Preparation method of nanometer WC-Co composite powder

A composite powder and nanotechnology, which is applied in the field of nano-WC-Co composite powder preparation, can solve the problems of difficult control of carbon content, complicated production process, increase of free carbon, etc., and achieves easy process control, short process flow and low energy consumption. Effect

Inactive Publication Date: 2010-08-25

FUJIAN JINXIN TUNGSTEN

View PDF1 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

ZL00110137.4 discloses a preparation method of tungsten carbide titanium carbide cemented carbide composite powder, which belongs to the water-soluble carbonization method, which is to dissolve the soluble salt containing tungsten, cobalt and titanium in water according to the proportion and stir it evenly, and the mist Form into small droplets with a size of less than 1 μm, dry with hot air, granulate, and roast and then carbonize to obtain WC-TiC-Co cemented carbide powder; the disadvantage of this method is: the addition of carbon elements in the composite powder and In terms of control, it is realized by ball milling carbon mixing and high-temperature carbonization. This method makes it difficult for the uniformity of carbon components to reach an ideal uniform state, and it is difficult to control the carbon content in the process, which will inevitably lead to an increase in free carbon in the powder, which will eventually affect improved the quality of the nanocomposite powder

Another nano-WC-Co composite powder preparation method, the scientific research achievement "atomization drying fixed bed technology" of the Institute of Metal Research, Chinese Academy of Sciences, is to use soluble salts containing tungsten and cobalt to make a precursor solution with uniform chemical components, and then dry it by atomization. , roasting, reduction and carbonization treatment to make nano-WC-Co composite powder, and then design the composition of nano-WC-Co composite powder according to actual needs, and also add some other alloy elements and grain growth inhibitors, and accurately control their content ; This method achieves the addition of carbon elements through the post-reduction carbonization process, which is difficult to ensure the accuracy and uniformity of the C content, and the entire production process is complicated and the cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

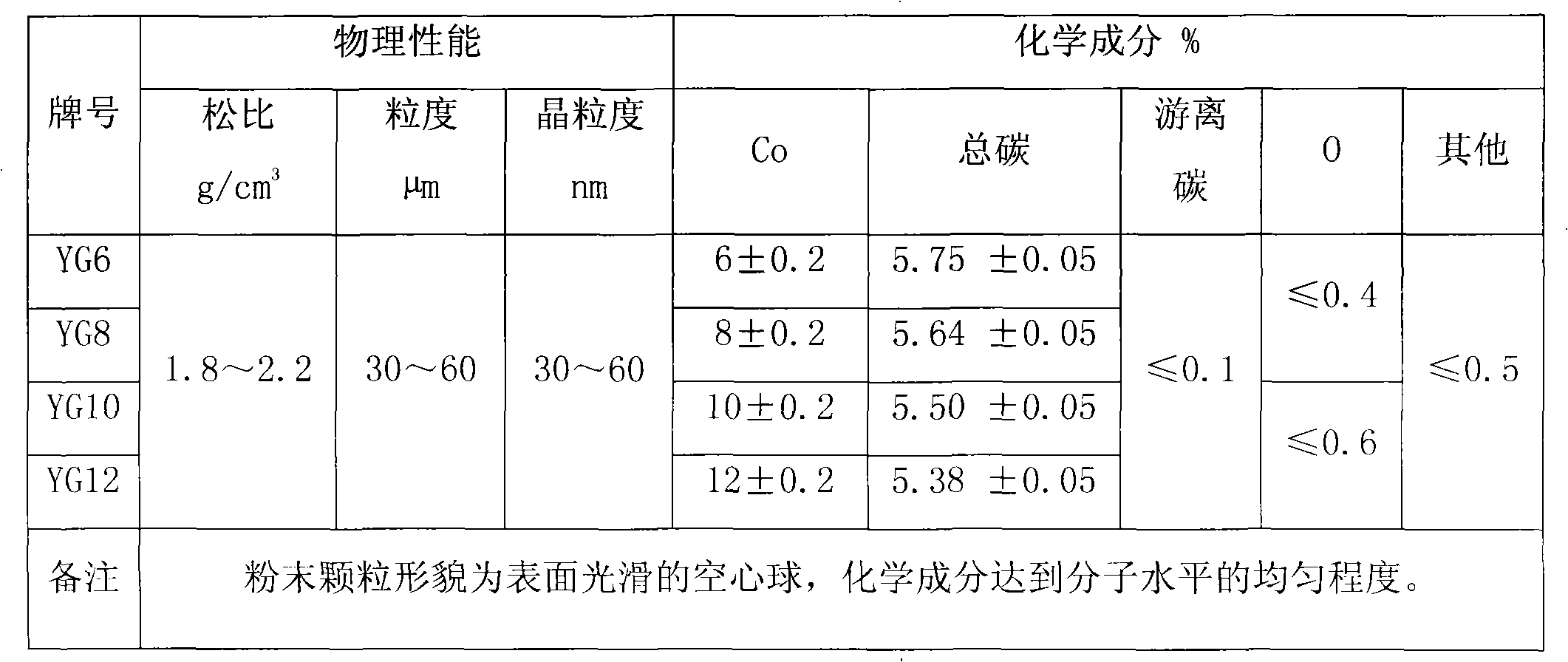

The invention discloses a preparation method of nanometer WC-Co composite powder. In the formula, soluble carbon source is directly added, carbon content is accurately controlled by regulating the hydrogen-carbon ratio of mixed gas in the carbonization and carbon regulation procedures. The specific steps are as follows: (1) according to the main ingredients of the WC-Co composite powder, calculating and weighing tungsten salt, cobalt salt and carbon source, dissolving the ingredients in water, evenly stirring, and preparing precursor solution; (2) preparing precursor pre-composite powder by spraying and drying mixed solution; (3) under the protection of neutral atmosphere, roasting the prepared precursor pre-composite powder to prepare original composite powder; (4) under the protection of hydrogen-carbon mixed gas, further carbonizing and regulating carbon for original composite powder at high temperature to prepare the nanometer WC-Co composite powder. The carbon element of the composite powder of the method has reasonable addition mode, easily precise control of carbon content, even chemical component, simple manufacturing technology and easy realization of industrial production.

Description

1. Technical field The invention relates to the preparation technology of cemented carbide composite powder, in particular to the preparation technology of nanometer WC-Co composite powder. 2. Background technology The physical and mechanical properties of cemented carbide materials (hereinafter referred to as alloys) are affected by the grain size of WC. In general, when the hardness of the alloy is high, the strength decreases and the overall material is brittle; when the alloy strength increases, the hardness decreases. reduce. When the WC grain size is less than 0.5 μm, the mechanical properties will change greatly, and the strength and hardness of the alloy will increase at the same time. With the development of science and technology, WC grains in alloys are constantly being refined, and ultra-fine cemented carbide materials, especially nano-carbide materials, have appeared; the advent of double-high alloys with high strength and high hardness has effectively improved...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22F9/24

Inventor 吴森德丁华堂彭石高颜启淡肖东山

Owner FUJIAN JINXIN TUNGSTEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com