Patents

Literature

38results about How to "Increase axial speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

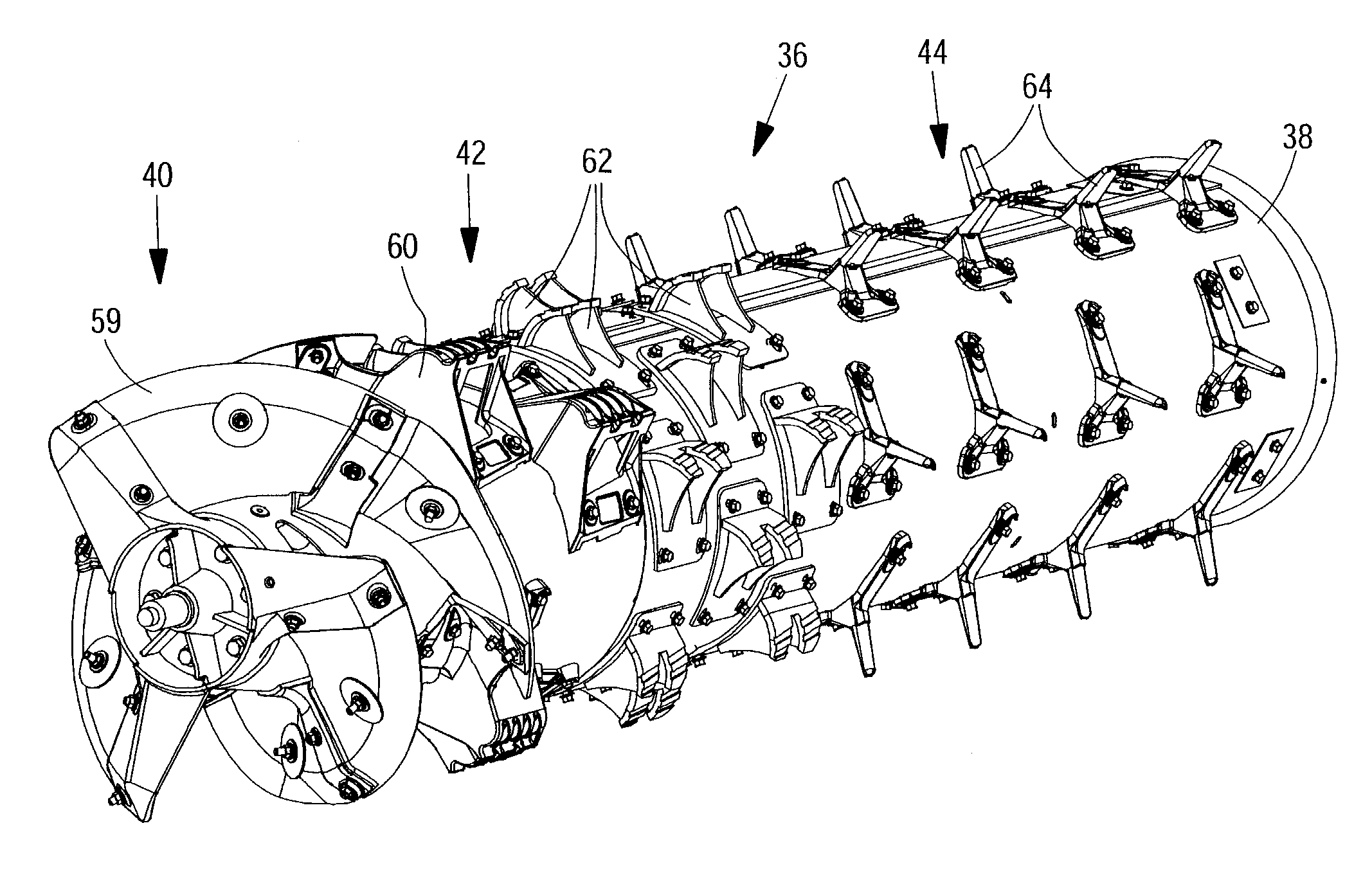

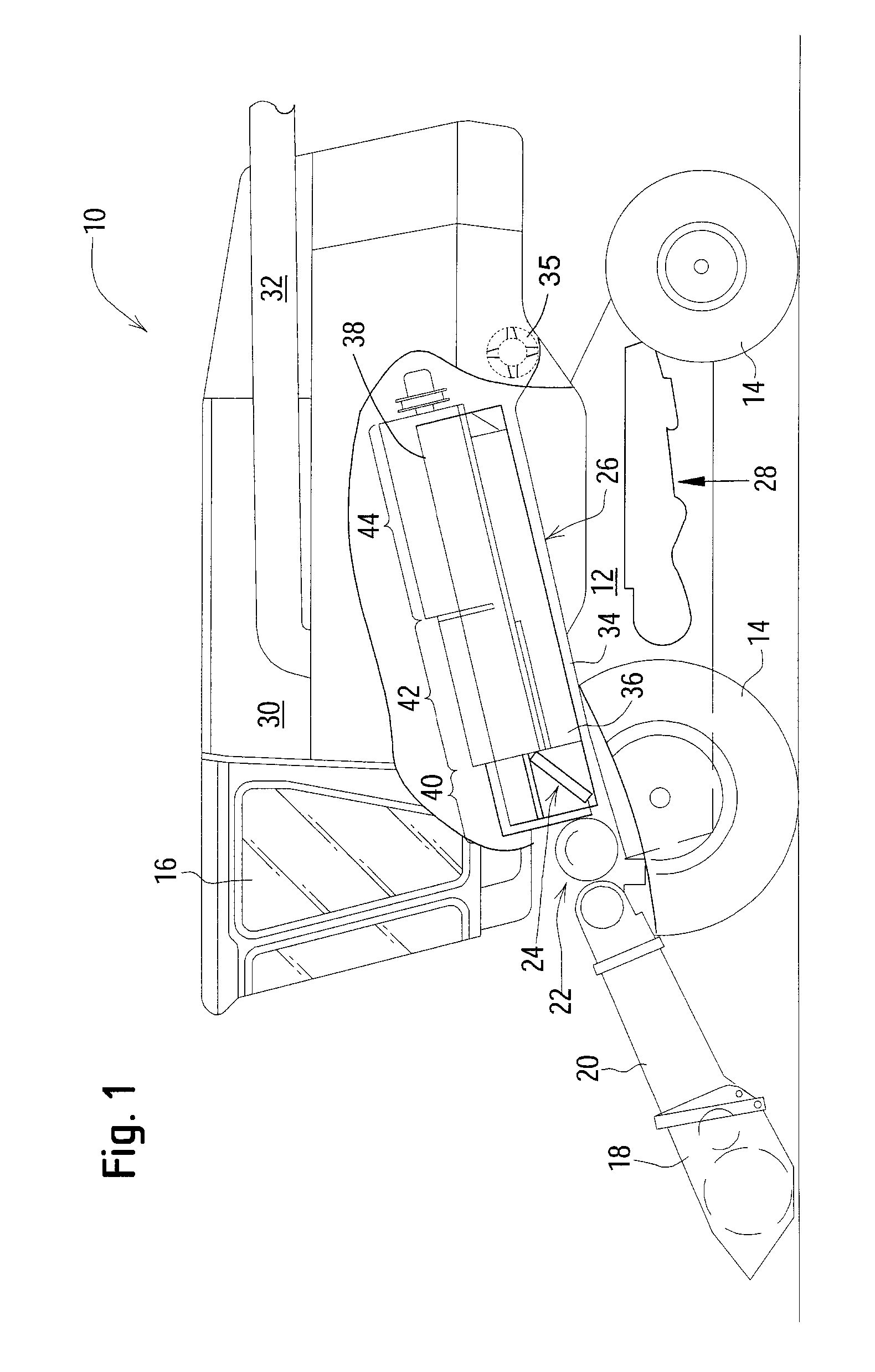

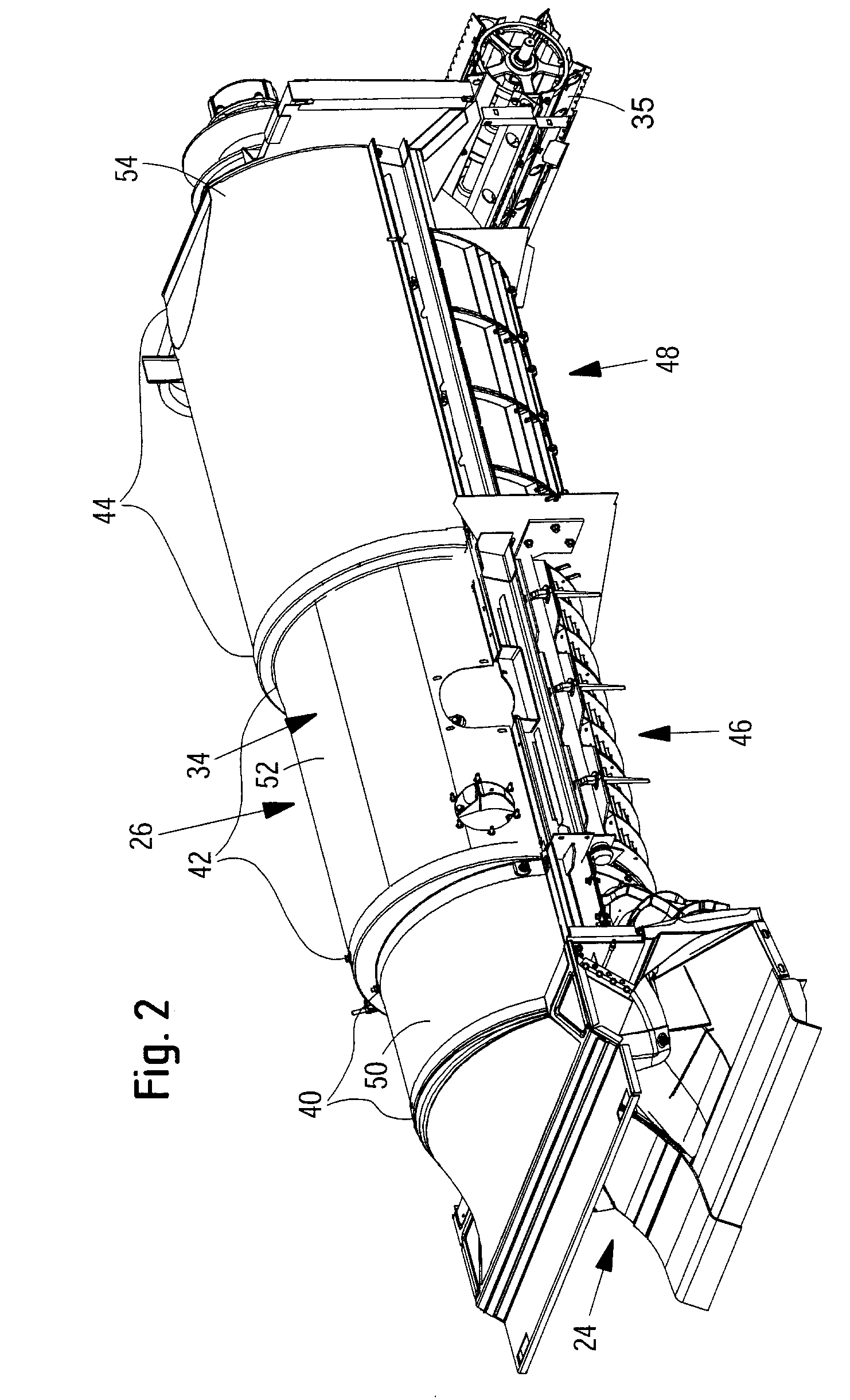

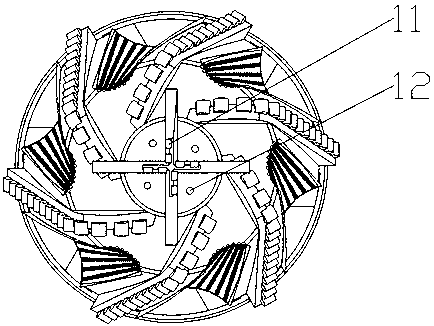

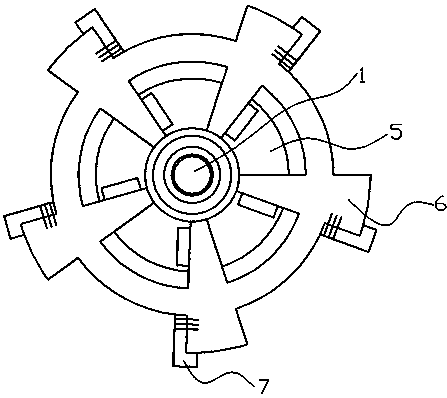

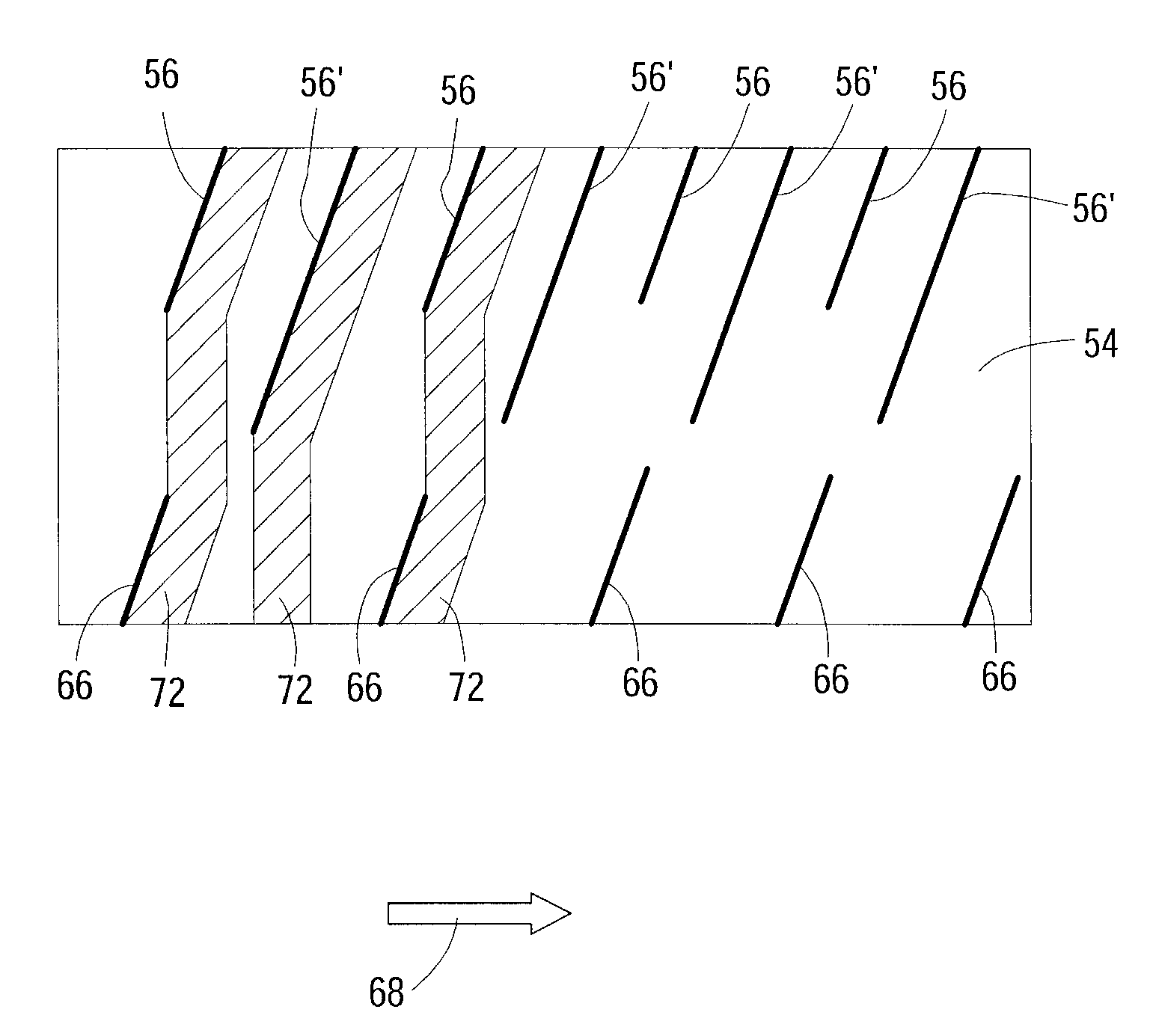

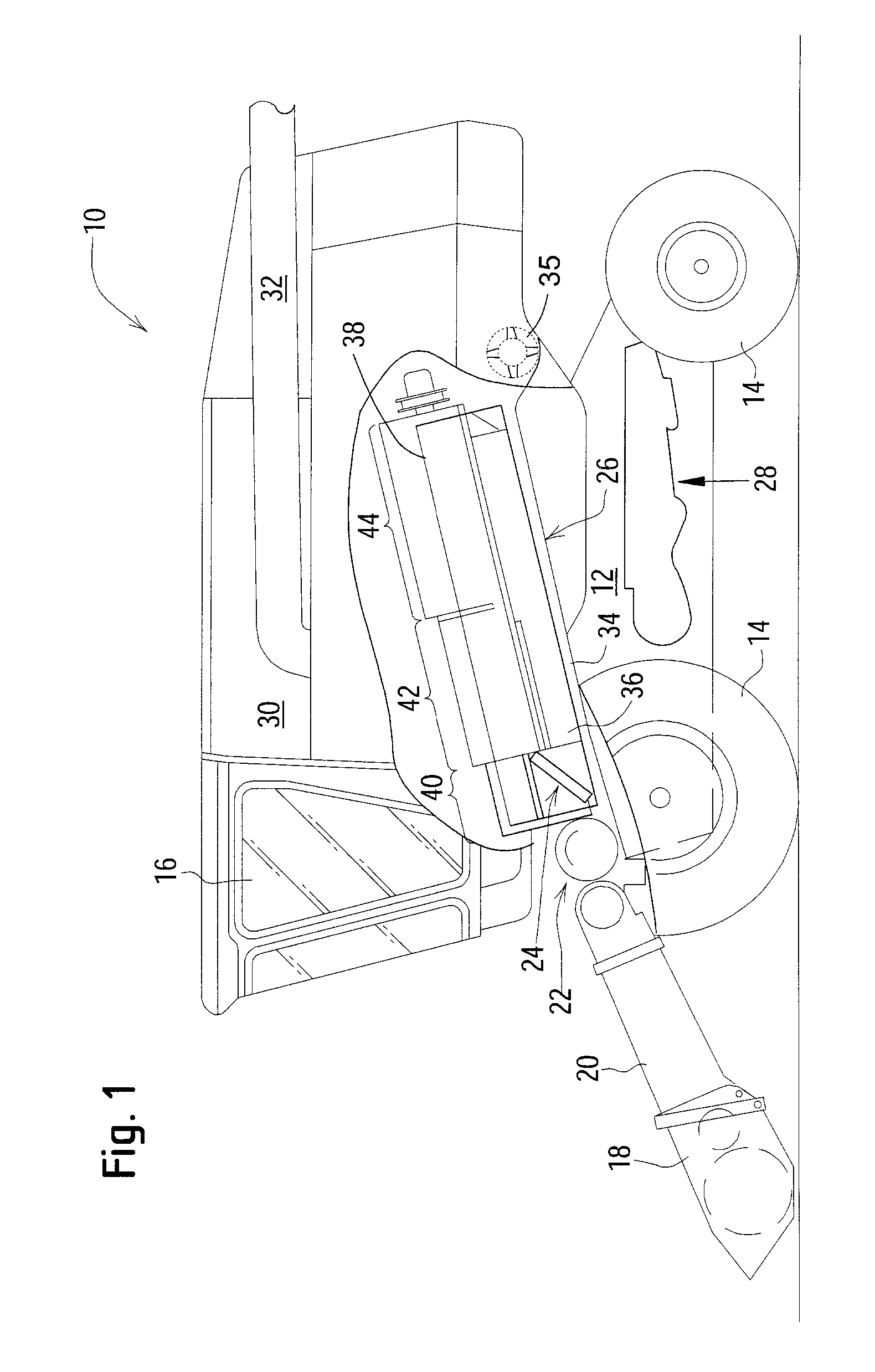

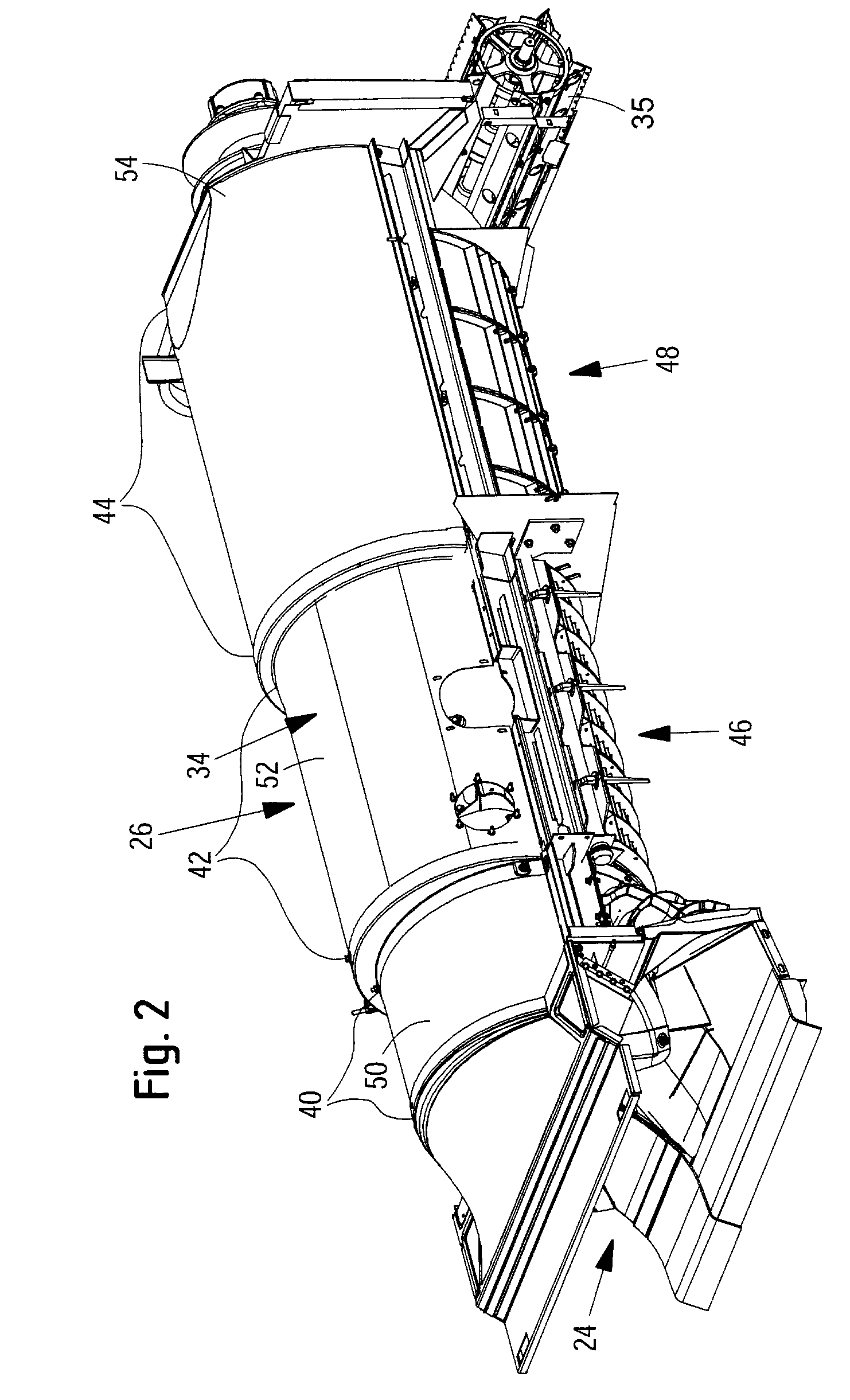

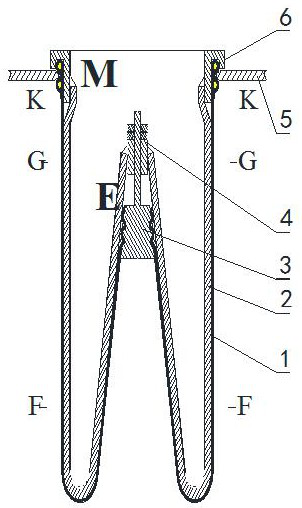

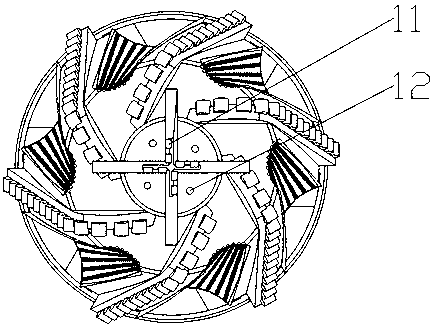

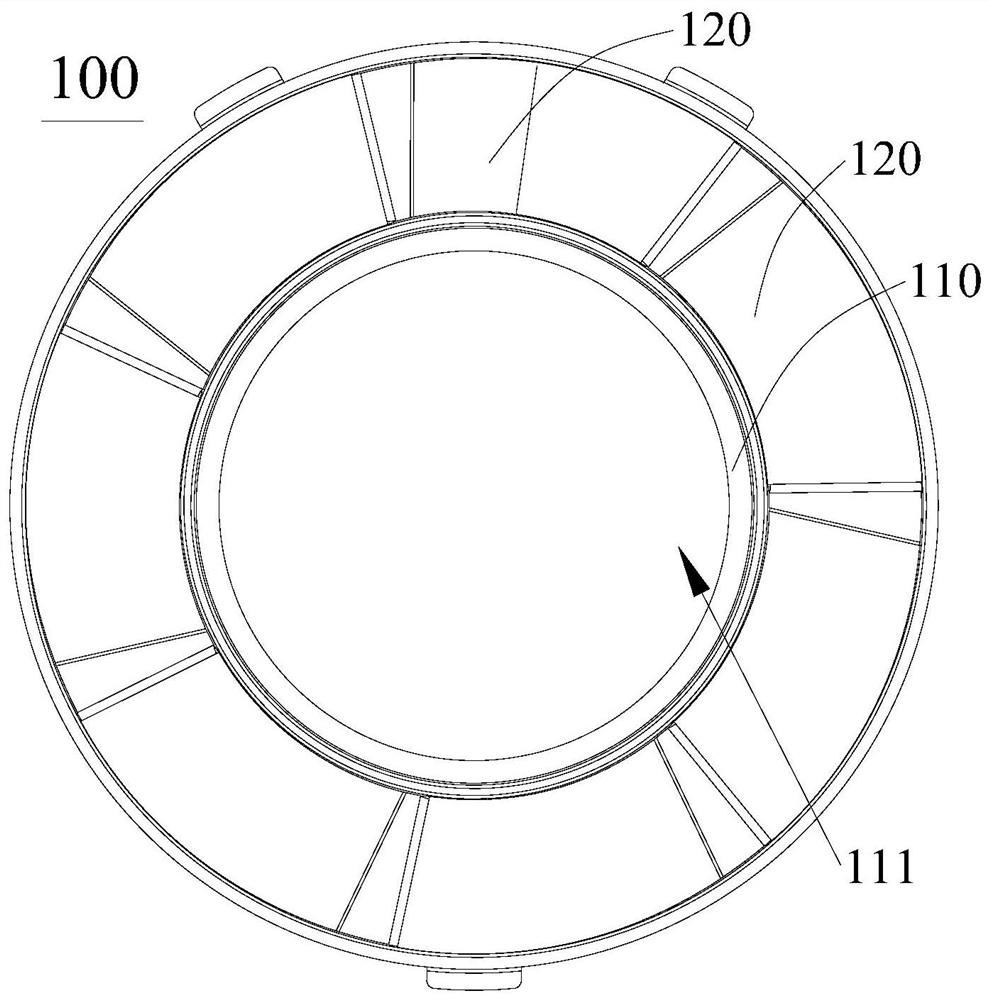

Harvested crop processing unit with number of circulation circuits depending on throughput

