Patents

Literature

262results about How to "High heat storage density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium-high temperature composite structural heat storage material, preparation method and application thereof

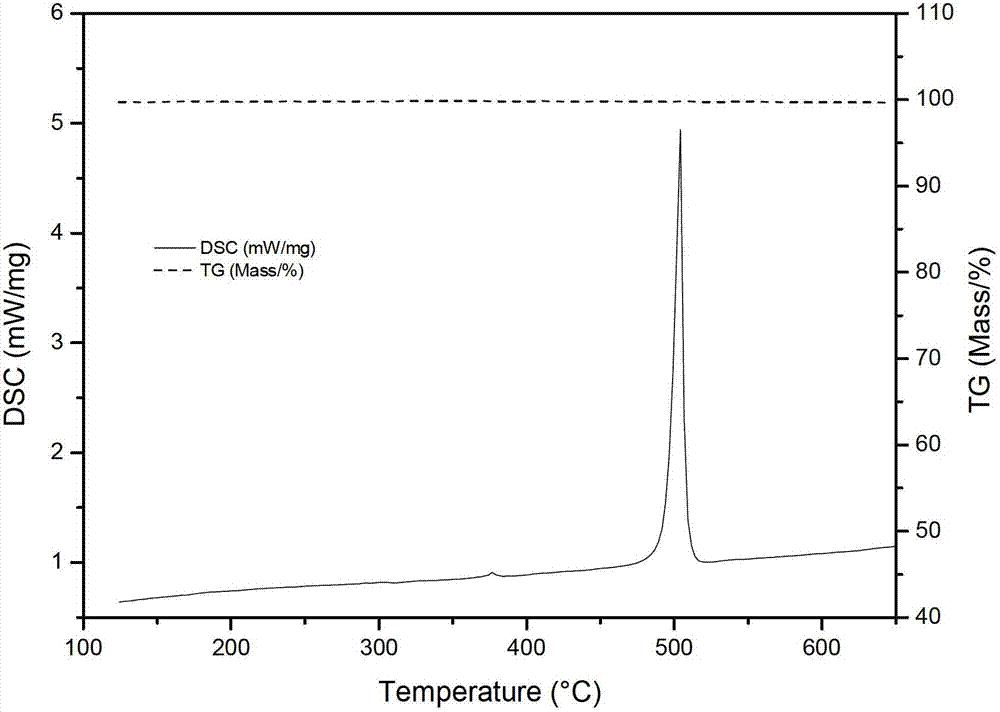

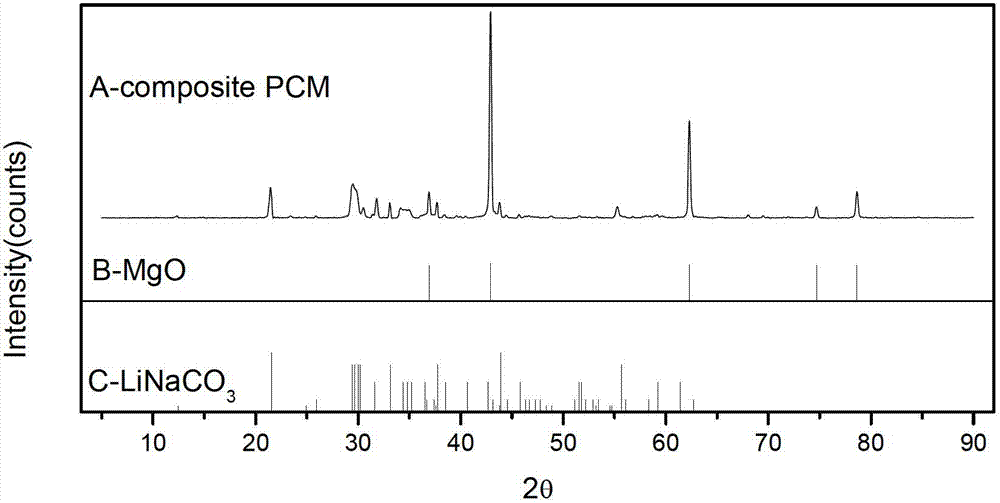

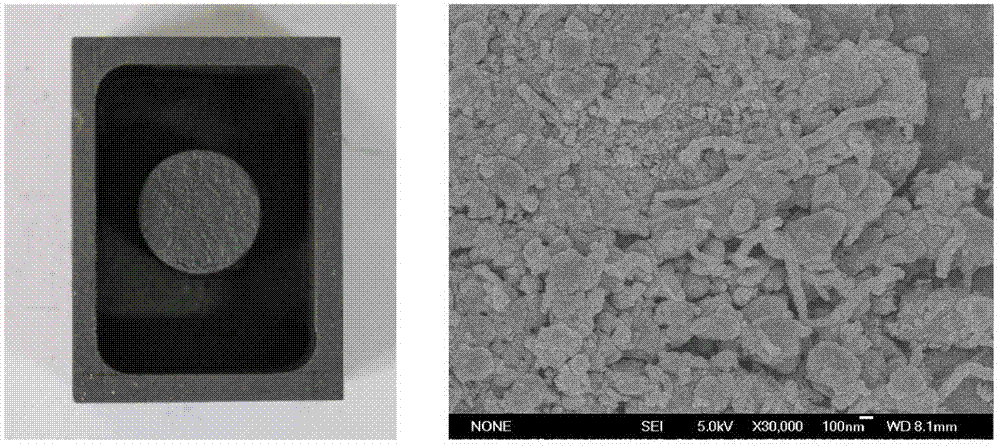

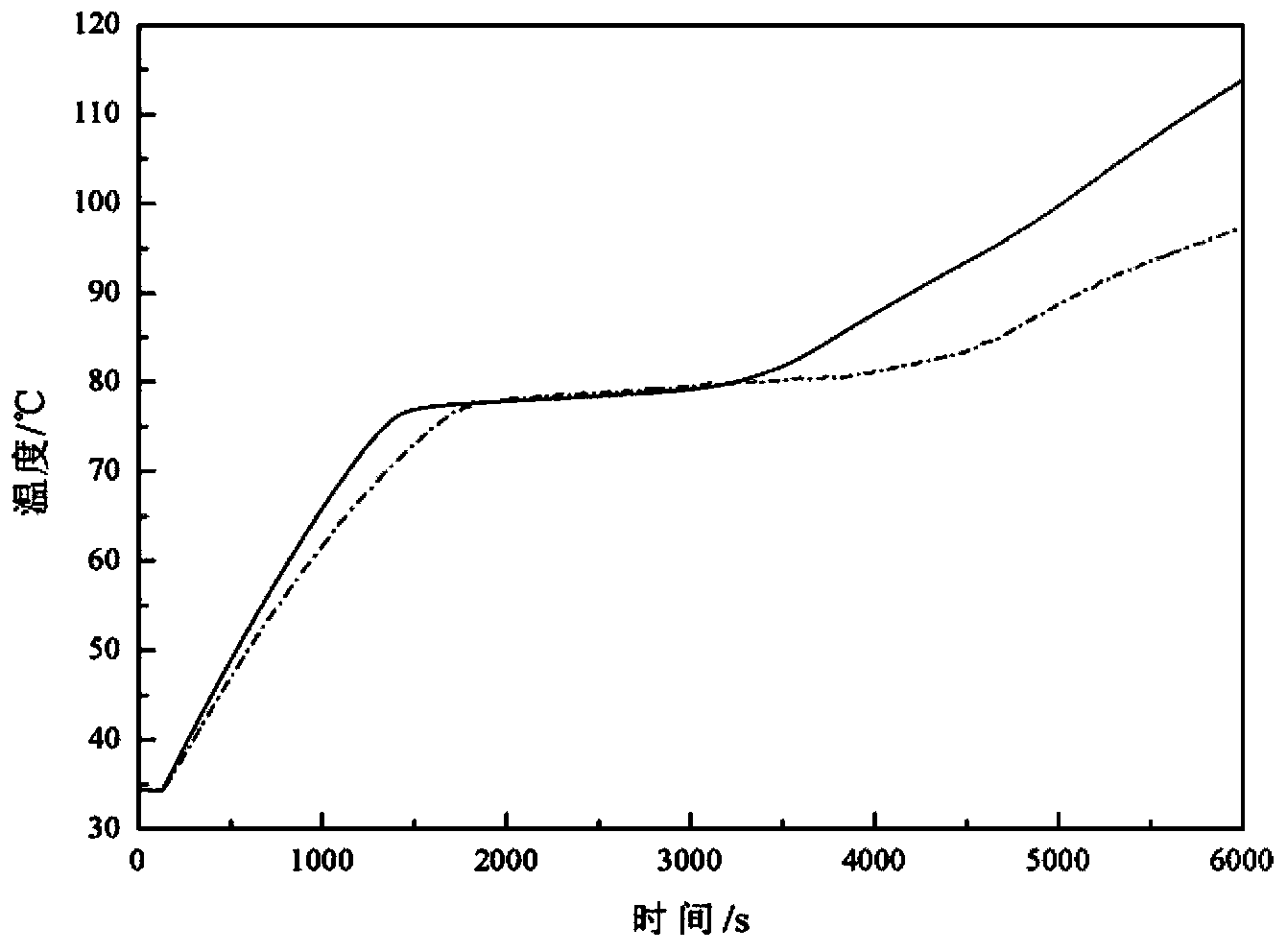

InactiveCN102888209AHigh phase change enthalpyGood chemical compatibilityHeat-exchange elementsMicro nanoMass ratio

The invention relates to a medium-high temperature (120-1000 DEG C or higher) composite structural heat storage material. The medium-high temperature composite structural heat storage material comprises an inorganic salt phase change latent heat material, a sensitive heat storage material and a heat conduction reinforcing material, wherein the mass ratio of the inorganic salt phase change latent heat material to the sensitive heat storage material is of 1: (0.1-10); and the heat conduction reinforcing material is of 0.0001-1kg / (kg heat storage material) based on mass ratio. The preparation method comprises steps as follows: uniformly mixing the inorganic salt phase change latent heat material with the sensitive heat storage material and the heat conduction reinforcing material; pressurizing to form green blank; and then heating and sintering, so as to obtain the medium-high temperature composite structural heat storage material. The medium-high temperature composite structural heat storage material provided by the invention is capable of obviously reducing the corrosion resistance of the sensitive heat storage material; meanwhile, the thermal conductivity of the composite heat storage material is markedly improved by virtue of the micro-nano doping of the heat conduction reinforcing material; and moreover, high heat storage density is achieved, and wide application prospect is provided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

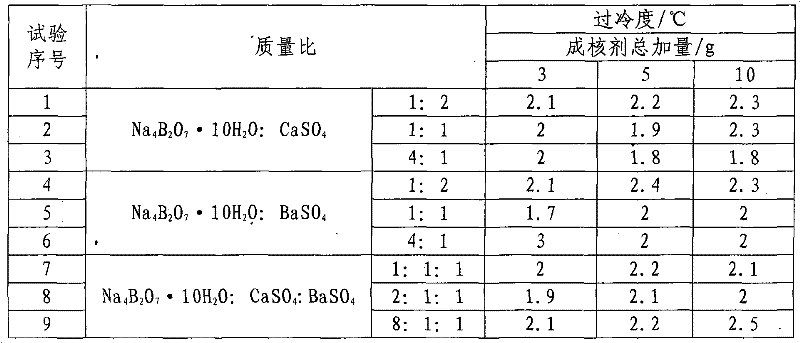

Foam metal composite phase-change material and preparation method thereof

InactiveCN103436240AImprove thermal performanceHigh heat storage densityHeat-exchange elementsHeat conductingImpurity

The invention relates to a foam metal composite phase-change material and a preparation method thereof, and belongs to the technical field of phase-change energy storage materials. A crystallized hydrated salt-foam metal composite phase-change energy storage material is prepared by adopting the adsorption characteristic of a porous foam metal skeleton structure, and a vacuum argon filling state is kept in a preparation process, so that impurities are prevented from entering, and the quality of a product is ensured. The phase-change material is relatively uniformly and sufficiently distributed in a substrate of the foam metal skeleton material, and the shaping characteristic of the composite material is maintained under the combined action of a capillary force and surface tension of foam metal, so that the phase-change material does not leak easily in a phase-change process, and the preparation method of the phase-change material is simple and convenient, high in recombination rate and good in operability. The composite phase-change material has the advantages of high phase-change latent heat in unit volume, high heat storage and release rates, good heat-conducting property, lower supercooling degree, and the like; and the lower heat conductivity and supercooling problems existing after the crystallized hydrated salt phase-change material is applied for a long time are solved effectively.

Owner:BEIHANG UNIV

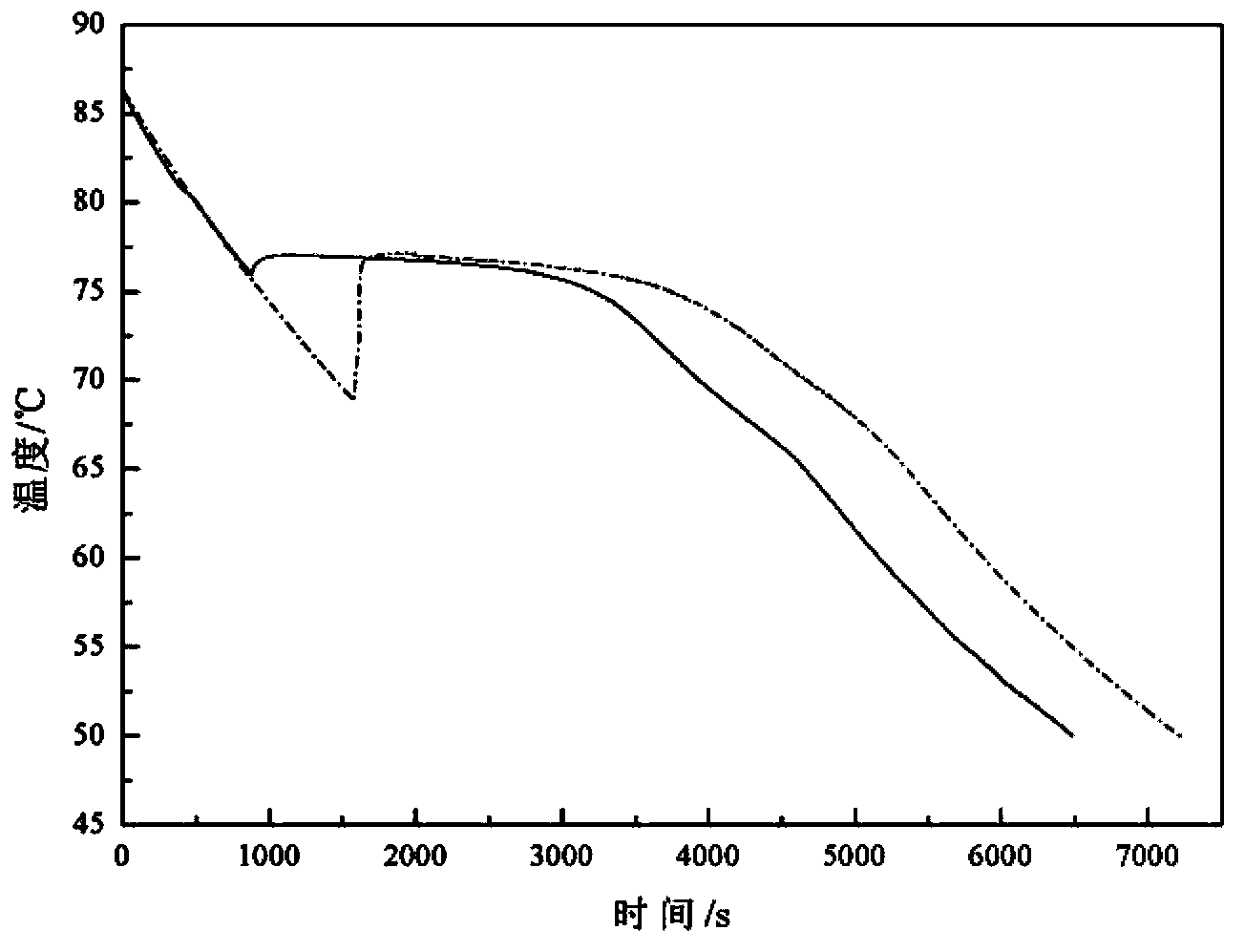

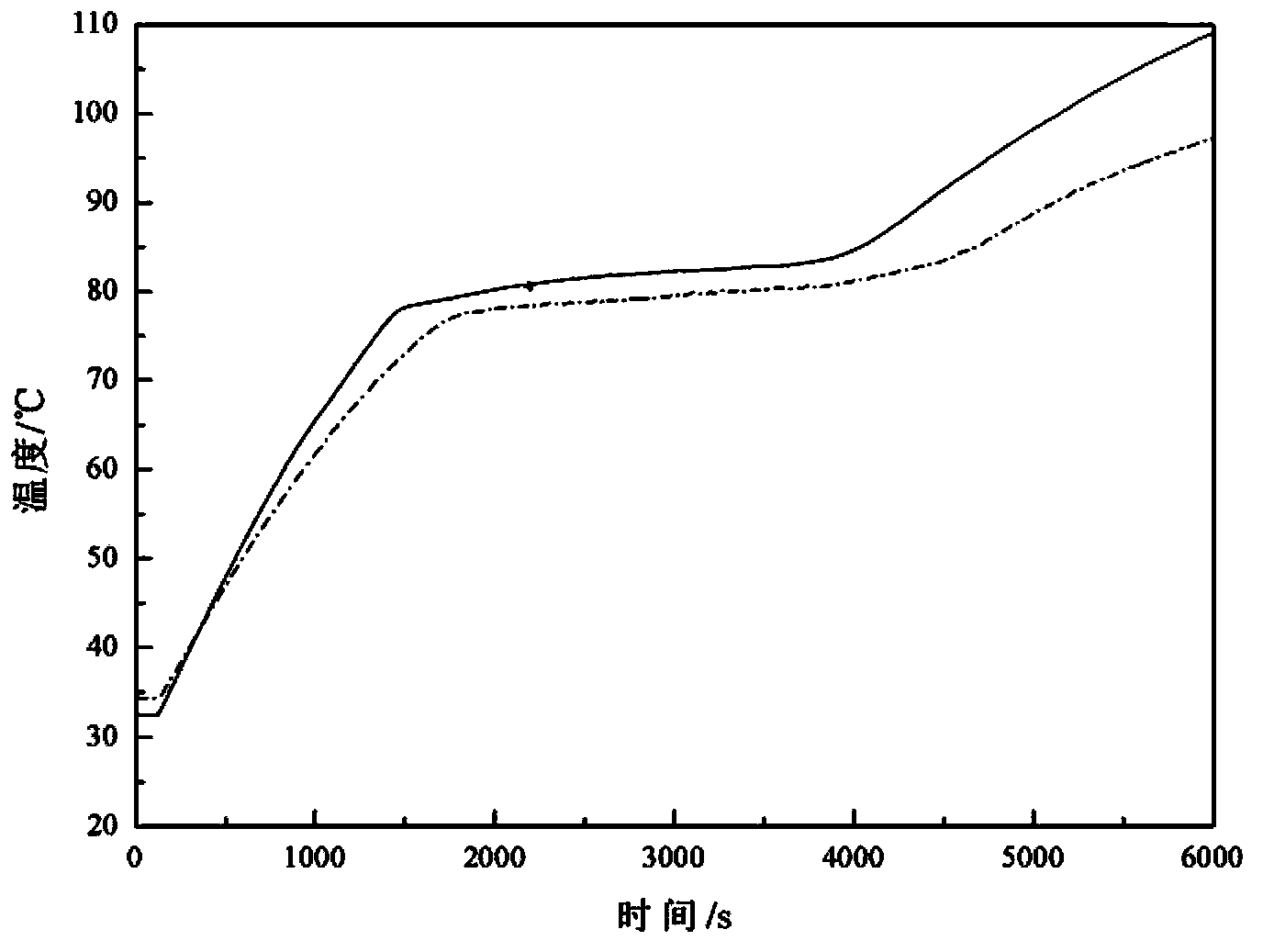

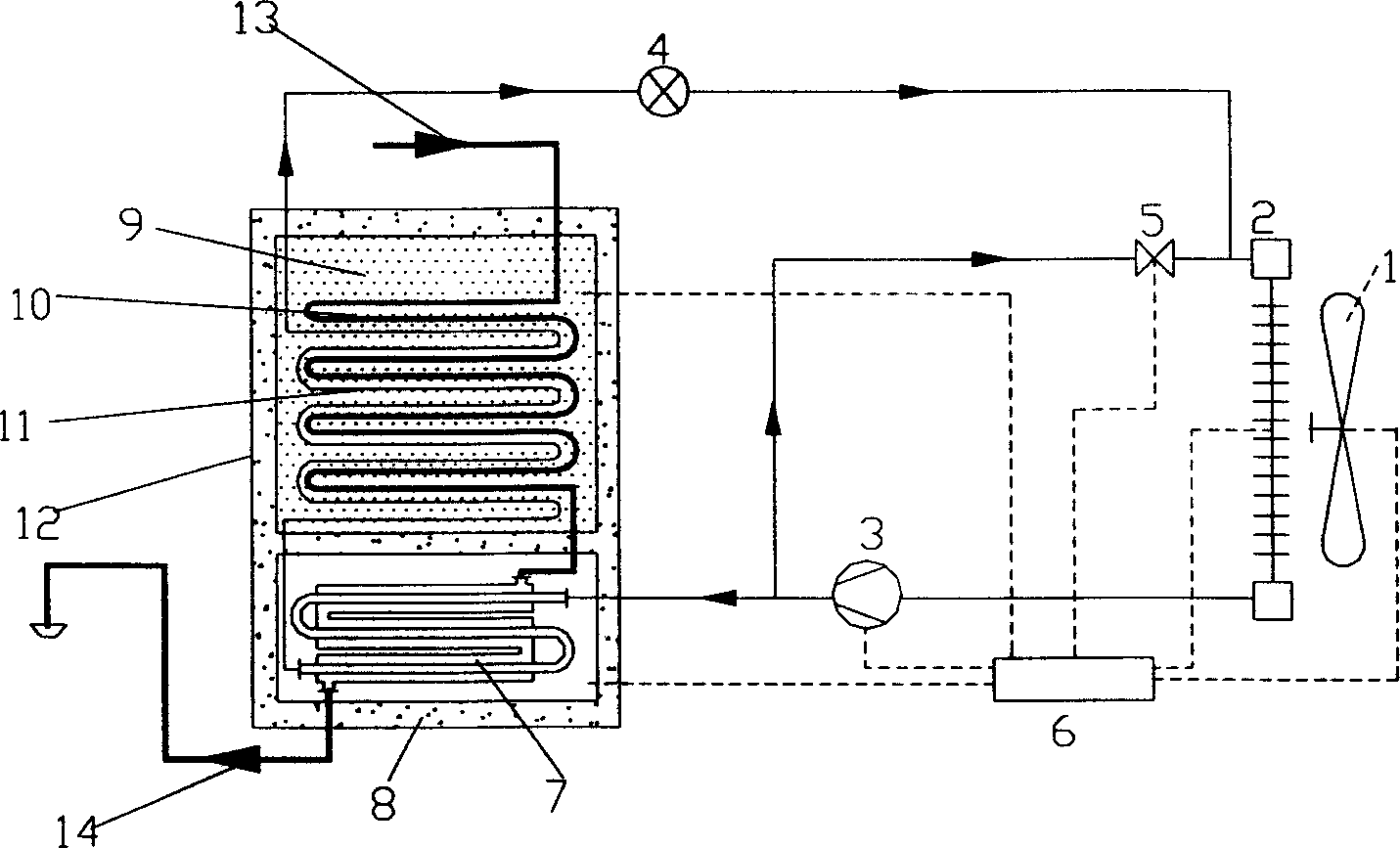

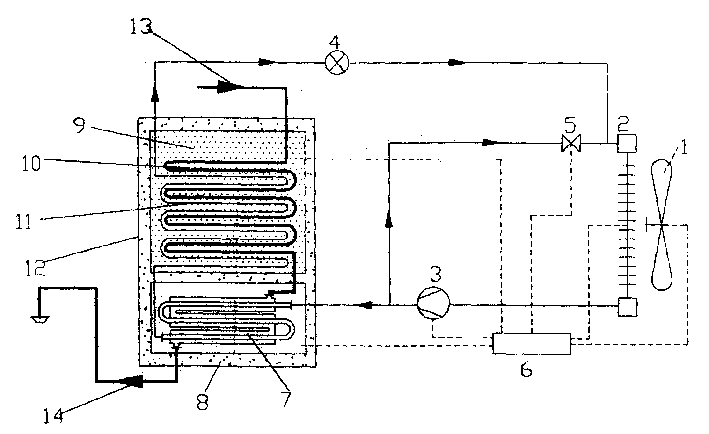

Preheating type heat pump water heater using stored heat caused by phase change

InactiveCN1462850AReduce heat loadReduce volumeHeat storage plantsEnergy efficient heating/coolingEngineeringPhase change

A phase-change heat-accumulation preheating type heat-type water heater is sequentially composed of evaporator, compressor, heating heat exchanger, heat-accumulating heat exchanger, throttle device and heat-getting heat exchanger. A blower is close to said evaporator. The heat-accumulating and heat-getting heat exchangers and the phase-change material are contained in an insulating container. Thesaid heat-pump heater is controlled by a controller. Its advantages are durable and stable supply of hot water, light weight, small size and low power consumption.

