Patents

Literature

50 results about "Inlet velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

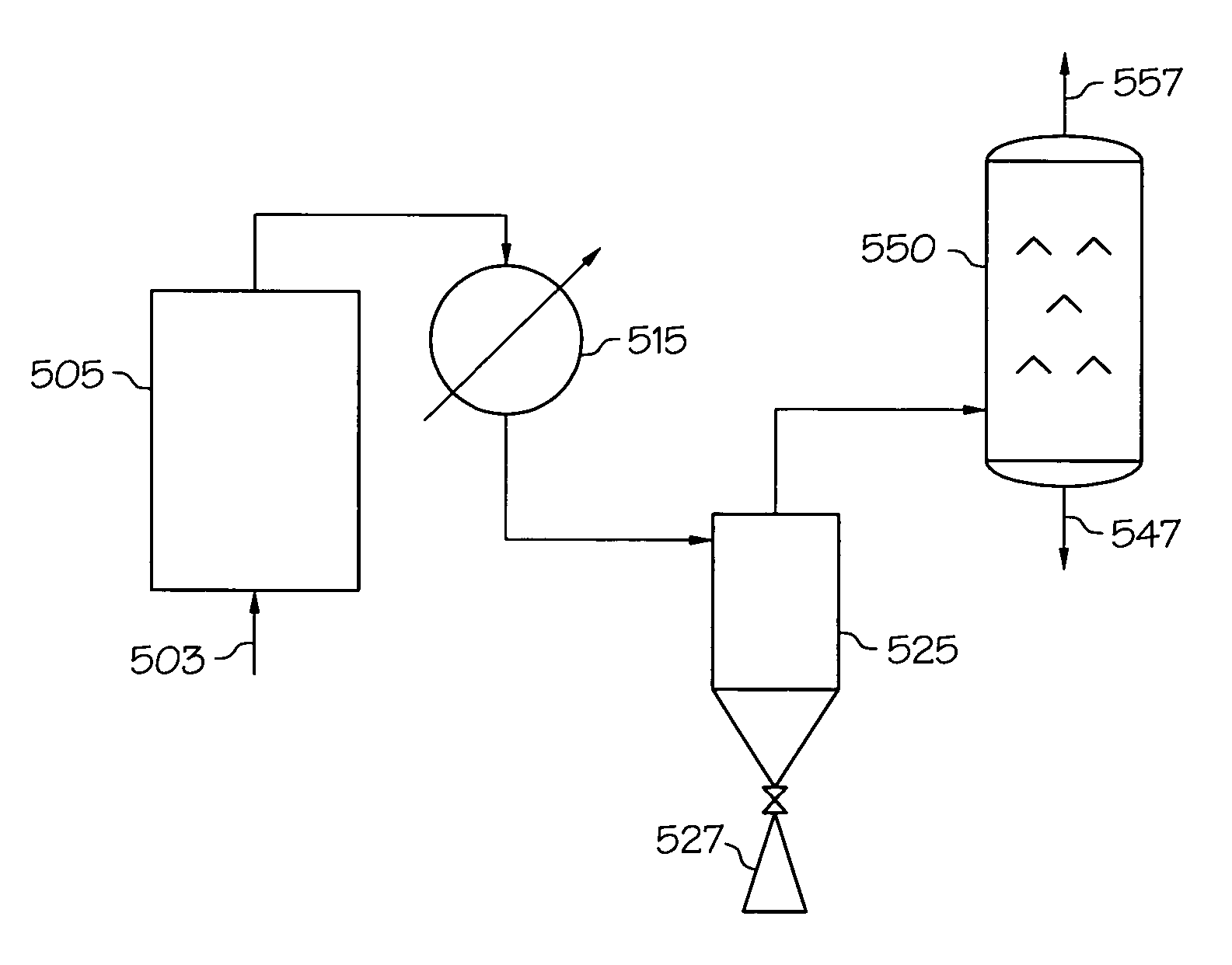

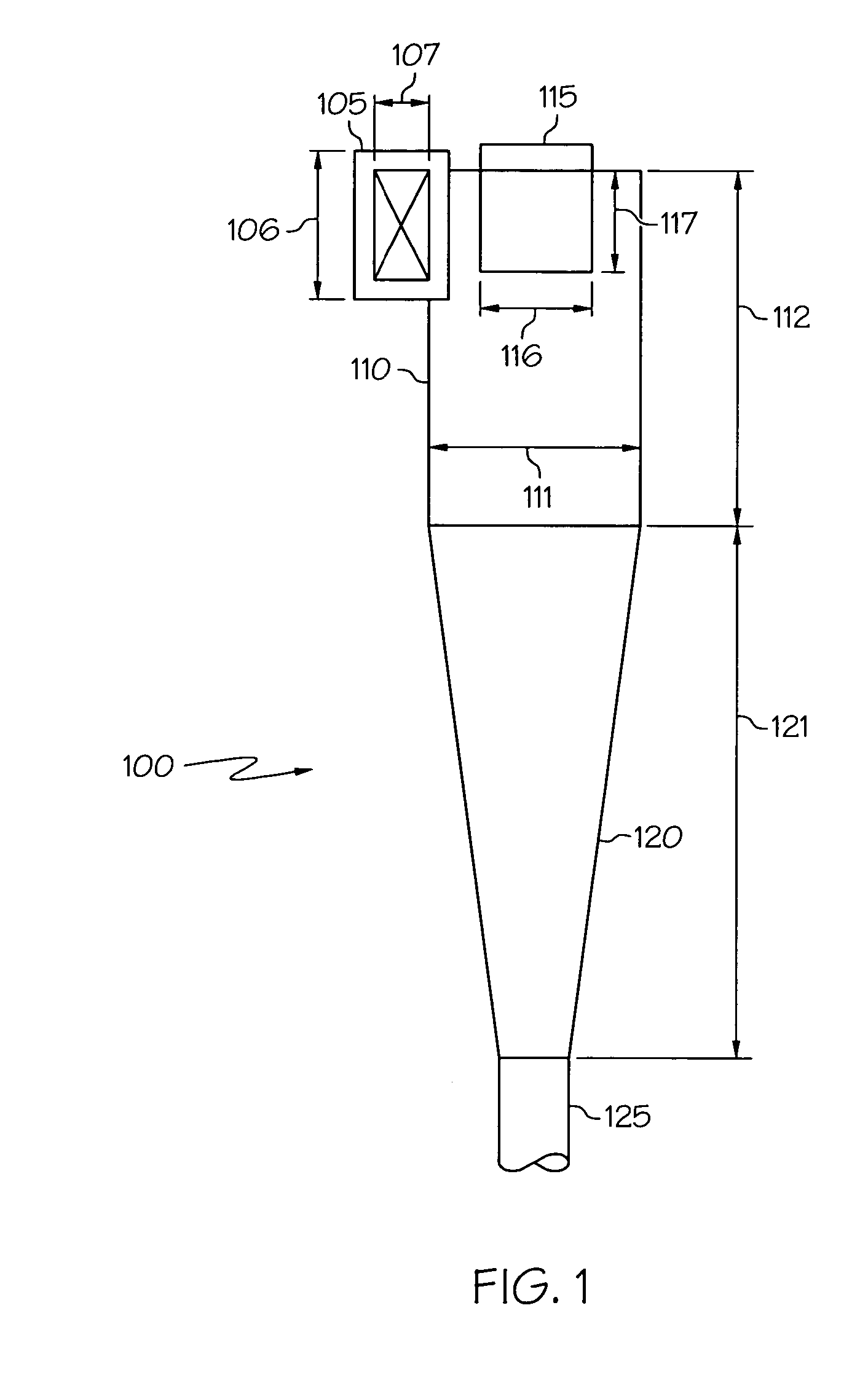

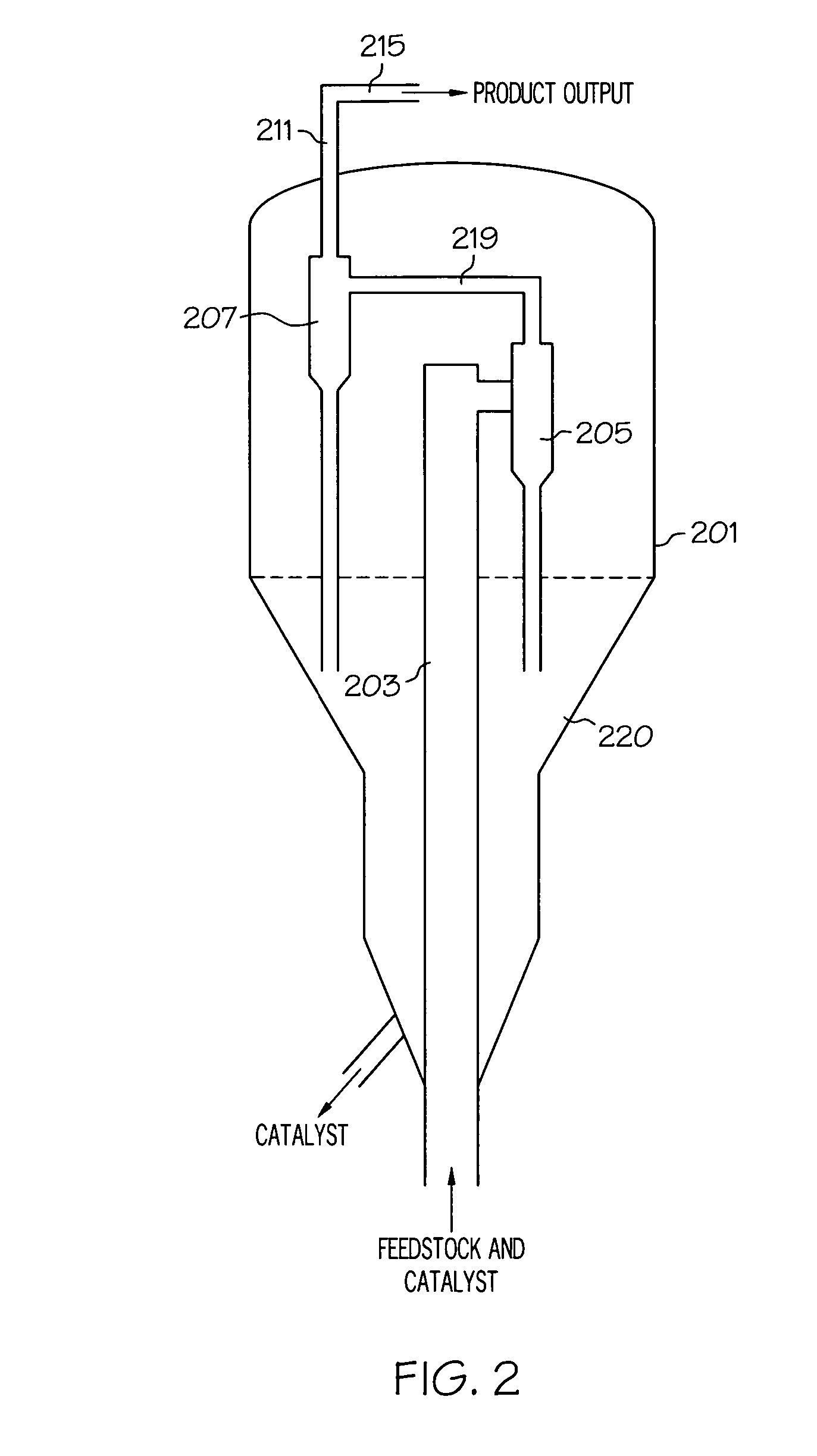

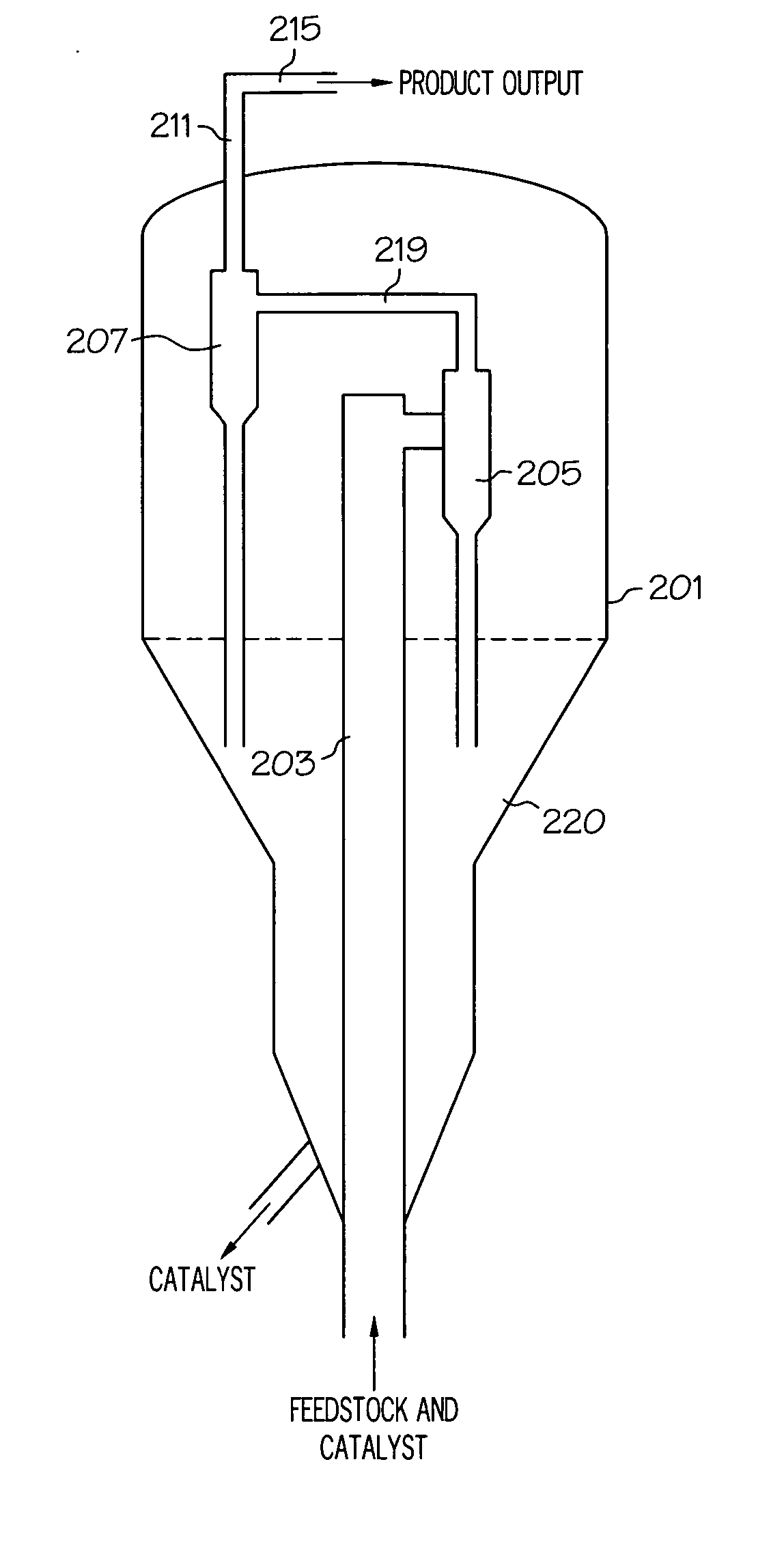

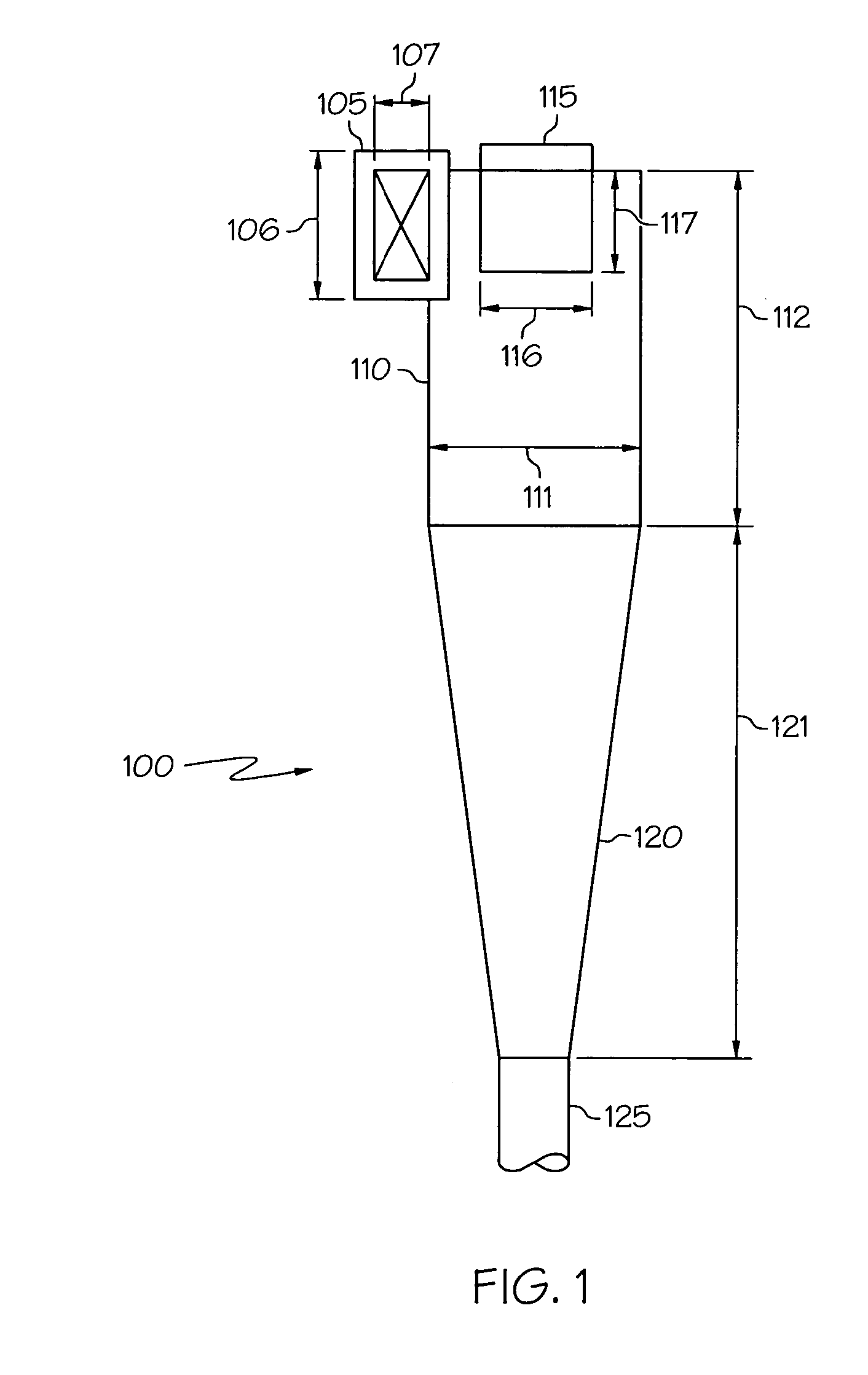

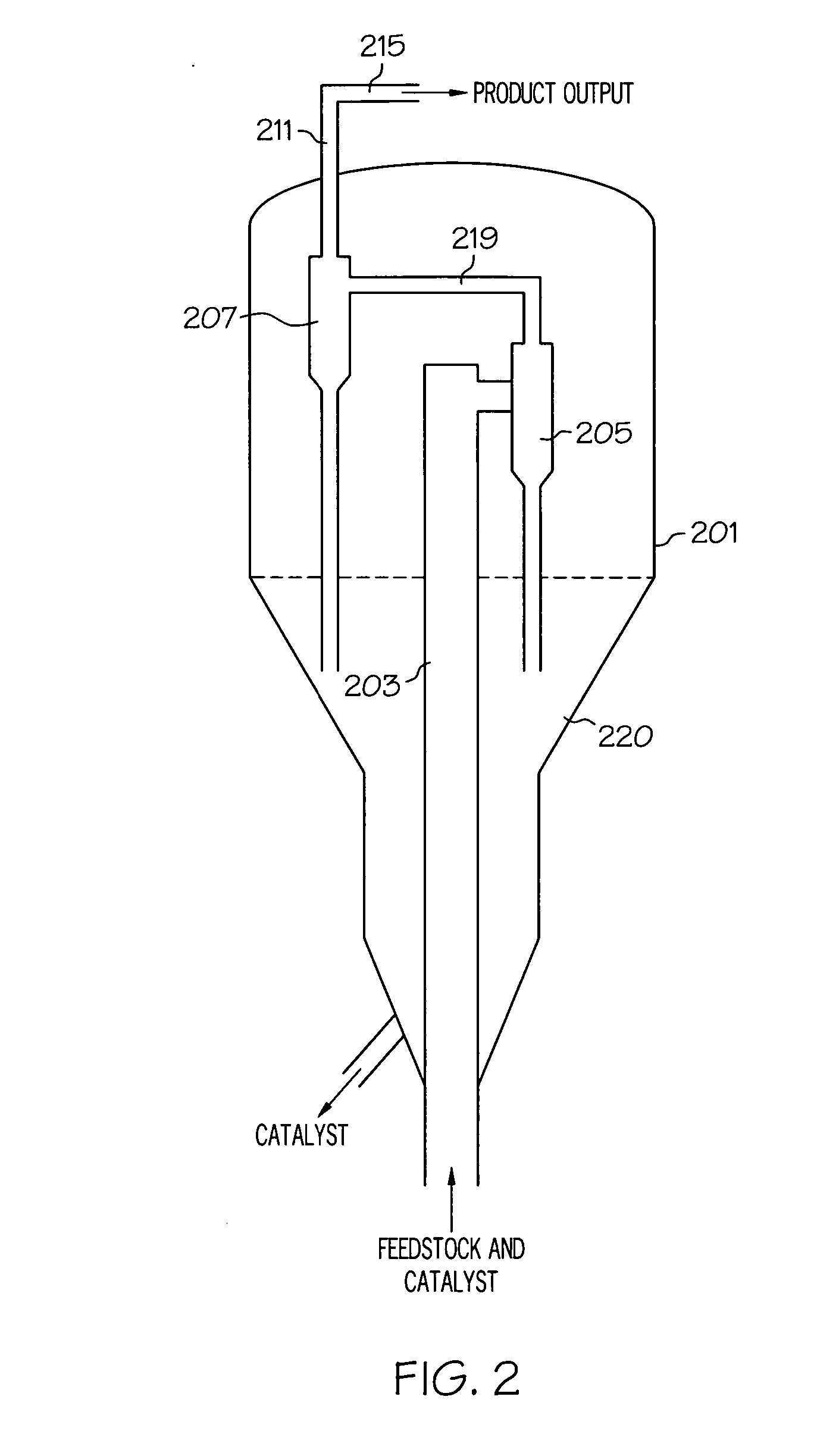

Process for removing solid particles from a gas-solids flow

Catalyst losses are prevented in riser reactor systems by using a low inlet velocity for the first cyclone separator in each multi-stage cyclone separator in the reactor. Catalyst particles not separated from the product output flow in an oxygenate-to-olefin reactor are also recaptured by cooling the product output flow and passing the flow through an electrostatic precipitator.