InactiveUS20090011807A1Increase axial speedAppropriate performanceGrain huskingGrain polishingEngineeringFront and back ends

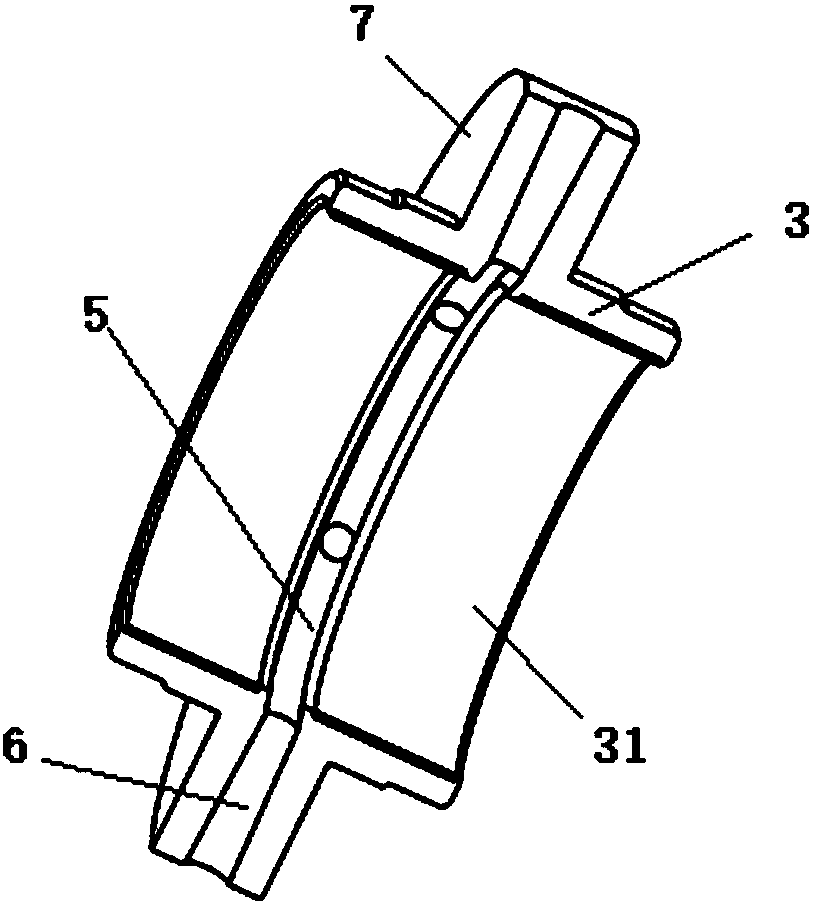

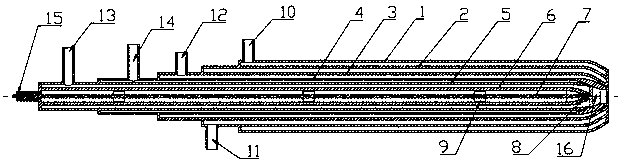

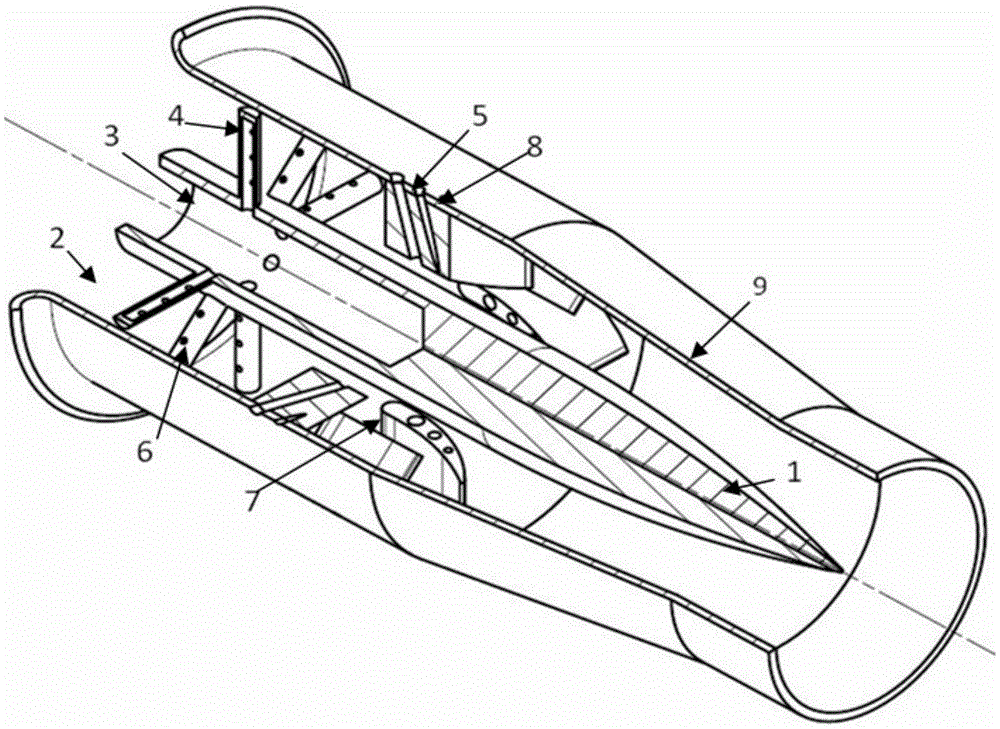

A harvested crop processing unit with a rotor and a rotor housing enclosing the rotor, that includes a cover element under which a first group of helically shaped guide rails and a second group of helically shaped guide rails are attached, where the guide rails of the two groups follow each other alternately and are provided with a leading end and a trailing end in the direction of rotation of the rotor and the guide rails of the first group are arranged offset to the rear of the guide rails of the second group in the direction of rotation of the rotor. The trailing ends of the guide rail of the first group are directed at the leading end of the guide rails of the second group following in the axial direction of the rotor housing.

Owner:DEERE & CO

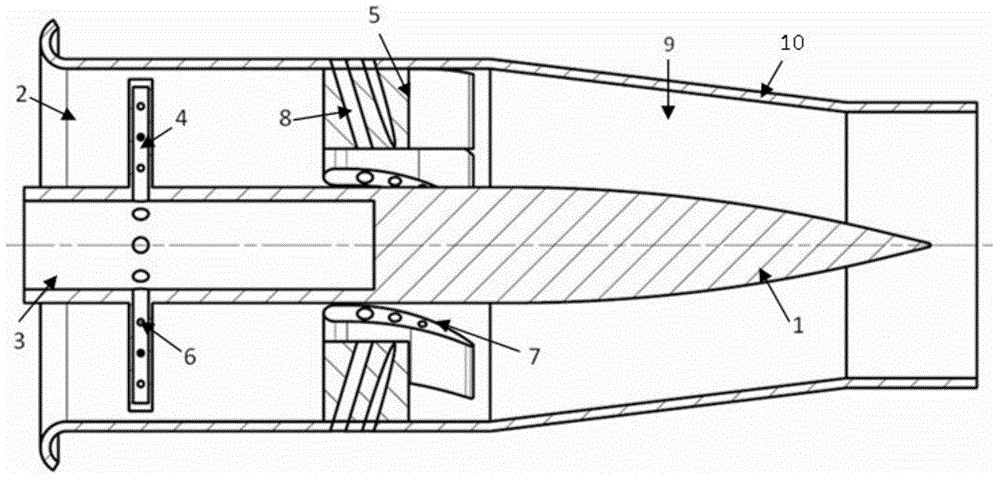

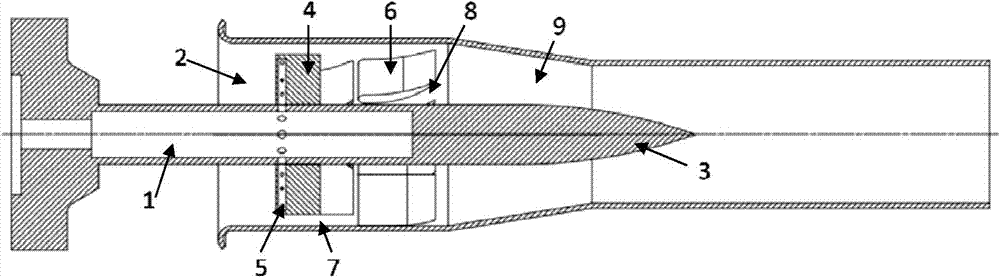

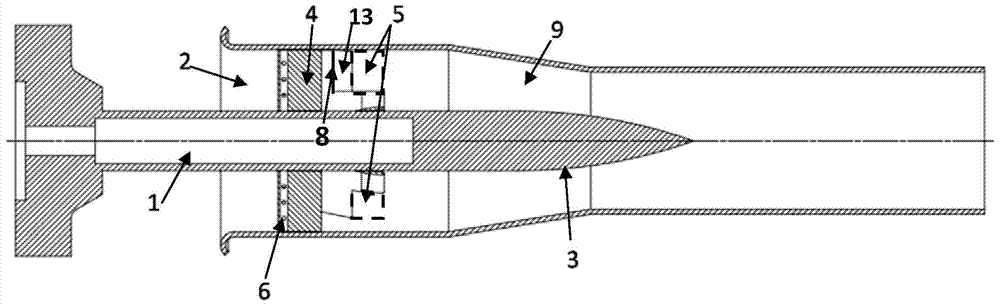

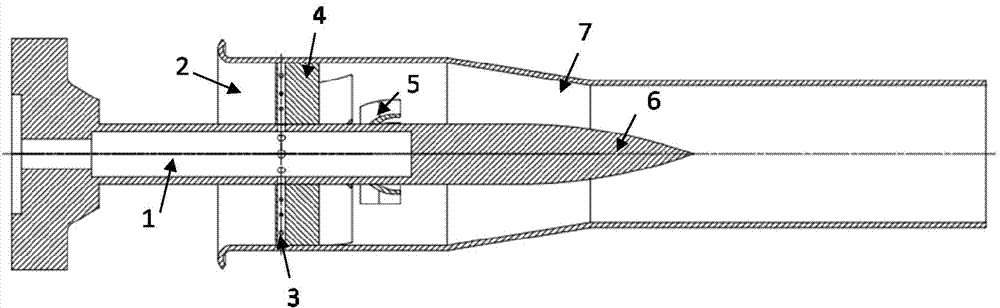

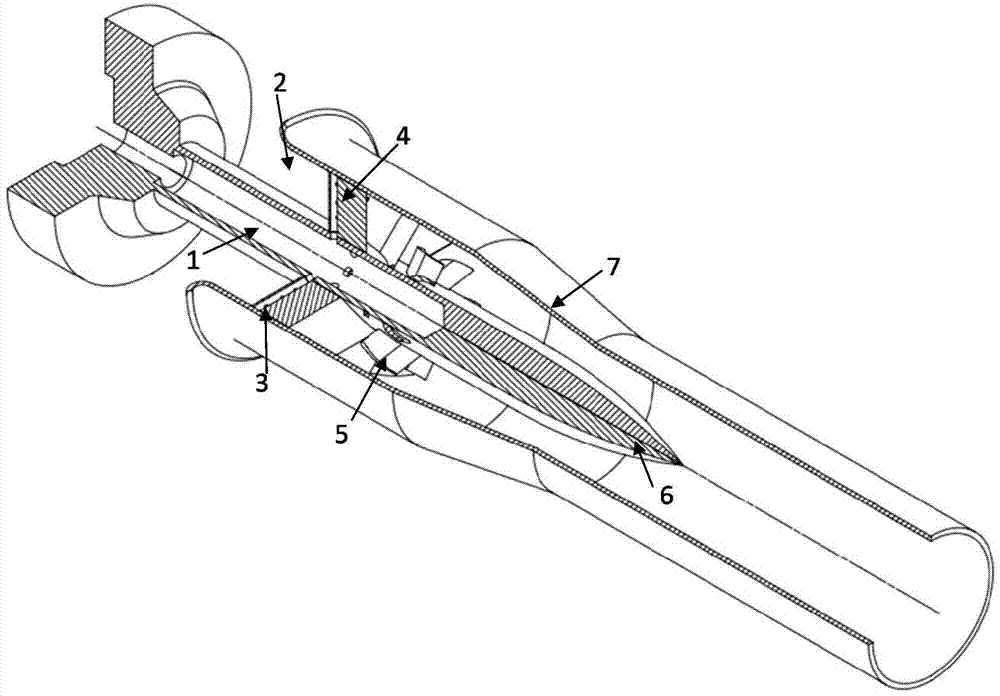

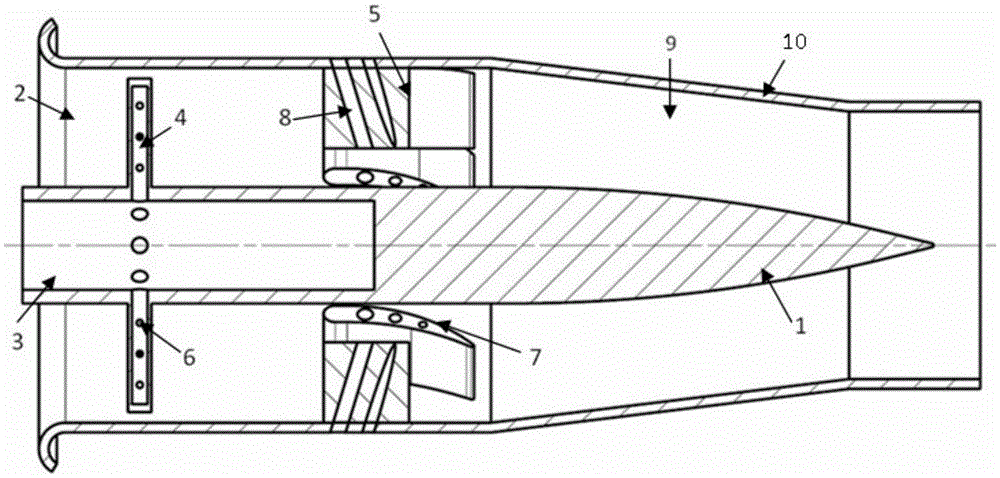

Blade type air inlet swirl nozzle for combustion chamber of gas turbine

ActiveCN104373962AIncrease axial speedContinuous combustion chamberCombustion chamberPollutant emissions

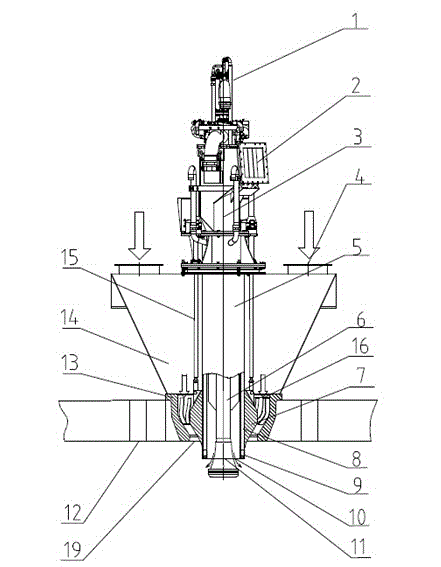

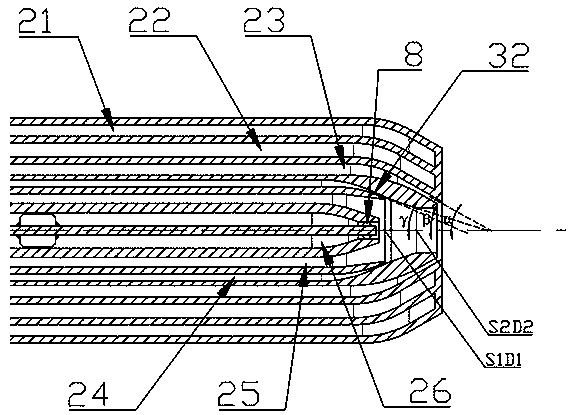

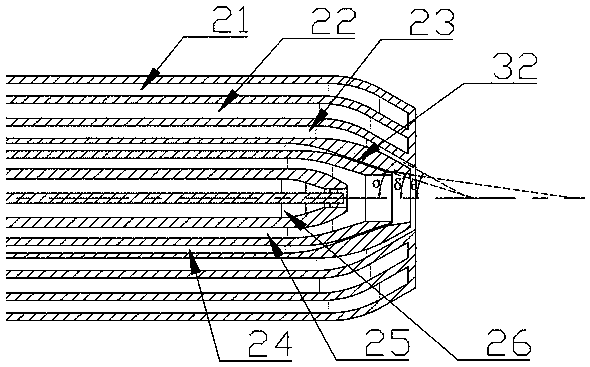

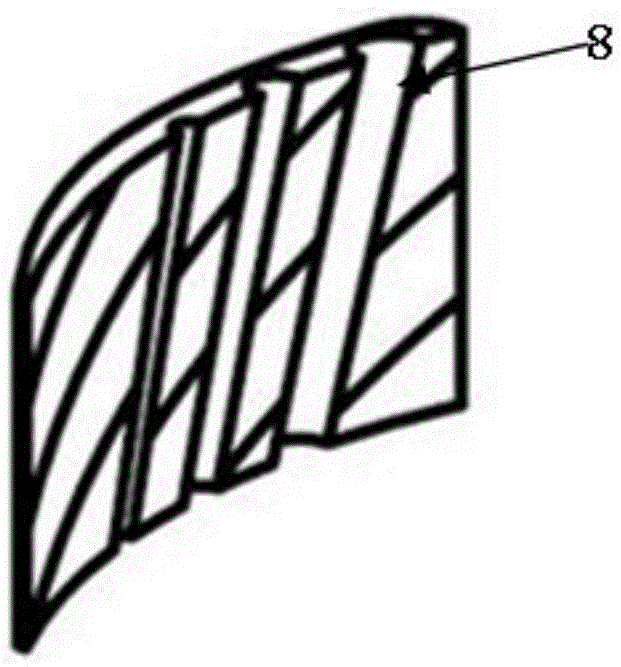

The invention relates to the technical field of gas turbines and discloses a blade type air inlet swirl nozzle for a combustion chamber of a gas turbine. The nozzle comprises a conical inner body, a shell body and multiple swirl blades, wherein the conical inner body is arranged in the shell body, an annular peripheral air channel is formed between the conical inner body and the shell body, the swirl blades are arranged on the inner wall of the shell body in the peripheral direction of the shell body, shell body through holes are formed in the shell body, air inlets communicated with the shell body through holes are formed in the swirl blades, and an angle is formed between each air inlet and the axial direction of the shell body. According to the blade type air inlet swirl nozzle for the combustion chamber of the gas turbine, air is fully mixed with fuel through the air inlets to enhance the mixing of air and fuel gas, and the momentum of airflow is increased in the axial direction and axial speed is increased so as to be matched with fuel concentration and speed distribution on an outlet of the nozzle. The nozzle has the advantages that combustion organization is achieved reasonably and effectively and pollutant discharge is controlled reasonably and effectively.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Aviation engine labyrinth seal structure with tapered leading air holes

PendingCN109139269AReduce leakageReduce air permeabilityLeakage preventionGas turbine plantsAviationAero engine

The invention relates to an aviation engine labyrinth seal structure with tapered leading air holes, which comprises a rotating shaft provided with a plurality of labyrinths, a labyrinth bushing ring,wherein an annular groove is arranged in the inner wall of the labyrinth bushing ring in the circumferential direction; the annular groove comprises an air inlet side wall, an air outlet side wall and an annular bottom wall, the air inlet side wall is obliquely arranged so that the connection part of the air inlet side wall and the inner wall of the labyrinth bushing ring is diffused in a horn shape to guide the leakage airflow flowing along the inner wall of the labyrinth bushing ring; the annular bottom wall is provided with a plurality of tapered leading air holes for introducing air flowalong the radial direction of the labyrinth bushing ring, the tapered leading holes are arranged in a conical shape, and the diameter of an air outlet end of the tapered leading holes is smaller thanthe diameter of an air inlet end so as to pressurize the air flow introduced into the annular groove; When assembled, the air inlet side wall and air outlet side wall of the annular groove are arranged in the same labyrinth cavity, and when the leakage air flow flows to the annular groove, the air flow enters the annular groove from the inlet side wall.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

Cyclone concentrate spray nozzle

The invention discloses a cyclone concentrate spray nozzle, which comprises a material conveying pipe, wherein a center oil gun is coaxially arranged in the material conveying pipe, an air chamber is fixedly arranged at the outer side of the material conveying pipe, and is in an inverted truncated cone shape, a cyclone bird nest water jacket for forming cyclonic air is fixedly arranged at the lower end of the air chamber, a material conveying pipe outer layer for providing cooling air is arranged at the outer side of the material conveying pipe, a cyclone pipe for forming cyclonic air is fixedly arranged at the lower ends of the material conveying pipe and the material conveying pipe outer layer, the cyclone bird nest water jacket is arranged at the outer side of the material conveying pipe, an air outlet is formed by a gap between the cyclone bird nest water jacket and the the material conveying pipe, the directions of rotary air formed by the cyclone bird nest water jacket and the cyclone pipe are the same, and a high-speed rotary flow field is formed at the combining part of a material outlet. The cyclone concentrate spray nozzle has the advantages that by arranging the two cyclone mechanisms, the two types of cyclonic air are combined, the concentrate and reaction gas can be fully mixed, and the smoke dust rate is reduced; by increasing the negative pressure value at the material outlet, the problems of air returning and material returning are effectively reduced, and the production capacity of concentrate feeding is improved.

