Executing mechanism of static pointing type rotary steerable drilling tool

A technology for rotary steerable drilling and actuators, which is applied in directional drilling and other directions, can solve the problems such as the lack of a disclosed spherical contact surface to form a seal, the insufficient pressure bearing capacity of the flexible bellows seal, and its easy to fail too quickly, and achieve long service life, The effect of high pressure bearing capacity and flexible swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

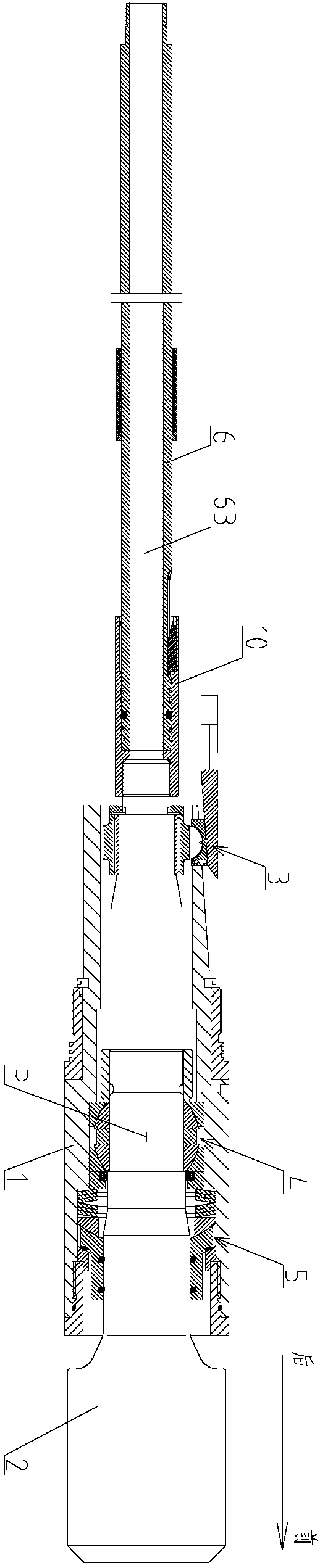

[0040] figure 1 It is a schematic structural diagram of the first preferred embodiment of the static directional rotary steering drilling tool actuator of the present invention.

