Patents

Literature

47results about How to "Reduce soot rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

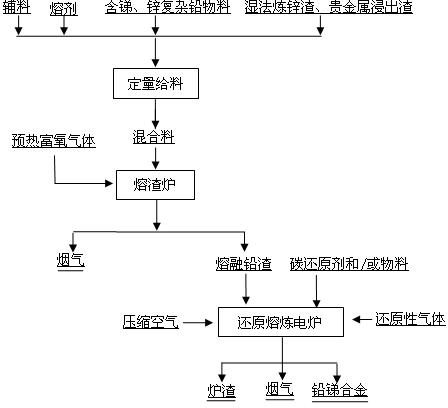

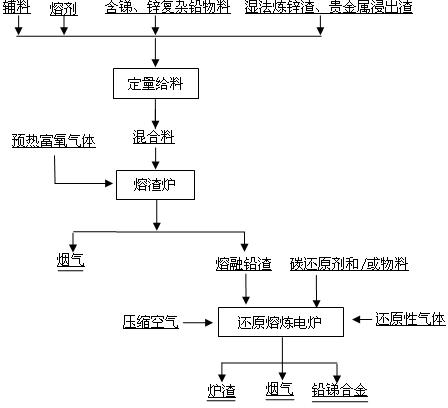

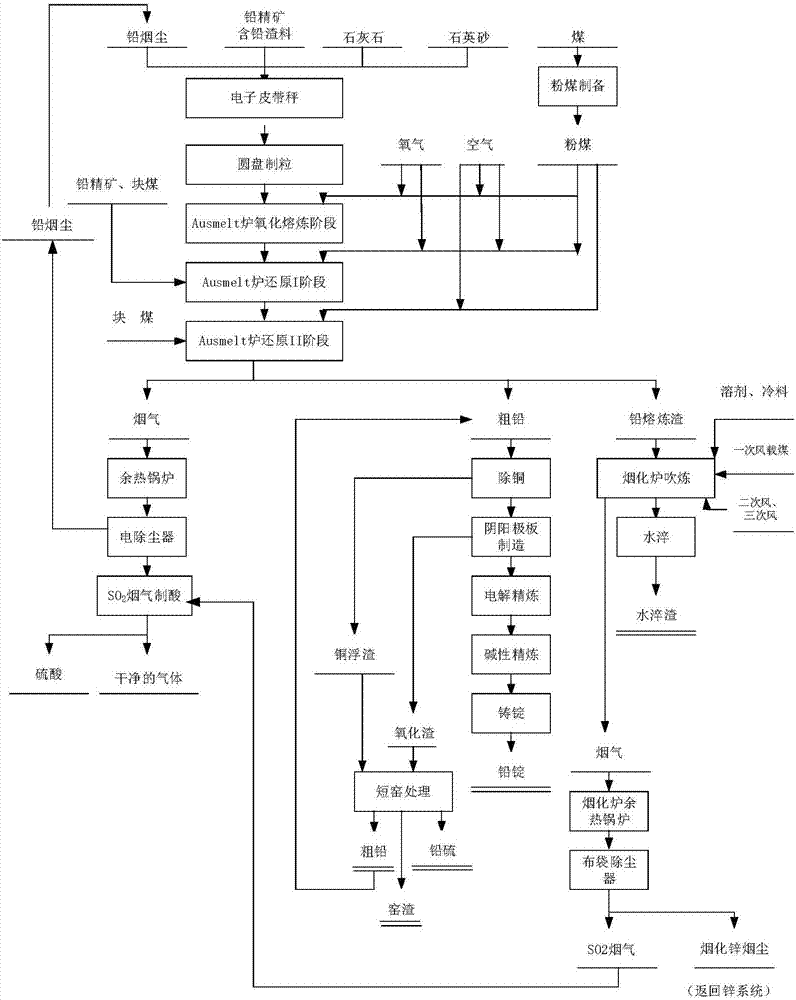

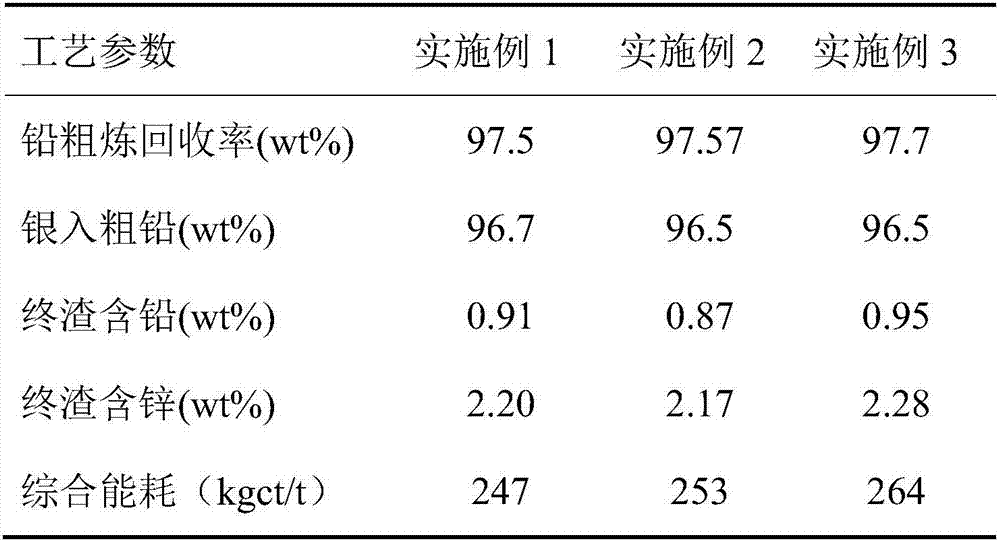

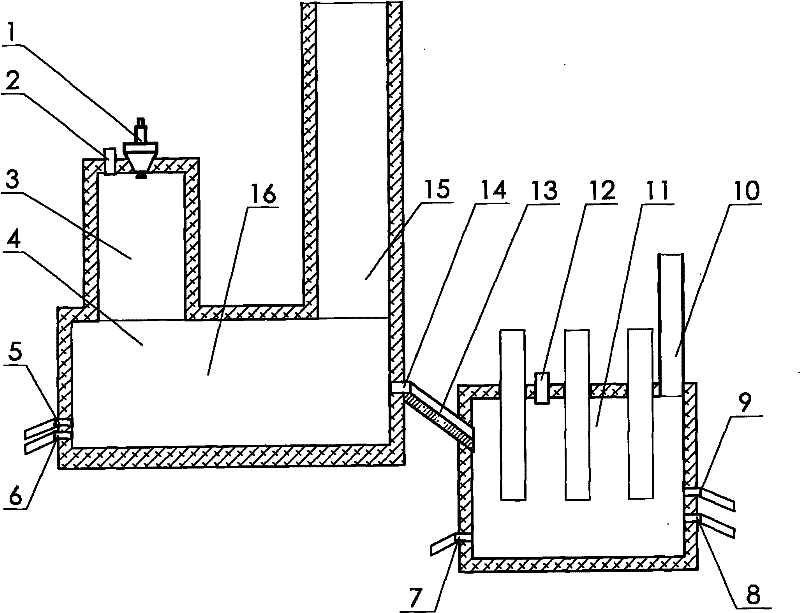

Smelting method of lead concentrate containing antimony and zinc

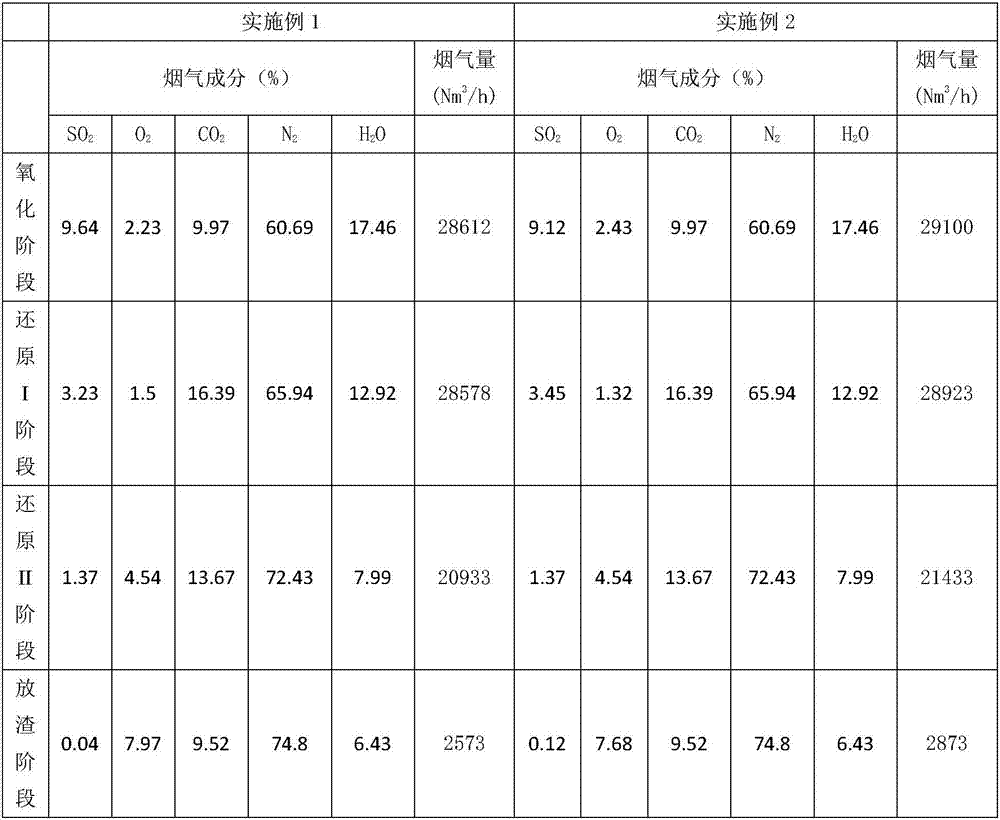

InactiveCN102433448AEfficient use ofNo explosion hazardProcess efficiency improvementFlue gasSmelting process

The invention relates to a nonferrous metal, and in particular relates to a smelting method of lead concentrate containing antimony and zinc. The smelting method is characterized in that in the smelting process, oxidizing smelting is performed to the lead concentrate containing antimony and zinc in a slagging furnace to generate a flue gas containing SO2, smelting dust and slagging furnace slag; then reduction smelting is performed to the slagging furnace slag in an electric furnace to generate a lead-antimony alloy, a flue gas and slag, and after the slag and the lead-antimony alloy are clarified and layered, the lead-antimony alloy is discharged from a lead discharge hole; and zinc oxide is recycled from the flue gas obtained in the reduction process and then the obtained flue gas is discharged to the outside. The method has the following advantages: the flow is short, continuous production is realized, energy is saved, the production capacity is large, resources can be efficiently utilized, the environment can be protected, the safety and labor hygiene are good, foamed slag has no explosion danger and the production is safe. The smelting method is suitable for not only the treatment of the complex lead materials containing antimony and zinc, but also the treatment of wet method zinc metallurgical slag and lead-precious metal system slag, lead, zinc and antimony are matched mutually, the lead-zinc-antimony combination enterprises are more superior and the recovery rates of lead and the associated valuable metals such as copper and antimony, and precious metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and method thereof

InactiveCN103374658ALead volatility is smallReduce soot rateReclaiming serviceable partsLead oxidesLead carbonateLead oxide

The invention discloses ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and a method for preparing the ultrafine lead oxide. The method comprises the following steps of: carrying out a desulfurization and lead plaster acid leaching process by causing the desulfurated lead plaster to react with acid, simultaneously adding a reducing agent, and carrying out solid-liquid separation after the reaction is ended to obtain a plumbic acid containing solution; carrying out a lead carbonate preparation process by causing the plumbic acid containing solution to react with sodium carbonate, carrying out solid-liquid separation, washing and drying to obtain the lead carbonate; carrying out a roasting process by preparing the ultrafine lead carbonate by roasting the lead carbonate, wherein the ultrafine lead oxide can be PbO, Pb3O4, or the mixture of the PbO and the Pb3O4, the mean particle granularity of the ultrafine lead oxide is less than 2 mu m, and the nanocrystalline grain size is less than 500nm. Compared with the prior art, the preparation method of the ultrafine lead oxide disclosed by the invention has the following beneficial effects: the active material of the ultrafine lead oxide powder compound for the production of a storage battery enterprise can be directly prepared, lead volatilize quantity is small, the ash rate is low, the direct lead yield is high, the energy consumption is low, pollutants of sulfur dioxide and the like are not generated, and the like.