Owner:JINCHUAN GROUP LIMITED +1

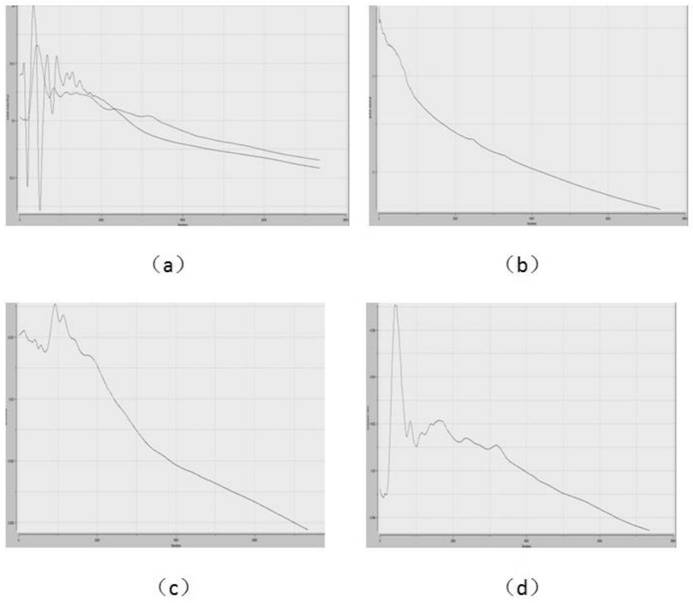

Gas turbine compressor casing anti-surge structure and surge margin evaluation method thereof

InactiveCN112160943AImprove flow statusReduce angle of attackPump componentsDesign optimisation/simulationEngineeringInlet flow

The invention discloses a gas turbine compressor casing anti-surge structure and a surge margin evaluation method thereof. The gas turbine compressor casing anti-surge structure comprises a compressorcasing, wherein a casing treatment section is arranged on the front portion of the compressor casing, the casing treatment section comprises an anti-flow-loss section inner cavity, an anti-flow-losssection inner ring is arranged on the inner side of the anti-flow-loss section inner cavity, an axial chute is formed in the anti-flow-loss section inner ring and communicates with a backflow cavity in the anti-flow-loss section inner cavity, and a radial baffle is arranged in the anti-flow-loss section inner cavity; the axial chute rotates by 90 degrees along the radius line of the circle where the axial chute is located, is parallel to the blade chord line of a rotor blade, and rotates by 45 degrees along the axis of the circle where the axial chute is located; by changing the structure of the axial chute, the air inlet amount and the air inlet flowing condition are changed; and meanwhile, an exhaust section is optimized, the axial speed is increased, the flow coefficient is increased, the flowing state with the too large top attack angle is improved, stability expansion is effectively carried out, and the beneficial effects of effectively reducing the increased air amount, reducingthe attack angle at the blade tip of a movable blade and reducing the flow of a stall point are achieved.

Owner:NAVAL UNIV OF ENG PLA

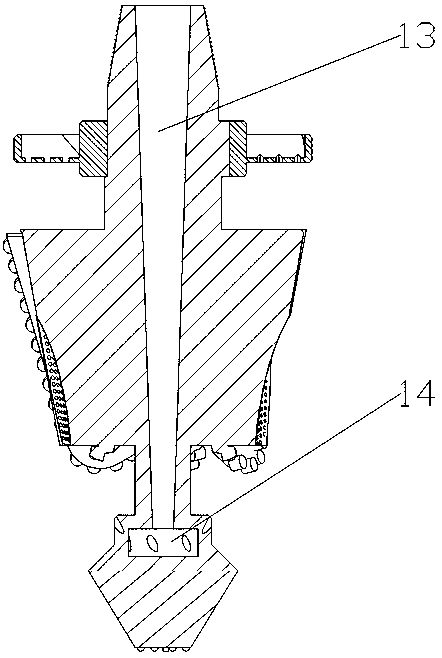

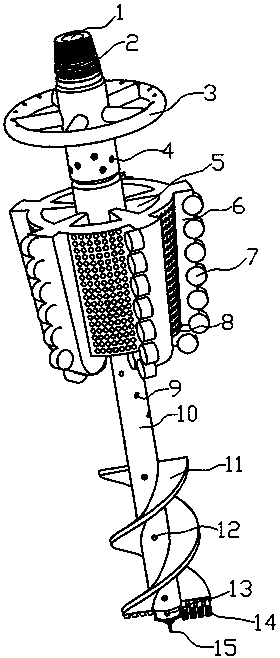

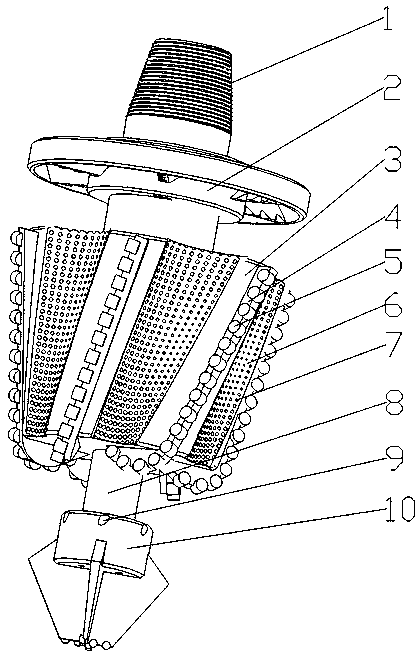

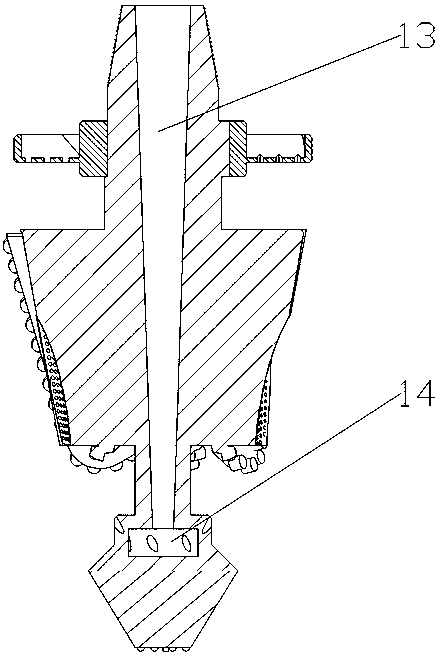

Composite drill bit for submarine natural gas hydrate layer

ActiveCN108678679AAchieve technical effectImprove rock breaking efficiencyDrill bitsConstructionsSedimentSubmarine

The invention discloses a composite drill bit for a submarine natural gas hydrate layer. The composite drill bit is mainly divided into three layers, wherein the first layer is a lead hole drill bit body for drilling a lead hole and is provided with a drilling fluid jet hole for cleaning the bottom of a well and assisting debris removal; the second layer is a hole expanding drill bit body for further expanding a wellbore and is provided with a spiral groove for facilitating discharge of rock debris; the third layer is a secondary crushing mechanism for refining large-diameter particles of hydrate sediments; meanwhile, a tapered flow passage for increasing a flow rate of the drilling fluid and a diffuser cavity for exciting the jet pressure are arranged in the drill bit body. The compositedrill bit provided by the invention is suitable for a fluidized mining process of submarine shallow natural gas hydrates, and is more in line with physical characteristics of a hydrate layer, therebyeffectively improving the crushing efficiency of a hydrate rock formation, realizing refinement of the large-diameter particles of the hydrate sediments, and solving problems of rock debris deposition, balling formation and drill tool sticking during long-distance horizontal drilling.

Owner:SOUTHWEST PETROLEUM UNIV

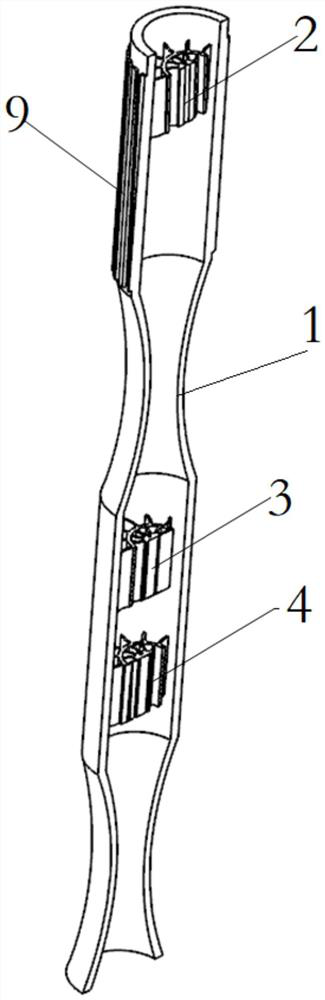

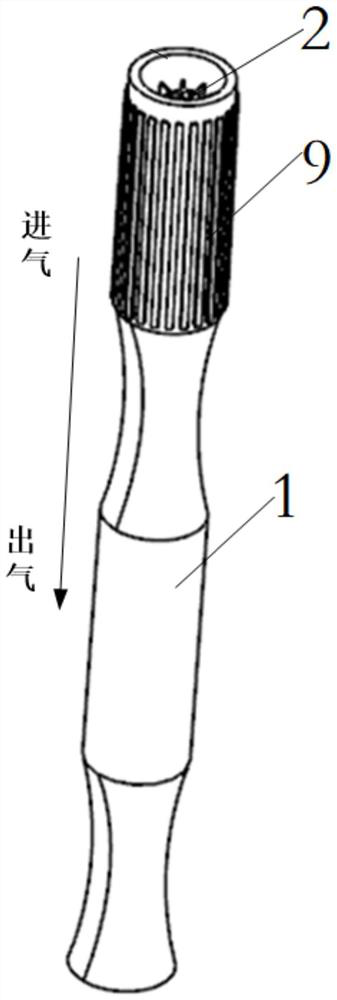

Multistage axial flow compressor with inter-static-blade self-circulating gas suction and injection functions

InactiveCN108661953AIncreased stability marginImprove efficiencyPump componentsAxial flow pumpsStability marginEngineering

The invention provides a multistage axial flow compressor with the inter-static-blade self-circulating gas suction and injection functions. The multistage axial flow compressor comprises a casing, a hub, N rows of static blades, a self-circulating gas suction and injection device and M rows of movable blades, wherein the hub is arranged at the center axis position of the casing, the N rows of static blades are arranged on the inner side of the casing in the axial direction of the casing, the self-circulating gas suction and injection device is arranged between one high-pressure-stage static blade and another low-pressure-stage static blade of the N rows of static blades, the M rows of movable blades are arranged on the outer side of the hub in the axial direction of the casing, the movableblades and the static blades are arranged in a staggered mode, N is greater than or equal to 2, M is greater than or equal to 1, and the self-circulating gas suction and injection device guides gas on suction surfaces of the high-pressure-stage static blades guided back to suction surfaces of the low-pressure-stage static blades for boundary-layer gas injection by utilizing the static pressure difference between the high-pressure stage and the low-pressure stage in the multistage axial flow compressor. According to the multistage axial flow compressor, the beneficial effects of boundary-layergas suction and injection technologies can both be achieved, so that the dual purposes of improving the stability margin and improving the efficiency can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

