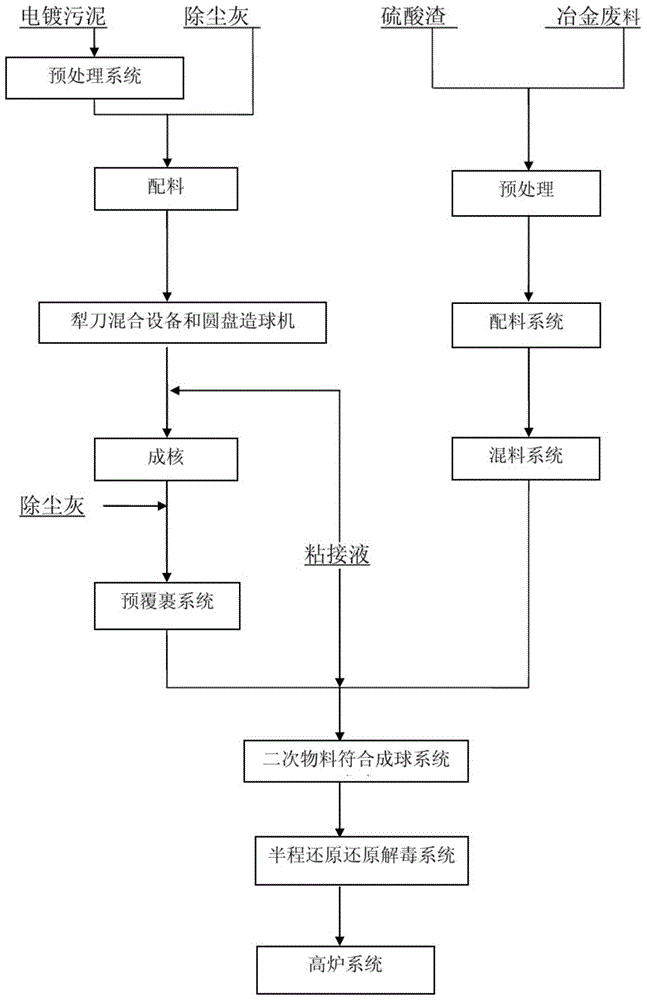

A process system for harmless treatment of electroplating sludge using metallurgical sintering blast furnace

ActiveCN104451138BShort distanceAdvanced technology is feasibleBlast furnace detailsProcess efficiency improvementProcess systemsCoating system

Owner:CHONGQING ANGRUIYUE SCI & TECH

A kind of preparation method of 2-hydroxy-4-methylthio-calcium butyrate

ActiveCN104356035BRaise the reaction temperatureResponse continuesSulfide preparationCoke rateDecomposition

