Strip mine mining boundary and mining program collaborative optimization method under complex coal seam conditions

A mining realm and collaborative optimization technology, applied in underground mining, multi-objective optimization, design optimization/simulation, etc., can solve problems such as synchronous collaborative optimization of mining realm and mining program, and inability to synchronize analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

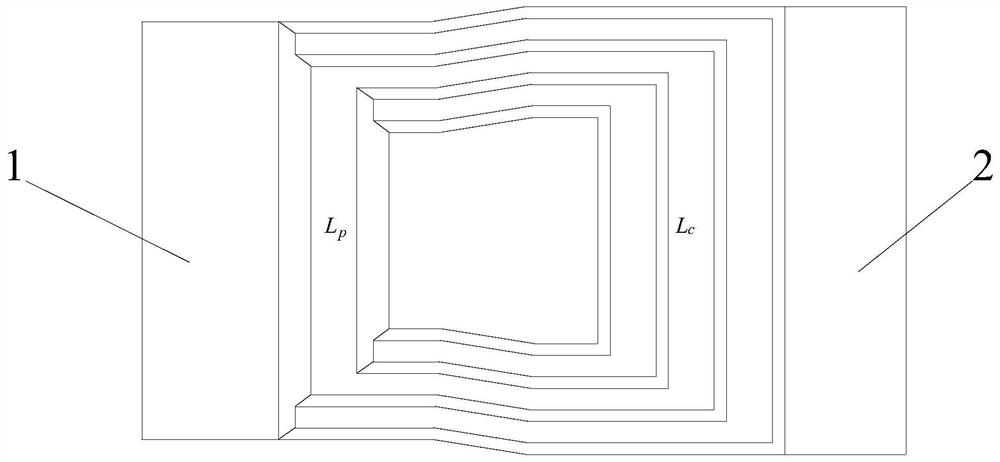

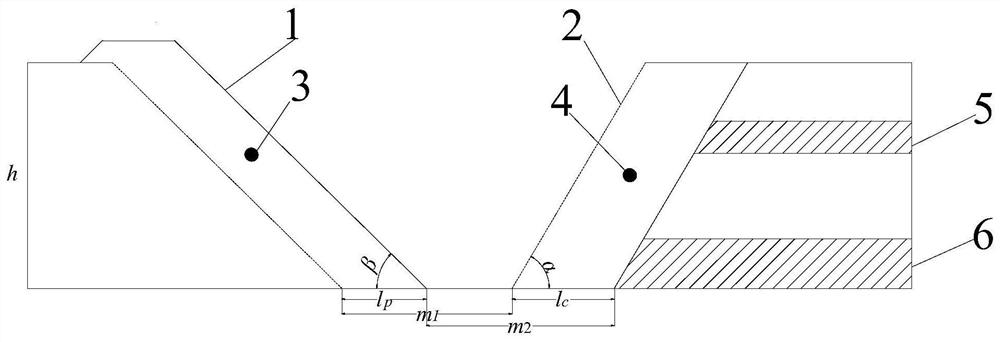

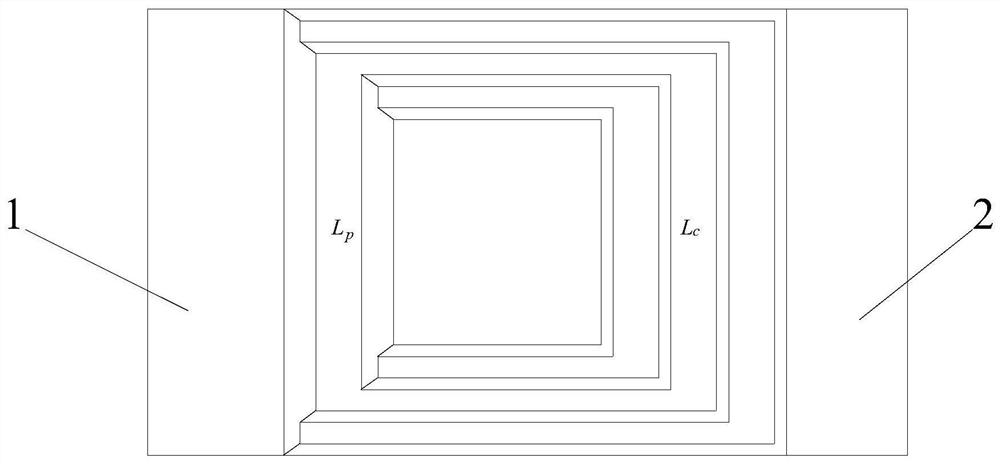

[0117] like Figure 1-9 As shown, the present invention provides a method for collaborative optimization of open-pit mine mining boundary and mining program under complex coal seam conditions, wherein, Figure 1-7 middle:

[0118] β is the side slope angle of the inner dump, °;

[0119] α is stope slope angle, °;

[0120] l c is stope advance distance, m;

[0121] l p is the advancing distance of the inner dump, m;

[0122] m 1 is the tracking distance of the inner row before the development of the inner dump in the stope, m;

[0123] m 2 is the tracking distance of the internal discharge after the development of the internal dump in the stope, m;

[0124] h is the height of the inner dump, m;

[0125] L c is the average working line length of the stope, m;

[0126] L p is the average working line length of the dump, m.

[0127] The optimization method includes the following steps:

[0128] Step S1, constructing the mining boundary model and the boundary model o...

Embodiment 2

[0217] The Huolinhe Coalfield is located in Huolingol City and Jhalut Banner, Inner Mongolia Autonomous Region. It is No. 2 coal with geological reserves of 11.92 billion tons, also known as aged lignite, with an average calorific value of 3100 kcal / kg. From north to south, the coalfield is divided into four exploration areas: the northern census area, the Shaerhure area, the second open-pit area, and the southwestern detailed investigation area. Huolinhe Coalfield No. 1 Open Pit Mine is 10km long from north to south, 3.4km wide from east to west, and has an approved mining surface area of 34.0013km 2 , mining depth from 864m to 432m elevation. The geographical coordinates are: east longitude 119°08′~119°46′, north latitude 45°10′~119°40′.

[0218] The Huolin Henan Open-pit Mine is located in Shaerhure Town. It was developed and constructed on September 1, 1981. The designed annual production capacity is 3 million tons. The scale of t annual output was handed over to produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com