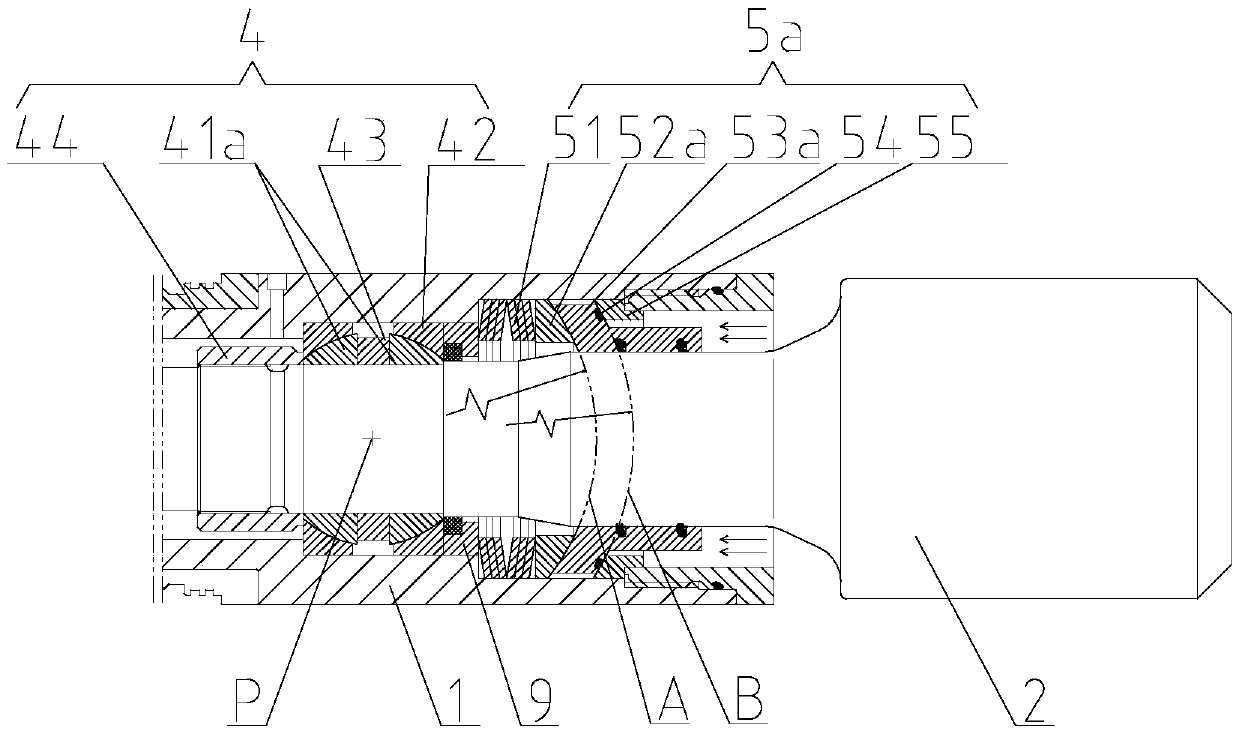

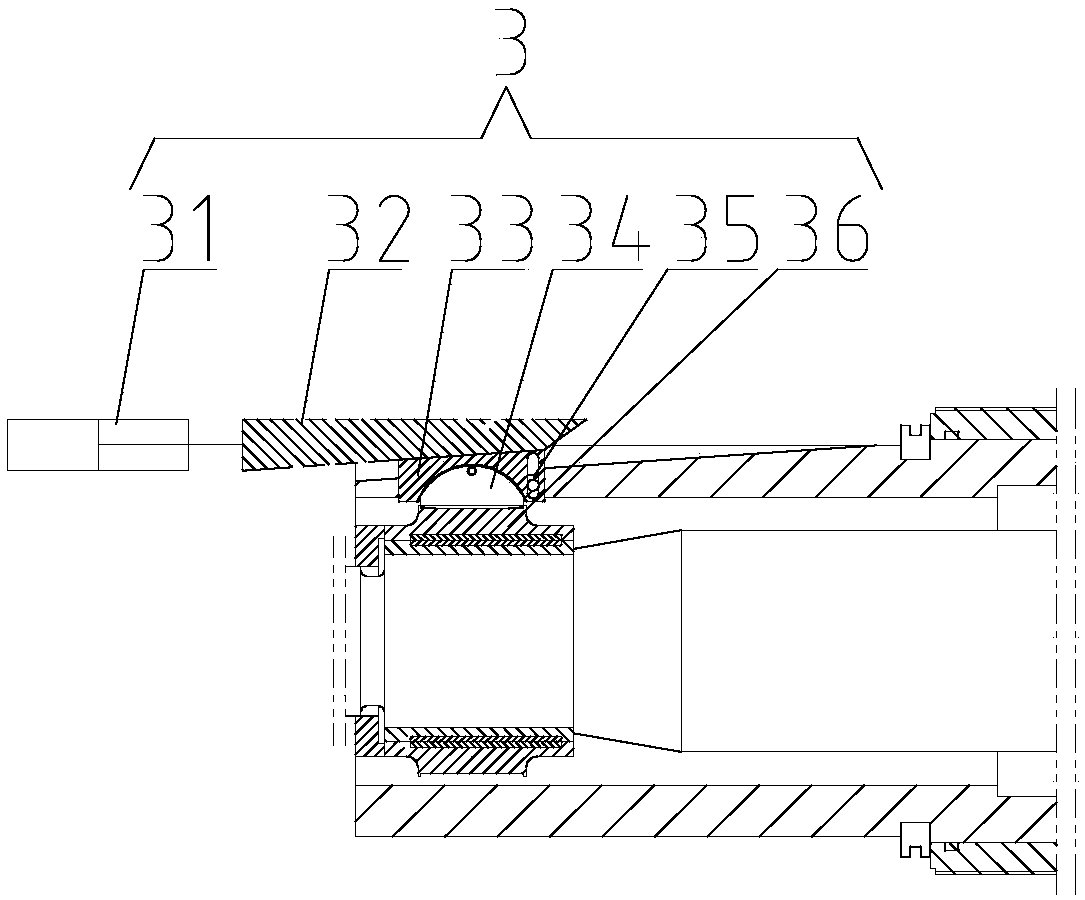

[0041] Please refer to figure 1 As shown, the actuator of the static directional rotary steering drilling tool of the present invention includes a housing 1, a transmission shaft 2, a biasing unit 3, a joint connection unit 4, a sealing unit 5 and a flexible shaft 6.

[0042] Such as figure 1 As shown, the front end of the transmission shaft 2 is connected with a drill bit, the rear end of the transmission shaft 2 is in transmission and sealing connection with the flexible shaft 6, the center of the flexible shaft 6 is provided with a guide hole 63, and the transmission shaft 2 is provided with a through hole ( figure 1 (Not shown), the drilling fluid passes through the diversion hole 63 of the flexible shaft 6 and the through hole of the transmission shaft 2 to the drill bit.

[0043] Such as figure 1 As sh...

Embodiment 2

[0063] The difference between this embodiment and embodiment 1 is only Figure 5 As shown, the inner ball sleeve 41b is integral. This technical solution reduces the number of components and improves the installation accuracy.

Embodiment 3

[0065] The difference between this embodiment and embodiment 1 lies in Image 6 As shown, the structure of the sealing unit 5b is different. The sealing unit 5b includes a fixed ball head 52b, a swing ball seat 53b, an elastic member 51 and a retaining ring 56, where the fixed ball head 52b is adjacent to the backing ring 9, and the swing ball seat 53b The spherical surface is connected with the spherical surface of the fixed ball head 52b to form a third spherical contact surface C. The third spherical contact surface C has the same central pivot point P as the inner ball sleeve 41b. A spherical seal 54 can be installed on the fixed ball head 52b. 的槽。 The slot.

[0066] Such as Image 6 As shown, the swing ball seat 53b is sealed and rotatably connected with the transmission shaft 2, for example, a sealing ring groove may be provided on the inner hole of the swing ball seat 53b. One end of the elastic member 51 of this embodiment is connected to the swing ball seat 53b, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com