Owner:ZHEJIANG UNIV

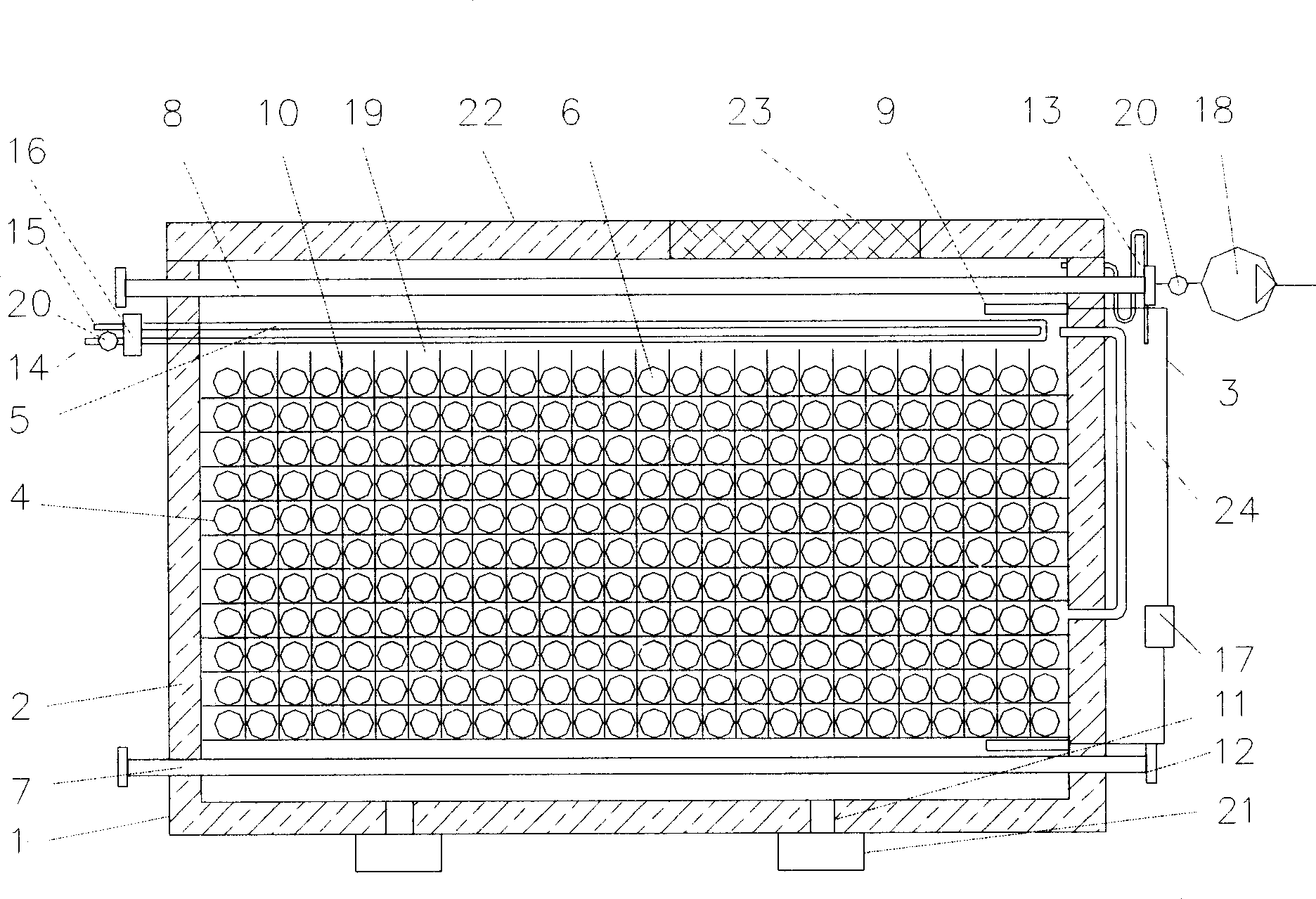

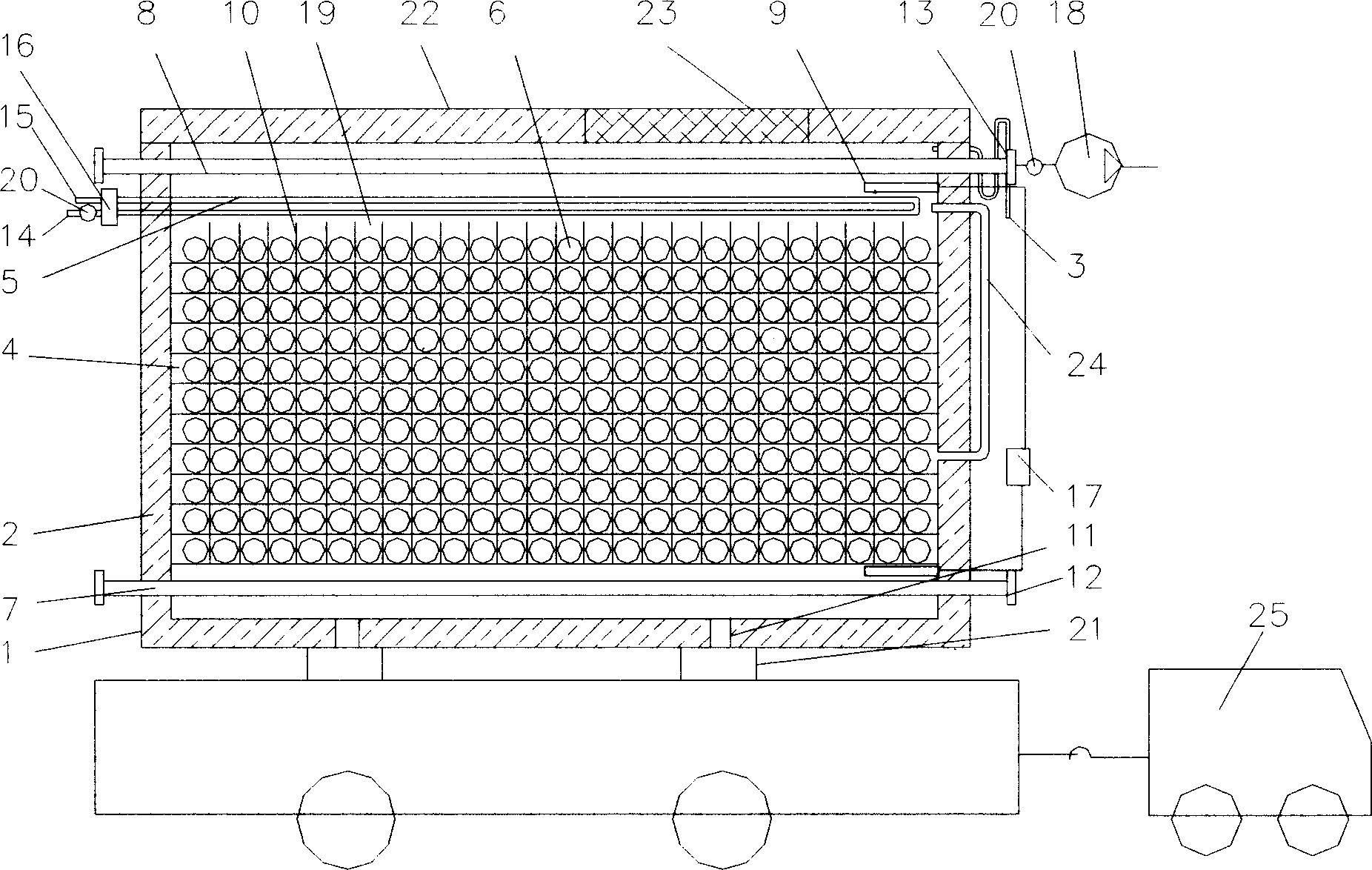

Movable heat supplying plant

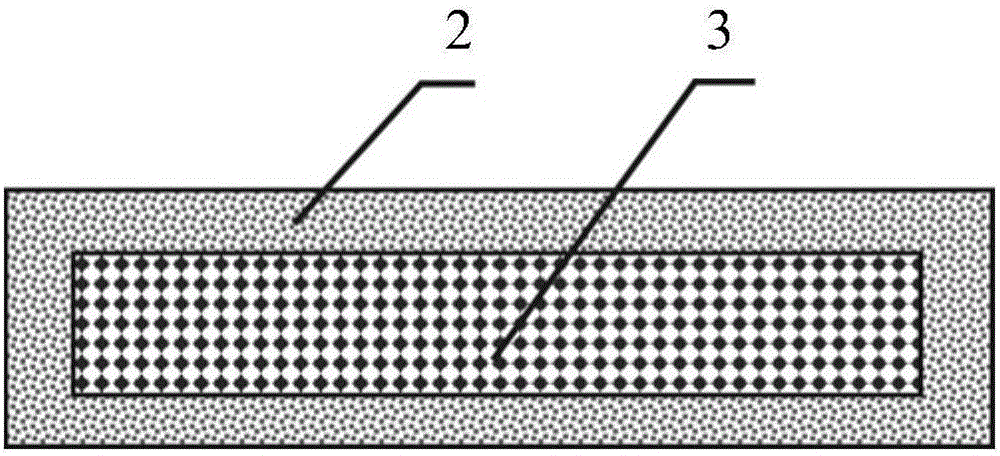

InactiveCN1854614AReduce consumptionReduce pollutionCentral heating with accumulated heatLighting and heating apparatusEngineeringControl valves

A movable rectangular heating station consisting of a casing, an insulating layer, an internal box body, a high-performance heat-storing body, a heat-exchanging coil, a heat recovery unit, a heating distributor, a temperature probe, a controller, a bottom stand, a circulating water inlet, a hot water outlet, a temp.-control valve and a thermal flow meter can recover residual heat and waste heat from the heating and power plant and the heat source plant and realize the heat-transfer without pipelines by the movable conveying, so as to transfer the stored heat into the users for heating and supplying the domestic water.

Owner:王少杰

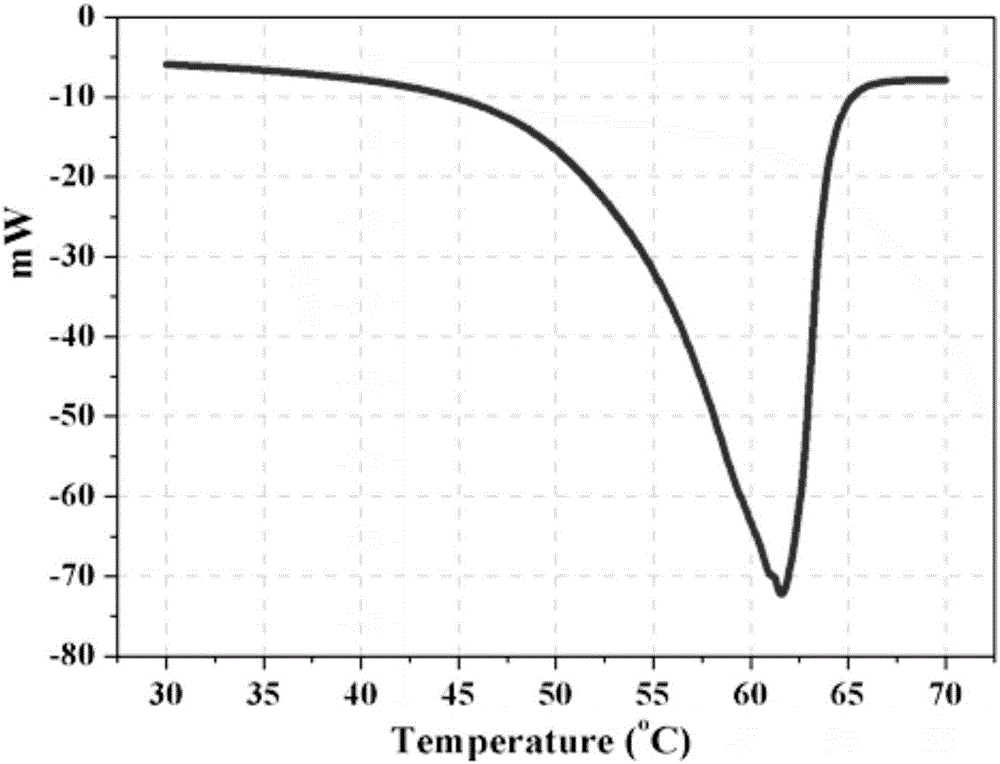

Composite phase-change material for mobile heat supply and preparation method thereof

ActiveCN103113854ANo precipitationFast heat storage and releaseChemical industryHeat-exchange elementsMolten stateMass ratio

The invention discloses a composite phase-change material for mobile heat supply and a preparation method thereof. The composite phase-change material is formed by compounding 97.5-99.5 wt% of mixed inorganic salts and 0.5-2.5 wt% of non-metal nano material. The preparation method comprises the following steps: mixing a plurality of inorganic salts according to mass ratio, stirring, adding into a vacuum heating furnace, and heating into a molten state, wherein the temperature of the vacuum heating furnace is controlled at 40-50 DEG C higher than the phase-change temperature of the mixed inorganic salts; and adding the non-metal nano material into the molten salts, and magnetically stirring for more than half an hour to prepare the uniform and stable molten-state composite phase-change material. Compared with the prior art, the composite phase-change material disclosed by the invention has the advantages of high heat-conducting property, high heat accumulation density, small volume shrinkage and the like, can satisfy different application requirements, and is especially suitable for moderate-temperature waste heat recovery.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

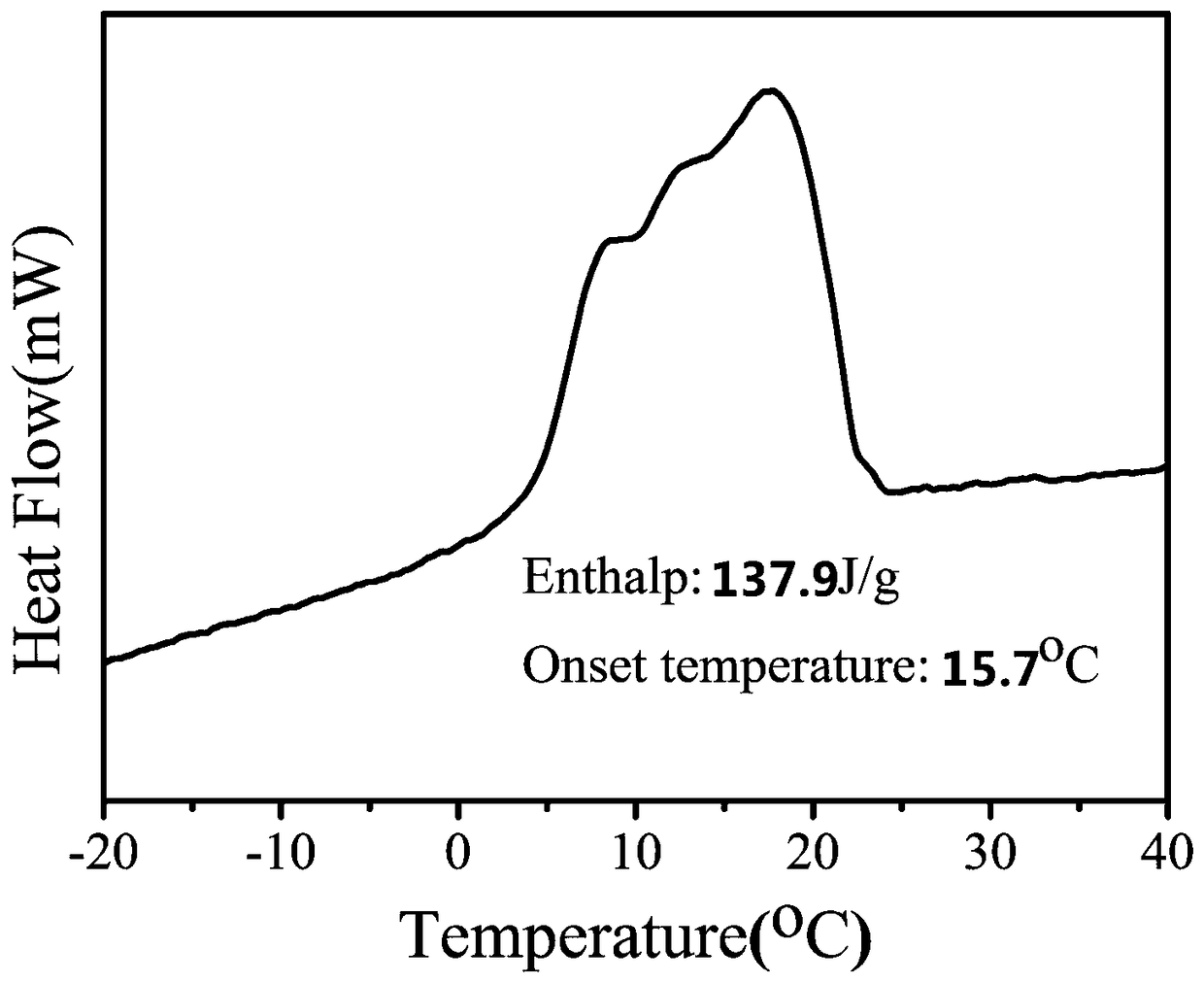

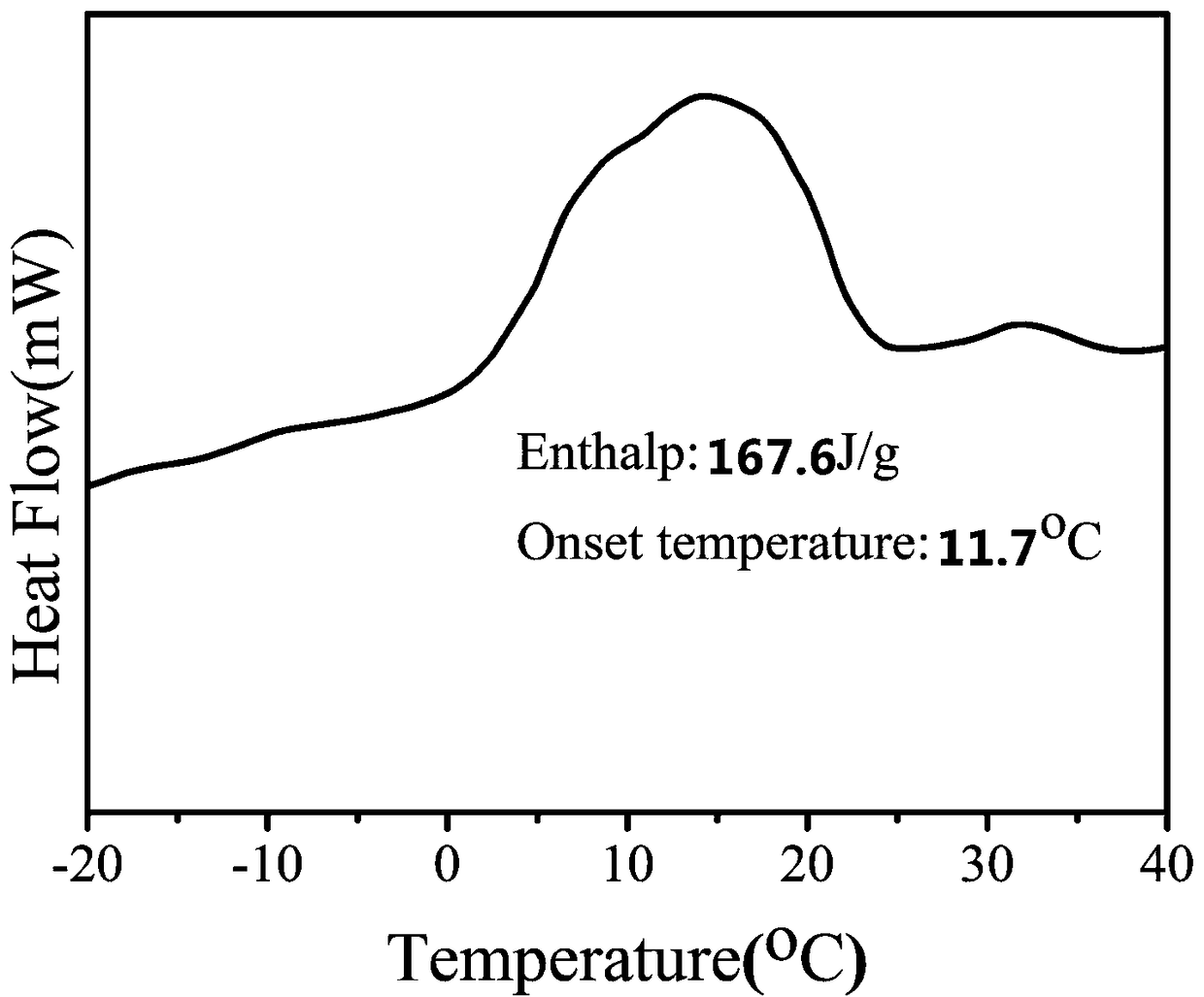

Low-phase-transition-temperature heat storage material and preparation method thereof

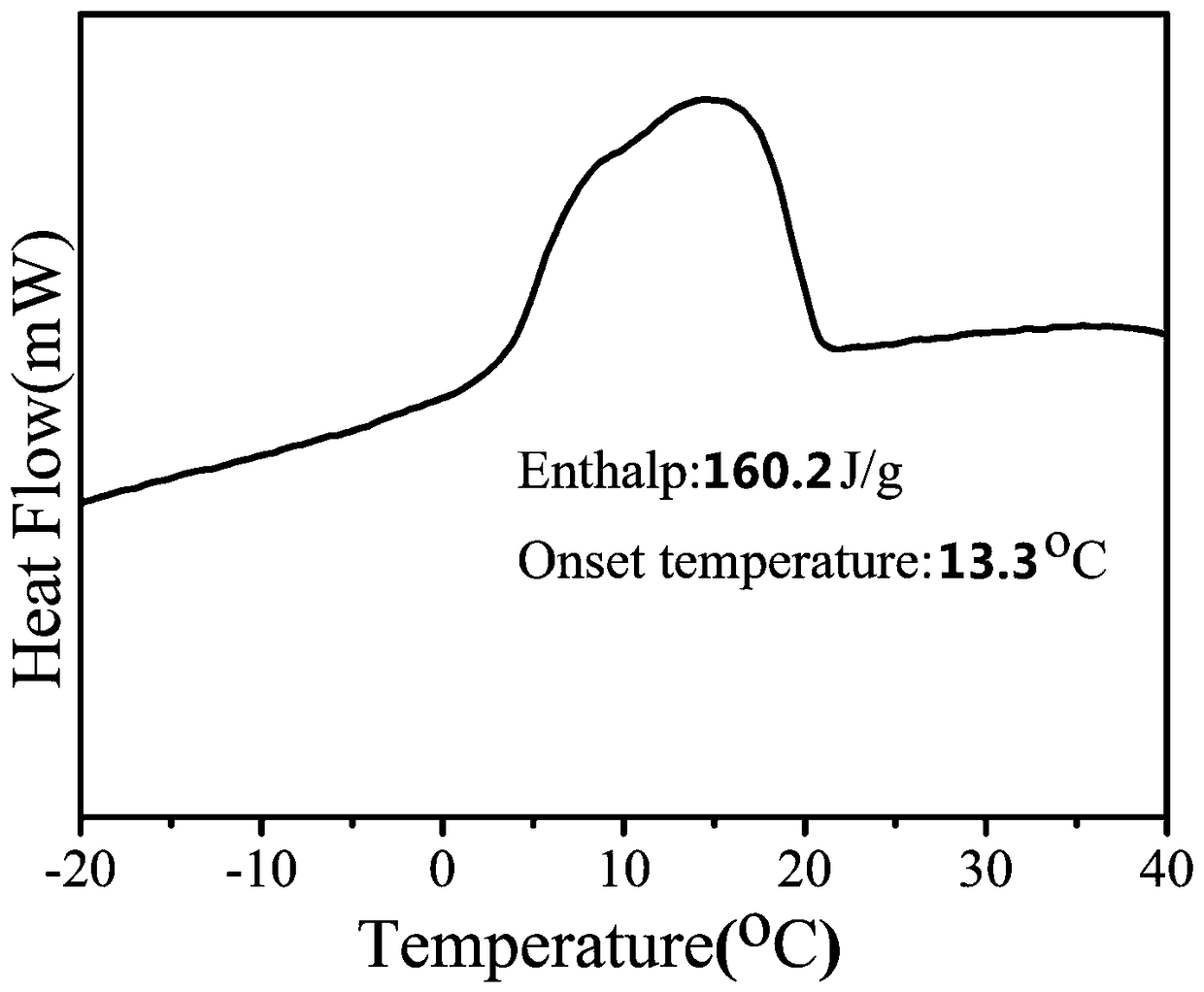

InactiveCN106753259AHigh heat storage densityWide application temperature rangeHeat-exchange elementsHeat storage materialSodium Acetate Trihydrate

The invention discloses a low-phase-transition-temperature heat storage material and a preparation method thereof. The low-phase-transition-temperature heat storage material comprises the following components in parts by weight: 55 to 93 parts of sodium acetate trihydrate, 1 to 40 parts of a temperature regulator, 2 to 6 parts of deionized water, 1 to 2 parts of a thickener, and 2 to 3 parts of a nucleating agent. The phase transition heat storage material provided by the invention has the adjustable phase transition temperature of 35 to 56 DEG C, and the phase transition latent heat of 200 to 280 kJ / kg. The application temperature range of a sodium acetate trihydrate system is expanded, and the phase transition heat storage material provided by the invention belongs to solid-liquid phase transition, has high heat storage density and can be effectively applied to the field of civil life.