Owner:EXXONMOBIL CHEM PAT INC

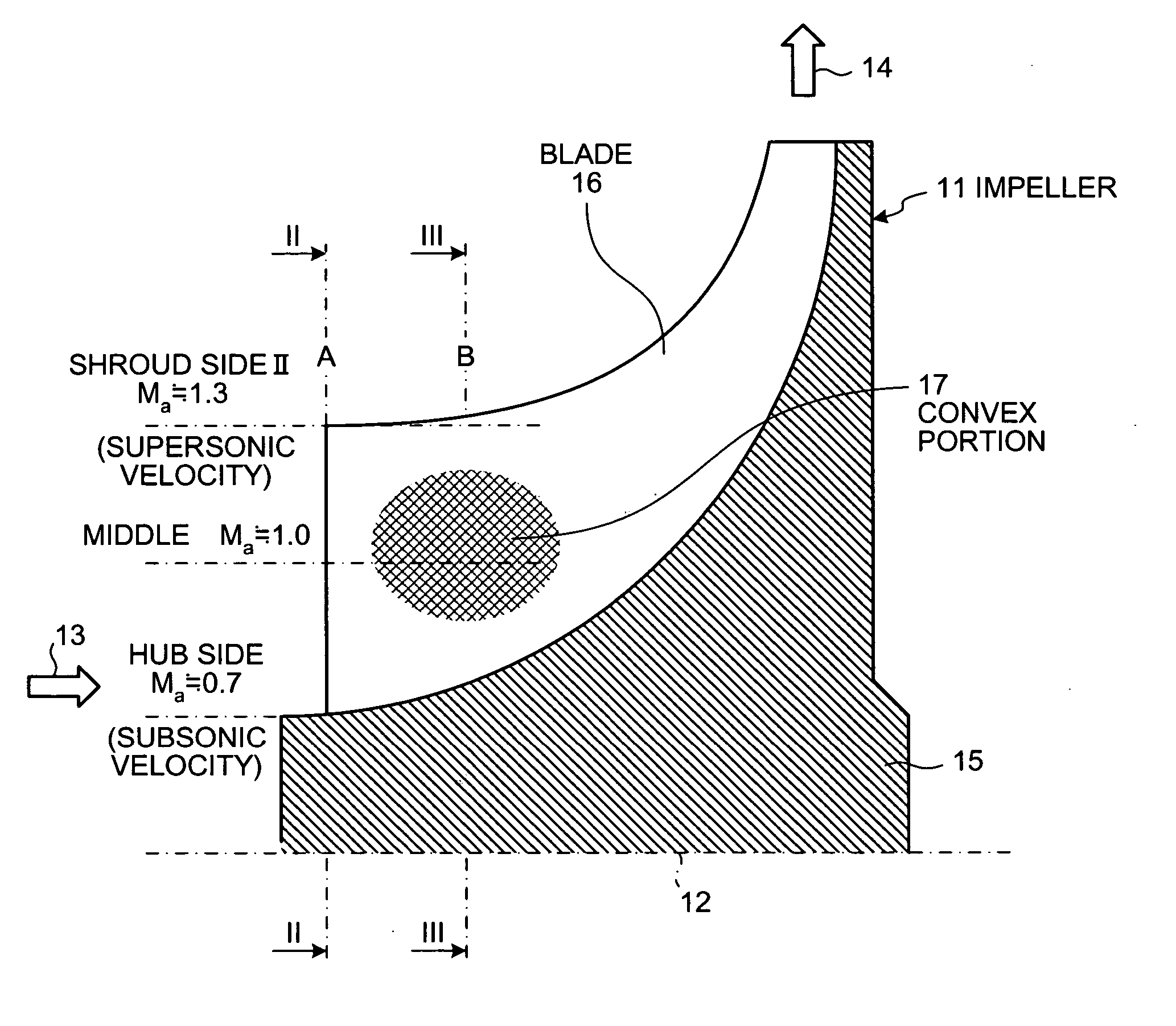

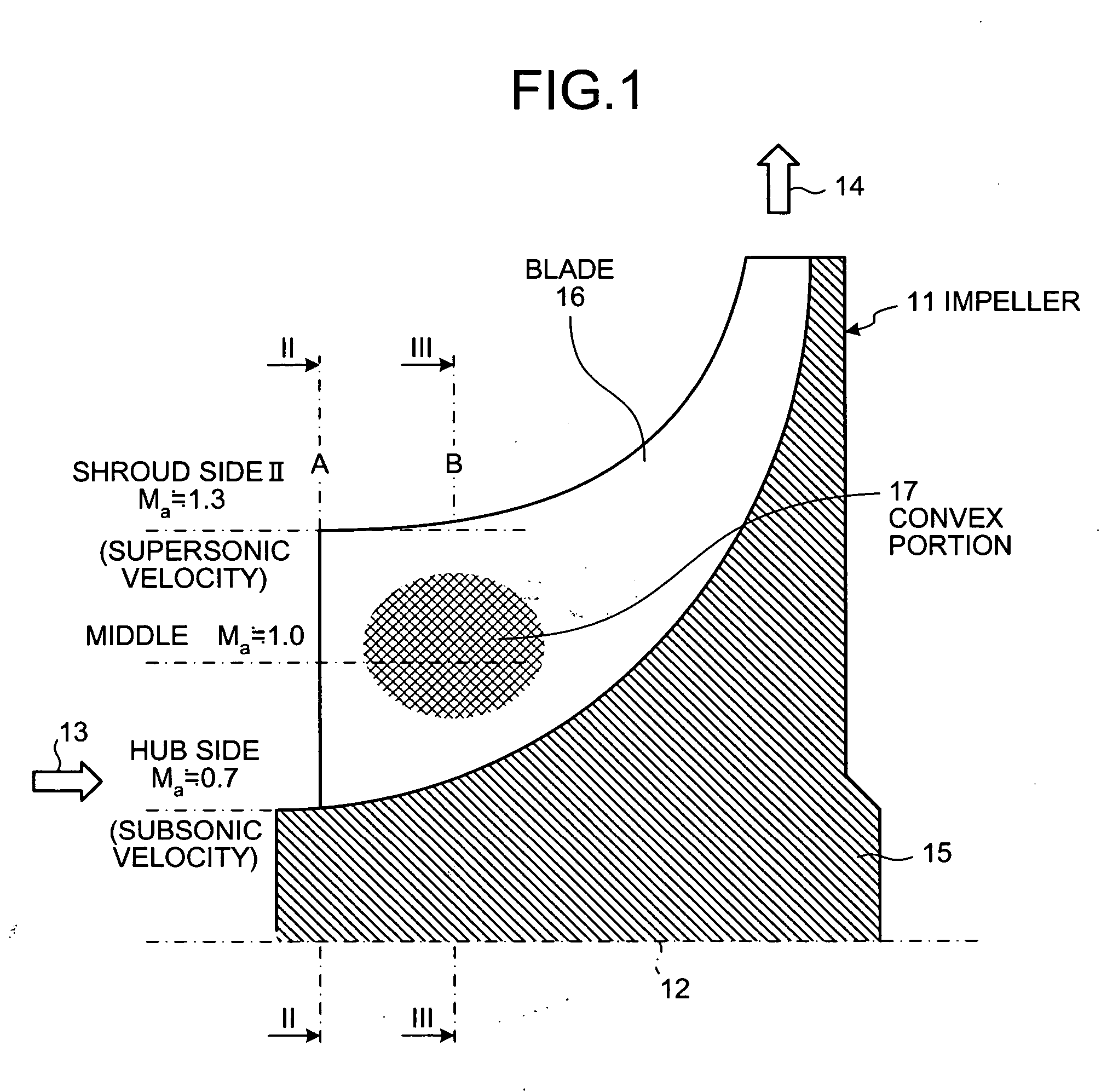

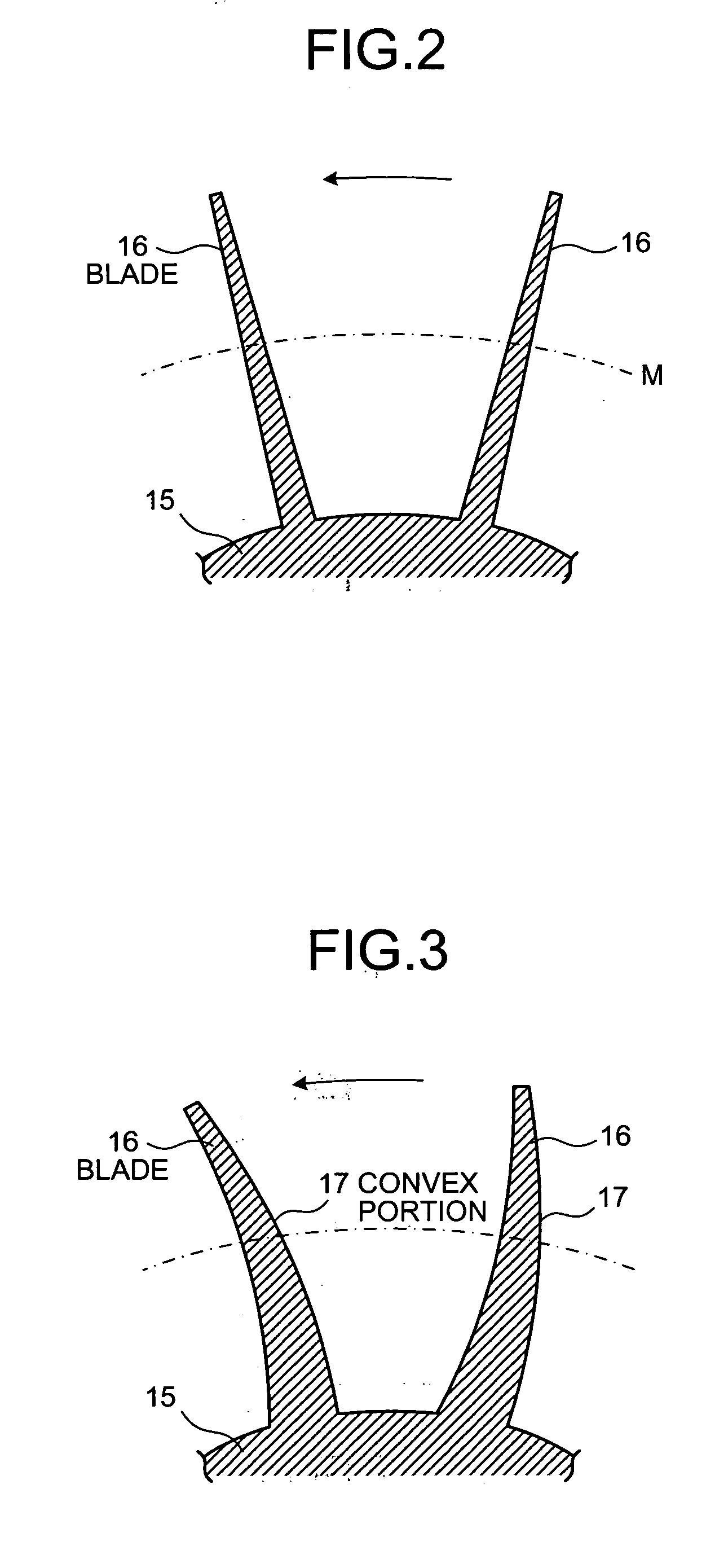

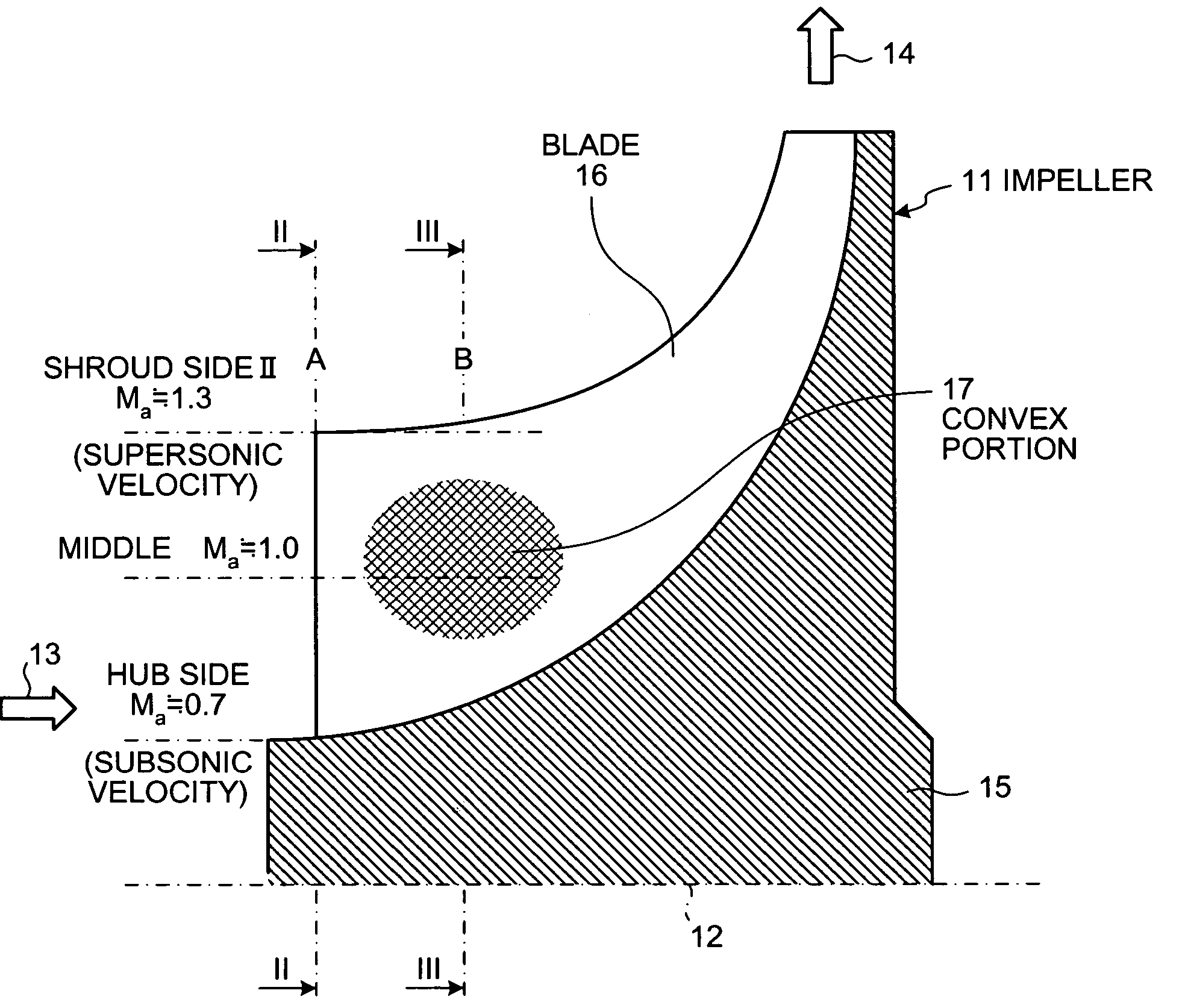

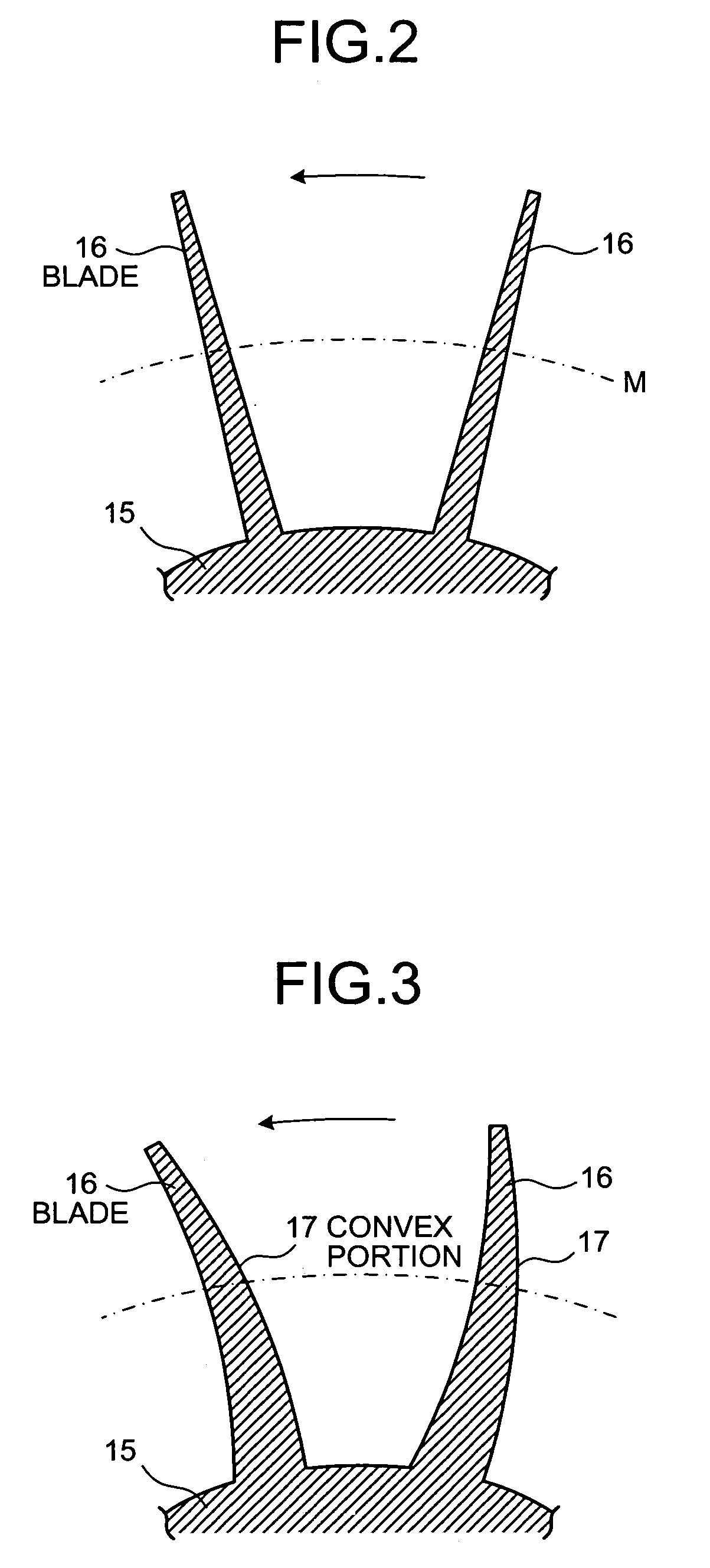

Centrifugal compressor and manufacturing method for impeller

InactiveUS20050260074A1Fall in efficiencyFall in performancePropellersSupersonic fluid pumpsEngineeringFront edge

On a suction surface side of a blade in an impeller, a convex portion is formed to assume a curved line from a front edge portion to a throat portion substantially in the middle in a radial direction, and this convex portion is formed to be flat assuming a curved line from the throat portion toward a rear edge portion, whereby this convex portion is formed in a position where a relative inlet velocity of fluid into the impeller is Mach number Ma≅1.

Owner:MITSUBISHI HEAVY IND LTD

Process for maximizing 371.degree. C.+ production in fischer-tropsch process

InactiveUS6458857B1Maximize productionLightweight productionOrganic compound preparationOxygen compounds preparation by reductionProduction rateNaphtha

A hydrocarbon synthesis (HCS) process wherein a Fischer-Tropsch reactor is operated to maximize the selectivity to 371.degree. C.+ boiling fraction while minimizing the production of less valuable products such as light gases (C.sub.1 -C.sub.4), naphtha and diesel fractions. Inventive modes of operation to offset the effects of catalyst deactivation and maximize selectivity to 371.degree. C.+ boiling fraction are utilized including (a) reducing gas inlet velocity to maintain an optimal CO conversion level, (b) introducing additional active catalyst until a maximum loading is reached, and (c) increasing reactor temperature until productivity reaches a predetermined cut-off level.

Owner:EXXON RES & ENG CO

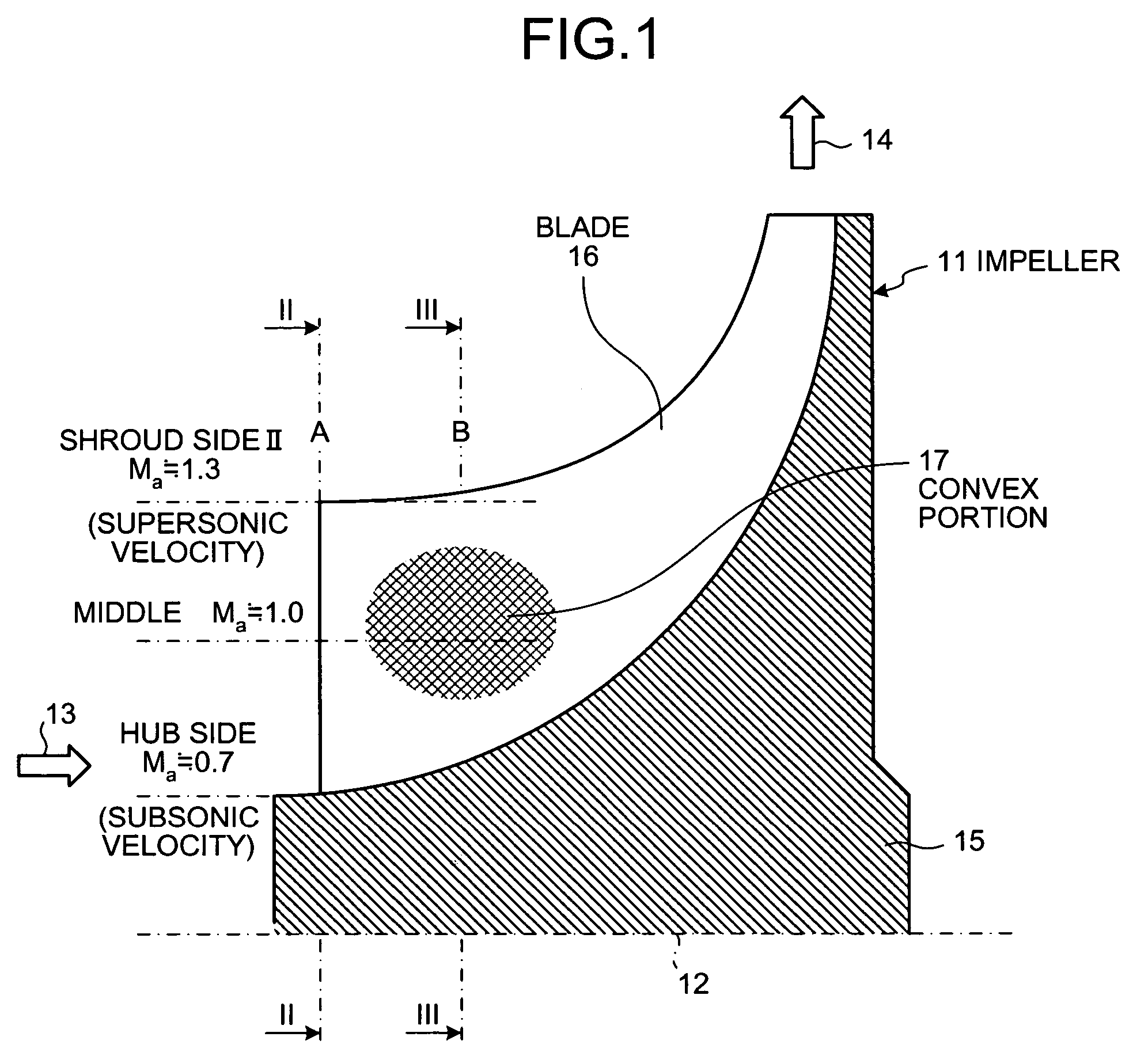

Centrifugal compressor and manufacturing method for impeller

InactiveUS7517193B2Fall in efficiency and performance is preventedIncrease rangeSupersonic fluid pumpsPropellersEngineeringFront edge

Owner:MITSUBISHI HEAVY IND LTD

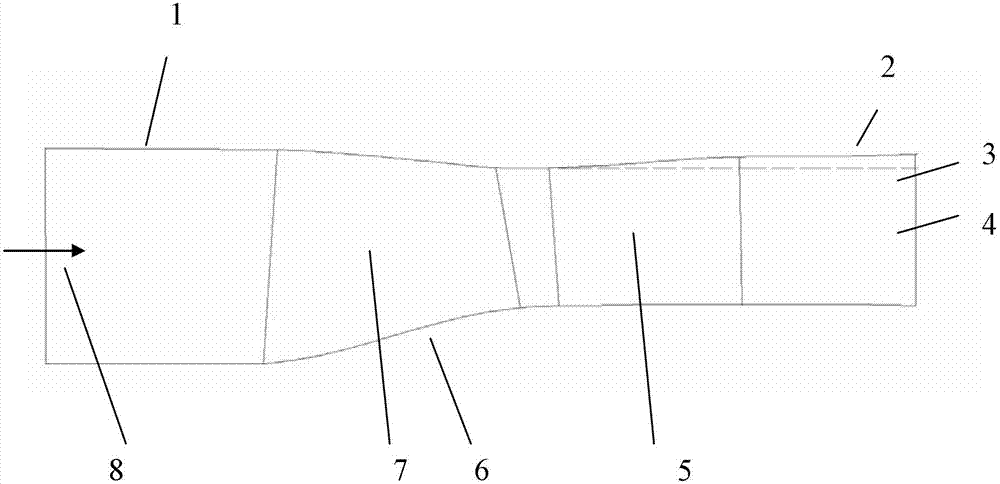

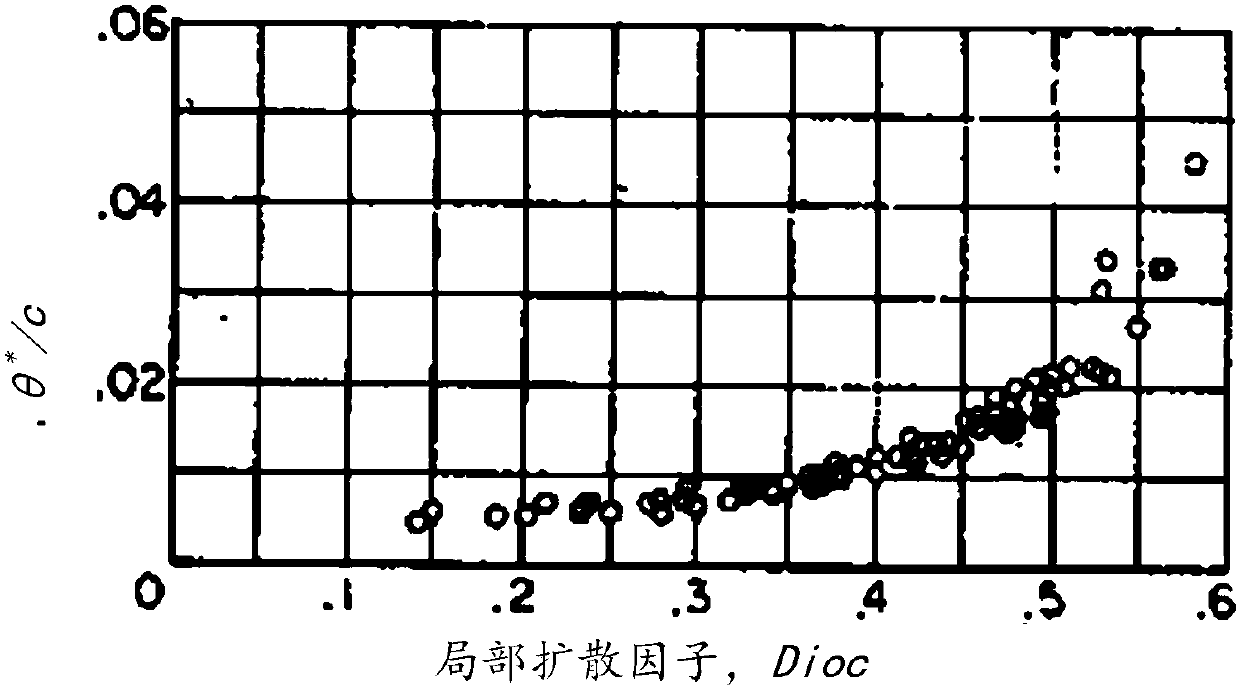

Aerodynamic design method of subsonic adsorption type axial compressor

ActiveCN103244459AIncrease axial speedReduce the diffusion factorPump componentsPumpsAxial compressorEngineering

The invention belongs to the technical field of axial compressors, and relates to an aerodynamic design method of a subsonic adsorption type axial compressor, in order to solve the problems of increasing of blade rotating angles of a subsonic axial compressor and boundary layer separated in a moving blade during stage load increasing as well as the problems of suction pipeline layout difficulty, blade strength reduction and the like caused by boundary layer suction in the moving blade. On the premise of unchanging an inlet velocity triangle, with design stage load coefficient increasing gradually and exceeding a conventional design value, outlet axial velocity of the moving blade is increased greatly so as to reduce diffusion factors in the moving blade, so that efficient flow of the moving blade is guaranteed; and boundary layer suction is utilized for achieving internal flow of a fixed blade. As boundary layer suction is performed in the moving blade as well as the fixed blade, problems of poor blade strength of a rotatable part and difficulty in suction structure design are solved effectively; and as compared with a tandem cascade technique, the aerodynamic design method has the advantages that blades can be decreased, and accordingly size and weight of an engine are reduced. The method can be applied to aerodynamic design of aero-engines with high thrust-weight ratio.

