Preparation method of sizing composite heat storage material for moderate-high temperature

A technology of thermal storage materials and composite phase change materials, which is applied in the field of preparation of composite thermal storage materials for medium and high temperature in shaping, can solve the problems of easy leakage, high price, leakage, etc., and achieve high thermal storage density, good thermal conductivity, and easy deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing a composite heat storage material for medium and high temperature, including the following steps:

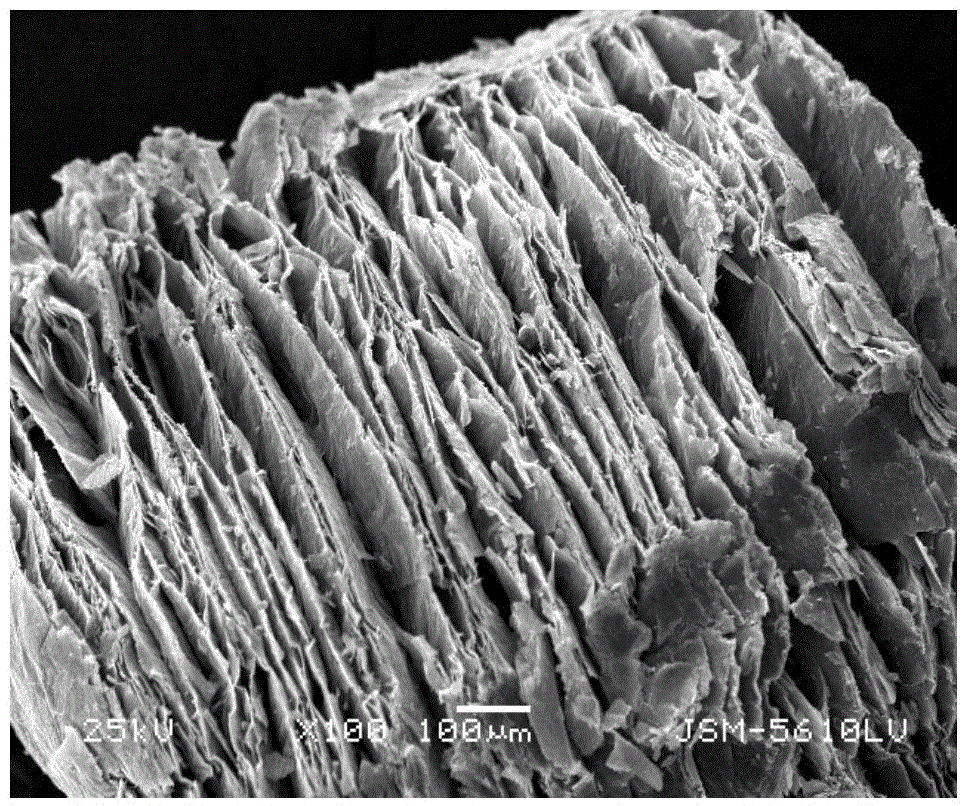

[0029] 1) Treat the vermiculite at a temperature of 1300°C for 20 minutes, and mix it with the phase-change material at a mass ratio of 1:10 after cooling. The phase-change material is composed of 40.0wt% MgCl 2 , 30.4wt% KCl and 29.6wt% NaCl composition;