Owner:宁波它世界生物科技有限公司

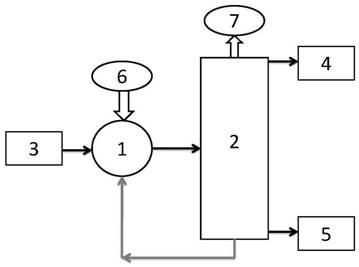

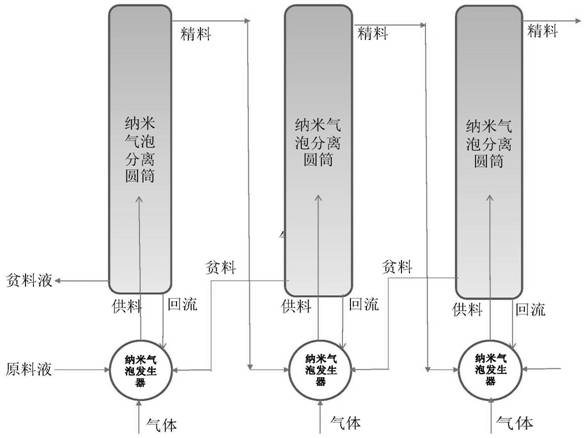

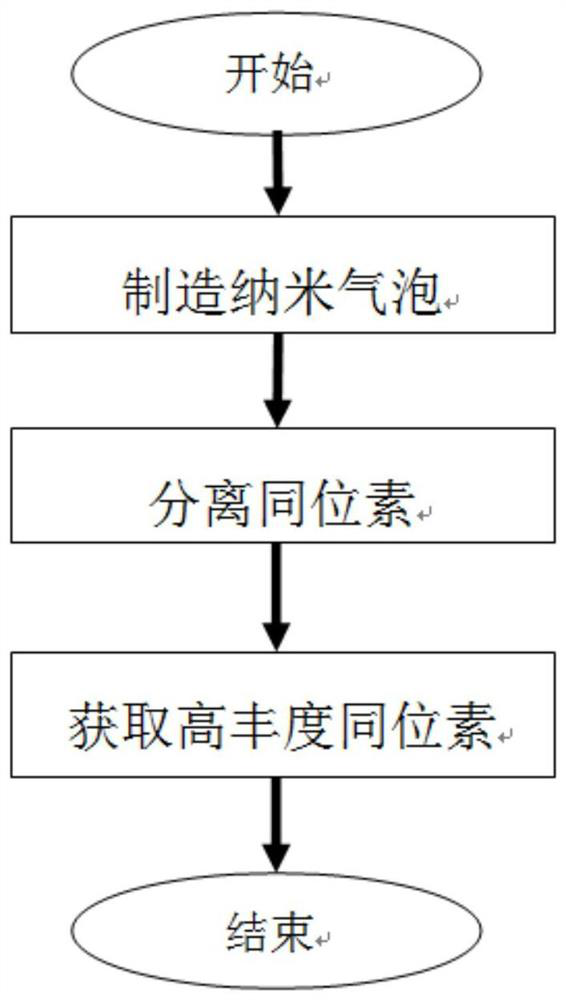

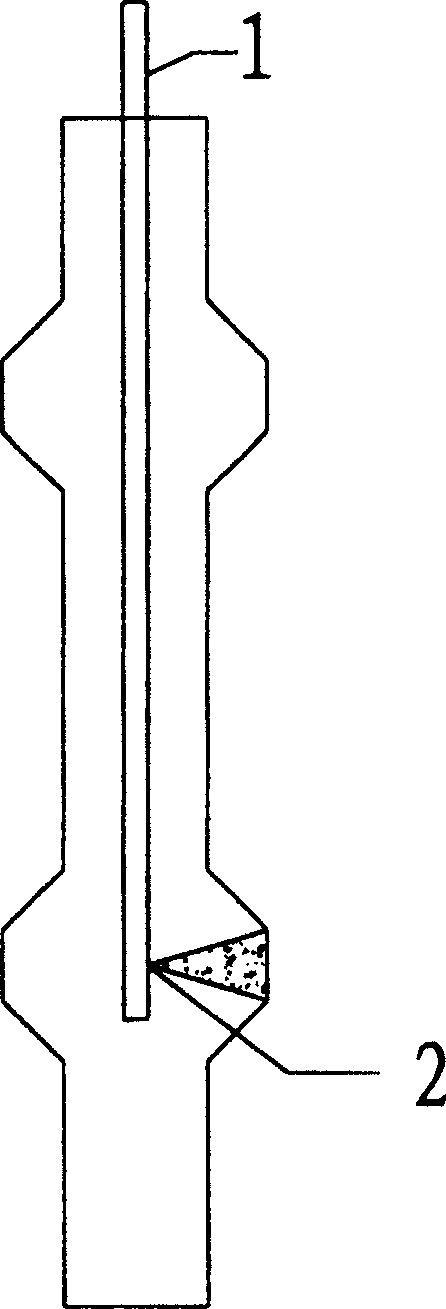

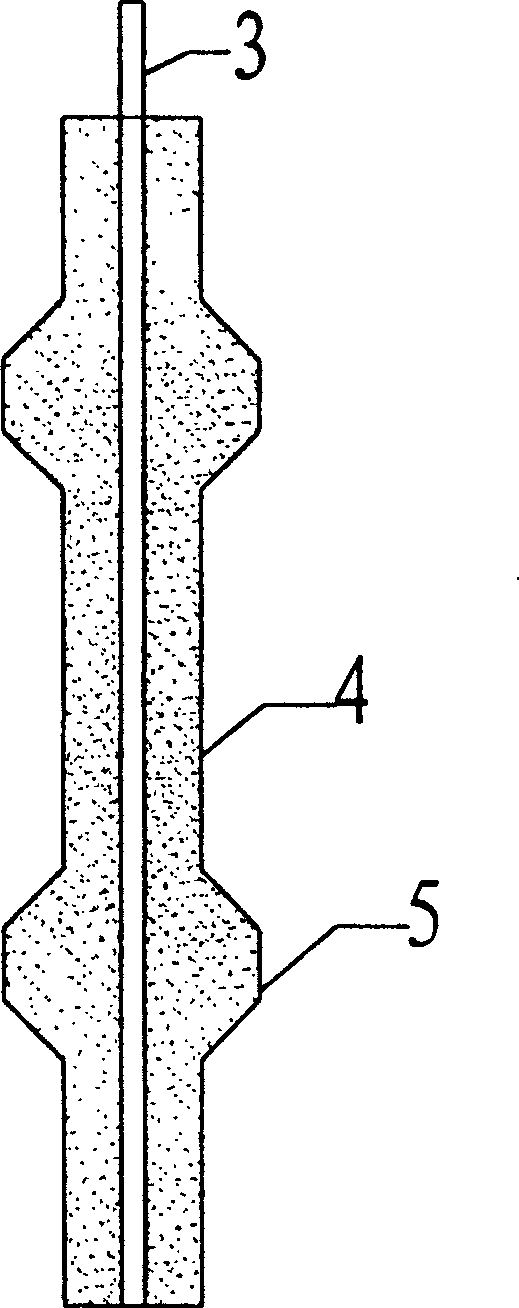

A kind of nanobubble isotope separation method and separation device and cascade

ActiveCN112473368BSolution to short lifeAchieve separationIsotope separationChemical physicsFluid phase

The invention relates to a nano-bubble isotope separation method, a separation device and a cascade. The method firstly prepares a liquid containing nano-bubbles, and then the nano-bubble contacts the liquid during the rising process. When the nano-bubble rises to a certain height, the The heavier isotope enrichment products can be obtained, while the lighter isotope enrichment products are in the liquid phase of the separation cylinder, thereby realizing isotope separation. The separation device of the present invention comprises a nano-bubble generator, a cylindrical separator and a material feeding and reclaiming device, and the cascade is a series-parallel combination of a plurality of separation devices. The invention can be applied to the isotope separation of various elements, and is especially suitable for the separation of light isotopes, especially the separation of lithium isotopes. The invention also has the advantages of less investment, low energy consumption, cheap raw materials, rapid production, flexible scale and no pollution.

Owner:陈邦林 +1

Section bar inserting and high-pressure rotary jetting method for forming pile with expanded plates in sink area

