High-concentration high-chroma wastewater treatment technique

A wastewater treatment, high-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Membrane replacement costs are expensive and other problems, to achieve the effect of shortening residence time, easy operation and maintenance, and good effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

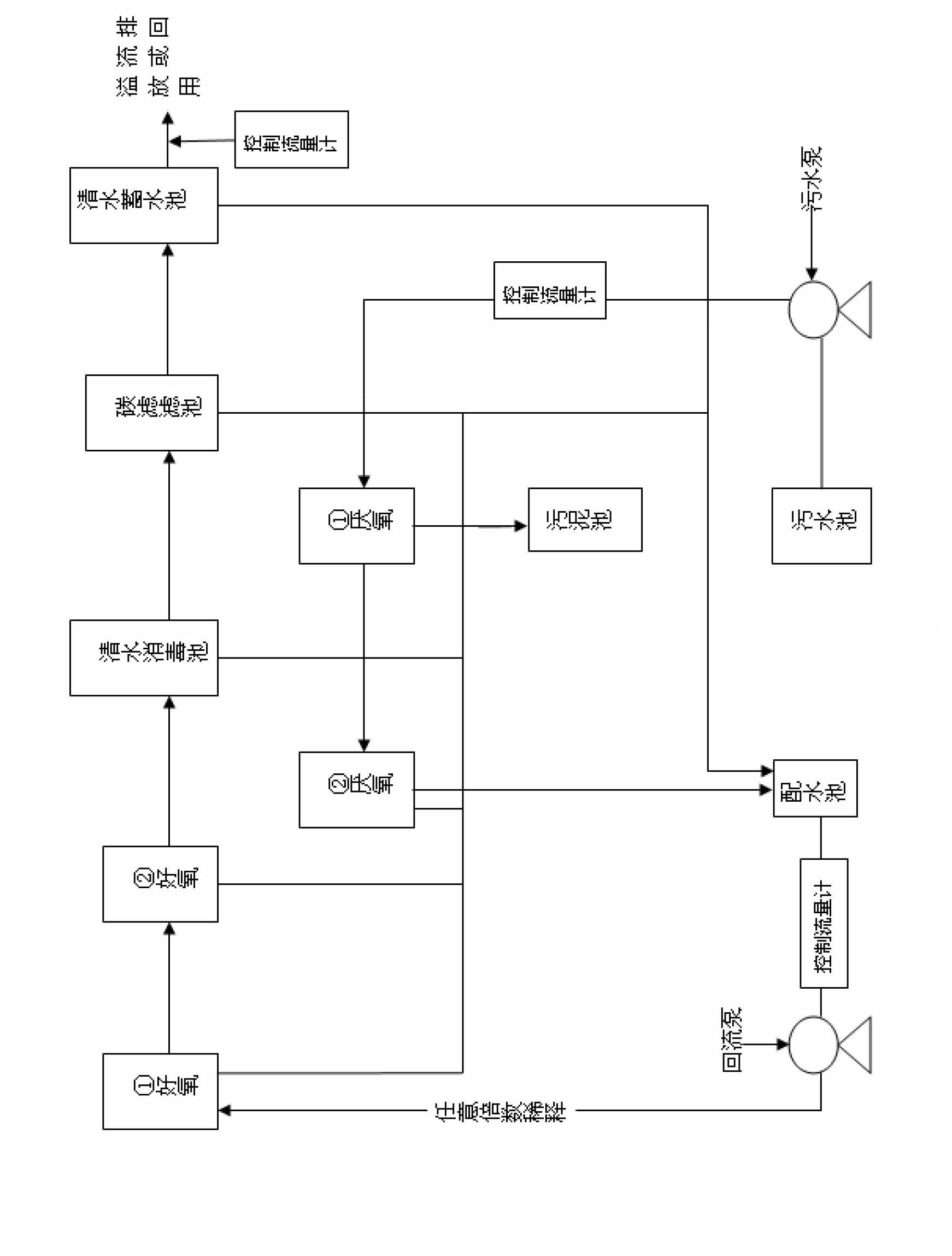

[0020] Embodiment one: a certain landfill site daily processing 300m3 landfill leachate is an example, the treatment process is as follows figure 1 As shown in , the total residence time of the designed two-stage anaerobic tank is 2-3 days, a total of 600-900m 3 ;The designed water distribution pool is 50m for any multiple dilution water distribution 3 ;According to different water quality, the total residence time of the three-stage aerobic pool is at least 300m a day 3 ; Clear water pool 50m 3 : filter pool 100m 3 . specific methods:

