Graphene-metal organic framework composite material modified electrode preparation method

A technology of metal-organic frameworks and composite materials, which is applied in the field of preparation of graphene-metal-organic framework composite materials modified electrodes, can solve the problems of poor electrochemical activity of MOF materials, achieve strong repeatability, large surface area, and simple synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

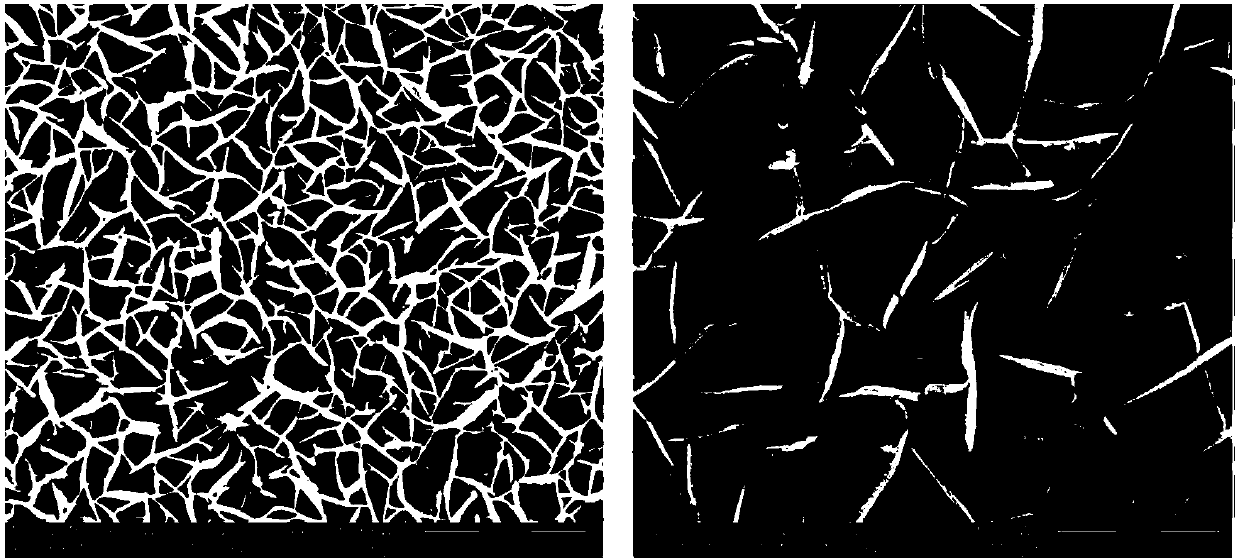

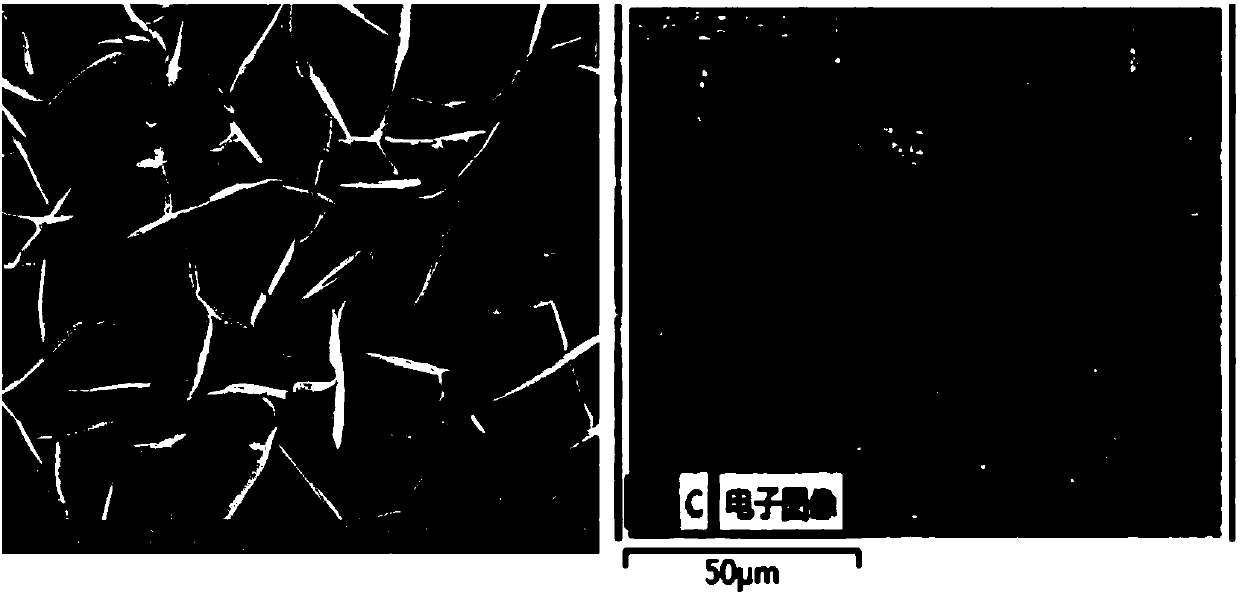

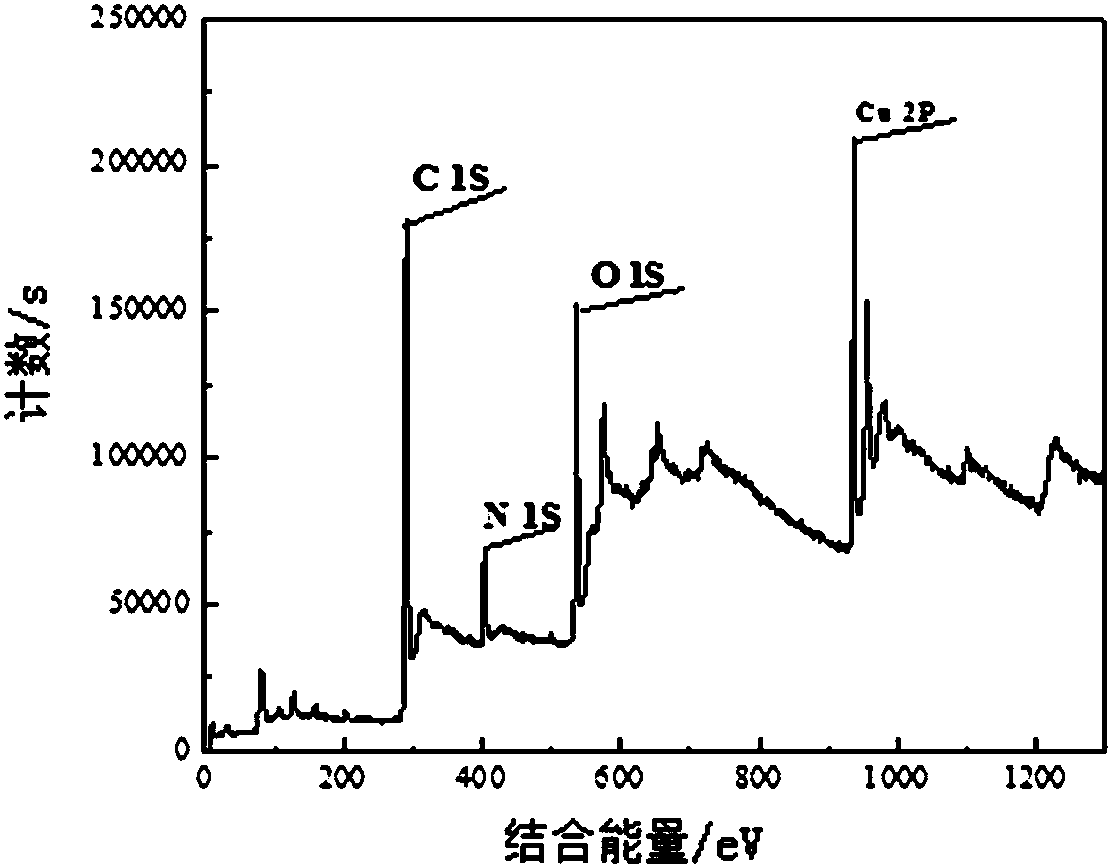

[0047] Embodiment 1 Preparation of graphene / MOF composite modified electrode

[0048] First, 3.6 mmol of copper nitrate trihydrate was stirred and dissolved in 12 mL of H 2 O; secondly, disperse 2.0 mmol of trimesic acid in 12 mL of absolute ethanol with ultrasonic stirring. Then, mix and shake the two, pour them into a 40mL stainless steel high-temperature reaction kettle, and react at 75°C for 8 days; cool to room temperature, and filter the obtained copper-based MOF suspension to filter out large-particle copper-based MOF Material, the filtrate was divided into 5mL aliquots and placed in weighing bottles.

[0049] Then, a 10×10×3 mm glassy carbon sheet was smoothed with 0.5 μm alumina powder on a polishing cloth, then ultrasonically cleaned in acetone and pure water for 10 minutes, and dried with high-purity nitrogen. Next, use a pipette gun to pipette 10 μL of 0.2 mg / mL carboxylated graphene solution and drop-coat it on the surface of the clean glassy carbon sheet, and d...

Embodiment 2

[0051] Embodiment 2 Preparation of graphene / MOF composite modified electrode