InactiveCN100485133CReduce occupancyImprove vertical bearing capacityBulkheads/pilesLand resourcesEconomic benefits

Owner:CHINA UNIV OF MINING & TECH

Extraction and dyeing method of natural red-brown dyestuff from camellia oleifera husk

InactiveCN102153882BMeet needsNo allergic reactionNatural dyesDyeing processCamellia oleiferaEcological environment

The invention discloses a method for extracting and dyeing reddish-brown natural dye of oil-tea camellia shells. After cleaned and air-dried, the oil-tea camellia shell is smashed and leached with taking sodium carbonate aqueous solution as solvent. Filtered filter residues are repeatedly leached with the sodium carbonate aqueous solution. Filtrate is combined to obtain natural dye concentrate of the oil-tea camellia shell by pressure reduction, distillation and concentration. The obtained concentrate is subjected to pectin removal, filtration, pressure reduction, distillation, concentration, spray and drying to obtain the powder natural dye of the oil-tea camellia shell. Pretreated pure cotton fabric can be dyed with the natural dye of the oil-tea camellia shell to obtain fabric which is uniform in gloss. The method for extracting and dyeing the natural dye of the oil-tea camellia shell is safe and environment-friendly by taking the oil-tea camellia shell as a raw material so as to effectively utilize natural waste. The fabric dyed by the method can be made into clothing that is safe, free of carcinogenic and deforming action or causing skin sensibility, good in compatibility with ecological environment and available for biodegradation.

