A process system for harmless treatment of electroplating sludge using metallurgical sintering blast furnace

A technology of harmless treatment and electroplating sludge, applied in blast furnaces, blast furnace details, improvement of process efficiency, etc., can solve the problems of insufficient and effective utilization of resources, insufficient treatment, high operating costs, and achieve convenient production connection and coordination, The economic and social benefits of the process are significant, and the operating costs are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

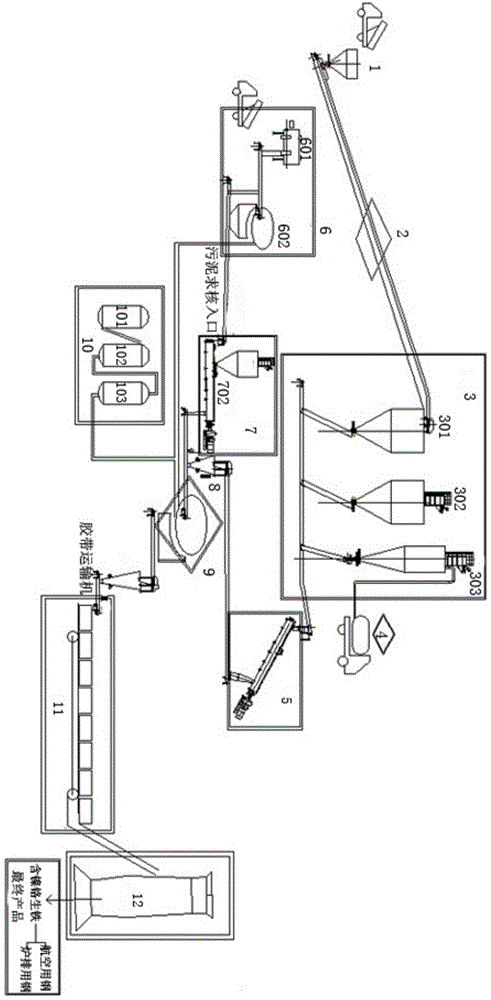

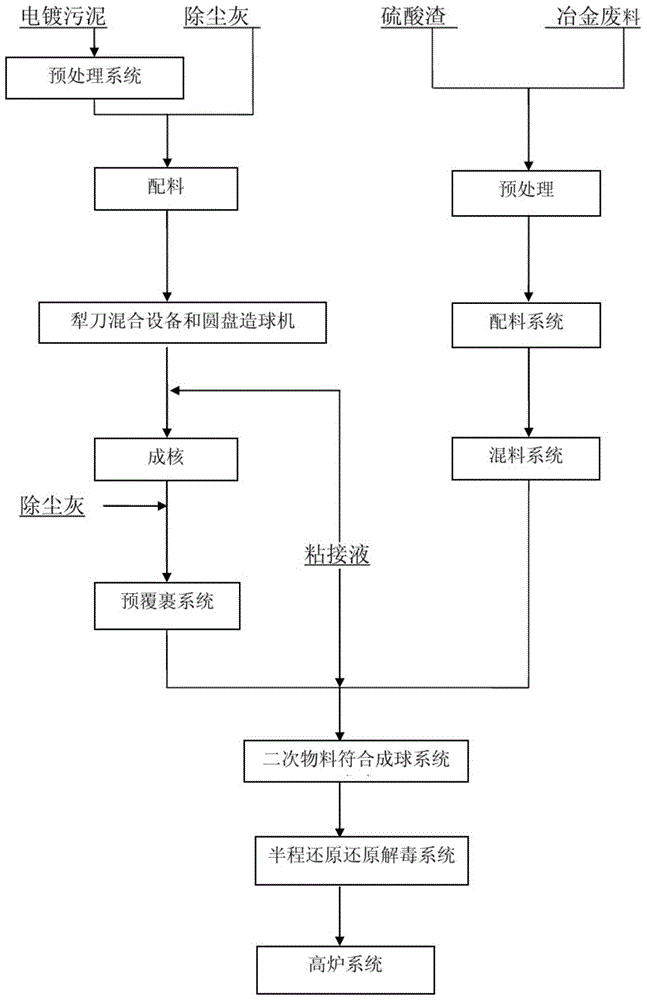

[0033] The process route of the present invention is to mix the pretreated electroplating sludge, dedusting ash, and reducing agent in the mixing nucleating system to form a ball nucleus, then add the dedusting ash to pre-coat it, and then transport it to the secondary pelletizing Equipment, adding sulfuric acid slag and metallurgical waste to produce secondary composite pellets of electroplating sludge.

[0034] see figure 1 , the process system for the harmless treatment of electroplating sludge by metallurgical sintering blast furnace includes electroplating sludge nucleation system, ball core pre-coating system, secondary composite ball manufacturing system and blast furnace sintering system, which are connected by conveying lines in turn , the first three systems are arranged in a closed environment.

[0035] The process route is: the electroplating sludge, reducing agent and dedusting ash pass through the electroplating sludge nucleation system (coulter mixing nucleatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com