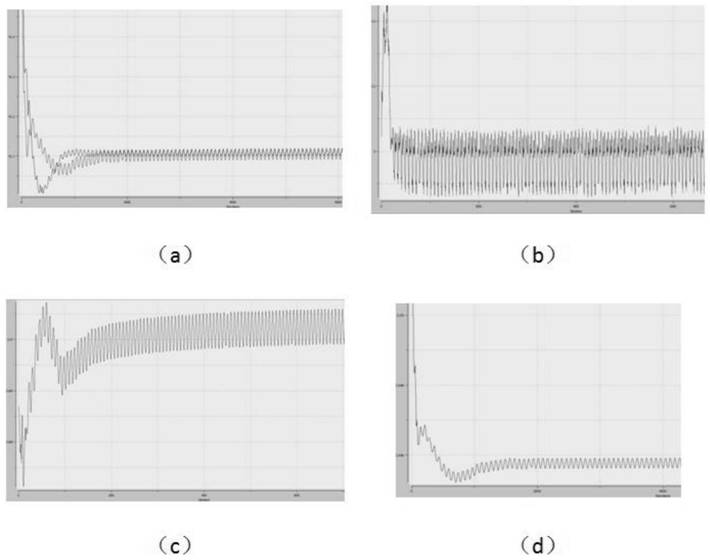

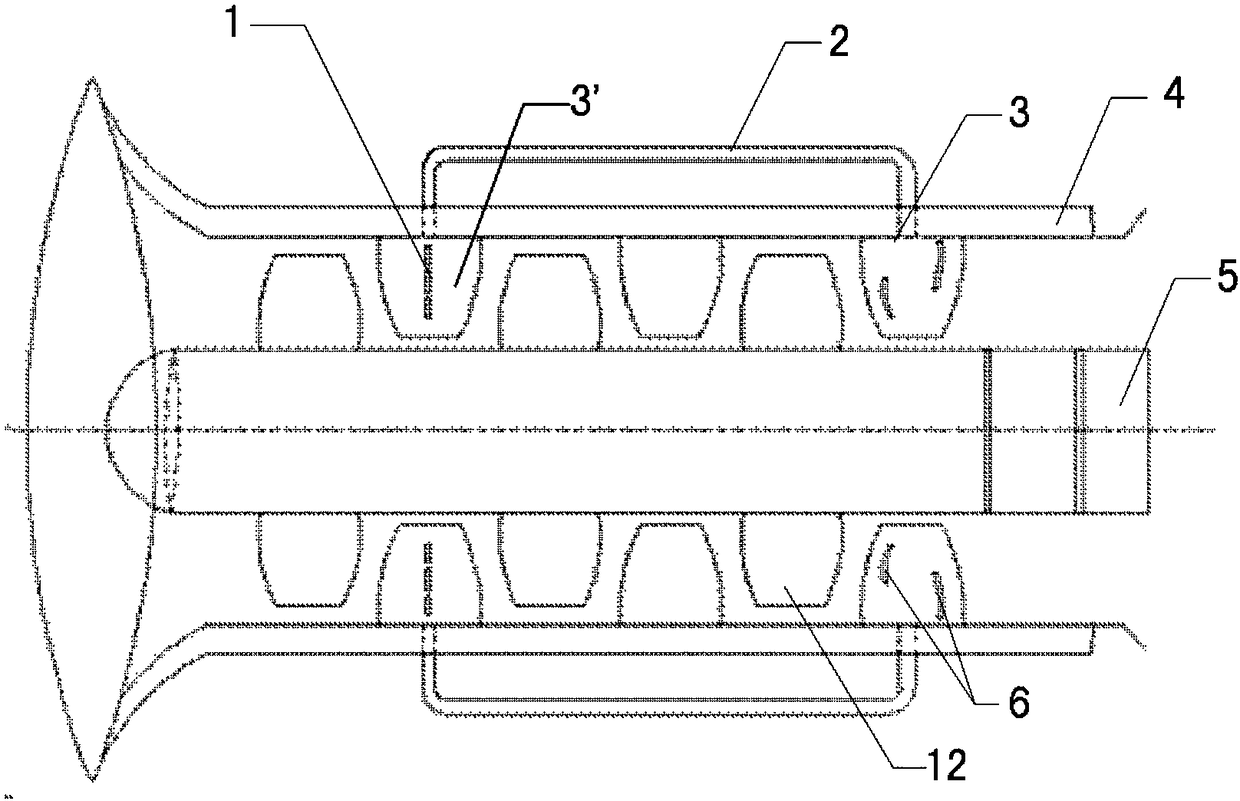

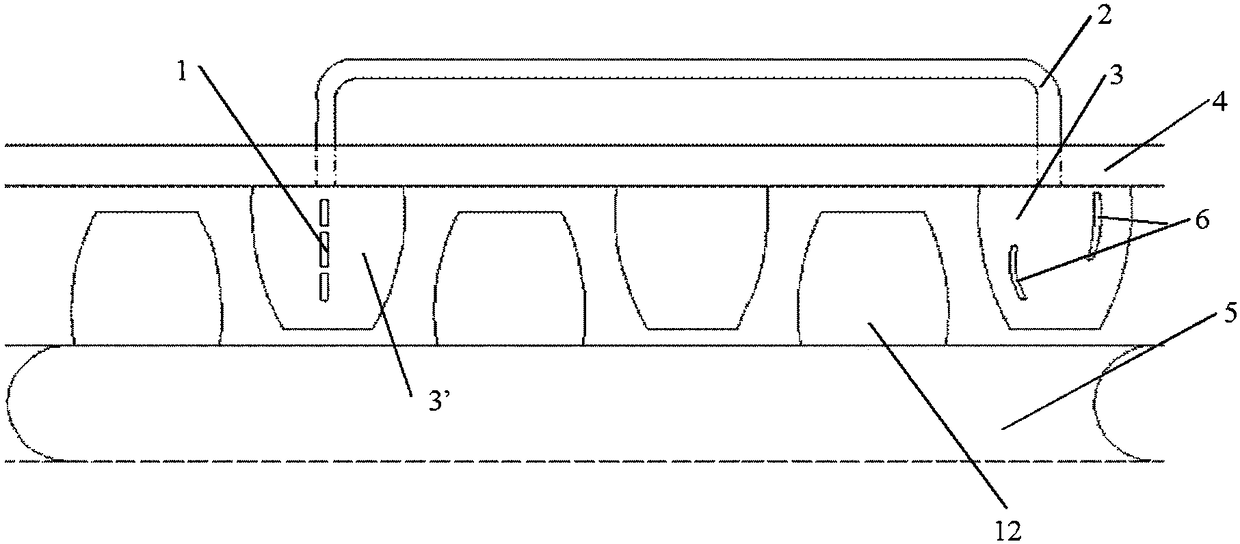

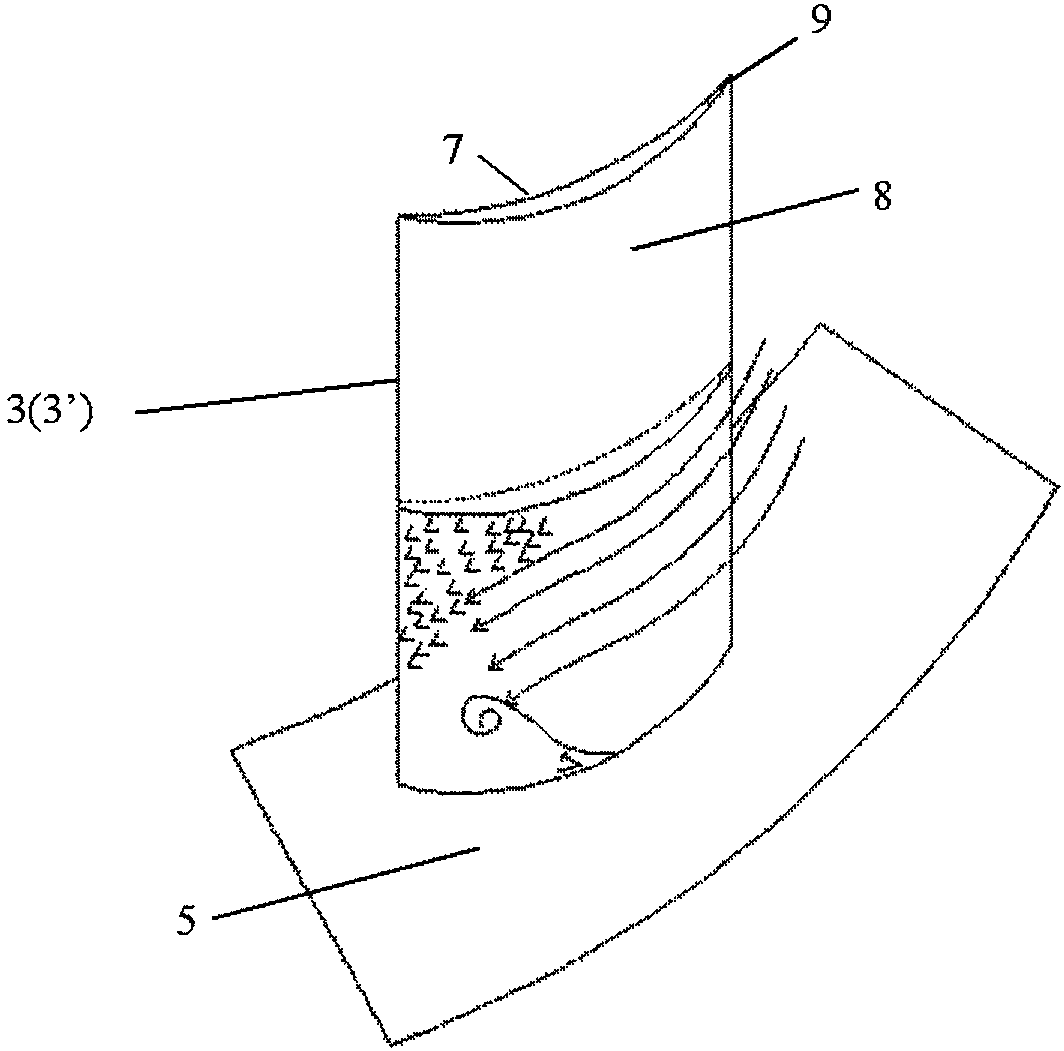

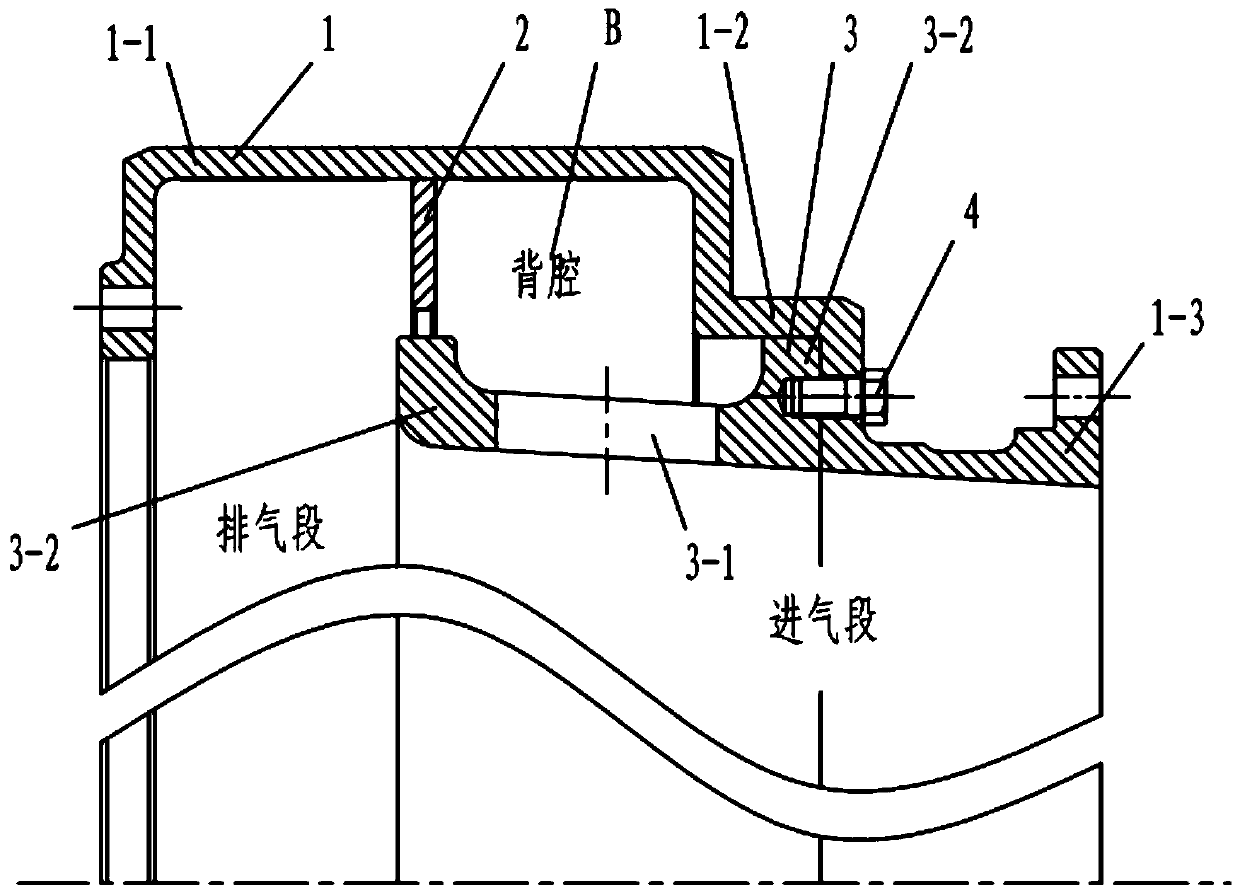

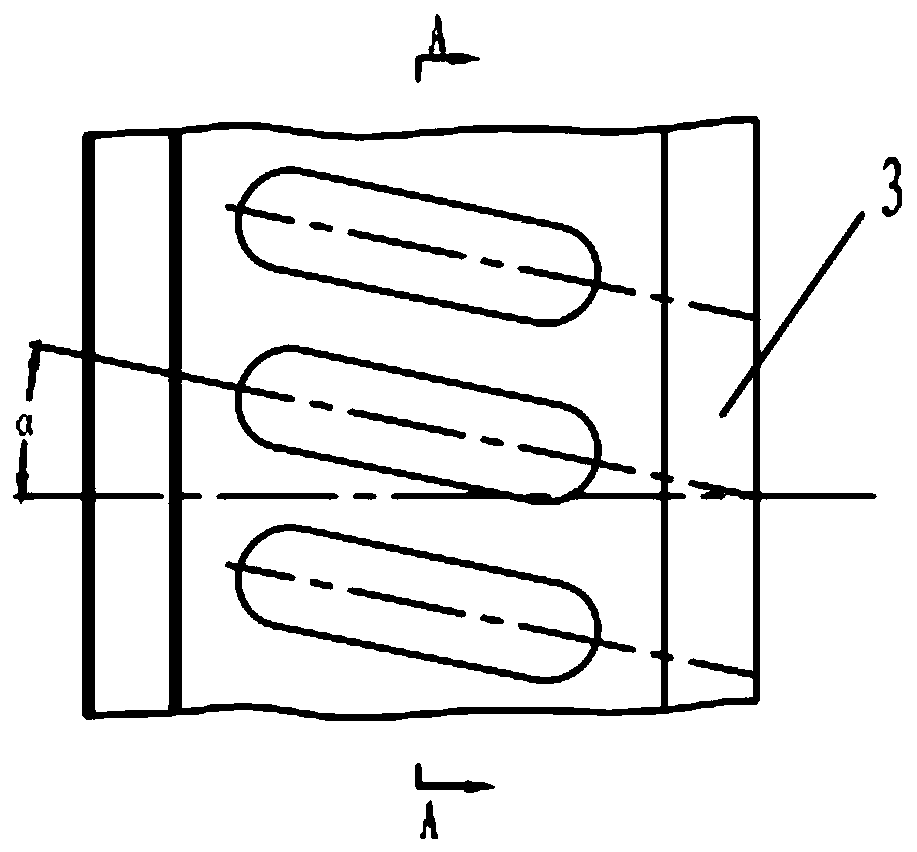

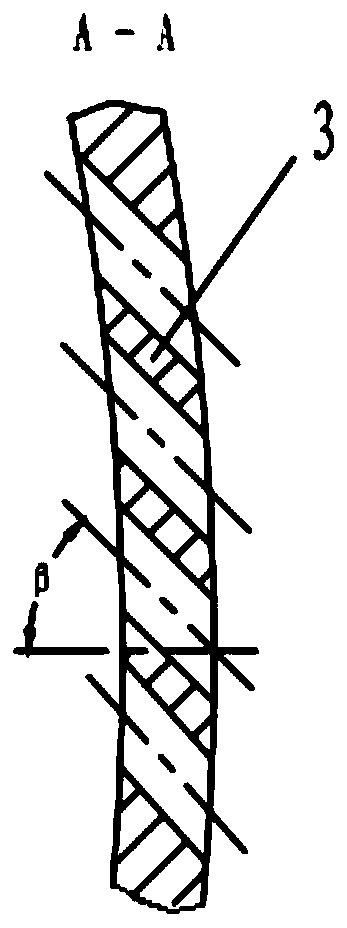

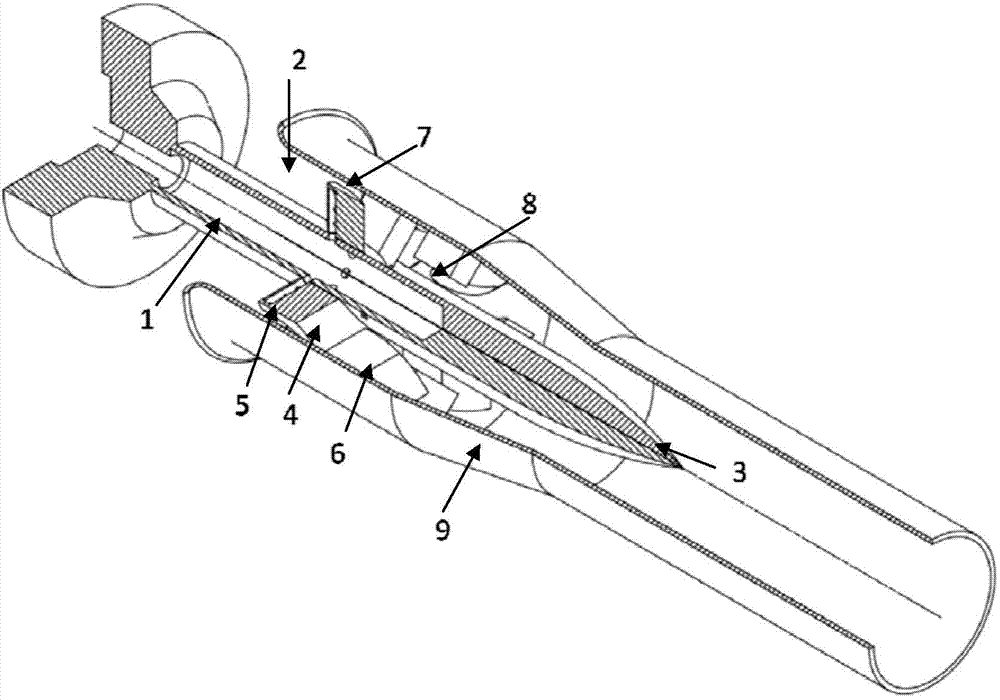

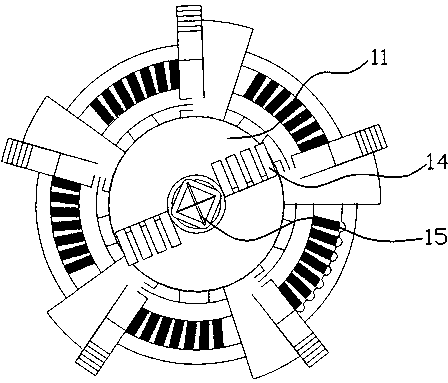

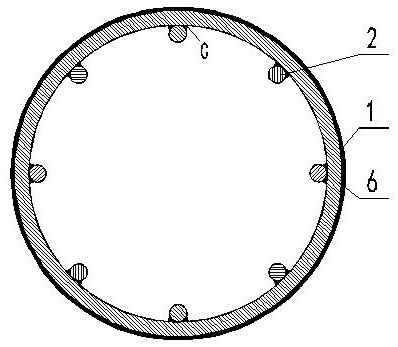

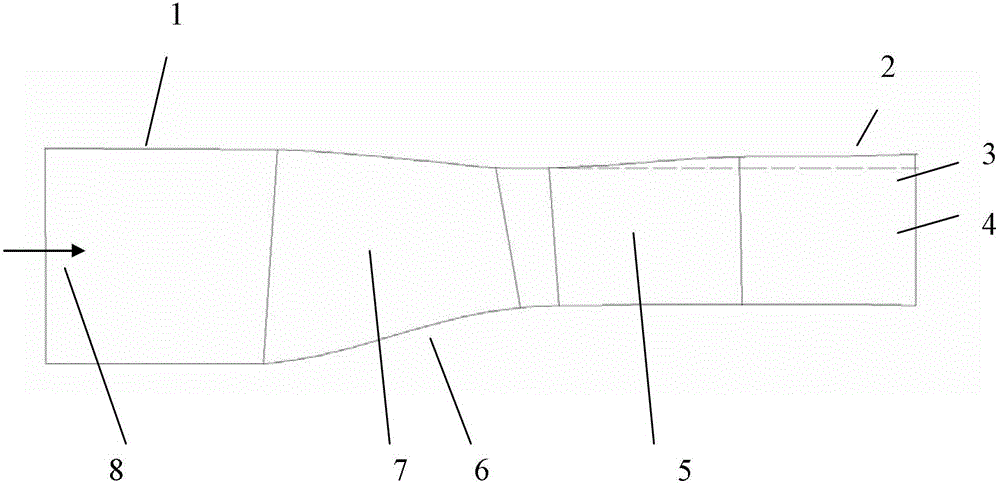

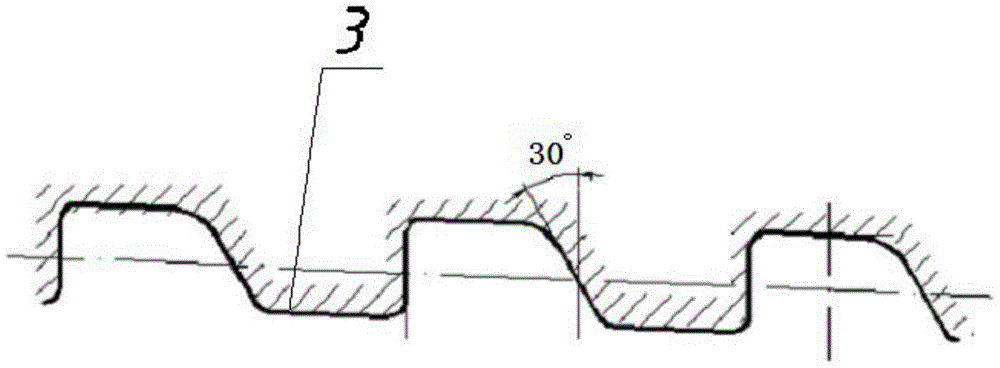

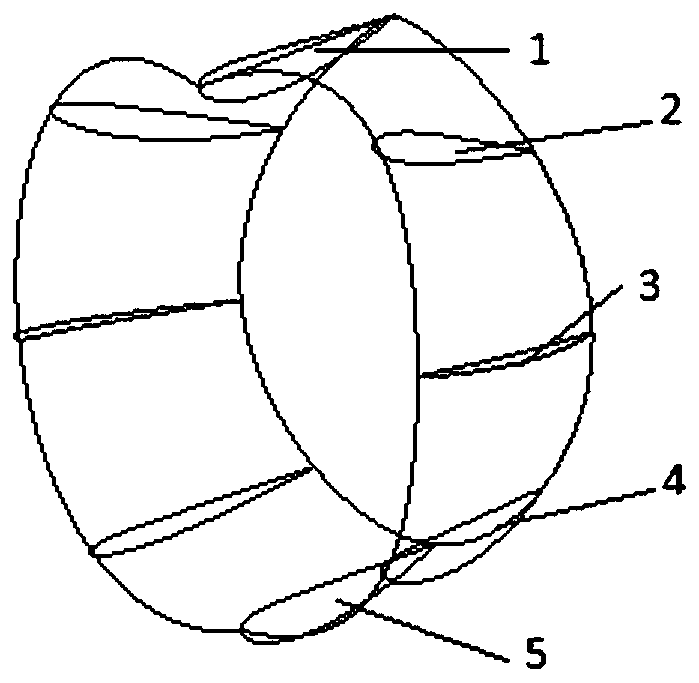

Axial chute type processing casing with back cavity for improving performance of gas compressor

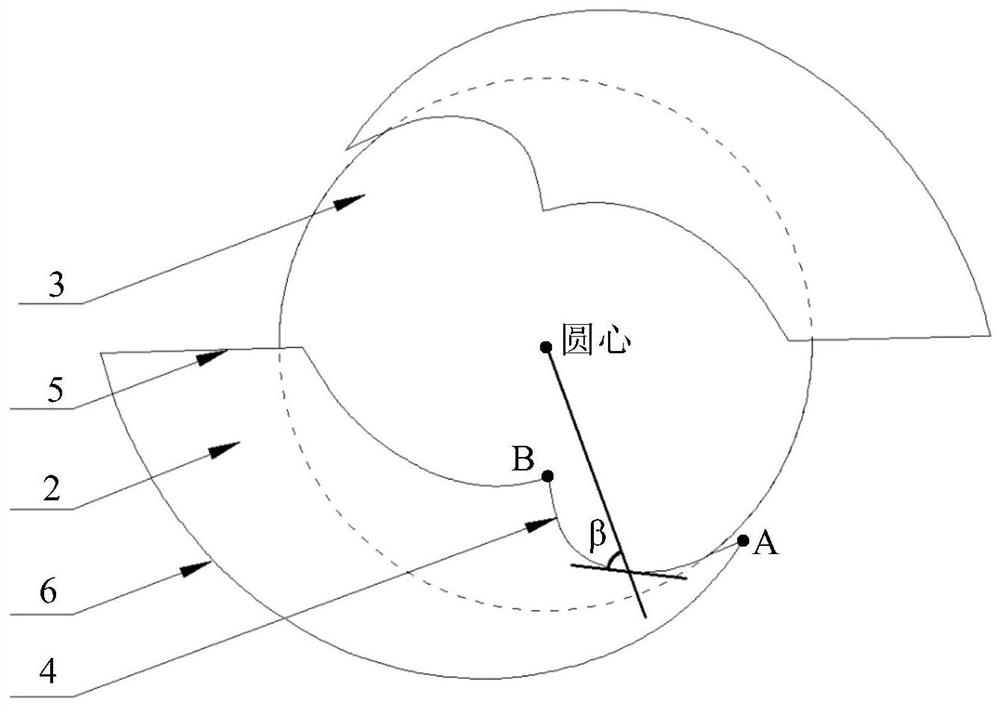

PendingCN111441991AIncrease axial speedReduce impact lossPump componentsPumpsGas compressorEngineering