Owner:HARBIN INST OF TECH

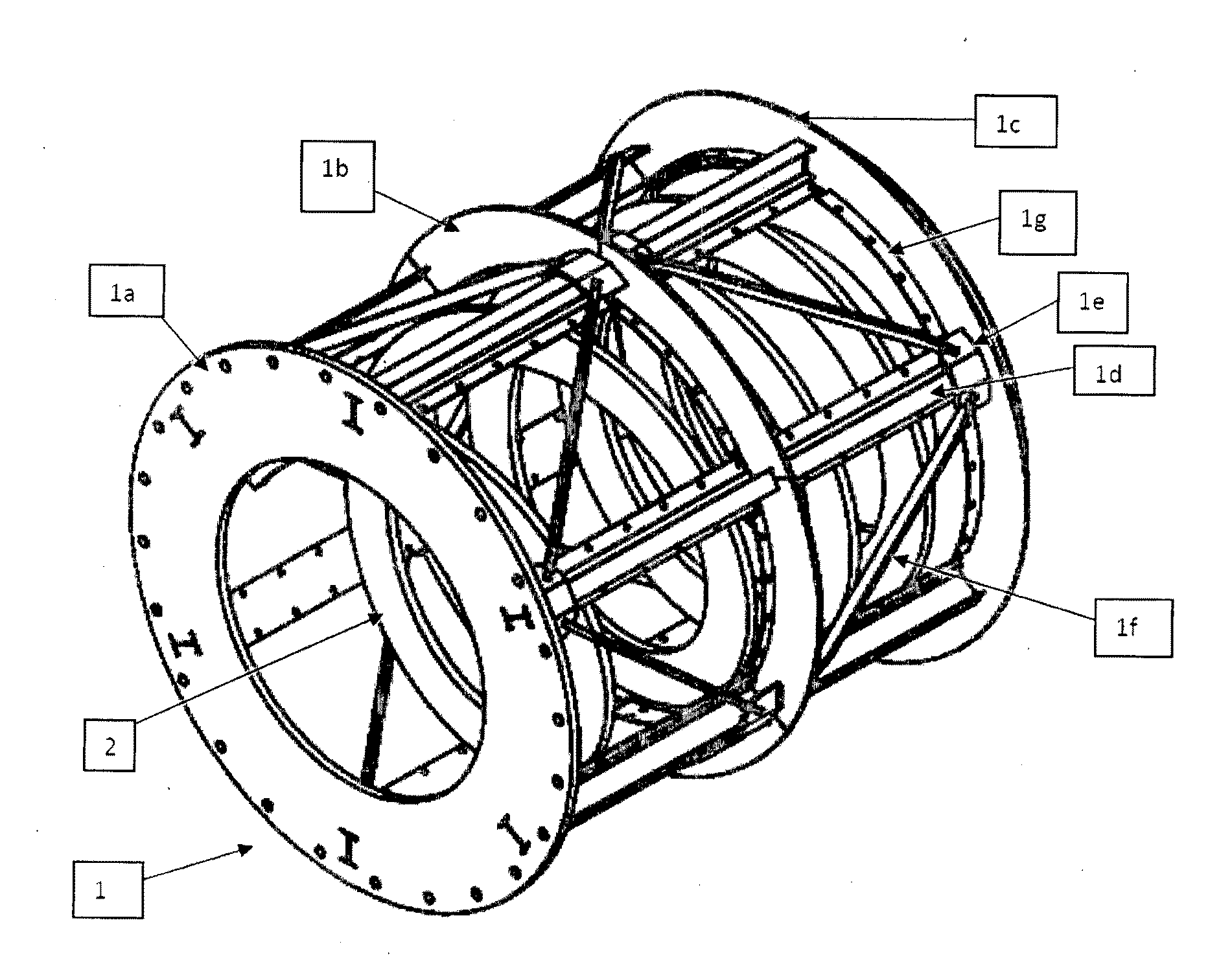

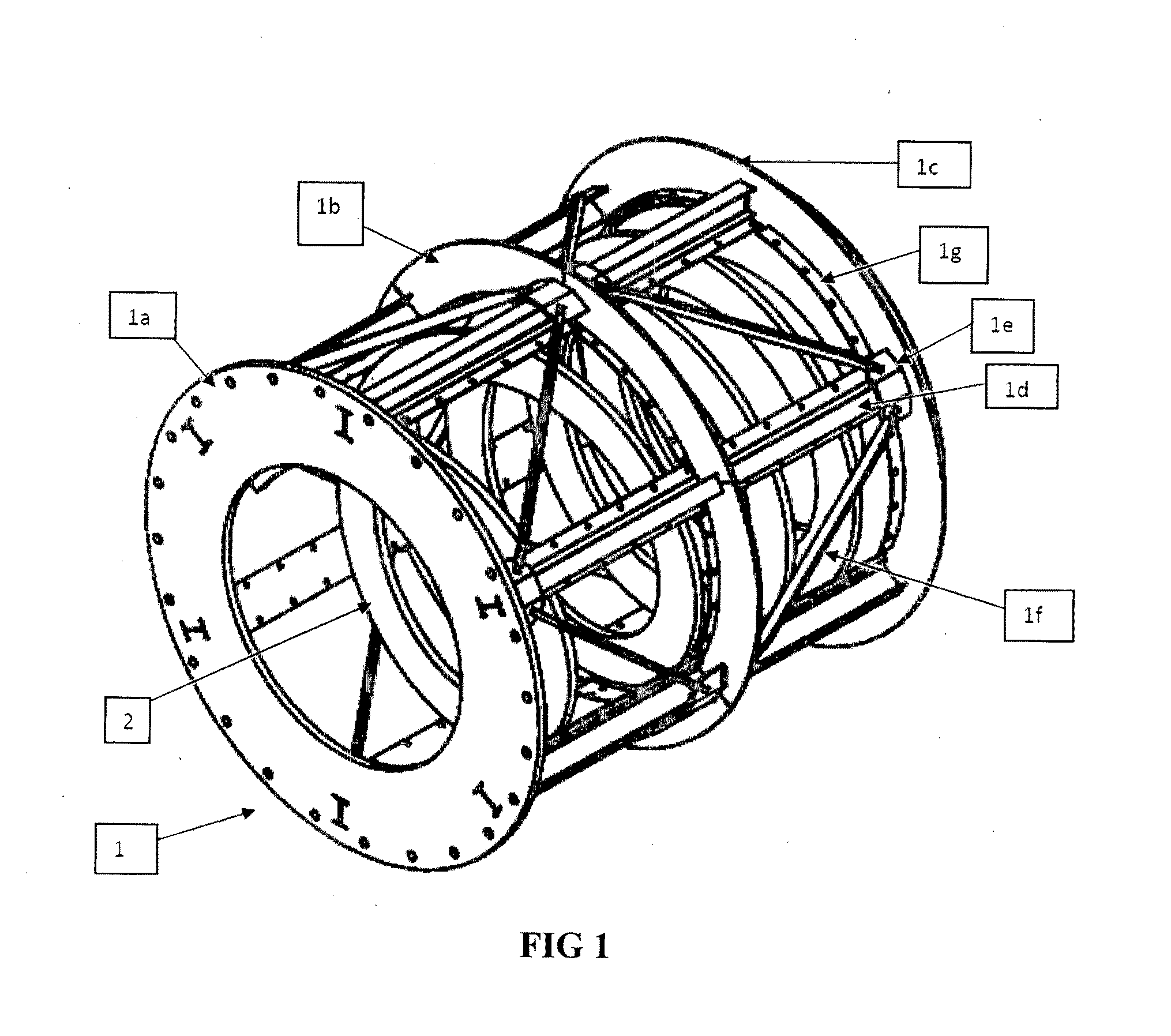

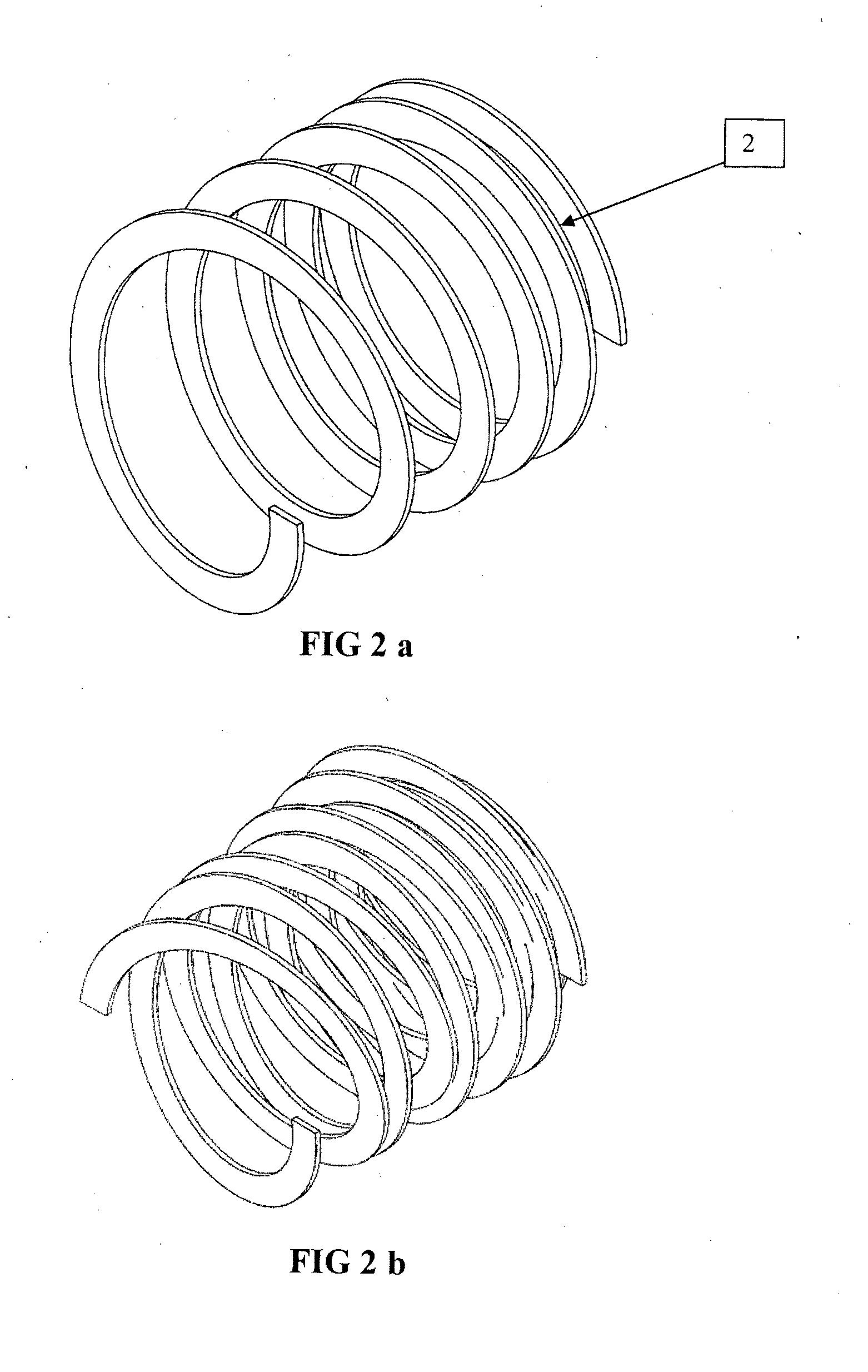

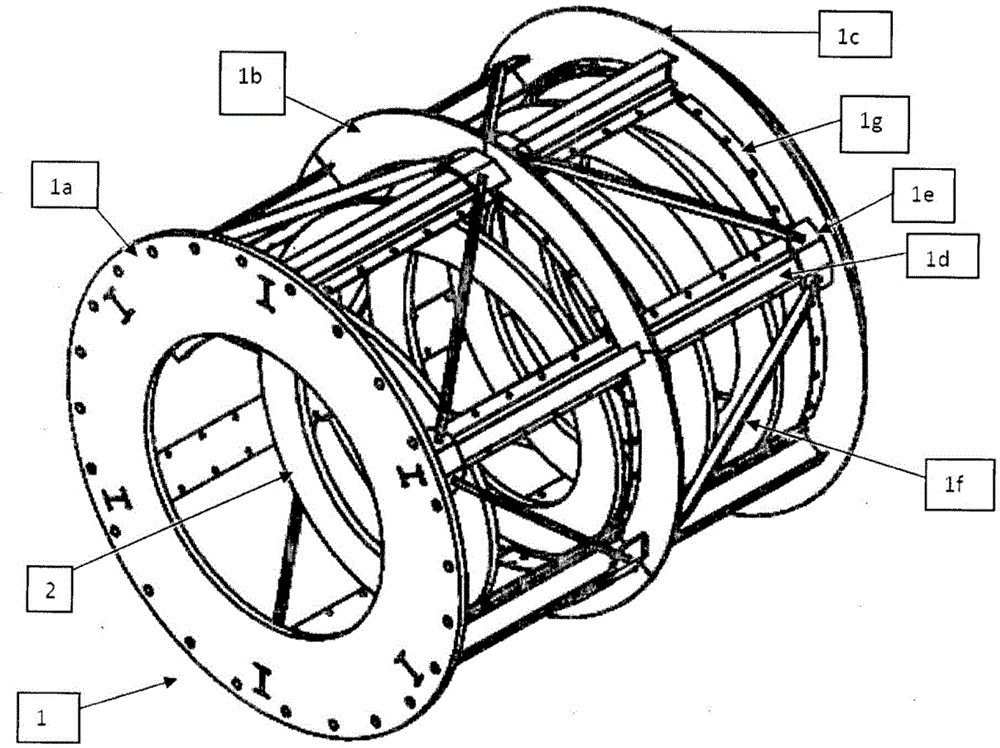

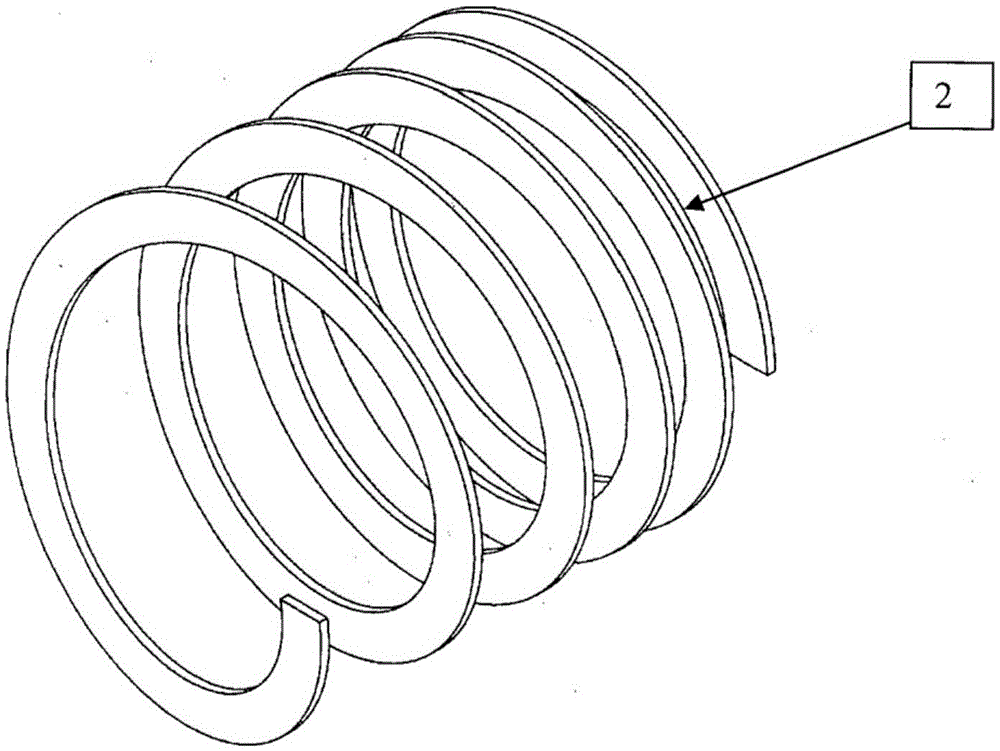

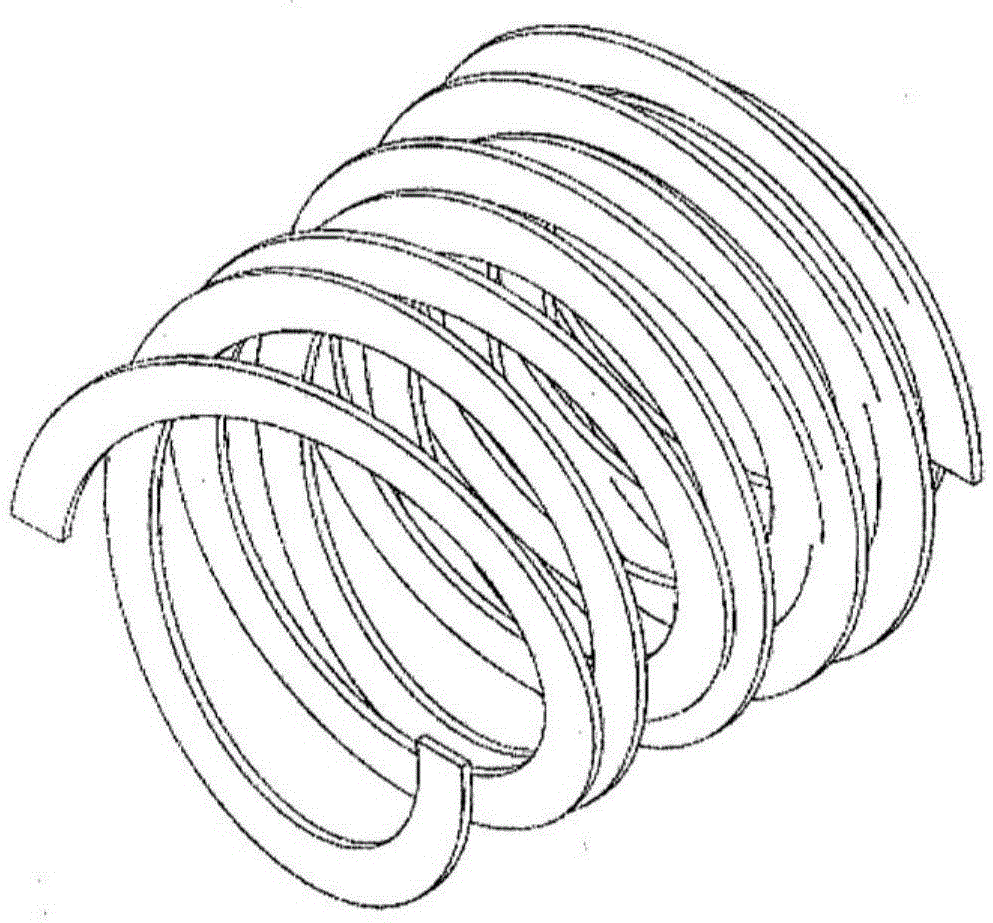

Trommel assembly having a spiral assembly with decaying pitch

InactiveUS20160129477A1Improve screening efficiencyReduce the overall heightSievingScreeningRetention timeEngineering

The trommel assembly (1) with a spiral assembly having a decaying spiral pitch (3) comprises rotating drum structure with the decaying spiral assembly (2) and screen panels (6) made of polymeric material or rubber compounds. The pitch (3) is at a maximum at the inlet and at a minimum at the outlet providing increased screening efficiency. Maximum pitch produces low media height with increased inlet velocity and minimum pitch increases media height. The spiral (2) is of single start, double start or multi start configuration. The pitch (3) decreases along the trommel such that screening efficiency is improved without affecting the retention time.

Owner:TEGA IND LTD +1

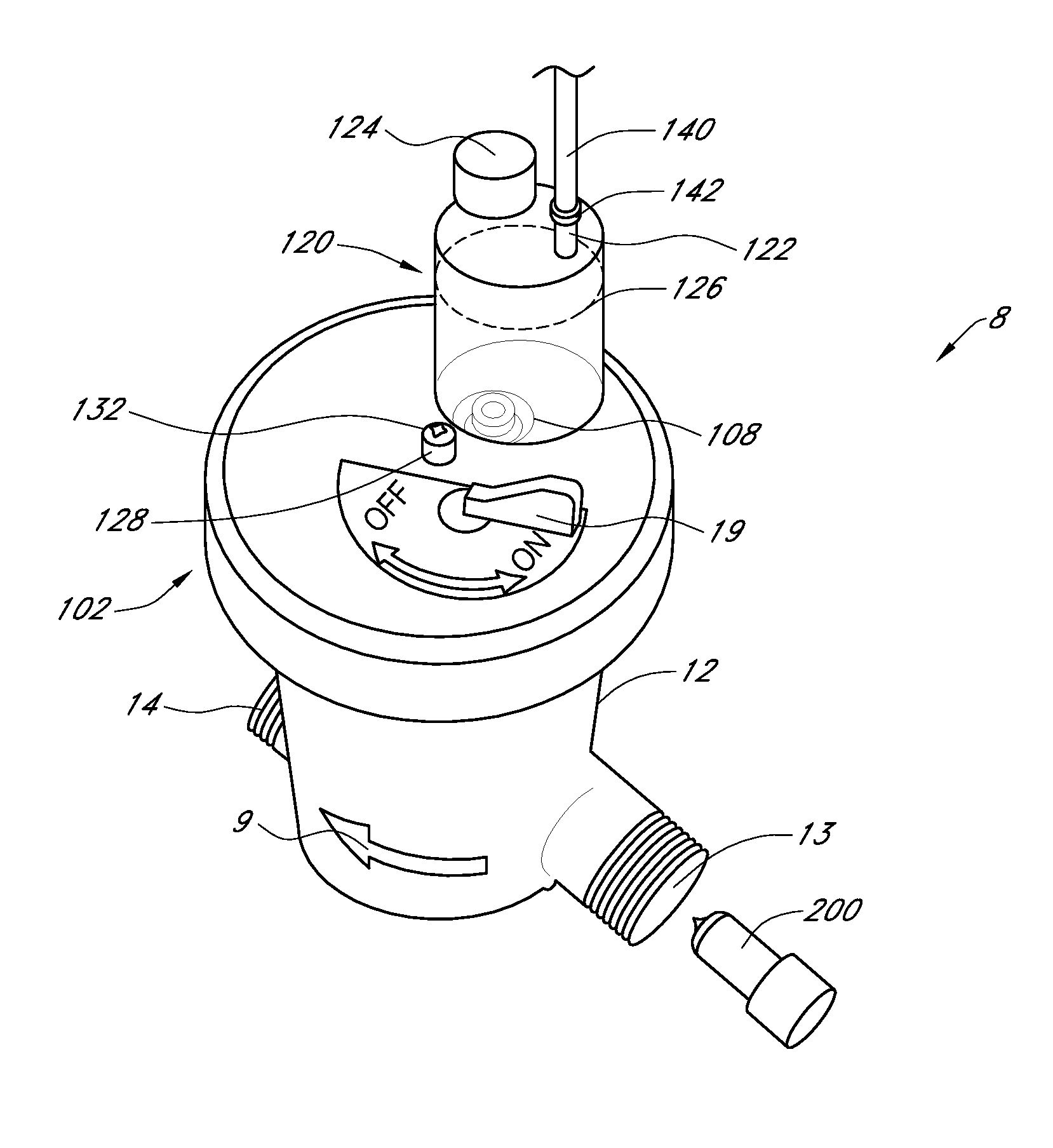

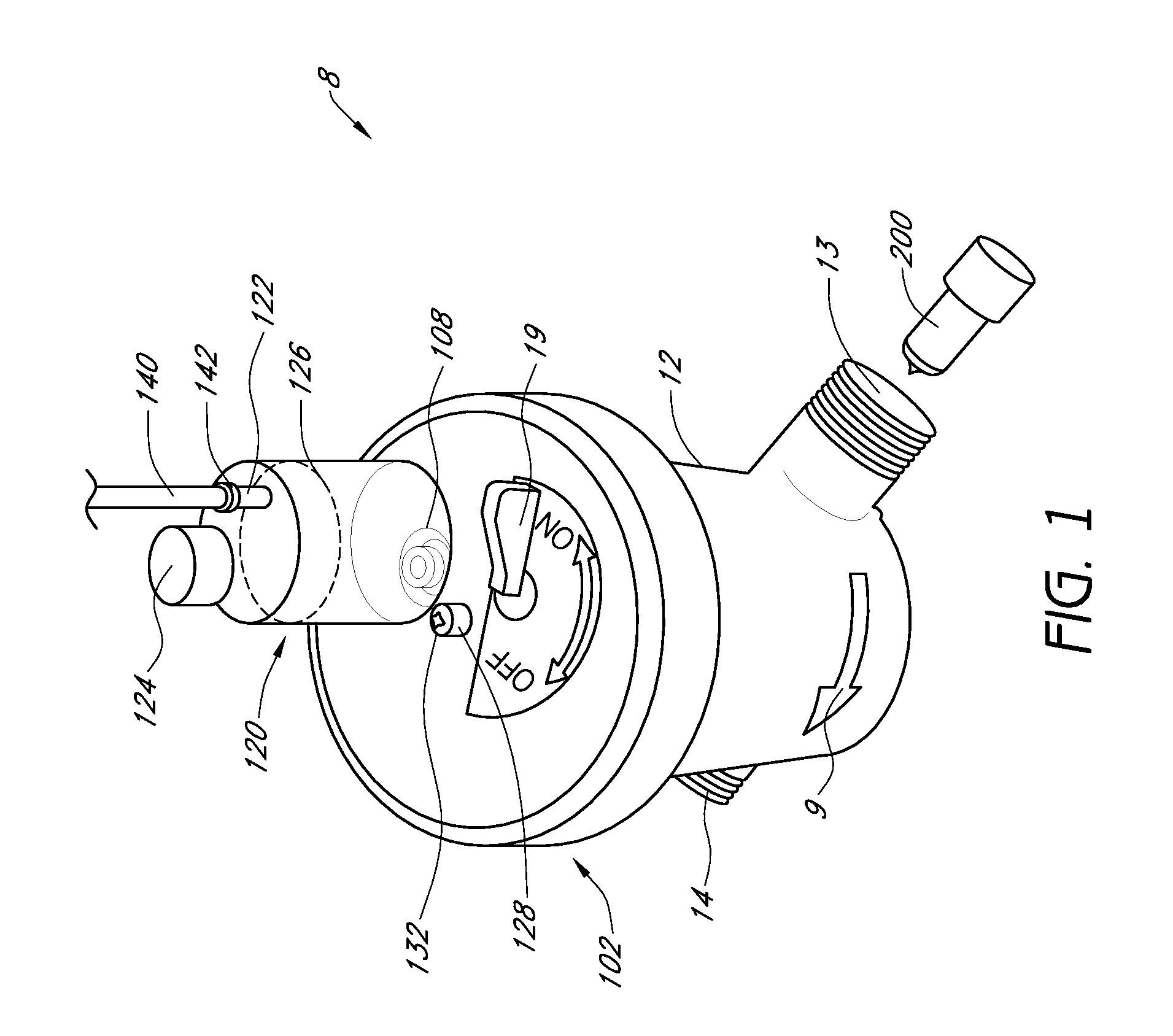

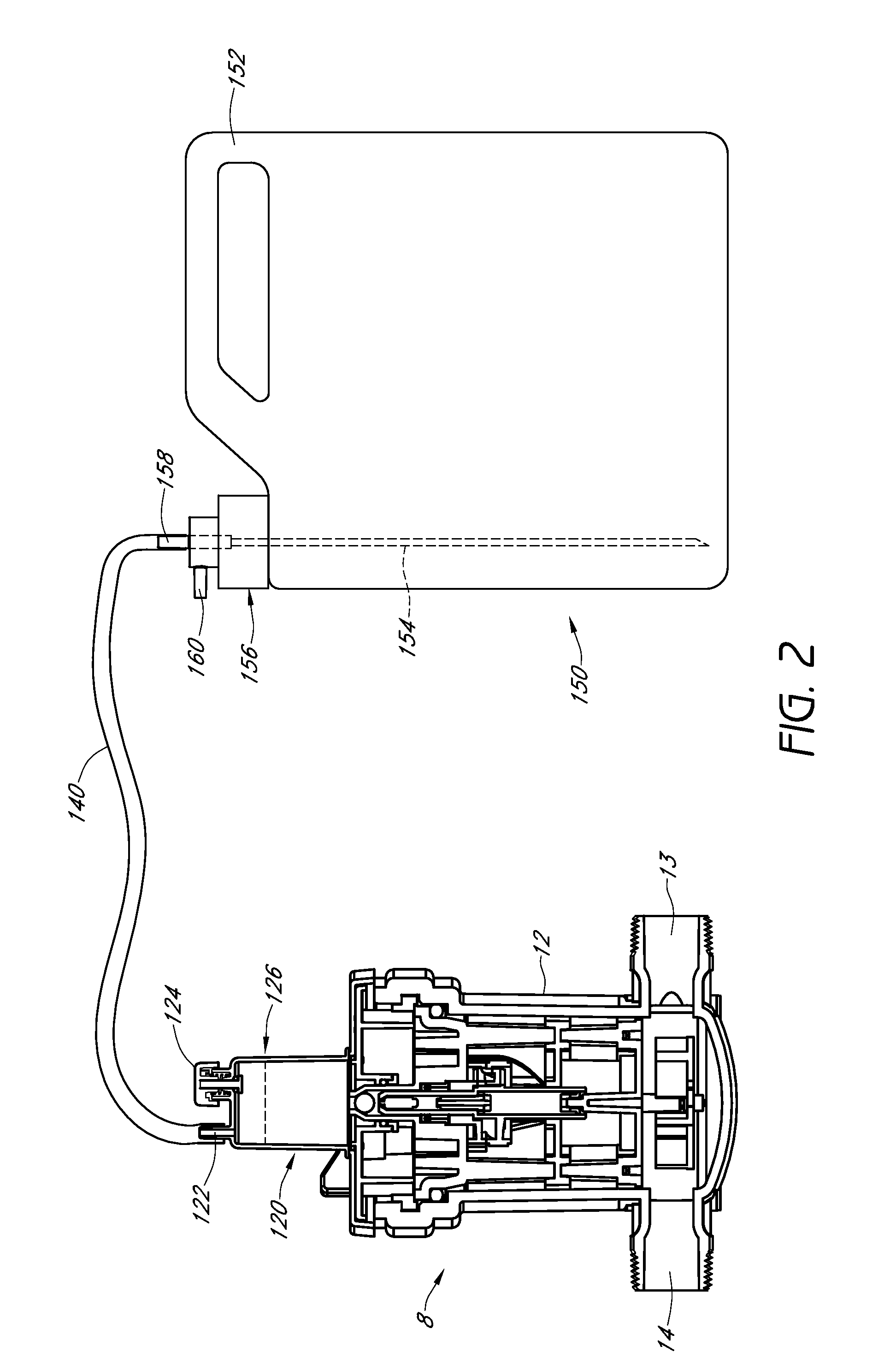

Apparatus and method for adding fertilizer or other liquids to an irrigation system

InactiveUS20100212764A1Promotes microbial actionIncrease profitFlow mixersLiquid fertiliser distributionImpellerLine tubing

Apparatus for adding liquid fertilizer to a water line of a sprinkler system includes a mechanical injector device powered by a paddle wheel turned by water flowing through the water line. As the paddle wheel is turned, liquid fertilizer can be advantageously mixed with the irrigation water or other fluid. The fertilizer reservoir can be positioned on the upper portion of the injector apparatus and can include an inlet connection and a button used to hydraulically prime the system. The fertilizer may be fed into the reservoir via tubing from a separately contained fertilizer source. In some embodiments, an inlet nozzle may increase the inlet velocity of the water, thereby permitting the paddle wheel to operate over a greater flow rate range. The tubing or other conduit can be connected to the fertilizer source container via a quick-connect fitting.