Owner:贺迈新能源科技(上海)有限公司

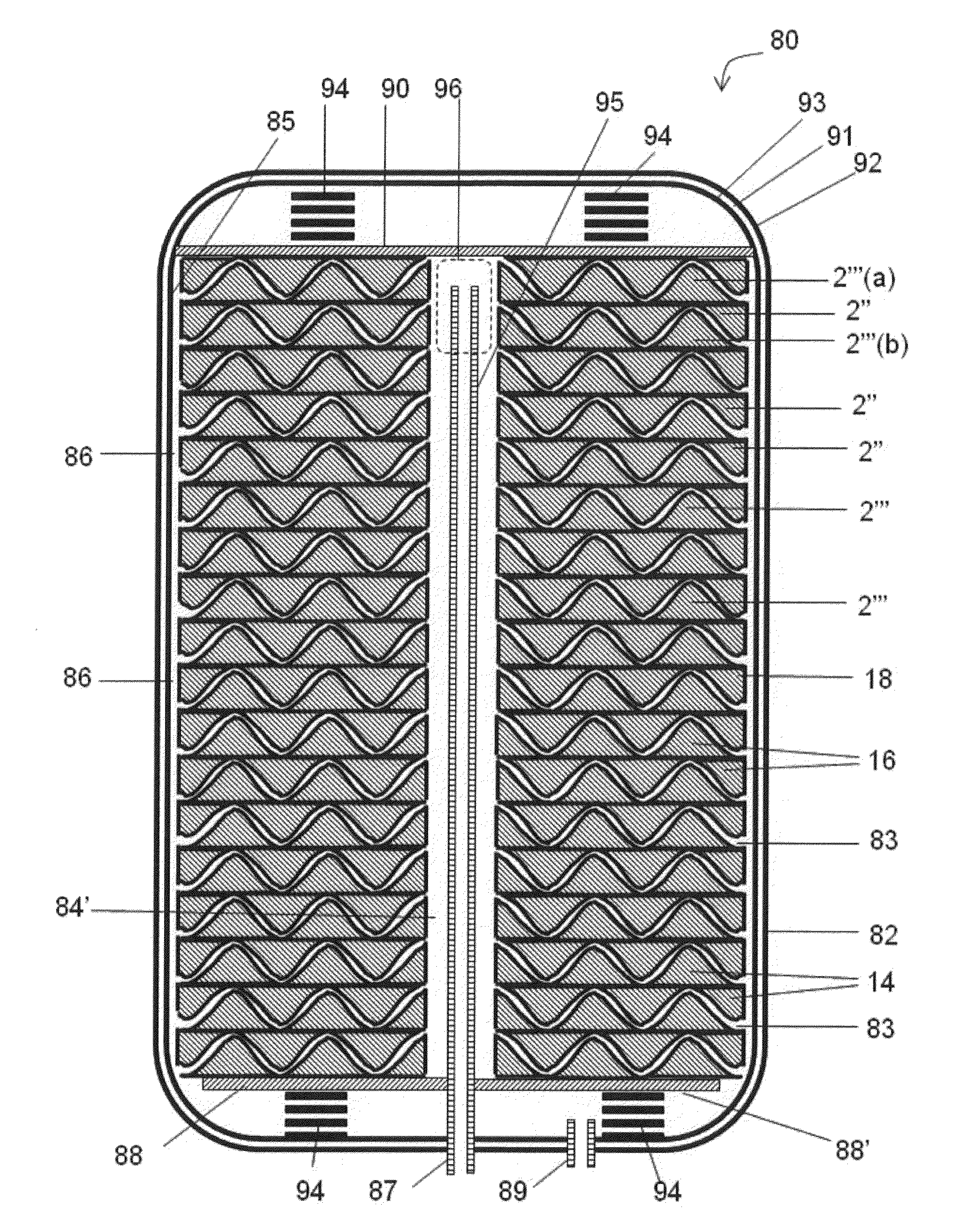

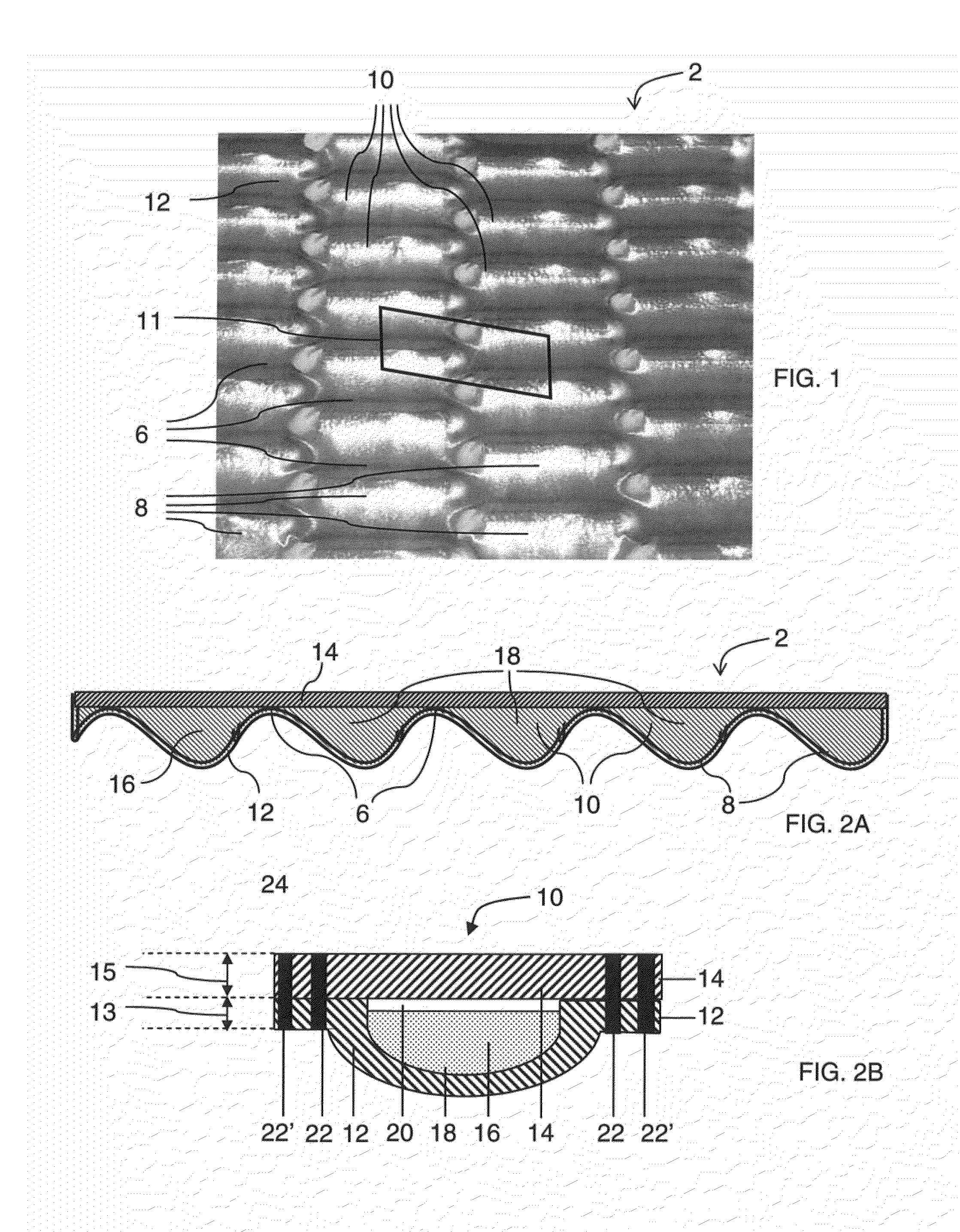

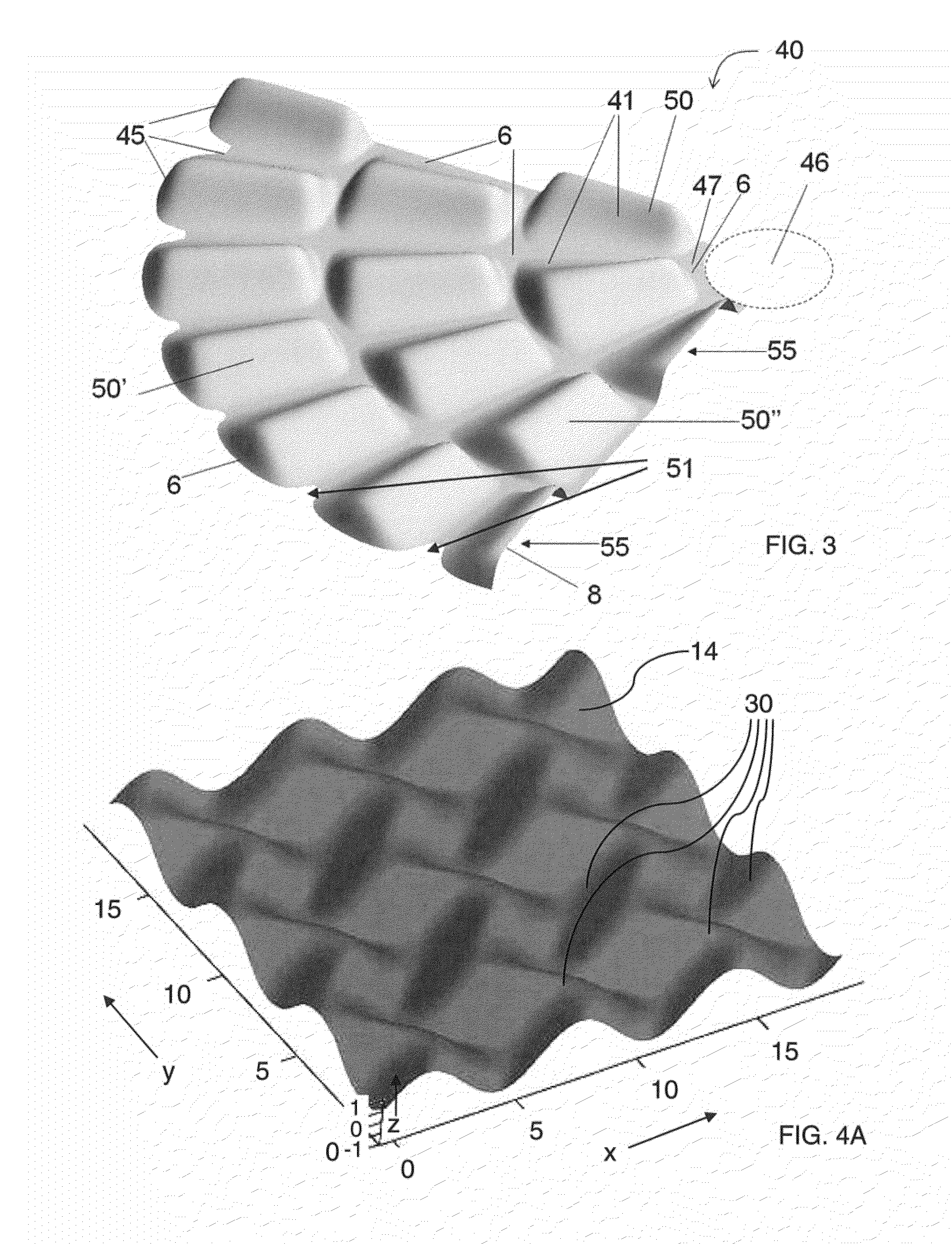

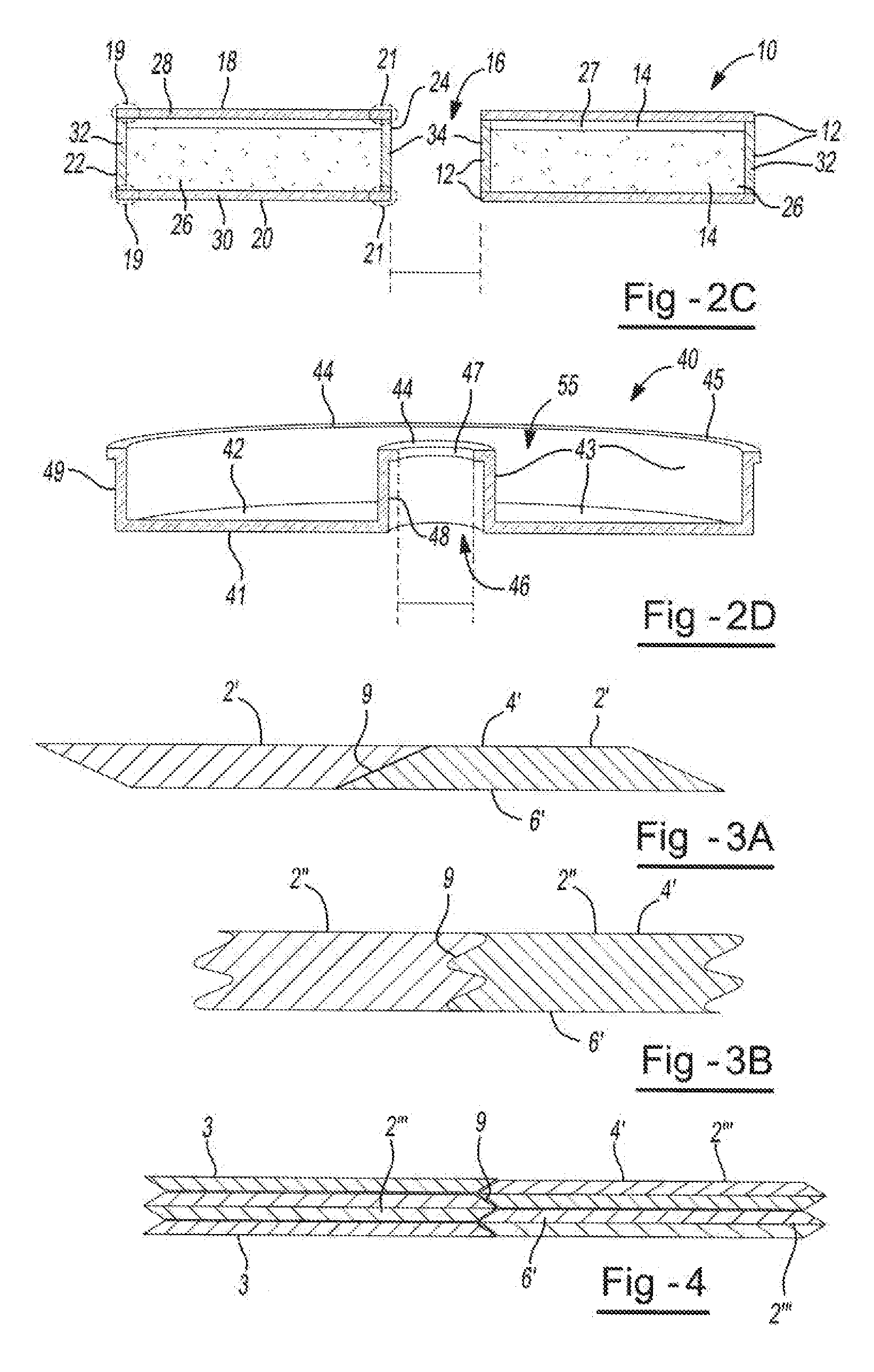

Articles and devices for thermal energy storage and methods thereof

InactiveUS20120037148A1Increase concentrationLarge specific surface areaReinforcing meansHeat storage plantsThermal energyThermal energy storage

The present invention relates to articles and heat storage devices for storage of thermal energy. The articles include a metal base sheet and a metal cover sheet, wherein the metal base sheet and the metal cover sheet are sealingly joined to form one or more sealed spaces. The articles include a thermal energy storage material that is contained within the sealed spaces. The sealed spaces preferably are substantially free of water or includes liquid water at a concentration of about 1 percent by volume or less at a temperature of about 25° C., based on the total volume of the sealed spaces. The articles include one or more of the following features: a) the pressure in a sealed space is about 700 Torr or less, when the temperature of the thermal energy storage material is about 25° C.; b) the metal cover sheet includes one or more stiffening features, wherein the stiffening features include indents into the sealed space, protrusions out of the sealed space, or both, that are sufficient in size and number to reduce the maximum von Mises stress in the cover sheet during thermal cycling; c) the metal cover sheet and / or the metal base sheet includes one or more volume expansion features; or d) the metal cover sheet has a thickness, tc, and the metal base sheet has a thickness, tb, wherein tc is greater than tb; so that the article is durable. For example, the article does not leak after thermal cycling between about 25° C. and about 240° C., for 1,000 cycles.

Owner:DOW GLOBAL TECH LLC

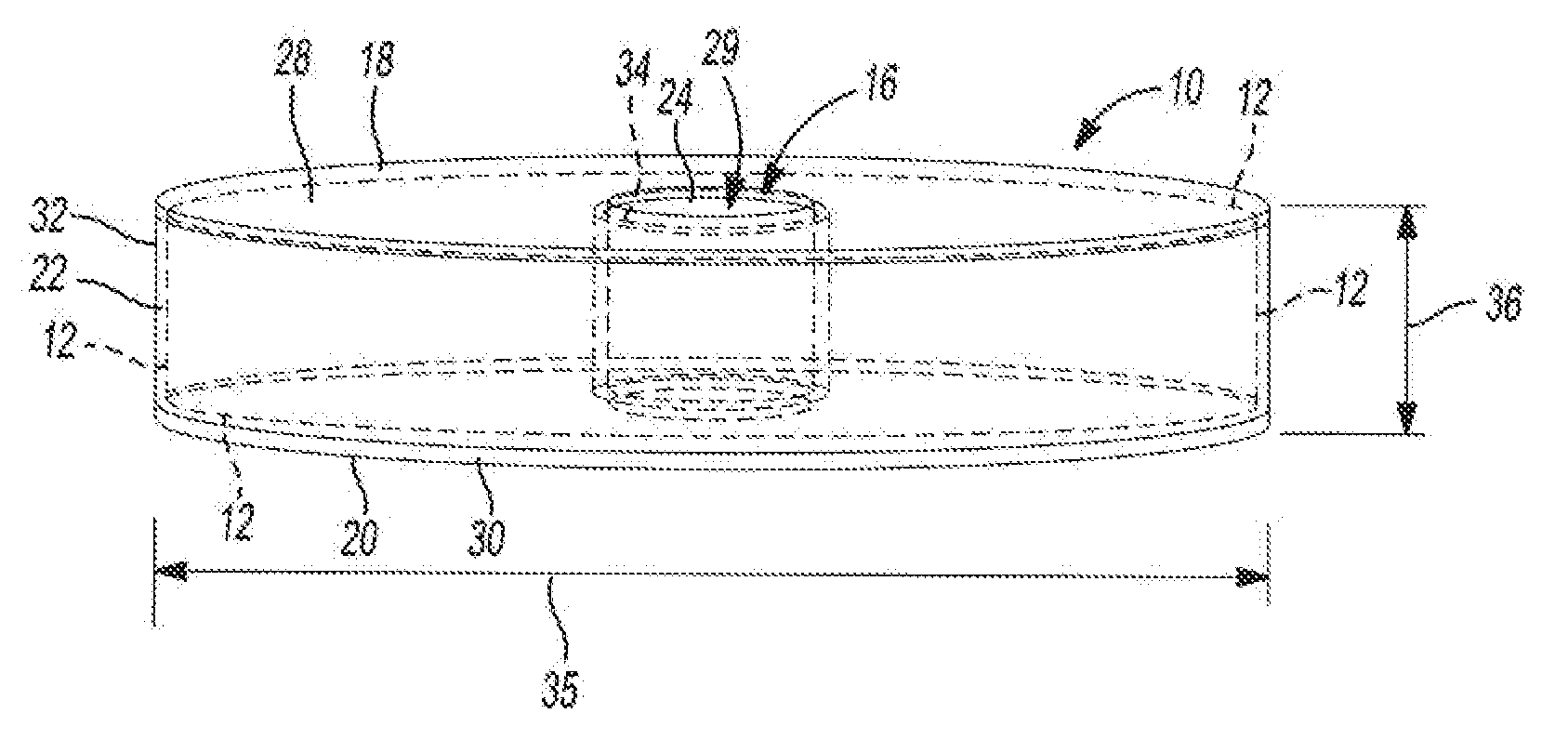

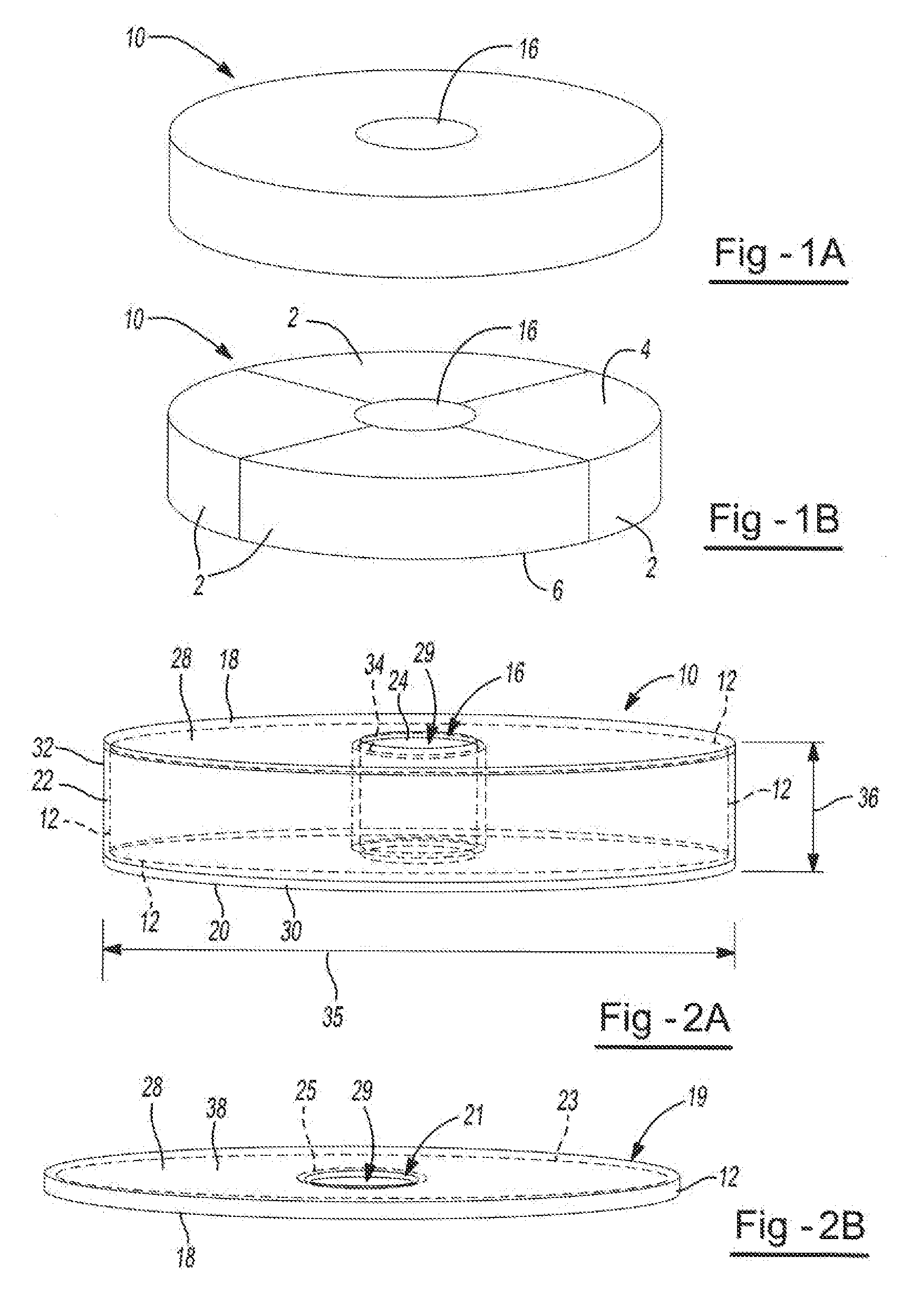

Thermal energy storage

InactiveUS20120279679A1Reduce hydraulic resistanceIncrease energy densityHeat storage plantsElectric propulsion mountingThermal energyThermal energy storage

The invention is directed at articles and devices for thermal energy storage, and for process of storing energy using these articles and devices. The articles comprise a capsular structure 10 having one or more sealed spaces 14, wherein the sealed spaces encapsulate one or more thermal energy storage materials 26: wherein the capsular structure has one or more fluid passages 16 which are sufficiently large to allow a heat transfer fluid to flow through the one or more fluid passages; and when a heat transfer fluid contacts the capsular structure 10 the thermal energy storage material 26 is Isolated from the heal transfer fluid. The devices include two or more articles arranged so that a fluid, such as a heat transfer fluid, may flow through the fluid passage 16 of an article before or after flowing through a space between two of the articles.

