A composite liquor automatic brewing production line

A production line and composite technology, applied in the field of brewing production line, can solve the problems of inappropriate overall layout, manual labor of operators, and large plant area, and achieve the effect of smooth material flow, reduced labor intensity, and compact process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

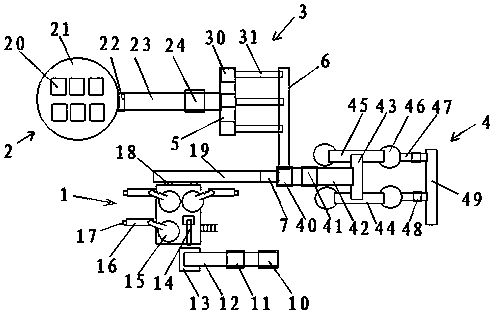

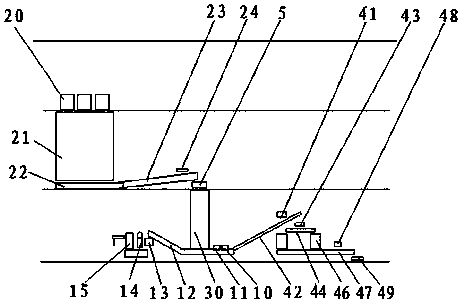

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a steamed wine production line 1, a steamed grain production line 2, a cultured saccharification production line 3 and a high-temperature accumulation production line 4. The type layout is located on the third floor and the second floor, and its discharge end is connected to the feed end of the cultivation and saccharification production line 3 on the first floor through the plate chain conveyor I5. Type layout, the 3 discharge end of the cultivation and saccharification production line and the 1 discharge end of the steamed wine production line are respectively connected to the feed end of the high-temperature accumulation production line 4 through plate chain conveyor II6 and plate chain conveyor III7.

[0016] The specific structure is as follows:

[0017] The steamed grain production line 1 includes a grain soaking box 20 located on the third floor, a steaming ball 21 is provided on the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com