Owner:FERTILE EARTH CORP

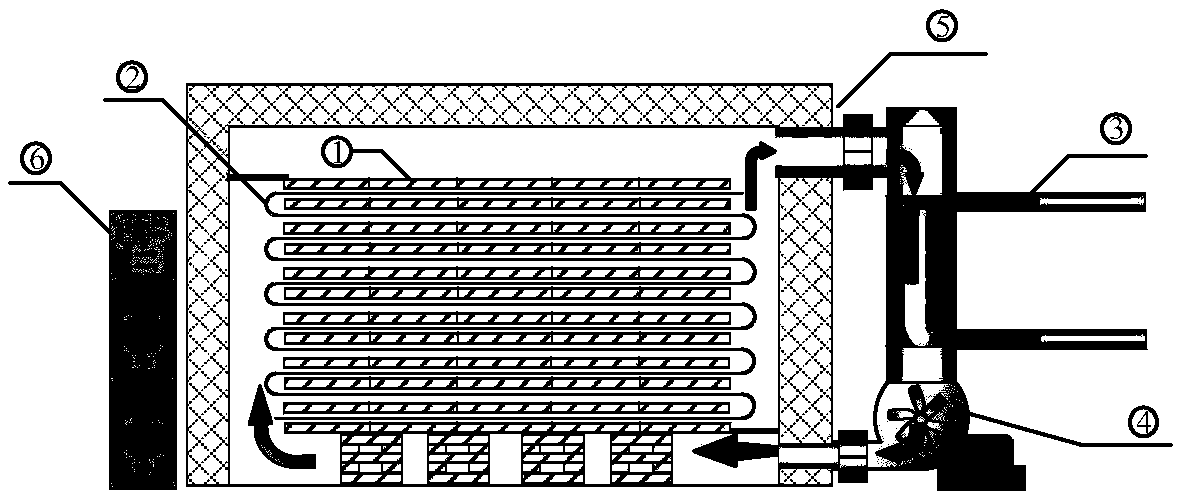

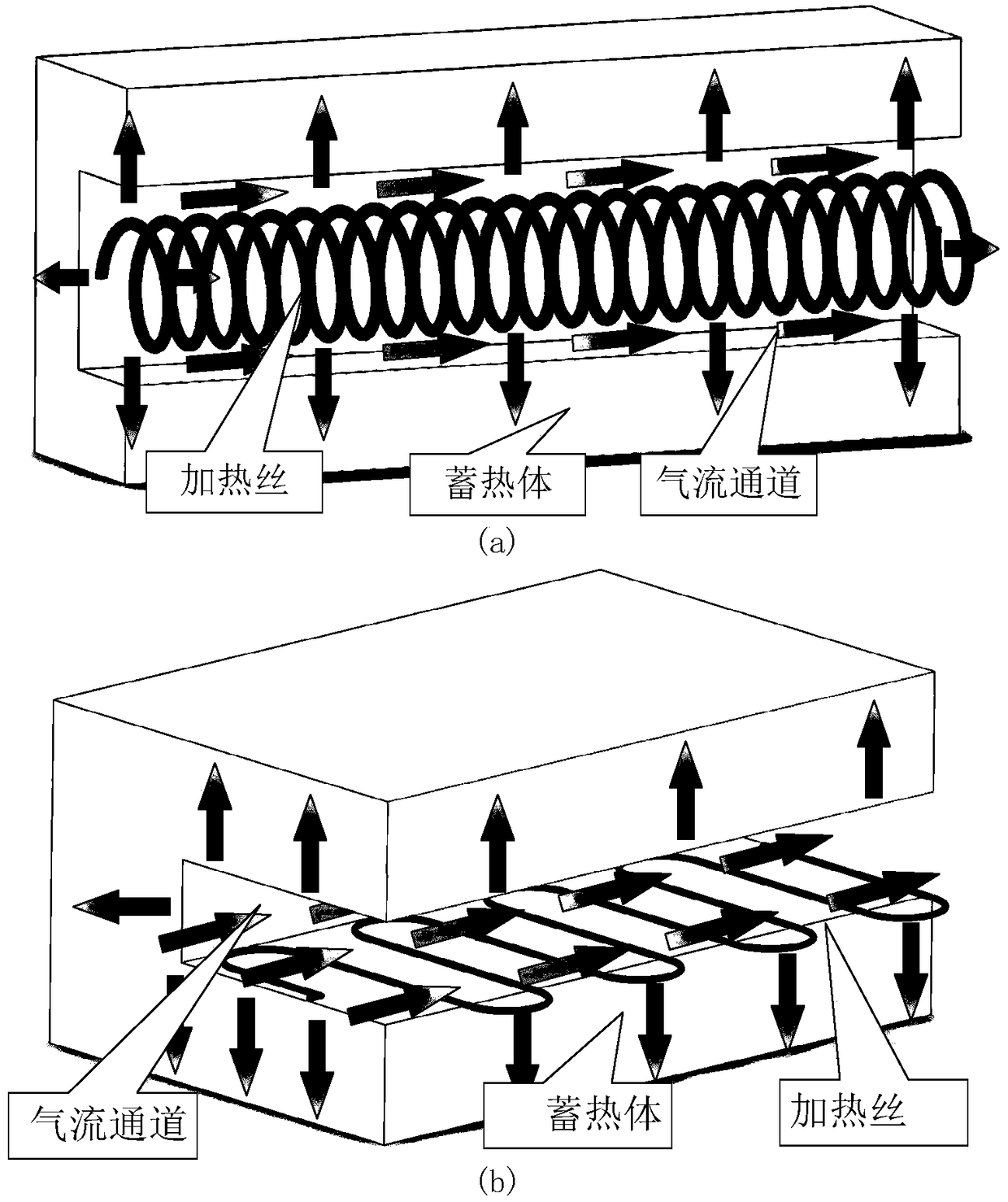

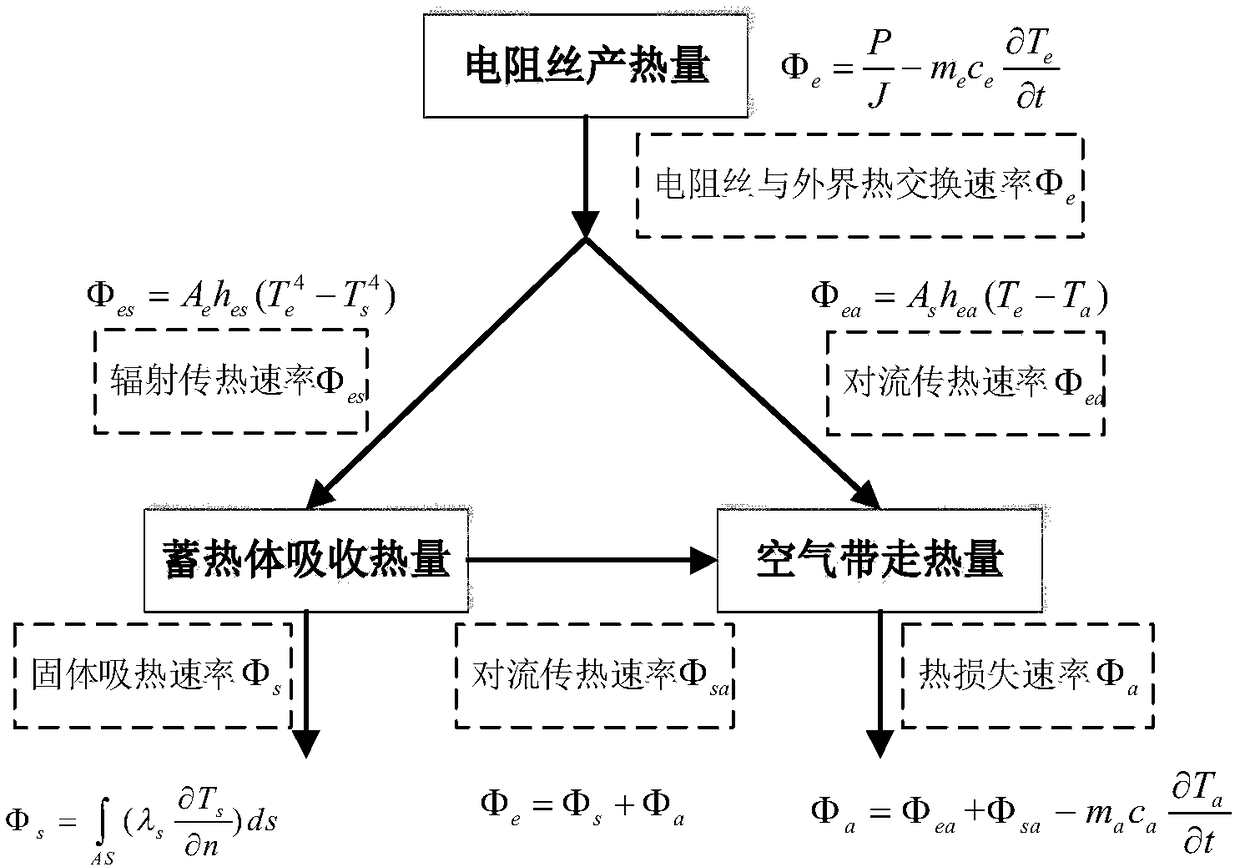

A solid-state heat storage and heating characteristic matching design method based on heat transfer rate balance

ActiveCN109446623AReduce surface temperatureExtended service lifeDesign optimisation/simulationSpecial data processing applicationsEngineeringOperating temperature range

The invention relates to a solid-state heat storage and heating characteristic matching design method based on heat transfer rate balance, which comprises the following steps of 1) obtaining structural data, material data and operating condition parameters of a high-temperature solid-state heat storage device; 2) establishing a heat transfer rate balance model between that high-temperature heat storage material and the electric resistance heating element; 3) establishing a heat transfer model between the high-temperature heat storage material and the electric resistance heating element according to the heat transfer rate balance model; 5) determining a heat transfer couple boundary condition between the air and the surface of the electric resistance heating element; 6) judging whether thesurface temperature of the electric resistance wire is in an operating temperature range. 7) obtaining the air inlet velocity parameter satisfying the design structure of the air duct of the regenerator and the operation temperature range, so that the structure and the performance of the electric heat element and the heat storage device are matched, thereby realizing the optimization of the wholestructure. (1) The rate of change of temperature is constant, according to which the heat transfer equilibrium equation can be calculated. (2) The heat storage material and the resistance wire match.(3) The shortening of the life of the electric heating element caused by the high temperature brittleness is avoided.

Owner:SHENYANG POLYTECHNIC UNIV

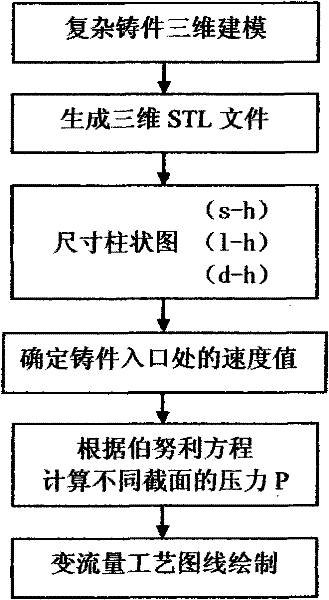

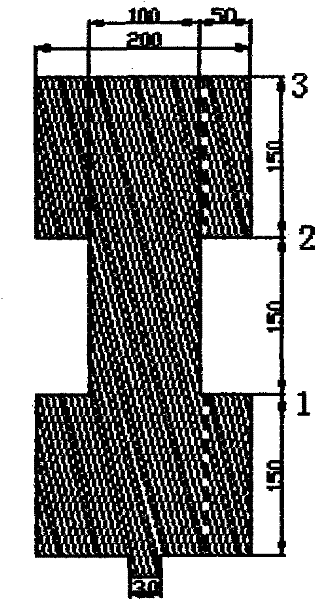

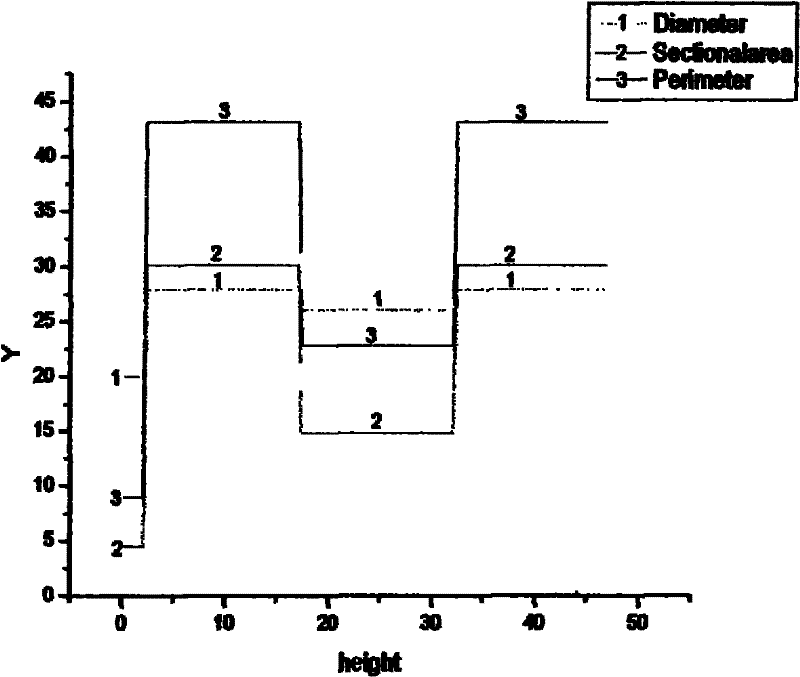

A variable flow electromagnetic low pressure mold filling method for aluminum alloy melt

An electromagnetic low-pressure mold filling method with variable flow rate of aluminum alloy melt is applied in the field of advanced manufacturing technology. The specific process is: three-dimensional modeling of castings and process drawings; generation of three-dimensional STL data files; Calculate the casting height (h), cross-sectional area (s) and perimeter (1) corresponding to the layer and the equivalent diameter (d) corresponding to each height, and use the equivalent diameter value at each place to calculate the average iso-flow pipe The diameter of the complex cross-section mutation casting is converted into a simple casting of the iso-flow tube type; the regular curve of the critical inlet velocity value of the ingate corresponding to the ratio of the cavity area to the ingate area obtained by the numerical simulation of the flat casting , to obtain the velocity value at the entrance of the casting; then use the actual liquid Bernoulli equation of fluid mechanics to calculate the pressure at different interfaces, so as to determine the P-t curve of the variable flow filling process of the casting; according to the variable flow P-t curve, use electromagnetic force to control the metal Hydraulic low pressure filling. The beneficial effect of the invention is that it can realize stable filling of the aluminum alloy melt, and the phenomena of splashing and air entrainment are not easy to occur during the filling process, thereby ensuring the quality of the casting.

Owner:北京北方恒利科技发展有限公司

Process for removing solid particles from a gas-solids flow

ActiveUS20060059870A1Speed up the processCombination devicesDispersed particle filtrationGas solidReactor system

Catalyst losses are prevented in riser reactor systems by using a low inlet velocity for the first cyclone separator in each multi-stage cyclone separator in the reactor. Catalyst particles not separated from the product output flow in an oxygenate-to-olefin reactor are also recaptured by cooling the product output flow and passing the flow through an electrostatic precipitator.

Owner:EXXONMOBIL CHEM PAT INC

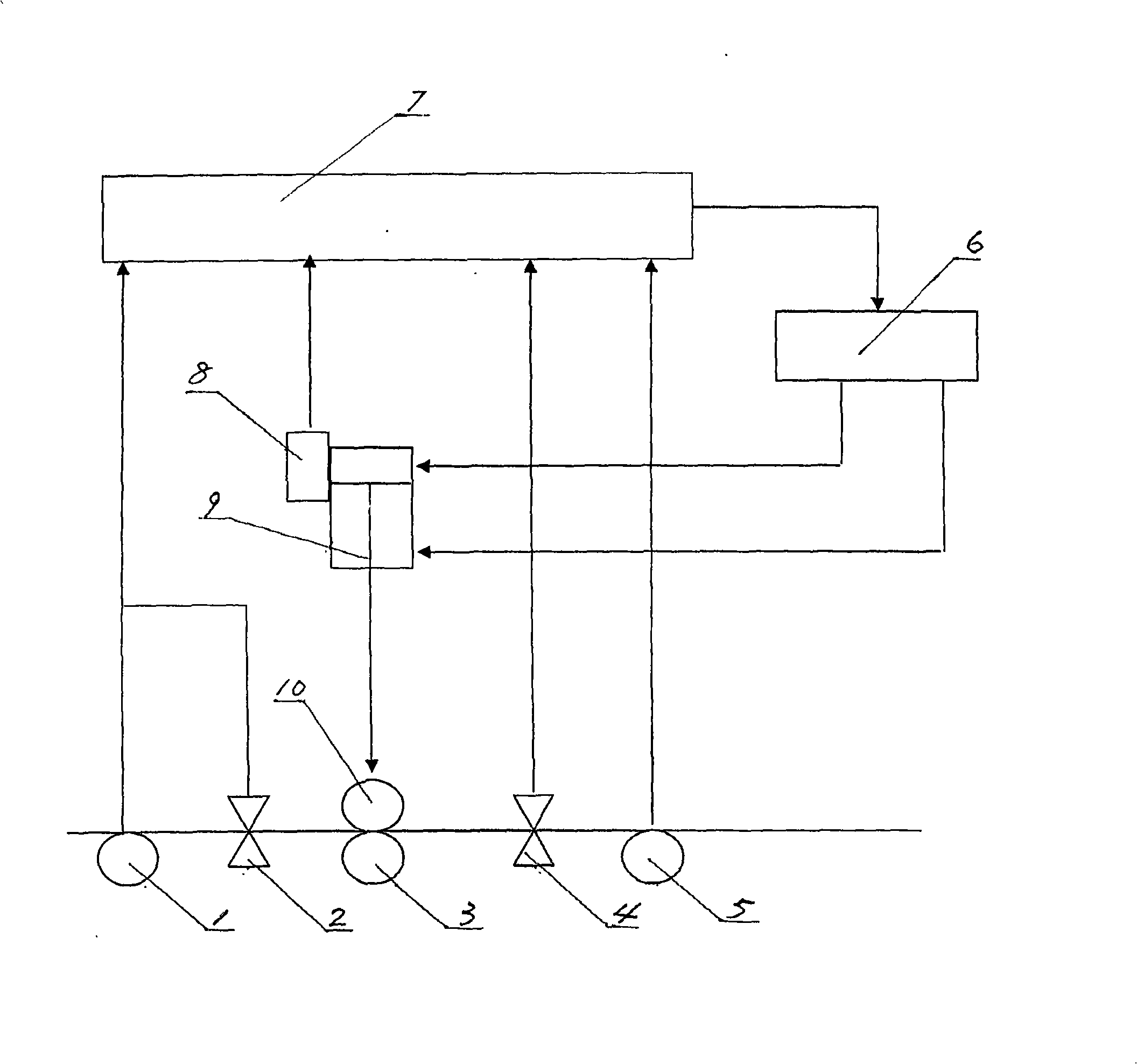

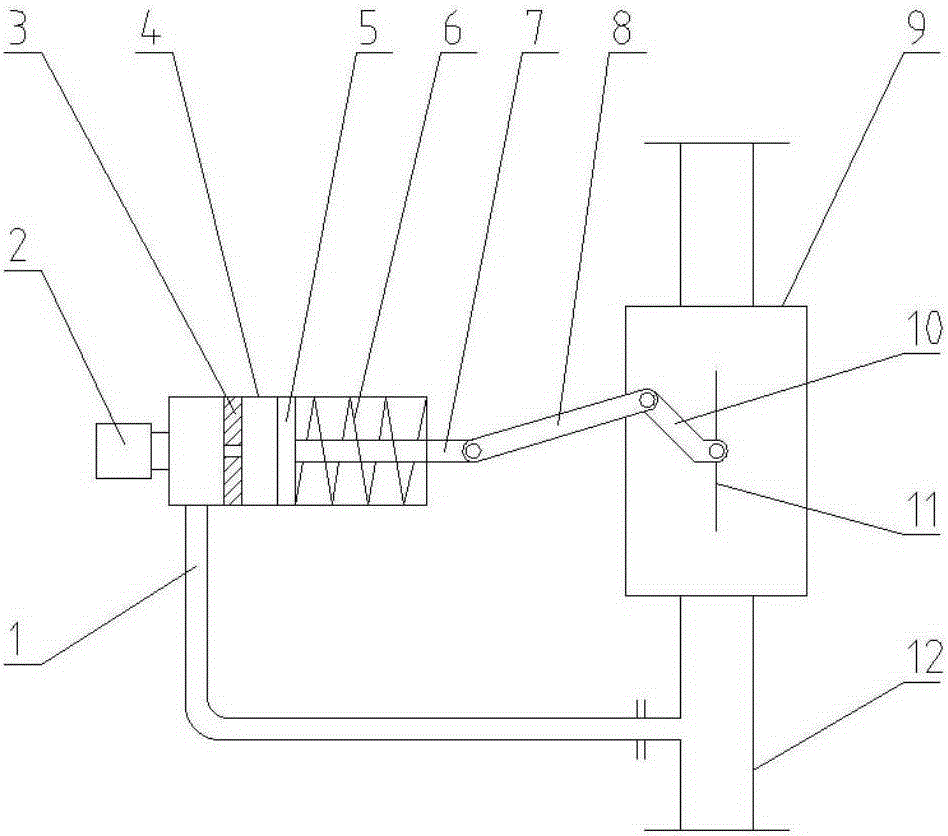

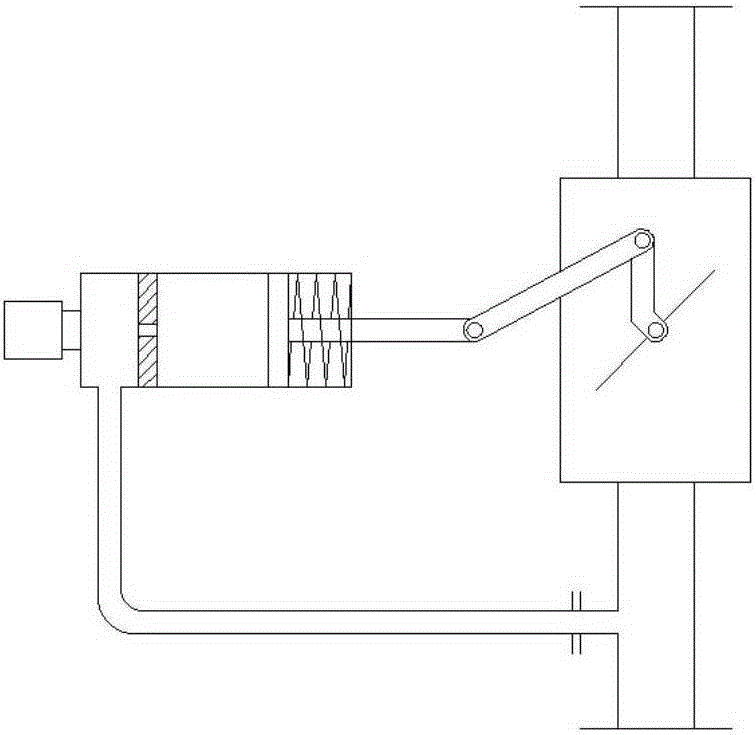

Automatic thickness control system for roller mill

InactiveCN101314166ANo manual adjustment requiredRoll mill control devicesMetal rolling arrangementsControl systemEngineering

The invention discloses an automatic thickness control system for a rolling mill, which comprises the rolling mill. The system is characterized in that: the system is also provided with a computer, a servo mechanism and a screwdown oil cylinder. The screwdown oil cylinder is positioned on the upper part of the rolling mill, a piston rod of the screwdown oil cylinder is downward and is connected with bearing supports at both ends of a working roll on the rolling mill, and an oil inlet and an oil outlet of the screwdown oil cylinder are respectively communicated with an oil inlet and an oil outlet of the servo mechanism. A control end of the servo mechanism is connected with the computer. The screwdown oil cylinder is provided with a position sensor which is connected with the computer by means of a conducting wire. An inlet side and an outlet side of the rolling mill are respectively provided with an inlet velocity measuring roll and an outlet velocity measuring roll which are both provided with encoders, and the two encoders are both connected with a tachometer circuit in the computer by means of conducting wires. The inlet side and the outlet side of the rolling mill are respectively provided with an inlet thickness tester and an outlet thickness tester which are both connected with a deviation port of the computer by means of conducting wires. The automatic thickness control system can guarantee the rolling quality of strip materials so that rolled strip materials have higher quality, and is applicable to control the rolling thickness of the strip materials.

