Fatty acid ester alkoxylating catalyst and its preparation method

A fatty acid ester alkane and catalyst technology, which is applied in the field of catalysts and its preparation, can solve the problems of fatty acid esters not being active, and achieve the effects of less by-products, short production time, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

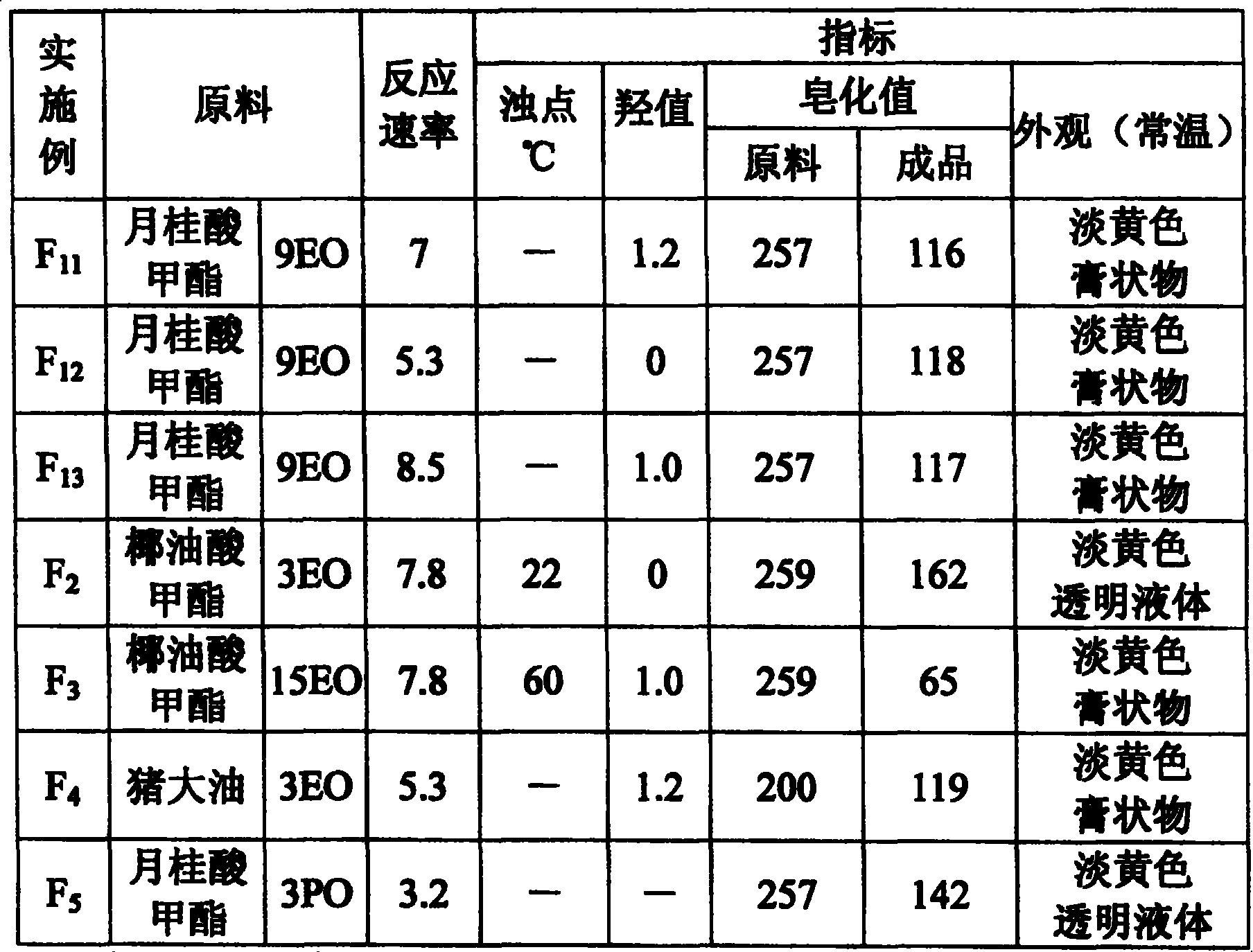

Examples

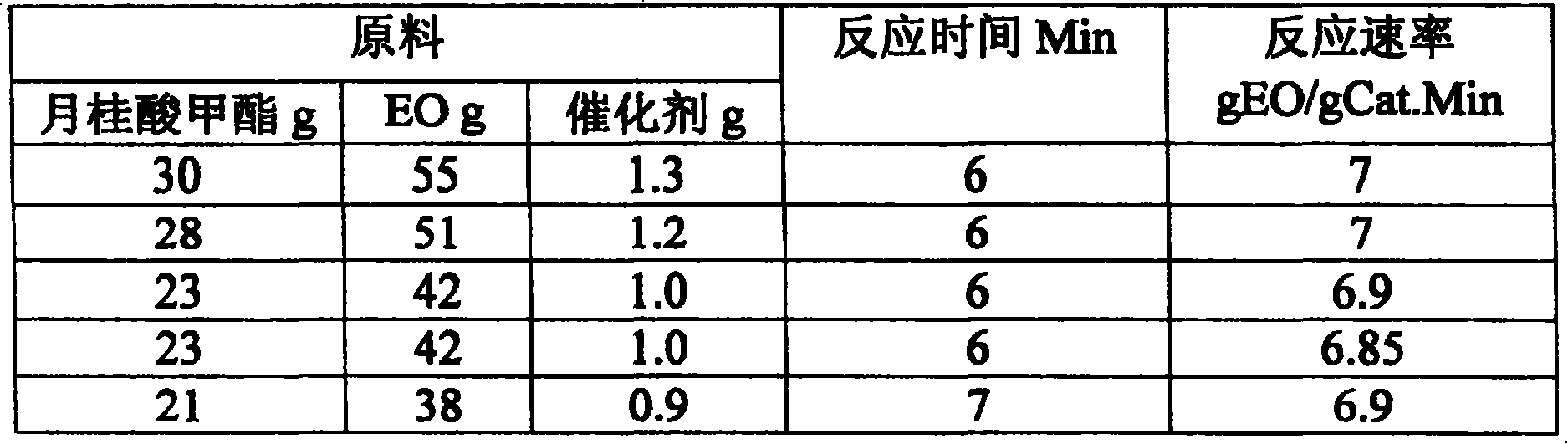

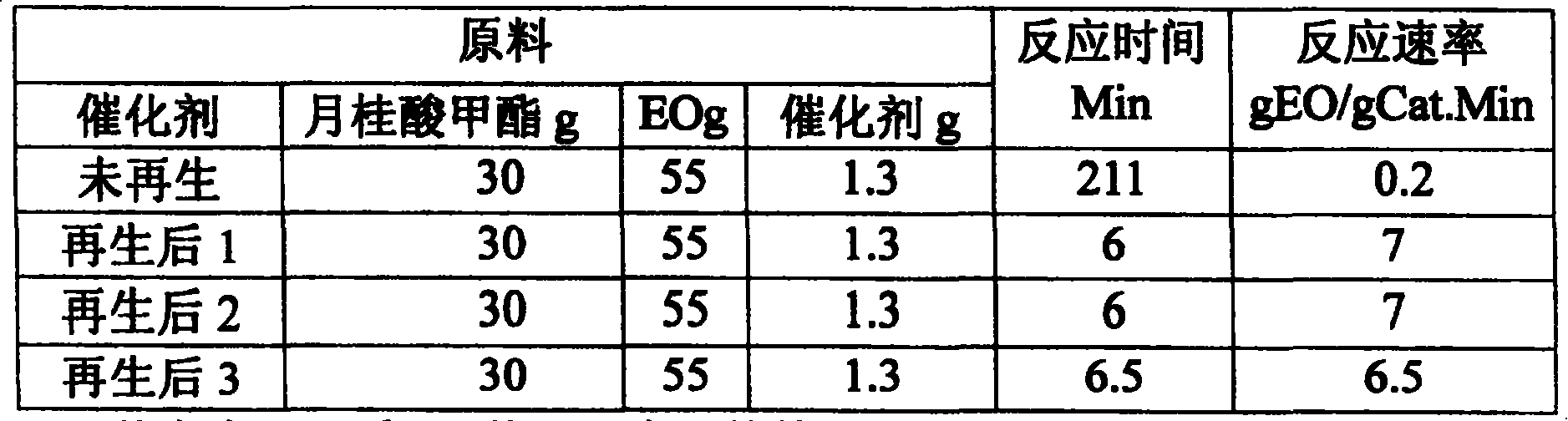

Embodiment 1

[0023] Weigh 17.6gAl(NO 3 ) 3 9H 2 O, add 21.4g deionized water, be made into aluminum nitrate solution, pour it into the separatory funnel after fully dissolving. Add 173g of deionized water into a 500ml beaker, place it on a magnetic heating stirrer, start stirring, slowly add 23g of MgO at 25°C, let it disperse completely for 15 minutes, then slowly add the prepared nitric acid dropwise at 25°C Aluminum solution, dripping for 15 minutes, aging at a constant temperature of 25°C for 30 minutes, and then washing. Add 200 ml of deionized water and stir for 10 minutes, filter under reduced pressure, and repeat washing and filtering until the pH of the system is between 6.5-7.5. 