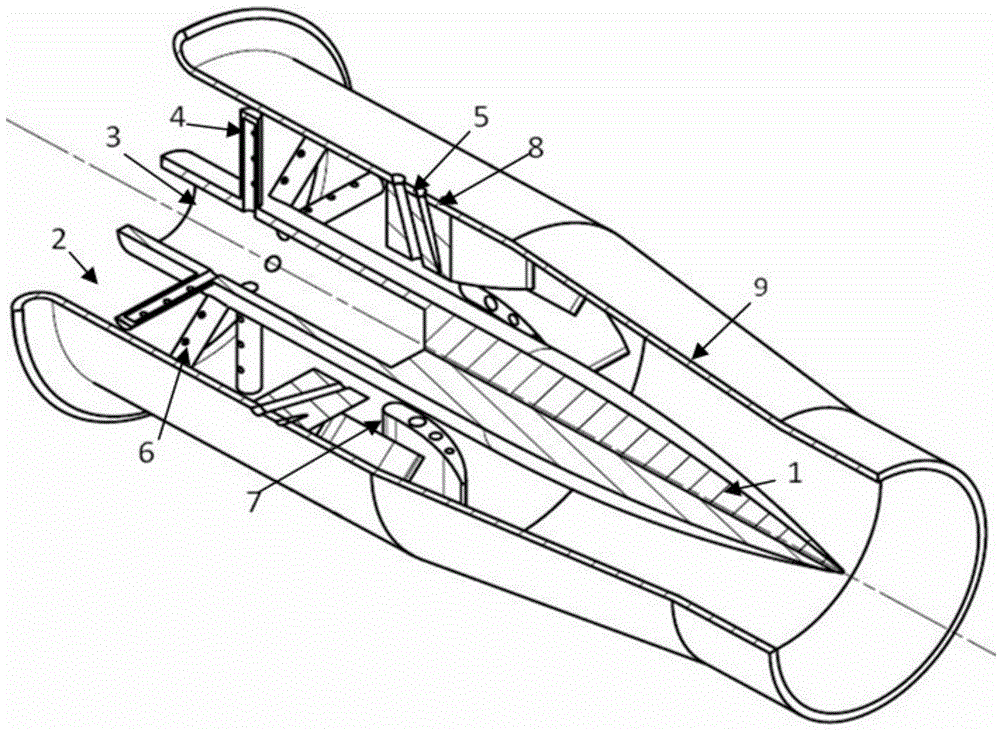

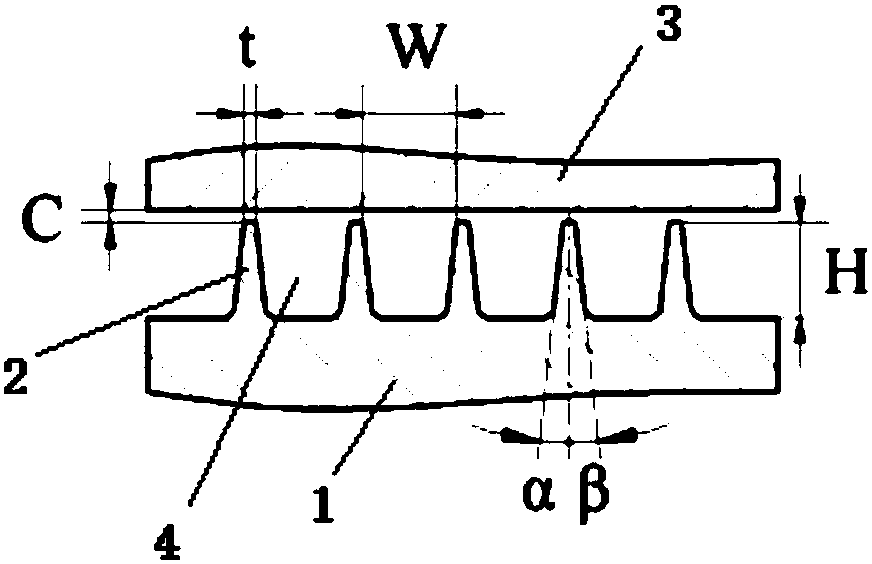

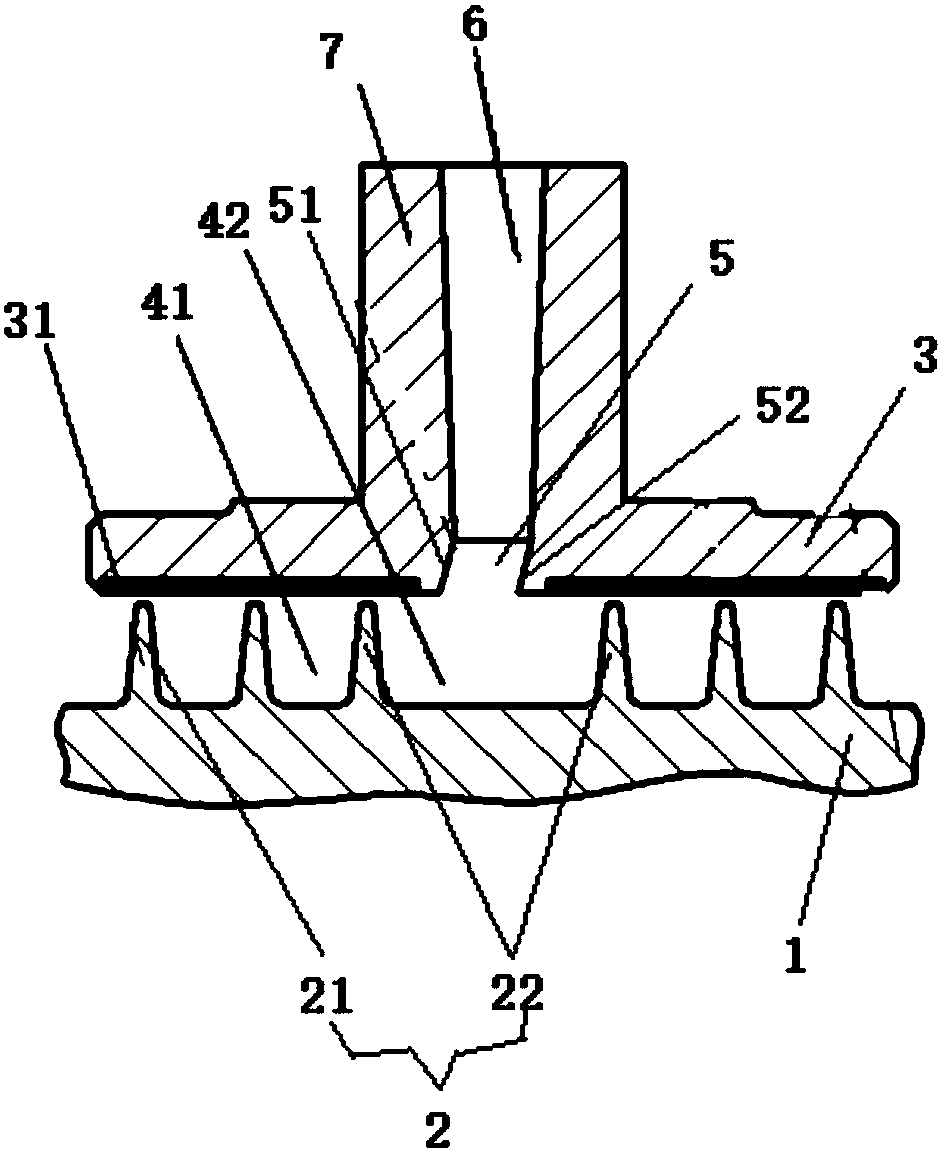

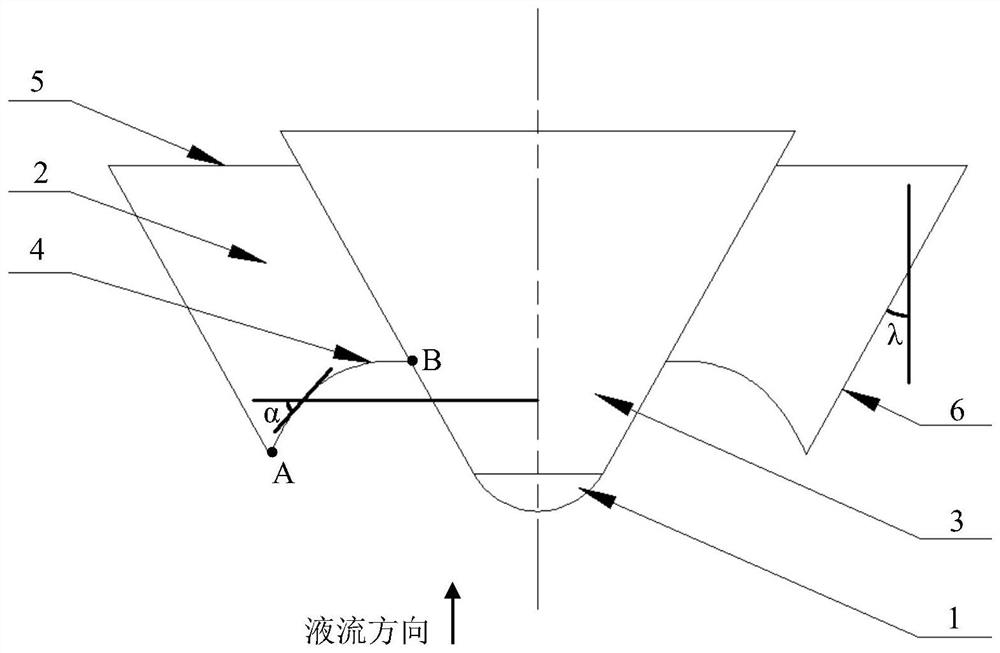

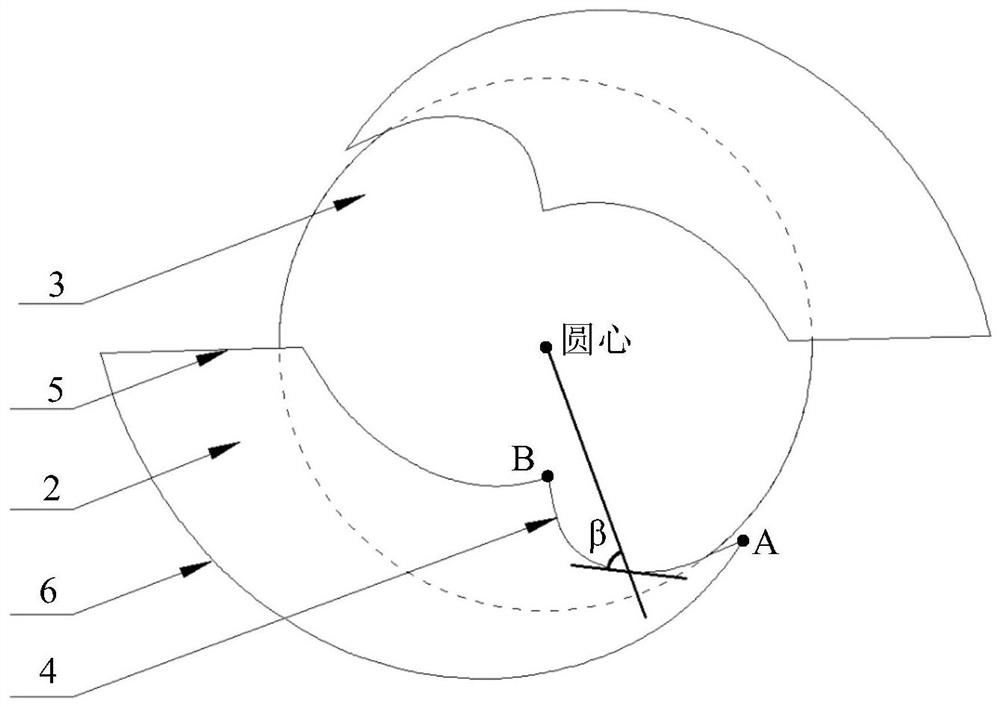

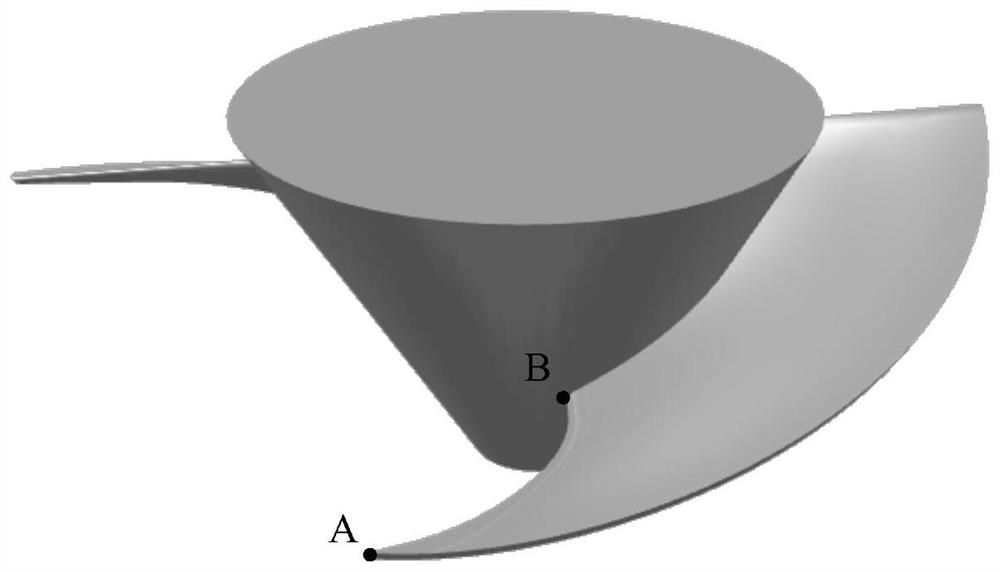

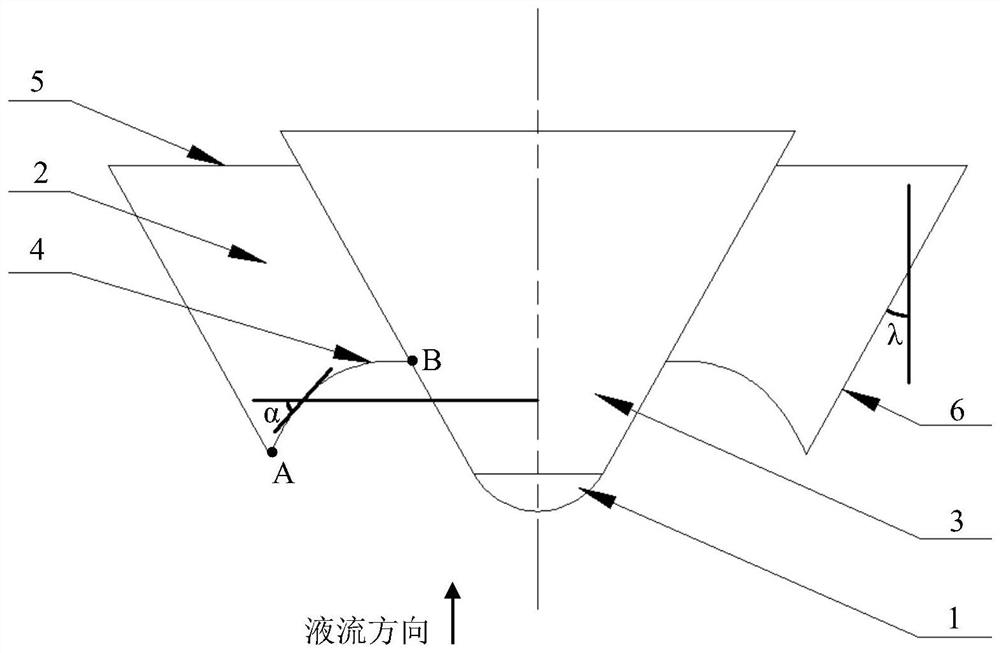

The invention relates to an axial chute type processing casing with a back cavity for improving the performance of a gas compressor, and relates to a casing. A problem that a peak efficiency of the gas compressor is excessively reduced in the existing axial chute type processing casing is solved. The axial chute type processing casing comprises an outer shell (1), an annular rib (2) and an axial chute (3), wherein the annular rib (2) is embedded into the outer shell (1), the axial chute (3) is arranged on an inner hole of the annular rib (2) and the outer shell (1), a plurality of slot holes (3-1) are formed in the axial chute (3) in an annular array manner, and are respectively inclined on an axial direction and a radial direction, wherein an axial inclination angle of each slot hole (3-1) is (alpha), and alpha is equal to 10-35 degrees, a radial inclination angle of each slot hole (3-1) is (beta), and the beta is equal to 30-50 degrees; and a space enclosed between the outer shell (1) and the axial chute (3) is a back cavity (B). And the axial chute type processing casing is used for improving performance of the gas compressor.

Owner:中船重工龙江广瀚燃气轮机有限公司

Gas turbine combustion chamber axial two-stage swirl nozzle

InactiveCN104266227AEnhanced Swirl MixingEvenly blendedContinuous combustion chamberCombustion chamberGas turbines

A gas turbine combustion chamber axial two-stage swirl nozzle is technically characterized in that a two-stage axial swirl device is arranged in the axial direction in a peripheral axial annular air channel. A first-stage swirl device is fixed on a center cone body, and a gap is reserved between the top of the first-stage swirl device and the outer wall face of the nozzle. A second-stage swirl device is arranged on the downstream of the first-stage axial swirl device and fixed on the outer wall face of the annular air channel, and a gap is reserved between the bottom and the center cone body. Two stages of swirl vanes are arranged in a staggering mode. The swirl angle of the second-stage swirl device is larger than that of the first-stage swirl device. The nozzle can ensure the swirl strength on the peripheral side of the inside and the outside of the air channel, the swirl on the inner peripheral side of the air channel is weak in strength, and the axial speed of the air flow can be increased. The swirl on the outer peripheral side of the air channel is high in strength, the combustion area can be controlled reasonably by matching the nozzle outlet speed distribution and the fuel air blending effect, the inner flowing field structure of the combustion chamber is maintained, and combustion stability and good outlet temperature distribution can be ensured.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

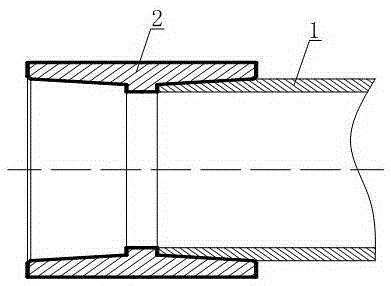

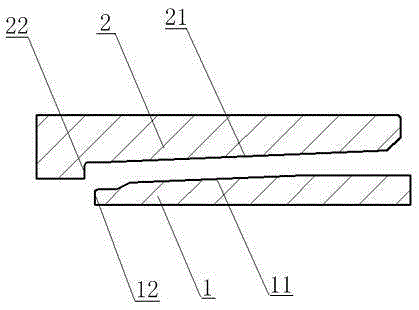

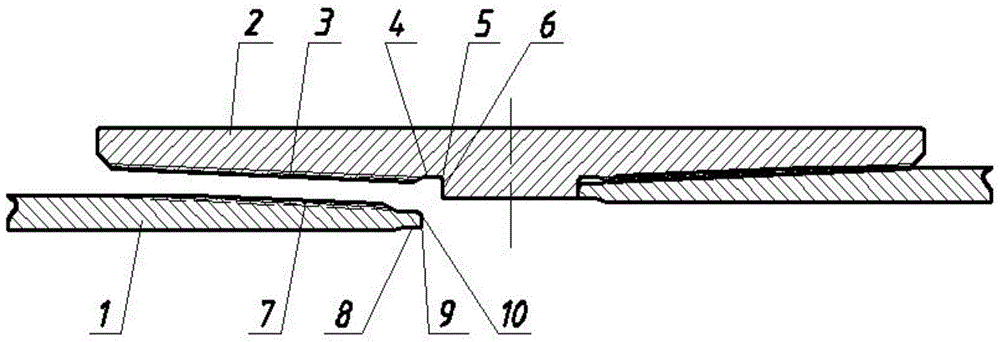

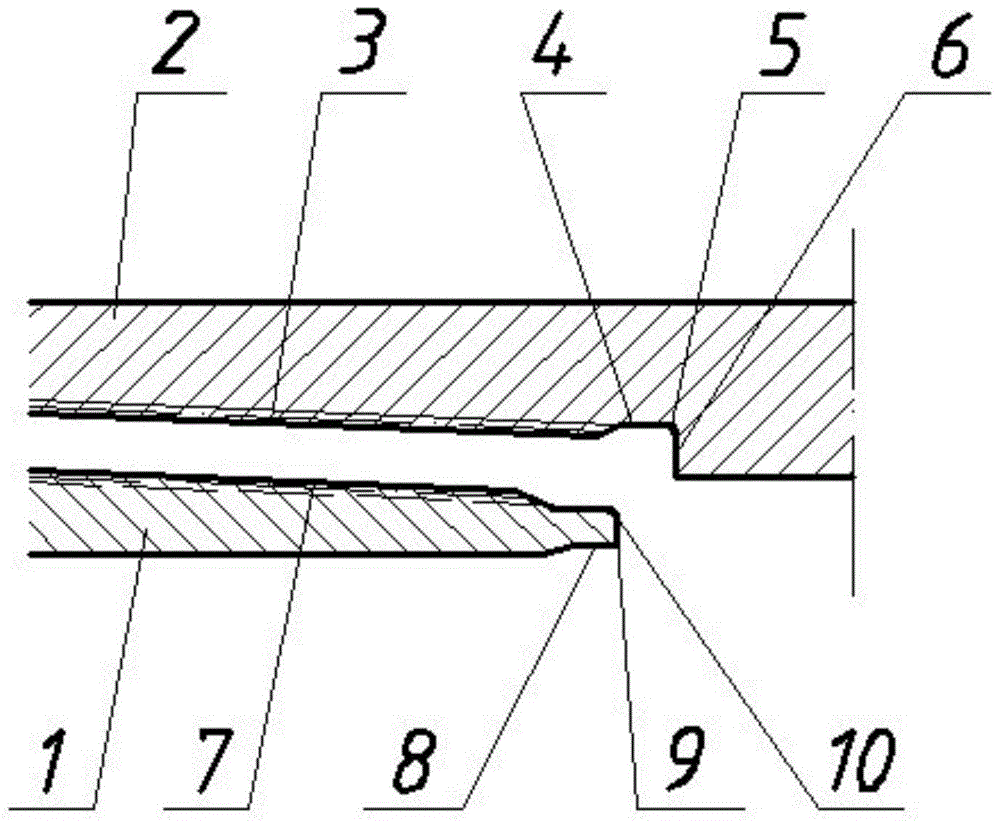

Sleeve joint structure

InactiveCN105298411AImprove connection strengthAvoid failureDrilling rodsDrilling casingsInterference fitUltimate tensile strength

The invention relates to the technical field of oil well sleeves, and discloses a sleeve joint structure. The sleeve joint structure comprises a sleeve body and an adaptive sleeve matched with the sleeve body. An external thread with the taper of 1:16 is arranged on the outer surface of one end of the sleeve body, an internal thread matched with the external thread is arranged on the inner surface of the end, matched with the sleeve body, of the adaptive sleeve, and the external thread and the internal thread are in interference fit. An outer circular bead face is arranged at one end of the sleeve body, and an inner circular bead face matched with the outer circular bead face is arranged on the adaptive sleeve. The external thread and the internal thread are both buttress threads, the toot height of the buttress threads ranges from 1.775 mm to 1.975 mm, the thread pitch of the buttress threads ranges from 3 threads per inch to 4 threads per inch, the angle of a guide face is 30+ / -2.5 degrees, and the angle of a bearing face ranges from 0 to 1 degree. According to the sleeve joint structure, wrong thread buckling or fast screwing on can be avoided, good sealing performance is achieved, connecting strength is high, drilling and production efficiency is improved, drilling and production cost is reduced, and the threads can be effectively prevented from failing or slipping.

Owner:CNPC BOHAI EQUIP MFG +1

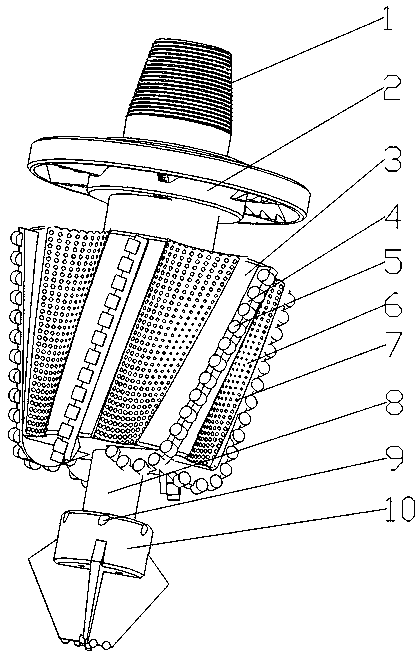

Deep-water shallow natural gas hydrate solid-state fluidization mining drill bit

ActiveCN109025830AImprove rock breaking efficiencyPromote formationDrill bitsConstructionsLarge particlePhysical property

The invention discloses a deep-water shallow natural gas hydrate solid-state fluidization mining drill bit mainly composed of four parts. The first part comprises a neck hole drill bit for neck hole drilling, and provided with a drilling fluid injection hole and a double spiral guide groove for cleaning a shaft bottom and assisting debris removal. The second part comprises a reaming drill bit forfurther enlarging a wellbore, and having a debris removal passage and a debris removal groove for facilitating debris removal. The third part comprises a refining device for refining a large-diameterhydrate silt cement body and a connecting tool. The fourth part comprises a tapered flow passage arranged inside a drill bit body to increase the jetting speed of the drilling fluid. The deep-water shallow natural gas hydrate solid-state fluidization mining drill bit specifically considers the structure and the physical property of a deep-water shallow gas natural gas hydrate layer, combines the demand of a fluidization mining process for the drill bit, not only realizes the refinement and the fluidization of hydrate silt cement large particle debris, but also solves the problems of debris deposition, poor fluidity and stuck drilling during long-distance horizontal drilling, thereby ensuring the efficient rock breaking and drilling efficiency in the horizontal section of the hydrate layer.

Owner:SOUTHWEST PETROLEUM UNIV

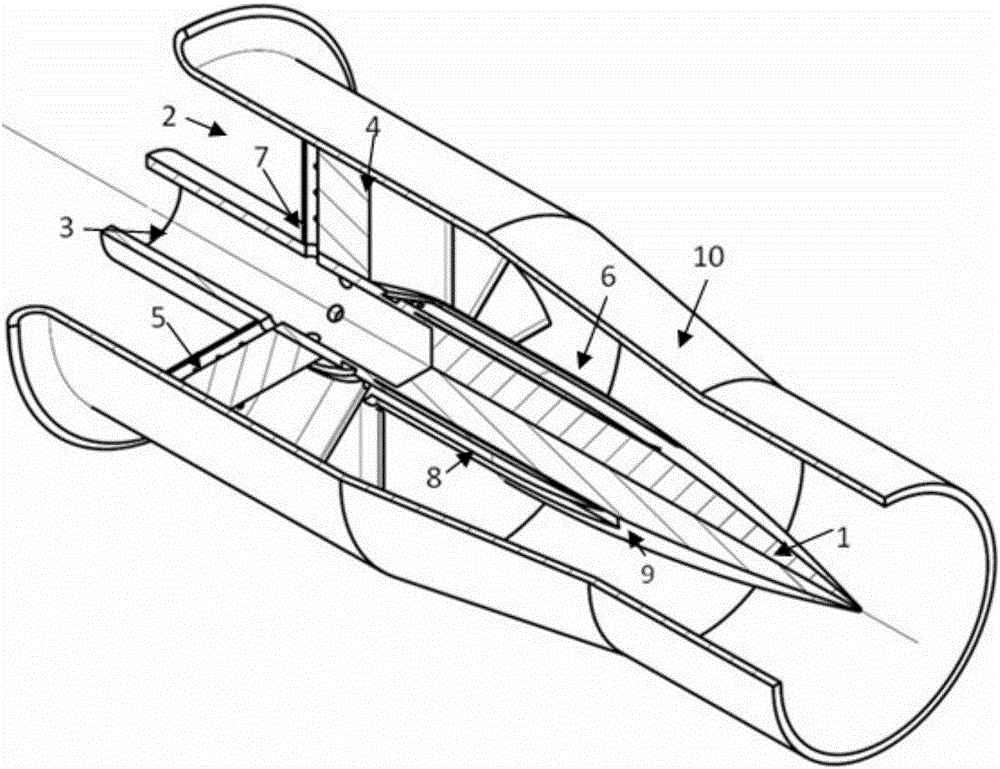

Distributed parameterized impeller self-circulation treatment casing

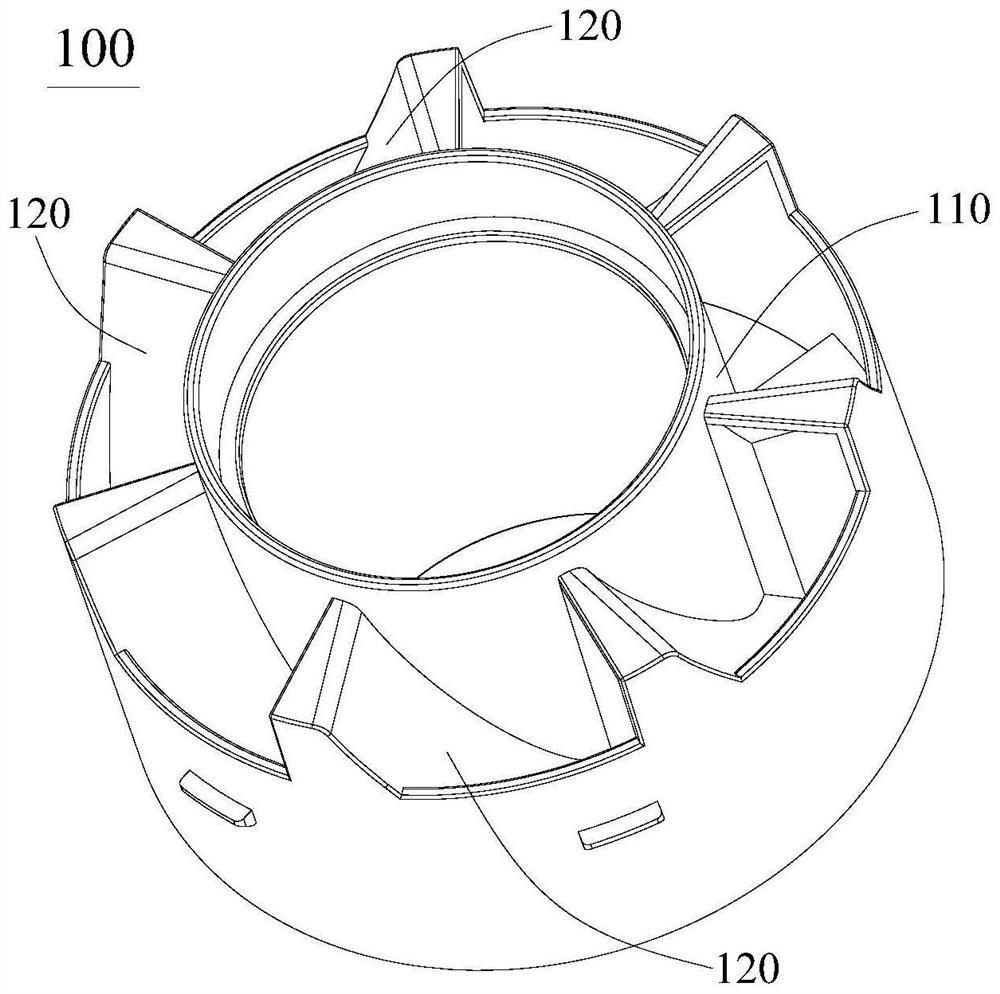

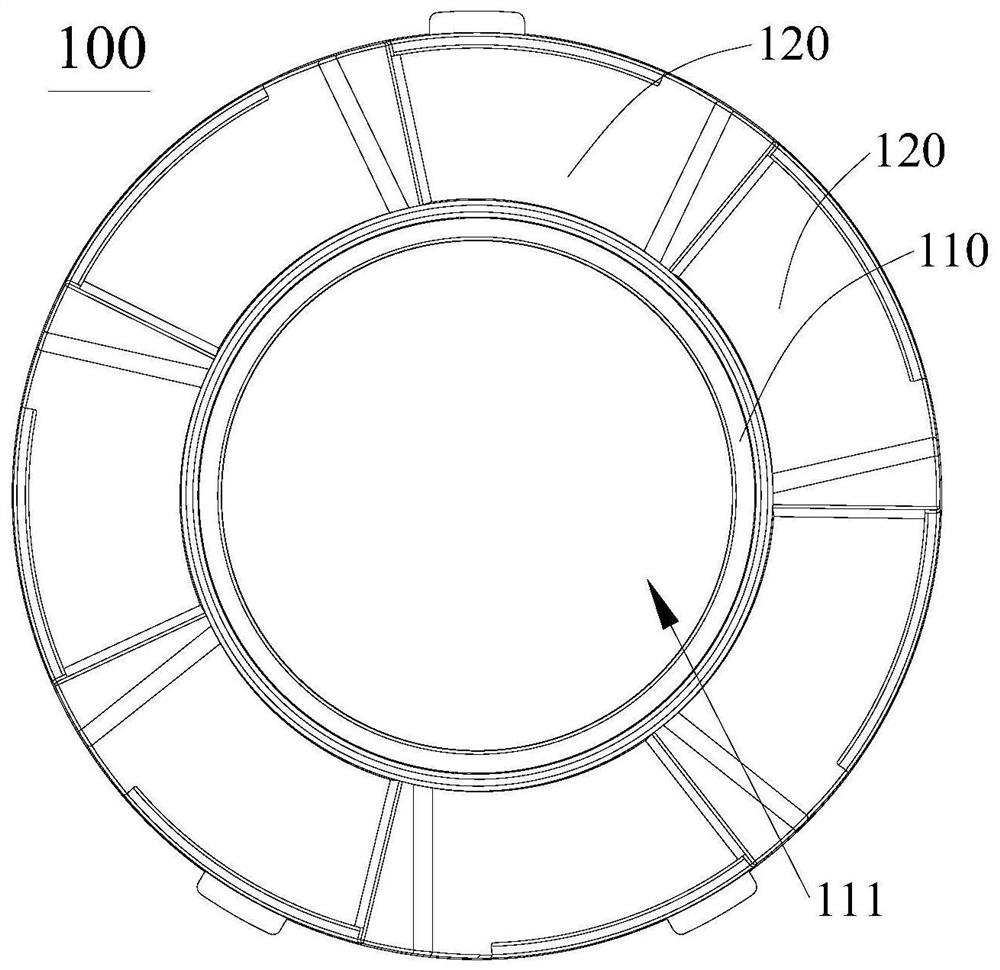

ActiveCN112539184AIncrease stall marginReduce efficiency lossPump componentsRadial flow pumpsImpellerInlet channel