Owner:WUXI HUANSHENG METAL PRODS

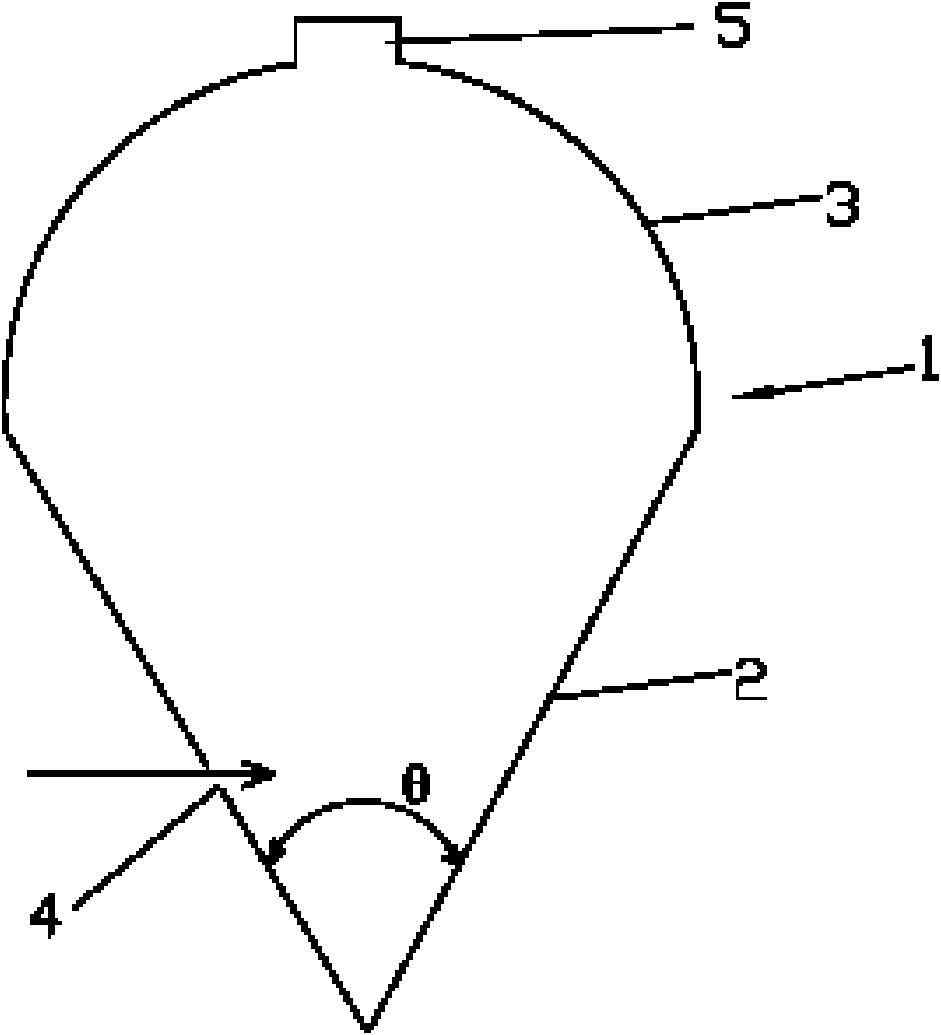

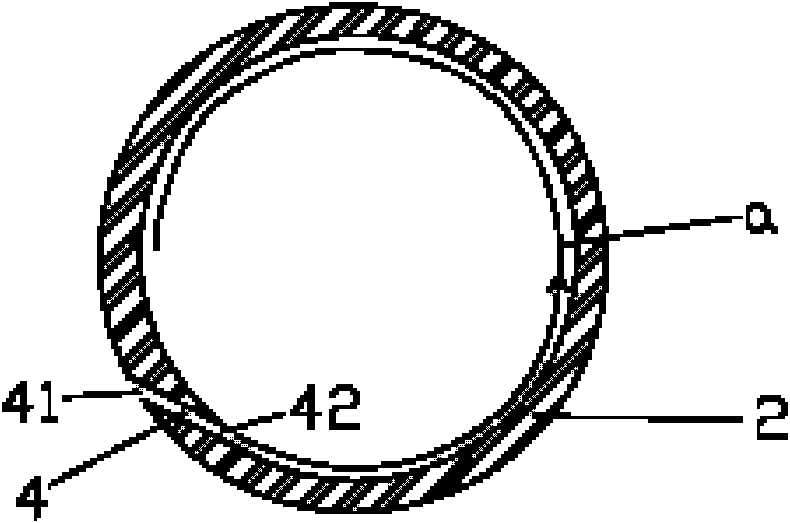

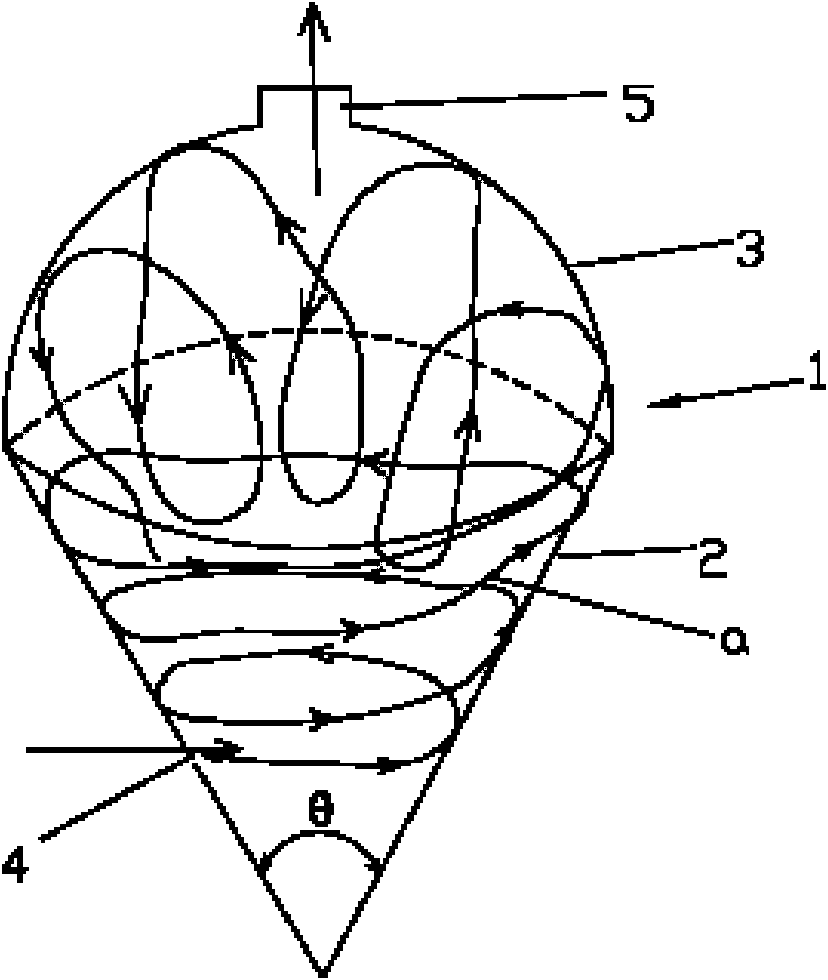

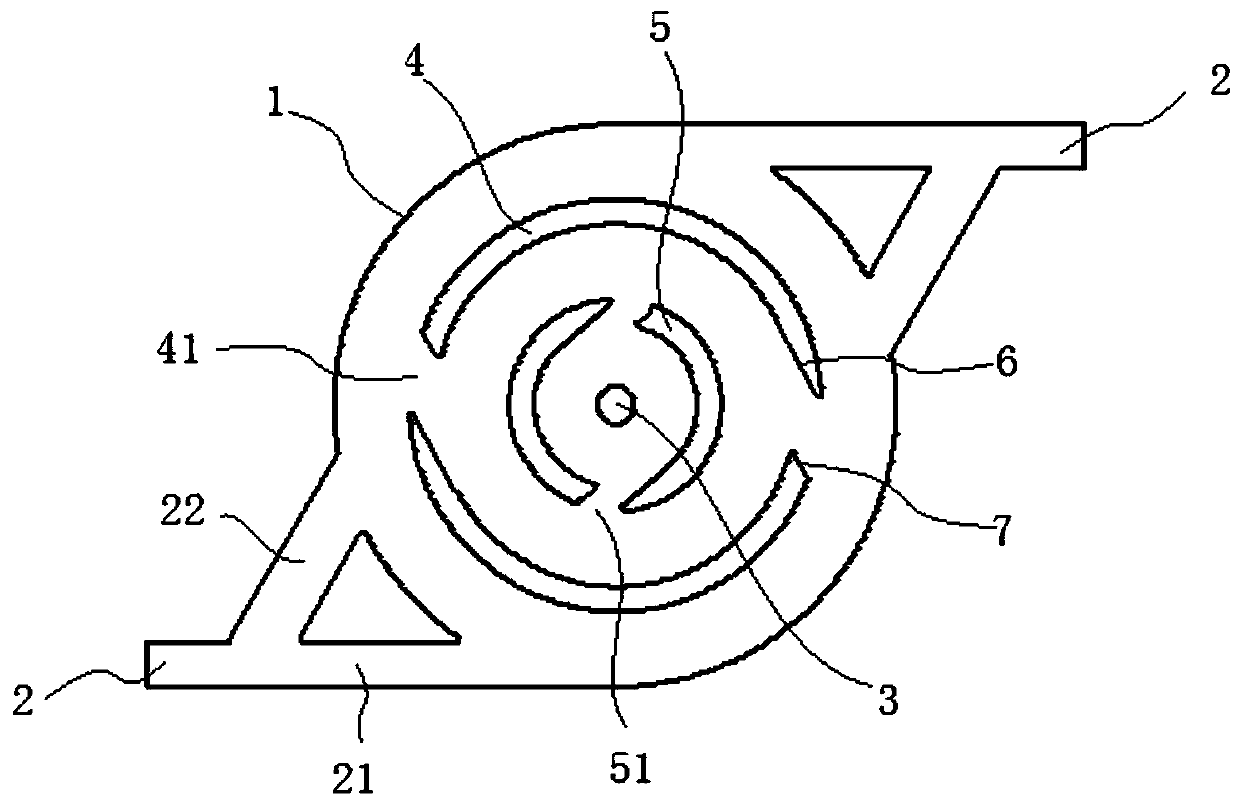

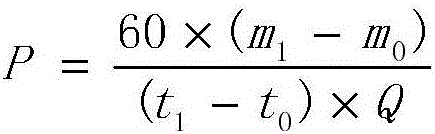

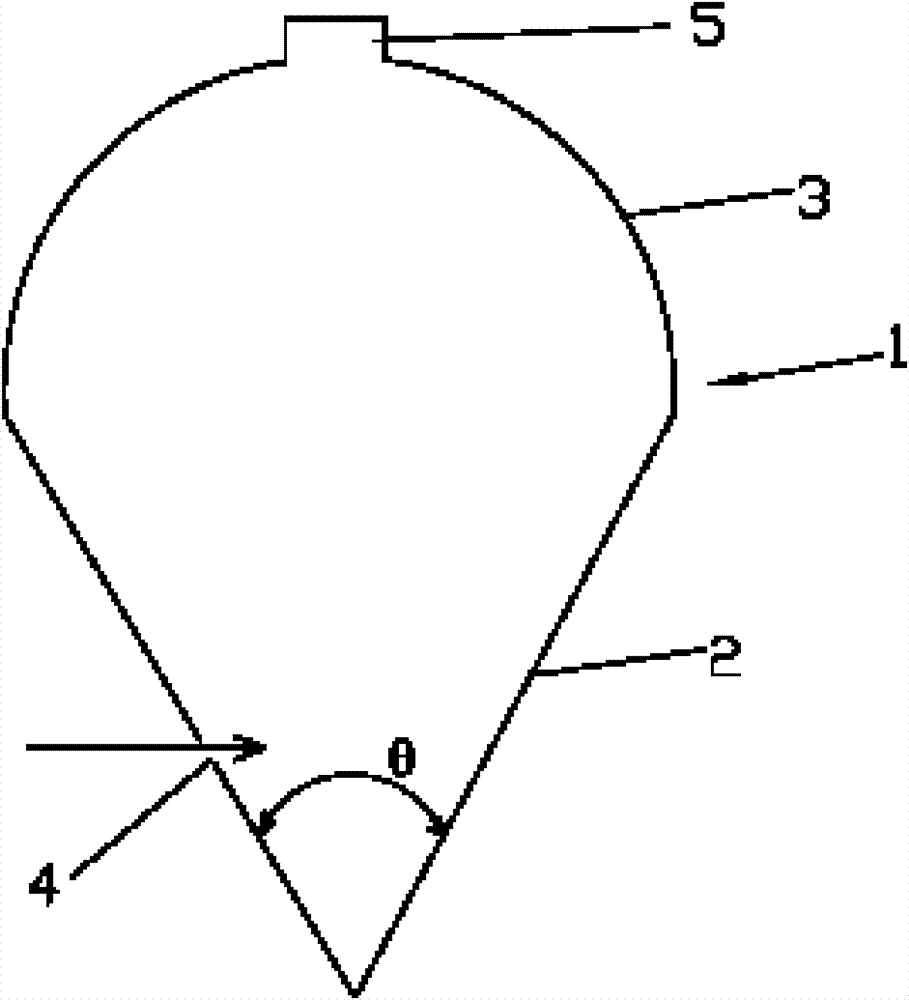

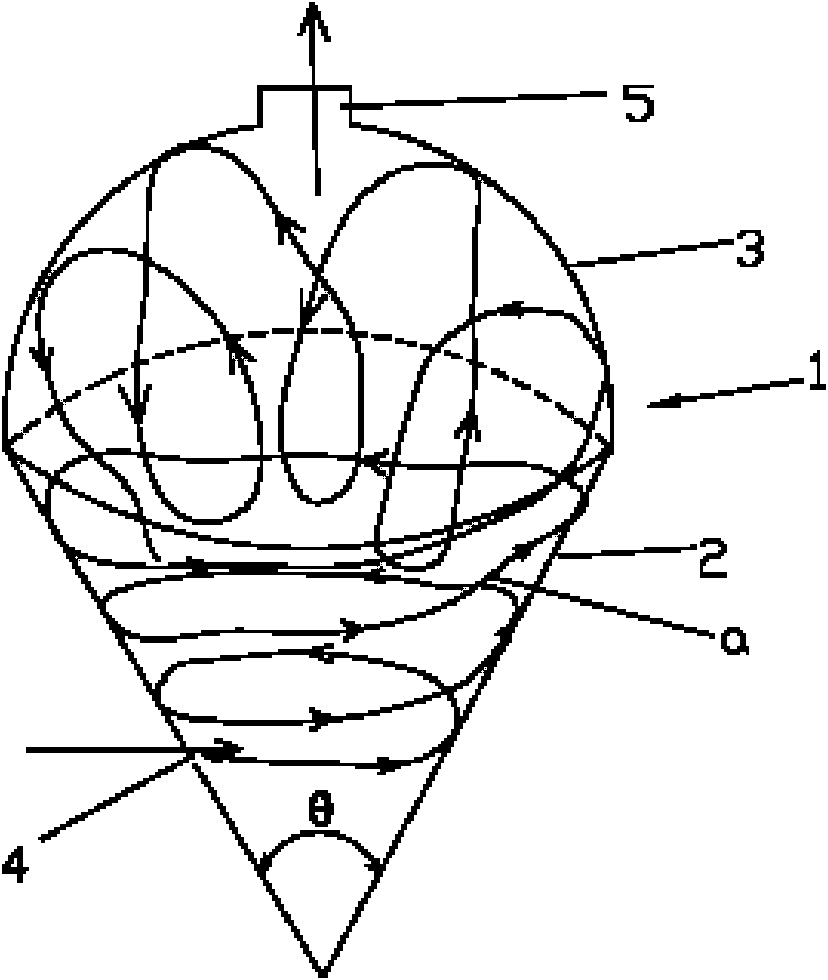

Reactor and method for realizing completely-mixed flow of gas-phase or gas-solid two-phase fluid

InactiveCN101829534ARealize full mixed flowSimple structureTransportation and packagingMixersGas solidMixed flow

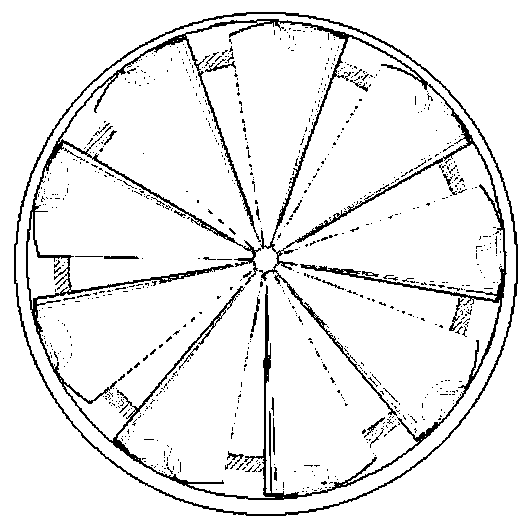

The invention discloses a reactor for realizing the completely-mixed flow of gas-phase or gas-solid two-phase fluid, which comprises an upper part and a lower part, wherein the upper part is connected with the lower part; the upper part and the lower part both are revolving bodies; the upper and lower revolving bodies have a structure in which the diameters of the sections of the revolving bodiesincrease gradually from the bottoms of the revolving bodies to the connection part of the upper and lower revolving bodies. The lower revolving body of the reactor is provided with at least a gas feeding channel, the top of the reactor is provided with an air outlet, and the gas feeding channel is arranged along the tangential direction of the inner periphery of the lower revolving body of the reactor. The invention also discloses a method for realizing an completely-mixed flow reaction by using the reactor, which comprises the steps of forming a spiral vertex flow first after feeding the gas, then forming an up-and-down vertex flow, and mixing the spiral vertex flow and the up-and-down vertex flow to realize back-mixing. The reactor can realize a gas-phase or gas-solid two-phase reactionby using the structure of the reactor, and has a simple structure, and can make the non-dimensional variance close to 1 by combining with the parameters such as inlet velocity and the like, thereby realizing the complete mixing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

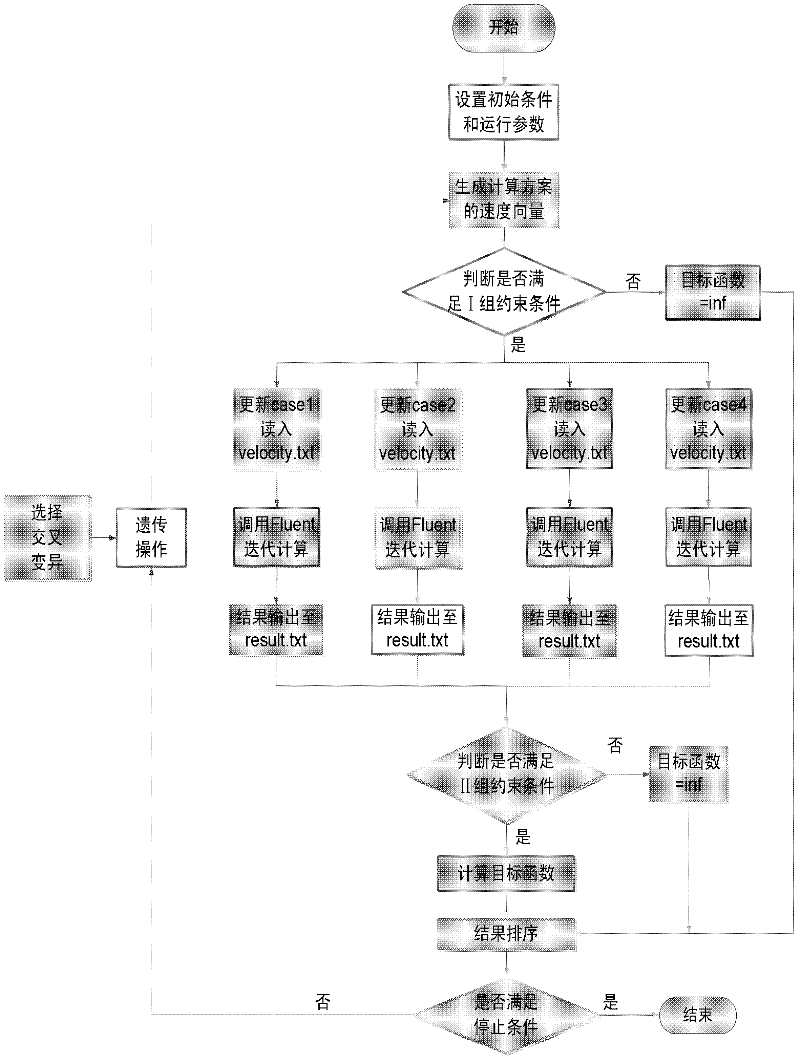

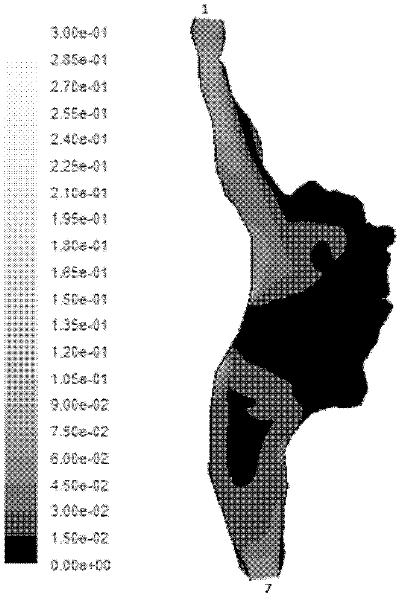

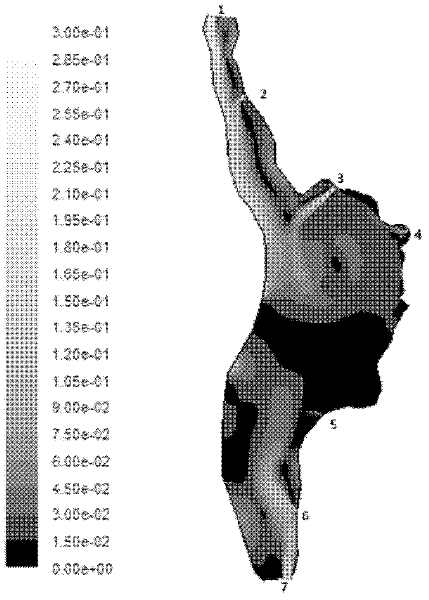

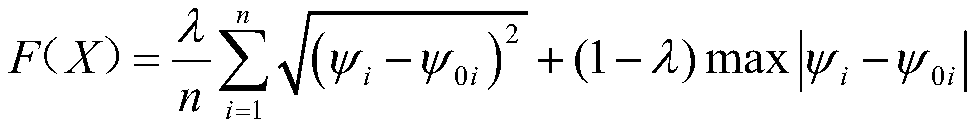

Design method for optimizing flow regime of urban large-size slow-flow landscape water bodies

InactiveCN102542108ATroubleshoot screening issuesReduce simulation calculation timeSpecial data processing applicationsWater flowWater quality

The invention relates to a design method for optimizing flow regime of urban large-size slow-flow landscape water bodies, provides design of optimizing the flow regime of slow-flow water bodies and operation evaluation index, and provides a design and operation method to water bodies with different circulation flows and different inlet velocities. The design method adopts multi-target optimal models to represent the mentioned problems, and analog computation speed is increased greatly by the aid of parallel computation technology on the basis of selecting the optimization algorithm to solve. Since the optimization index of the flow regime is put forwards and multiple schemes are subjected to analog computation and comparison, parameters including the water body flow weighted mean, water body velocity distribution parameters, low-flow water body percentage and the like obtained from the optimum scheme are better than corresponding indexes generated from a water body circulation scheme put forwards by the existing computation method, and water body circulation effect and water body quality are improved accordingly.

Owner:TIANJIN UNIV

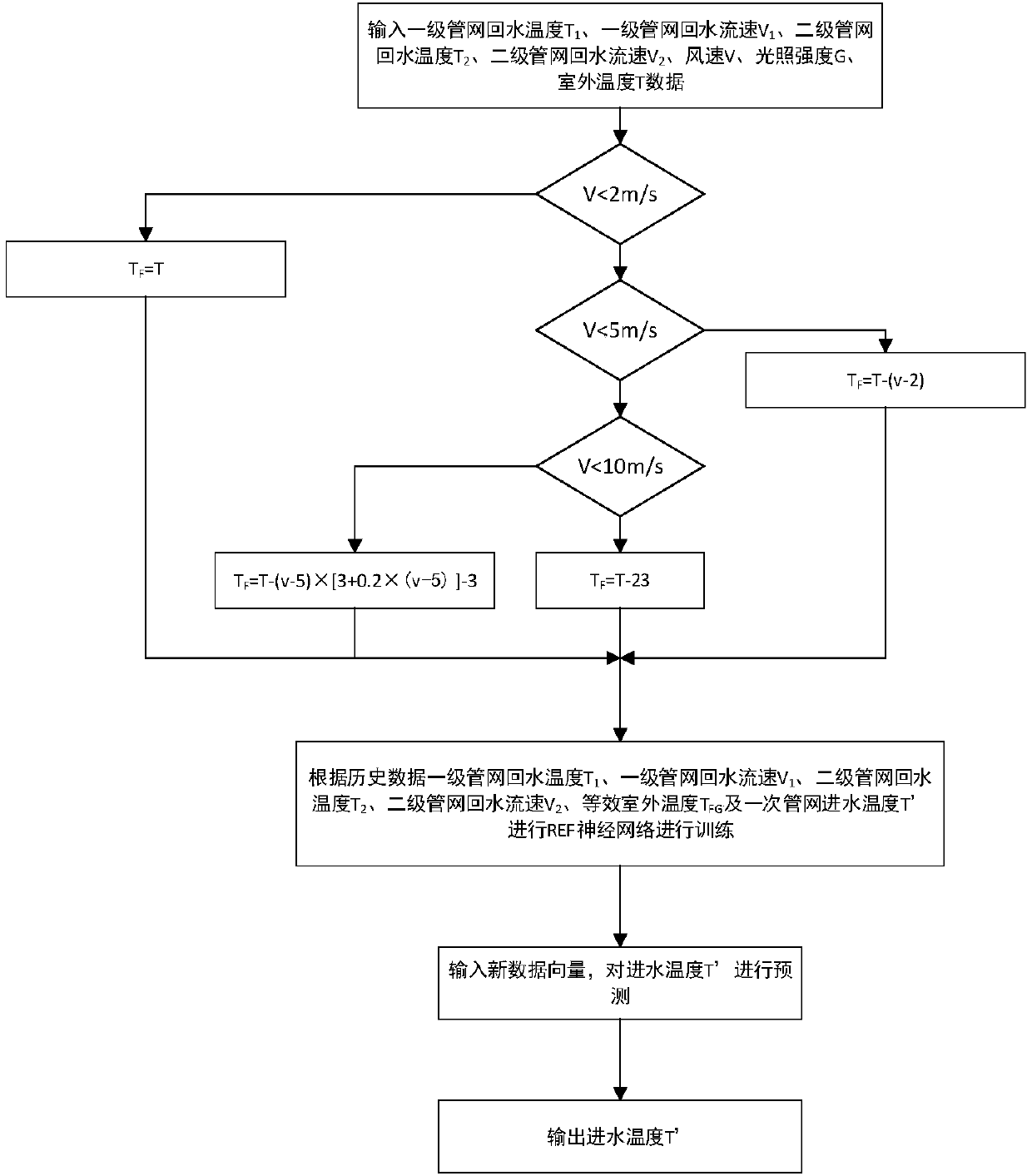

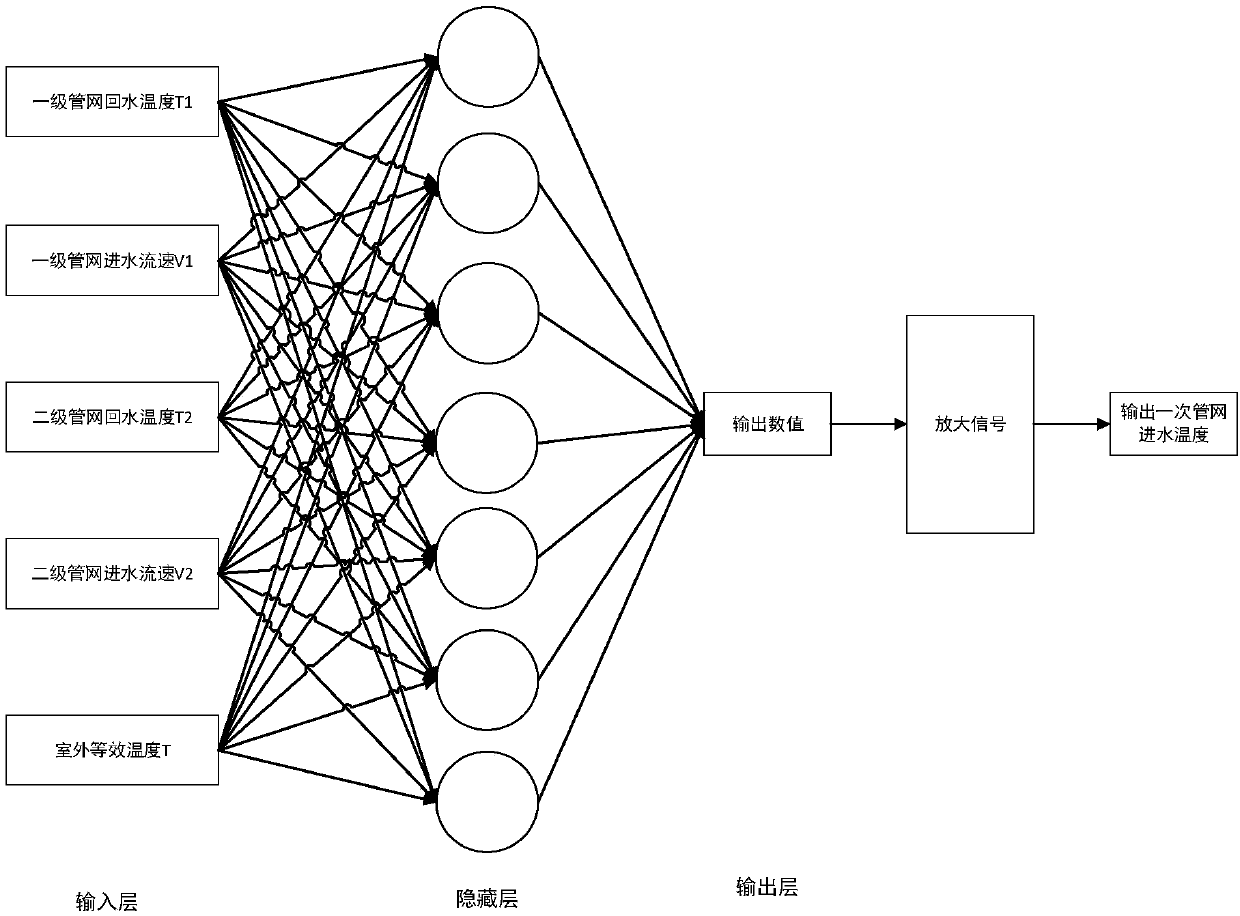

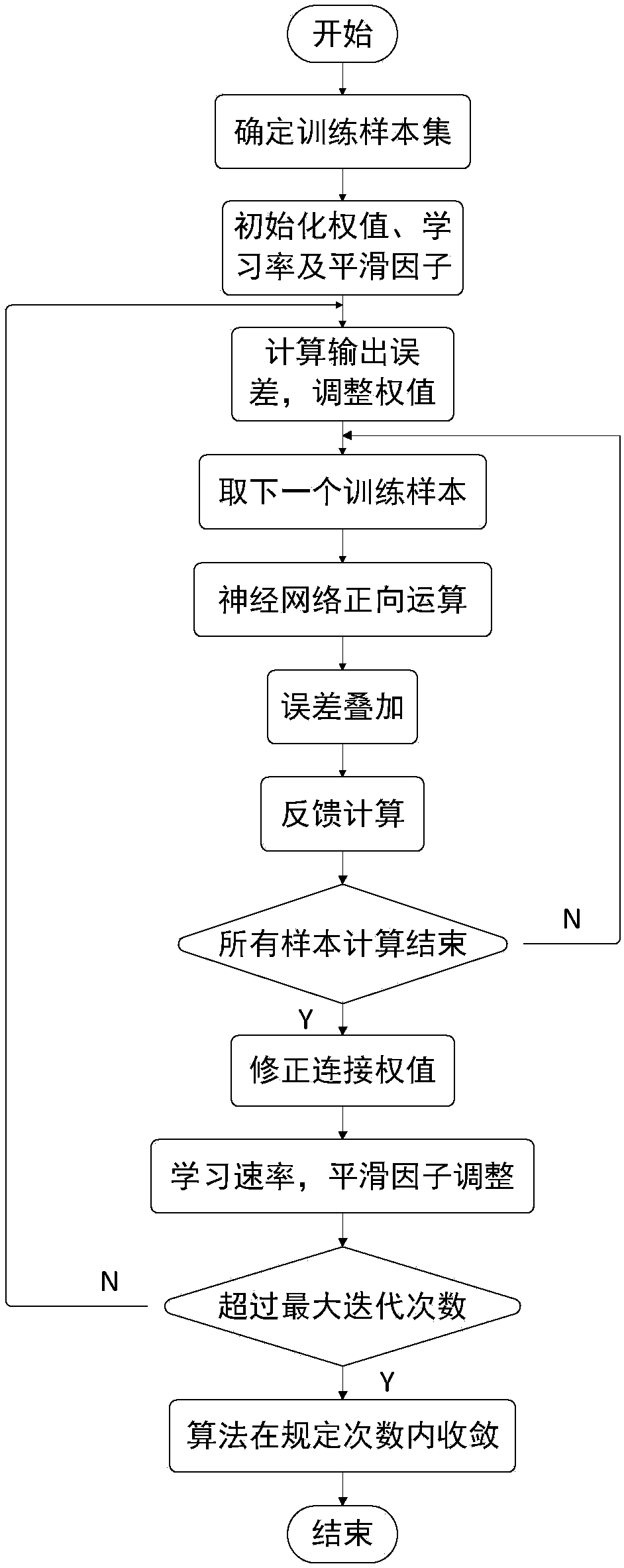

Energy supply feedback and meteorology factor thermal load prediction method

InactiveCN108376294ARealize joint unified schedulingTo achieve the purpose of heat load forecastingForecastingNeural learning methodsNerve networkEnergy supply

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST

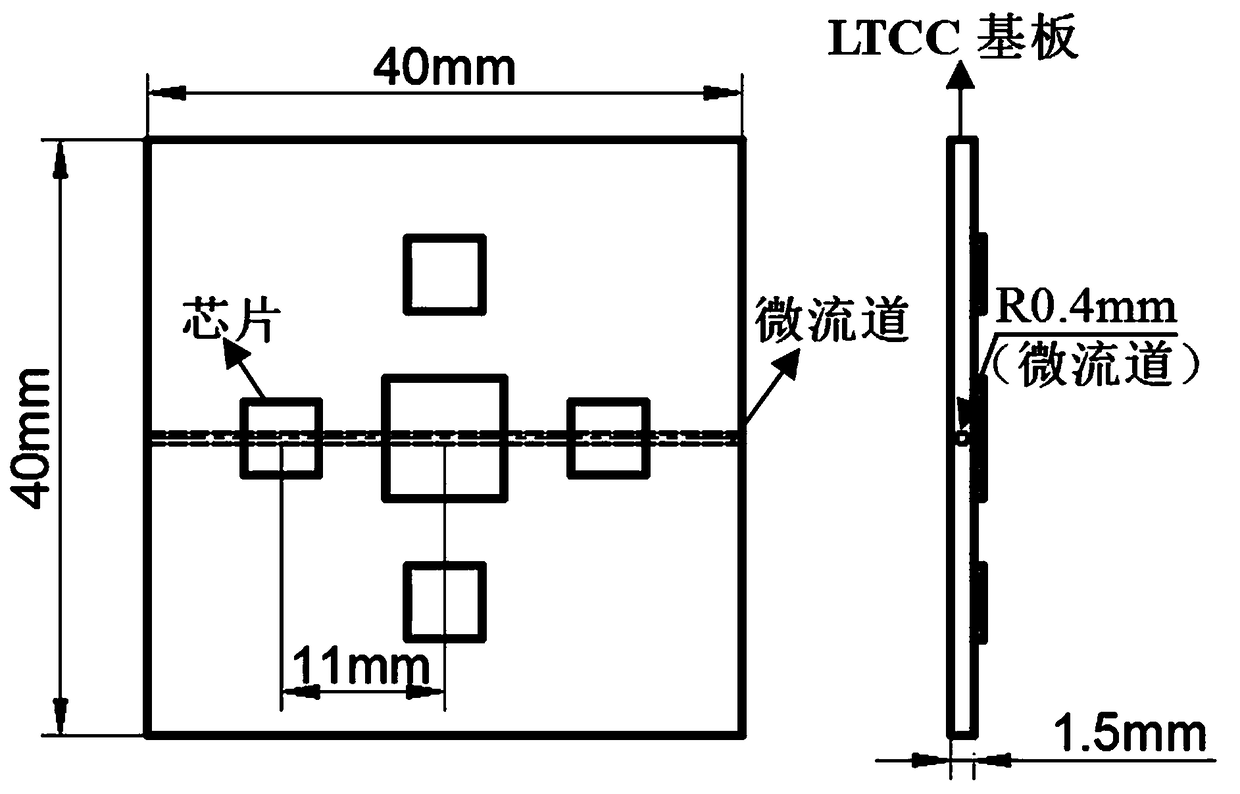

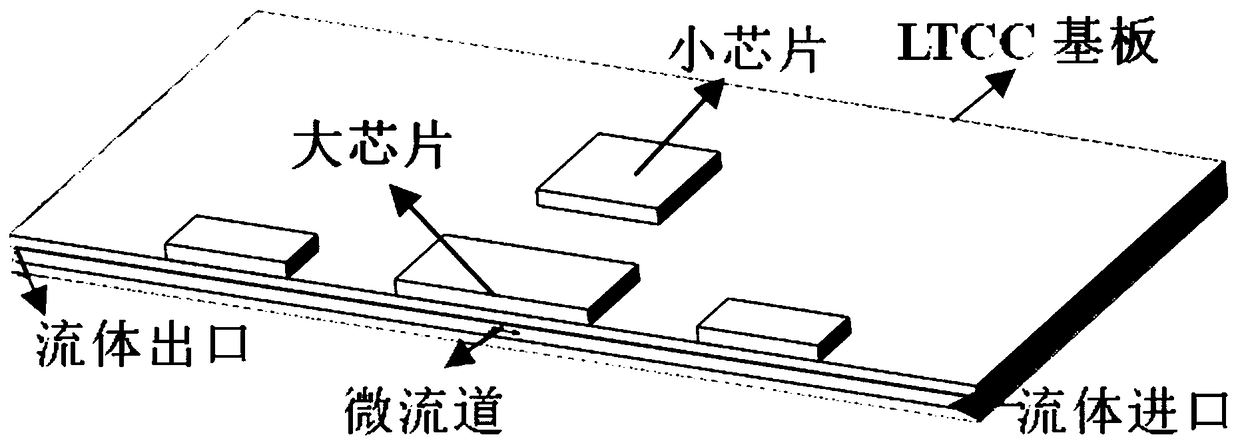

A method for optimizing the heat dissipation structure of the micro-channel of a multi-chip module

InactiveCN109002644AEasy to calculateSimple designGeometric CADDesign optimisation/simulationElement modelEngineering

The invention discloses a method for optimizing the heat dissipation structure of the micro-channel of a multi-chip module. The diameter of the micro-channel in the multi-chip module, the microchannelstructure, and the inlet velocity of the micro-channel coolant is taken as a design parameters, and the high temperature in the finite element model is taken as the target value, and nine groups of effective test simulation are designed. Range analysis is preformed on the experimental result data through the orthogonal design experiment method, and the optimized combination and the primary and secondary relationship of the influencing factors can be obtained. Through the experimental results, the variance analysis can be made, and the significant influence of the influencing factors on the heat dissipation performance of the micro-channel can be obtained. This method also has a guiding role in the optimization design of other interconnection structures.