Owner:SOUKHOJAK ANDREY N +2

High-compactness thermal-storage concrete and preparation method thereof

The invention relates to a high-compactness thermal-storage concrete and a preparation method thereof, and belongs to the technical field of the thermal-storage material. The high-compactness thermal-storage concrete disclosed by the invention is prepared from 12.0-26.0 parts of sulphoaluminate cement, 65.0-80.0 parts of aggregate consisting of steel slag and basalt, 1.0-5.0 parts of graphite, 1.0-5.0 parts of slag powder, 3.0-10.0 parts of water and 0.1-1.0 part of water reducing agent. The gradation of the aggregate is designed by vast experiments, so that the aggregate accumulation achieves the tight accumulation state, the self compactness of the concrete is improved, and the problem of small thermal-storage density of the concrete is fundamentally solved. Therefore, the high-compactness thermal-storage concrete disclosed by the invention has excellent thermal performances, such as big thermal-storage density and good thermal conductivity. The preparation method disclosed by the invention has a simple method and is easy to operate. Because the steel slag is used as the fine aggregate, the industrial waste slag is fully utilized, and the production cost is lowered.

Owner:UNIV OF JINAN

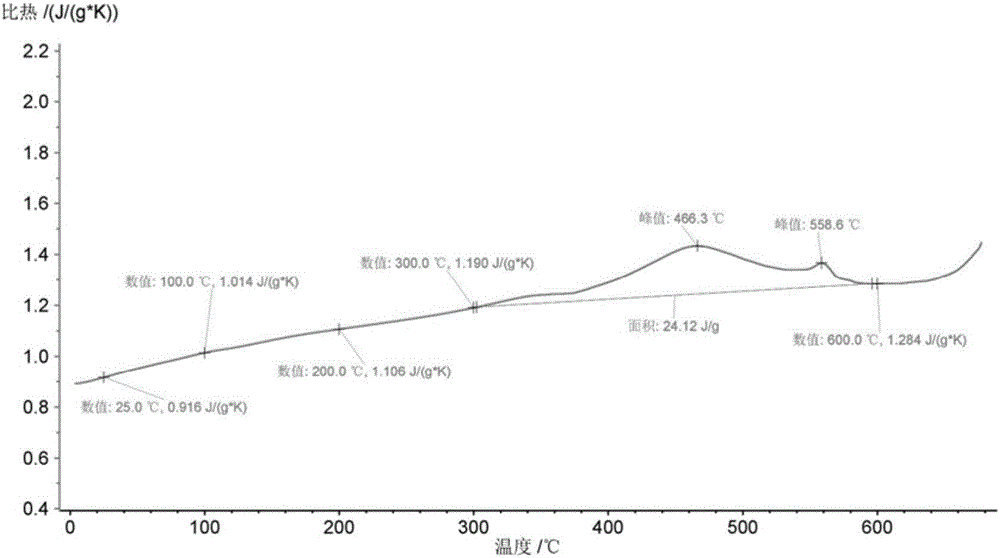

Solid composite phase-change thermal storage material and preparation method thereof

InactiveCN106701034ANo pollution in the processHigh heat storage densityHeat-exchange elementsVolumetric Mass DensityHydroforming

The invention discloses a solid composite phase-change thermal storage material, belonging to the technical field of energy storage materials. The solid composite phase-change thermal storage material comprises water, sodium carbonate, potassium carbonate, magnesium oxide, kieselguhr, quartz sand and kaolin. The thermal storage material is non-toxic, harmless and free of pollution. The invention further discloses a preparation method of the solid composite phase-change thermal storage material. The preparation method comprises the following steps: stirring, rubbing sand, filtering, performing hydraulic molding, and performing sintering molding. By adopting the preparation method, the thermal storage density is improved, the thermal storage density of the material is 2 times better than that of a common material, the thermal storage material can endure high temperature, can be heated to be greater than 650 DEG C, and is not liable to efflorescence when being used for a long time.

Owner:BEIJING SONDEX ENERGY TECH

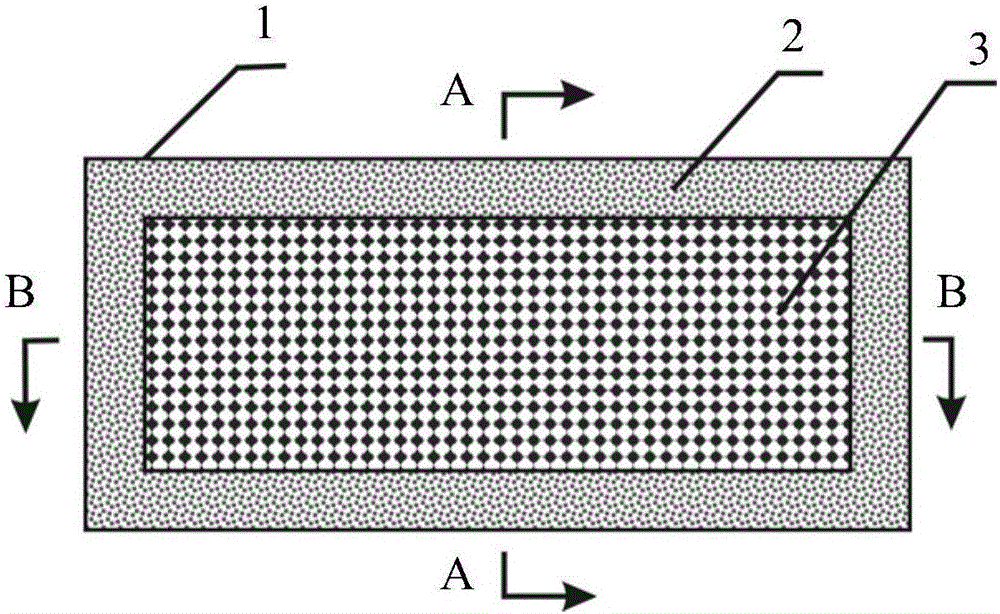

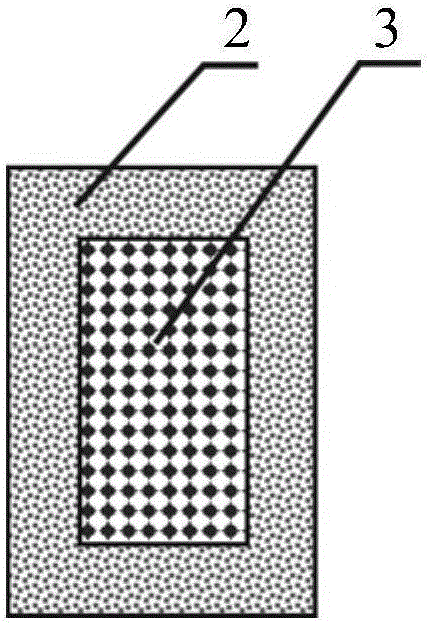

Composite phase-change heat storage brick coated by refractory material

PendingCN106518125AHigh heat storage densitySuitable temperature rangeHeat-exchange elementsIndustrial wasteCarbon nanotube

The invention specifically relates to a composite phase-change heat storage brick coated by a refractory material, belonging to the field of energy storage materials. A composite phase-change heat storage material composed of an inorganic phase-change material and a ceramic material is coated by the refractory material with a certain thickness; the composite phase-change heat storage material is a standard brick, common brick or special-shape brick with a certain size and a certain shape; and highly-heat-conducting materials like amorphous graphite, crystalline flake graphite, carbon fibers, carbon nanotubes and copper slag are added into the composite phase-change heat storage material and the refractory material. The composite phase-change heat storage brick coated by the refractory material meets the requirements of a heat storage medium for high heat storage capability and good heat conduction capability and improves the strength, heat storage stability and long-term operation reliability of the heat storage material. The composite phase-change heat storage brick coated by the refractory material makes full use of sensible heat and latent heat heat-storage methods, can effectively the efficiency of energy utilization, protectes the environment and has critical application prospects in fields like utilization of solar heat, storage of off-peak electricity, recycling of industrial waste heat and energy conservation of industrial and civil buildings and air-conditioners.

Owner:赵岩 +1

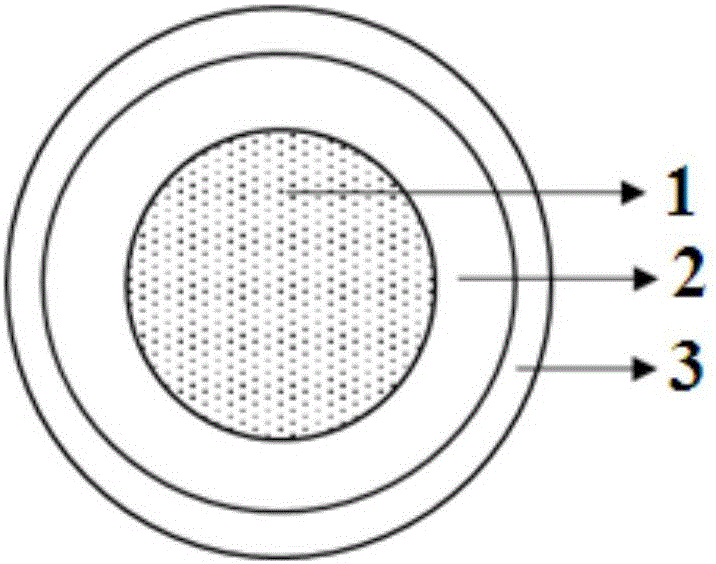

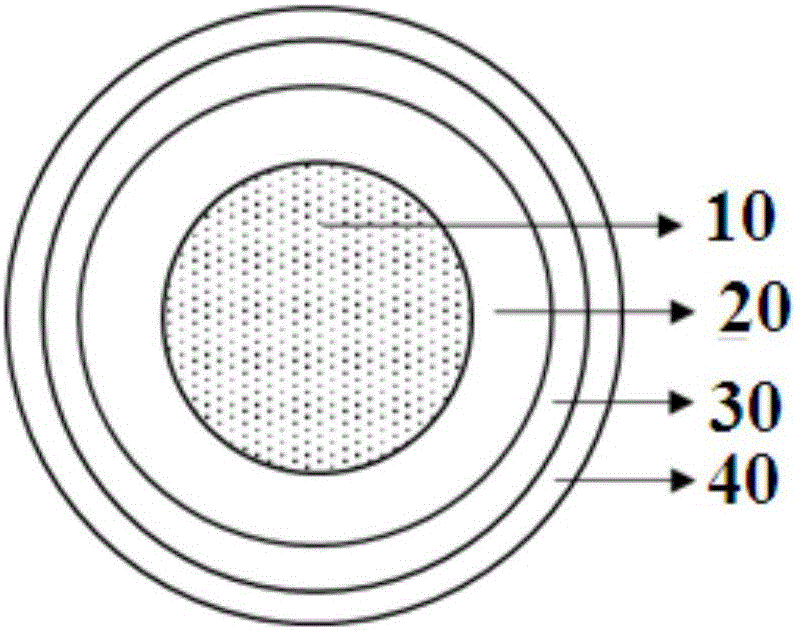

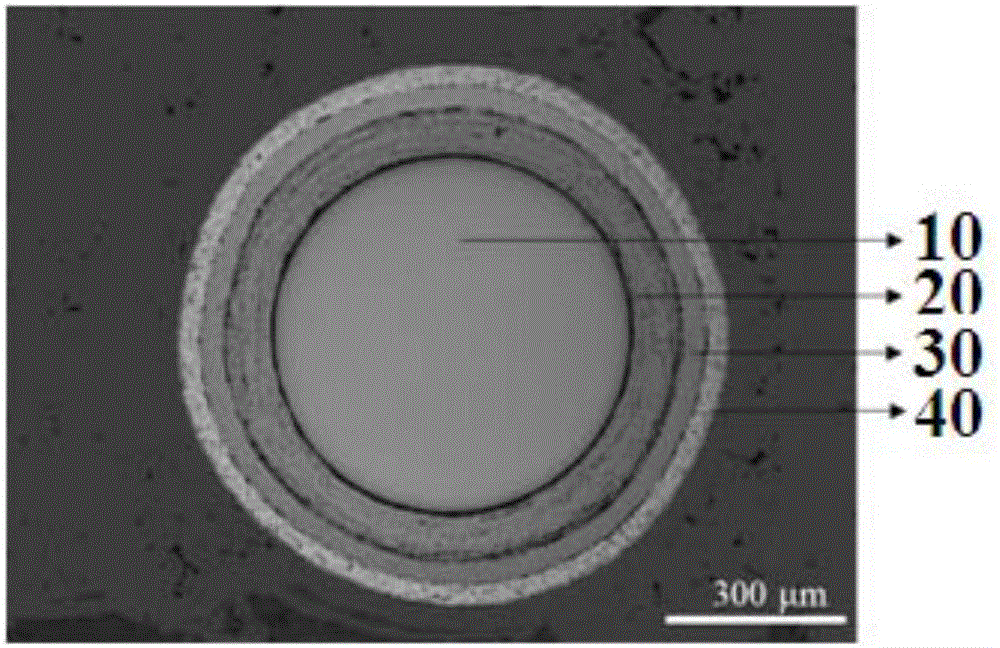

Inorganic nonmetal cladding high-temperature phase change heat storage microcapsule and preparation method thereof

ActiveCN105855537AHigh heat storage densityGood thermal cycle performanceTransportation and packagingMetal-working apparatusMicrospherePyrolytic carbon

The invention relates to an inorganic nonmetal cladding high-temperature phase change heat storage microcapsule. The inorganic nonmetal cladding high-temperature phase change heat storage microcapsule comprises a metal phase change material microsphere, a loose pyrolytic carbon layer and a compact pyrolytic carbon layer. The metal phase change material microsphere is surrounded by the loose pyrolytic carbon layer, and the loose pyrolytic carbon layer is surrounded by the compact pyrolytic carbon layer. The diameter of the metal phase change material microsphere is 500-2000 [mu]m. The density of the loose pyrolytic carbon layer is 0.5-1.5 g / cm<3>. The density of the compact pyrolytic carbon layer is 1.8-2.0 g / cm<3>. The invention further provides a preparation method of the inorganic nonmetal cladding high-temperature phase change heat storage microcapsule. The inorganic nonmetal cladding high-temperature phase change heat storage microcapsule provided by the invention has the advantages of being large in heat storage density, good in heat cycling performance, resistant to high temperature, acid and alkali corrosion and oxidation and the like. According to the provided preparation method of the inorganic nonmetal cladding high-temperature phase change heat storage microcapsule, the product quality is uniform, the yield is high, and the preparation method is suitable for industrial production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

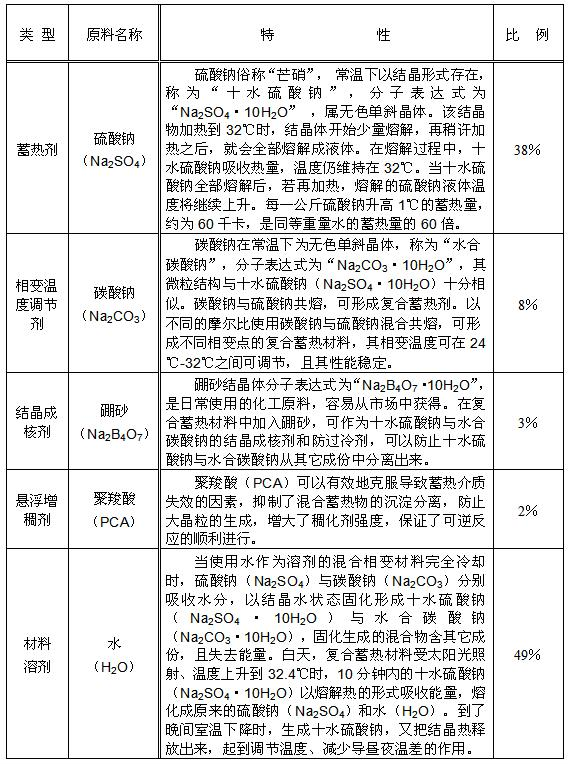

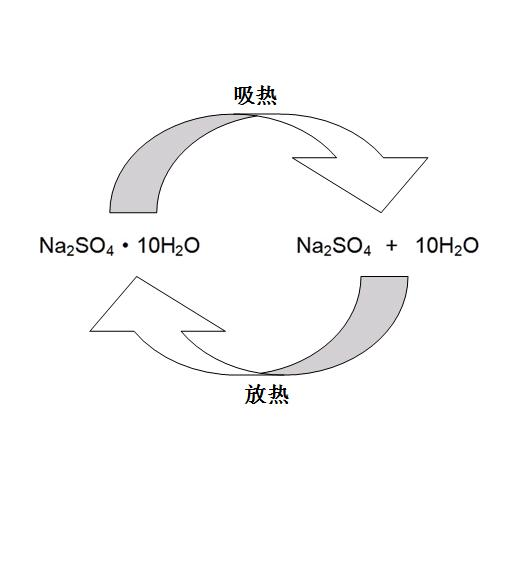

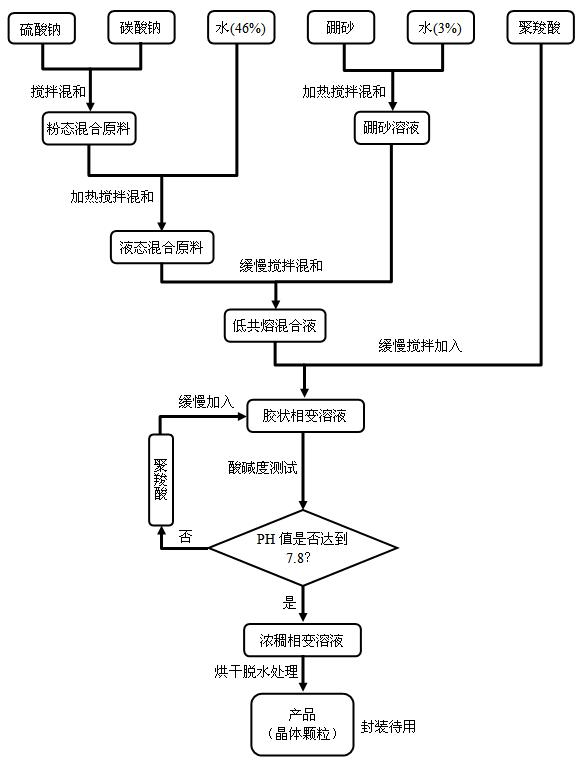

Composite phase-change heat storage material

InactiveCN102585774AHigh heat of solutionHigh heat storage densityRoof covering using slabs/sheetsRoof covering using tiles/slatesSolventPhase change temperature

The invention relates to a phase-change heat storage material, in particular to a composite phase-change heat storage material with sodium sulfate decahydrate as a main body. The composite phase-change heat storage material disclosed by the invention overcomes the defects of small heat capacity, low thermal conductivity, poor stability and the like of the traditional well-know phase-change material; a brand-new composite phase-change heat storage material is formed by co-melting sodium sulfate, sodium carbonate, sodium borate, polycarboxylic acid, water used as a heat storage agent of the material, a temperature regulator, a crystallization nucleating agent, a suspension thickener and a raw material solvent; the composite phase-change heat storage material has the advantages of high heat capacity, proper phase-change temperature, high thermal conductivity, difficulty in generation of super-cooling phenomenon and the like; the heat storage material not only is suitable for daily heating requirements of organizations, enterprises, troops, families and the like, but also is applicable to special occasions such as high altitude, polar regions, oceans, desert, highland and mountainous areas with large temperature difference between day and night; in addition, the composite phase-change heat storage material disclosed by the invention has the characteristics of simple implementation, simple and easy manufacturing, durability, broad market prospect, and higher economic added value and social application value.

Owner:郑小玲

Sodium sulfate decahydrate phase change energy storage material compositions

InactiveCN102212341AHigh heat storage densityGood temperature regulationHeat-exchange elementsChemistryLatent heat

The invention discloses sodium sulfate decahydrate phase change energy storage material compositions. The compositions mainly comprises sodium sulfate decahydrate, a nucleating agent, a thickening agent and the like; and the phase change temperature is between 30 and 32 DEG C, the degree of supercooling is less than 3 DEG C and the phase change latent heat is more than 220kJ / kg. The compositions have quite good phase change stability and have passed 3,000 times of cold and heat cycle tests; moreover, the uniformity of the phase change system can be maintained for a long time.

Owner:WIDE SPACE PHASE CHANGE TECH

Preparation method of high-temperature phase-change thermal storage type composite catalyst carrier

ActiveCN103406156AHigh heat storage densityHeat absorption and release rapidlyCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsGelatin productAluminium

The invention provides a preparation method of a high-temperature phase-change thermal storage type composite catalyst carrier. A metallic compound and gelatin are sampled according to the mass ratio of 0.5-1 to 1-2, then are dissolved into water according to the solid-to-liquid ratio of 1.5-3 to 100-150, then aluminum powder is added according to the mass ratio that the metallic compound to aluminum powder is 0.5-1 to 1-2 under a stirring condition until being dispersed in the solution completely, a NH4F solution with the concentration of 0.2 to 0.25 mol / L is dripped at the speed of 5 to 8mL per minute after the temperature of the solution reaches 40 DEG C, filtering is performed after reaction for 15 min, water is used for washing sediment for three times, after constant-temperature drying at 100 DEG C, and obtained powder is roasted for 20 to 30 min at the temperature of 100 DEG C, namely the high-temperature phase-change thermal storage type composite catalyst carrier is obtained. According to the invention, the sintering-resisting capability of the catalyst is improved, and the stabilizing of the reactivity of the catalyst is also facilitated on the other hand. Two functions of catalyzing and thermal storing are combined, the obtained material can absorb and emit heat in a position near a phase change point, high-density heat storage is achieved, and the stability during the process of catalytic reaction is ensured.