Owner:CHANGZHOU UNIV +1

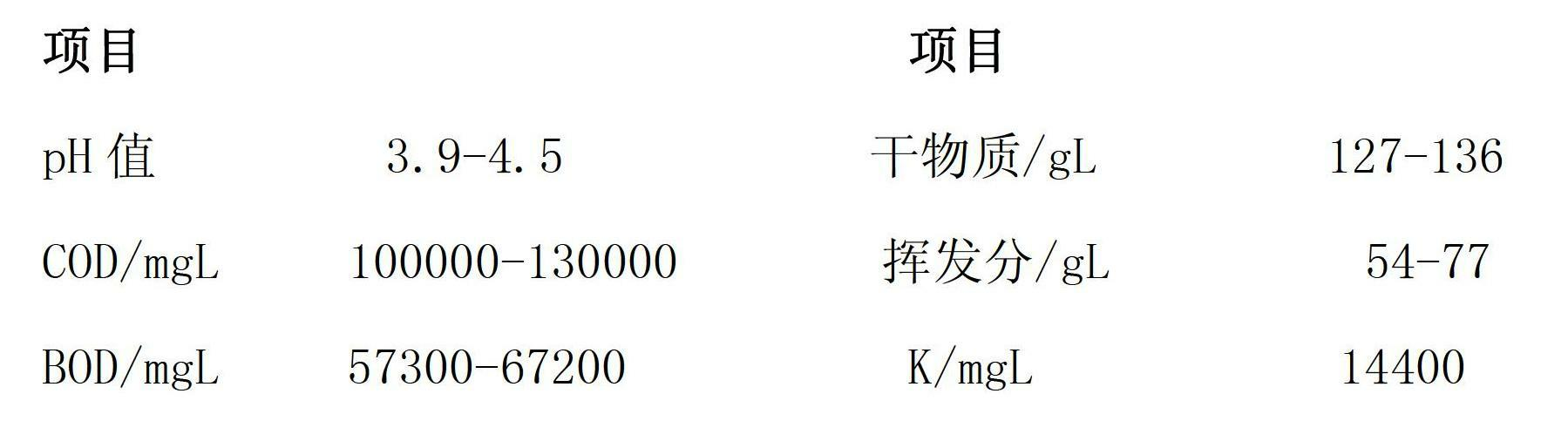

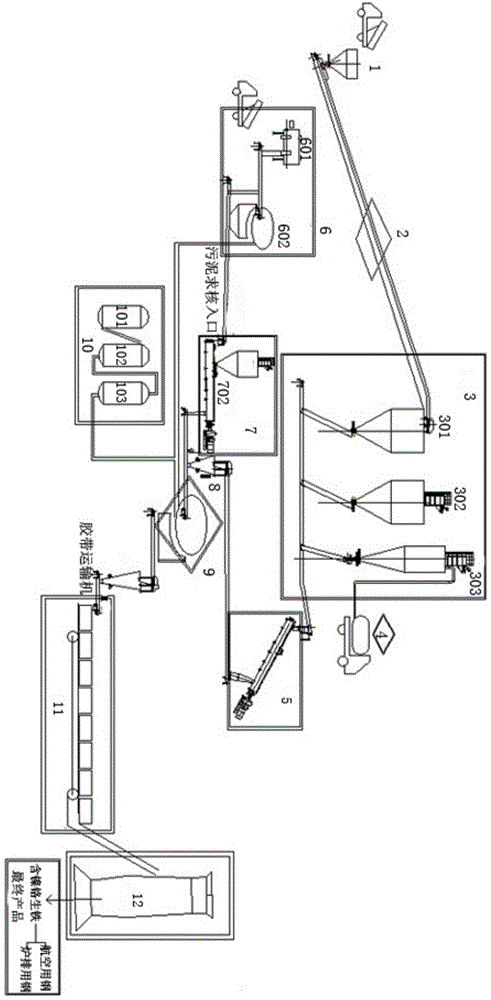

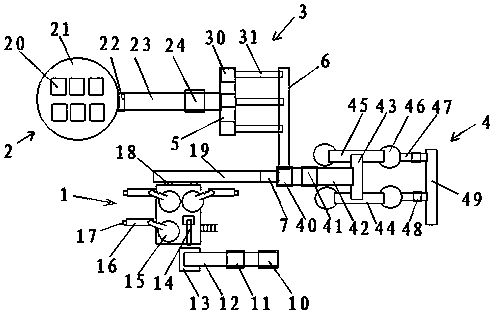

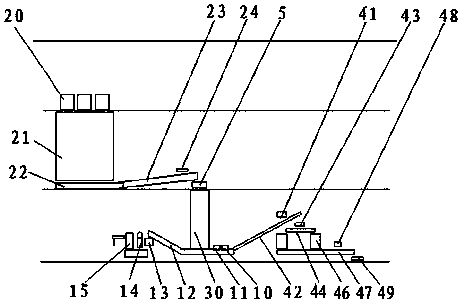

A composite liquor automatic brewing production line

ActiveCN105950417BSpeed up the flowAdapt to rationalityAlcoholic beverage preparationProduction lineBrewing

