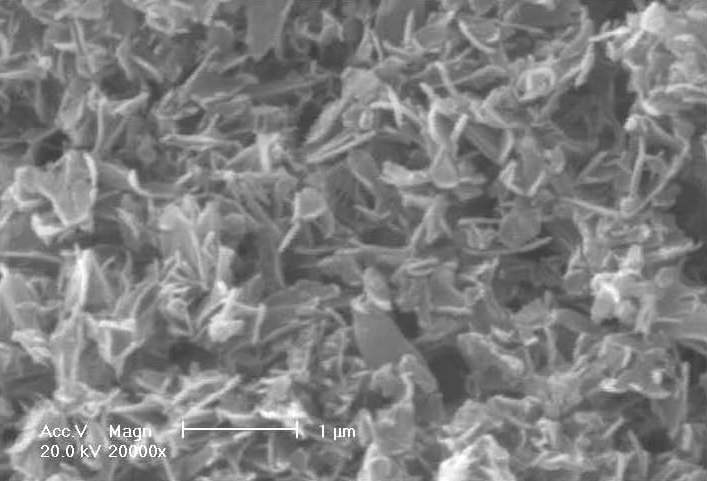

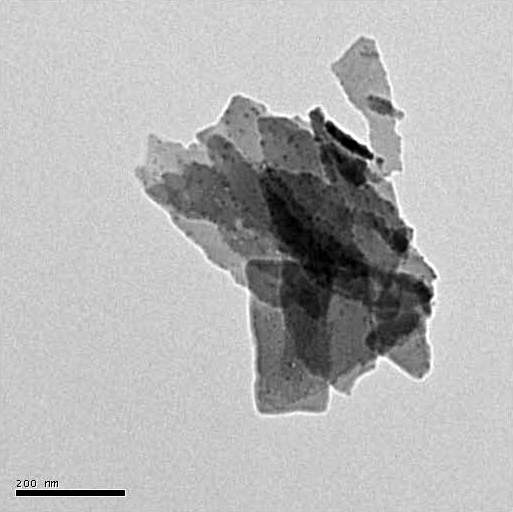

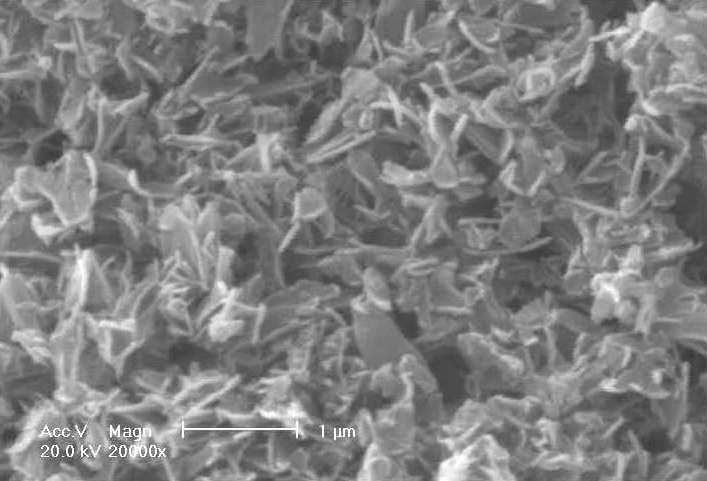

Method for preparing flaky nano copper powder

A technology of nano-copper powder and flakes, which is applied in the field of preparation of flake-shaped nano-copper powders, can solve the problems of uneven particle size and easy agglomeration of spherical nano-copper powders, achieve uniform shape, narrow particle distribution, avoid agglomeration and The effect of growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0015] The preparation method of the flaky nano-copper powder of the present embodiment has the following steps:

[0016] ①Sequentially weigh 100.0g of copper sulfate aqueous solution with a concentration of 0.01mol / L, 5.0g of SDS and 5.0g of Tween-80, put them into a beaker in turn, and mix the materials in the beaker by mechanical oscillation to obtain The mixed solution A containing copper sulfate was transferred to a 250ml three-necked flask for use. The water, SDS and Tween-80 in the copper sulfate aqueous solution form a surfactant complex system.

[0017] ②Sequentially weigh 100.0g of sodium borohydride aqueous solution with a concentration of 0.01mol / L, 5.0g of SDS and 5.0g of Tween-80, put them into a beaker in turn, and mix the materials in the beaker thoroughly by mechanical oscillation. A mixed solution B containing sodium borohydride was obtained. Water, SDS and Tween-80 in the sodium borohydride aqueous solution form a surfactant complex system.

[0018] ③Unde...

Embodiment 2)

[0021] ①Sequentially weigh 95.0g of copper sulfate aqueous solution with a concentration of 0.01mol / L, 10.0g of SDS and 5.0g of Tween-80, put them into a beaker in turn, and mix the materials in the beaker by mechanical oscillation to obtain The mixed solution A containing copper sulfate was transferred to a 250ml three-necked flask for use. The water, SDS and Tween-80 in the copper sulfate aqueous solution form a surfactant complex system.

[0022] ②Sequentially weigh 95.0g of sodium borohydride aqueous solution with a concentration of 0.01mol / L, 10.0g of SDS and 5.0g of Tween-80, put them into a beaker in turn, and mix the materials in the beaker thoroughly by mechanical oscillation A mixed solution B containing sodium borohydride was obtained. Water, SDS and Tween-80 in the sodium borohydride aqueous solution form a surfactant complex system.

[0023] ③At a temperature of 25°C and under stirring, drop the mixed solution A containing copper sulfate obtained in step ① into ...

Embodiment 3~ Embodiment 6)

[0026] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1. The concentration of the copper salt aqueous solution is 0.01 mol / L, and the concentration of the reducing agent aqueous solution is also 0.01 mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com