Owner:KUNMING UNIV OF SCI & TECH

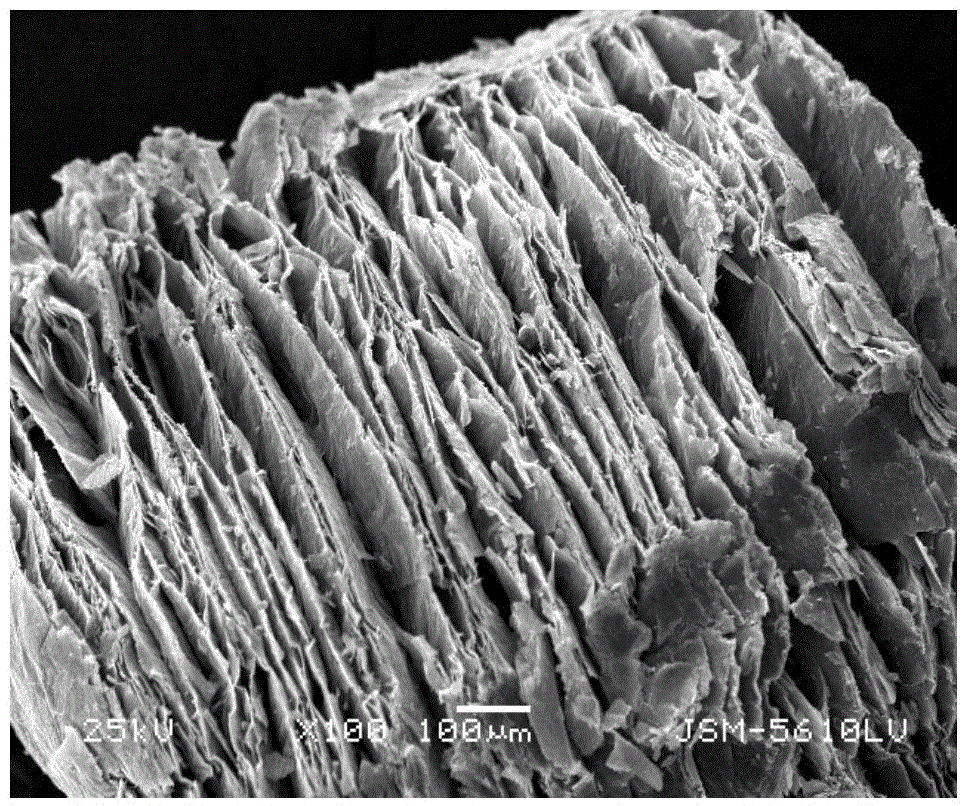

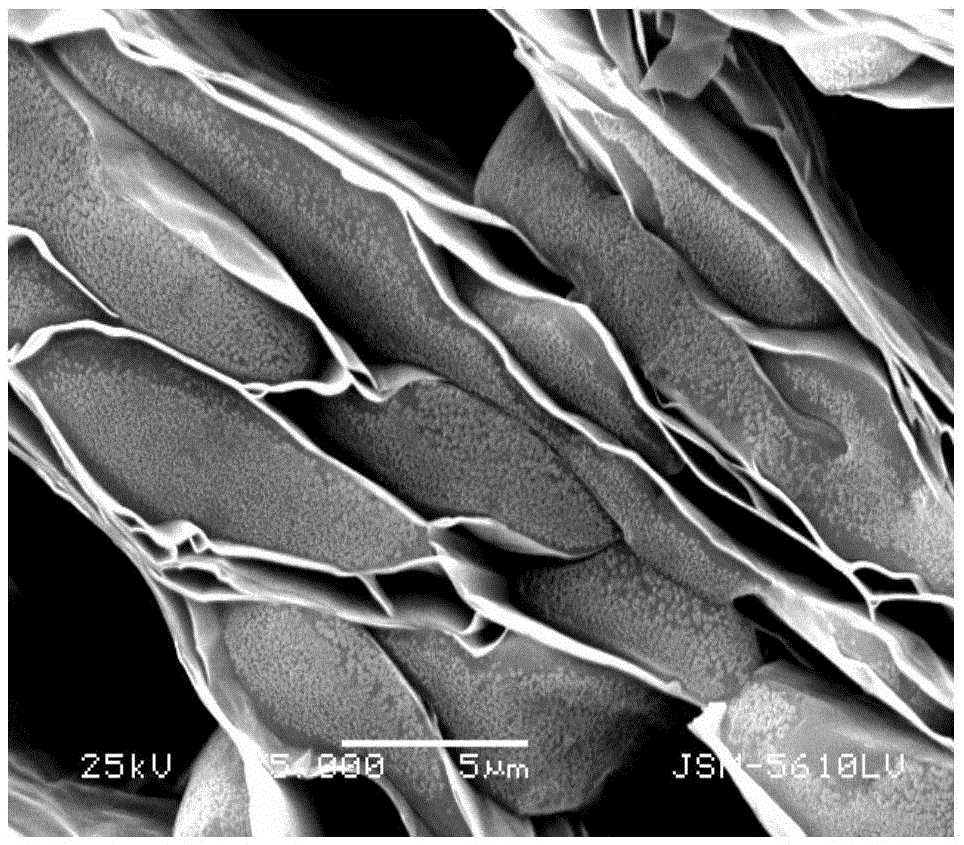

Cellulose-based flexible heat storage composite material and preparation method thereof

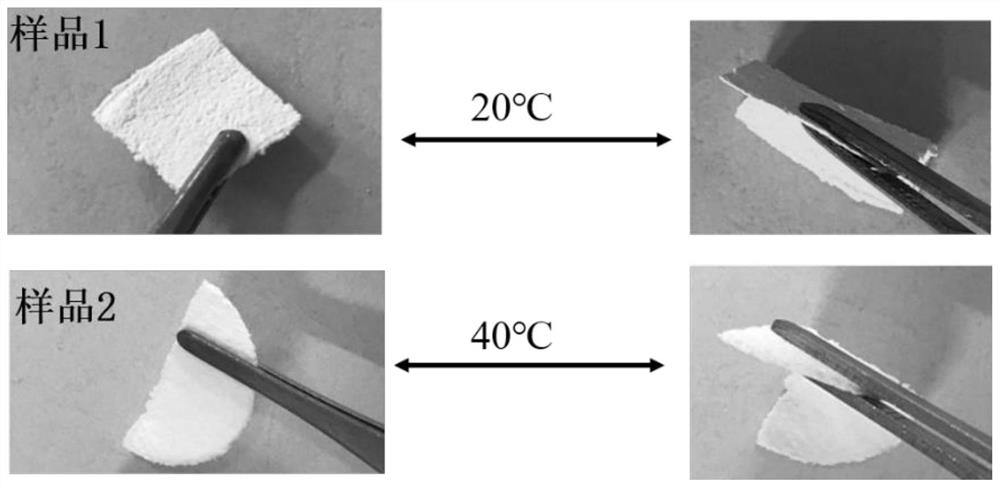

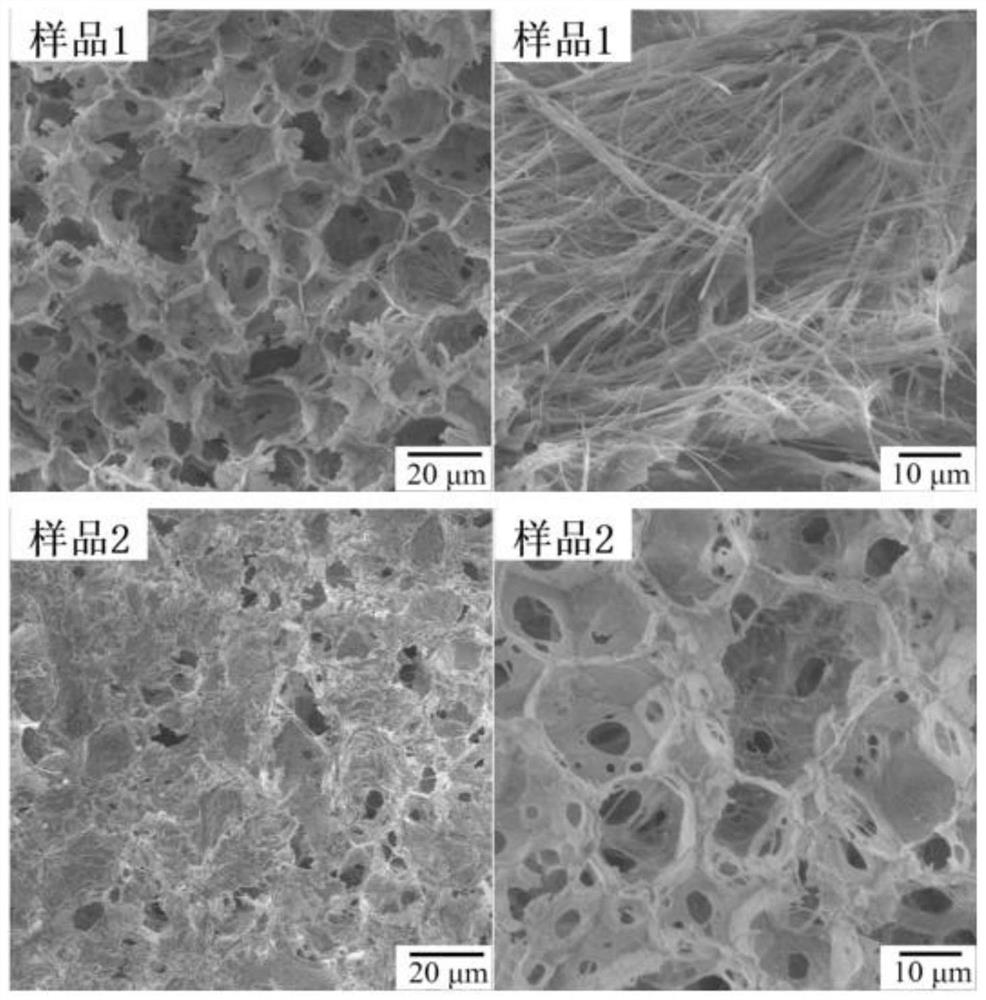

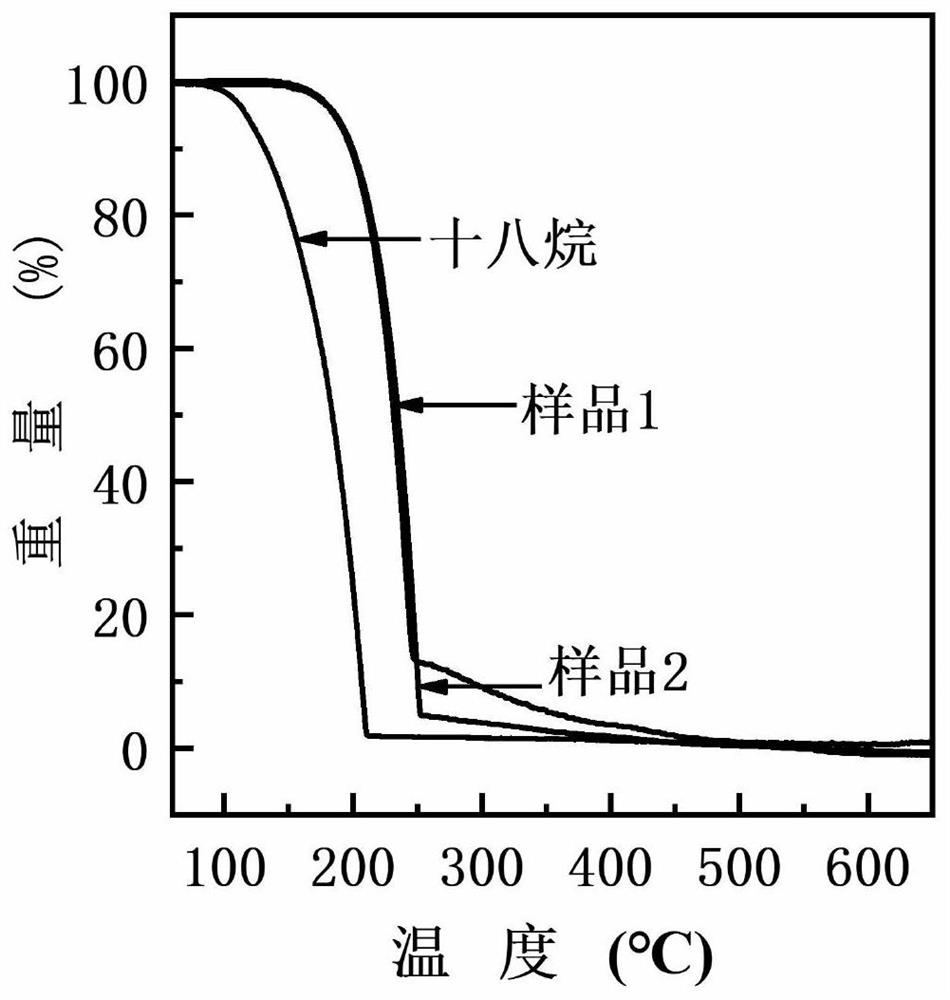

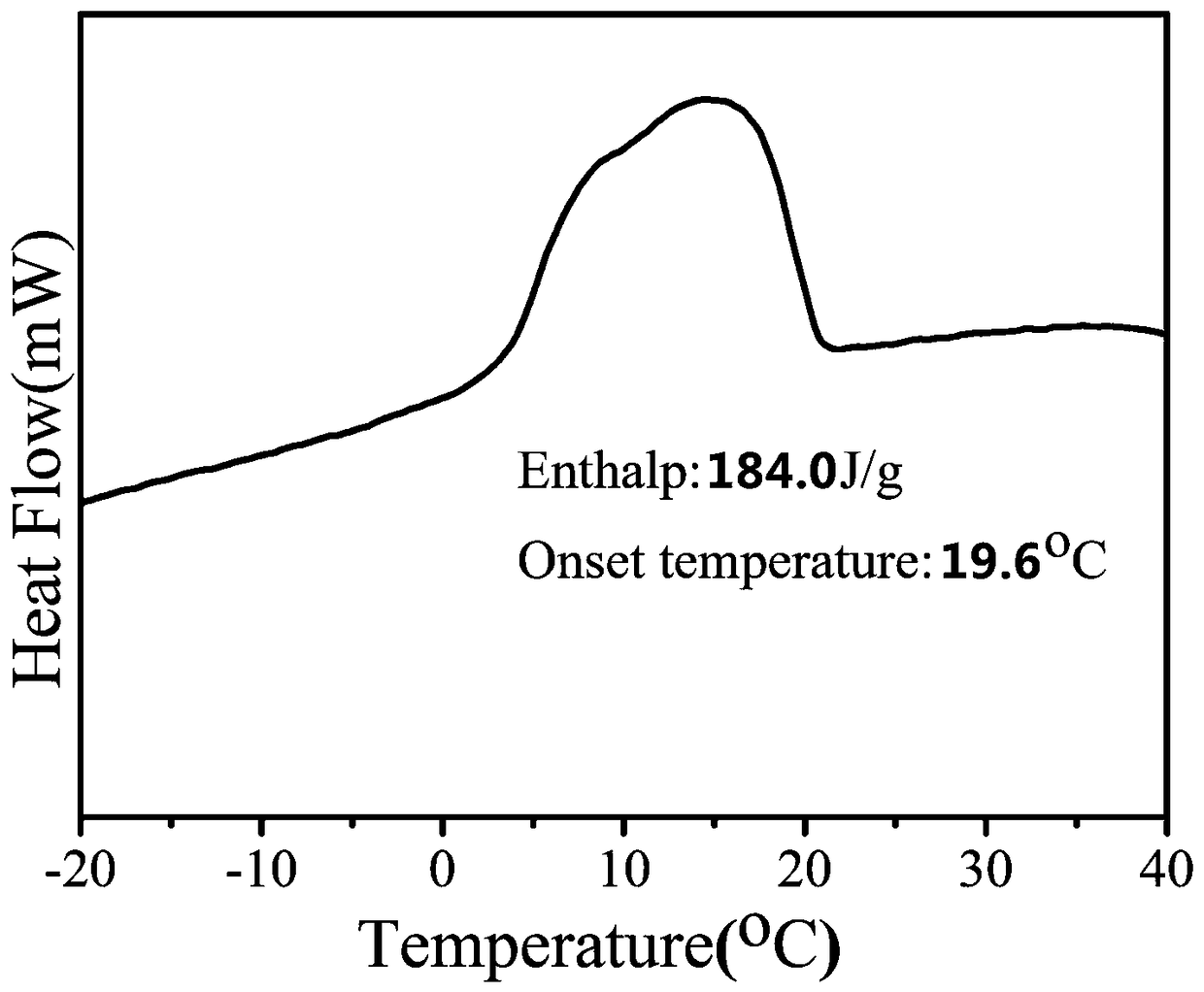

ActiveCN113337252AStabilize cross-linking defectsLess cross-linking defectsHeat-exchange elementsCellulosePtru catalyst

The invention provides a cellulose-based flexible heat storage composite material and a preparation method thereof, and the preparation method comprises the following steps: uniformly mixing an oil phase and a water phase to obtain an oil-in-water type high internal phase emulsion, wherein the oil phase is an organic phase change material, the water phase comprises a water-soluble emulsifier, a cellulose suspension and water; adding a cross-linking agent and a catalyst into the oil-in-water type high internal phase emulsion, realizing interfacial polymerization of the cellulose emulsion through heating, forming a cross-linked polymer at an interface, and obtaining the heat storage composite material through heating drying and freeze drying. The appearance of the heat storage composite material can be controlled through a mold for containing the high internal phase emulsion during polymerization, a nanofiber structure is arranged in the heat storage composite material, the heat storage density of the material after heating and drying can reach 200 J / g, the heat storage density of the material after freeze drying can reach 250 J / g, and the heat storage composite material has flexibility, can be curled and folded at the room temperature and the temperature of 40 DEG C or above and is good in heat conduction performance.

Owner:SUZHOU UNIV

Heat conduction enhanced inorganic PCM (phase change material) and preparation method thereof

InactiveCN108997976AFast heat responseFast heat conductionHeat-exchange elementsCarbon nanotubeBoron nitride

The invention discloses a heat conduction enhanced inorganic PCM (phase change material). The heat conduction enhanced inorganic PCM is prepared from an inorganic PCM as a core material and melamine resin containing heat conduction enhanced nano-particles as a wall material, wherein the heat conduction enhanced nano-particles are boron nitride, CNTs (carbon nano tubes) and graphene oxide that aremodified. A preparation method of the heat conduction enhanced inorganic PCM comprises the following steps: 1) modifying the heat conduction enhanced nano-particles; 2) preparing a prepolymer of the wall material added with the modified heat conduction enhanced nano-particles; 3) melting the inorganic PCM; and 4) preparing the heat conduction enhanced inorganic PCM. The heat conduction enhanced inorganic PCM has the advantages that 1) the heat response speed is high, i.e. the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and4) the technical characteristics that raw materials are safe and non-toxic and are not leaked easily are achieved. Therefore, the heat conduction enhanced inorganic PCM is better in heat conductivityand stability, the using ratio of energy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

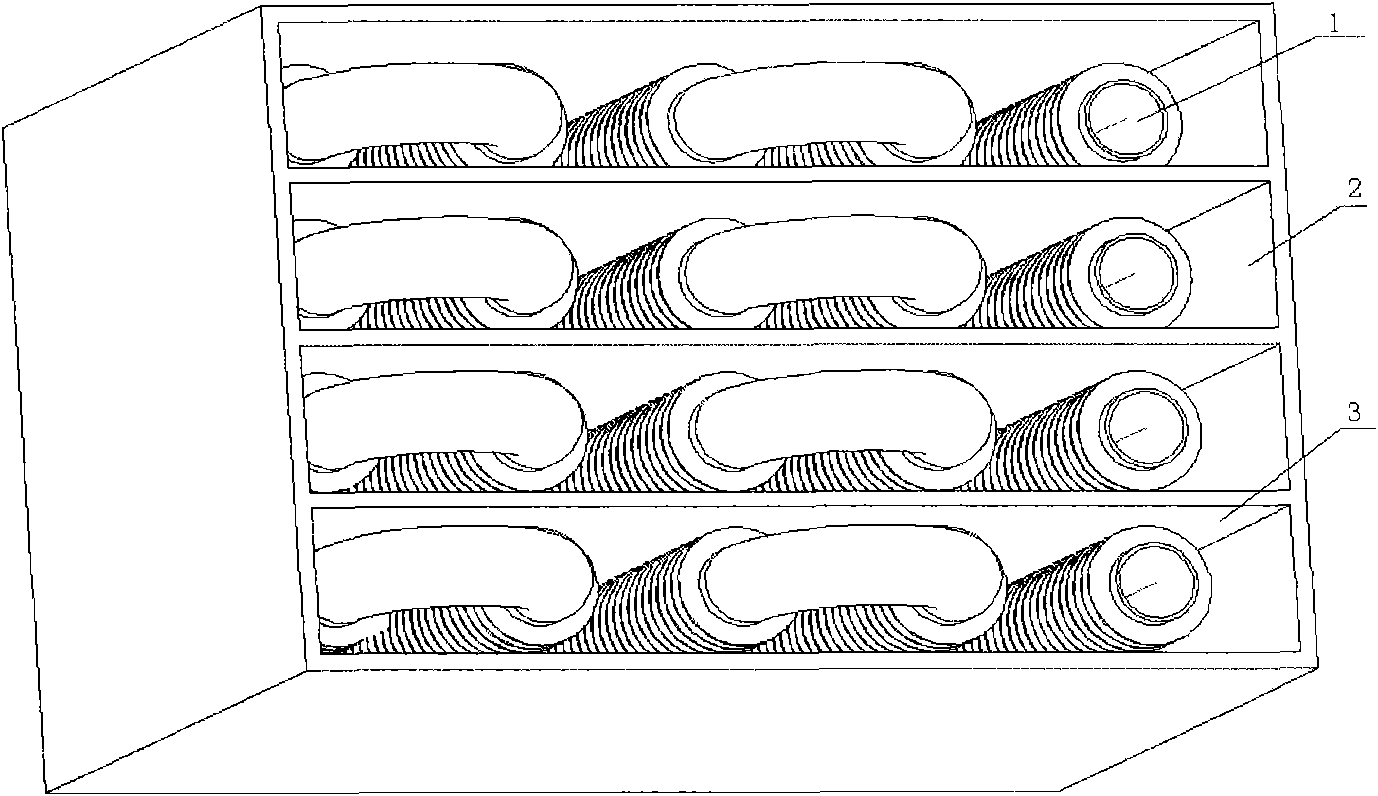

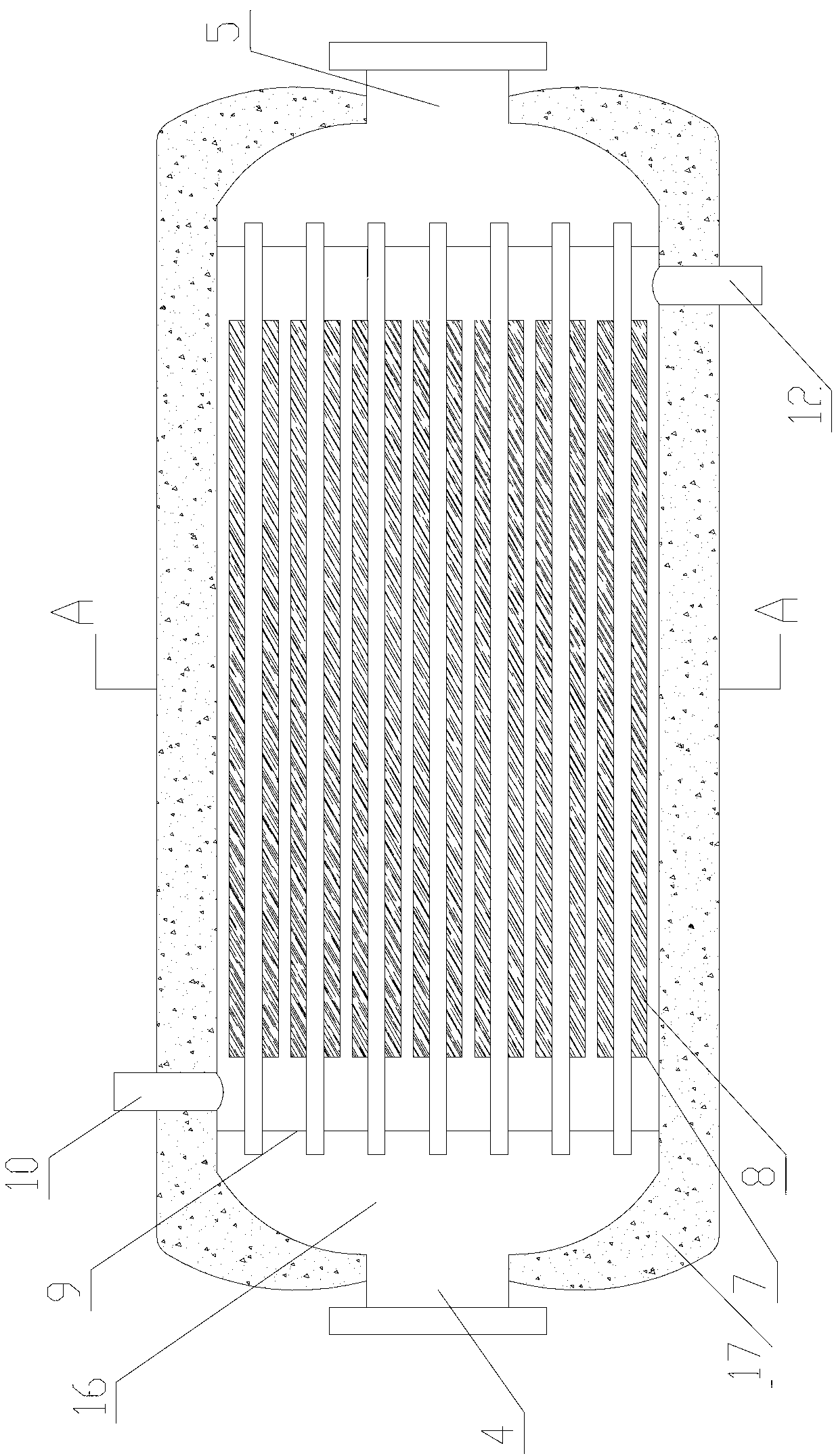

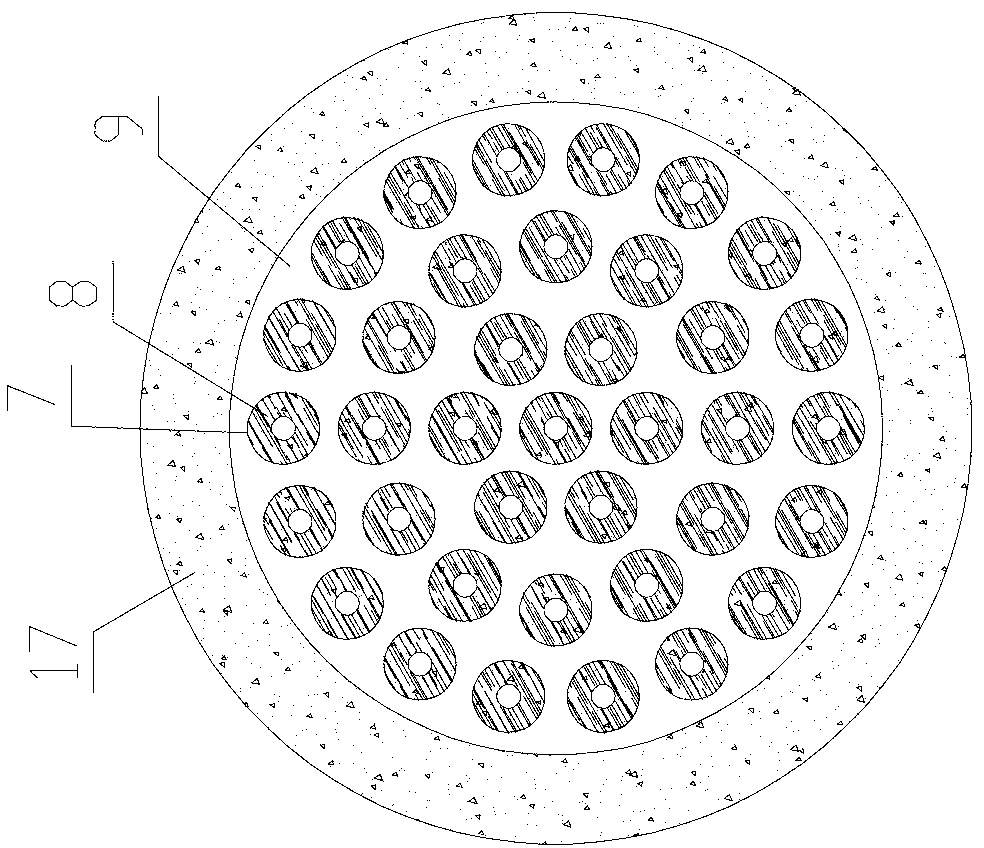

High-temperature phase change heat accumulation pipe and heat accumulator

InactiveCN101598513ASmall volumeHigh heat storage densityHeat storage plantsHeat-exchange elementsMolten saltEngineering

The invention provides a high-temperature phase change heat accumulation pipe and a heat accumulator. The heat accumulator comprises a casing and a high-temperature phase change heat accumulation pipe arranged in the casing. The high-temperature phase change heat accumulation pipe is characterized in that the high-temperature phase change heat accumulation pipe comprises an S-shaped working medium conduit, the outer side of the S-shaped working medium conduit is provided with annular fins, a fan ring heat accumulation unit is installed between the annular fins, a phase change material is filled in the fan ring heat accumulation unit, and a working medium is installed in the S-shaped working medium conduit and is mixed molten salt. The invention utilizes the solid-liquid phase change process of the phase change material to complete the storage and release of energy, has the advantages of small volume, large heat accumulation density and constant-temperature heat release and has a certain development prospect.