The invention discloses a distributed parameterized impeller self-circulation treatment casing which is composed of a casing body, an air inlet channel, impeller blades, a front channel, a rear channel and air entraining bridge circuits; the air entraining bridge circuits are fixed to the outer side of an impeller casing, and air flows back in the bridge circuits through the front channel and therear channel connected to a channel front edge of the impeller casing; and the front channel and the rear channel of the impeller self-circulation treatment casing are located at the positions with different axial chord lengths away from an impeller inlet respectively, an inner wall face two-dimensional molded line is formed by fitting and optimizing a structured curve so as to ensure that jet flow is close to the wall face as much as possible, and the outer wall face molded line is a controllable contraction molded line, so that the effects of guiding and accelerating airflow are achieved. The impeller self-circulation treatment casing utilizes the airflow pressure difference in rotor channels corresponding to the self-circulation front channel and the self-circulation rear channel to perform air exhaust and air injection. According to the treatment casing structure, the blocking margin and the stall margin of the centrifugal impeller can be improved, the purpose of reducing the efficiency loss is achieved, and the impeller can operate and work at a larger margin.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

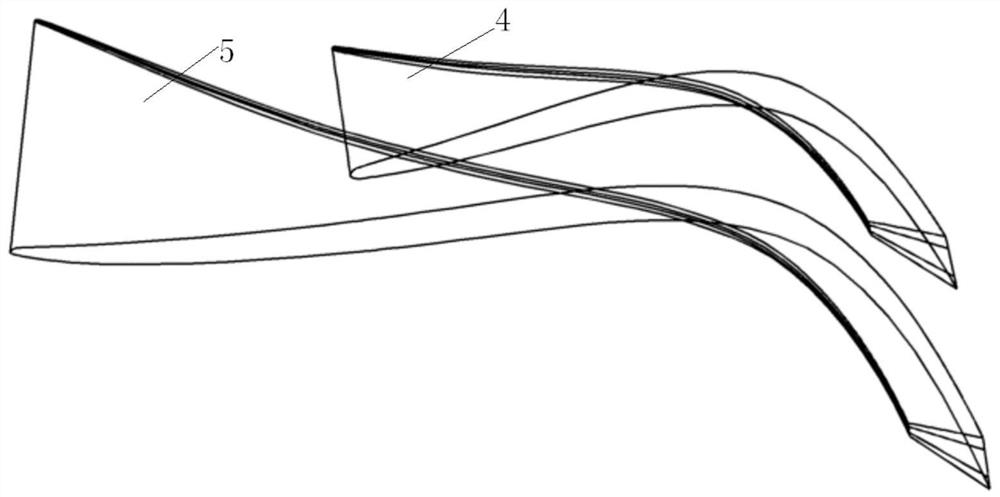

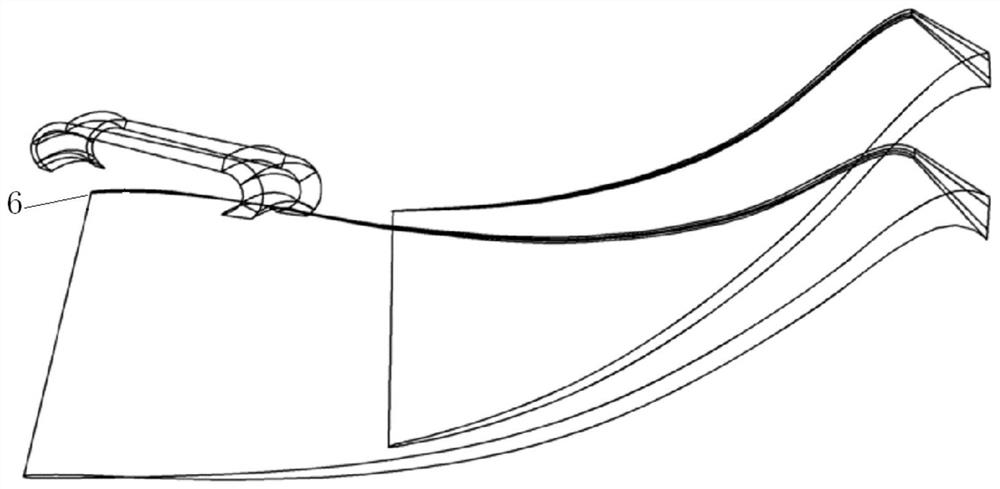

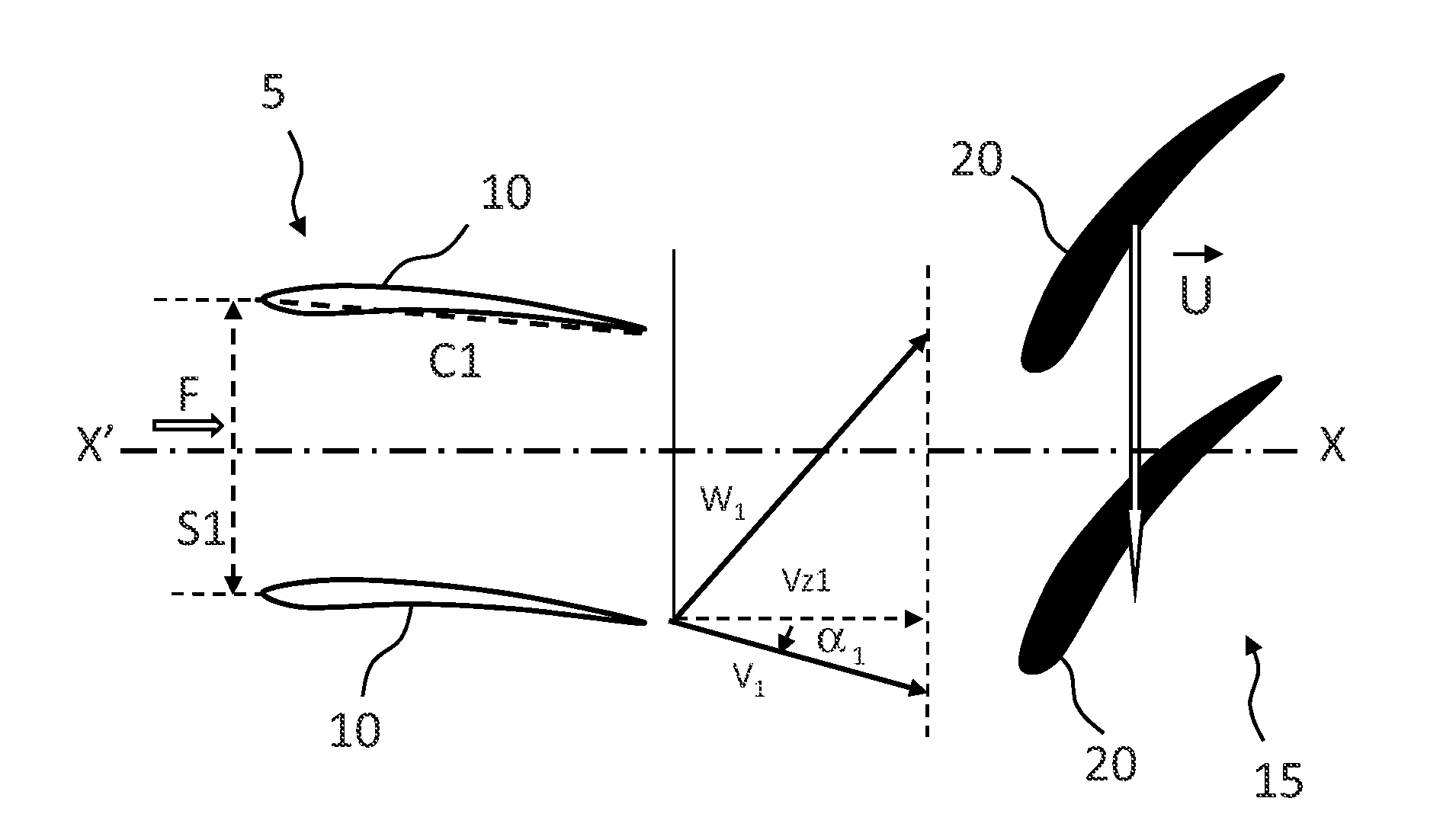

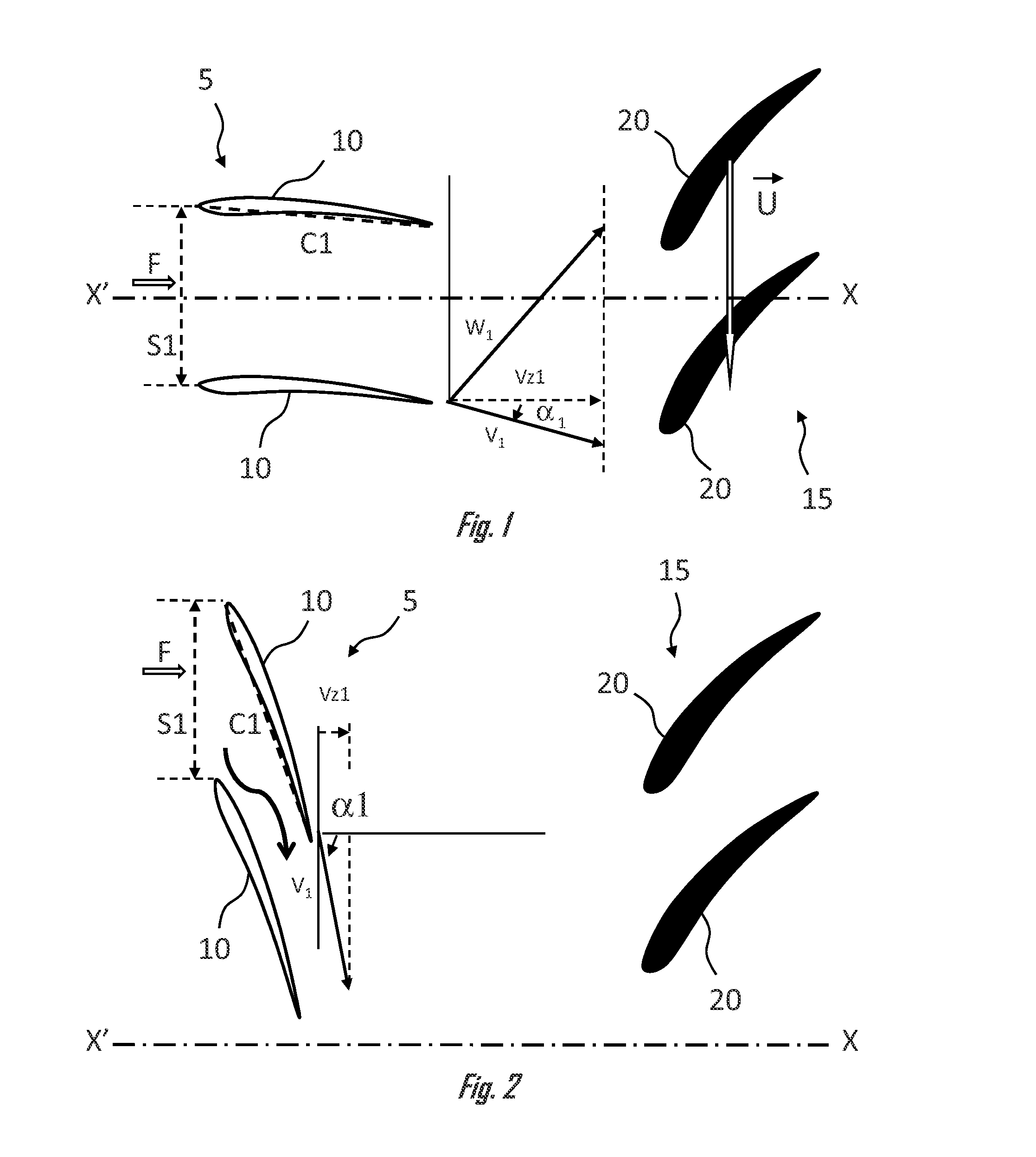

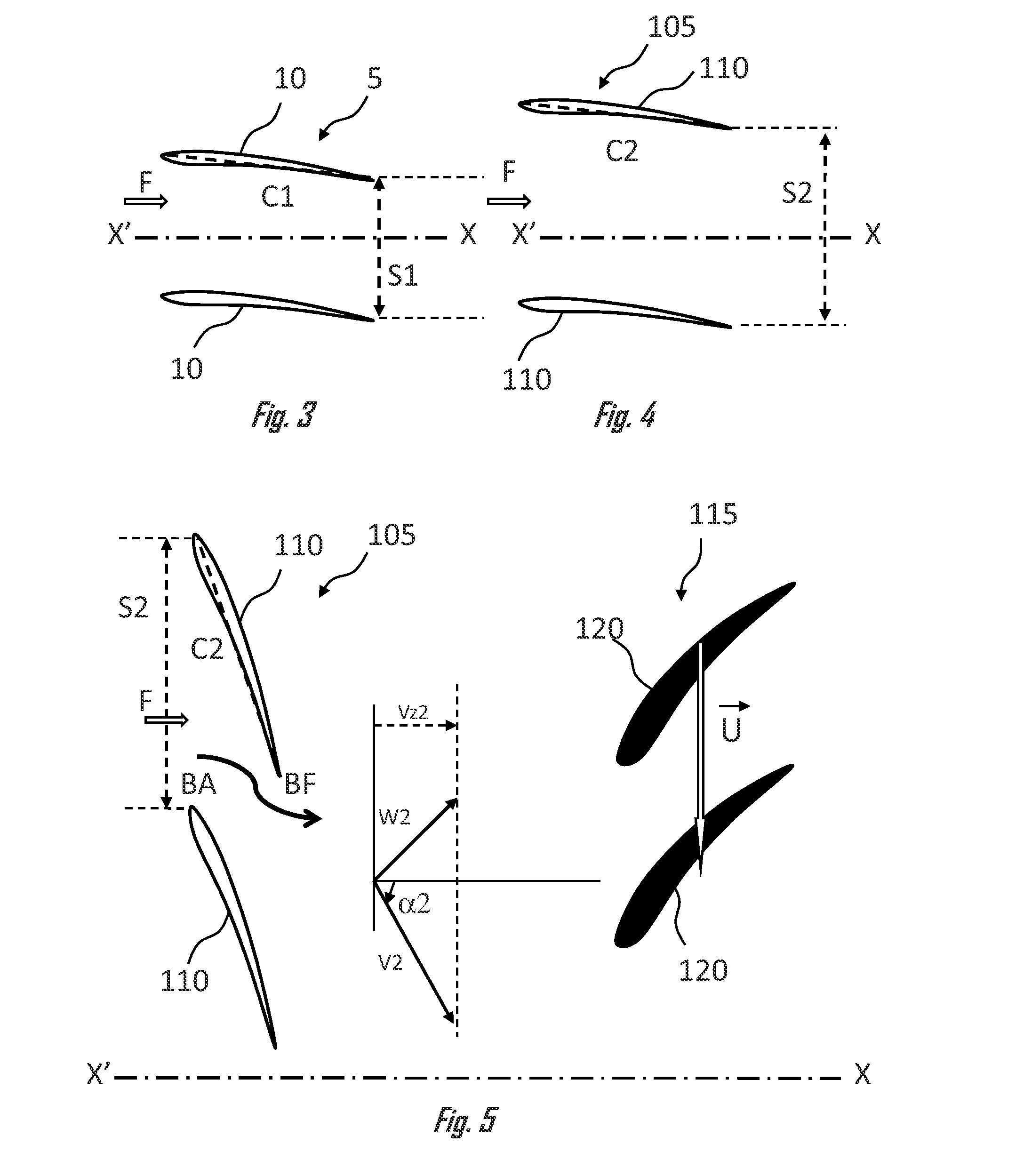

Compression assembly for a turbine engine

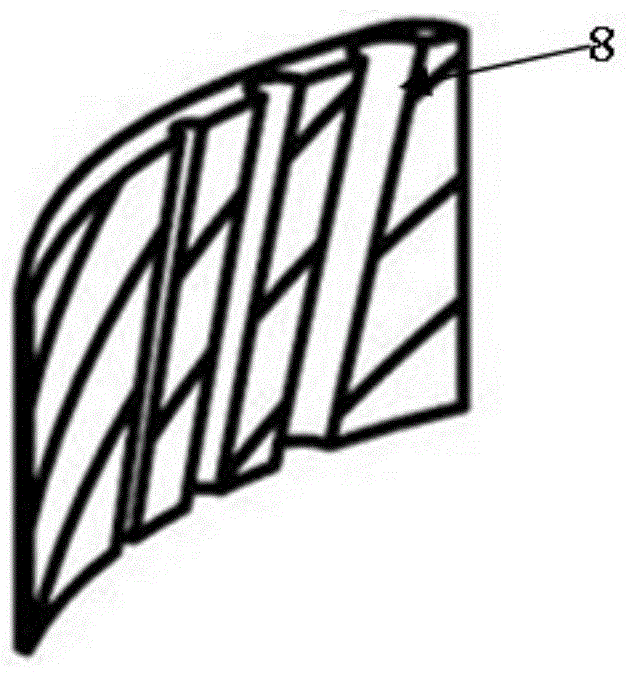

ActiveUS20150275681A1Simple structurePreventing aerodynamic malfunctionWind motor controlPump componentsImpellerAir compression

Compression assembly for a turbine engine, in particular a turboshaft engine, said assembly comprising an air inlet duct capable of receiving an air flow, at least one air compression stage comprising at least one movable compressor wheel onto which the duct discharges, and a pre-rotation grille which is positioned in the air inlet duct upstream of the movable compressor wheel in order to adjust the speed of the air in said flow at the inlet of the movable wheel and comprises a plurality of variable-setting vanes, the assembly being characterized in that the pitch between two consecutive vanes of the grille is greater than the chord of one of the two vanes at a given height of the air duct, preferably in its upper part.

Owner:SAFRAN HELICOPTER ENGINES

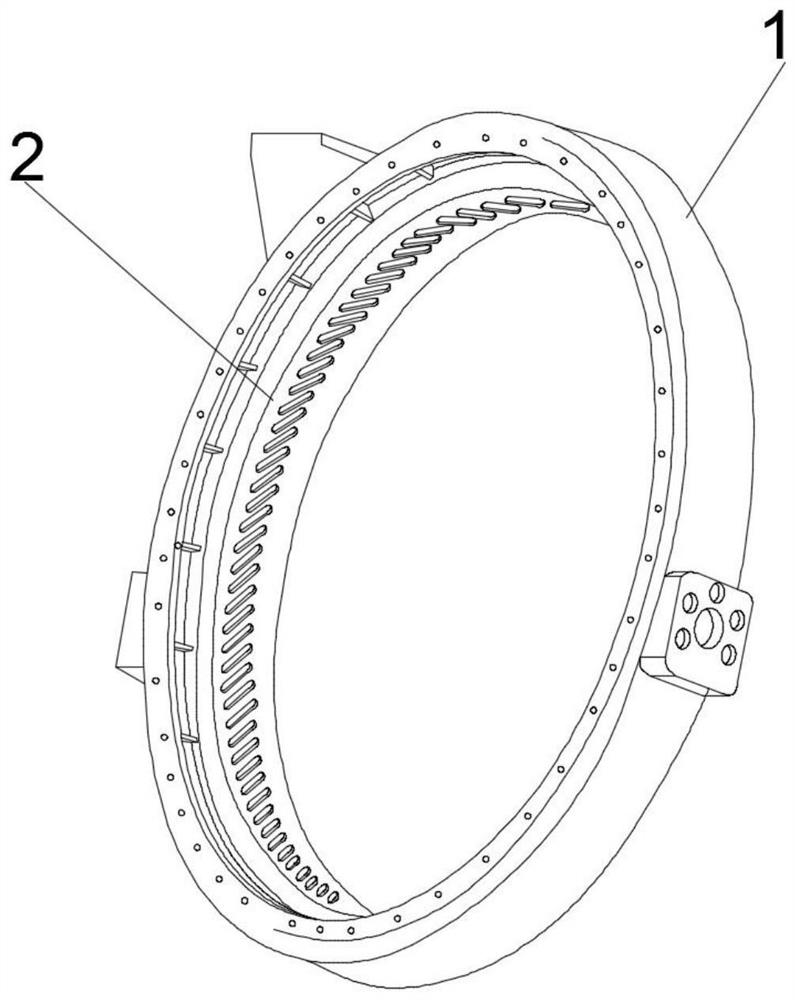

Harvested crop processing unit with number of circulation circuits depending on throughput

InactiveUS7632181B2Increase axial speedAppropriate performanceGrain huskingGrain polishingEngineeringFront and back ends

A harvested crop processing unit with a rotor and a rotor housing enclosing the rotor, that includes a cover element under which a first group of helically shaped guide rails and a second group of helically shaped guide rails are attached, where the guide rails of the two groups follow each other alternately and are provided with a leading end and a trailing end in the direction of rotation of the rotor and the guide rails of the first group are arranged offset to the rear of the guide rails of the second group in the direction of rotation of the rotor. The trailing ends of the guide rail of the first group are directed at the leading end of the guide rails of the second group following in the axial direction of the rotor housing.

Owner:DEERE & CO

Integrated water/oil/tar/coal slurry process nozzle with gas film protection function

ActiveCN109810729AReduce direct contact frictionExtended service lifeGranular/pulverulent flues gasificationEpoxyTar

The invention discloses an integrated water / oil / tar / coal slurry process nozzle with a gas film protection function. The integrated water / oil / tar / coal slurry process nozzle is of a sleeve-type structure and sequentially comprises a nozzle cooling water outer pipe, a nozzle cooling water inner pipe, an outer epoxy pipe, a gas film oxygen pipe, a coal slurry pipe and a central oxygen pipe from the outermost layer to the innermost layer; an ignition rod is arranged in the central oxygen pipe, and the length of the gas film oxygen pipe can be larger than the length of the outer epoxy pipe and can also be 1 / 2 smaller than the length of the outer epoxy pipe; and the ignition end of the nozzle is in a necking shape, and the outlet end close to the central oxygen pipe is provided with an ignitionrod rotational flow support for supporting the front end of the ignition rod. Through isolation of different channels, direct contact friction between water / oil / tar coal slurry and the inner wall faces of the channels can be greatly reduced, thus the protection effect is achieved, and the service life of the nozzle is greatly prolonged; and the ignition rod rotational flow support is adopted, theaxial speed of the water / oil / tar coal slurry and a central oxygen mixing medium after internal mixing is decreased, the axial speed of the mixing medium is increased, the water / oil / tar slurry and central oxygen are internally mixed more uniformly, and the atomization performance of the nozzle is improved.

