bhc quick sleeve threaded joint

A technology of threaded joints and casing joints, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of increasing the cost of oil extraction, and achieve the effects of saving make-up time, improving operation efficiency, and reducing the number of screwing turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solution of the present invention more clearly understood, it will be described in detail below in conjunction with the accompanying drawings and embodiments.

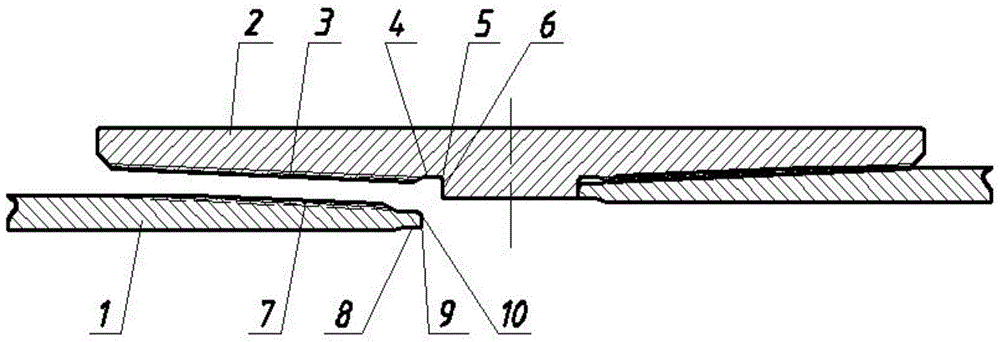

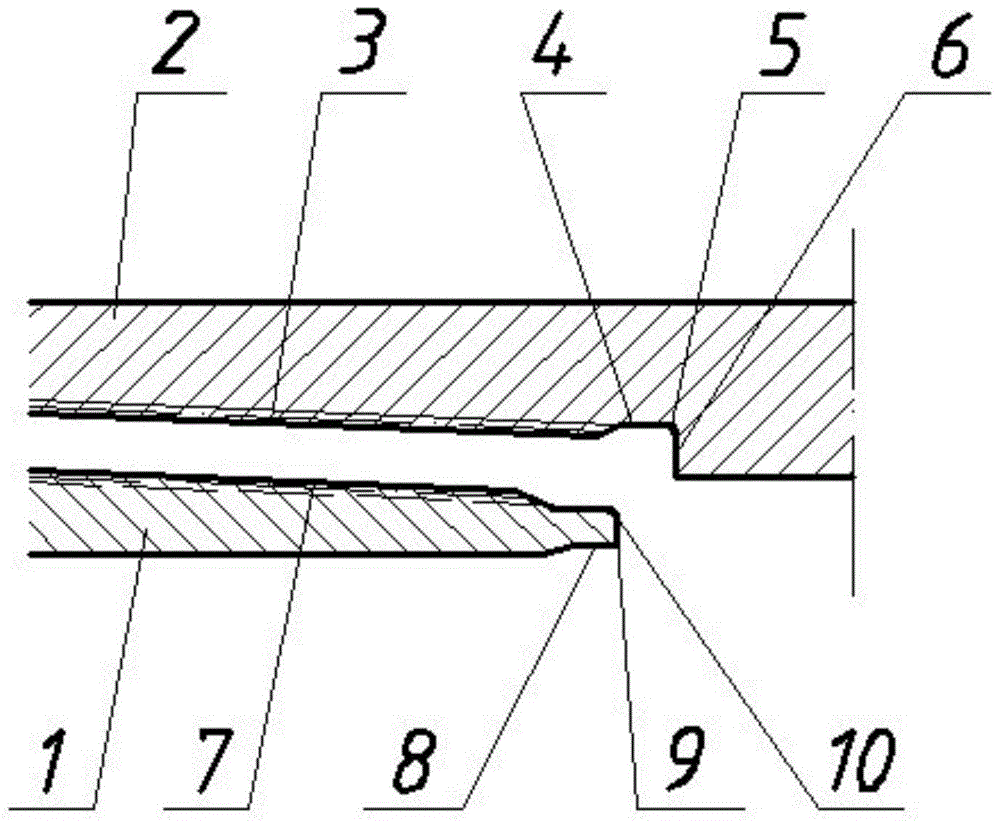

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , the BHC quick casing threaded joint of the present invention comprises a collar 2 and two casing joints 1 respectively connected to the two ends of the collar 2;

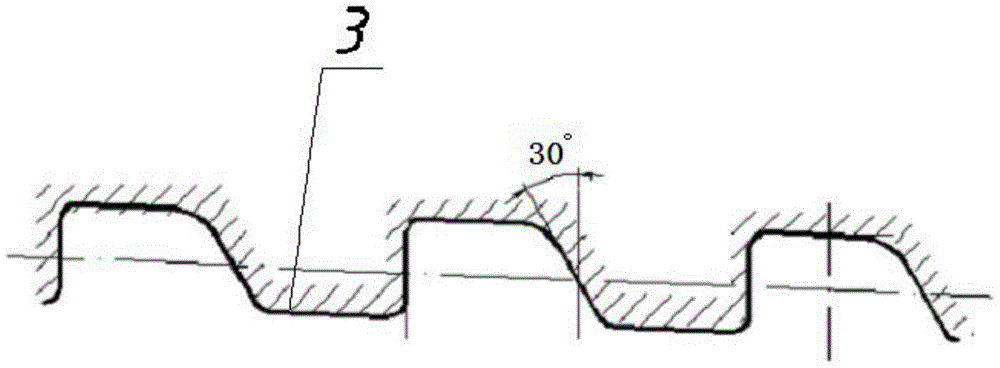

[0028] The outer diameter of the casing joint 1 is provided with a tapered pipe external thread 7 that gradually shrinks from outside to inside, and the inner diameter of the coupling 2 is provided with a tapered pipe external thread 7 that gradually shrinks from outside to inside and fits with the tapered pipe external thread 7 . Tapered pipe internal thread 3;

[0029] The outer surface of the casing joint 1 is provided with an outer shoulder transition surface 10 and an outer torque shoulder 9 sequentially from the outside to the inside in addition to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com