The invention discloses a composite automatic white wine brewage production line which comprises a wine steaming production line, a grain steaming production line, a bacterium culture-saccharification production line and a high-temperature accumulation production line. The production line is arranged in a three-floor factory building; grain steaming production line equipment is positioned on the third floor and the second floor in a stereoscopic L shape, and a discharge end of the grain steaming production line is connected with a feed end of the bacterium culture-saccharification production line on the first floor through a plate link chain conveyer I; wine steaming production line equipment on one side of the bacterium culture-saccharification production line is arranged in a U shape; and a discharge end of the bacterium culture-saccharification production line and a discharge end of the wine steaming production line are connected with a feed end of the high-temperature accumulation production line respectively through a plate link chain conveyer II and a plate link chain conveyer III. The integrated production line effectively utilizes the spatial arrangement of the factory building according to the technological requirements, so that various materials flow smoothly in the production process; and thus, the integrated production line has the advantages of minimum equipment investment and shortest production process, thereby forming the composite automatic white wine brewage production line with optimal proper redistribution arrangement.

Owner:JIANGSU KINGS LUCK BREWERY

Nitrogen-phosphorus high-efficient expansion type wood flame-proof agent and its preparation method

ActiveCN101121277BIncrease the speed of polycondensationShort synthesis timeWood impregnation detailsWater bathsCelsius Degree

The present invention discloses a phosphorus-nitrogen high-efficiency expansion wood fire retardant; urea phosphate crystallization mother liquor is taken as the raw material and Fe, Mg, Ca, A1 metalion activating agent and boric acid are added and mixed evenly; and then the solution is put into a decompression distilling device for decompression distillation for 1.5 to 2 hours with a temperatureof 80 to 90 Celsius degrees after water bath heating; the water content of mother liquor at then is less than 8 percent; the crystallization mother liquor after water removal is put into a polymerizing-kettle which is equipped with an electric mixer; the electric mixer and heating switch are switched on for heating at a speed of 4 to 6 Celsius degrees per minute and the rotation speed of the electric mixer is adjuted at 150 rpm which is comparatively low. Two gases of ammonia and carbon dioxide are input through a gas steel cylinder; the pressure of ammonia is 0.4 to 0.7 MPa and the carbon dioxide pressure is 0.3 to 0.6 MPa in the process of inputting the gases; the total pressure in the kettle is kept at 1.2 to 1.4 MPa; when the reaction temperature reaches 160 to 229 Celsius degrees, the reaction temperature is kept for 1.5 to 2 hours and the temperature of the reaction product is reduced to the normal temperature; the reaction product is crushed to fire retardant powder. The present invention boasts of simple process, easy industrialization, low cost, low investment, short treatment cycle, rational phosphorus-nitrogen proportion and excellent synergetic fire retardant effect; in addition, the present invention is clean without pollution.