Owner:中国东方电气集团有限公司 +1

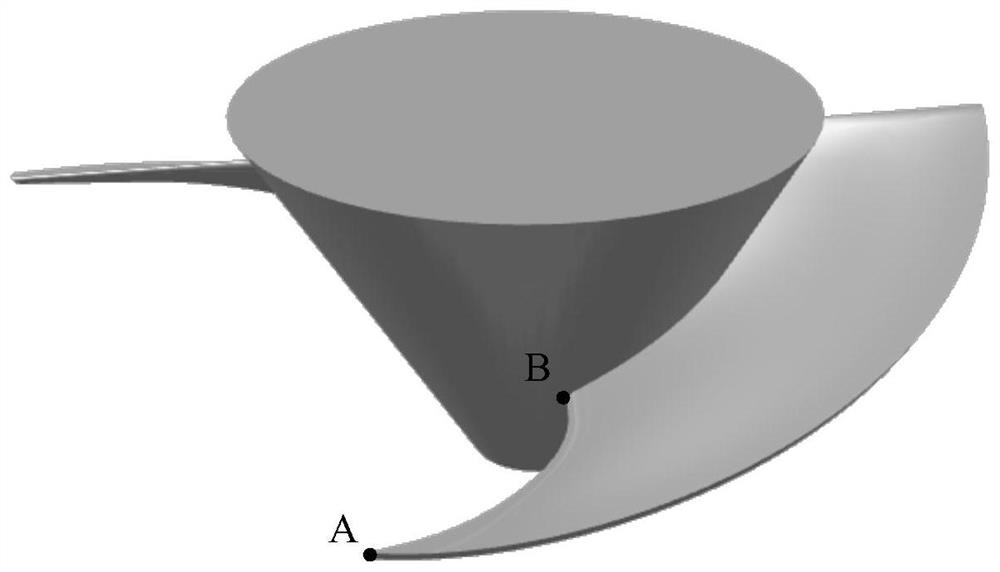

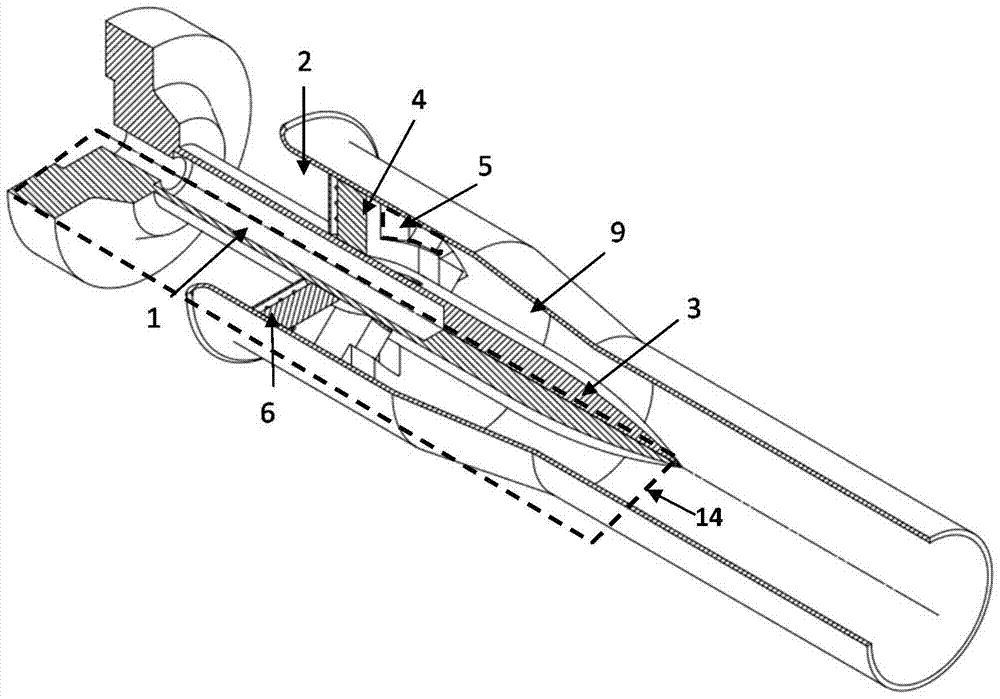

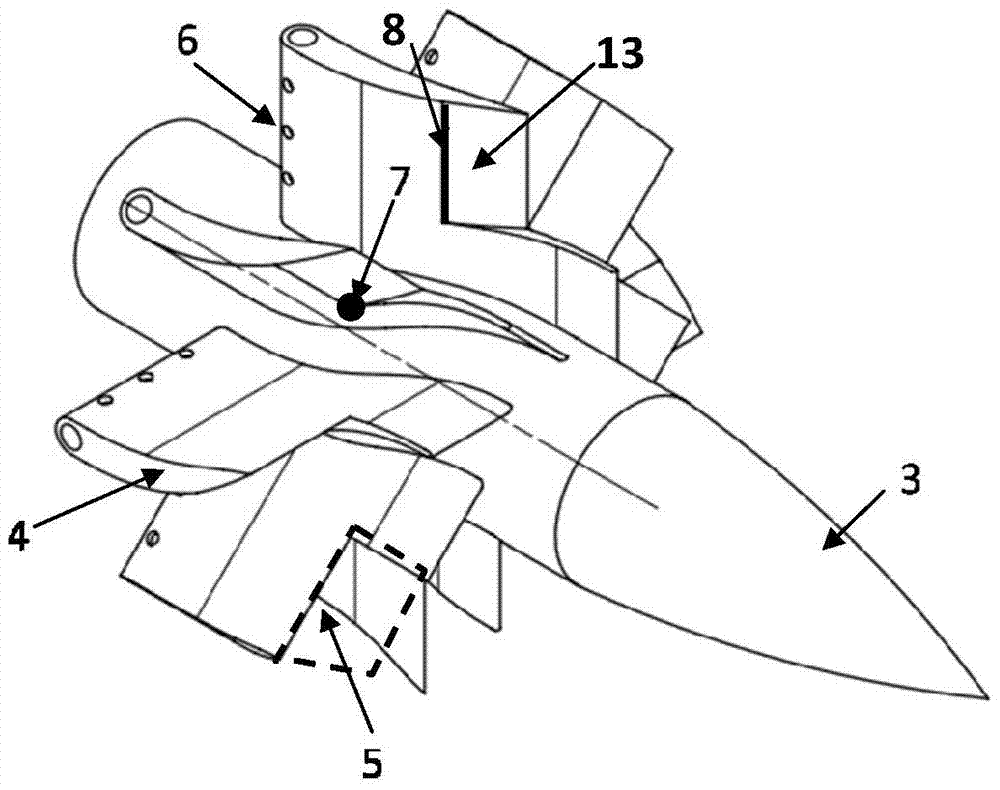

Slotted swirl nozzle in center body of gas turbine combustor

ActiveCN104373963BChange flow patternIncrease axial speedContinuous combustion chamberCombustion chamberCombustor

The invention relates to the technical field of gas turbines and discloses an inner body slotting type swirl nozzle for a combustion chamber of a gas turbine. The nozzle comprises a conical inner body, a shell body and multiple swirl blades, wherein the conical inner body is arranged in the shell body, an annular peripheral air channel is formed between the conical inner body and the shell body, the swirl blades are arranged on the conical inner body in the peripheral direction of the conical inner body, multiple slots are formed in the outer circumference of the conical inner body, and the slots and the swirl blades are arranged in a spaced mode. According to the inner body slotting type swirl nozzle for the combustion chamber of the gas turbine, due to the fact that the multiple slots are formed in the conical inner body, the flowing mode of the inner side of the conical inner body is changed, and the strength of mixed cyclonic air current is reduced and axial speed is increased so as to be matched with fuel concentration and speed distribution on an outlet of the nozzle. The nozzle has the advantages that combustion organization is achieved reasonably and effectively and pollutant discharge is controlled reasonably and effectively.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

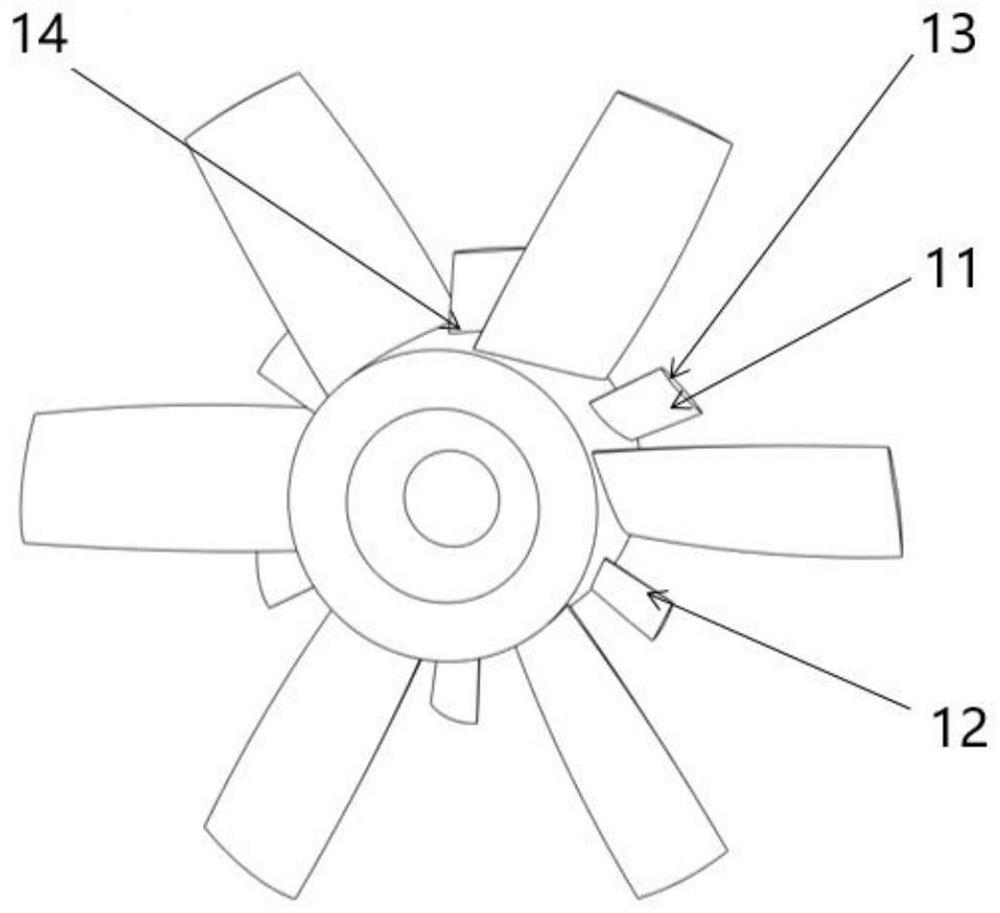

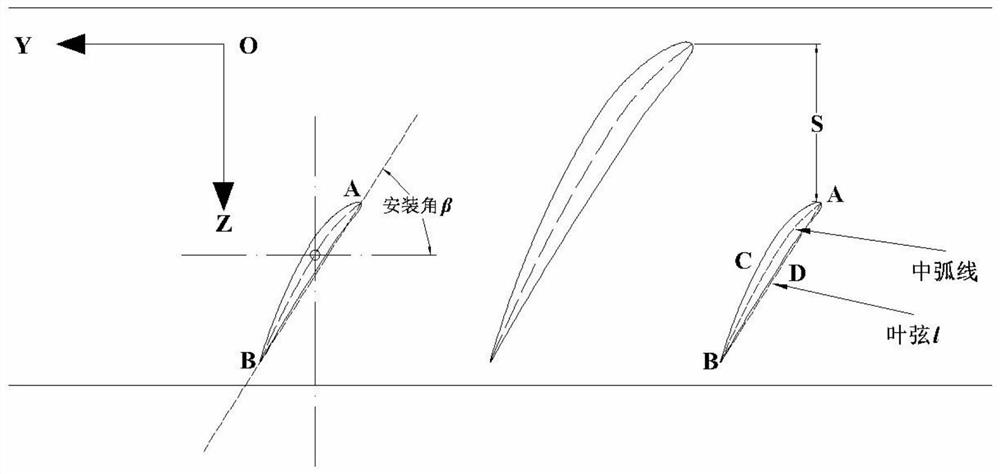

Axial flow impeller with splitter blades

PendingCN113653672AImprove stable working rangeWeaken the phenomenon of lateral secondary flowPump componentsPumpsImpellerEngineering

The invention belongs to the field of fans, and particularly discloses an axial flow impeller with splitter blades. The splitter blades are installed between axial flow blades of the axial flow impeller, and blade roots of the splitter blades are connected with a hub of an axial flow fan. The splitter blades are similar to the axial flow blades in shape, the height of the splitter blades is obtained by multiplying the height of the axial flow blades by a height coefficient sigma, and the section of the splitter blades is obtained by multiplying the section of the axial flow blades at the same height by a reduction coefficient tau, wherein the height coefficient sigma ranges from 0.1 to 0.6, and the reduction coefficient tau ranges from 0.3 to 0.7. According to the axial flow impeller, through the improved design of given key parameters, the axial speed near the blade roots can be effectively increased, the area of a tail edge low-speed region is reduced, tail edge separation is weakened, low-energy fluid near an end wall is taken away, the development of passage vortexes and corner separation vortexes is restrained, and therefore the aerodynamic performance of the axial flow fan is improved.

Owner:FOSHAN CITY NANHAI POPULA FAN +1

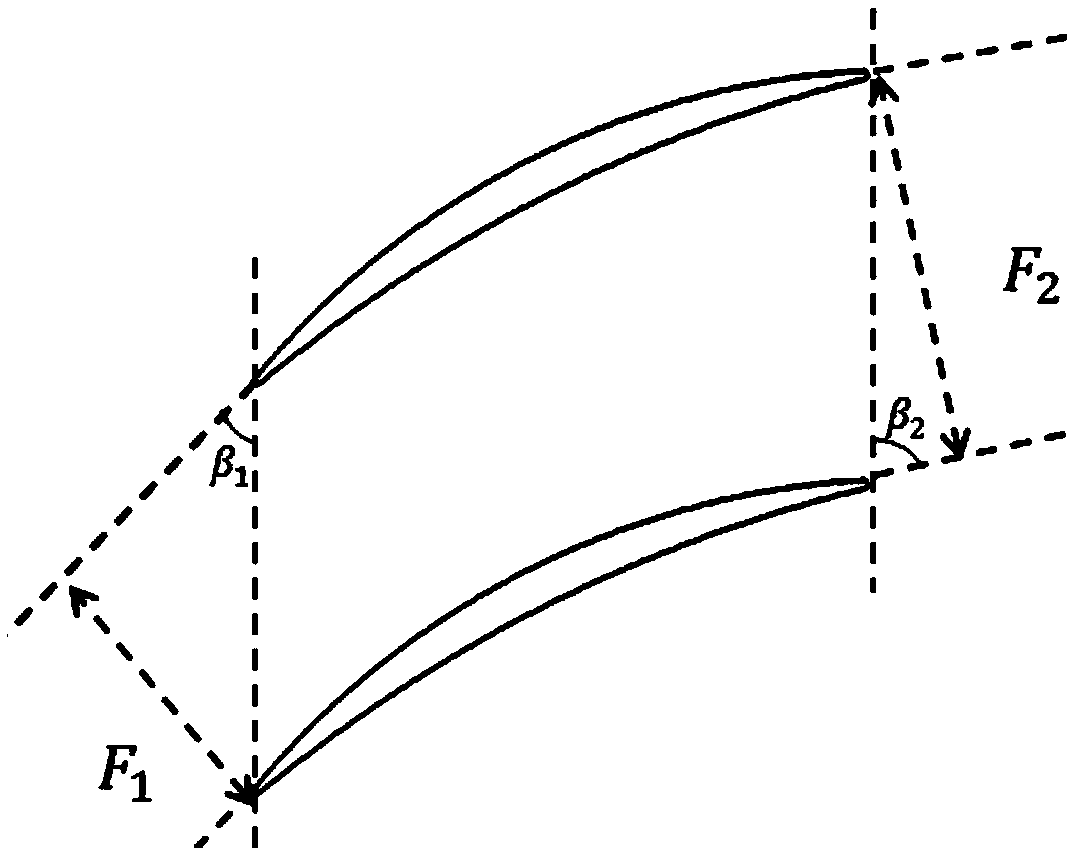

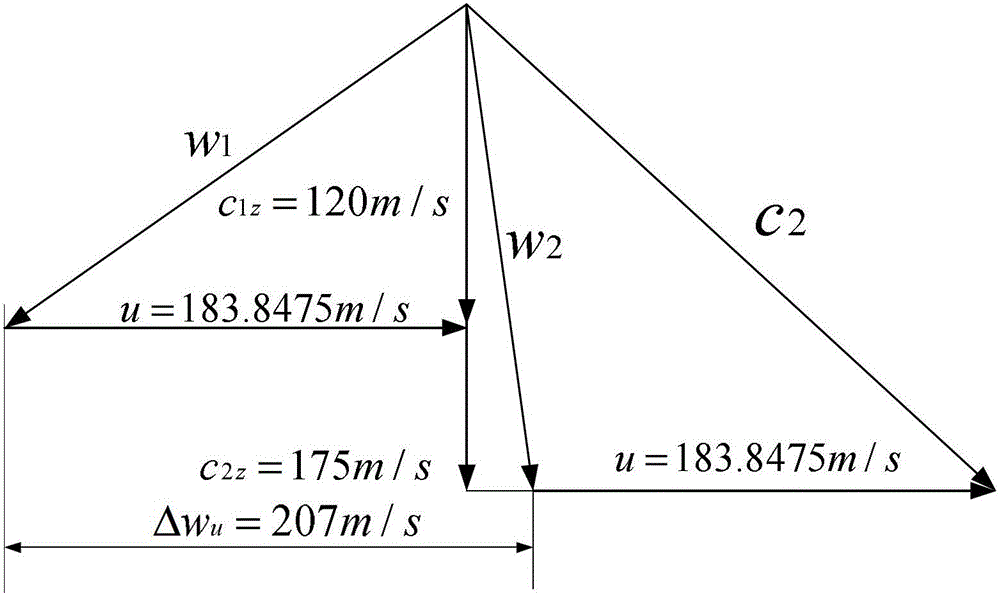

High-load helium compressor cascade structure with self-suction function

InactiveCN108799205AImprove economyImprove stabilityPump componentsSteam engine plantsEngineeringAtmospheric pressure

The invention provides a high-load helium compressor cascade structure with a self-suction function. The high-load helium compressor cascade structure comprises a compressor cascade, wherein the compressor cascade is an expanding and contracting type cascade, the cascade is expanded in a range from an inlet of the cascade to 70%-80% of a chord length, the cascade is contracted from an outlet of the cascade to the last 20%-30% of the chord length, a contraction structure of a compressor is positioned in a range of the last 20%-30% of a cascade chord length, air flow accelerates in a contractionchannel to produce a self-suction effect, and thus further development of a boundary layer is inhibited. According to the high-load helium compressor cascade structure with the self-suction function,under the condition that a tangential speed of a blade tip of a helium compressor does not change, the purpose of increasing the load is realized by increasing an axial speed and adopting larger negative pre-rotation. And meanwhile, the development of the boundary layer on a suction surface of the compressor is controlled by using the flow channel self-suction effect generated by the special flowchannel form of the design method, and separation of the suction surface is prevented, so that the compressor has good economy and stability under the condition of ultra-high load.

Owner:HARBIN ENG UNIV

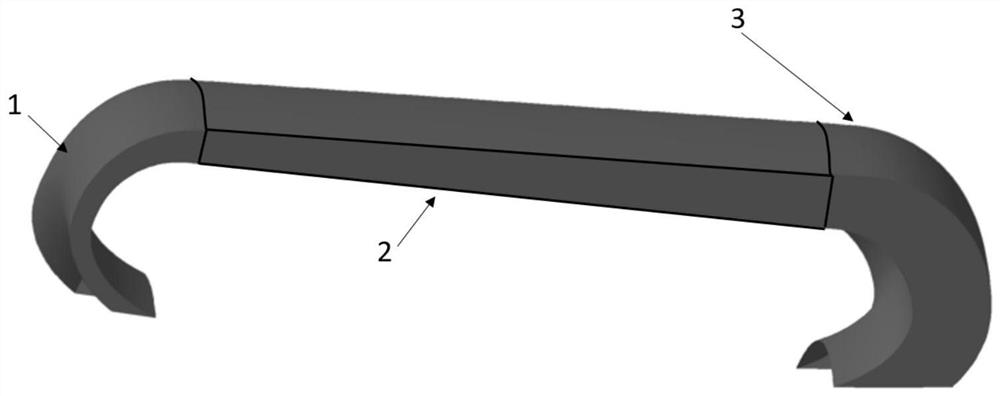

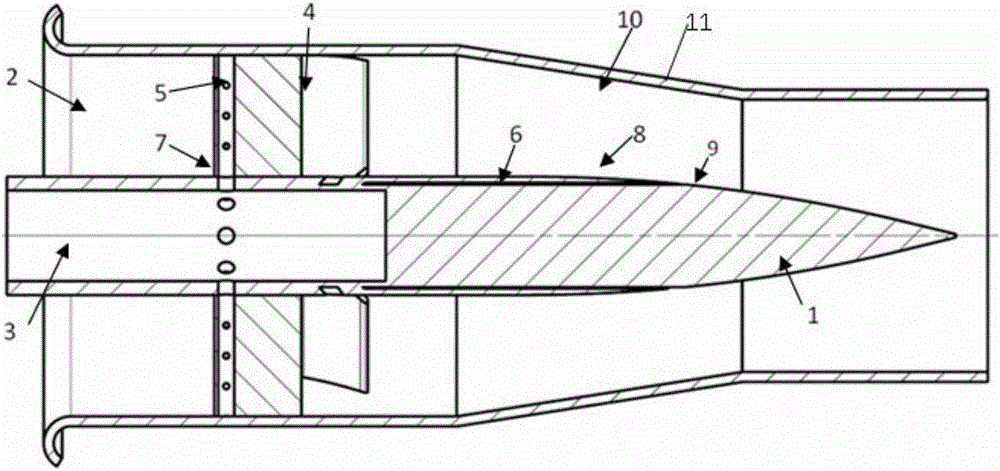

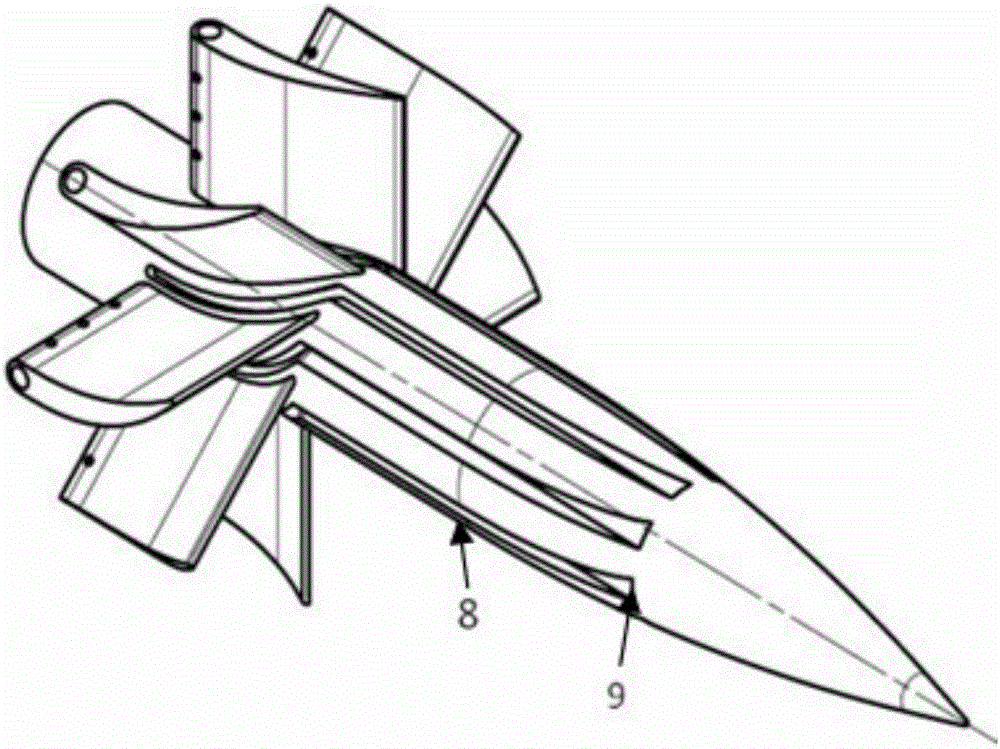

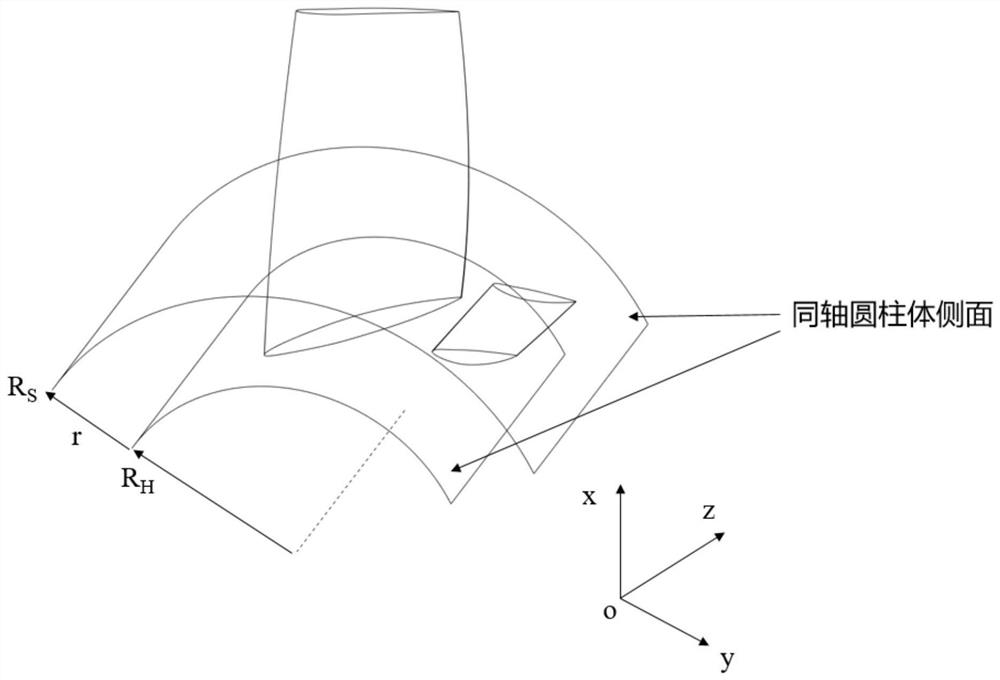

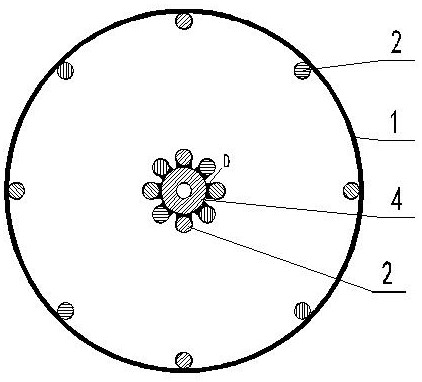

Axial flow pump impeller and axial flow pump

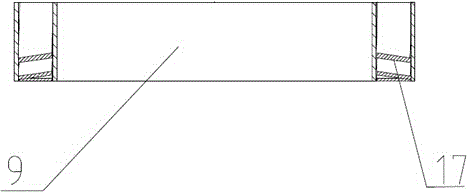

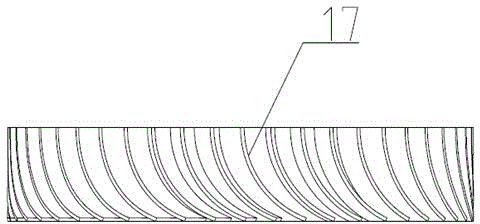

ActiveCN111664114AIncrease axial speedReduce the probability of impactPump componentsAxial flow pumpsImpellerAxial-flow pump