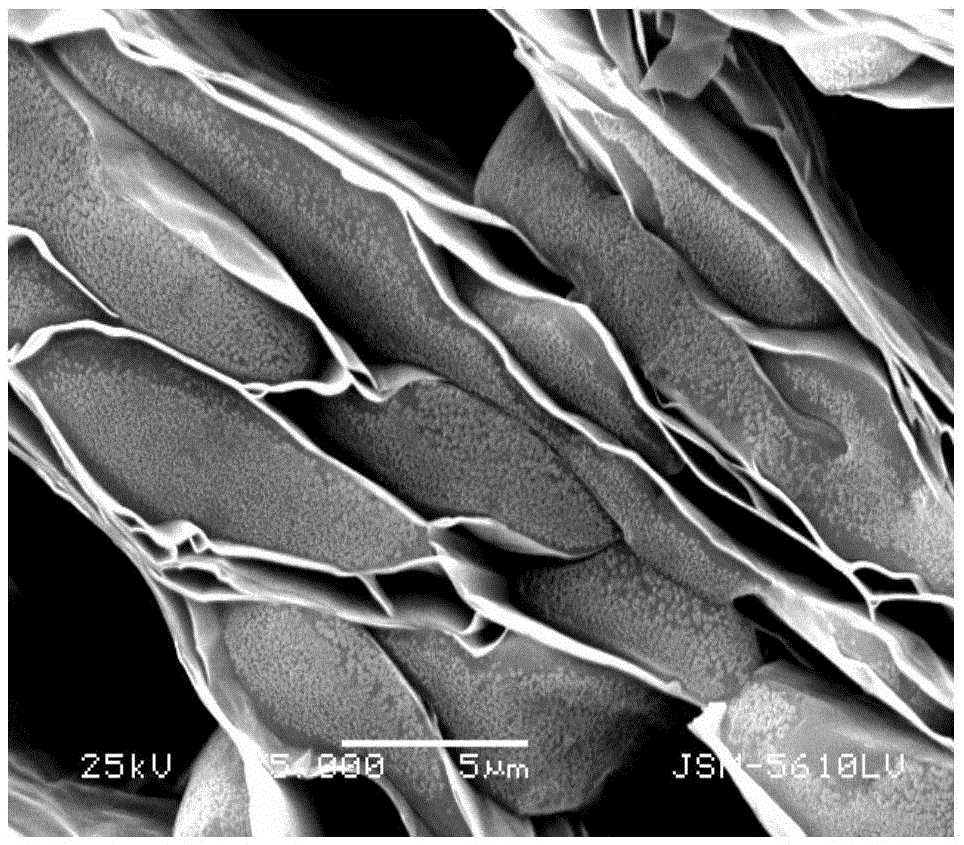

[0030] 2) The above mixture was kept at 400°C for 6 hours under the condition of a negative pressure of -15kPa to prepare a composite phase change material, then mechanically crush the composite phase change material to 40 mesh, add modified carbon fiber and then mechanically mix for 24 hours. Modified carbon fiber accounts for 2% of the total mass of the composite phase change material;

[0031] 3) Adding a high-temperature binder dropwise, pressing and molding under a pressure of 10 MPa, and finally curing at a temperature of 300° C. for 30 minutes to obtain the compos...

Embodiment 2

[0043] This embodiment is roughly the same as Embodiment 1, except that the modified carbon fiber accounts for 4% of the total mass of the composite phase change material.

[0044] After testing: the thermal storage density of the thermal storage material is 285.6J / g, and the thermal conductivity measured by the thermal conductivity meter is 1.86W / (m·K). After 200 cycles of solidification and melting at a temperature of 450°C, the composite heat storage material has no damage in appearance, and its mass has decreased by 1.3%. After 500 cycles, the appearance of the heat storage material has no damage, and its mass has decreased by 1.3%. It shows that the shaped heat storage material prepared in this example is not easy to leak.

Embodiment 3

[0046] This embodiment is roughly the same as Embodiment 1, except that the modified carbon fiber accounts for 8% of the total mass of the composite phase change material.

[0047] After testing: the thermal storage density of the thermal storage material is 264.1J / g, and the thermal conductivity measured by the thermal conductivity meter is 2.52W / (m·K). After 200 cycles of solidification and melting at a temperature of 450°C, the composite thermal storage material has no damage in appearance and a mass reduction of 1.2%. After 500 cycles, the thermal storage material has no damage in appearance and a mass reduction of 1.2%. It shows that the shaped heat storage material prepared in this example is not easy to leak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com