Owner:湖北金洋冶金股份有限公司 +1

Zinc leaching slag treatment method

ActiveCN103421955AShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

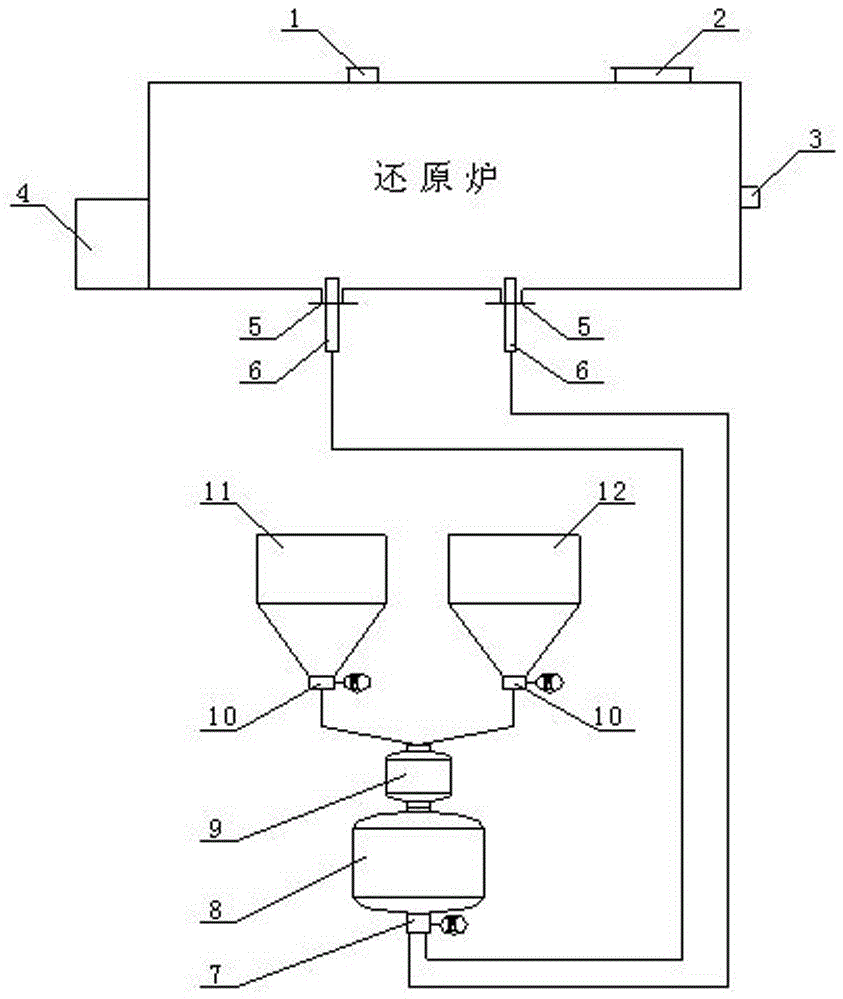

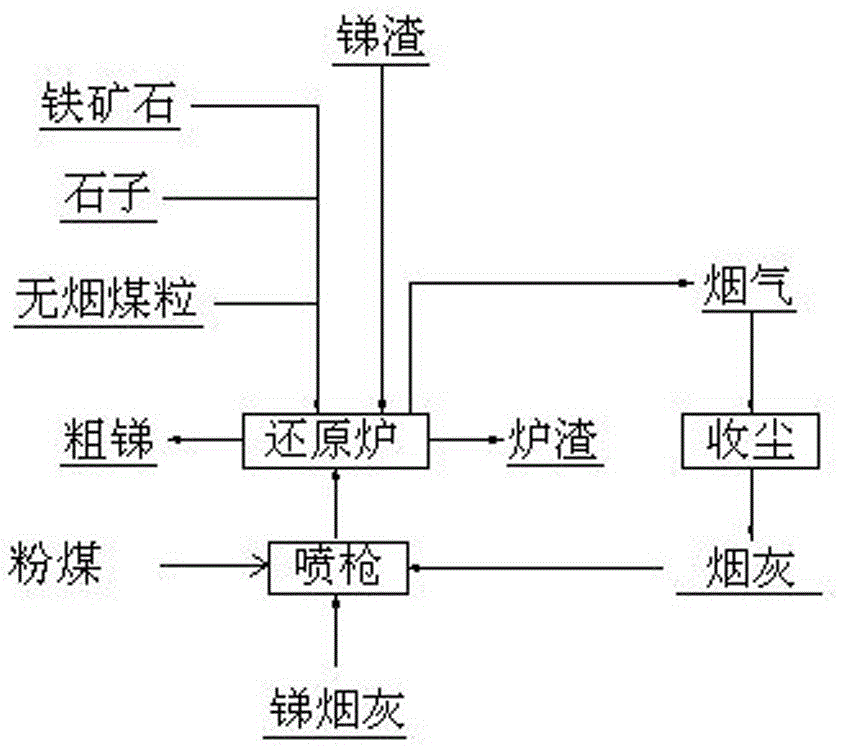

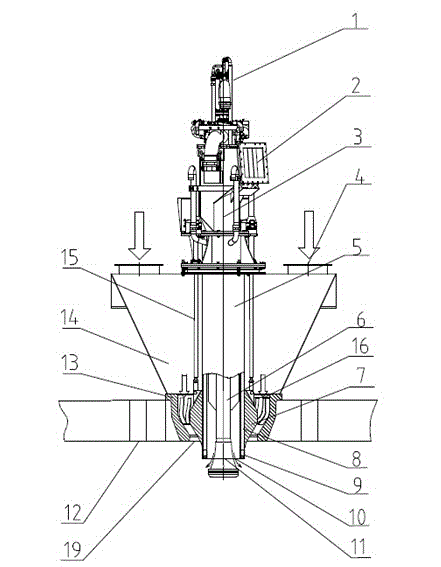

Device and process for directly reducing smelt antimony from antimony slag and antimony ash

InactiveCN105603197AImprove thermal efficiencyReduce soot rateProcess efficiency improvementIronstoneSlag

The invention relates to the non-ferrous metal metallurgy industry, in particular to a device and a process used for directly reducing smelt antimony from antimony slag and antimony ash and having the characteristics of short process, low energy consumption and high applicability. A reduction furnace comprises an antimony ash supply system, a powdered coal supply system and a flue gas dust collection system. The antimony slag is directly fed into the reduction furnace; iron ores, pebbles and anthracite particles are continuously supplied into the reduction furnace and serve as a slag former and a reducer at the same time; and the antimony ash, ash collected by the flue gas dust collection system and powdered coal as fuel are blown into the reduction furnace through a spray gun, so that materials in the reduction furnace are enabled to quickly produce a reduction reaction. The device and process are short in technological process, high in reduction degree, high in antimony direct recovery rate and low in energy consumption; and in addition, the environmental pollution is alleviated and the labor intensity is reduced.

Owner:HENAN YUGUANG GOLD & LEAD

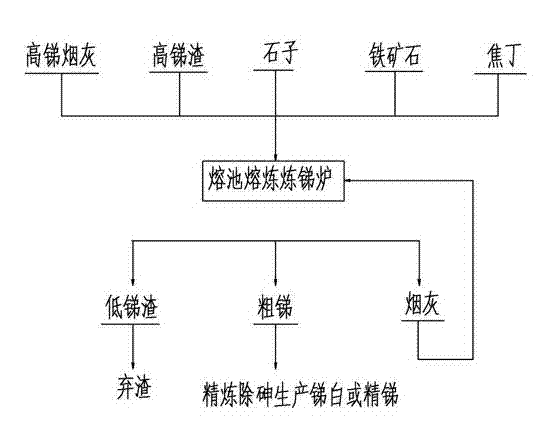

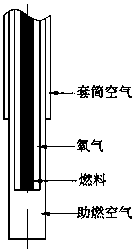

Technology and device thereof adopting bottom blowing molten bath for antimony reduction and smelting

InactiveCN102758094ASpeed up smeltingEasy to handleProcess efficiency improvementMelting tankMolten bath

The invention belongs to the technical field of antimony smelting in the industry of non-ferrous metal metallurgy, and particularly relates to a technology and a device thereof adopting bottom blowing molten bath for antimony reduction and smelting in the process of antimony smelting, wherein the bottom blowing molten bath smelting technology is adopted, antimonial raw material and burden are uniformly blended according to a suitable proportion and fed into a molten bath antimony smelting furnace for smelting to carry out reduction and slag making reaction; oxygen, nitrogen, natural gas or coal gas are fed into the melt through a gas spray gun from the bottom part or bottom side part of the molten bath antimony smelting furnace; the gas is combusted to release heat, so as to ensure the temperature of the furnace, participate in the oxidation and reduction reaction of the burden, and vigorously blend the melt, as a result, the heat and mass transfer and reaction speed in the smelting furnace can be improved, the burden can be quickly reacted to produce lean antimony slag, crude antimony and flue gas, the antimony can be continuously processed, and the slag type with little corrosion on the refractory material is produced. The technology and the device have the advantages of low investment, energy consumption and cost, high automation degree and environmental protection.

