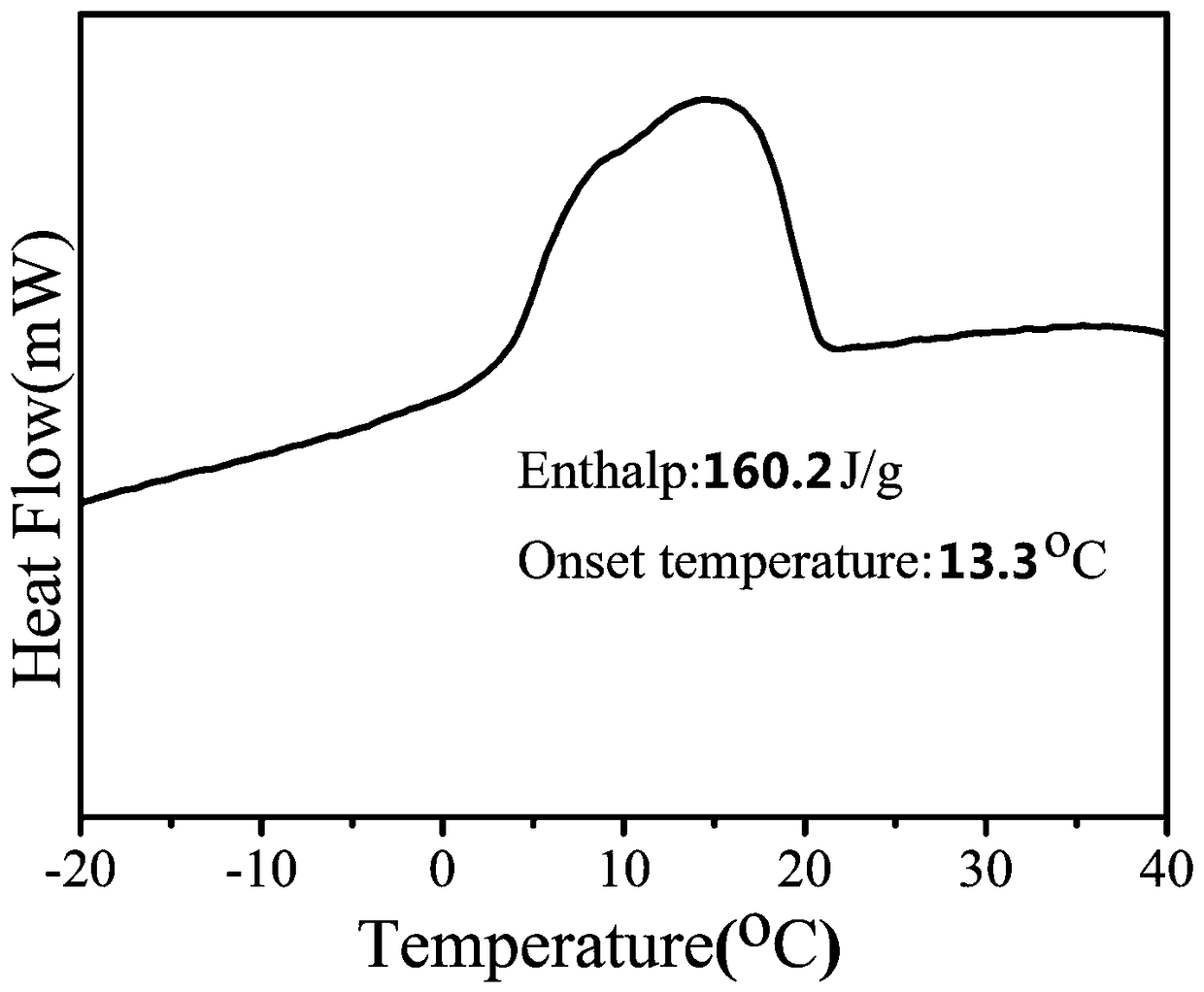

Heat conduction enhanced organic PCM (phase change material) and preparation method thereof

A phase-change energy storage material and energy storage material technology, applied in the field of heat conduction-enhanced organic phase-change energy storage materials and their preparation, can solve the problems of low thermal conductivity and achieve high thermal conductivity, low cost, and no corrosion in the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Preparation method of heat conduction enhanced organic phase change energy storage material:

[0035] Step 1, the emulsification process of the organic phase change material, first mix the nanoparticles and the organic phase change material and ultrasonically disperse for 30 minutes to form a uniform dispersion. Then, after mixing the dispersion with emulsifier and solvent evenly, stirring and emulsifying at 40-70°C and 1000-1500 RMP for 2 h to form a stable and uniform emulsion, and obtain an organic phase change material containing nanoparticles;

[0036] Step 2, take a clean and dry beaker, add porous material, and dry in an oven at 110°C for 30 minutes;

[0037] Step 3, mixing the dry porous material obtained in step 1 and the organic phase change material containing nanoparticles obtained in step 2, and ultrasonically dispersing for 10 min, so that the phase change material and the porous material are evenly mixed;

[0038] Step 4, put the mixed sample into a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com