Axial chute type processing casing with back cavity for improving performance of gas compressor

A technology for processing casings and compressors, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc. Margin, effect of expanding stable operation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

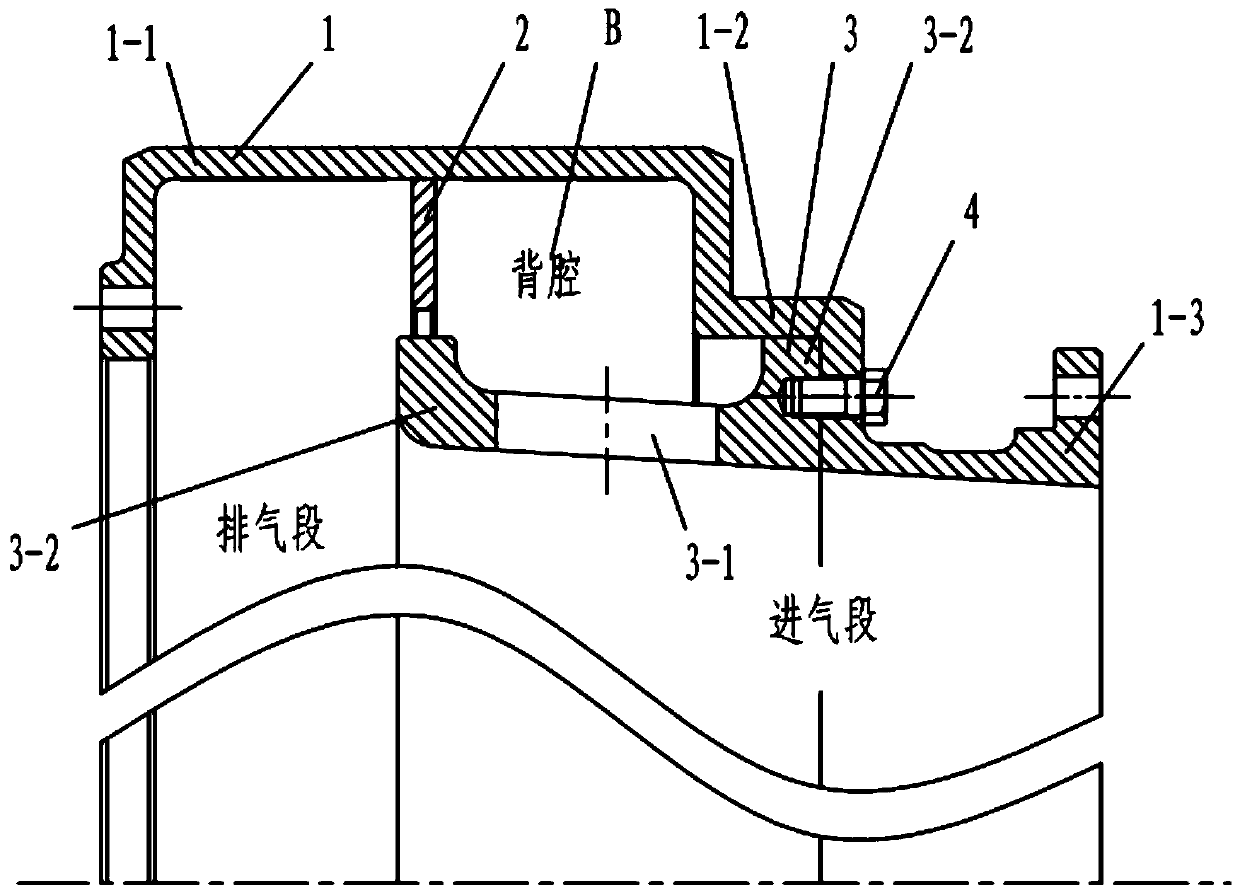

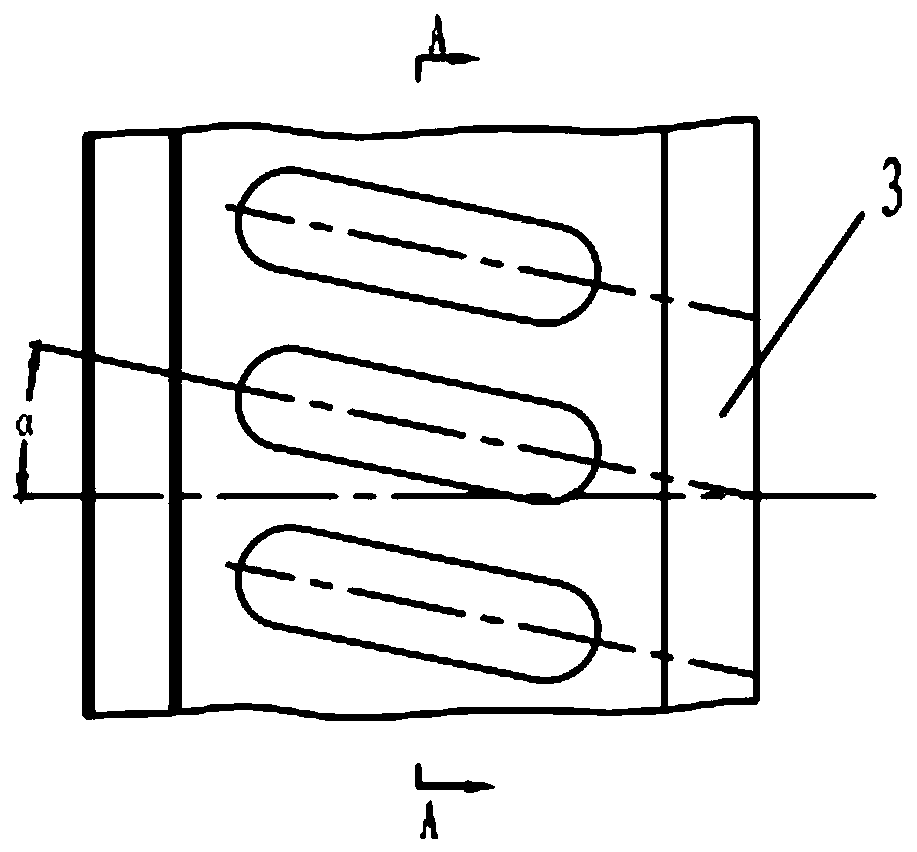

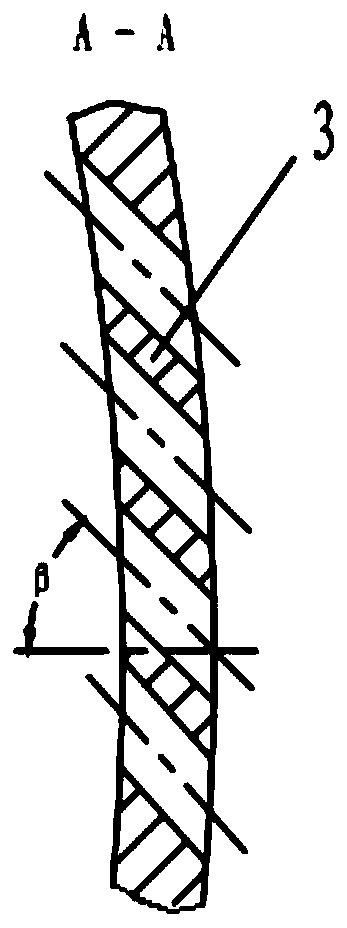

[0018] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, an axial chute processing casing with a back chamber for improving compressor performance in this embodiment includes an outer shell 1, an annular rib 2 and an axial chute 3, and the annular rib 2 is embedded in the outer shell 1, the axial chute 3 is installed in the inner hole of the annular rib 2 and the outer shell 1, and the axial chute 3 is provided with a plurality of slots 3-1 in the form of an annular array, and the slots 3-1 are respectively on the shaft Inclined upward and radially, the axial inclination angle of the slot 3-1 is α, α=10°~35°, the radial inclination angle of the slot 3-1 is β, β=30°~50°, the outer shell The space enclosed between 1 and the axial chute 3 is the back chamber B.

[0019] In this embodiment, the outer casing and the right side of the annular rib form an air intake section, and the outer casing and the left side of the annular rib form an exh...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the outer casing 1 of this embodiment includes a first ring segment 1-1, a second ring segment 1-2 and a third ring segment 1-3, the first ring segment 1-1, the second ring segment 1 -2 and the third ring segment 1-3 are coaxially arranged in sequence from left to right and made into one body. Such arrangement facilitates the installation of the annular rib and the axial chute, and also facilitates production. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 Referring to this embodiment, the inner diameters of the first ring segment 1-1, the second ring segment 1-2 and the third ring segment 1-3 in this embodiment decrease sequentially from left to right. Such arrangement facilitates a smooth transition with the inner diameter of the axial chute. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com