Battery module heat management method and apparatus based on thermo-electric effect

A battery module, thermoelectric effect technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of large heat generation on the heating surface, low air-cooled heat dissipation efficiency, insufficient cooling efficiency, etc., and achieves high heat transfer coefficient. The effect of buffering mechanical stress and reducing interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

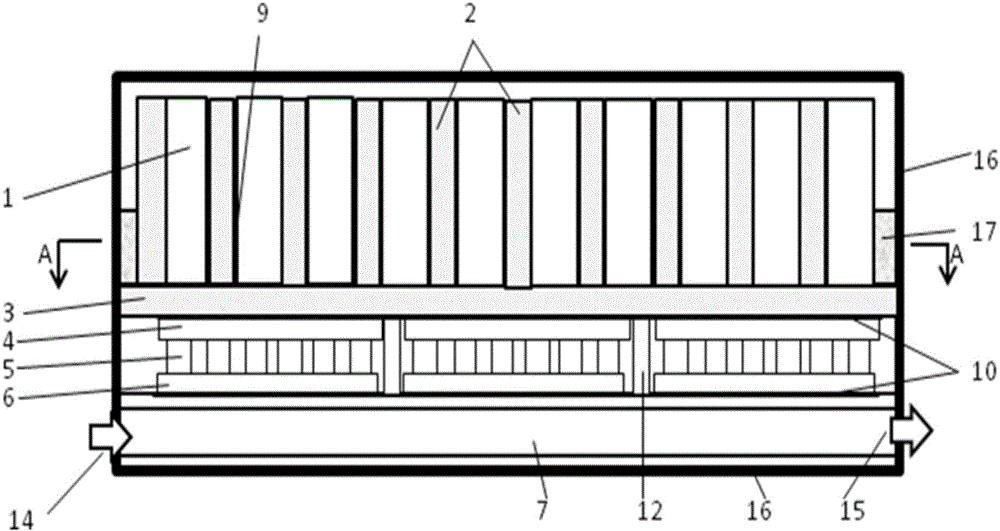

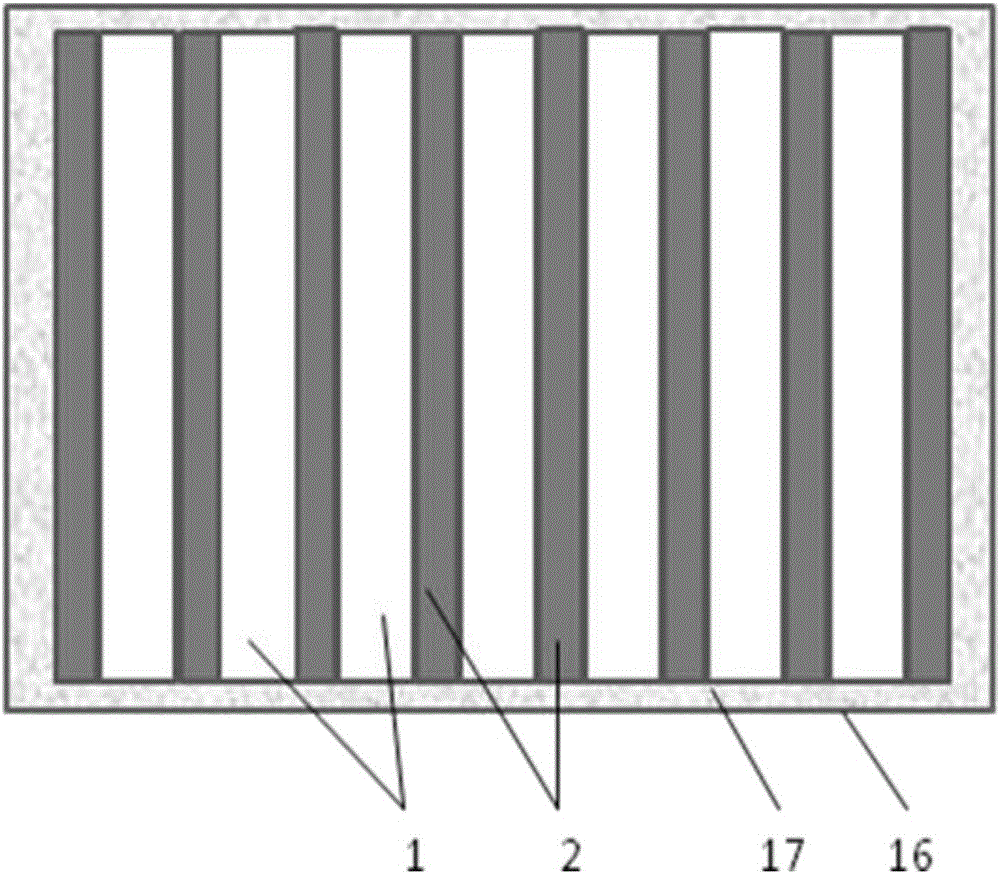

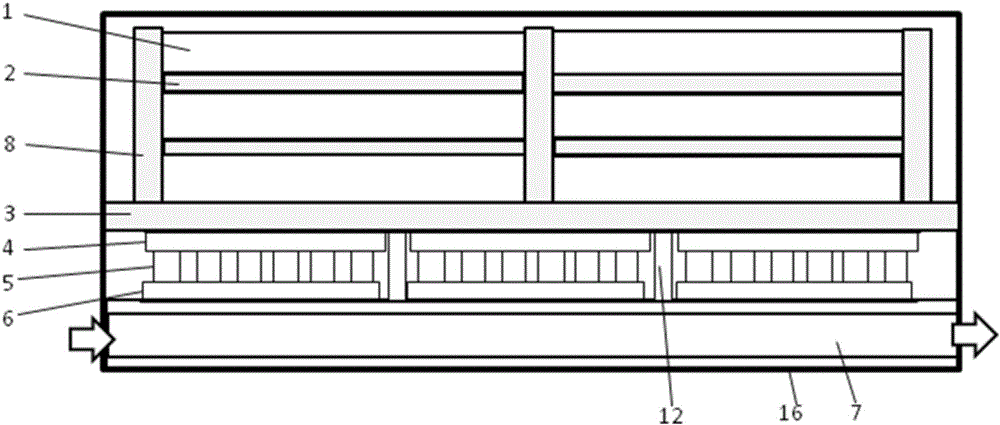

[0057] The present invention will be further described below in conjunction with accompanying drawing.

[0058] Such as figure 1 , image 3 and Figure 4 As shown, inside the battery pack box 16, the battery module 1, the heat conduction support plate 3, the semiconductor thermoelectric component and the liquid heat conduction channel 7 are arranged in close contact with each other from top to bottom, and a plurality of them are evenly distributed in the battery module 1. The heat conductor, the lower part of the heat conductor is close to the heat conduction support plate 3, forming a heat conduction path formed by the battery module-heat conductor-semiconductor thermoelectric component-liquid heat conduction channel, wherein:

[0059] The heat conduction support plate 3 is placed horizontally, and its surrounding edges are close to the inner wall of the battery pack box 16;

[0060] The semiconductor thermoelectric assembly includes a horizontal first heat exchange plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com