[0021] 1. In the anaerobic pool and the aerobic pool, respectively put bacteria and micellar bacteria into them. The types of bacteria are: Achromobacter, Aerobacter, Alcaligenes, Nitrosomonas, Bacillus, Bacillus, and Corynebacterium Genus, Comamonas, Flavobacterium, Microbacterium, Nocardia, Pseudomonas, Sarcina, Spirillum, Kinetoglia, Coccomonas, Bdellovibrio One or more of the genus, Pseudocoliform, Thiobacillus, Acinetobact...

Embodiment 2

[0029] Embodiment 2: A certain sugar factory processes 300m per day 3 Alcohol waste mash as an example:

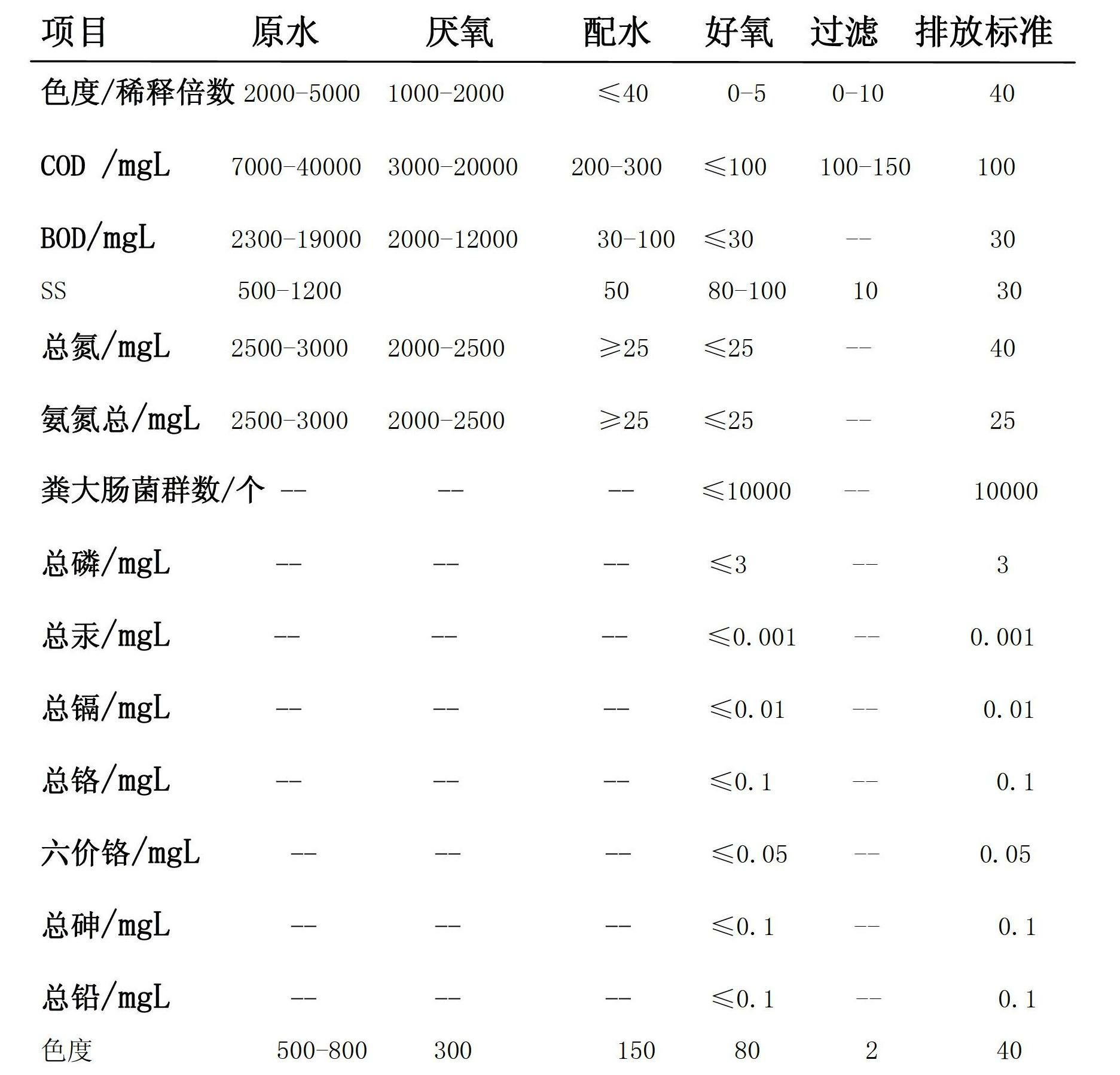

[0030] The water quality of alcohol waste mash from a sugar factory is shown in Table 2 below

