Aerodynamic design method of subsonic adsorption type axial compressor

An axial-flow compressor, pneumatic design technology, applied in mechanical equipment, machines/engines, non-variable-capacity pumps, etc., can solve the problems of difficult suction pipeline layout, increase in blade rotation angle, and decrease in blade strength, to avoid problems such as Blade strength and suction structure design to ensure efficient flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

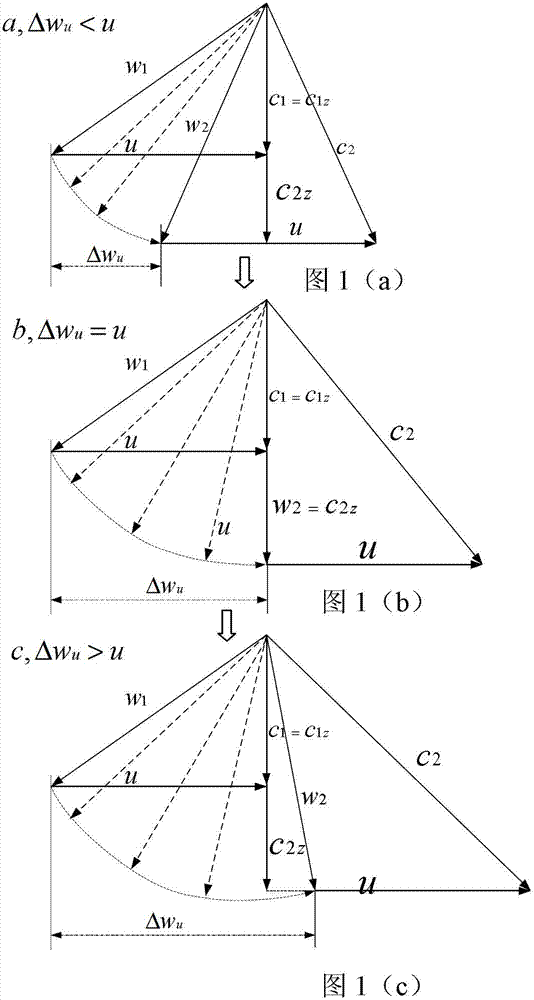

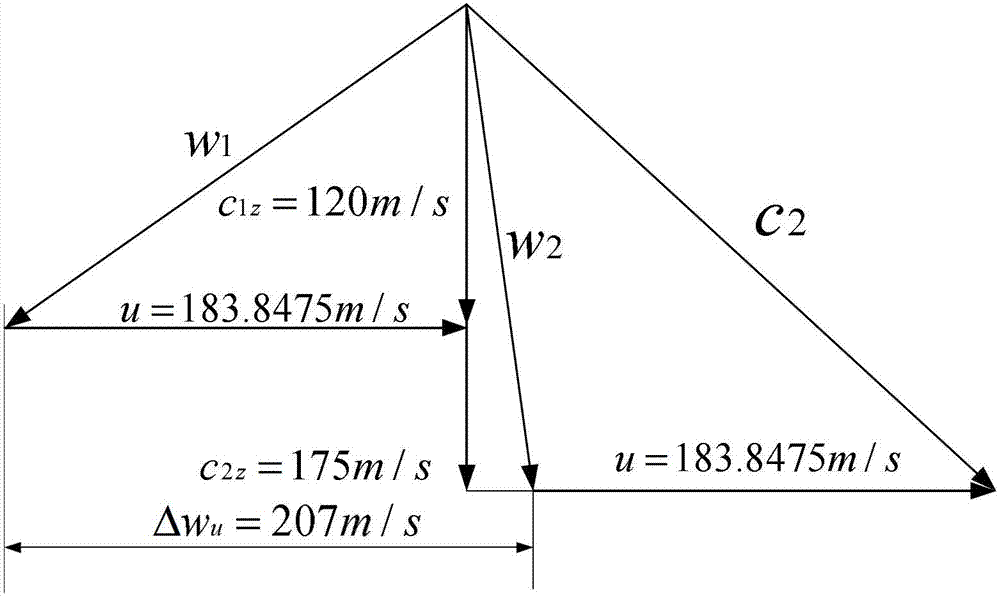

[0020] For the axial flow compressor stage with subsonic inlet relative velocity, in the conventional design, the axial velocities at the rotor blade inlet, rotor blade outlet and stator blade outlet are usually equal or have little change. On the premise that the velocity triangle at the inlet of the rotor blade remains unchanged, as the stage load increases to a certain level, boundary layer flow separation will occur inside the rotor blade. At this time, by increasing the contraction range of the meridional flow channel, the axial velocity of the rotor blade outlet is increased to reduce the reverse pressure gradient of the gas in the rotor blade, avoid boundary layer separation flow in the rotor blade, and improve the gas flow efficiency in the rotor blade. From a one-dimensional point of view, the method for determining the value of the increase in the axial velocity at the outlet is as follows:

[0021] D = 1 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com