Owner:WENGFU (GRP) CO LTD

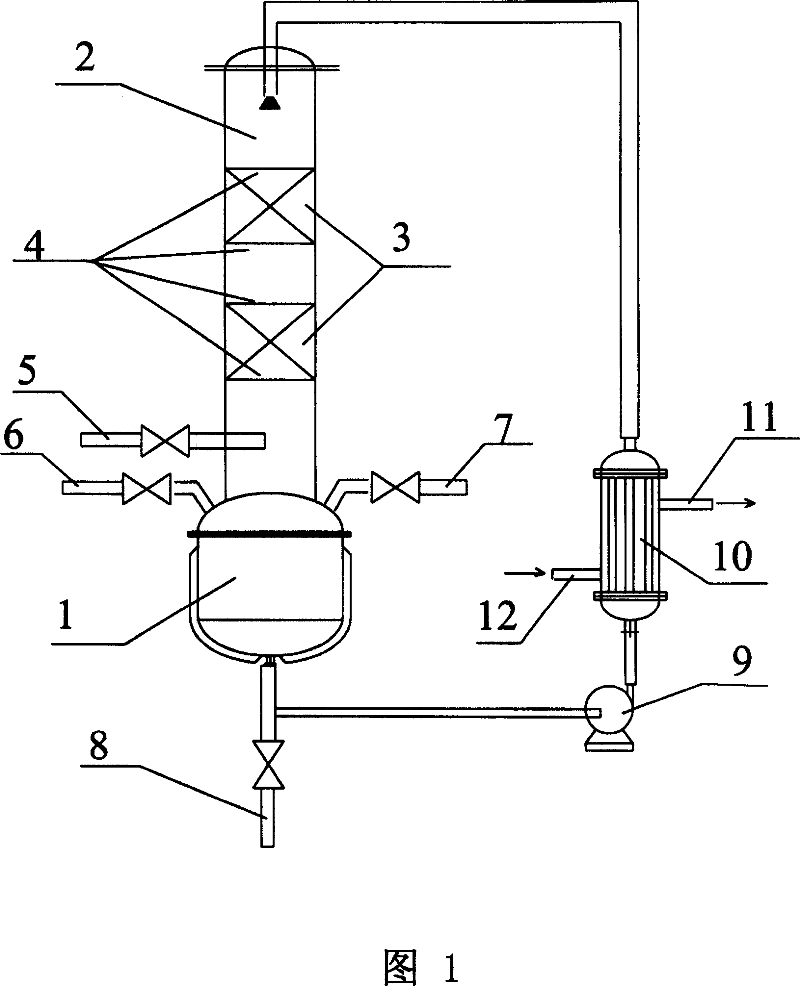

Fatty acid ester alkoxylating method and dedicated equipment therefor

ActiveCN100357248CHigh reactivityGood reaction selectivityOrganic compound preparationCarboxylic acid esters preparationHydrogenAfter treatment

The invention discloses a method of fatty acid ester alkoxylating and its reactor, which is to solve problems of unsuitness of the current alkoxylating method for alkoxylation of fatty acid ester not containing reactive hydrogen and after-treatment existence and unsuitness of the current reactor for this inventive method, presents employing composite aluminum-magnesium catalyst for the method and reactor in this invention, the reactor comprising catalyst fixing bed, tower still, heat-exchange machine and circulating pump, the method in this invention is characterized by no existence of after-treatment, simple process, small investment for device, short producing time, low energy consumption, no environmental pollution and wide application range.

Owner:LIAONING OXIRANCHEM INC +3

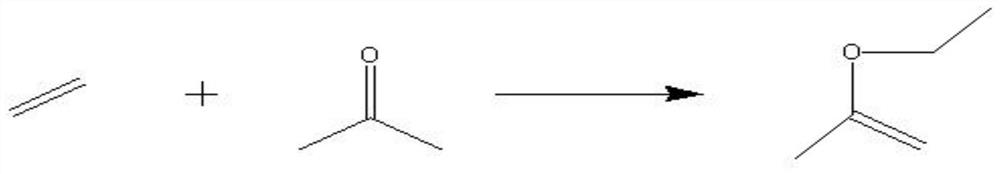

A kind of preparation method of ethoxypropylene

ActiveCN109761761BSimple production processThree wastes are produced lessEther preparation by compound additionPtru catalystOrganic synthesis

The invention relates to a preparation method of ethoxypropylene, which solves the technical problems of high cost, low yield, low return, long reaction route, many by-products and environmental pollution in the prior art synthesis method of ethoxypropylene . The invention provides a preparation method of ethoxypropylene, which comprises the following steps: Step S1: In the reaction stage, acetone gas and ethylene gas are passed into a fixed-bed reactor, and the fixed-bed reactor is equipped with modified The catalyst catalyzes the addition reaction of ethylene under normal pressure of 120-180°C; step S2: product separation, the gas after the reaction in step S1 is condensed, separated, and recovered to obtain pure ethoxypropylene. The invention is widely used in the technical field of organic synthesis.

Owner:SHANDONG GUOBANG PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com