Owner:HARBIN ENG UNIV

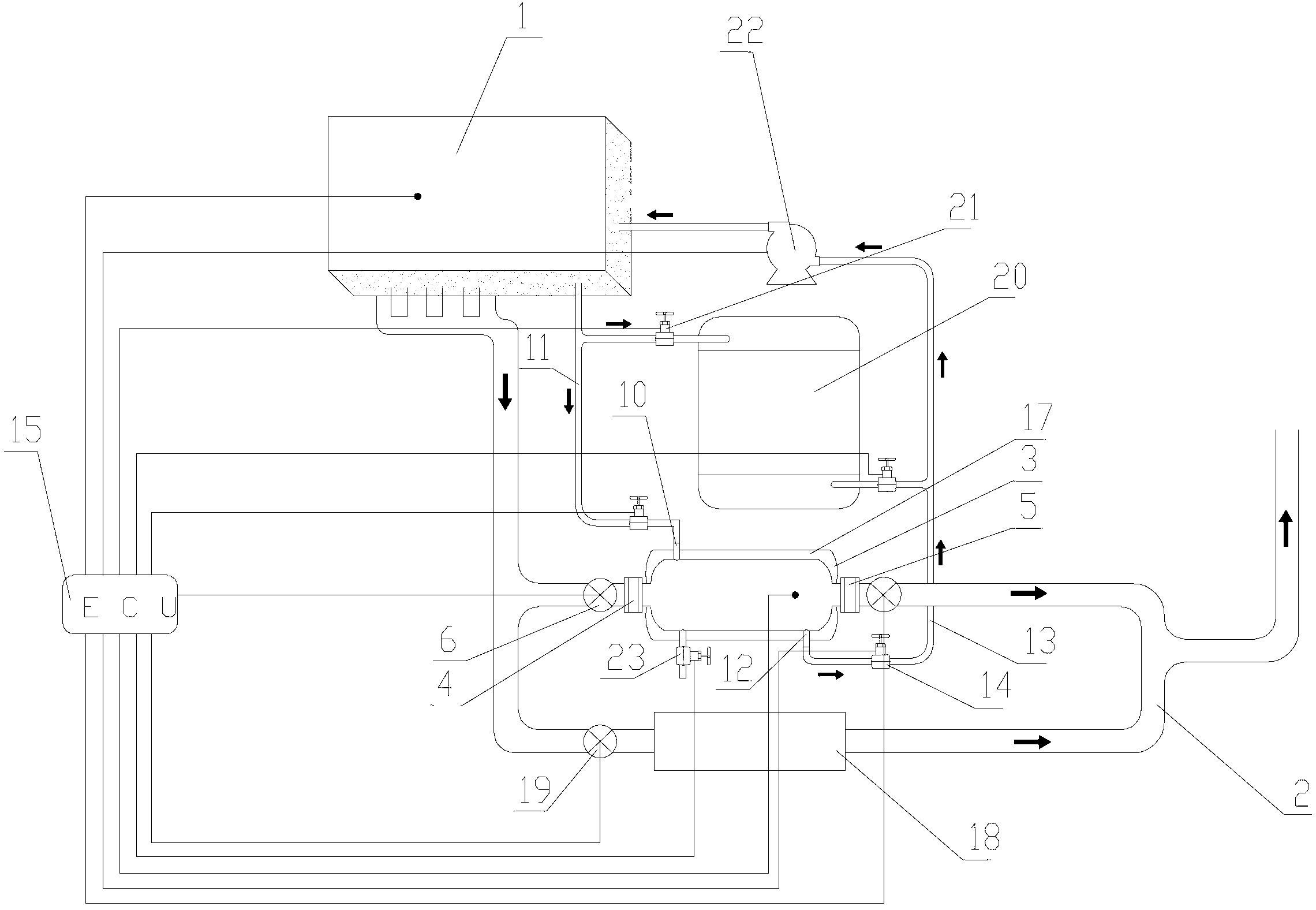

Engine cold-start preheating device

InactiveCN103061947AHigh exhaust gas temperatureStable warm-up performanceInternal combustion piston enginesExhaust apparatusEngineeringPhase change

The invention discloses an engine cold-start preheating device. A heat storing heat exchanger (3) is in a parallel connection with an exhaust pipe (2) of an engine (1), the heat storing heat exchanger (3) is used for storing exhaust air waste heat of the engine (1), the heat storing heat exchanger (3) is in a columnar structure, a plurality of heat storing units are distributed in the heat storing heat exchanger (3), each heat storing unit is a concentric casing pipe (7) which comprises an inner pipe and an outer pipe, a phase change thermal storage material (8) is encapsulated in annular space between the inner pipe and the outer pipe, two ends of the inner pipe are welded on two flow guide plates (9) respectively, a hollow cavity for enabling cooling water of the engine (1) to flow through is formed by the two flow guide plates (9) and inner walls of the heat storing heat exchanger (3), and the inner walls of the heat storing heat exchanger (3) are located between the two flow guide plates (9). The engine cold-start preheating device has the advantages of being low in costs, small in size, efficient, energy-saving and convenient to popularize and use in a wide range.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation method of sizing composite heat storage material for moderate-high temperature

The invention discloses a preparation method of a sizing composite heat storage material for moderate-high temperature, comprising the following steps: treating vermiculite under the temperature of 1300 DEG C for 20min, cooling, and mixing with phase change materials according to a mass ratio of 1 to 10, wherein the phase change materials consist of MgCl2, KCl and NaCl, and the sum of the phase change materials is 100 percent; preserving the heat of the mixture for 6h under the conditions of 400 DEG C and negative pressure of -15kPa, preparing a composite phase change material, mechanically crushing the composite phase change material into 40 meshes, adding modified carbon fiber, and then mechanically mixing for 24h, wherein the mass of the modified carbon fiber accounts for 2-8 percent of the total mass of the composite phase change material; dropwise adding a high temperature binder, performing compression moulding under the pressure of 10-20MPa, and finally preserving heat under the temperature of 300 DEG C for curing, thus obtaining the sizing composite heat storage material for moderate-high temperature. The sizing composite heat storage material is reasonable in material selection, strong in heat conductivity, high in heat storage density and wide in base material source, and the prepared sizing composite heat storage material has better heat stability, little leakage possibility and better application prospect.

Owner:SUZHOU PORCELAIN INSULATOR WORKS

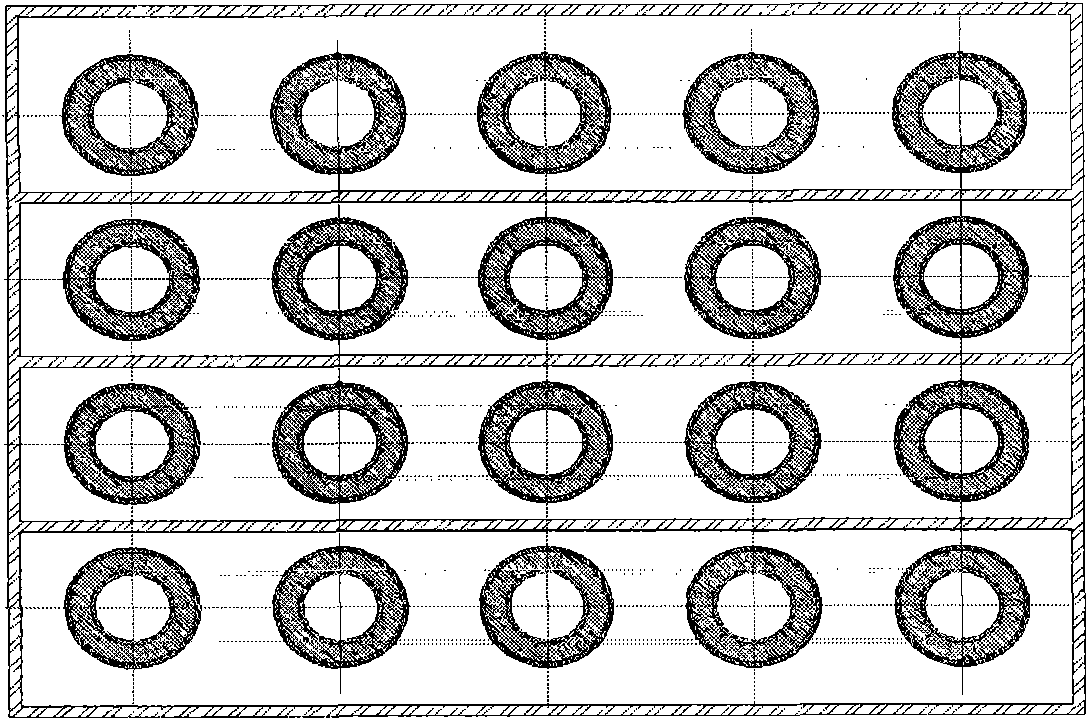

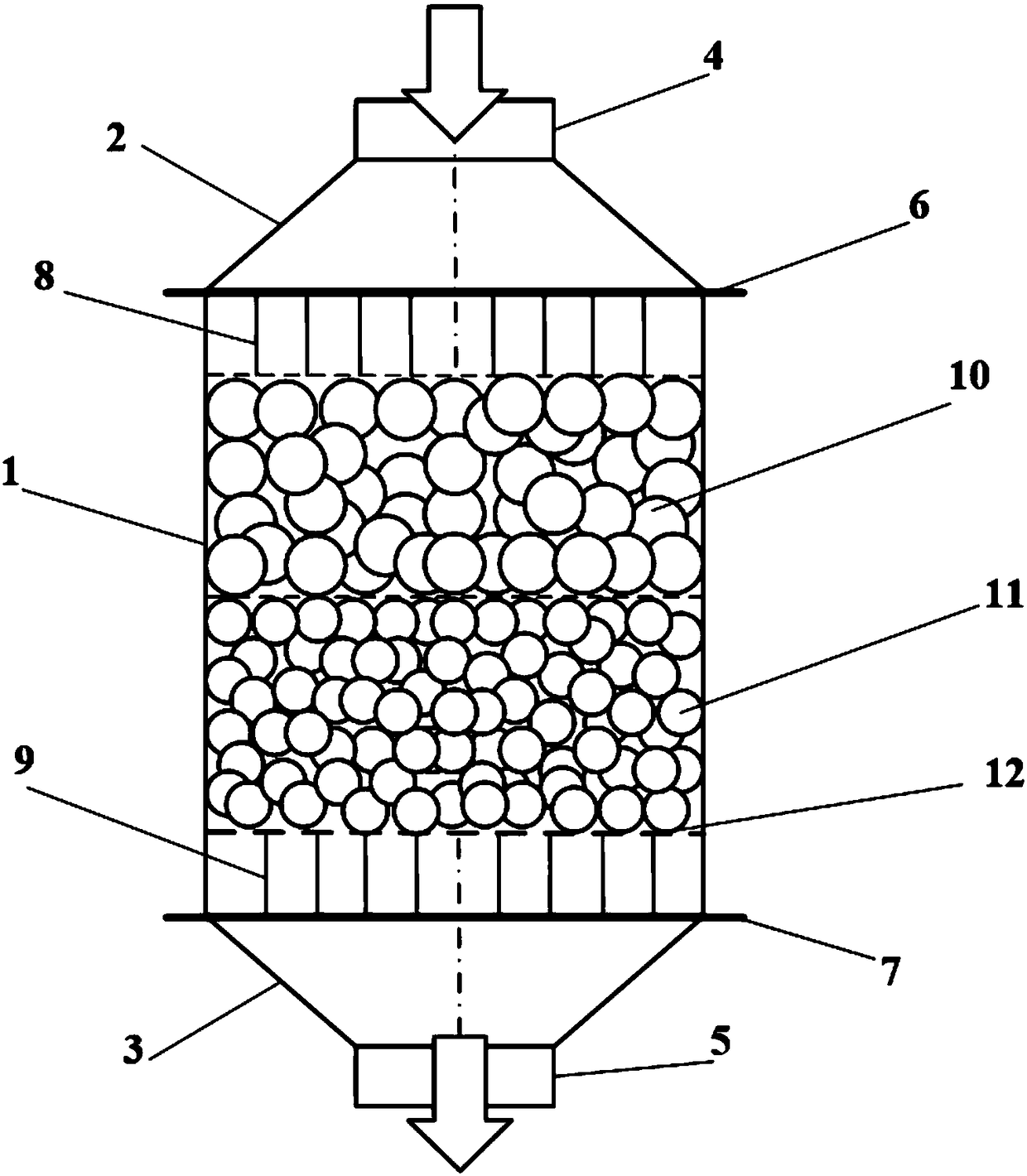

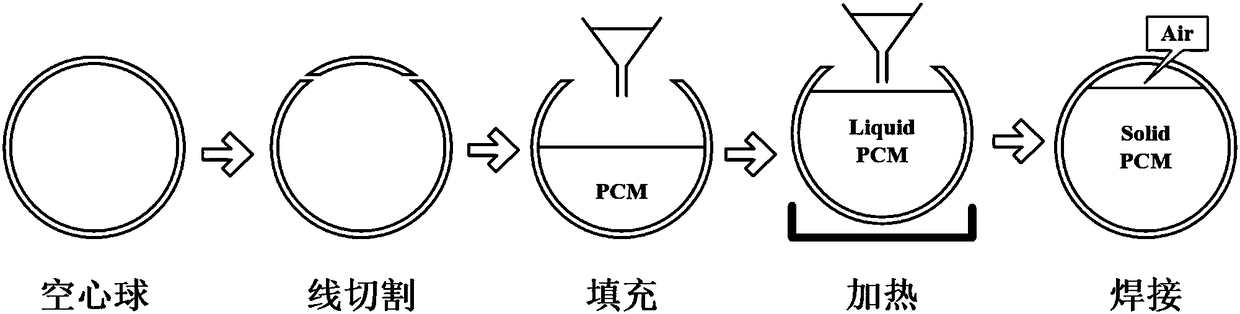

Packed bed heat storage device and preparation method of heat storage ball

ActiveCN108534578AIncrease heat storage rateHigh heat storage densityHeat storage plantsHeat exchange apparatusOptimal combinationBall diameter

The invention discloses a two-layer variable ball diameter packed bed heat storage device and provides a preparation method of a heat storage ball. A large-diameter heat storage ball is arranged on the upper layer of the packed bed heat storage device, and a small-diameter heat storage ball is arranged on the lower layer of the packed bed heat storage device. The packed bed heat storage structurecomprehensively considers two important evaluation indexes of the heat storage device, namely heat storage rate and heat storage density, the maximum heat storage rate of the packed bed heat storage device serves as a design principle, and an optimal combination of diameters of the heat storage balls in the packed bed is obtained by virtue of an optimization design, so that the heat storage devicehas optimal heat storage performance. According to the preparation method of the heat storage ball provided by the invention, the heat storage ball with advantages of high heat storage density, excellent heat-conducting property, high mechanical strength, excellent sealing property and simple preparation process can be prepared.

Owner:XI AN JIAOTONG UNIV

Phase change micro-emulsion as cooling working substance, and applications thereof

InactiveCN107841291ASmall temperature changeImprove liquidityHeat-exchange elementsInorganic saltsPhase change enthalpy

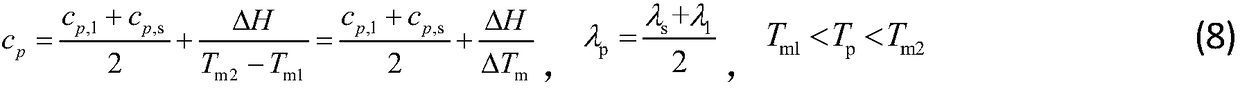

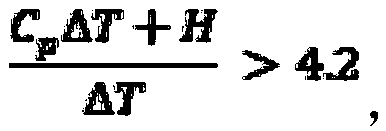

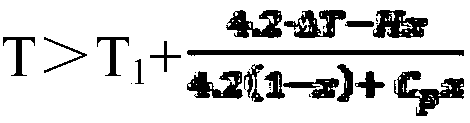

The invention discloses a phase change micro-emulsion as a cooling working substance. The phase change micro-emulsion comprises a phase change material, a surfactant, water and an inorganic salt, wherein the phase change material is a mixture formed from one or a variety of paraffins. According to the present invention, the phase change micro-emulsion has good fluidity, can reduce the temperaturechange of the cooling liquid during heat absorbing, and can greatly improve the heat dissipation efficiency and increase the system stability; and the phase change material meets the following conditions that (Cp[delta]T+H) / [delta]T is more than 4.2, [delta]T is T2-T1, and T is more than T1+{(4.2*[delta]T-Hx)} / {4.2(1-x)+Cpx}, wherein where Cp (kJ / kg / K) is the specific heat of the phase change material, H (kJ / kg) is the phase change enthalpy of the phase change material, T2 (DEG C) is the maximum temperature of the cooling liquid at the outlet position when the cooling liquid is water after theheat exchange work is completed, T1(DEG C) is the temperature of the cooling liquid at the inlet position when the cooling liquid is water, T (DEG C) is the phase change temperature of the phase change material, and X is the mass fraction of the phase change material accounting for the phase change micro-emulsion.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Heat conduction enhanced organic PCM (phase change material) and preparation method thereof

InactiveCN108997977AFast heat responseFast heat conductionChemical industryHeat-exchange elementsCarbon nanotubeBoron nitride

The invention discloses a heat conduction enhanced organic PCM (phase change material). The heat conduction enhanced organic PCM is prepared from an organic PCM containing nano-particles as a core material and a porous material as a wall material, wherein the nano-particles are boron nitride, CNTs (carbon nano tubes), expanded graphite and graphene oxide. A preparation method of the heat conduction enhanced organic PCM comprises the following steps: 1) a process of emulsifying the organic PCM; 2) a process of adsorbing the organic PCM containing the nano-particles by the porous material undera vacuum condition; and 3) a process of taking out a product obtained after vacuum adsorption. The heat conduction enhanced organic PCM has the advantages that 1) the heat response speed is high, i.e.the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and 4) raw materials are safe, non-toxic and non-corrosive, and the technical characteristics of being simple in preparation process and low in cost are achieved. Therefore, the heat conduction enhanced organic PCM is better in heat conductivity and stability, the using ratio ofenergy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

High temperature phase change heat storage material

ActiveCN109609099AHigh heat storage densityImprove thermal conductivityTransportation and packagingMetal-working apparatusSilicon alloyCopper oxide

Belonging to the technical field of ceramic materials, the invention provides a high temperature phase change heat storage material. The high temperature phase change heat storage material is preparedby the steps of: first, mixing quartz sand powder, corundum powder, copper oxide and zinc oxide evenly in proportion, conducting compression moulding, and then performing heat treatment to obtain a sieving material A; second, mixing the sieving material A, carbon black, silicon powder and aluminum oxalate evenly in proportion, and performing heat treatment to obtain an abrasive B; and third, mixing corundum particles, corundum powder, the abrasive B, aluminum-silicon alloy, silicon powder, silicon carbide powder and thermosetting phenolic resin evenly in proportion, conducting compression moulding, and then performing heat treatment to obtain a finished product. The high temperature phase change heat storage material prepared by the method provided by the invention has a working temperature above 600DEG C, and has the characteristics of large heat storage density, high heat conductivity coefficient, high compressive strength, high thermal shock stability, low production cost, simple process and the like.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

