Section bar inserting and high-pressure rotary jetting method for forming pile with expanded plates in sink area

A technology of high-pressure rotary spraying and molding methods, which is applied in sheet pile walls, buildings, and foundation structure engineering, etc., can solve problems such as unfavorable economic development in mining areas, inconvenience in production and life, and cumbersome examination and approval work, and achieve economic benefits in mining areas and wide practicability , The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

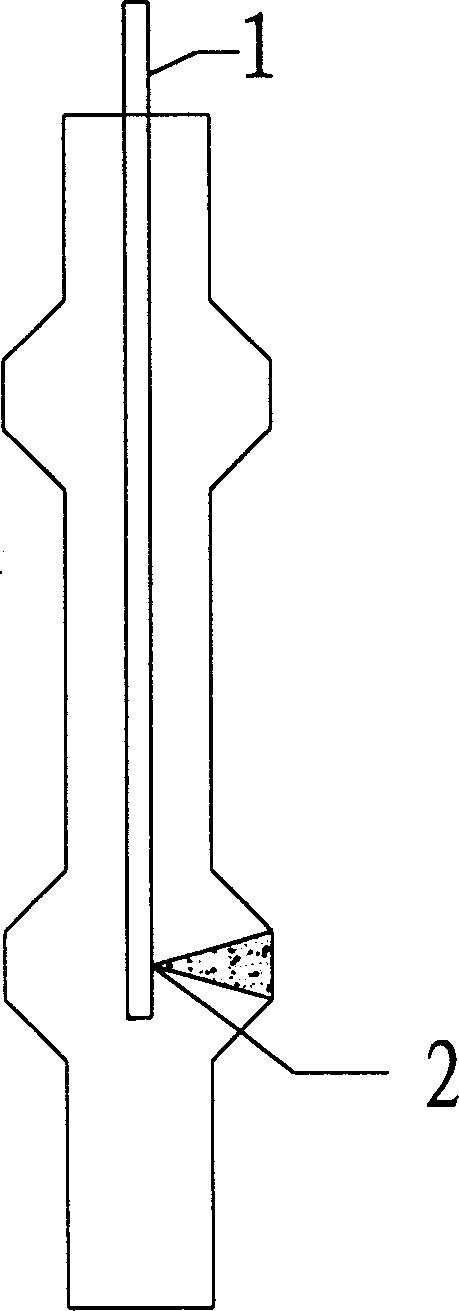

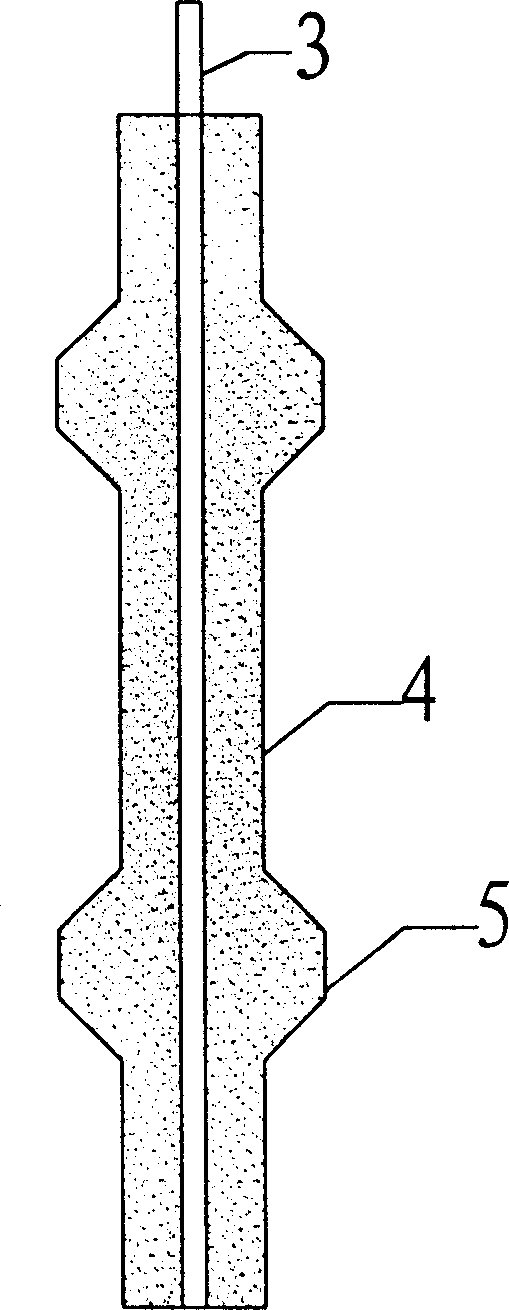

[0010] The molding method of the present invention for inserting ribs and high-pressure rotary jet grouting expansion piles in the subsidence area firstly drills multiple drill pipes 1 to a predetermined depth, and puts the pile body 4 formed by rotary jet grouting in the subsidence area on the pile body 4 formed by rotary jet grouting According to the soil quality, pressurize or change the injection time to increase the amount of cement slurry ejected by the drill pipe nozzle 2 per unit time to form a trapezoidal expansion plate 5, and a trapezoidal expansion plate 5 can be set according to the requirements of the required expansion pile bearing capacity. or more ( figure 1 shown), and finally insert H-shaped steel 3 or tensile material into the pile body 4, thereby increasing its vertical bearing capacity and horizontal bearing capacity, and can also be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com