The invention provides an axial flow pump impeller and an axial flow pump. The axial flow pump impeller comprises a flow guide cap 1, impeller blades 2 and an impeller hub 3; the flow guide cap 1 is of a sphere local structure, the impeller hub 3 is of a circular truncated cone structure, the flow guide cap 1 is connected with the bottom of the impeller hub 3, and the generatrix of the impeller hub 3 is tangent to the contour line of the sphere local structure; the impeller blade 2 is fixed on the impeller hub 3 and comprises a blade front edge 4, a blade rear edge 5 and a blade rim 5; and theradius of a blade rim 6 is gradually increased in the liquid flow direction, the plane where the blade rim 6 is located is a circular truncated cone side face, and the generatrix of the circular truncated cone side face where the blade rim 6 is located is parallel to the generatrix of the impeller hub 3. The impeller with the gradually-changed outer diameter is adopted, the outer diameter of theinlet of the impeller is small, the axial speed of liquid flow and pump passing organisms is increased, and therefore the collision probability of the organisms and the blade front edge 4 can be reduced; and in addition, the diameter of the outlet of the impeller is kept large, and it can be guaranteed that the pump lift and efficiency meet the use requirements of a pump station.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

An axial flow pump impeller and axial flow pump

ActiveCN111664114BIncrease axial speedReduce the probability of impactPump componentsAxial flow pumpsImpellerAxial-flow pump

The invention provides an impeller of an axial flow pump and an axial flow pump. The impeller of the axial flow pump includes a diversion cap 1, impeller blades 2 and an impeller hub 3; The cap 1 is connected to the bottom of the impeller hub 3, and the generatrix of the impeller hub 3 is tangent to the outline of the local structure of the sphere; the impeller blade 2 is fixed on the impeller hub 3, and the impeller blade 2 includes a blade leading edge 4, a blade trailing edge 5 and a blade The radius of the rim 5 and the blade rim 6 gradually increases along the liquid flow direction, and the surface of the blade rim 6 is the side of the circular platform, and the generatrix of the side of the circular platform where the blade rim 6 is located is parallel to the generatrix of the impeller hub 3 . The present invention adopts the impeller with gradually changing outer diameter, and the outer diameter at the inlet of the impeller is smaller, so as to increase the liquid flow and the axial velocity of the organism passing through the pump, thereby reducing the collision probability between the organism and the leading edge 4 of the blade. In addition, the diameter of the impeller outlet is kept relatively large, which can ensure that the pump head and efficiency meet the requirements of the pumping station.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

Evaporation pipe structure for engine combustion chamber, combustion chamber device and preparation method

PendingCN111927629AIncreased turbulenceImprove mixing conditionsContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberEngineering

The invention discloses an evaporation pipe structure for an engine combustion chamber, a combustion chamber device and a preparation method. An evaporation pipe body of the evaporation pipe structureis arranged in an evaporation pipe combustion chamber of a double-layer combustion chamber body, the air inlet end of the evaporation pipe body makes contact with the inner wall of the rear end of the double-layer combustion chamber body, and a rear cover oil inlet hole communicated with the evaporation pipe body is formed in the inner wall of the rear end of the double-layer combustion chamber body; and the air outlet end of the evaporation pipe body is located in the evaporation pipe combustion chamber of the double-layer combustion chamber body, the inner walls of the front end of the double-layer combustion chamber body are arranged at intervals, the included angle between the axis of the evaporation pipe body and the axis of the double-layer combustion chamber body is 15-25 degrees,evaporation pipe bodies are evenly arranged in the circumferential direction of the inner wall of the rear end of a combustion chamber flame tube of the double-layer combustion chamber body and form an angle with the axis of the flame tube, a fuel nozzle is inserted into the evaporation pipe along a certain angle and forms reverse injection with incoming air, and stable, efficient and ultralow-pollution combustion is achieved through the high-temperature and low-oxygen condition in a high-temperature fuel gas backflow area.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

An air swirling device arranged in the nozzle of a gas turbine combustor

ActiveCN104329688BGuaranteed swirl strengthGuaranteed mix and matchContinuous combustion chamberCombustion chamberCombustor

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

A kind of dust cleaning method and filter device of bag bottom reinforced filter bag with variable inner channel

ActiveCN111544973BHigh strengthIncrease impact speedGas treatmentDispersed particle filtrationFiltrationEngineering

The invention discloses a bag-bottom-enhanced dust-cleaning method and a filter device with a variable inner channel, which are used for strengthening the dust-cleaning of the filter bag. Method: The cross-sectional area of the cleaning air flow into the inner channel decreases along the direction from the opening of the filter bag to the bottom of the filter bag, and flows to the bottom of the filter bag, continuously reducing the cross-sectional area of the inner channel of the filter bag to continuously compress and clean the filter bag. Ash airflow and increase the impact pressure and impact velocity of the ash-cleaning airflow. The device includes a cage frame and a frame pressing sleeve. A cloth bag is set on the outside of the cage frame and the bag is attached to the cage frame. The cage frame includes a cohesive connector and at least 3 V-shaped steel circles, one end is fixed to the cohesive connector and A conical inward concave cavity is formed, and the other end is folded in the skeleton pressure sleeve, and a cloth bag tensioning slider is arranged in the conical inward concave cavity, one end of the cloth bag is set on the skeleton pressure sleeve, and the other end is folded in the cloth bag The tight slider is embedded in the tapered inward concave cavity along with the bag tensioning slider and is fastened by one end of the V-shaped steel garden.

Owner:SOUTHEAST UNIV

Composite drilling bit for subsea natural gas hydrate layer

ActiveCN108678679BImprove rock breaking efficiencyReduce chip removal efficiencyDrill bitsConstructionsSedimentSubmarine

Owner:SOUTHWEST PETROLEUM UNIV

Axial two-level direction inverse rotational flow nozzle of combustor of gas turbine

The invention discloses an axial two-level direction inverse rotational flow nozzle of combustor of gas turbine, wherein a two-level rotational flow direction inverse rotational flow nozzle is arranged in the periphery axial circular air passage along the axial direction and fixed on the centre cone; the first level rotational flow device adopts the hollow blade and is connected to a centre fuel passage, two sides of the hollow blade are opened with the fuel spraying hole; the air inlet of the second level rotational flow device is tightly pasted to the air outlet of the first level rotational flow device, the air in corner of the second level rotational flow device is the same with the air flow corner at the outlet of the first level rotational flow device, the blades of the level rotational flow devices are arranged alternately. The axial two-level direction inverse rotational flow nozzle of combustor of gas turbine can effectively increase the gas flow speed at the inner side of the air passage, strengthen the mixing rate of the fuel gas and the air, guaranteeing reasonable distribution of the outlet speed of the nozzle, evenly mix the fuel air for raising the burning stability. The impact to the outlet speed of the nozzle of the centre core attaching layer can be reduced, the downstream of the centre cone will not have the backflow region and the burning reliability can be raised.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

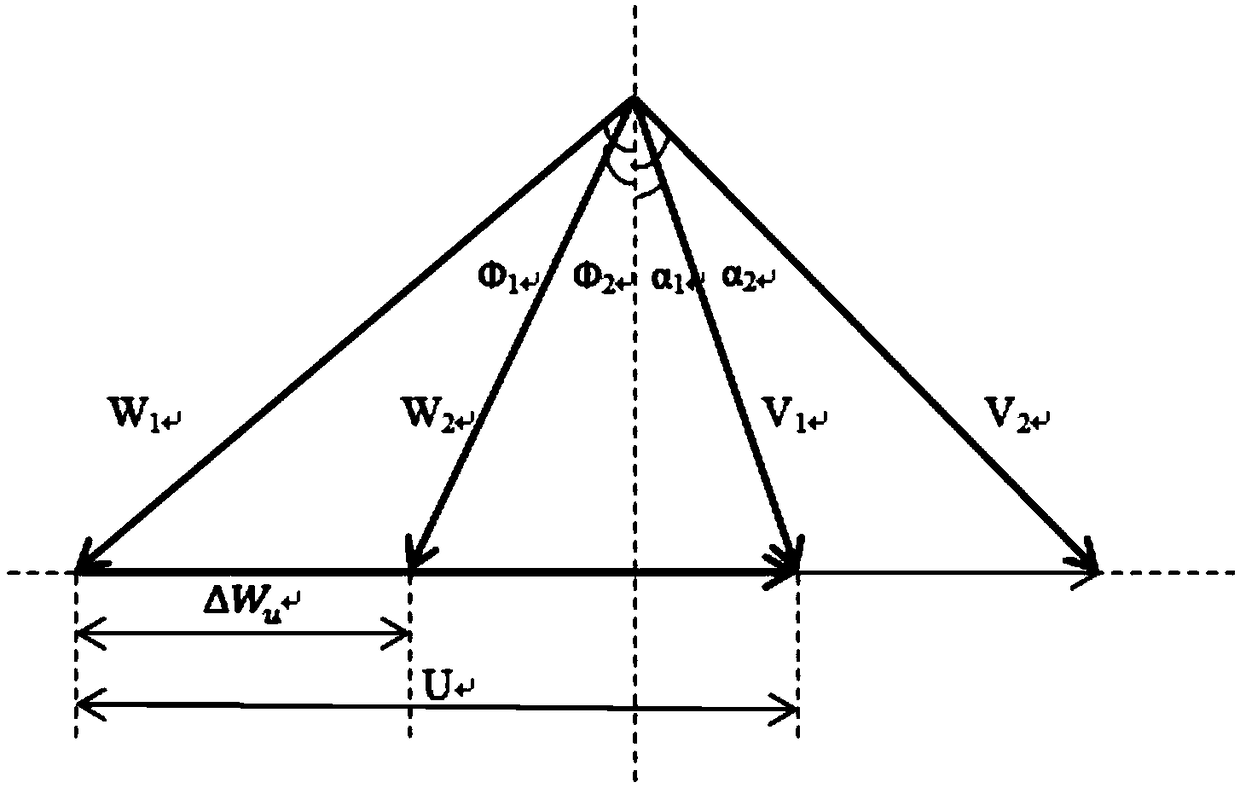

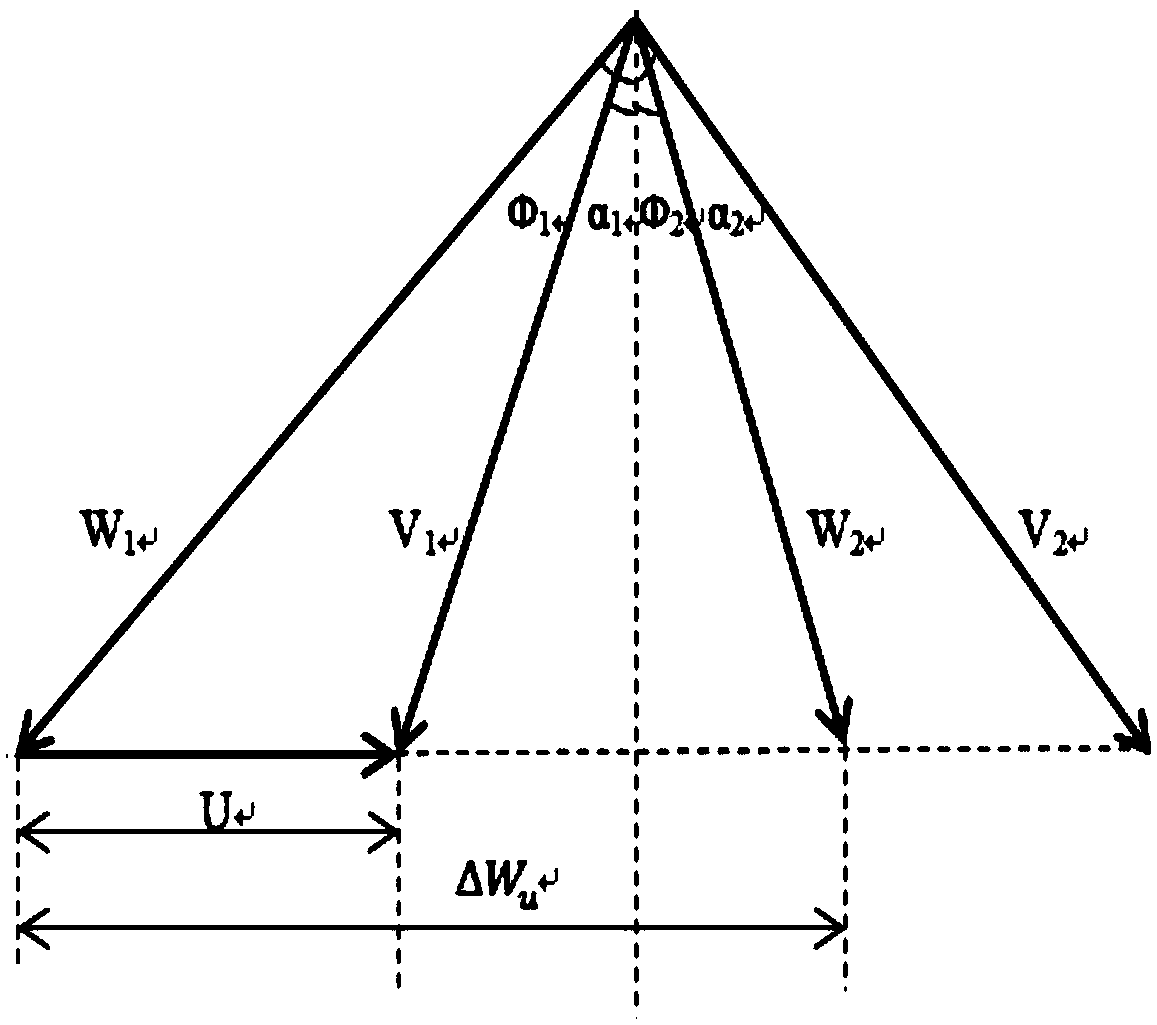

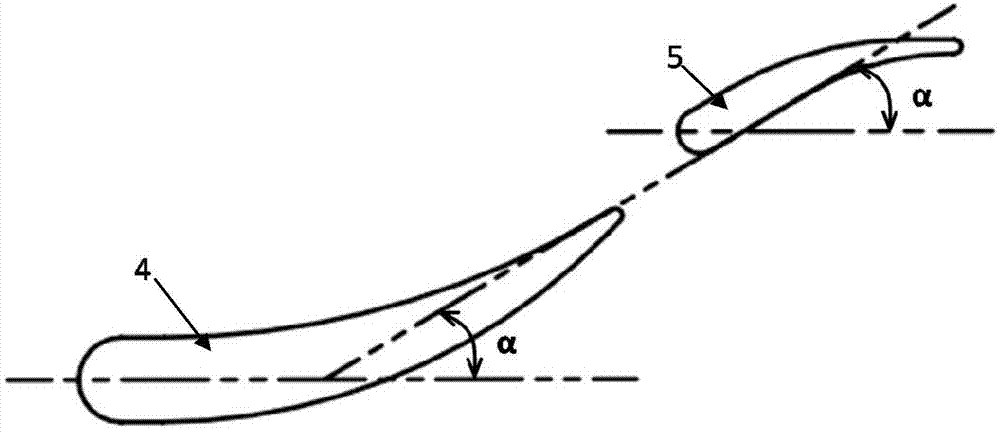

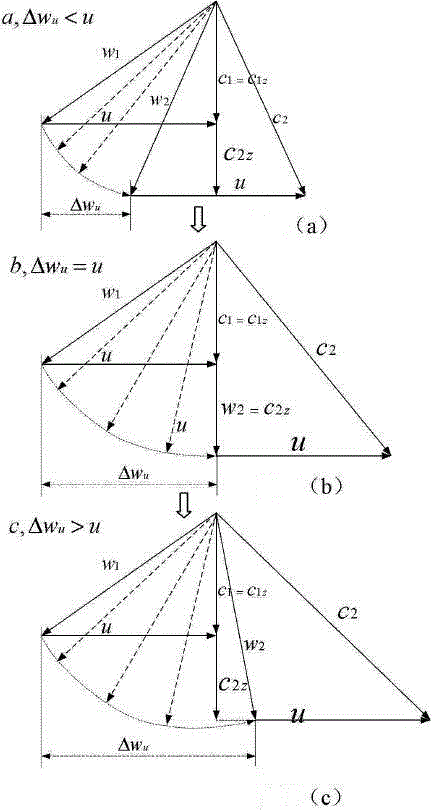

A kind of aerodynamic design method of subsonic adsorption axial flow compressor

ActiveCN103244459BRealize high load aerodynamic designEfficient flowPump componentsPumpsAxial compressorEngineering

The invention belongs to the technical field of axial compressors, and relates to an aerodynamic design method of a subsonic adsorption type axial compressor, in order to solve the problems of increasing of blade rotating angles of a subsonic axial compressor and boundary layer separated in a moving blade during stage load increasing as well as the problems of suction pipeline layout difficulty, blade strength reduction and the like caused by boundary layer suction in the moving blade. On the premise of unchanging an inlet velocity triangle, with design stage load coefficient increasing gradually and exceeding a conventional design value, outlet axial velocity of the moving blade is increased greatly so as to reduce diffusion factors in the moving blade, so that efficient flow of the moving blade is guaranteed; and boundary layer suction is utilized for achieving internal flow of a fixed blade. As boundary layer suction is performed in the moving blade as well as the fixed blade, problems of poor blade strength of a rotatable part and difficulty in suction structure design are solved effectively; and as compared with a tandem cascade technique, the aerodynamic design method has the advantages that blades can be decreased, and accordingly size and weight of an engine are reduced. The method can be applied to aerodynamic design of aero-engines with high thrust-weight ratio.

Owner:HARBIN INST OF TECH

bhc quick sleeve threaded joint

InactiveCN104153718BReduce the angleReduced bearing surface angleDrilling rodsDrilling casingsEngineeringScrew thread

Owner:CNOOC ENERGY TECH & SERVICES

A gas turbine combustor vane inlet swirl nozzle

The invention relates to the technical field of gas turbines and discloses a blade type air inlet swirl nozzle for a combustion chamber of a gas turbine. The nozzle comprises a conical inner body, a shell body and multiple swirl blades, wherein the conical inner body is arranged in the shell body, an annular peripheral air channel is formed between the conical inner body and the shell body, the swirl blades are arranged on the inner wall of the shell body in the peripheral direction of the shell body, shell body through holes are formed in the shell body, air inlets communicated with the shell body through holes are formed in the swirl blades, and an angle is formed between each air inlet and the axial direction of the shell body. According to the blade type air inlet swirl nozzle for the combustion chamber of the gas turbine, air is fully mixed with fuel through the air inlets to enhance the mixing of air and fuel gas, and the momentum of airflow is increased in the axial direction and axial speed is increased so as to be matched with fuel concentration and speed distribution on an outlet of the nozzle. The nozzle has the advantages that combustion organization is achieved reasonably and effectively and pollutant discharge is controlled reasonably and effectively.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Flow guide part, dust-gas separation mechanism and cleaning equipment

PendingCN114631752AIncrease axial speedImprove vacuuming effectSuction filtersGas separationEngineering

The invention discloses a flow guide part, a dust-gas separation mechanism and cleaning equipment, the flow guide part is applied to the dust-gas separation mechanism in the cleaning equipment, the flow guide part comprises a plurality of flow guide conical blades, the flow guide conical blades are arranged between a backflow part and a dust collection part in the circumferential direction of the backflow part, and each flow guide conical blade is provided with a flow guide face; the flow guide surfaces spirally extend in the axial direction of the flow guide part, each flow guide surface comprises an axial acceleration section and a tangential acceleration section, the axial acceleration sections are connected to the sides, deviating from the air inlet side, of the tangential acceleration sections, a flow guide space is formed between any two adjacent flow guide surfaces, and the air inlet side communicates with an air inlet of the cleaning equipment through the flow guide space. According to the technical scheme, the problems that the dust collection performance of the dust collector is reduced and the dust collection effect is poor due to the fact that the filtering structure is prone to being blocked along with continuous increase of working time in the using process of existing cleaning equipment such as the dust collector can be solved.

Owner:KINGCLEAN ELECTRIC

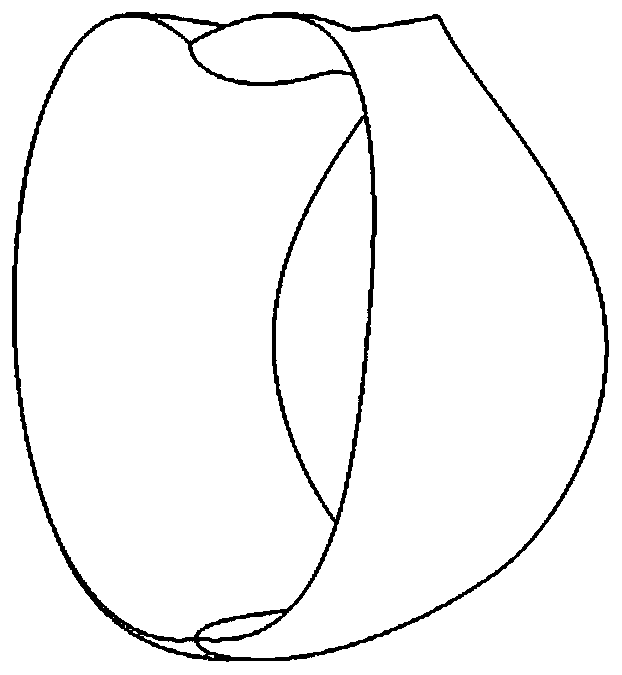

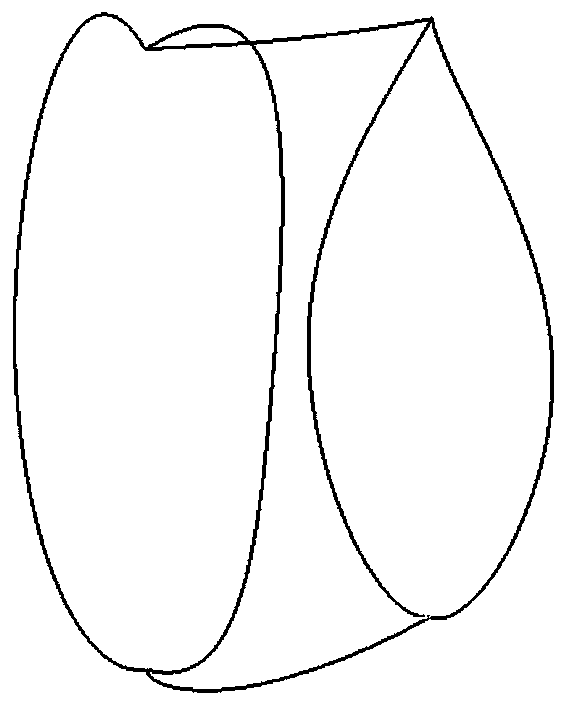

Asymmetric duct for behind ship propeller

The invention provides an asymmetric duct for a behind ship propeller. The duct is symmetric left and right, an inlet and an outlet of the duct are irregular curves and are not in a plane, the top ofthe inlet curve is inward concave, the middle and bottom of the inlet curve are flat and smooth, a sharp protrusion is arranged at the top of the outlet curve and declines from the top curve to the middle curve in a straight line shape, an outer protrusion is arranged in the middle, the camber and an attack angle along the duct perimeter profile wing section profiles change in the axial direction,and the shapes and thicknesses of the various profiles in the length direction of the duct are different. The asymmetric duct can improve wake of a stern, so that the asymmetric wake at a propeller disc surface is homogenized, vibration noise of the propeller is reduced and the efficiency of the propeller is improved, so that the effects of improving the efficiency and improving the vibration noise are achieved.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com