System for fast mounting steel pull rod in ultra-long and large-dip-angle tunnel anchorage and operation method

An installation system and a technology with a large inclination angle, applied in the erection/assembly of bridges, bridge parts, bridge forms, etc., can solve the problems of long traction distance, low efficiency, slow transportation, etc., to reduce transportation distance, save costs, and improve installation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

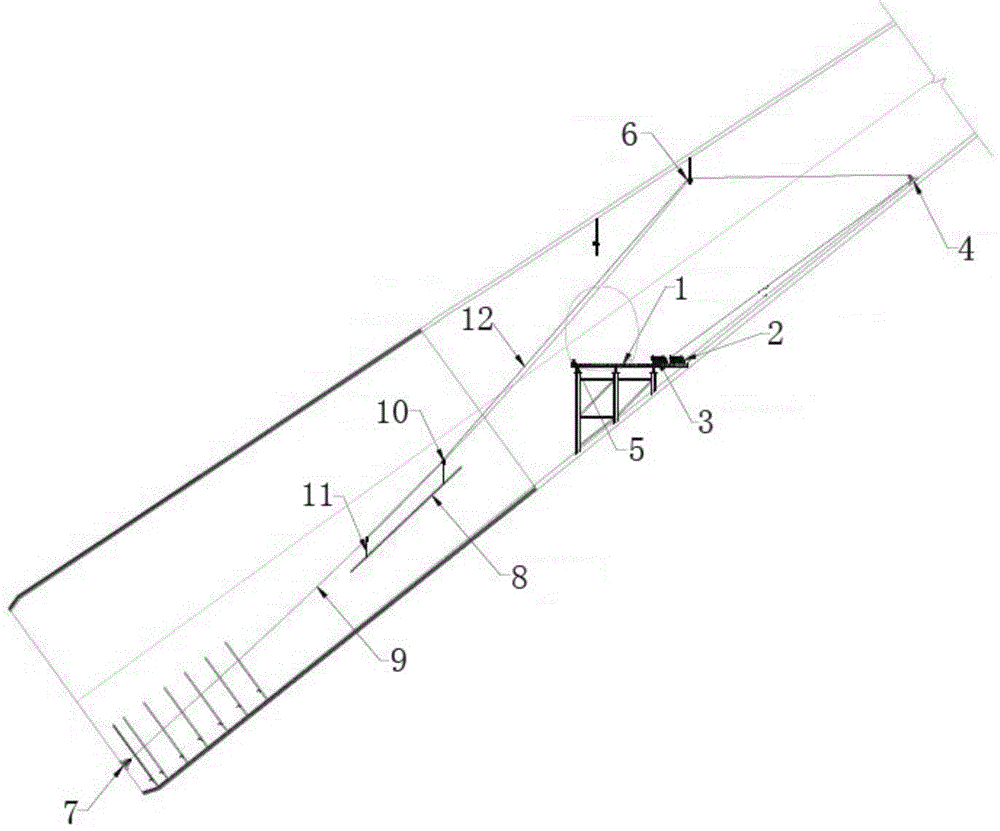

[0027] A fast installation system for super-long and large-inclination tunnel anchor steel rods, such as figure 1 As shown, it includes a hole platform 1 composed of section steel, and a 10t load-bearing rope hoist 2 and a 5t traction hoist 3 are installed at the rear of the horizontal hole exit platform 1; the load-bearing rope hoist 2 is mainly used for hoisting and auxiliary transportation of steel tie rods , the main function of the traction hoist 3 is to transport the steel pull rod; a rope limiter 5 is installed at the end of the platform. damage;

[0028] At the bottom of the hole far above the platform, two guide wheels 4 are set, which function to turn the load-bearing rope and the traction rope 12; a double-door block 6 is installed at the top of the hole between the guide wheels and the platform, and the steel rope will pass through. pulley for construction;

[0029] At the bottom of the tunnel anchor hole, an anchor point 7 is set near the bottom, and the angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com