Owner:HENAN YUGUANG GOLD & LEAD

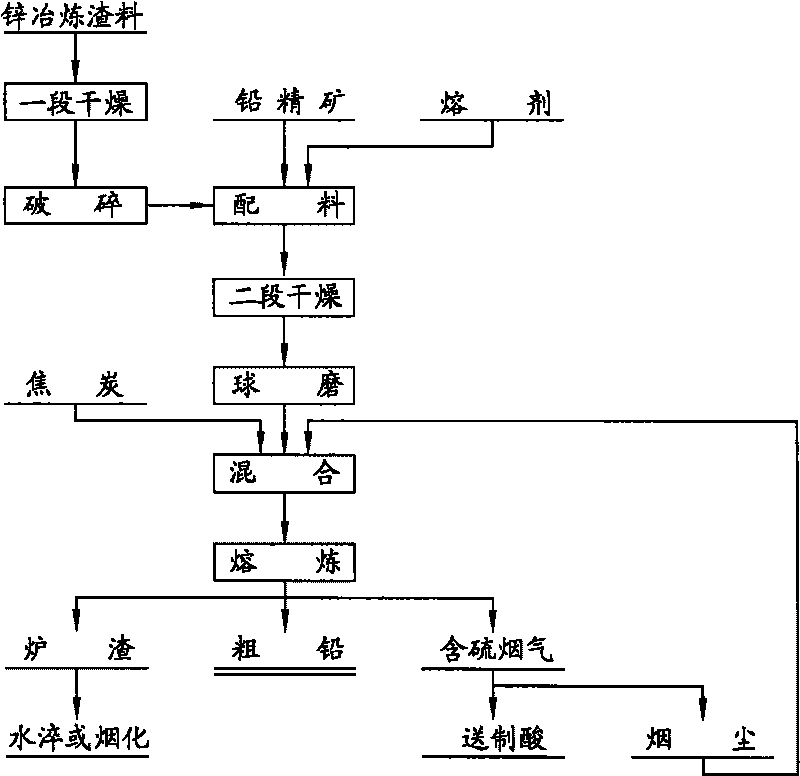

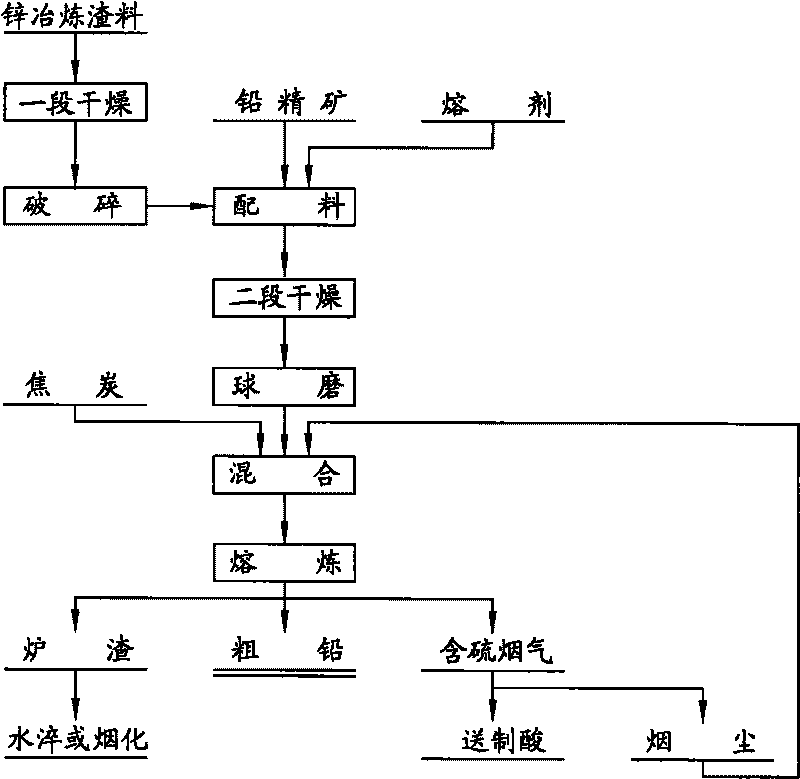

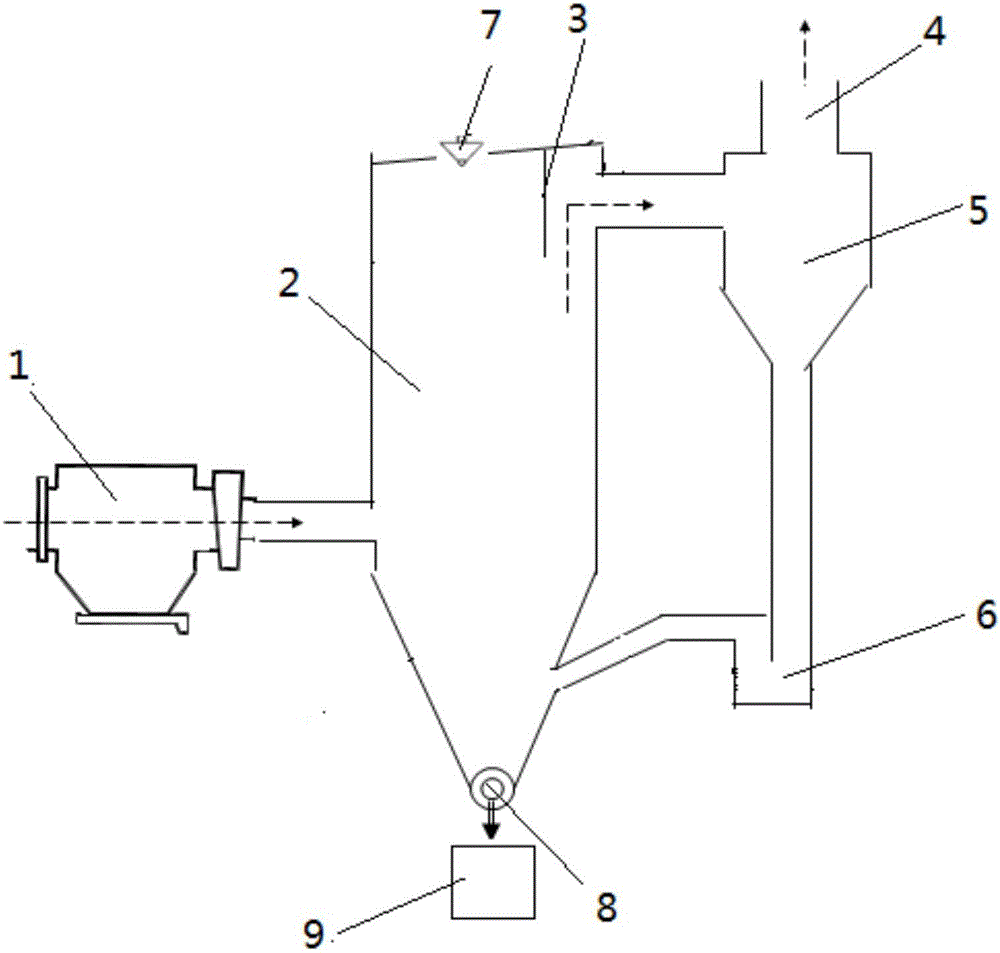

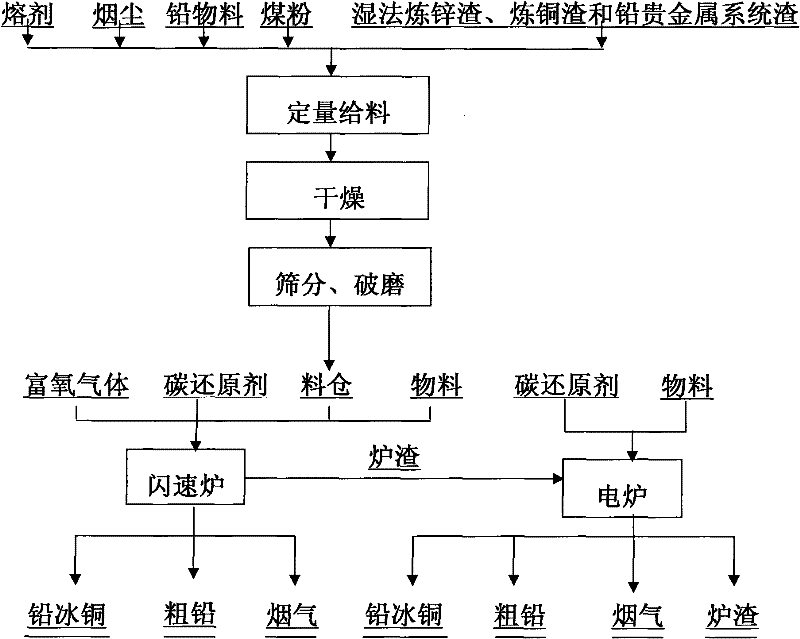

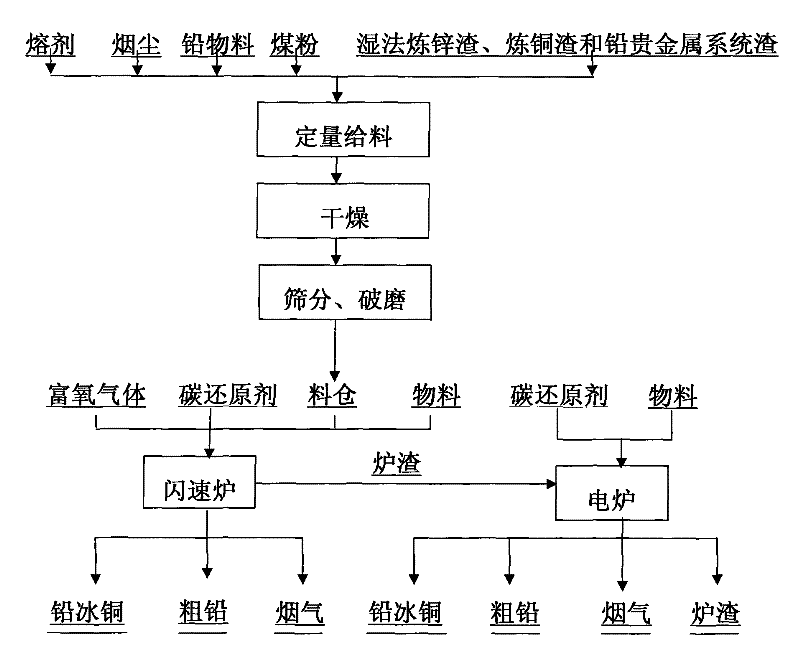

Direct lead smelting method for processing zinc smelting slag by matching

ActiveCN101705366AMeet energy consumptionEliminate polluted environmentProcess efficiency improvementLead smeltingFlash smelting

The invention discloses a direct lead smelting method for processing zinc smelting slag by matching. The method comprises the following steps of: drying zinc smelting slag at the first stage; batching the zinc smelting slag together with raw materials and solvents containing lead to obtain a lead-containing furnace charge with stable components; drying at the second stage and then ball milling; uniformly mixing the furnace charge with reducing agent coke and smelting return dust respectively according to preset measurements, and continuously adding the obtained mixed powder from an oxygen nozzle so as to ensure that the mixed powder enters a lead smelting furnace together with pure oxygen to carry out flash smelting and respectively obtain crude lead and secondary zinc oxide; sending slag into a fuming furnace for blowing or water quenching; and sending gas fume containing sulphur into a sulfuric acid system. The lead smelting method has short technological process and strong raw material adaptability and can smelt low-grade furnace charges containing more than 25 percent of Pb, and meanwhile, a large amount of the zinc smelting slag can be processed by matching. The lead smelting method can produce all crude lead in a metallurgical furnace, and the content of lead in the slag can be controlled to be below 3.5 percent without adopting a blast furnace or other devices to carry out high lead slag reduction. The lead smelting method belongs to true lead smelting or one-step lead smelting.