Owner:GUILIN UNIV OF ELECTRONIC TECH

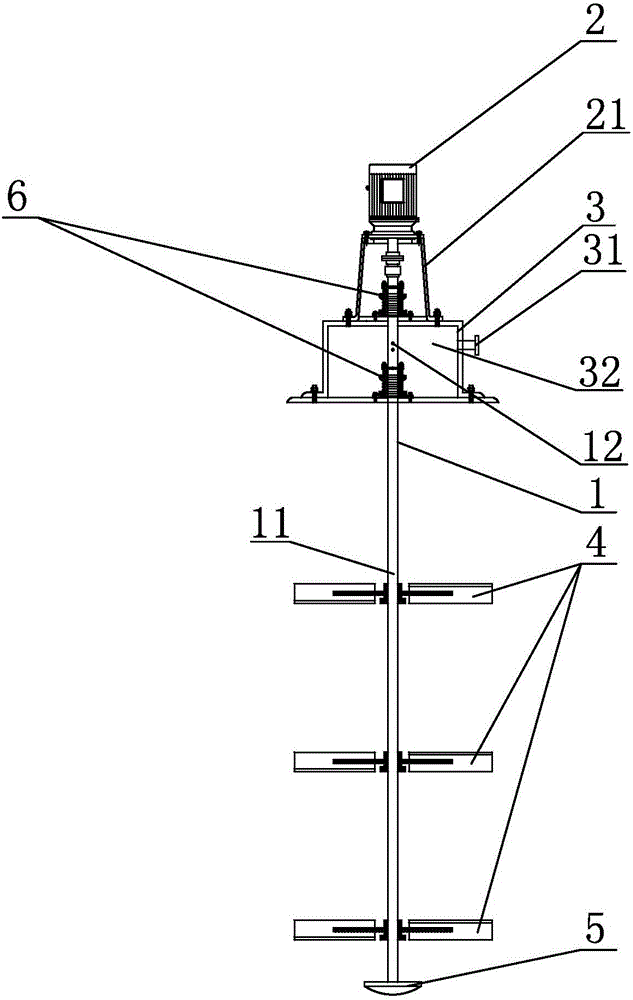

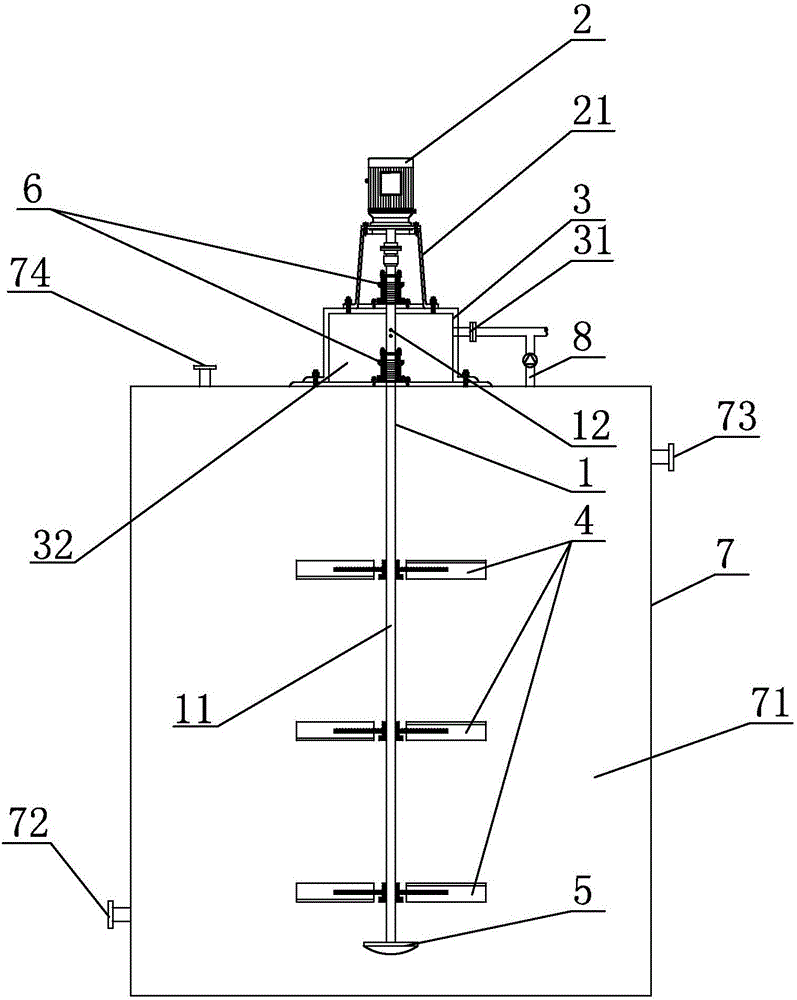

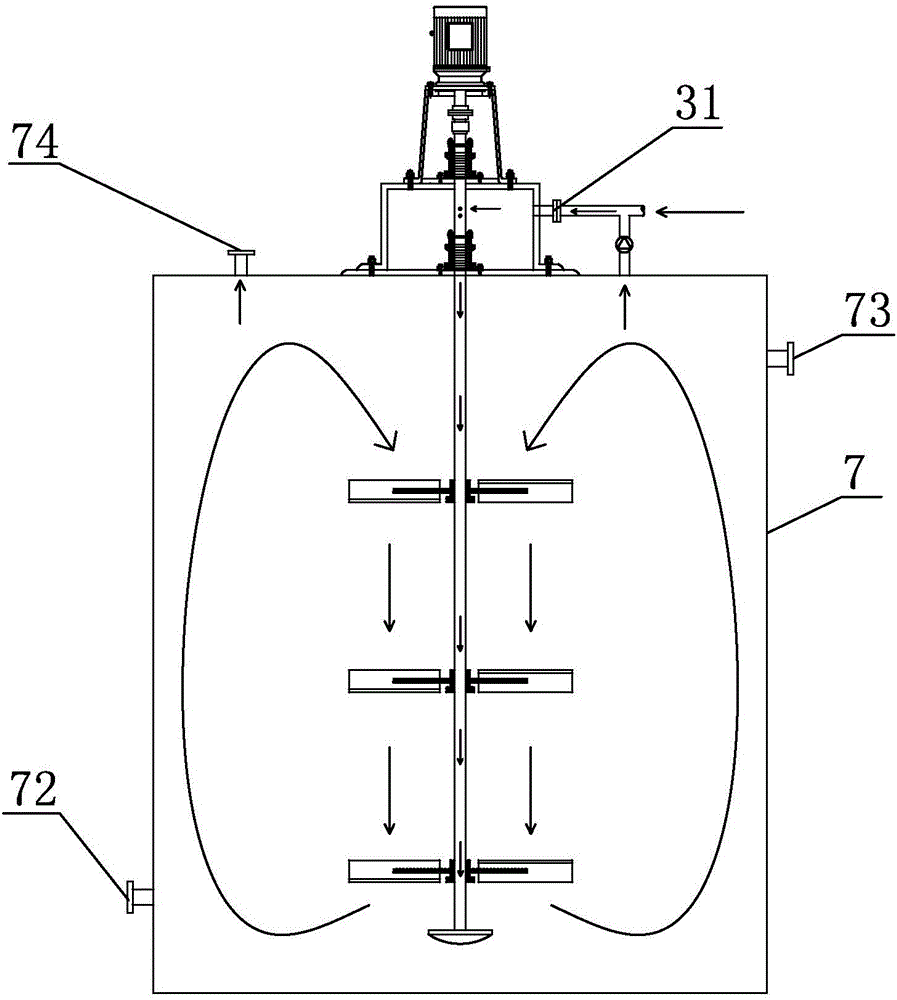

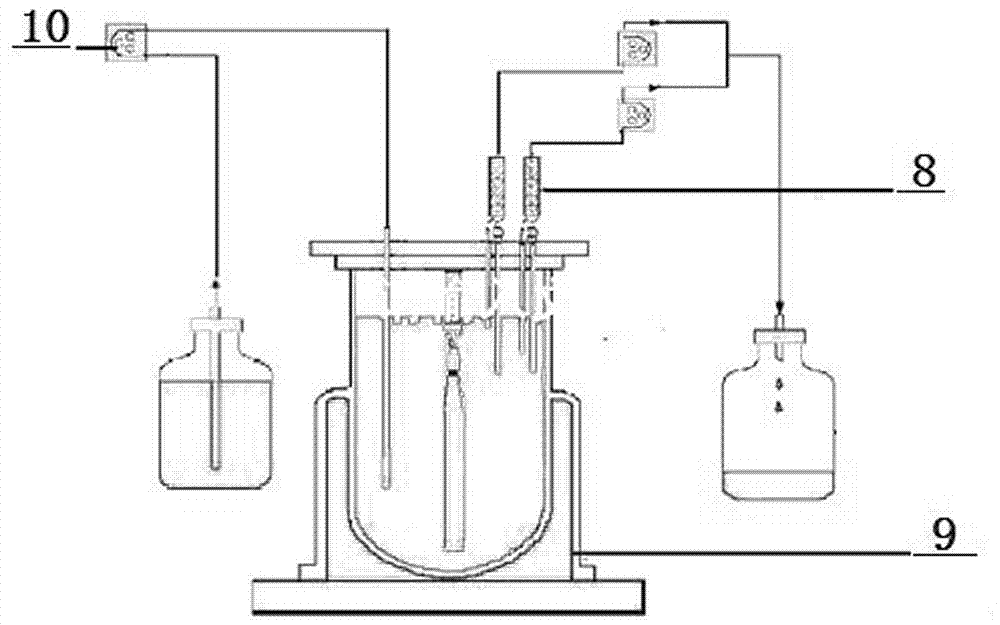

Integrated device for conveying gas and stirring materials, and bioreactor comprising same

InactiveCN105695309AReduce shockEfficient and thorough conversionBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discEngineering

The invention discloses an integrated device for gas conveying and material stirring, which comprises a rotating stirring shaft and a motor; The connection between them is sealed; the stirring part of the rotating stirring shaft is equipped with a slanted blade disc turbine agitator, and the bottom end is equipped with a microporous aeration device; the shaft wall of the rotating stirring shaft in the buffer air inlet chamber is provided with ventilation The ventilation channel is arranged in communication with the microporous aeration device through the air inlet chamber provided in the rotating stirring shaft. The invention increases the buffer air intake chamber to reduce the impact on the microorganisms when the air intake velocity fluctuates, and uses a microporous aeration device to increase the contact area between fine air bubbles and microorganisms, and at the same time cooperates with a multi-layer oblique blade disc turbine agitator The material in the bioreactor can be circulated downward from the center and then upward along the inner wall around the main body of the bioreactor to strengthen the biotransformation process of the gas.

Owner:BEIJING UNIV OF CHEM TECH +1

Hybrid microwave water heater

InactiveCN102434958AAchieve reliabilityAchieve accuracyWater heatersTemperature controlInsulation layer

The invention provides a hybrid microwave water heater, which mainly comprises a heat exchange box and a heater. The hybrid microwave water heater is characterized in that: the interior of the heat exchange box is divided into a microwave heating box and an electric heating box; a microwave heating pipe is positioned in the microwave heating box, a water inlet pipe is formed by winding a plurality of independent coiled pipes on the microwave heating pipe, and a trigger is arranged at the front end of the water inlet pipe; a temperature controller is connected with a heating power adjustor and a water quantity adjusting tap and positioned in the electric heating box; the temperature controller can be used for setting the temperature range of the outlet water and correspondingly adjusting the heating power of the heating power adjustor and the water inlet velocity; a metal fiber radiation-proof layer is arranged on the outer wall of the microwave heating box; and a heat insulation layer is arranged between a shell and an inner container of the microwave heating box. The hybrid microwave water heater for heating by adopting microwave with the aid of electric heating can have sterilization effect, and can realize instant heating by adopting the plurality of coiled pipes for heating.

Owner:SUZHOU JIAYAN ENERGY EQUIP

Denitrifying low-NOx circulating fluidized bed boiler and denitrifying low-NOx emission control process

InactiveCN108302521AImprove healthImprove denitrification efficiencyFluidized bed combustionApparatus for fluidised bed combustionAir volumeSlag

The invention relates to denitrifying low-NOx emission control process for a circulating fluidized bed boiler. The denitrifying low-NOx emission control process comprises the following steps that thearea of the evaporating heating surface in the boiler is increased, and the heat absorption capacity of the evaporating heating surface of a boiler furnace is changed; the size of hood small holes ofa wind-distribution plate is adjusted, and the size of slag discharging holes of the wind-distribution plate and the size of hood openings in the surrounding wall surfaces are increased; the inlet velocity and incident angle of an inlet flue of a cyclone separator are adjusted, the circulation area of a riser is adjusted according to the amount of fired coal of the boiler and the efficiency of thecyclone separator, the circulation area and the air volume of material-returning air of a material returning valve are adjusted, the flow rate of materials on the interface of a material returning system is controlled at 90-150kg / s through adjustment, the material circulation of the boiler is increased, and the burning temperature is reduced; and an appropriate amount of low-oxygen flue gas is extracted between a dust remover of the boiler and a draft fan and sent to a primary air inlet or a hot primary air outlet of an air pre-heater, the initial oxygen content of coal combustion is reduced,then the low-oxygen flue gas is fed into a primary air chamber at the bottom of the boiler, and the excess air coefficient of the primary air chamber at the bottom of the boiler is adjusted to be 0.4-0.8.

Owner:浙江百能科技有限公司 +2

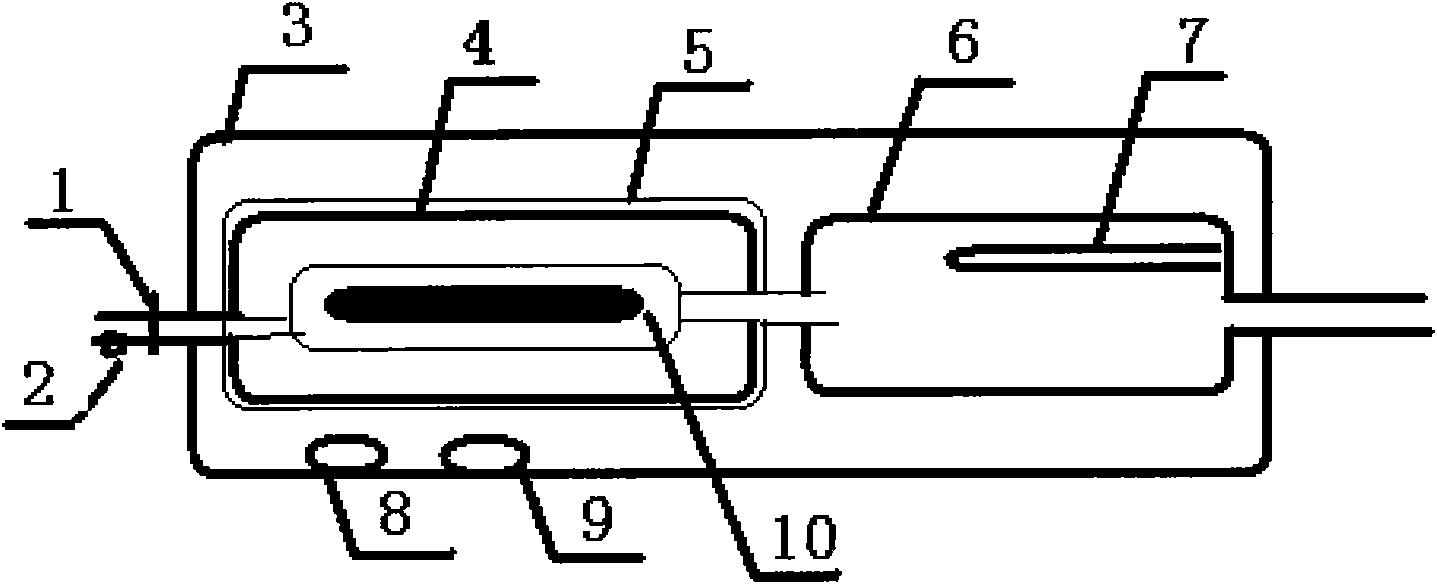

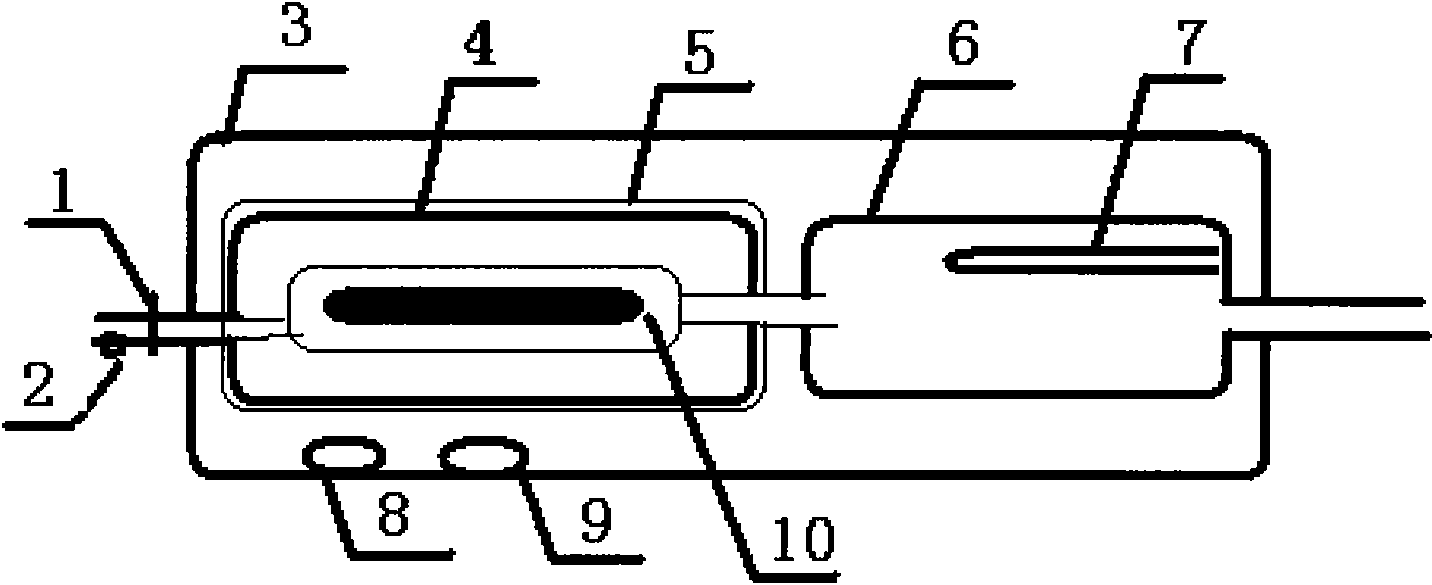

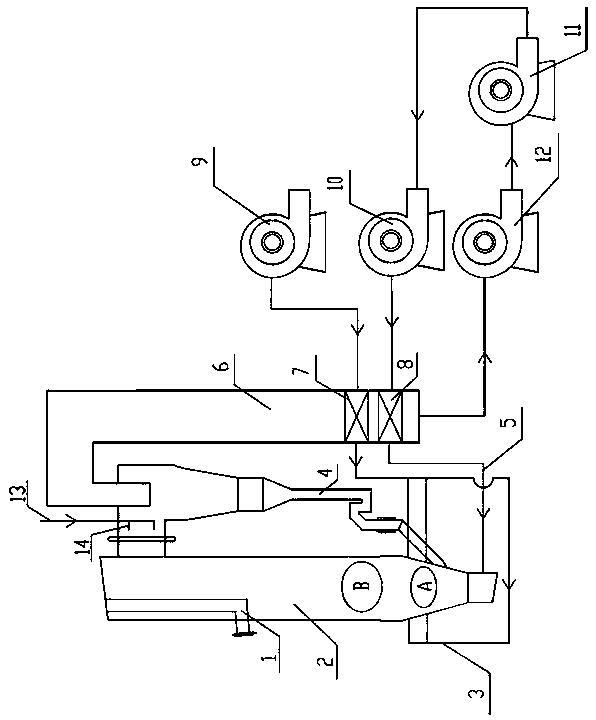

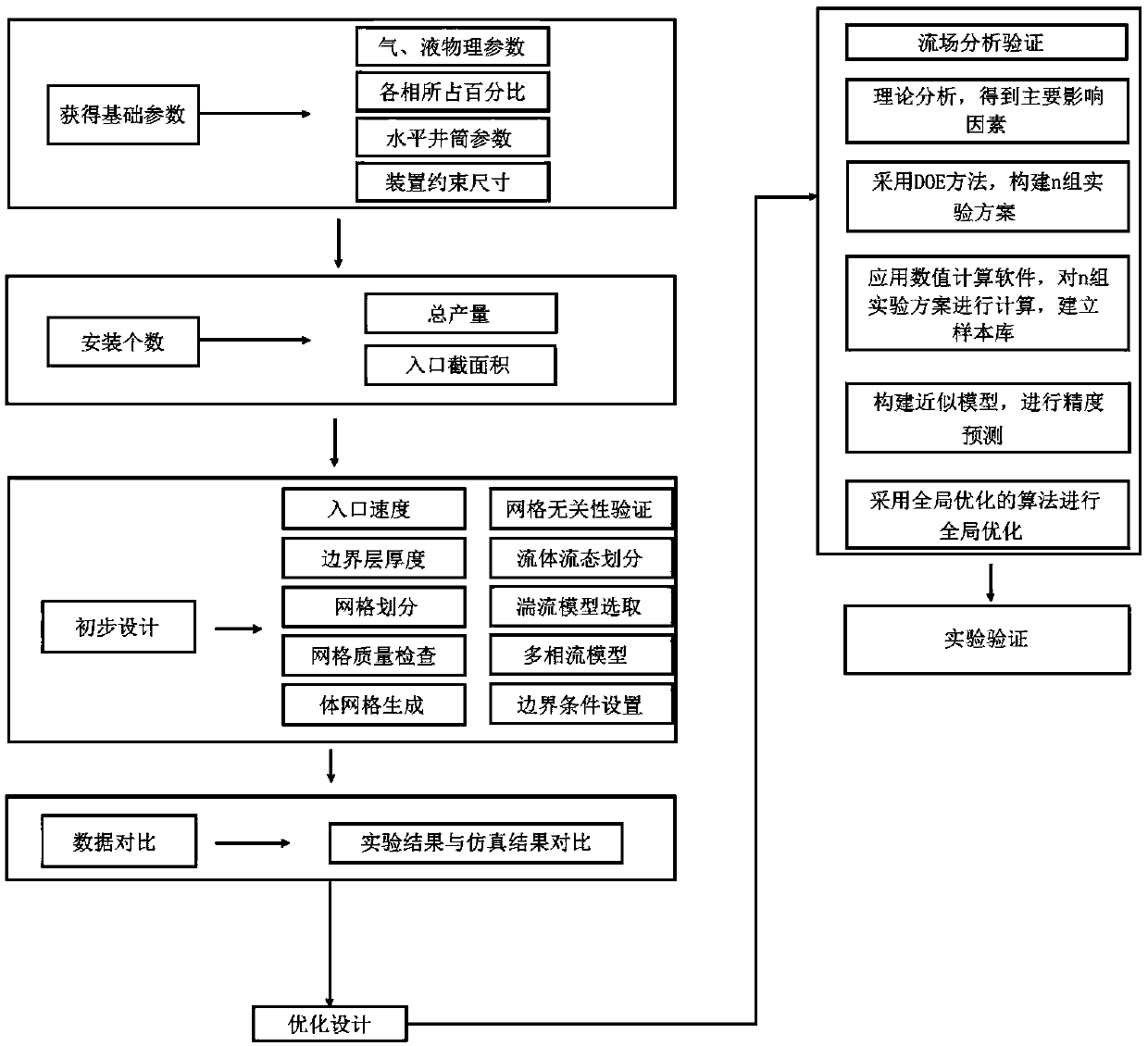

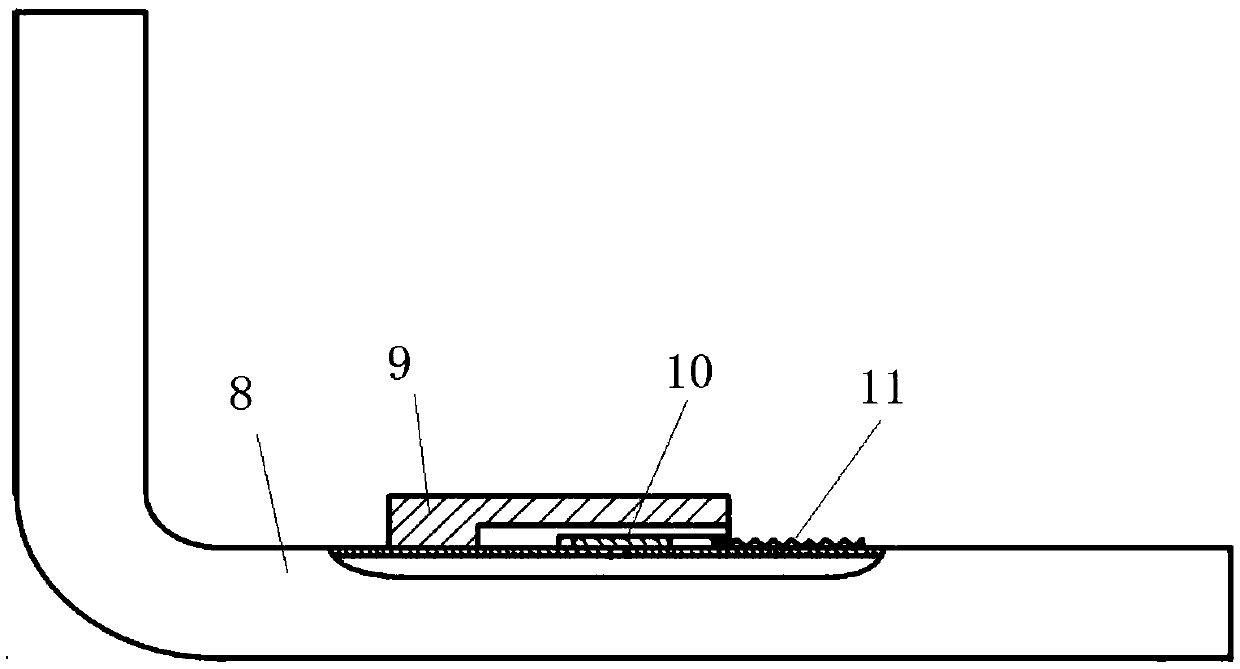

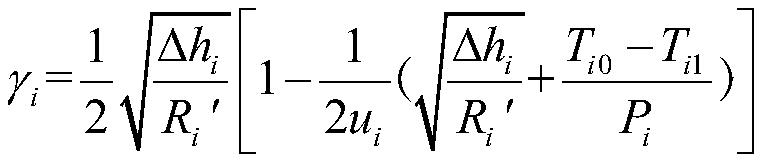

Gas well self-adaptive flow-regulating water-controlling device and design method thereof

ActiveCN111322036AIncrease the effect of water control and production increaseImprove research efficiencyFluid removalDesign optimisation/simulationThermodynamicsHorizontal wells