8 grams of clay was added, and it was pressed into shape, and the shaped ring-shaped catalyst was placed in a constant temperature box, and dried at a constant temperature of 100° C. for 10 hours. Then take 5g of 5% potassium alkoxide liquid and evenly spray morphine on it, place it in a desiccator at...

Embodiment 2

[0025] Weigh 30g of Al(NO 3 ) 3 9H 2 O, add 30g deionized water, be made into aluminum nitrate solution, pour it into the separatory funnel after fully dissolving. Add 124g of deionized water into a 500ml beaker, place it on a magnetic heating stirrer, start stirring, slowly add 31g of MgO at 25°C, make it completely dispersed for 15 minutes, then slowly add the prepared nitric acid dropwise at 25°C Aluminum solution, dripping for 15 minutes, aging at a constant temperature of 25°C for 30 minutes, and then washing. Add 200ml of deionized water and stir for 10 minutes, filter under reduced pressure, repeat washing and filtering until the pH of the system is between 6.5-7.5, and then filter with suction. Add 6.6 grams of clay, and press it into shape. The shaped ring-shaped catalyst is placed in a constant temperature box and dried at a constant temperature of 100° C. for 10 hours. Then take 8g of 5% potassium alkoxide liquid and evenly spray morphine on it, place it in a de...

Embodiment 3

[0027] Weigh 17.6gAl(NO 3 ) 3 9H 2 O, add 21.4g deionized water, be made into aluminum nitrate solution, pour it into the separatory funnel after fully dissolving. Add 173g of deionized water into a 500ml beaker, place it on a magnetic heating stirrer, start stirring, slowly add 23g of MgO at 25°C, let it disperse completely for 15 minutes, then slowly add the prepared nitric acid dropwise at 25°C Aluminum solution, dripping for 15 minutes, aging at a constant temperature of 25°C for 30 minutes, and then washing. Add 200 ml of deionized water and stir for 10 minutes, filter under reduced pressure, and repeat washing and filtering until the pH of the system is between 6.5-7.5. 4 grams of clay was added, and it was pressed into shape. The shaped ring-shaped catalyst was placed in a constant temperature box and dried at a constant temperature of 105° C. for 8 hours. Then take 5g of 5% potassium alkoxide liquid and evenly spray morphine on it, place it in a desiccator at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com