Owner:CINF ENG CO LTD

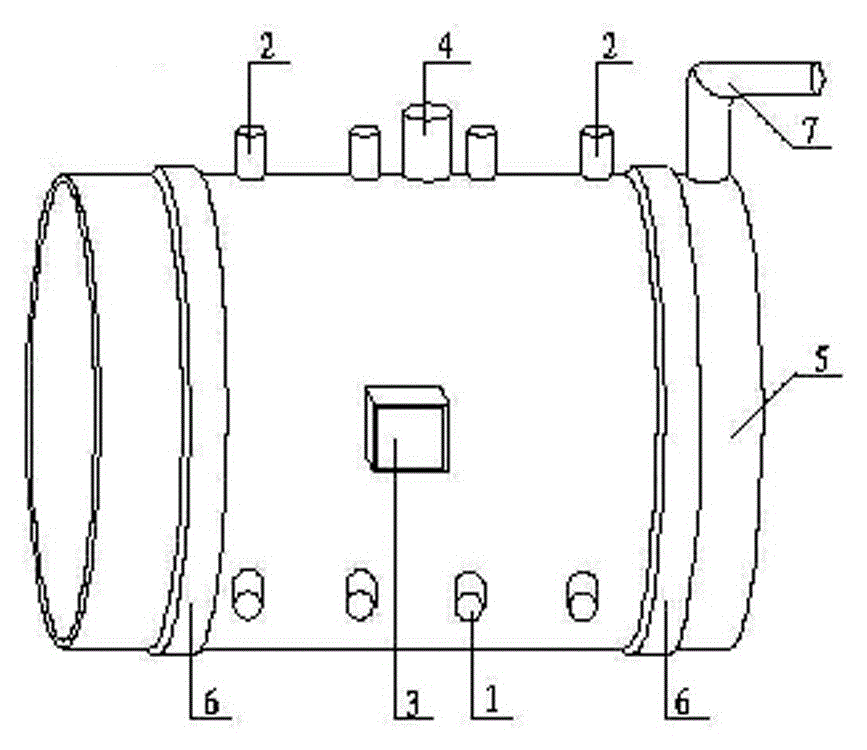

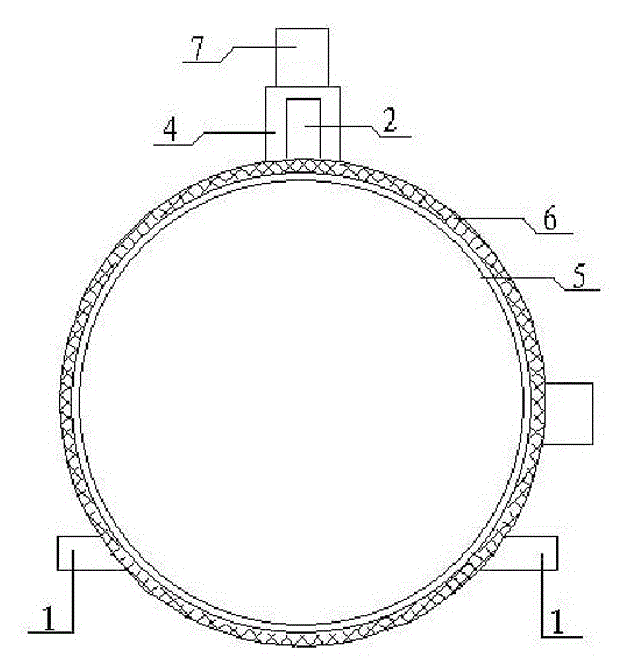

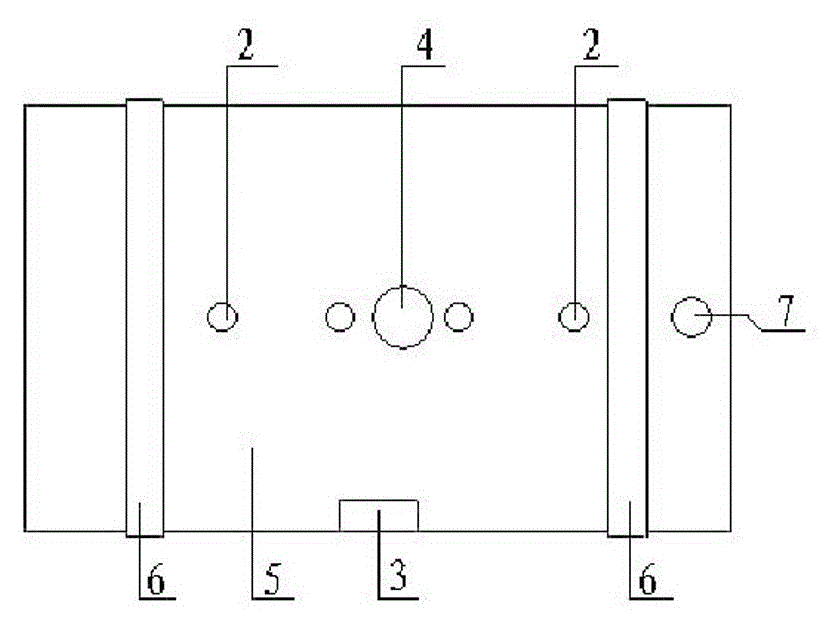

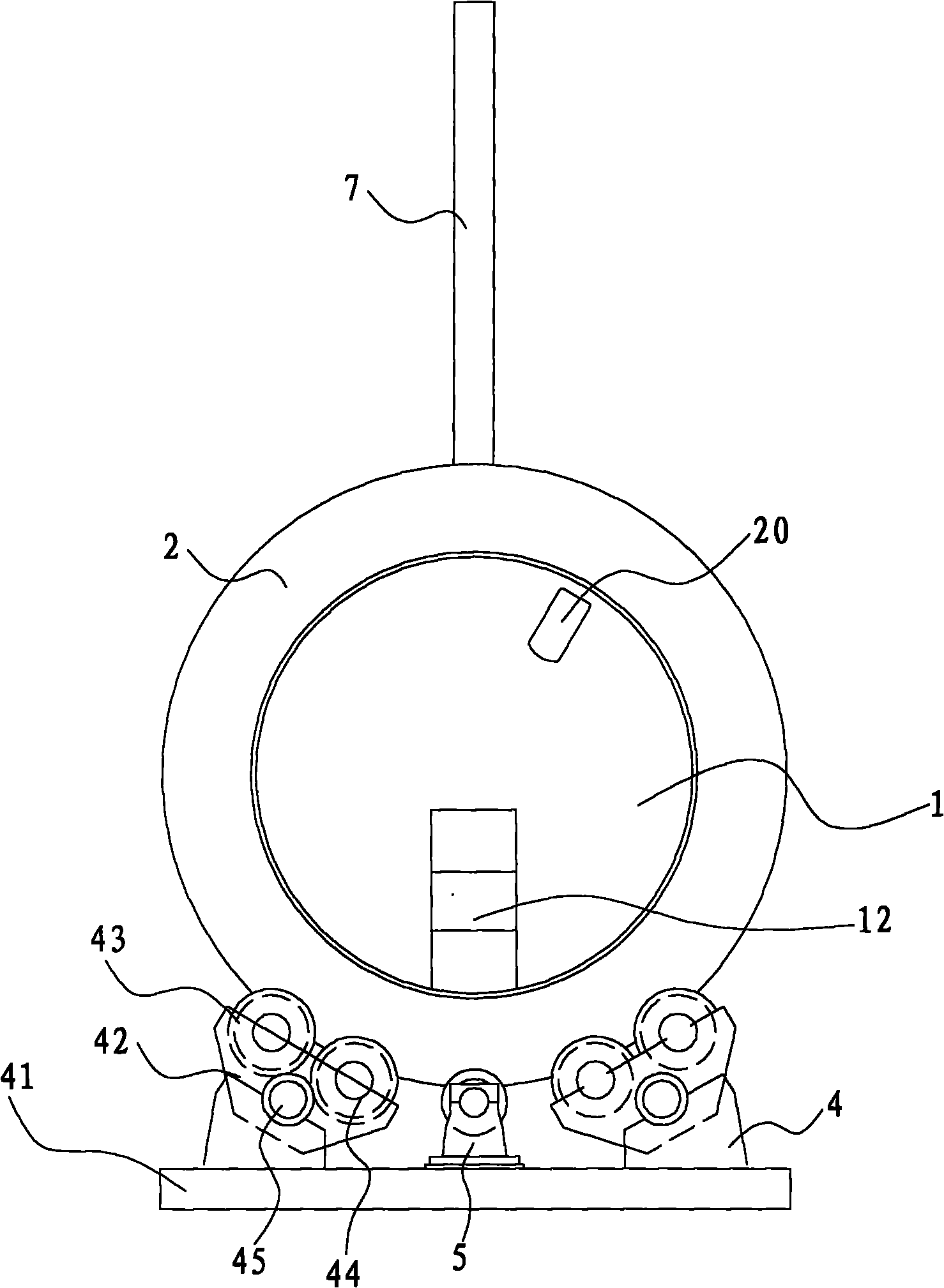

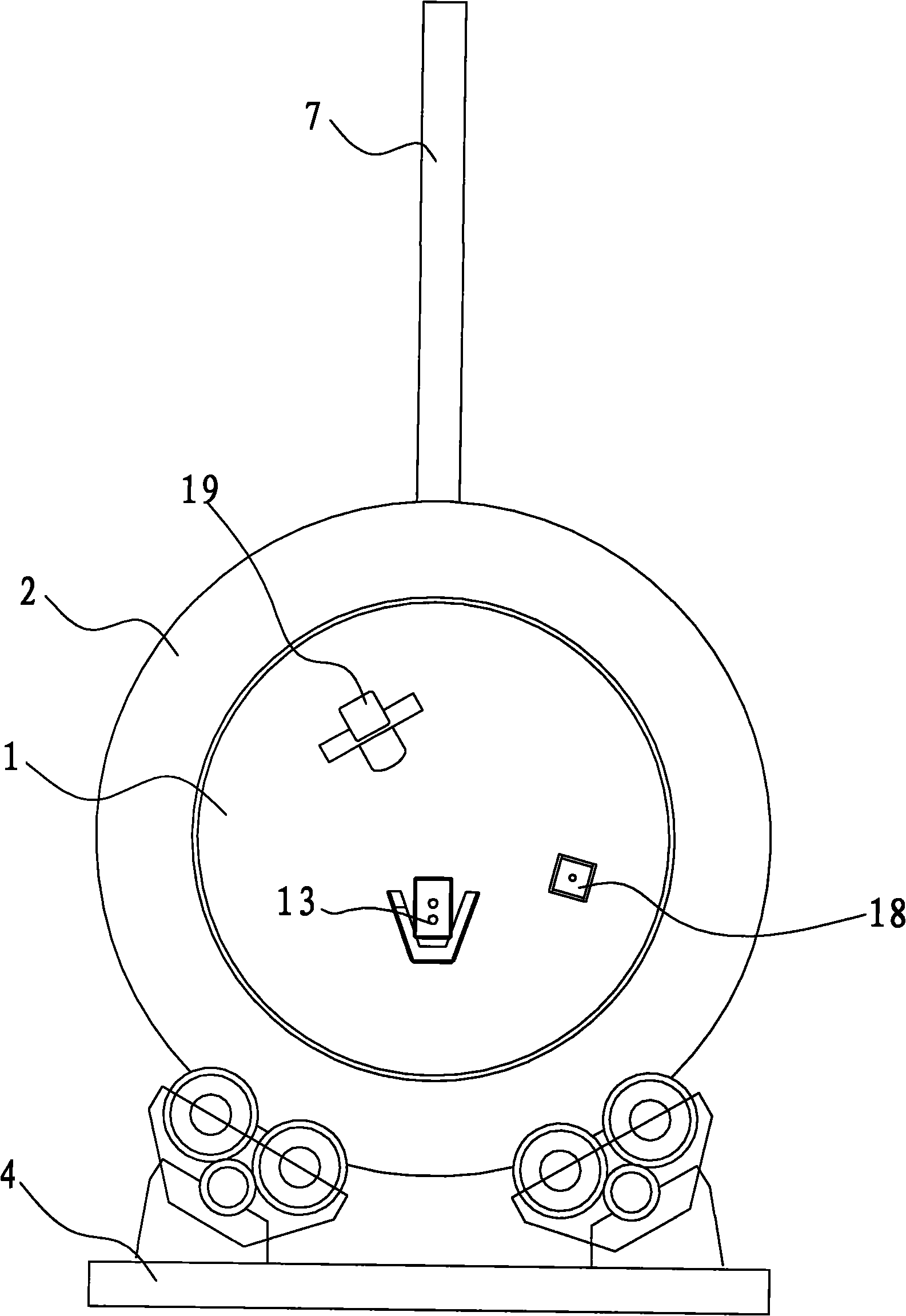

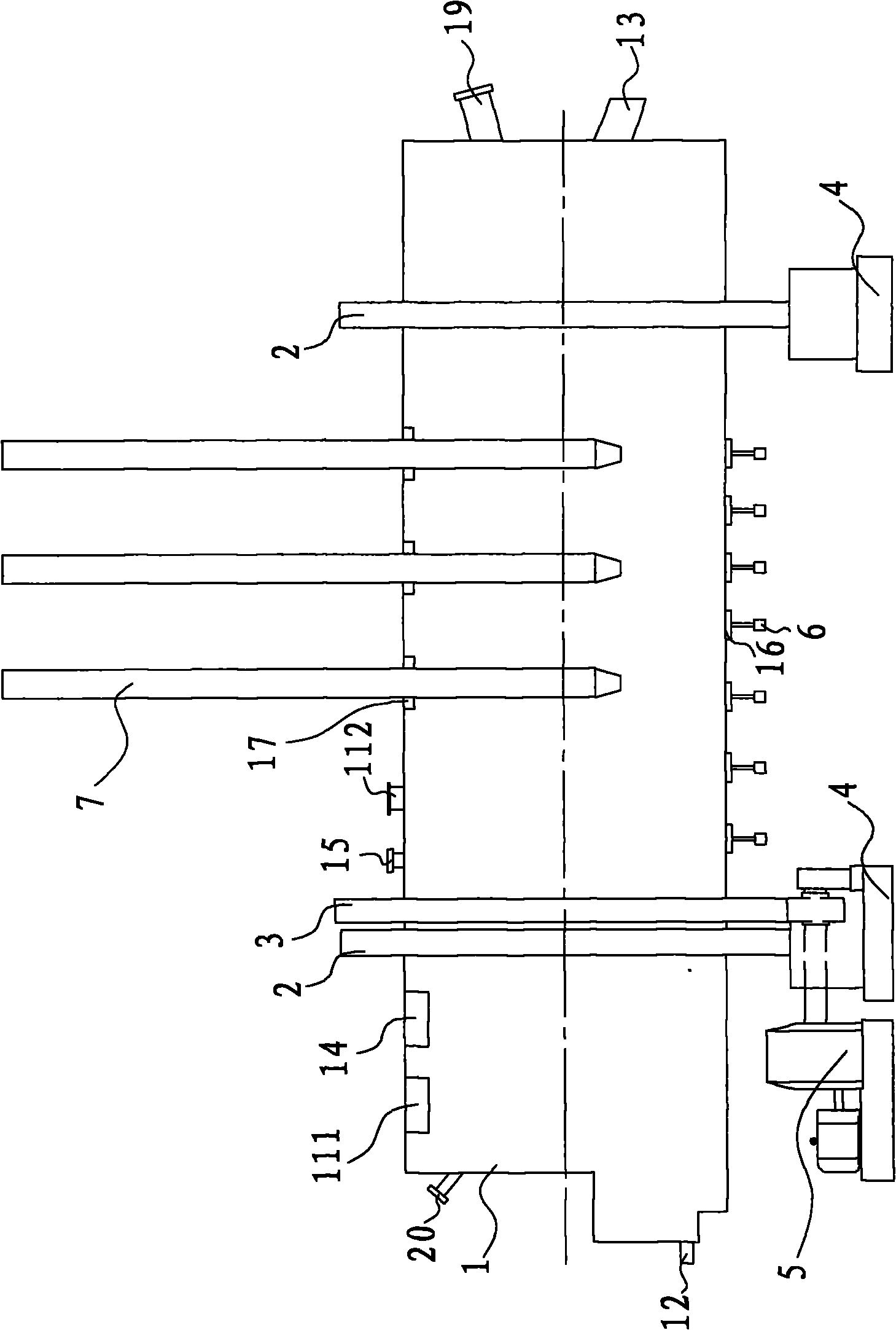

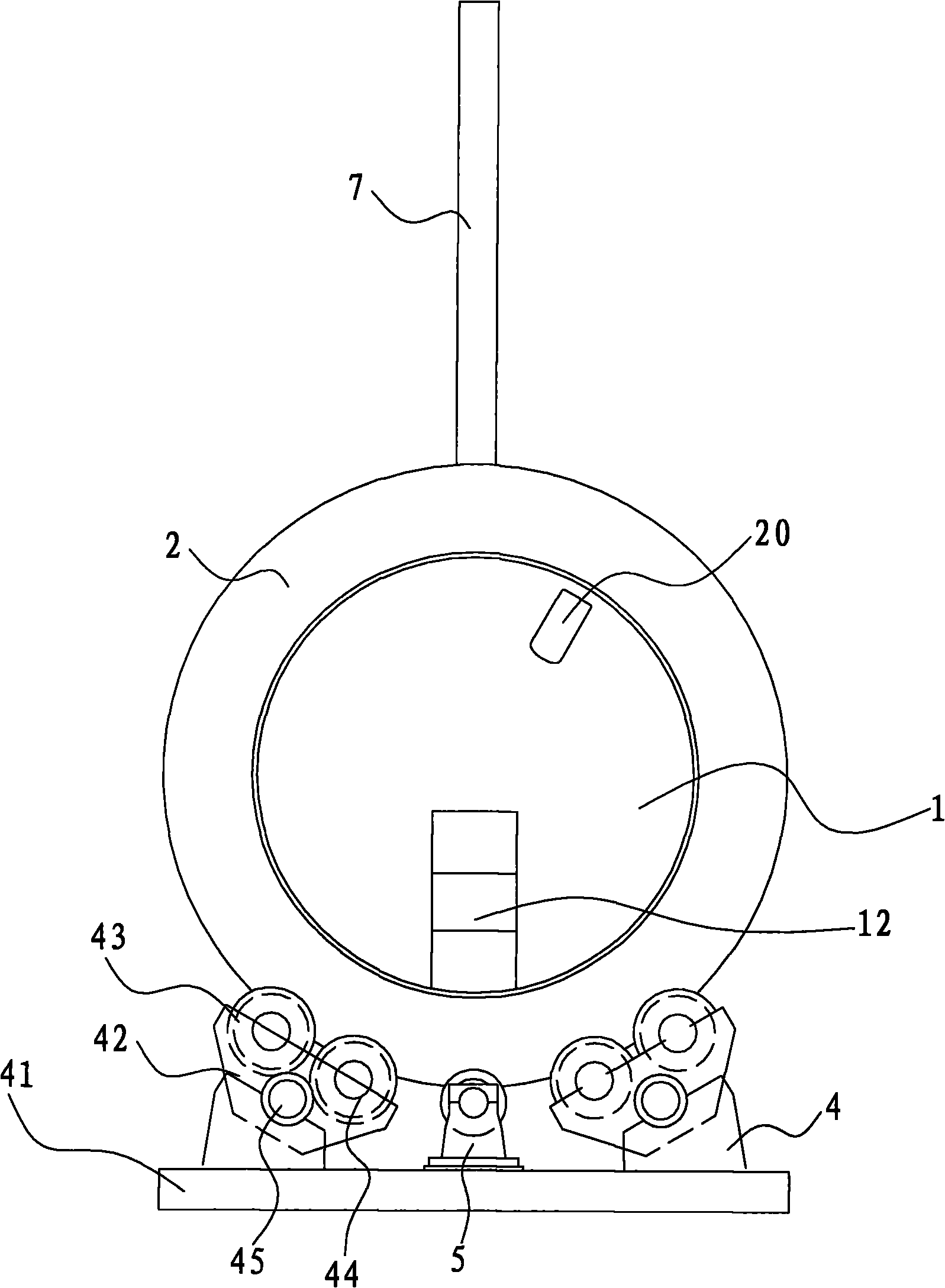

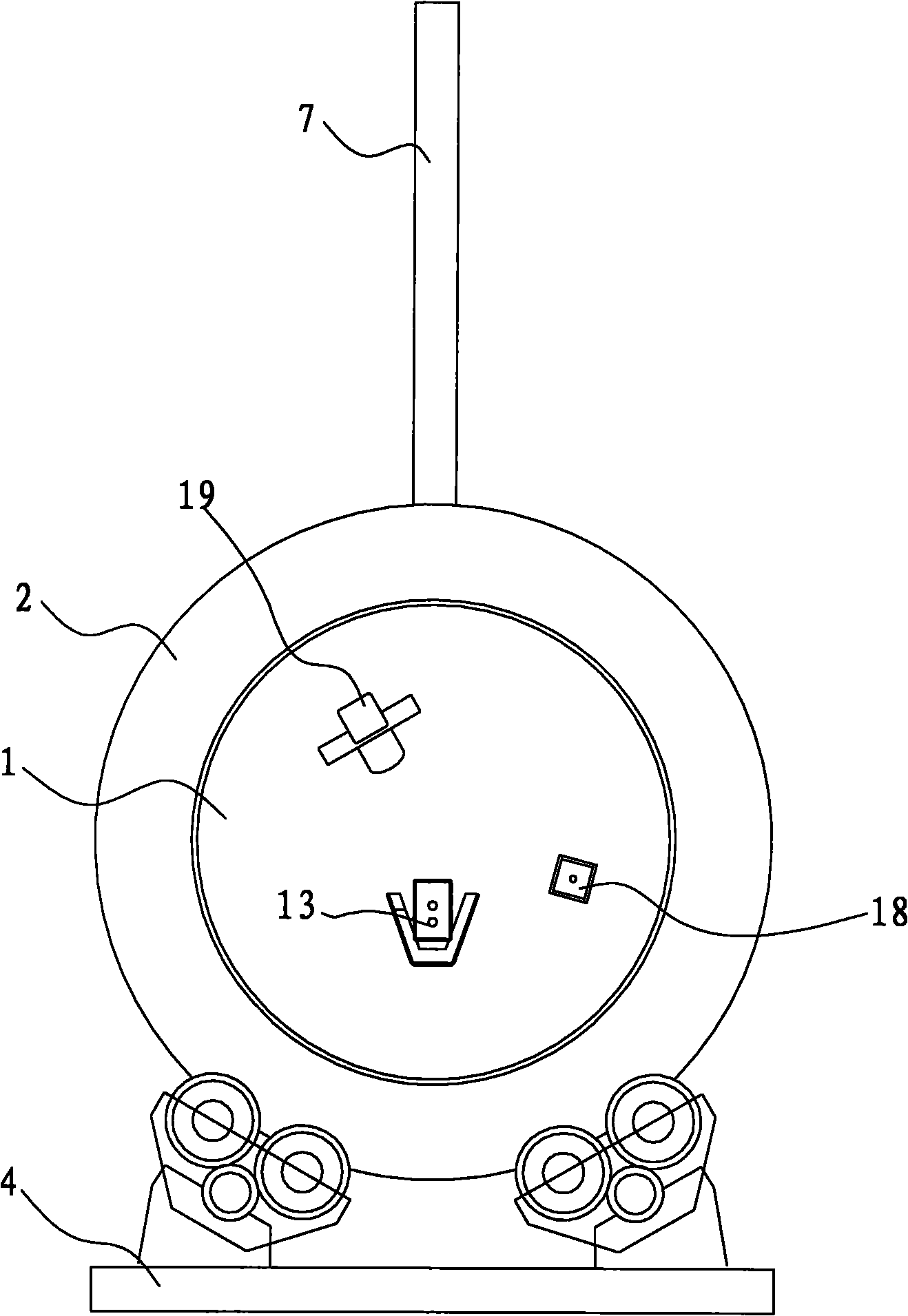

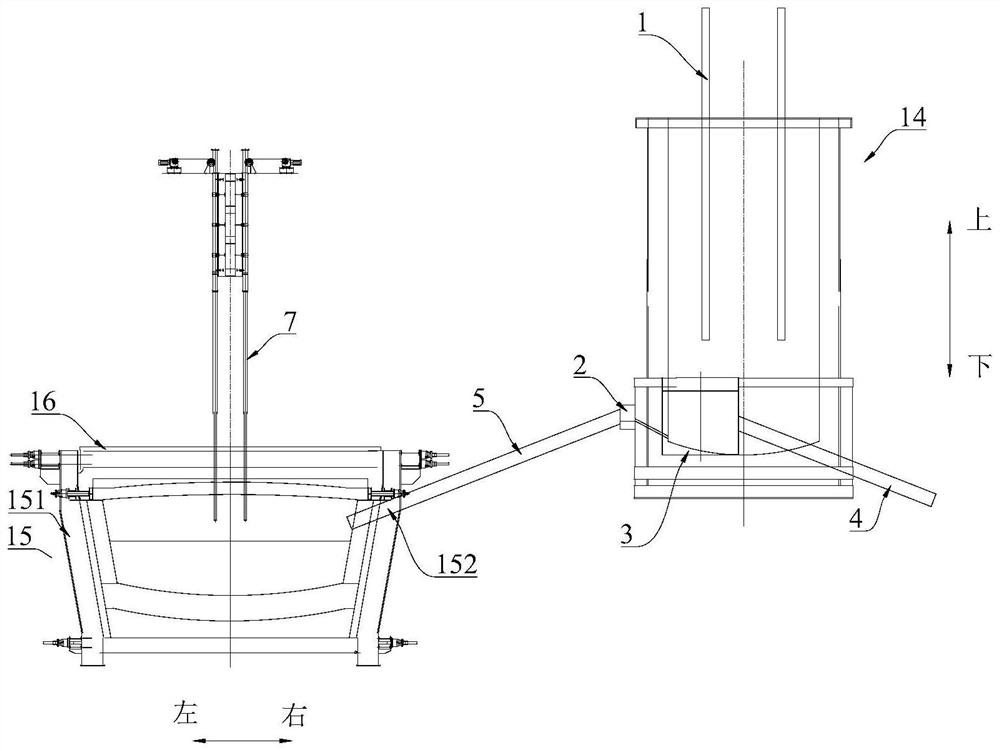

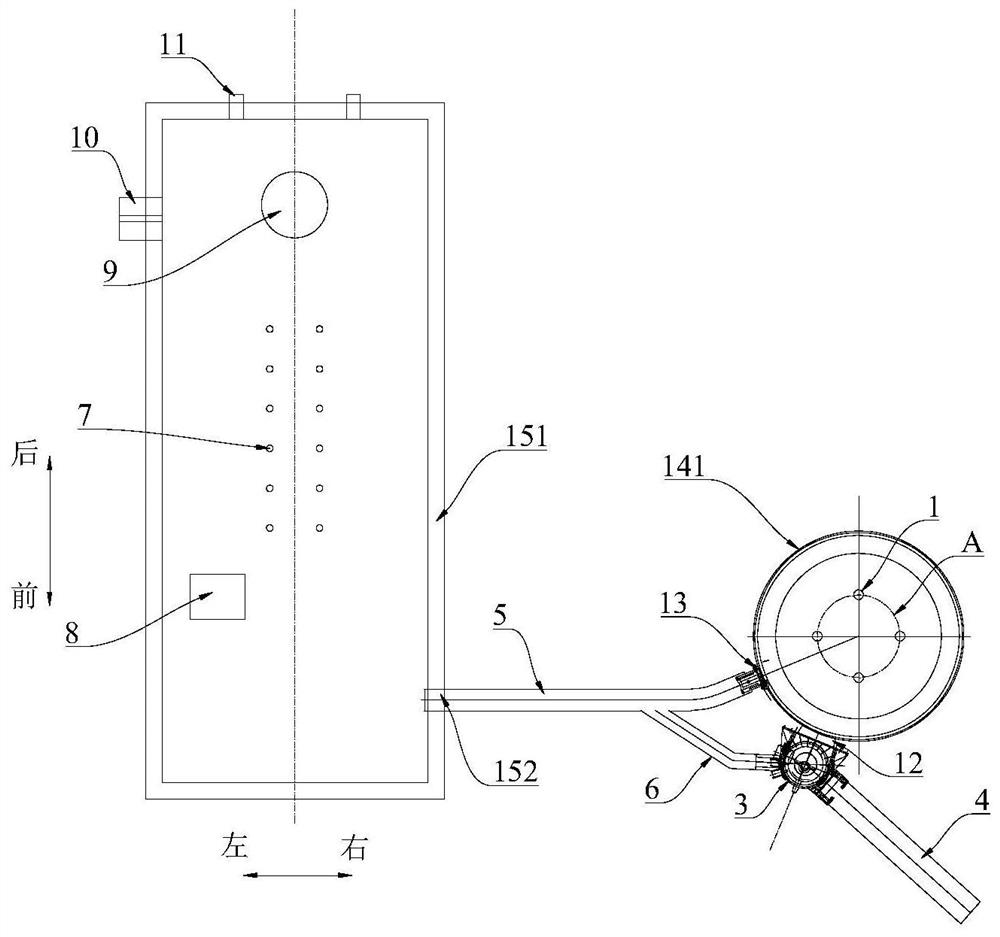

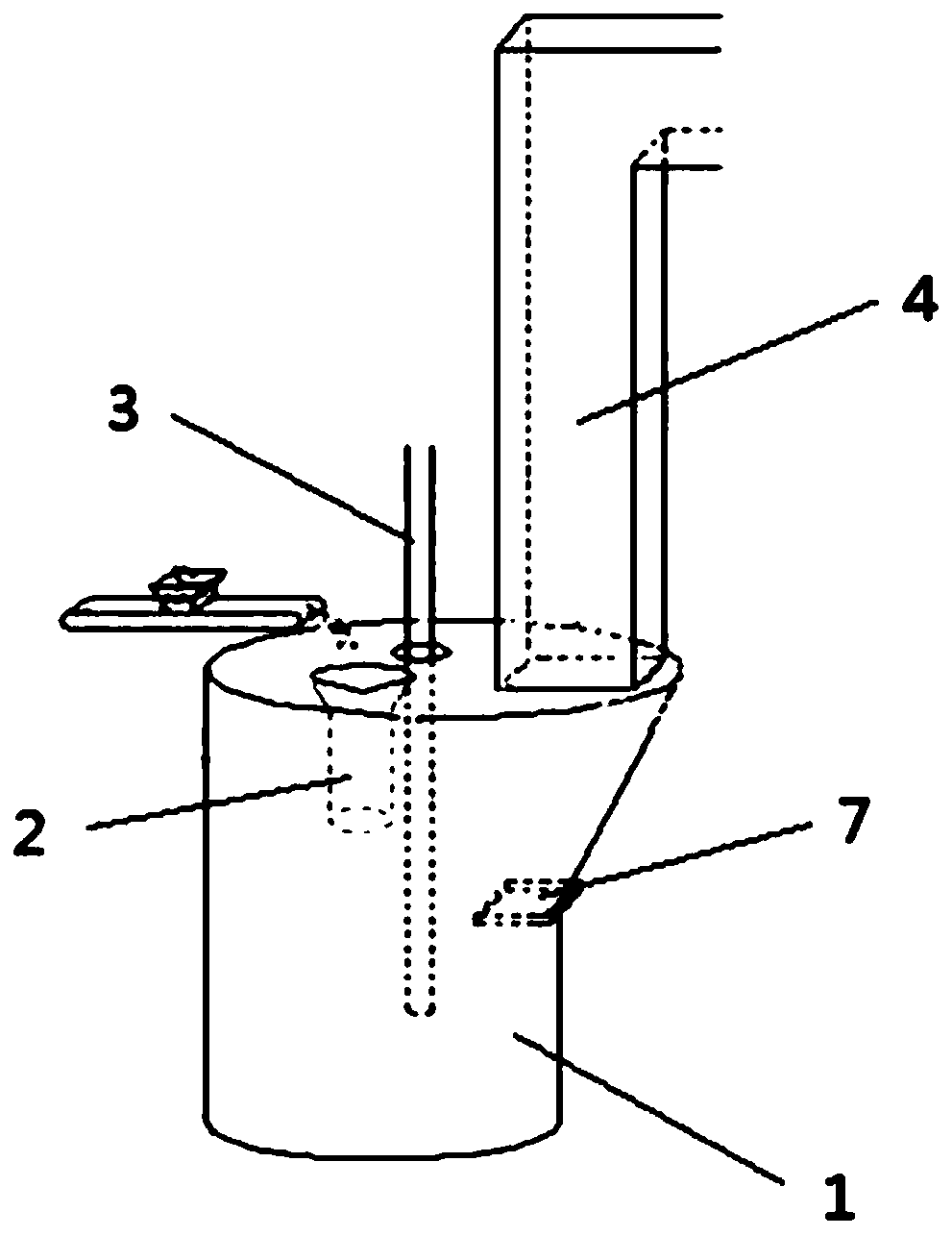

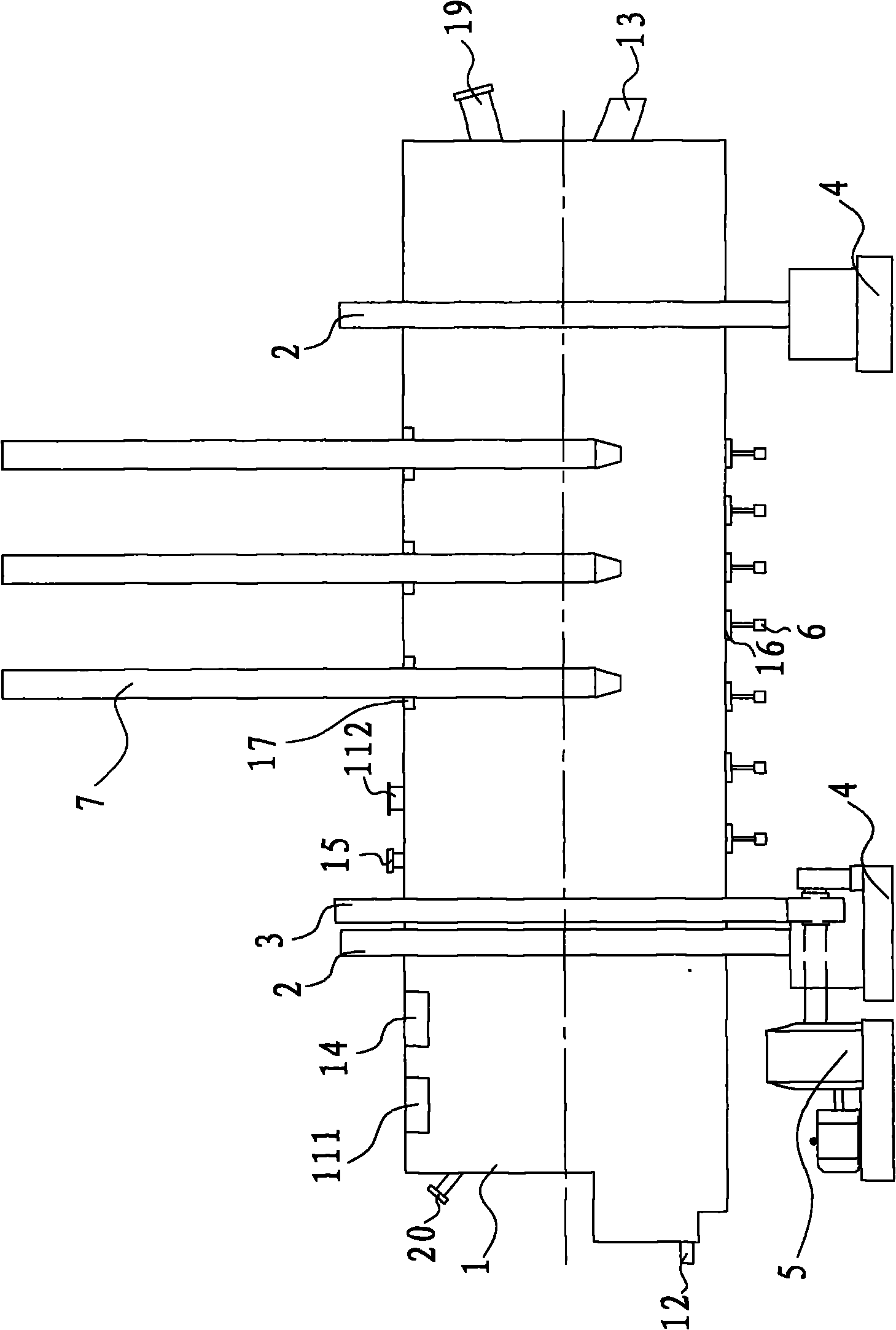

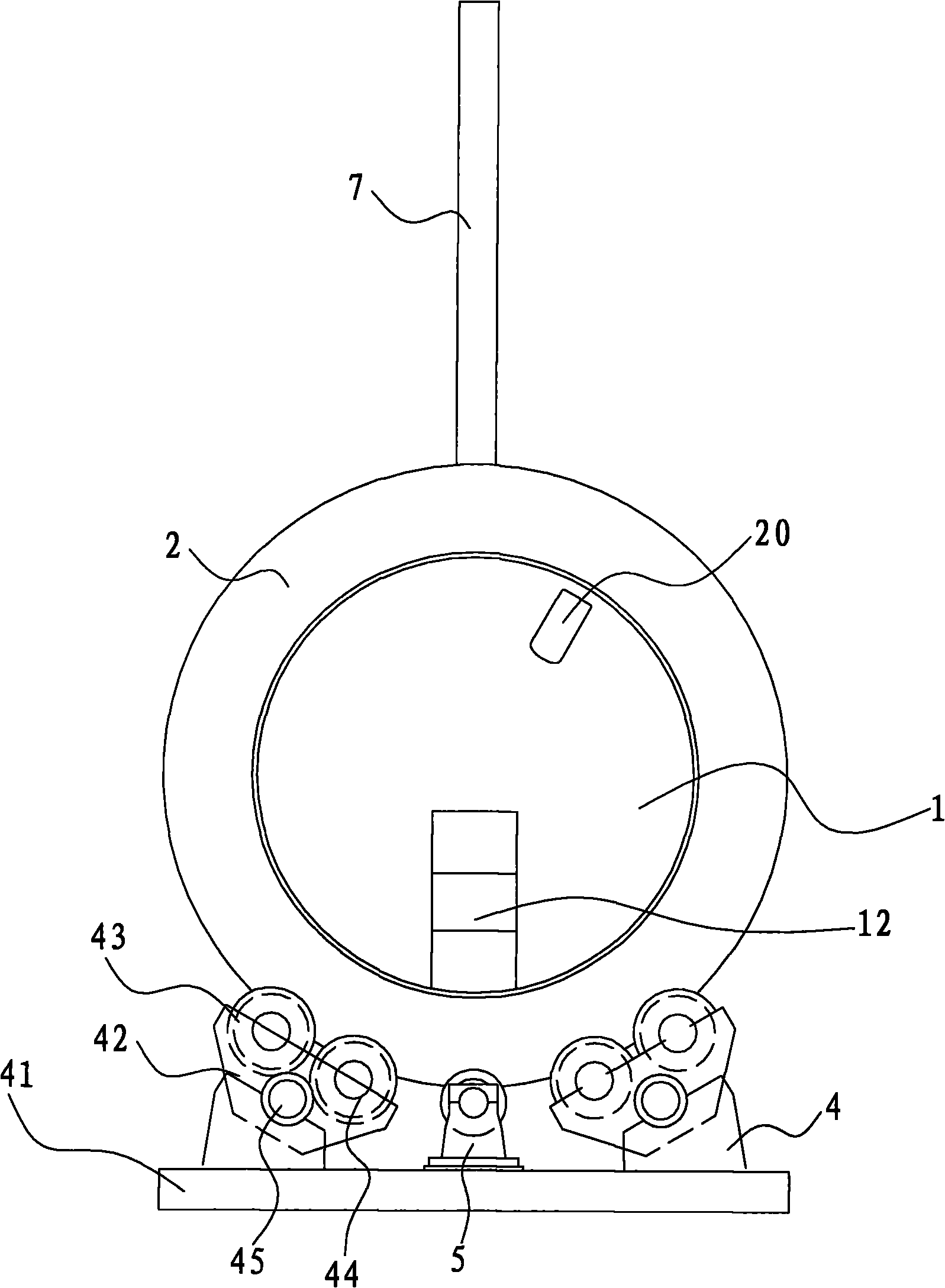

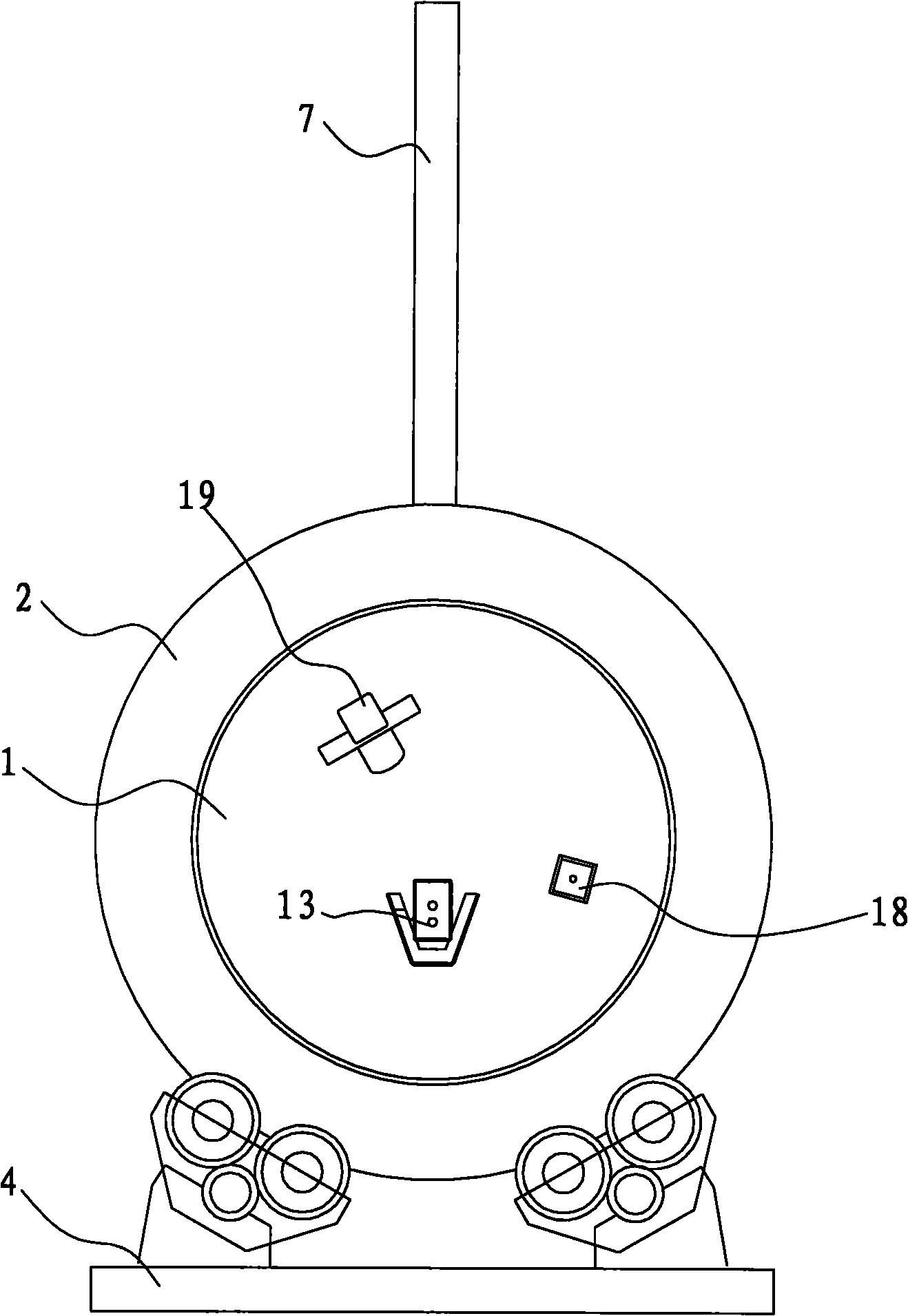

Method and device for preparing crude silver alloy through anode slime

ActiveCN105063363AReduce moistureReduce soot rateProcess efficiency improvementAlloyEnergy consumption

The invention discloses a method and device for preparing crude silver alloy through anode slime. According to the method for preparing crude silver alloy through anode slime, the anode slime is used as the raw material, and the crude silver alloy with the silver content being 80-95 wt% is obtained after the steps