Method and device for preparing 6N polycrystalline silicon by vacuum microwave refining of industrial silicon

A technology of vacuum microwave and industrial silicon, which is applied in chemical instruments and methods, silicon compounds, final product manufacturing, etc. It can solve problems such as insufficient yield, large silicon volatilization loss, and phosphorus removal effect not reaching 0.1ppm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

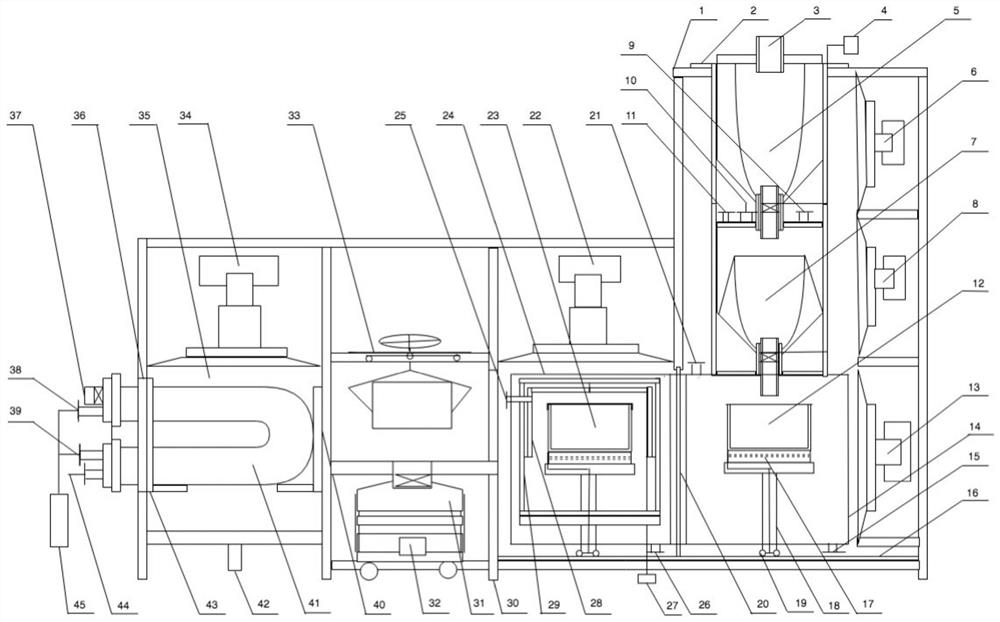

[0056] A device for preparing 6N polysilicon by vacuum microwave continuous refining of industrial silicon melt, such as figure 1 As shown, it includes furnace shell 1, oxidation and refining furnace frame 2, feed inlet I3, controller I4, primary oxidation and refining furnace 5, microwave generator I6, secondary oxidation and refining furnace 7, microwave generator II8, vacuum interface I9, Feed inlet II10, gas inlet I11, directional solidification crucible I12, microwave generator III13, directional solidification feed chamber 14, gas inlet II15, slideway 16, cooling device 17, support rod 18, pulley 19, electromagnetic door I20, vacuum Interface Ⅱ21, microwave generator Ⅳ22, directional solidification crucible Ⅱ23, directional solidification chamber 24, gas inlet Ⅲ25, vacuum interface Ⅲ26, controller Ⅱ27, thermal field 28, insulation chamber 29, electromagnetic door Ⅱ, crusher 31, screening machine 32, Cubing machine 33, microwave generator V34, microwave resonant cavity 35...

Embodiment 2

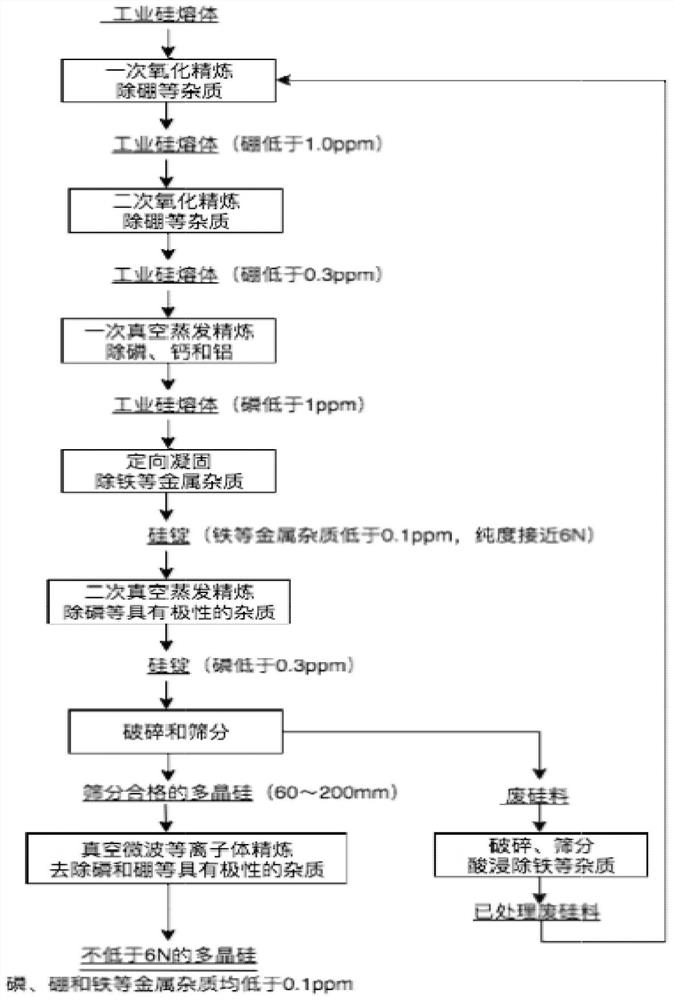

[0074] A method for preparing 6N polysilicon by vacuum microwave continuous refining of industrial silicon melt, such as figure 2 As shown, the method includes the following two stages of purification, five steps in total, the first stage of purification includes steps (1) to (3), the second stage of purification includes steps (4) to (5), using the method of Example 1 device, the specific steps are as follows:

[0075] (1) Flow the industrial silicon melt containing Si with a mass fraction of more than 98% into the primary oxidation refining furnace 5 from the feed port I3, open the bottom blowing gate valve of the primary oxidation refining furnace 5, and feed in a gas with a volume fraction of 70% from the bottom gas inlet. Mixed gas I of Ar and 30% water vapor by volume, the flow rate is about 30L / min, and SiO is added from the feed port I3 at the same time 2 Powder 0.6g / L, turn on the microwave generator I6, the controller I4 adjusts the microwave power of the microwave...

Embodiment 3

[0084] A method for preparing 6N polysilicon by vacuum microwave continuous refining of industrial silicon melt, the method includes the following two stages of purification, a total of five steps, the first stage of purification includes steps (1) to (3), and the second stage of purification includes steps (4)~(5), use the device of embodiment 1, concrete steps are as follows:

[0085] (1) Flow the industrial silicon melt containing Si with a mass fraction of more than 98% from the feed port I3 into the primary oxidation refining furnace 5, open the bottom blowing gate valve of the primary oxidation refining furnace 5, and feed a volume fraction of 90% from the bottom gas inlet. Mixed gas I of Ar and water vapor with a volume fraction of 10%, the flow rate is about 20L / min, and SiO is added from the feed port I3 at the same time 2 Powder 6g / L, turn on the microwave generator I6, the controller I4 adjusts the microwave power of the microwave generator I6, controls the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com