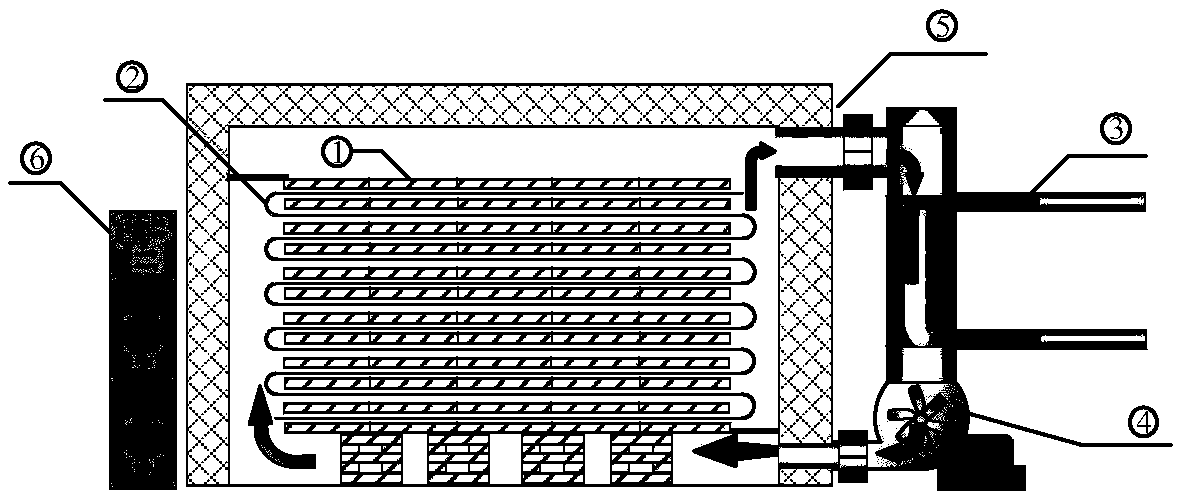

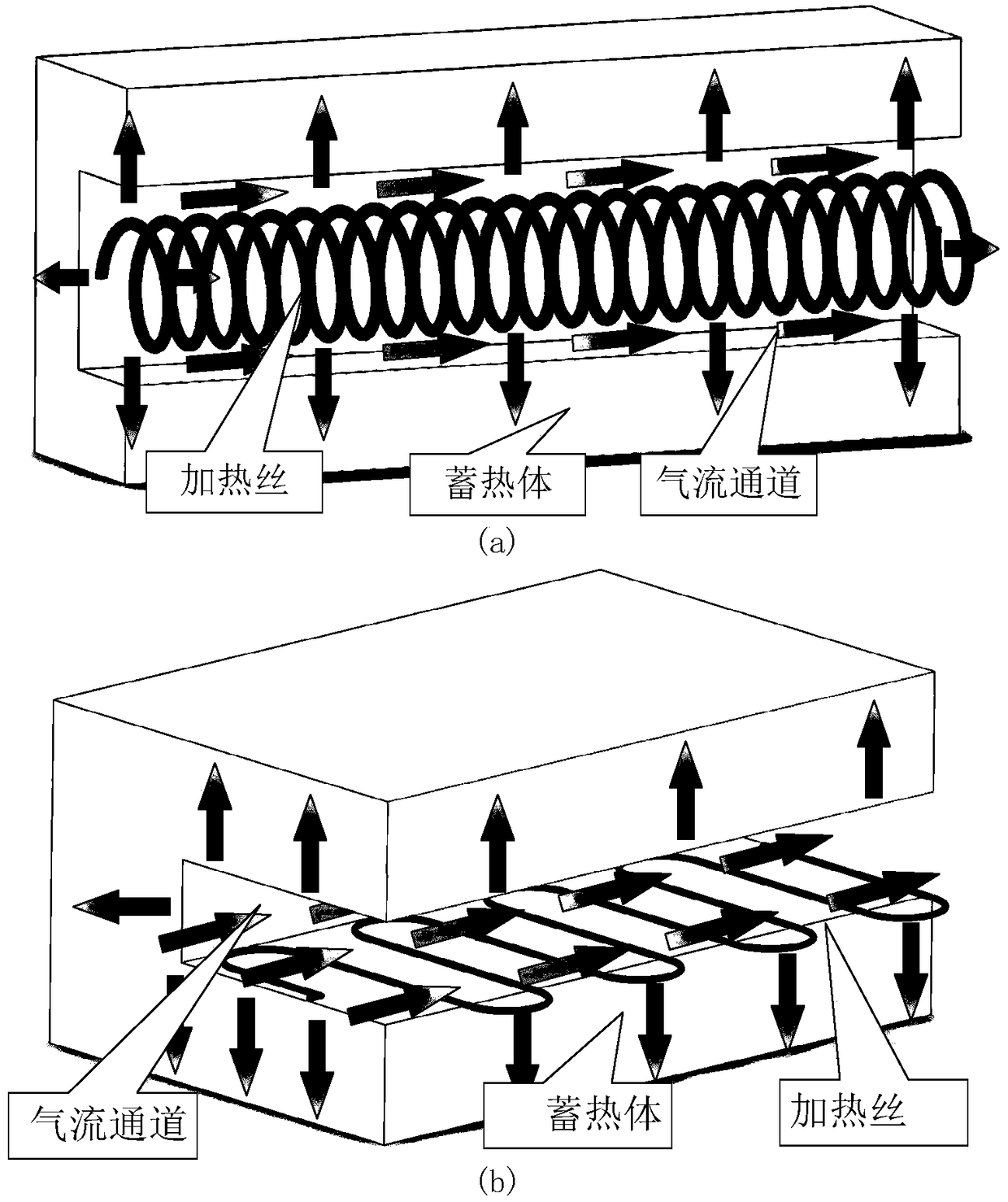

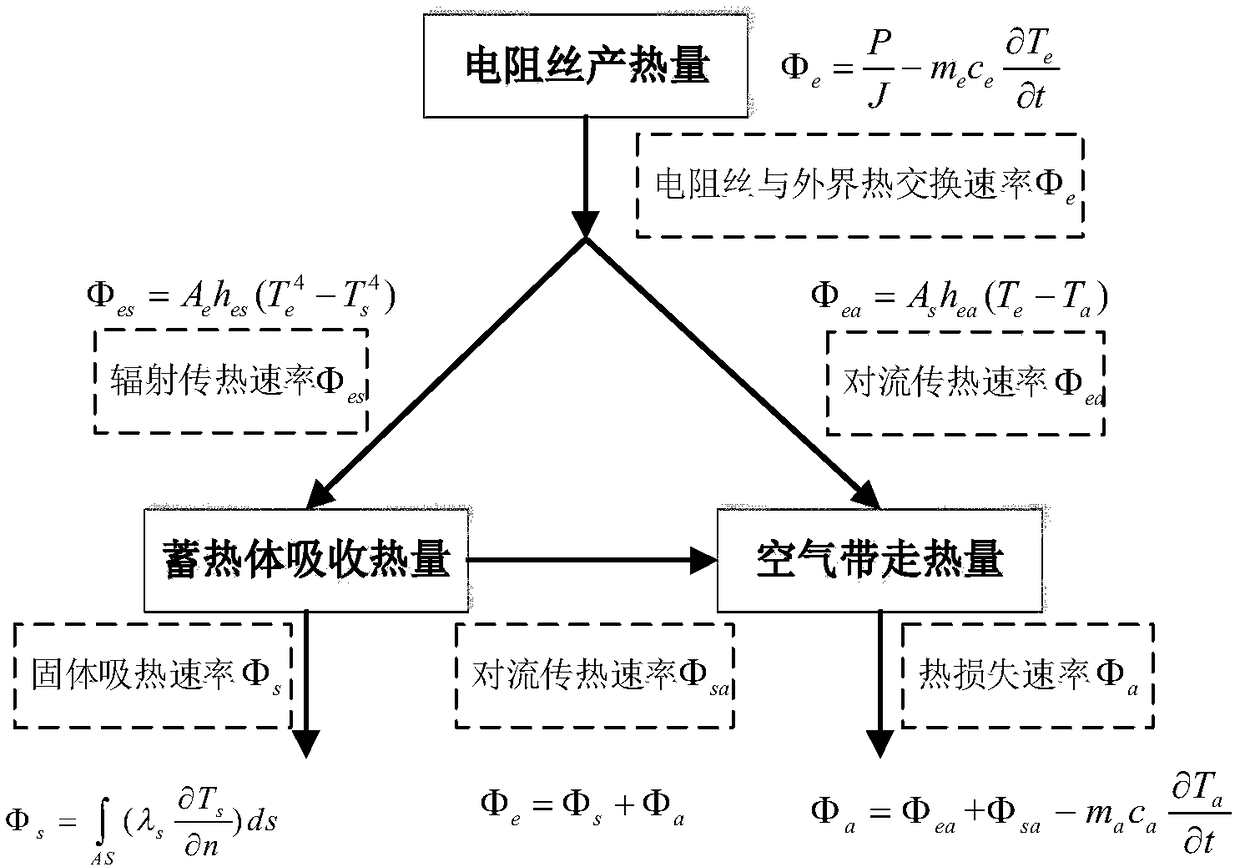

A solid-state heat storage and heating characteristic matching design method based on heat transfer rate balance

ActiveCN109446623AReduce surface temperatureExtended service lifeDesign optimisation/simulationSpecial data processing applicationsEngineeringOperating temperature range

The invention relates to a solid-state heat storage and heating characteristic matching design method based on heat transfer rate balance, which comprises the following steps of 1) obtaining structural data, material data and operating condition parameters of a high-temperature solid-state heat storage device; 2) establishing a heat transfer rate balance model between that high-temperature heat storage material and the electric resistance heating element; 3) establishing a heat transfer model between the high-temperature heat storage material and the electric resistance heating element according to the heat transfer rate balance model; 5) determining a heat transfer couple boundary condition between the air and the surface of the electric resistance heating element; 6) judging whether thesurface temperature of the electric resistance wire is in an operating temperature range. 7) obtaining the air inlet velocity parameter satisfying the design structure of the air duct of the regenerator and the operation temperature range, so that the structure and the performance of the electric heat element and the heat storage device are matched, thereby realizing the optimization of the wholestructure. (1) The rate of change of temperature is constant, according to which the heat transfer equilibrium equation can be calculated. (2) The heat storage material and the resistance wire match.(3) The shortening of the life of the electric heating element caused by the high temperature brittleness is avoided.

Owner:SHENYANG POLYTECHNIC UNIV

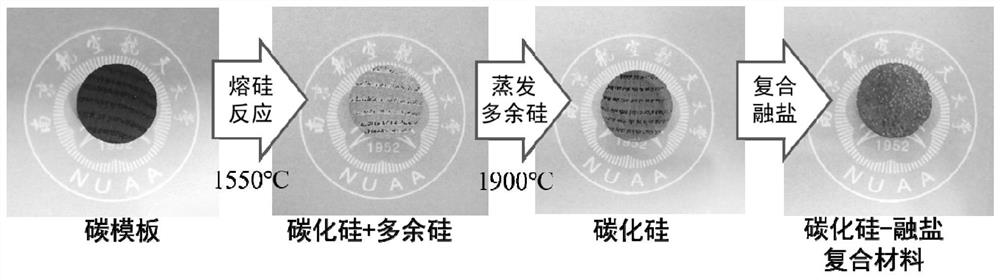

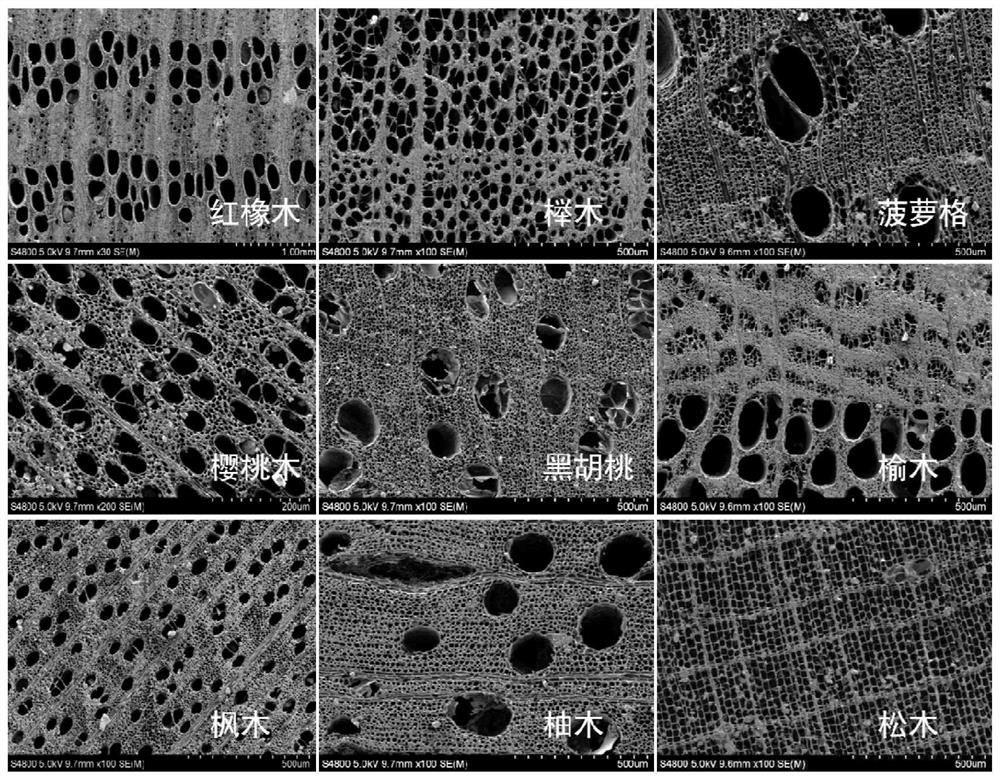

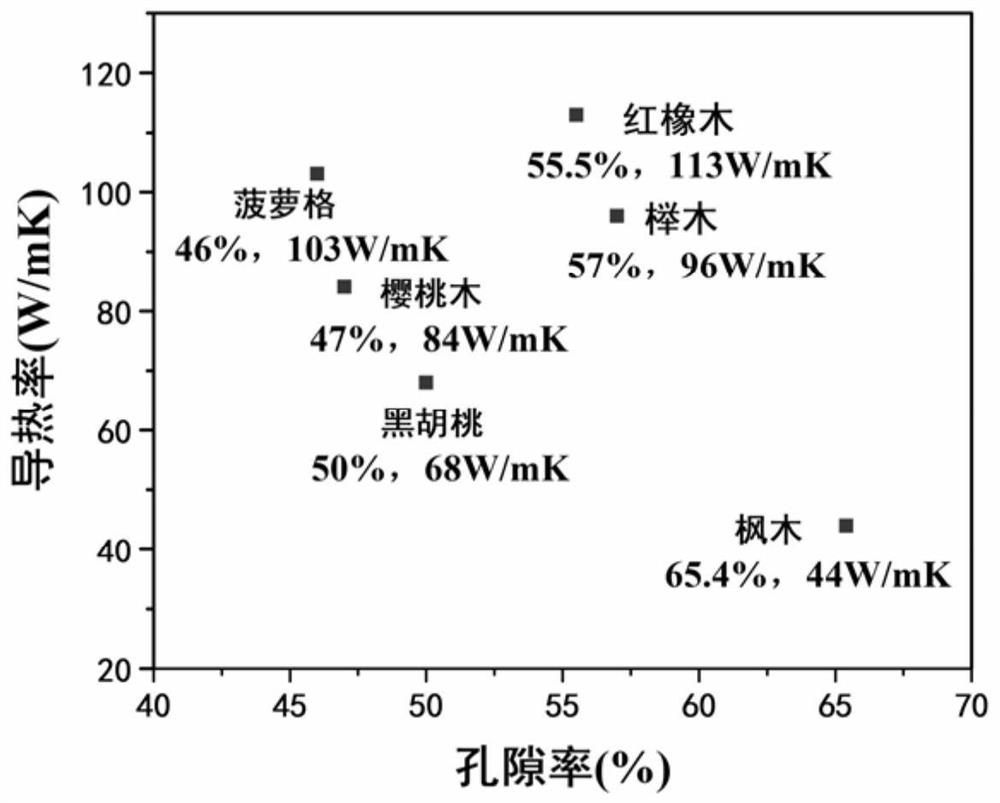

Biomorphic silicon carbide ceramic high-temperature photo-thermal storage material

ActiveCN112521153AImprove thermal conductivityImprove spectral absorption capacityHeat-exchange elementsCeramicwareMolten siliconPhase-change material

The invention provides a biomorphic silicon carbide ceramic high-temperature photo-thermal storage material and a preparation method thereof. The heat storage material is prepared by compounding a biomorphic silicon carbide ceramic framework and chlorate. The biomorphic silicon carbide ceramic is a ceramic material generated by high-temperature reaction of molten silicon and a charcoal porous precursor, and silicon carbide ceramic frameworks with different porosities can be obtained by different wood precursors. The phase-change heat storage material is prepared by fully and uniformly mixing sodium chloride and potassium chloride in a ball mill and drying to obtain the sodium-potassium chloride eutectic salt. The biomorphic silicon carbide ceramic framework is coated with the phase changeheat storage material by adopting a vacuum impregnation method, so that pores of the ceramic framework are filled with the phase change material, thereby obtaining the biomorphic silicon carbide ceramic high-temperature photo-thermal storage material. The composite material prepared by the invention has the excellent characteristics of high thermal conductivity (116 W / mK), high spectral absorptionperformance (92%) and high heat storage density (453 kg / kJ), and is expected to promote the development of constructing a clean, low-carbon, efficient and safe energy system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

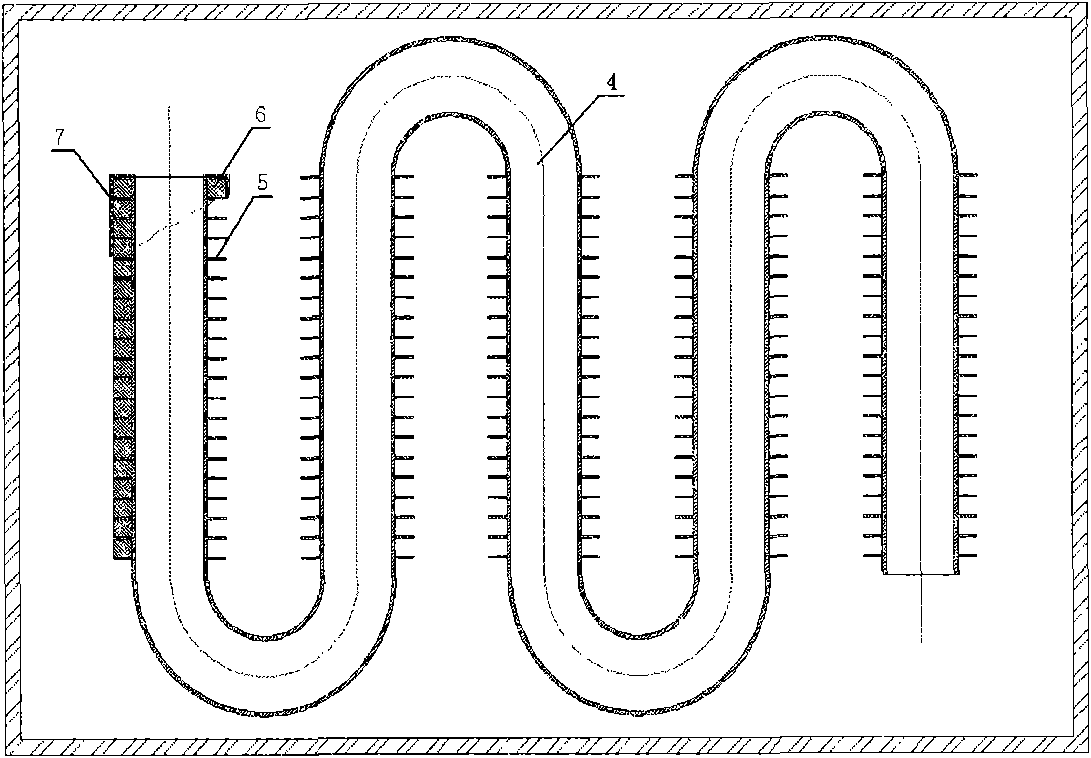

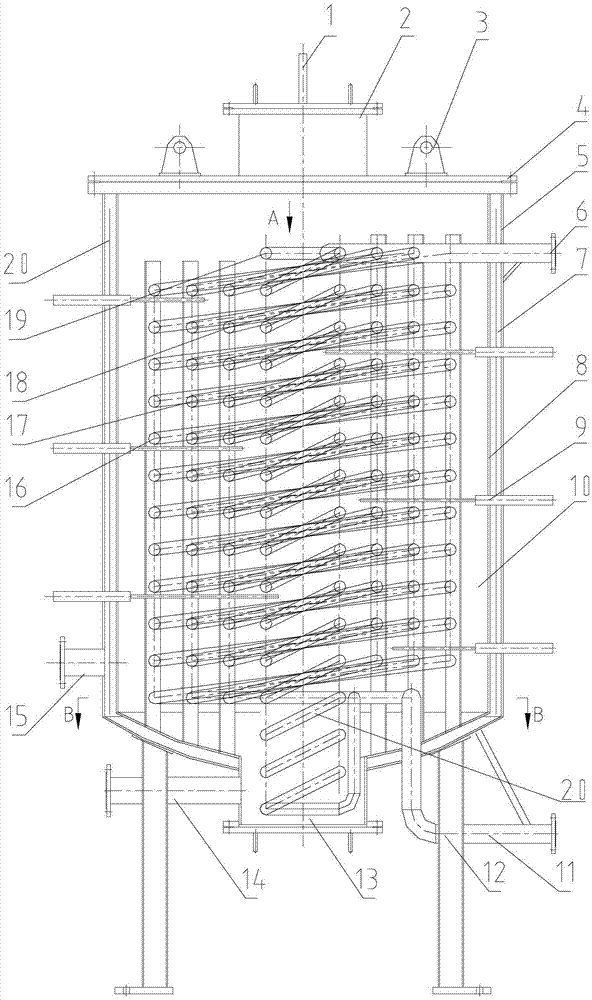

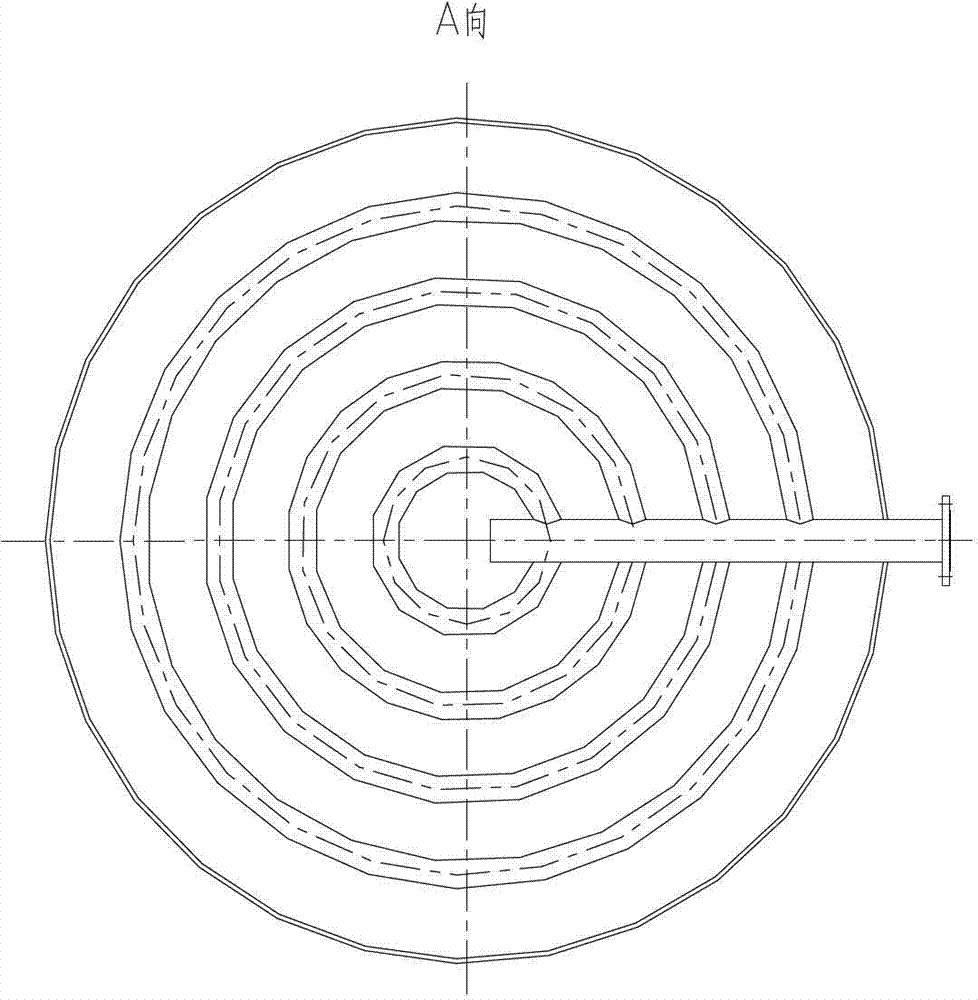

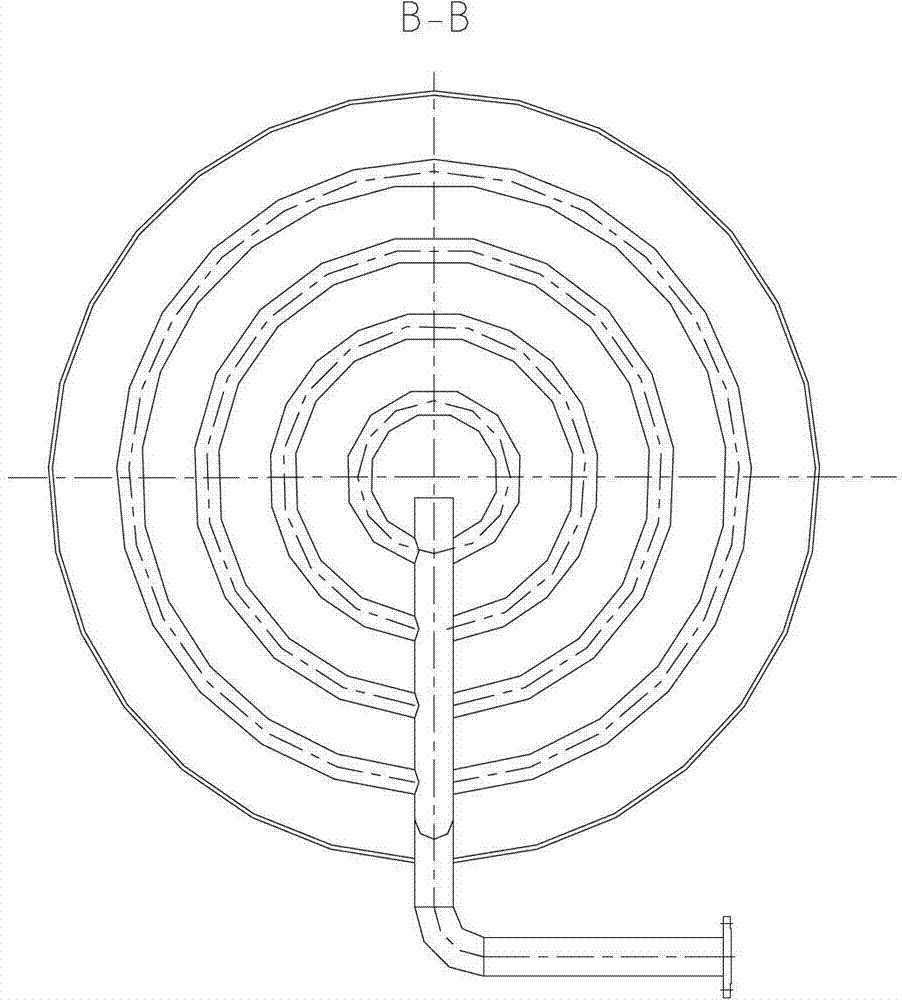

Single tank phase change thermal storage device for solar energy

InactiveCN103115443ASimple structureHigh heat storage densitySolar heating energySolar heat devicesThermal energyEngineering

The invention belongs to the field of solar energy, relates to the solar-thermal energy thermal storage technology, and in particular relates to a single tank phase change thermal storage device for solar energy. The single tank phase change thermal storage device is characterized in that a respiration port, a thermal storage medium inlet, a upper cover, a thermal storage medium outlet and a thermal storage medium discharge gate are arranged on the tank body, a polycyclic multilayer heat exchange coil is arranged in the tank body, and the polycyclic multilayer heat exchange coil is connected between a heat-transfer medium outlet pipe arranged on the upper end of the heat exchange coil and a heat-transfer medium inlet pipe arranged on the lower end of the heat exchange coil in parallel, thus forming a heat-transfer medium circulation pipeline; a thermal storage chamber of the tank body, which contains the thermal storage mediums, is enclosed by the inner wall, the upper cover and the thermal storage medium discharge gate; a sealed heat insulation sandwich is composed of the inner wall of the storage tank and the outer wall of the storage tank; and a thermometer is arranged in the tank. The device disclosed by the invention has the advantages that the phase change thermal storage technology is adopted to enable the thermal storage density to be improved greatly, and the thermal storage volume is efficiently reduced on the premise of same thermal storage capacity; and the storage and release processes of the phase change materials heat are carried out in the same device, thus simplifying the structure of thermal storage device efficiently, and reducing the cost.