[0052] First, 1 mmol of copper nitrate trihydrate was stirred and dissolved in 6 mL of H 2 O; secondly, disperse 2.0 mmol of trimesic acid in 12 mL of absolute ethanol with ultrasonic stirring. Then, mix and shake the two, pour them into a 40mL stainless steel high-temperature reaction kettle, and react at 65°C for 10 days; cool to room temperature, and suction-filter the obtained copper-based MOF suspension to filter out large-particle copper-based MOF Material, the filtrate was divided into 5mL aliquots and placed in weighing bottles.

[0053] Then, a 10×10×3 mm glassy carbon sheet was smoothed with 0.5 μm alumina powder on a polishing cloth, then ultrasonically cleaned in acetone and pure water for 10 minutes, and dried with high-purity nitrogen. Next, use a pipette gun to pipette 10 μL of 0.4 mg / mL carboxylated graphene solution and drop-coat it on the surface of the clean glassy carbon sheet,...

Embodiment 3

[0055] Embodiment 3 Preparation of graphene / MOF composite modified electrode

[0056] First, 5 mmol of copper nitrate trihydrate was stirred and dissolved in 18 mL of H 2 O; secondly, disperse 2.0 mmol of trimesic acid in 12 mL of absolute ethanol with ultrasonic stirring. Then, the two were mixed and shaken, poured into a 40mL stainless steel high-temperature reaction kettle, and reacted at 85°C for 6 days; cooled to room temperature, and the resulting suspension of copper-based MOF was suction-filtered to filter out large-particle copper-based MOF Material, the filtrate was divided into 5mL aliquots and placed in weighing bottles.

[0057] Then, a 10×10×3 mm glassy carbon sheet was smoothed with 0.5 μm alumina powder on a polishing cloth, then ultrasonically cleaned in acetone and pure water for 10 minutes, and dried with high-purity nitrogen. Next, use a pipette gun to pipette 10 μL of 0.3 mg / mL carboxylated graphene solution and drop-coat it on the surface of the clean g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com