of pelletizing, charging and melting, slagging and emission, oxidizing slagging and crude silver alloy discharging. The device is a side-top-combined smelting converter which comprises a plurality of side blowing spray guns (1), a plurality of top blowing spray guns (2), a discharging opening (3), a feed inlet (4), a converter body (5), two rotating racks (6) and a smoke duct (7). According to the method for preparing the crude silver alloy through the anode slime, reduction smelting and oxidizing refining are finished through the side-top-combined smelting converter; compared with traditional two furnaces, the heat efficiency is good, energy consumption is lowered by 20-40%, and cost is reduced; smelting time is shortened to be within 4 days from 6.5 days, and the smelting efficiency is improved; the crude silver alloy can be prepared without additional reducing agents and flux, operation is simple and convenient, and cost is reduced.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Lead skim reducing process

The invention discloses a lead skim reducing process, comprising the following steps: adding flux and fused lead skim into the hearth of a lead skim reducing furnace; heating the materials in the hearth by utilizing an electrode; spraying powder coal into the furnace from the bottom of the lead skim reducing furnace; and respectively discharging rough lead, waste slag and smoke from a lead discharging port, a slag tap and a smoke outlet. The reducing process of the invention has small needed powder coal amount, small smoke amount, low soot rate, high lead recovery rate and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

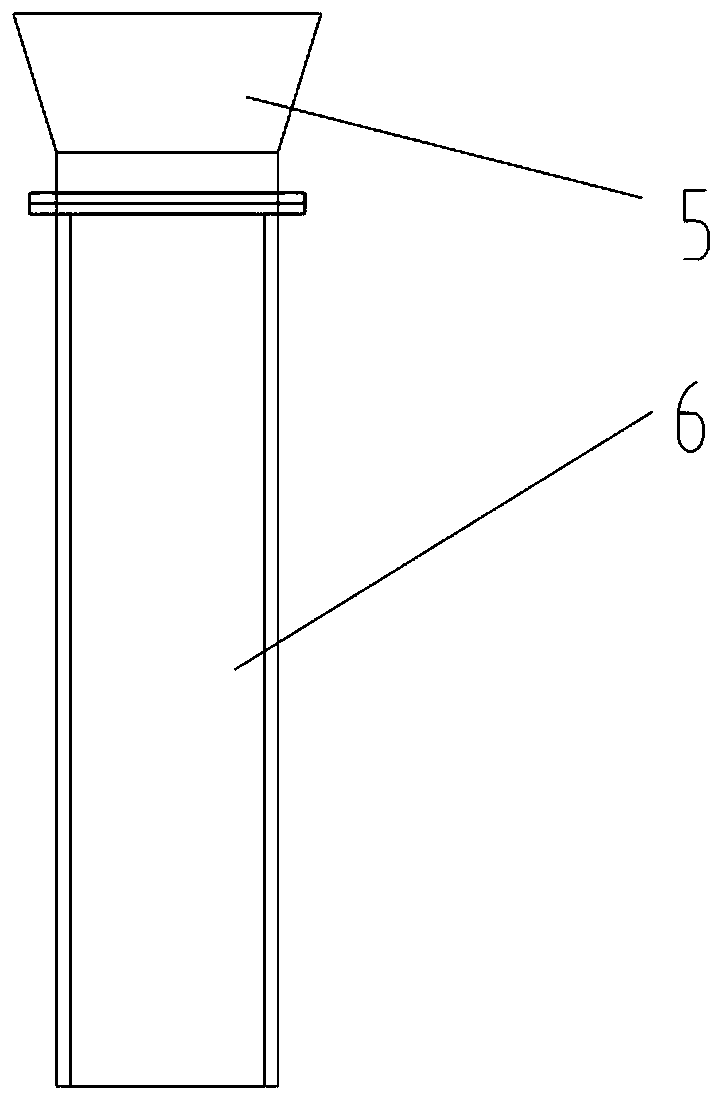

Cyclone concentrate spray nozzle

The invention discloses a cyclone concentrate spray nozzle, which comprises a material conveying pipe, wherein a center oil gun is coaxially arranged in the material conveying pipe, an air chamber is fixedly arranged at the outer side of the material conveying pipe, and is in an inverted truncated cone shape, a cyclone bird nest water jacket for forming cyclonic air is fixedly arranged at the lower end of the air chamber, a material conveying pipe outer layer for providing cooling air is arranged at the outer side of the material conveying pipe, a cyclone pipe for forming cyclonic air is fixedly arranged at the lower ends of the material conveying pipe and the material conveying pipe outer layer, the cyclone bird nest water jacket is arranged at the outer side of the material conveying pipe, an air outlet is formed by a gap between the cyclone bird nest water jacket and the the material conveying pipe, the directions of rotary air formed by the cyclone bird nest water jacket and the cyclone pipe are the same, and a high-speed rotary flow field is formed at the combining part of a material outlet. The cyclone concentrate spray nozzle has the advantages that by arranging the two cyclone mechanisms, the two types of cyclonic air are combined, the concentrate and reaction gas can be fully mixed, and the smoke dust rate is reduced; by increasing the negative pressure value at the material outlet, the problems of air returning and material returning are effectively reduced, and the production capacity of concentrate feeding is improved.