Owner:兰州大成科技股份有限公司 +2

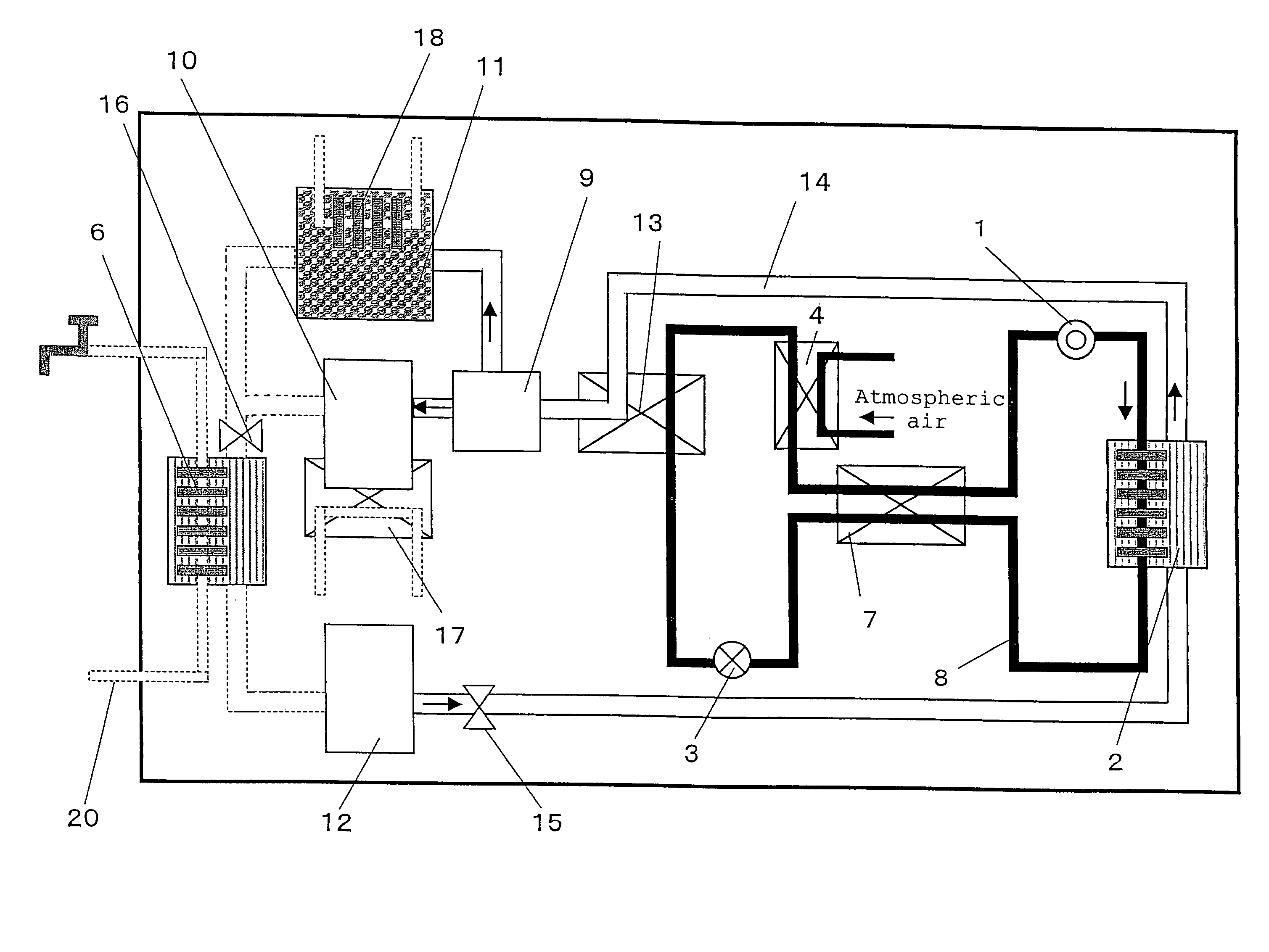

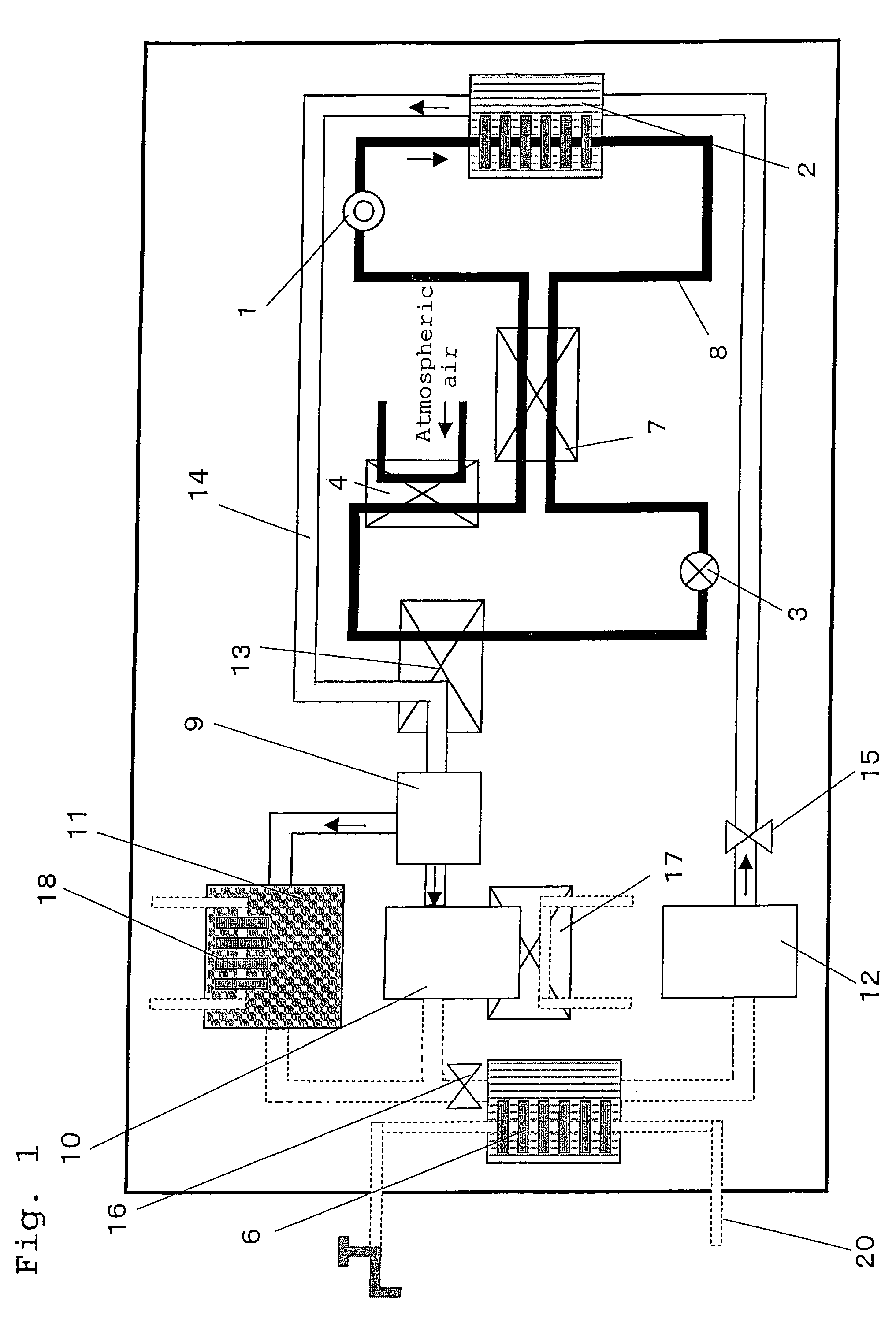

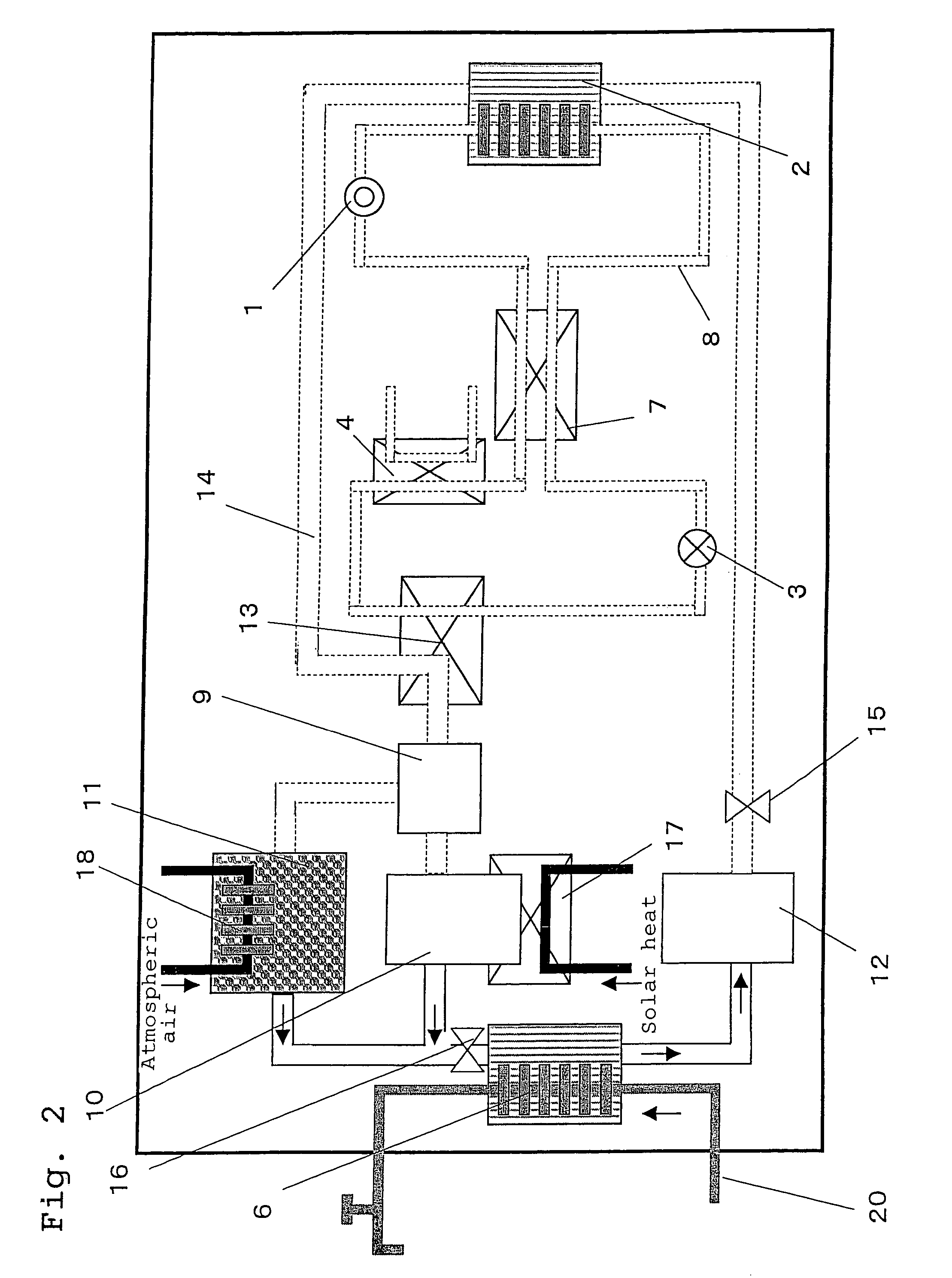

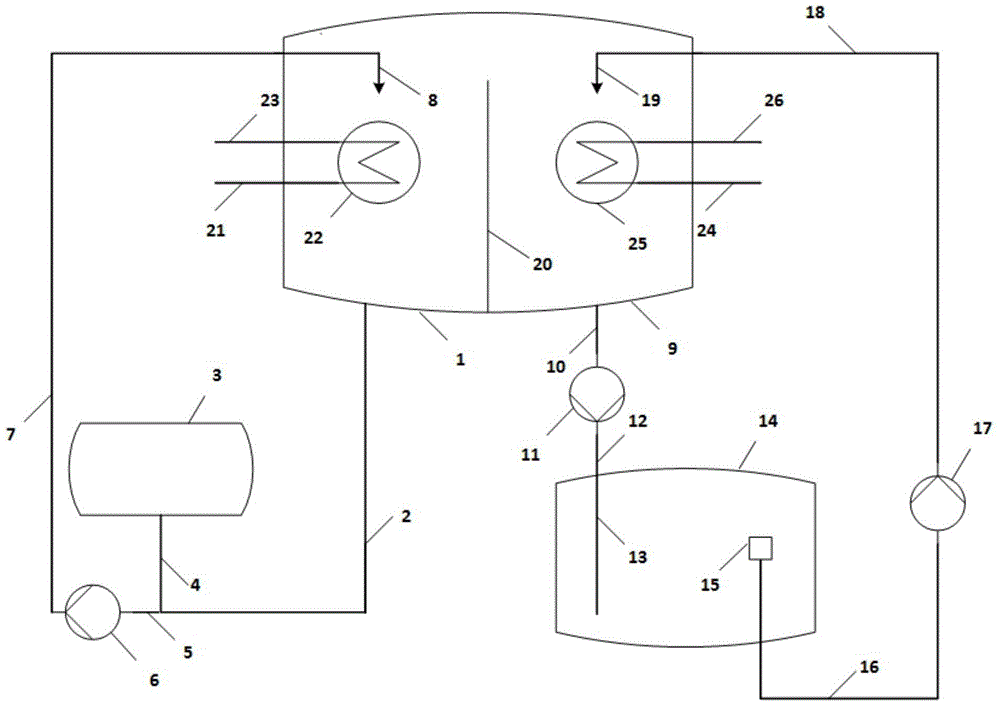

Regenerative heat pump system

InactiveUS6997010B2Small sizeHigh installation propertyCompressorHeat pumpsEngineeringHeat storage material

The present invention provides a regenerative heat pump system including a heat pump cycle, first storage vessel for storing a heat storage material, heat exchange device between first refrigerant and heat storage material for heating and decomposing the heat storage material by heat from a refrigerant, and heat exchange device between second refrigerant and an other heat storage material for transferring heat from the separated heat storage material to the refrigerant. The system also includes second storage vessel for storing the decomposed heat storage material, and heat generating device for generating heat by recombining the heat storage material stored in the second storage vessel and for heating a heating medium. The heat exchange device between the first refrigerant and the heat storage material is also used as a radiator of the heat pump cycle, and the heat exchange device between second refrigerant and the other heat storage material is also used as at least a part of an evaporator of the heat pump cycle.

Owner:PANASONIC CORP

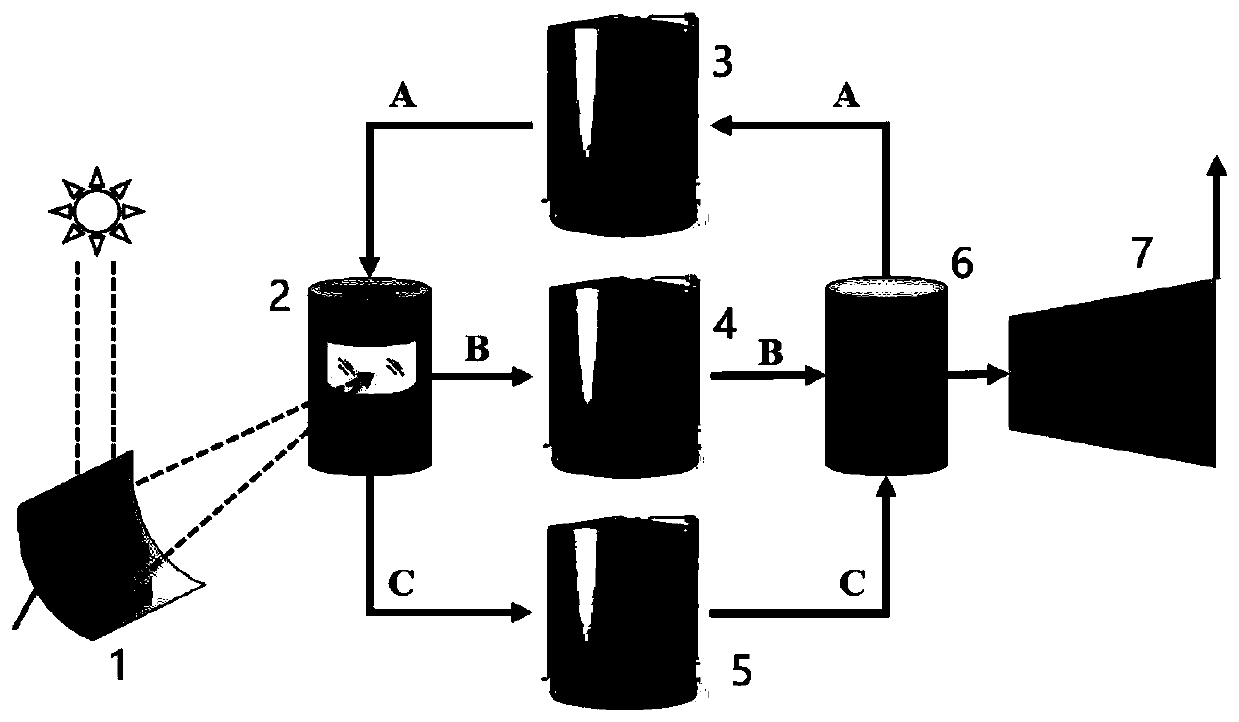

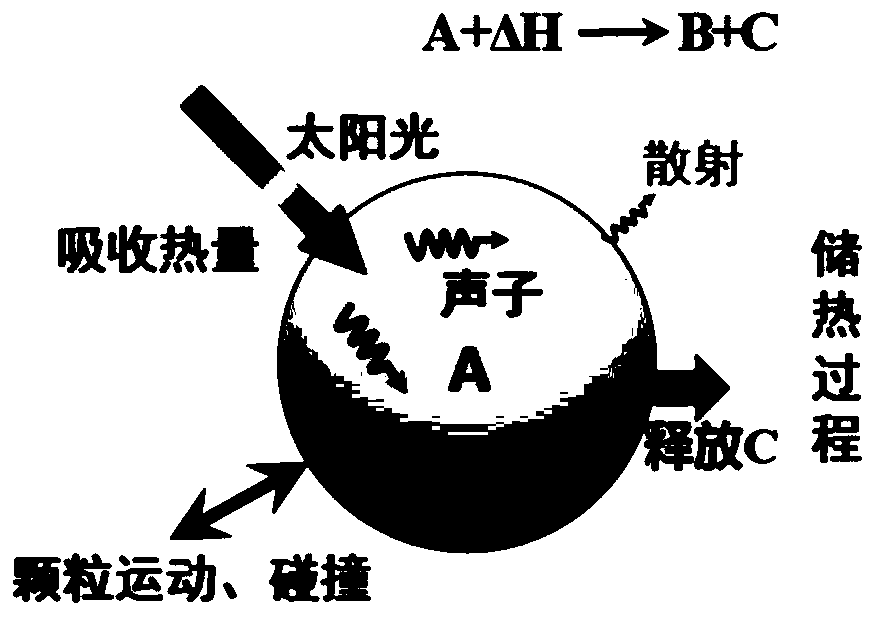

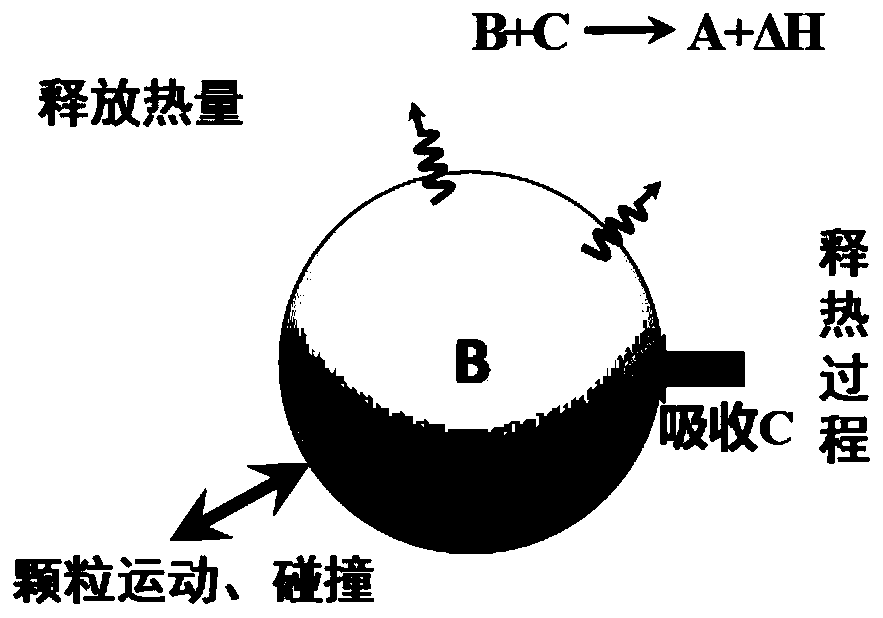

Thermochemical energy storage system

InactiveCN109959177AReduce heat transferReduce thermal resistanceSolar heating energySolar heat collector controllersTracking systemEnergy analysis

The invention discloses a thermochemical energy storage system. The thermochemical energy storage system comprises a light focusing and tracking system, an endothermic reaction system, a first sealedstorage tank system, a second sealed storage tank system, a third sealed storage tank system, a heat releasing reaction system and a heat utilization system, wherein the light focusing and tracking system focuses and projects sunlight to the endothermic reaction system, the endothermic reaction system performs endothermic chemical reactions, gas and solid products generated by the chemical reactions of the endothermic reaction system are stored inside the third sealed storage tank system and the second sealed storage tank system correspondingly to be taken as reactants of the heat releasing reaction system, and the heat releasing reaction system performs heat releasing chemical reactions and delivers released heat to the heat utilization system and stores the products generated by the chemical reactions inside the first sealed storage tank system to be taken as the reactants of the endothermic reaction system at the same time. By means of the thermochemical energy storage system, solarphoton energy is directly supplied to heat storage material particles, the internal temperature of the heat storage material particles is distributed evenly, the heat storage material sintering resistance is improved, and the system circulation stability is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Distributed energy resource station absorption type cold storage and heat storage dual-purpose energy storer

InactiveCN104634151ALow investment costShorten payback periodHeat storage plantsChemical reactionEngineering

The invention relates to a distributed energy resource station absorption type cold storage and heat storage dual-purpose energy storer. The energy storer comprises a heat exchanger with dual uses of a condenser and an evaporator, a heat exchanger with dual-use of a reactor and a absorber, a cooling agent storage tank and an absorbing agent storage tank, wherein a thermal separation baffle is used for separating the bottoms of the heat exchanger with the dual uses of the condenser and the evaporator and the heat exchanger with the dual uses of the reactor and the absorber, the upper portions of the heat exchanger with the dual uses of the condenser and the evaporator and the heat exchanger with the dual uses of the reactor and the absorber are communicated with each other, heat exchange tubes of the two heat exchangers are each communicated with a piping system of the distributed energy resource station through pipelines, the cooling agent storage tank is connected with the heat exchanger with the dual uses of the condenser and the evaporator to form a circulation loop through pipelines, and the absorbing agent storage tank is connected with the heat exchanger with the dual uses of the reactor and the absorber to form a circulation loop through pipelines. Compared with the prior art, by means of a absorption heat chemical reaction, energy storage of waste heat of distributed energy resource station generator sets is achieved; when cold supply is needed, cooling quantity is released; when heat supply is needed, heat quantity is released. Accordingly, a function with dual uses of accumulation of cold and accumulation of heat is achieved.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com