Chemical dust suppressing agent for mines

A dust suppressant and chemical technology, applied in the field of mineral mining, can solve the problems of high price of dust and smoke suppressant, unsatisfactory dust removal effect, and difficulty in obtaining raw materials, etc., and achieves short preparation time, small equipment investment and good fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The chemical dust suppressant used in mines consists of the following raw materials in parts by weight:

[0065] 15 parts of alkylphenol polyoxyethylene ether,

[0066] α-olefin sulfonate 25 parts,

[0067] Alkyl amidopropyl betaine 15 parts,

[0068] 10 parts of tetrapolylysine,

[0069] 0.5 parts of water glass,

[0070] Calcium chloride 1 part,

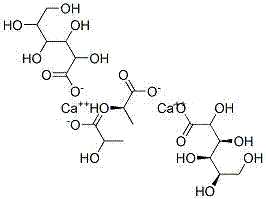

[0071] Calcium lactogluconate 1 part,

[0072] 2 parts epoxy resin,

[0073] 0.05 parts of sodium 2-methylisocitrate,

[0074] 1,2-propanediol 5 parts,

[0075] 100 parts of water,

[0076] Wherein the alkylphenol polyoxyethylene ether is a mixture of octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether with a mass ratio of 1:2; the α-olefin sulfonate is α-olefin sulfonate sodium acid; the alkyl amidopropyl betaine is lauryl amidopropyl betaine.

Embodiment 2

[0078] The chemical dust suppressant used in mines consists of the following raw materials in parts by weight:

[0079] 22 parts of alkylphenol polyoxyethylene ether,

[0080] α-olefin sulfonate 20 parts,

[0081] Alkyl amidopropyl betaine 20 parts,

[0082] 6 parts of tetrapolylysine,

[0083] 0.8 parts of water glass,

[0084] Calcium chloride 0.8 part,

[0085] Calcium lactogluconate 0.8 parts,

[0086] 7 parts of epoxy resin,

[0087] 0.06 parts of sodium 2-methylisocitrate,

[0088] 1,2-propanediol 3 parts,

[0089] 100 parts of water,

[0090] Wherein the alkylphenol polyoxyethylene ether is a mixture of octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether with a mass ratio of 1:2; the α-olefin sulfonate is α-olefin sulfonate sodium acid; the alkyl amidopropyl betaine is lauryl amidopropyl betaine.

Embodiment 3

[0092] The chemical dust suppressant used in mines consists of the following raw materials in parts by weight:

[0093] 20 parts of alkylphenol polyoxyethylene ether,

[0094] α-olefin sulfonate 22 parts,

[0095] Alkyl amidopropyl betaine 18 parts,

[0096] 7 parts of tetrapolylysine,

[0097] 0.7 parts of water glass,

[0098] Calcium chloride 0.9 part,

[0099] Calcium lactogluconate 0.6 parts,

[0100] 6 parts of epoxy resin,

[0101] 0.07 part of sodium 2-methylisocitrate,

[0102] 1,2-propanediol 2 parts,

[0103] 100 parts of water,

[0104] Wherein the alkylphenol polyoxyethylene ether is a mixture of octylphenol polyoxyethylene ether and dinonylphenol polyoxyethylene ether with a mass ratio of 1:2; the α-olefin sulfonate is α-olefin sulfonate sodium acid; the alkyl amidopropyl betaine is lauryl amidopropyl betaine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com