Asymmetric duct for behind ship propeller

A rear propeller, asymmetrical technology, applied in ship propulsion, ship components, ship construction, etc., to achieve the effect of equalizing the stern wake, improving efficiency, and improving wake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples describe the present invention in more detail.

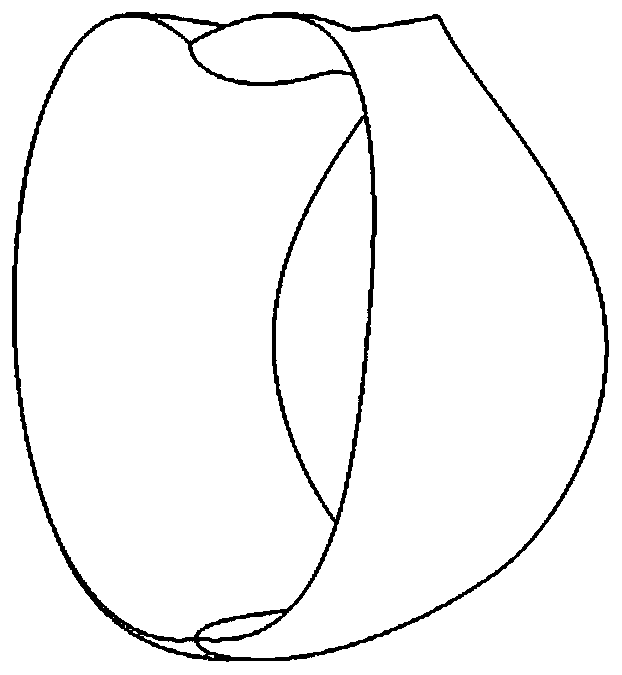

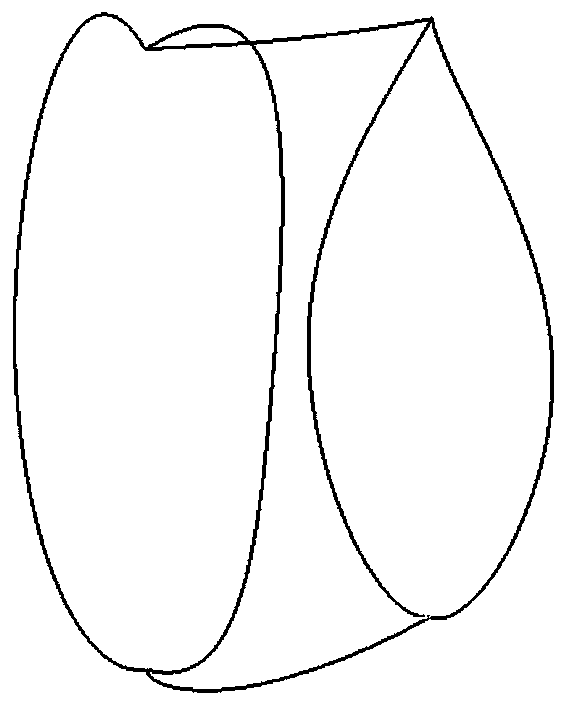

[0024] to combine figure 1 and figure 2 , the asymmetric duct used for the rear propeller of the present invention is symmetrical left and right, and its cross section varies along the circumference according to the wake of the stern. The camber and angle of attack of its airfoil section vary according to the axial wake of the stern. The upper part uses the form of accelerating duct to increase the axial velocity of the water flow in front of the propeller; the lower part uses the form of decelerating duct to reduce the axial velocity of the water flow in front of the propeller. Thereby, the wake at the propeller disc surface is uniformized, thereby improving the propeller efficiency, and greatly reducing the vibration and noise of the propeller.

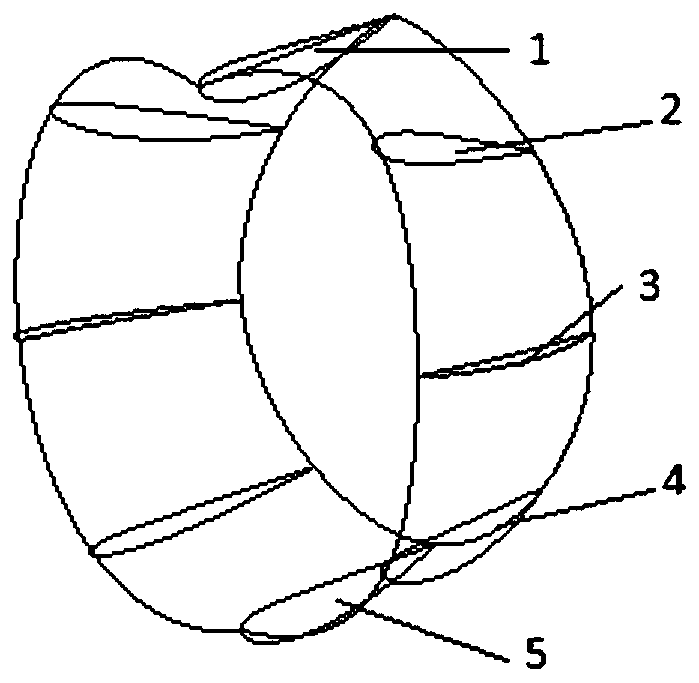

[0025] to combine image 3 as well as Figure 4a to Figure 4e , image 3 5 cross-sections at 5 positions of the asymmetric catheter are marked in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com