[0031]

[0032]

[0033] The water quality control of each process before and after treatment is shown in the following table 3

[0034]

[0035] Note: The discharge standard is "Sewage Comprehensive Discharge Standard" ).

[0036] The treatment steps in this embodiment are the same as the landfill leachate treatment steps in Embodiment 1. In order to save operating costs to a greater extent, at the front end of the present invention, the alcohol waste mash of Pingguo, Guangxi can be used as the boiler ash flushing water patent, and the ash flushing water enters the process of the present invention for treatment.

Embodiment 3

[0037] Example 3: The paint workshop of an automobile factory handles 300m per day 3 Electrophoretic paint phosphating wastewater as an example:

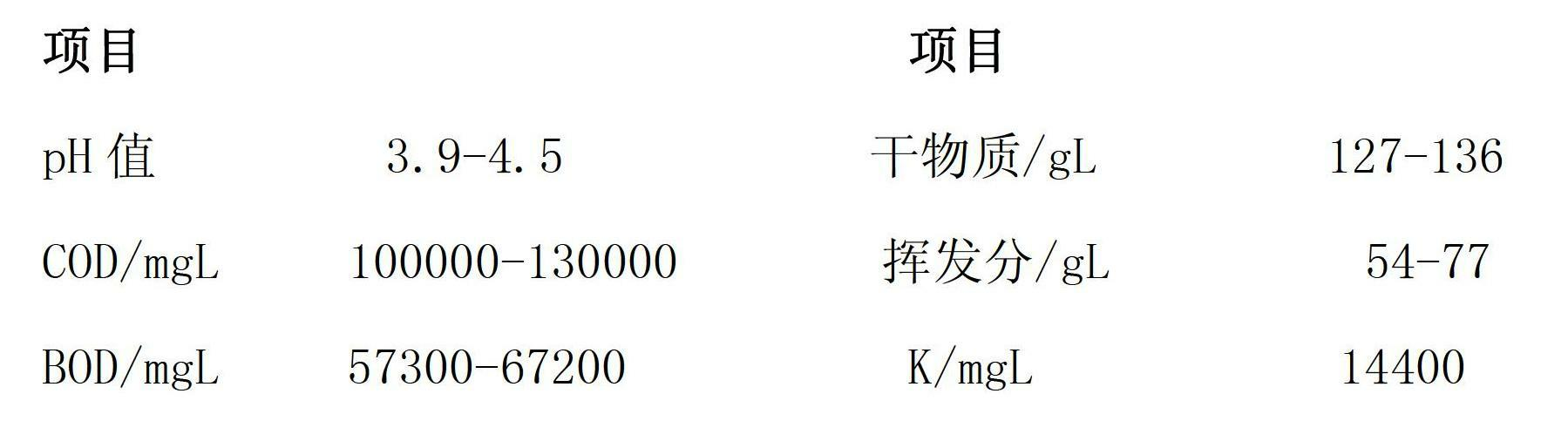

[0038] The comparison of water quality before and after treatment of electrophoretic paint phosphating wastewater in the paint workshop of an automobile factory is shown in Table 4 below:

[0039]

[0040] Note: The discharge standard is "Sewage Comprehensive Discharge Standard" .

[0041] The treatment steps in this embodiment are the same as the landfill leachate treatment steps in Embodiment 1.

[0042] Case 4: A wool spinning factory plans to process 1500m per day 3 Dyeing and dyeing wastewater as an example

[0043] The water quality comparison of each process before and after the treatment of dyeing and finishing wastewater in a wool spinning mill is shown in Table 5 below:

[0044]

[0045]

[0046] Note: The discharge standard is "Sewage Comprehensive Discharge Standard" .

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com