The invention relates to a gas well self-adaptive flow-regulating water-controlling device and a design method thereof. The design method comprises the following steps that step one, basic parametersof a certain horizontal well are obtained; step two, the flow and inlet speed of each self-adaptive flow-regulating water-controlling device are determined according to the installation number of self-adaptive flow-regulating water-controlling devices of the horizontal well; step three, according to the basic parameters of the step one and the inlet speed of the step two, a preliminary geometricalmodel is designed and the simulation calculation condition is arranged, and simulation parameter exploration is carried out on the preliminary geometrical model; step four, the preliminary geometrical model and the simulation calculation condition in the step three are tested, and data compassion is carried out on a tested experimental result and a simulation result; and step five, numerical optimization is carried out on the self-adaptive flow-regulating water-controlling device based on DOE orthogonal experimental design. According to the design method, the problems of indistinct design thought, low simulation precision and the like are solved, and the water-controlling yield-increasing effect of the gas well self-adaptive flow-regulating water-controlling device is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

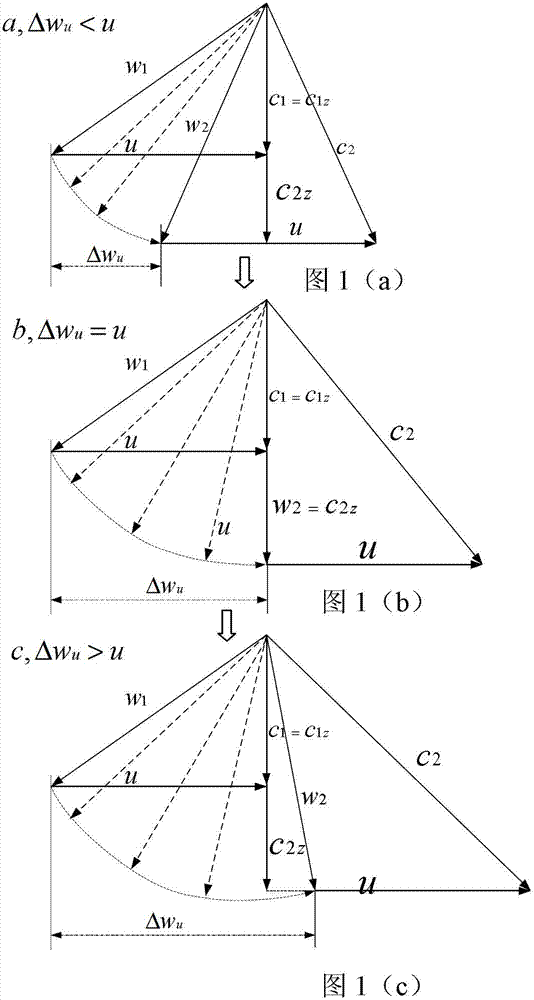

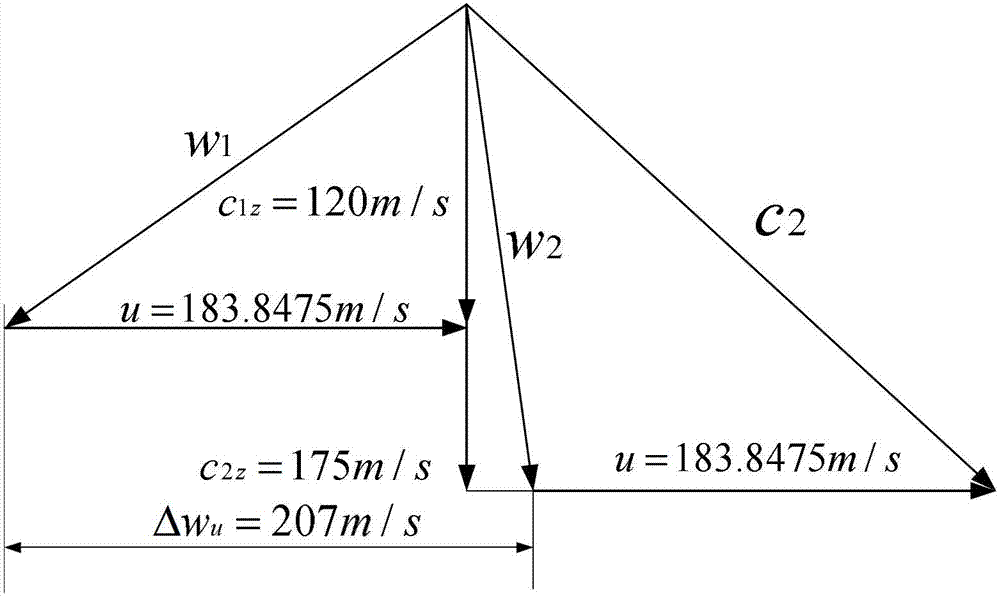

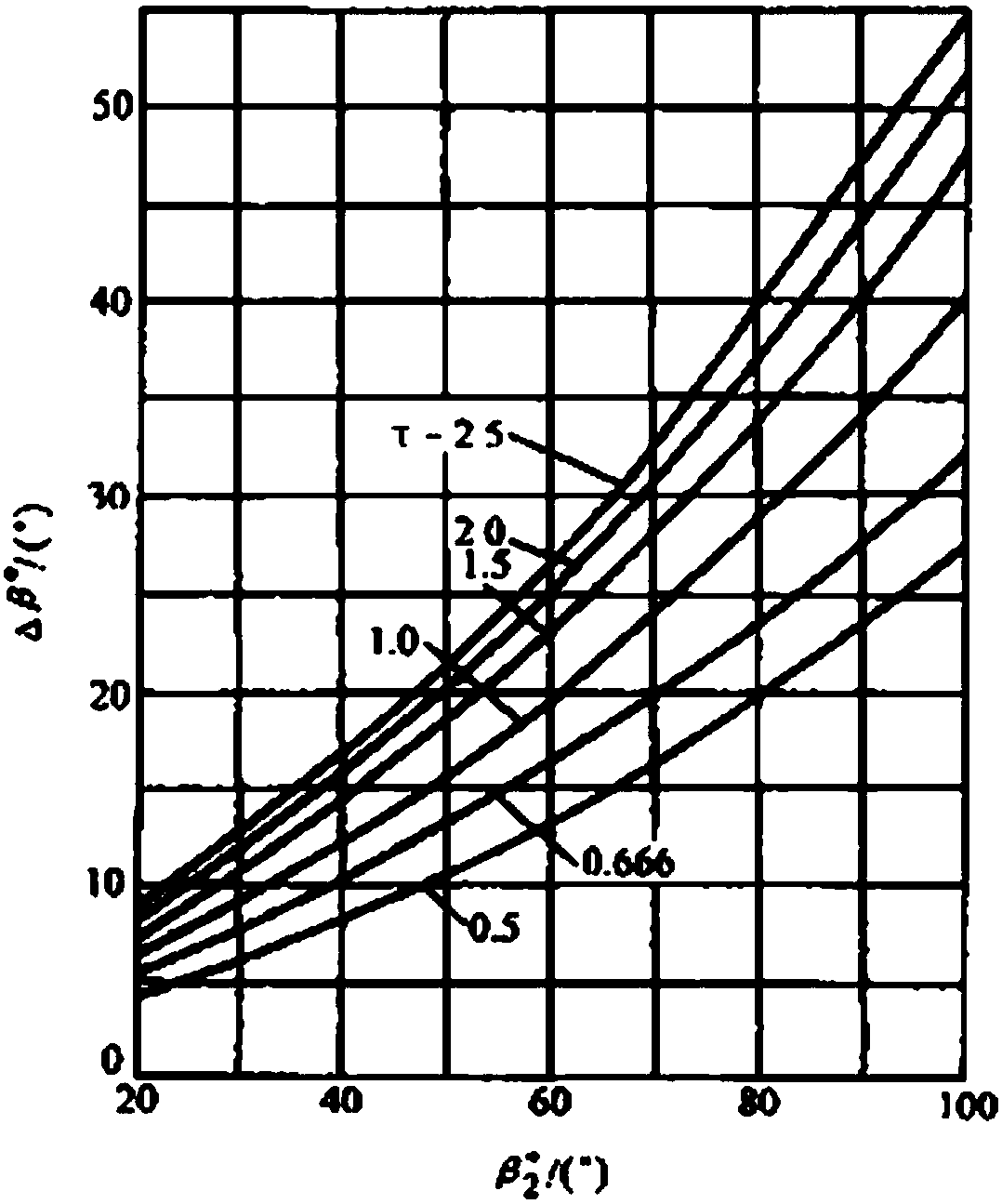

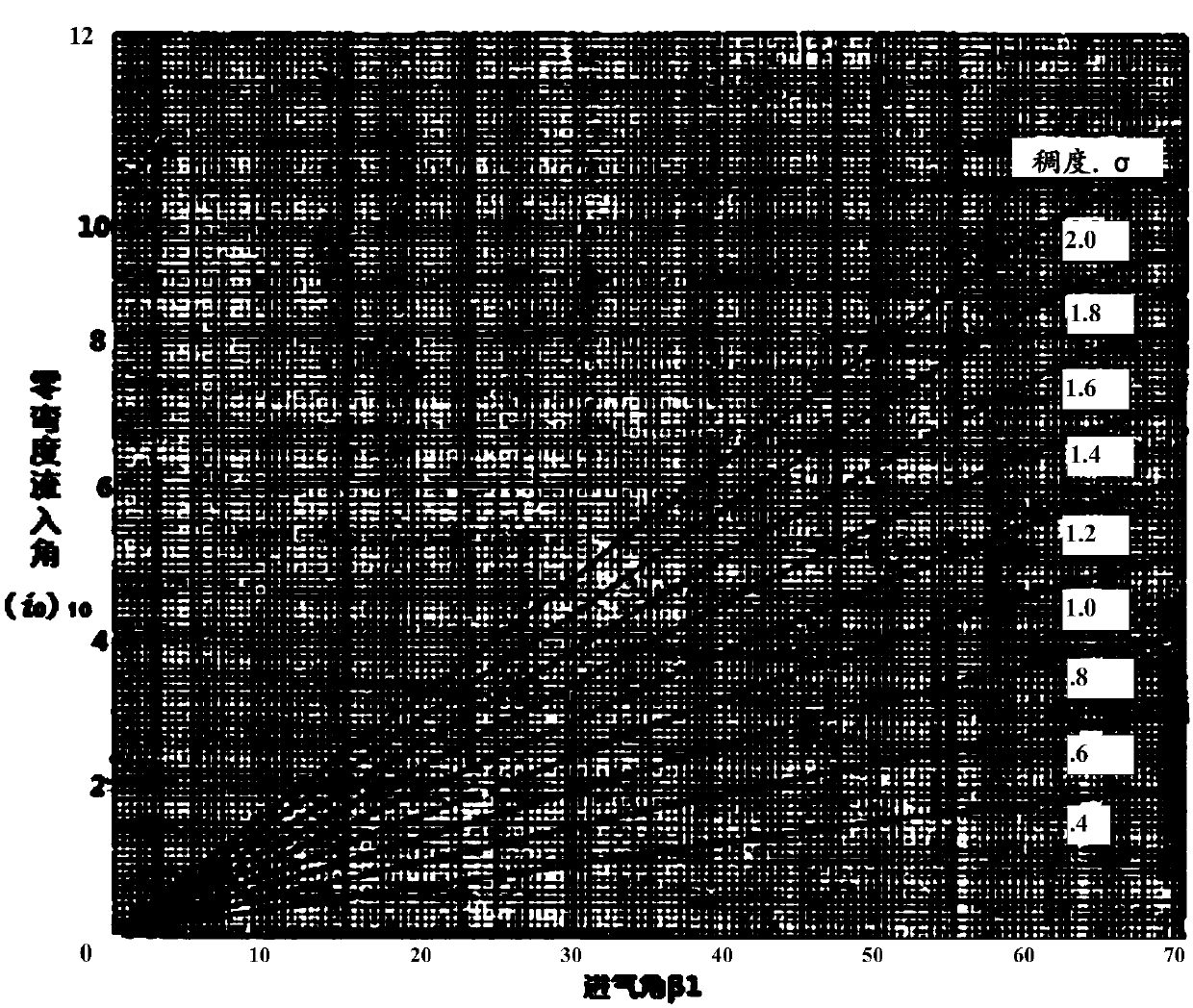

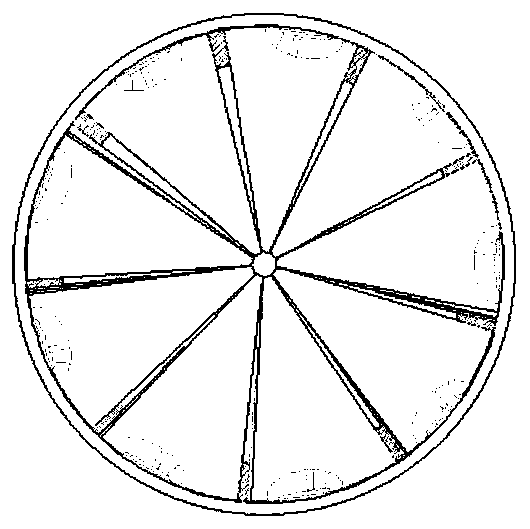

Model airplane axial flow ducted fan design method

ActiveCN108518348AReduce consistencyImprove aerodynamic efficiencyPump componentsAxial flow pumpsJet aeroplaneEngineering

The invention provides a model airplane axial flow ducted fan design method. The model airplane axial flow ducted fan design method comprises the following steps of 1, according to the flow and the total pressure rise of a fan, designing an inlet velocity triangle and an outlet velocity triangle of a fan rotor and an inlet velocity triangle and an outlet velocity triangle of a fan stator; and 2, according to the inlet velocity triangle and the outlet velocity triangle of the fan rotor and the inlet velocity triangle and the outlet velocity triangle of the fan stator, designing geometric parameters of the rotor and the stator.

Owner:成都飞擎航空科技有限公司

Transfer method and transferring apparatus for transferring rod-shaped article

ActiveUS20170113879A1Easy to take care ofIncrease speedCigarette manufactureConveyor partsEngineeringMechanical engineering

Owner:INT TOBACCO MACHINERY POLAND

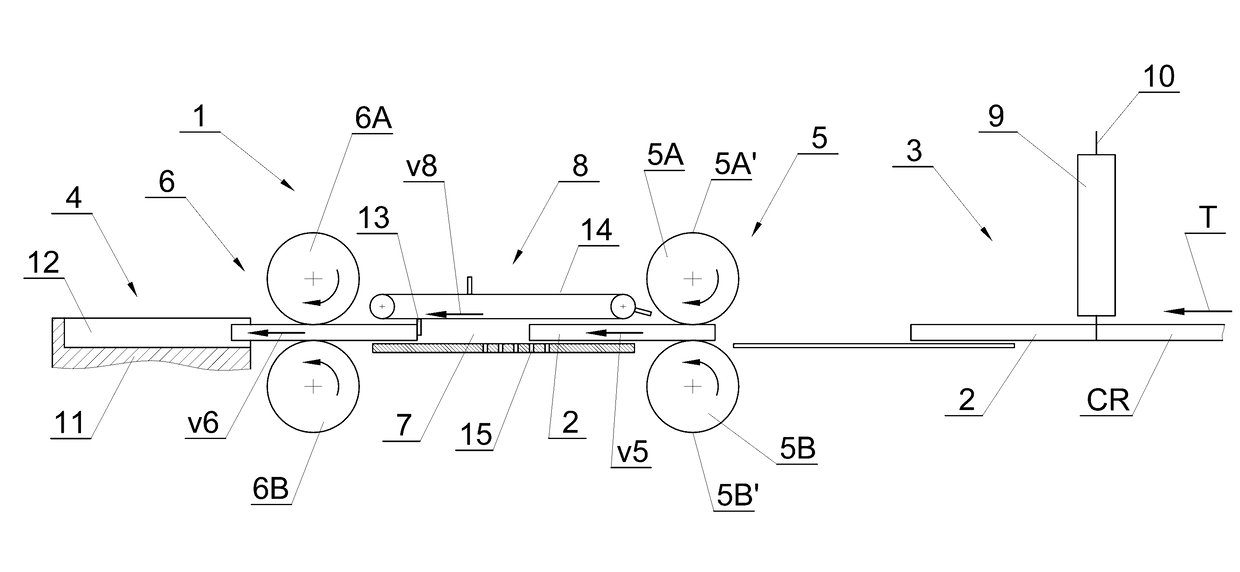

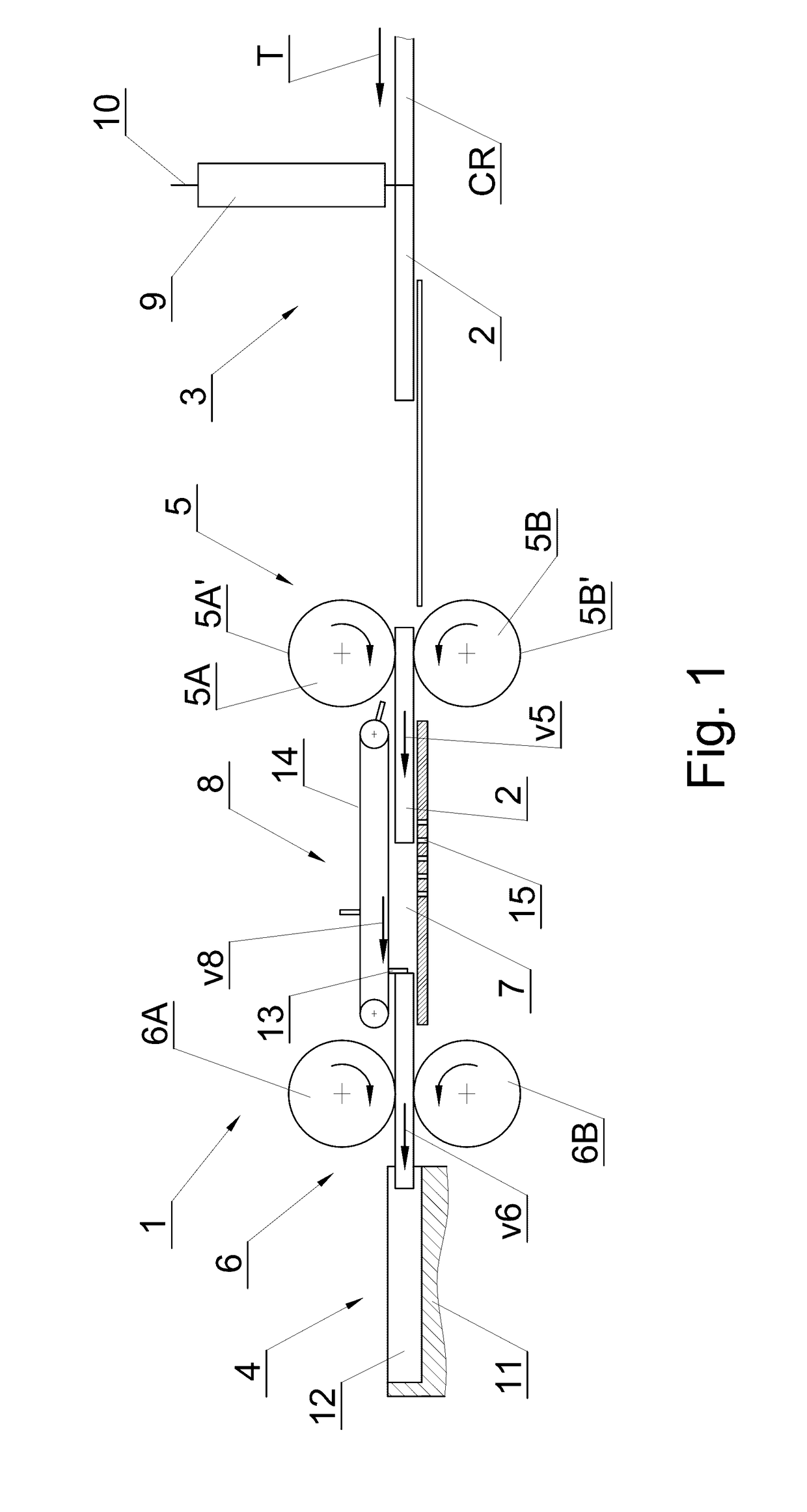

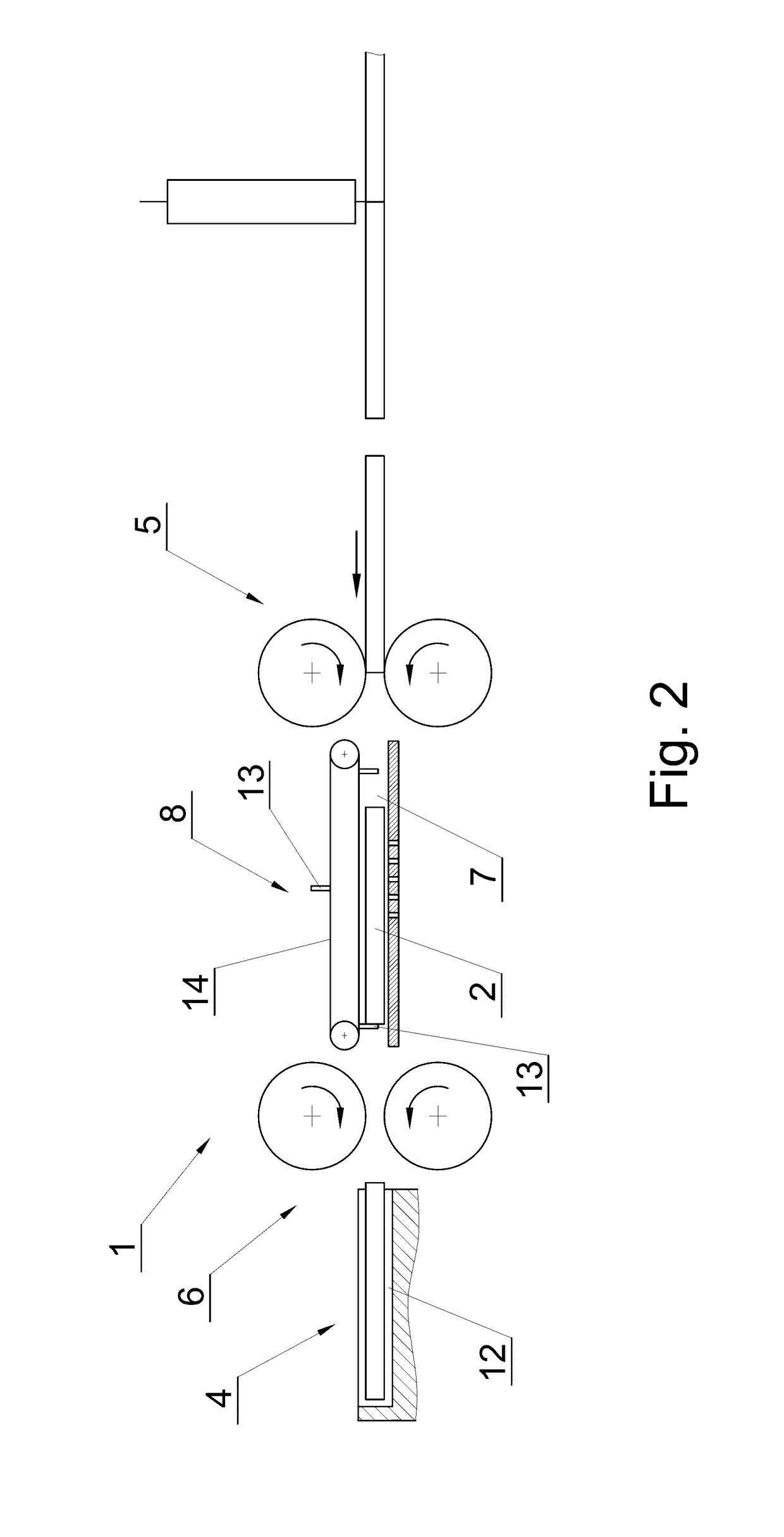

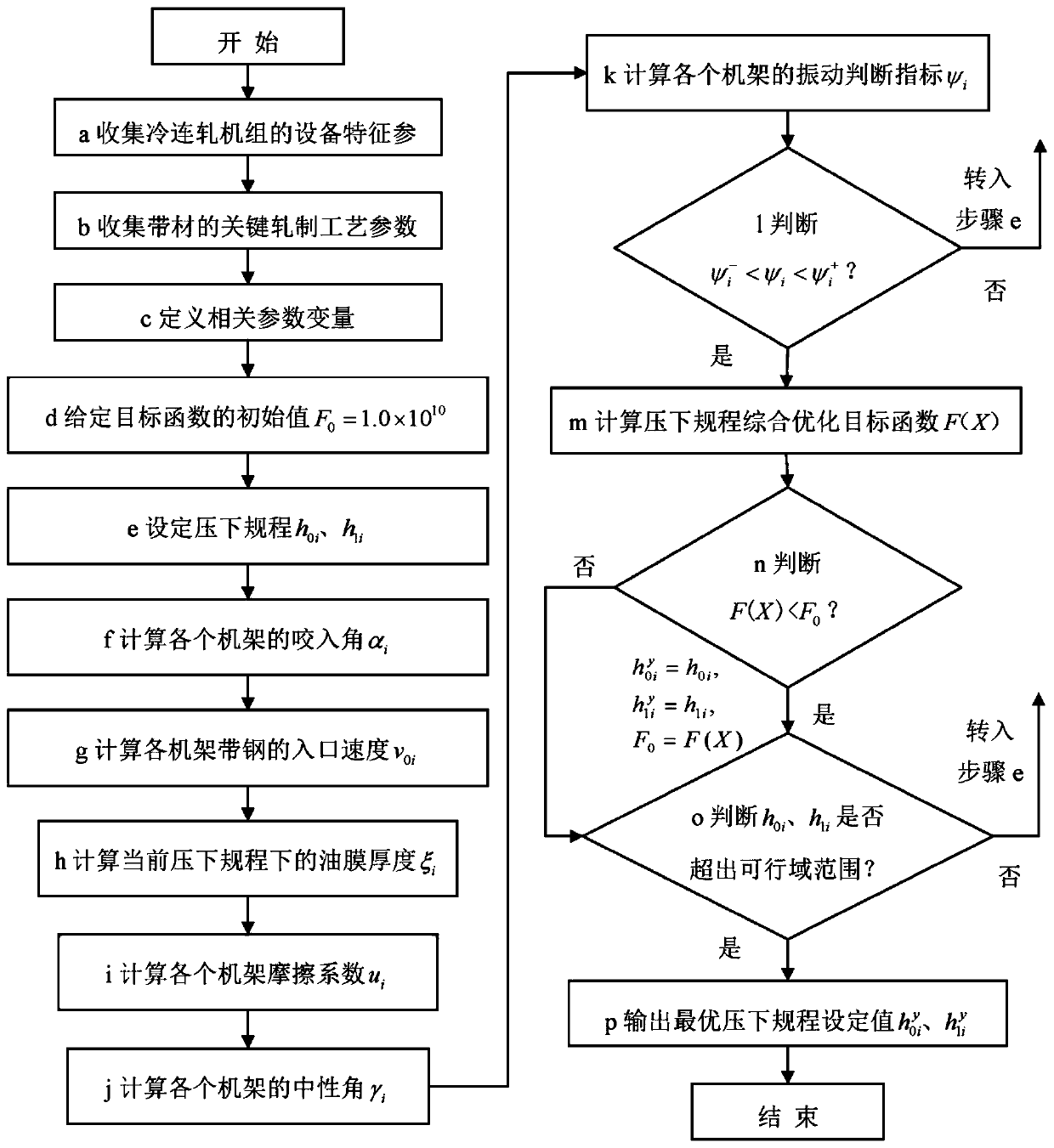

Reduction schedule setting method of cold continuous rolling unit taking vibration abatement as target

ActiveCN111495980AAchieve governanceImprove quality stabilityVibration control deviceMetal rolling arrangementsStructural engineeringStrip steel

The invention relates to a reduction schedule setting method of a cold continuous rolling unit taking vibration abatement as a target and belongs to the field of rolling. The method comprises the following steps of collecting unit associated parameters and strip-rolling process parameters; defining vibration judging indexes of racks; giving a reduction schedule taking vibration abatement as the target to optimize an initial set value of a target function comprehensively; setting the reduction schedule; calculating bit angles of the racks, the inlet speeds and oil film thicknesses of strip steel of the racks, friction coefficients between working rollers of the racks and the strip steel and the neutral angles of the racks; calculating the vibration judging indexes of the racks; and by taking the minimum mean square errors of the rolling mill vibration judgment index optimum value and rolling mill vibration judging index values solved in an actual rolling process and the minimum value ofthe maximum rolling mill vibration judgment index values of the racks as the optimized target function and by taking a lower threshold value of the vibration judgment index solved as a rolling process is in a sub-lubricated state when the neutral angle is as half as the bit angle as a constraint condition, optimizing the reduction schedule of the rolling process of the cold continuous rolling unit finally.

Owner:BAOSHAN IRON & STEEL CO LTD

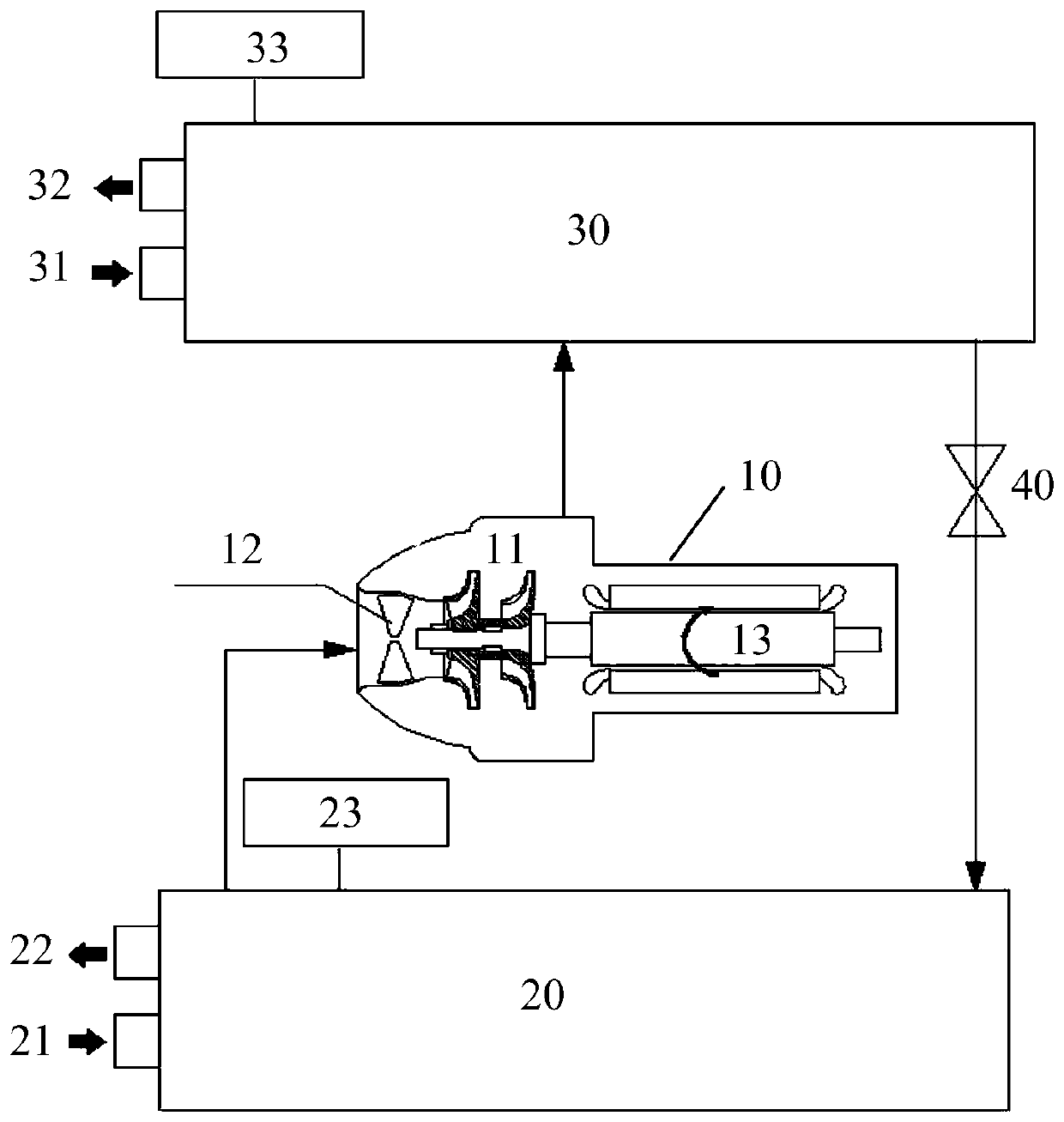

Compressor guide vane opening control method and device, and air conditioning unit

ActiveCN111140544AReal-time fast and precise adjustmentSolve the adjustmentPump componentsPump controlImpellerAir conditioning

The invention discloses a compressor guide vane opening control method and device and an air conditioning unit. The method comprises the following steps that the impeller inlet velocity of a compressor is determined according to a target refrigerating capacity; target opening is determined according to the relationship between the impeller inlet velocity and guide vane opening; and the opening ofa guide vane is adjusted to the target opening. According to the compressor guide vane opening control method, the required impeller inlet velocity is determined according to the target refrigeratingcapacity, and then the target opening of the guide vane is calculated in real time according to the relationship between the guide vane opening and the airflow velocity, so that the guide vane is quickly and accurately adjusted in real time according to the target opening, the problem that the adjustment of the guide vane is hysteretic and not accurate when the working condition is changed is effectively solved, the surge can be avoided, and the efficient and stable operation of the unit is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

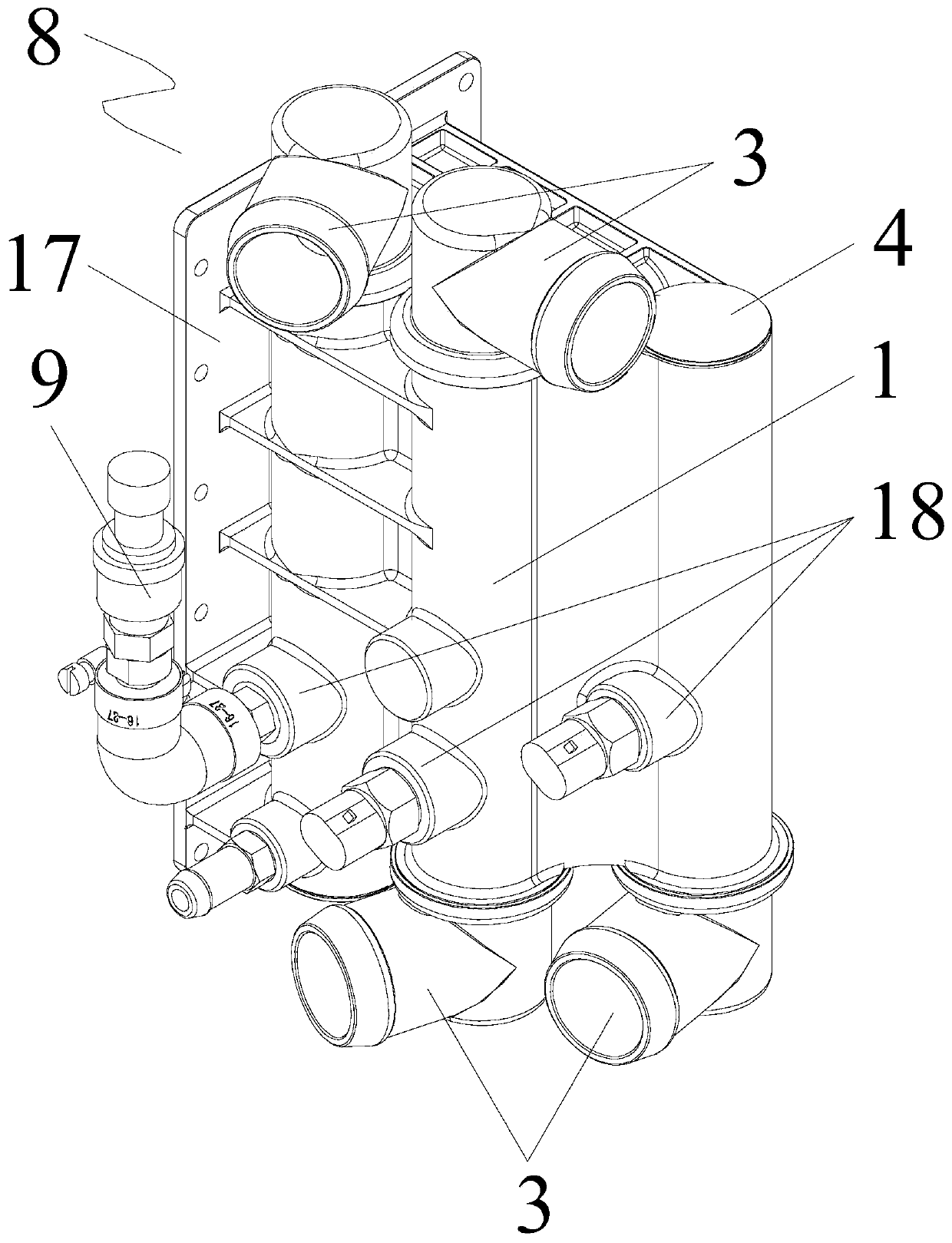

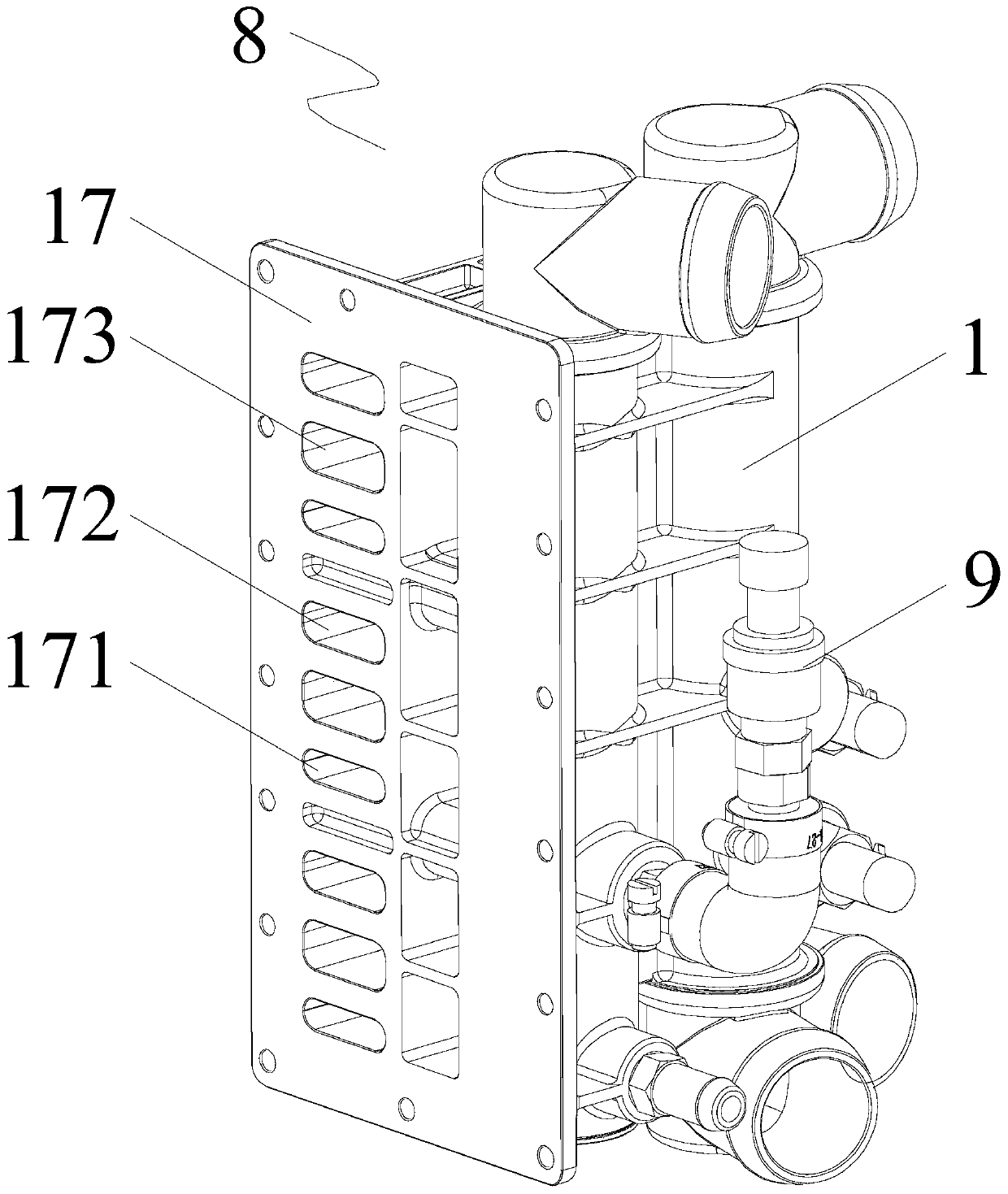

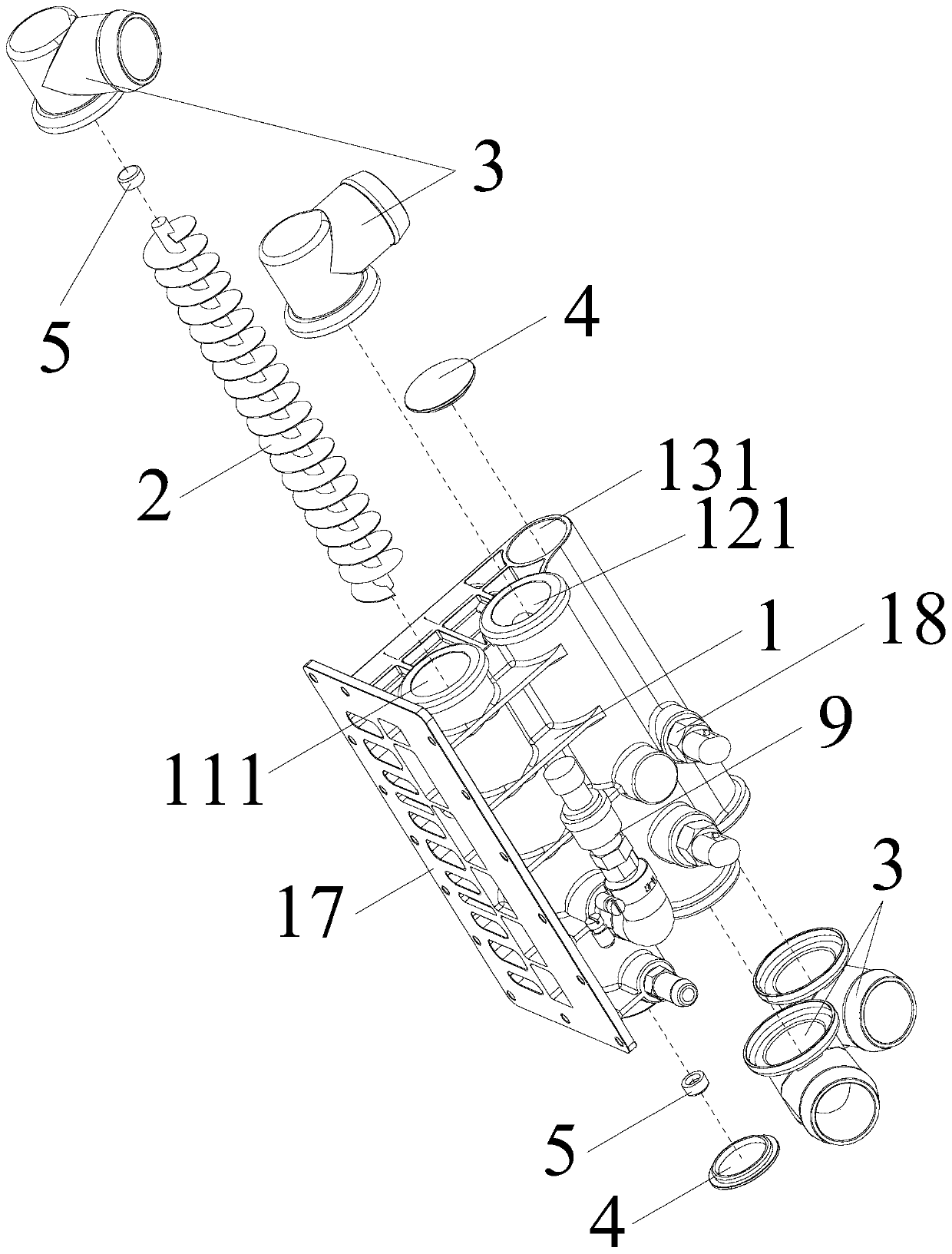

Electric pile gas-liquid distribution device and fuel cell applying same

The invention discloses an electric pile gas-liquid distribution device and a fuel cell applying the same. The device comprises a collecting block body, and the collecting block body is provided witha hydrogen main flow channel for hydrogen to circulate, an air main flow channel for air to circulate and a cooling liquid main flow channel for cooling liquid to circulate; the hydrogen main flow channel, the air main flow channel and the cooling liquid main flow channel face vertically and are separated from one another, and spiral auger blades are installed in the hydrogen main flow channel. After entering the hydrogen main flow channel, the humid hydrogen mixed gas spirally flows upwards along the spiral auger blades to form an outer spiral gas flow; a centrifugal force can be generated inthe rotating process of the external rotating airflow; hydrogen in the external rotation gas flow rotationally rises to an elbow at the top of the hydrogen main flow channel, liquid drops with high density in the external rotation gas flow are thrown to the wall surface of the hydrogen main flow channel, lose inertia force after being in contact with the wall surface, fall along the wall surfaceby virtue of the momentum of inlet speed and downward gravity, and enter the bottom, so the effect of water-vapor separation is achieved.

Owner:ZHONGSHAN BROAD OCEAN

A cavity air inlet flow velocity adjusting device

InactiveCN106609874AIntake velocity changes smoothlyAir intake is easy to controlOperating means/releasing devices for valvesSemiconductor/solid-state device manufacturingEngineeringAtmospheric pressure

The invention relates to an air inlet flow velocity adjusting device, in particular to an adjusting device which can change air inlet velocity with the change of cavity air inlet flow in the manufacture of semiconductors. The device can adjust air inlet flow velocity and enables air inlet velocity to decrease along with the increase of air flow quantity. The device comprises an air cylinder air inlet pipe, a pressure adjusting valve, a small hole blocking sheet, an air cylinder, a piston, a spring, a piston rod, a connecting rod, a valve body, a valve plate rod, a valve plate and an air inlet pipe, which form an air cylinder execution part and a valve body part. The increase of air inlet quantity can change the displacement of the piston; the piston rod can make the valve plate rotate via the connecting rod and the valve plate rod, and the rotation of the valve plate can adjust the flow velocity of air inlet. When air in a cavity is discharged or extracted out and the air pressure in the cavity becomes stable, the piston and the valve plate can return to the initial positions. The device enables the change of cavity air inlet velocity to be gentle, enables air inlet quantity to be easily controlled, shortens the time of an air inlet process and increases the capacity of apparatuses.

Owner:PIOTECH CO LTD

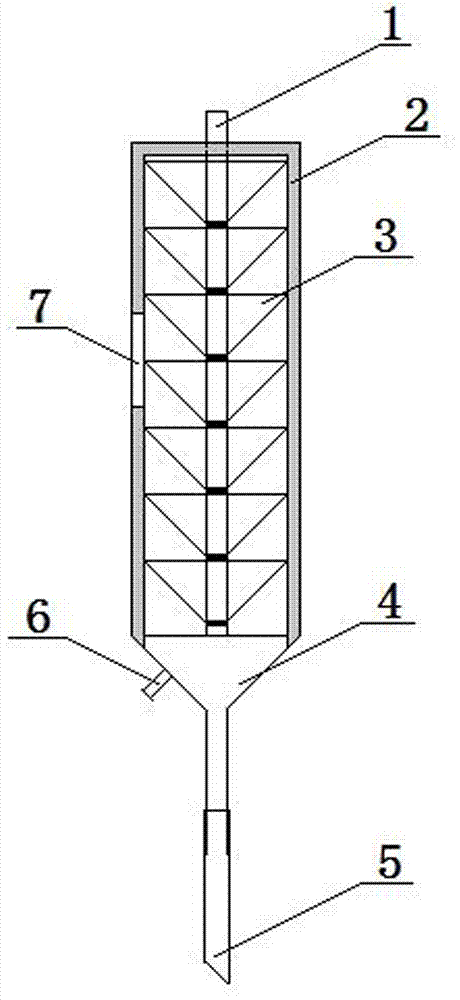

Enhanced cell microcarrier perfusion culture entrapment method

ActiveCN107541464AControl liquid levelIncrease in sizeBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureReflux

The invention provides an enhanced cell microcarrier perfusion culture entrapment device and method. A device body is internally provided with a layered funnel, a sedimentation chamber is formed in the bottom of the layered funnel, a culture medium-microcarrier inlet is formed in the sedimentation chamber, a connecting pipe is connected to the bottom of the sedimentation chamber, a culture medium-microcarrier reflux inlet is formed in the lower portion of the connecting pipe, a culture inlet is formed in the top of the layered funnel, and an observation window is formed in the portion, at oneside of the device body, of the layered funnel. The device has the advantages that the functions of solid-liquid sedimentation separation and liquid level control are achieved, cell microcarrier perfusion volume and entrapment efficiency are increased, the problem that a microcarrier is not prone to sedimentation so as to run off due to the fact that the liquid inlet velocity is too high is solved, and damage to cell is small in the microcarrier entrapment process.

Owner:SHANDONG YIDU BIOTECH

Trommel assembly having a spiral assembly with decaying pitch

InactiveCN105579150AImprove screening efficiencySievingScreeningRetention timeMechanical engineering

Owner:TEGA IND LTD +1

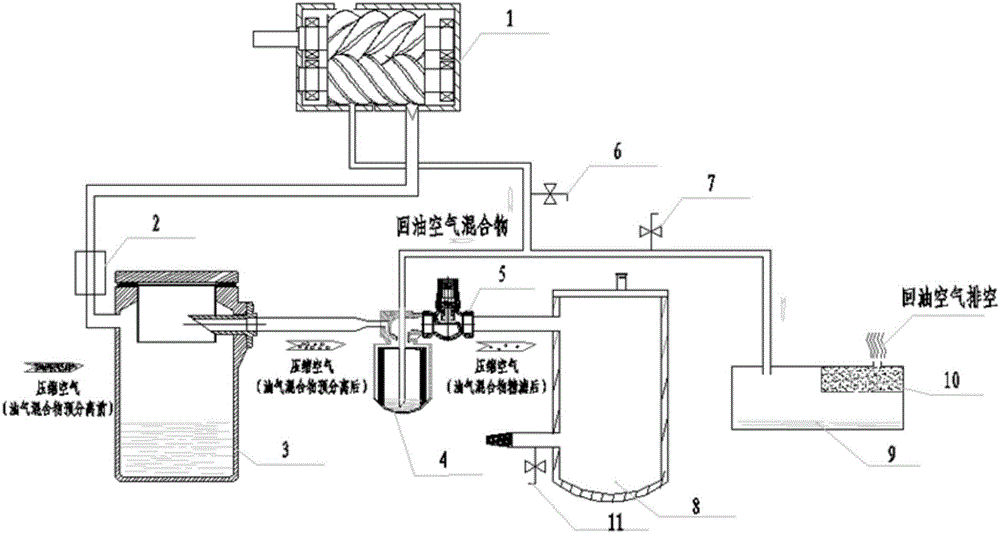

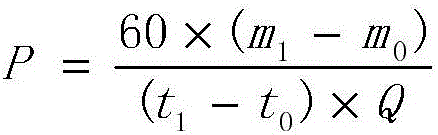

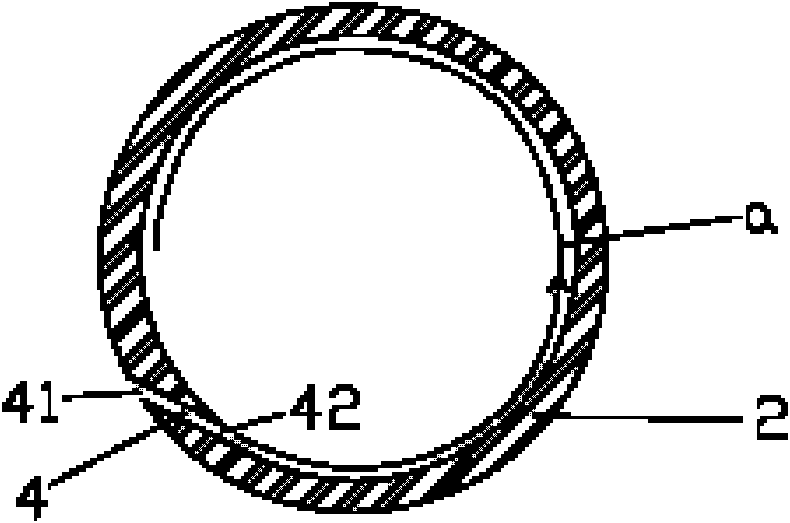

Pre-separation effect test method for oil-gas separator

ActiveCN106640660AThe testing process is simpleValid testRotary/oscillating piston pump componentsLiquid fuel engine componentsAfter treatmentEngineering

The invention relates to a pre-separation effect test method for an oil-gas separator. By the method, pre-separation effects of the oil-gas separator can be simply and effectively tested, the matching relation between an oil-gas separator separation structure with optimal separation effects and inlet velocity is sought by testing, the oil removing pressure of an after-treatment system is reduced, the replacement period of damageable and consumable parts of the after-treatment system can be effectively prolonged, maintenance cost is reduced, and compressed air quality grade is improved.

Owner:NANJING CRRC PUZHEN HAITAI BRAKE EQUIP CO LTD

Reactor and method for realizing completely-mixed flow of gas-phase or gas-solid two-phase fluid

InactiveCN101829534BRealize full mixed flowSimple structureTransportation and packagingMixersGas solidMixed flow

The invention discloses a reactor for realizing the completely-mixed flow of gas-phase or gas-solid two-phase fluid, which comprises an upper part and a lower part, wherein the upper part is connected with the lower part; the upper part and the lower part both are revolving bodies; the upper and lower revolving bodies have a structure in which the diameters of the sections of the revolving bodiesincrease gradually from the bottoms of the revolving bodies to the connection part of the upper and lower revolving bodies. The lower revolving body of the reactor is provided with at least a gas feeding channel, the top of the reactor is provided with an air outlet, and the gas feeding channel is arranged along the tangential direction of the inner periphery of the lower revolving body of the reactor. The invention also discloses a method for realizing an completely-mixed flow reaction by using the reactor, which comprises the steps of forming a spiral vertex flow first after feeding the gas, then forming an up-and-down vertex flow, and mixing the spiral vertex flow and the up-and-down vertex flow to realize back-mixing. The reactor can realize a gas-phase or gas-solid two-phase reactionby using the structure of the reactor, and has a simple structure, and can make the non-dimensional variance close to 1 by combining with the parameters such as inlet velocity and the like, thereby realizing the complete mixing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

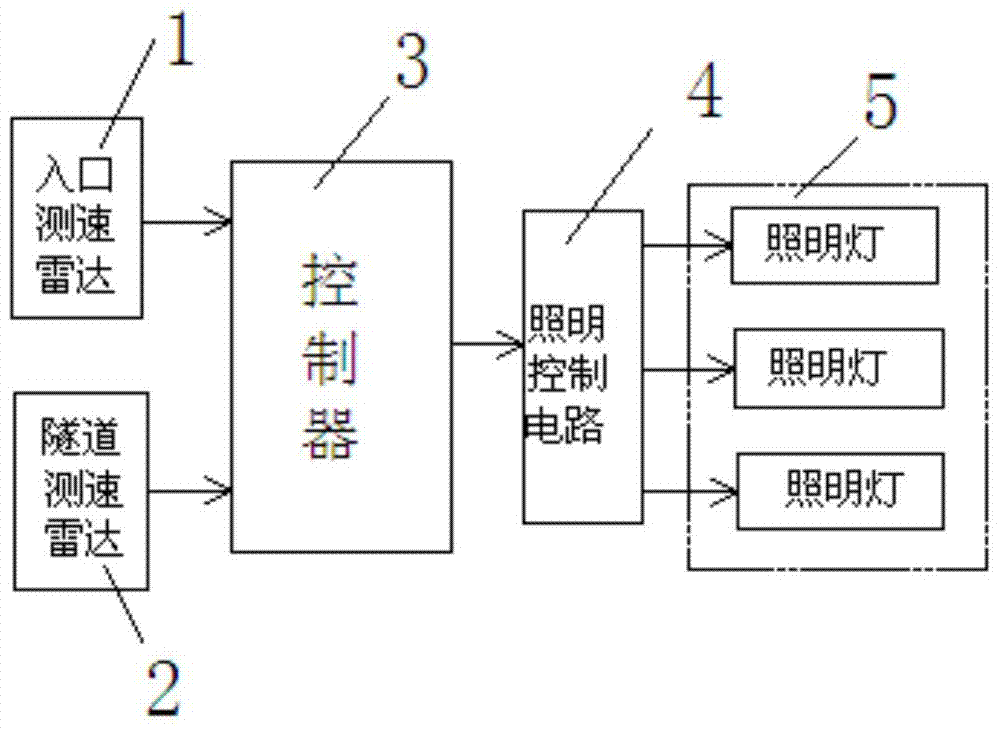

A kind of vehicle tunnel safe driving lighting system and lighting control method

ActiveCN105101563BEasy accessIt is good for darkening the situation where the road conditions cannot be seen clearlyElectric light circuit arrangementDriver/operatorEffect light

A lighting system for safe driving in a car tunnel, comprising an entrance speed measuring radar and a tunnel speed measuring radar, the entrance speed measuring radar and the tunnel speed measuring radar are respectively electrically connected to an input terminal group of a controller, and the output terminal of the controller is connected to the input terminal of a lighting control circuit, The output end group of the lighting control circuit is connected with a group of lighting lamps in turn. The speed measuring radar at the entrance detects the vehicle in front of the tunnel entrance, and controls the lighting in the tunnel through the controller. The speed measuring radar is used to detect whether there is a vehicle in the tunnel or not. When the tunnel entrance speed radar detects that there is a vehicle in front of the tunnel entrance, all the lights in the tunnel will be turned on, and the first 10 lights at the tunnel entrance will be controlled to be the brightness of other lights. 3 times or even more times of that, which is beneficial for the driver to avoid traffic accidents when entering the tunnel due to the darkened eyes caused by brightness changes and unable to see the road conditions clearly.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com