Owner:JINCHUAN GROUP LIMITED +1

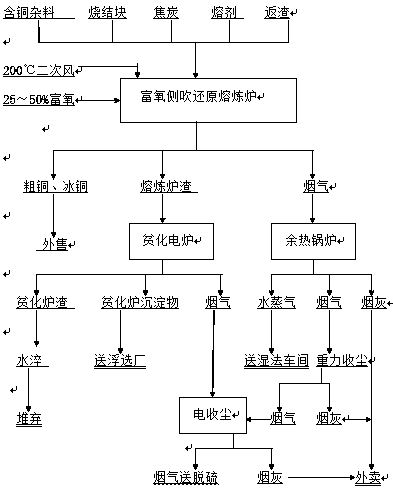

Sintering combined oxygen-enriched side-blown smelting process of vertical drying kiln

InactiveCN108998661AHigh recovery rateGood sealingProcess efficiency improvementSludgeNon-ferrous extractive metallurgy

The invention discloses a sintering combined oxygen-enriched side-blown smelting process of a vertical drying kiln in the technical field of environmental protection systems. The smelting process comprises the following steps of adding little lime and fine anthracite to copper and nickel-contained sludge, mixing the lime, the fine anthracite and the copper and nickel-contained sludge proportionally and stirring evenly to obtain a mixture; pelletizing the mixture by a pelletizer to obtain pellets, and adding the pellets evenly into the vertical drying kiln from a kiln crown by a feeding device,wherein the pellets move down by dead weight; adding obtained agglomerated cakes from the furnace top of an oxygen-enriched side-blown smelting furnace continuously together with inorganic hazardouswastes, such as waste anode scraps, quartz stone, limestone, non-ferrous metal smelting waste and incineration disposal residues; making obtained slag enter an electric slag cleaning furnace after theobtained slag is discharged from the oxygen-enriched side-blown smelting furnace, reheating and clarifying and separating the slag by the electric slag cleaning furnace, thereby clarifying and separating copper and nickel mechanically entrained in the slag once again, and discharging the slag from the electric slag cleaning furnace and performing water quenching to make the slag become water-quenched slag; and disposing generated flue gas by processes of waste heat recovery, shock chilling, bag dust collection, sulfur removal, denitration, fluorine and chlorine removal and the like, thereby realizing up-to-standard discharge.

Owner:广州叶林环保科技有限公司

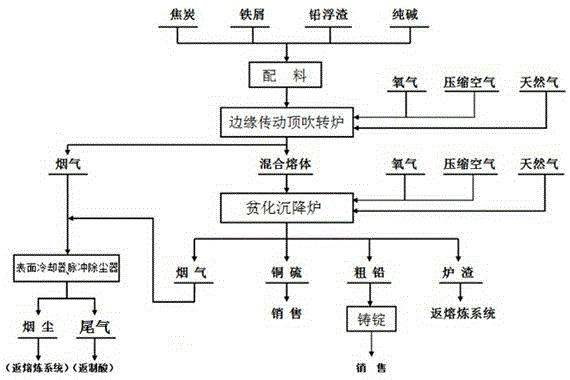

Edge transmission top-blown converter and depleted sedimentation furnace combined lead dross treatment method

The invention belongs to the technical field of metallurgy, and particularly relates to an edge transmission top-blown converter and depleted sedimentation furnace combined lead dross treatment method. The edge transmission top-blown converter and depleted sedimentation furnace combined lead dross treatment method comprises the following steps of (1) preparing and feeding materials, (2) smelting and (3) blowing, wherein in Step (1) 87-92% of lead dross, 3-5% of coke, 1-2% of scrap iron, and 4-6% of sodium carbonate by mass percent are uniformly mixed, and added to an edge transmission top-blown converter for 2-3 times; in step (2), the smelting is performed for 3-4h with the temperature of the edge transmission top-blown converter kept at 1000-1200 degrees, and a copper and dross mixed melt after the smelting is shifted to a depleted sedimentation furnace; and in Step (3), the blowing is performed for 2-4h with the temperature of the depleted sedimentation furnace kept at 1000-1200 degrees, and after stable liquid lead, copper matte and dregs produced in the depleted sedimentation furnace are laminated, copper sulfur, crude lead and slags are separated out. Compared with the existing lead dross treatment method, the edge transmission top-blown converter and depleted sedimentation furnace combined lead dross treatment method reduces the energy consumption and the consumption of the auxiliary materials (the coke, scrap iron and sodium carbonate) greatly, and the total cost is reduced by around 50%.

Owner:青海西豫有色金属有限公司 +1

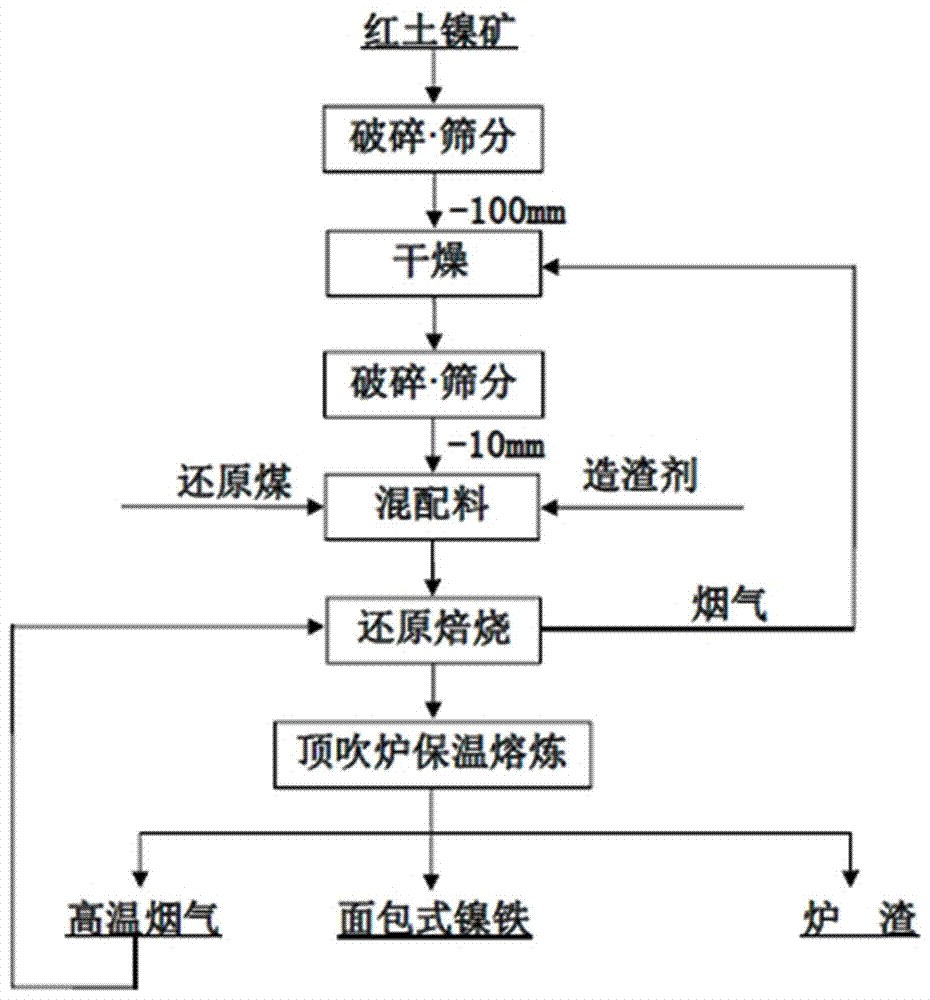

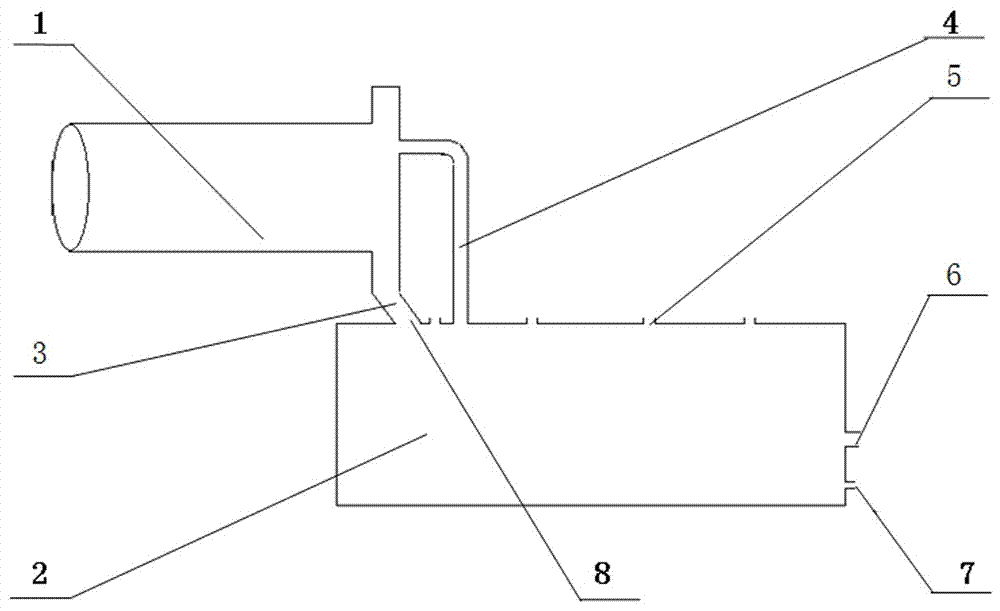

Method and device for producing ferronickel through nickel-laterite ore direct reduction and top-blown smelting method

The invention belongs to the field of nickel metallurgy and particularly relates to a method for producing ferronickel through a nickel-laterite ore rotary kiln direct reduction and flue gas top-blown smelting method and a smelting device adopting the same. The method comprises the following steps of (1) drying treatment of nickel-laterite ores; (2) crushing and screening; (3) ingredient mixing; (4) reduction roasting; and (5) flue gas top-blown smelting. By means of the method, the problems of high energy consumption, serious environmental pollution, poor material adaptability and the like in the process of treating nickel-laterite ores through an existing pyrogenic process are solved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

Lead concentrate processing technology

ActiveCN106893871AAdaptableSimple preparationProcess efficiency improvementMaterials preparationLead smelting

The invention discloses a lead concentrate processing technology. The lead concentrate processing technology comprises an oxidization smelting step carried out in an Ausmelt furnace, a reduction smelting step I, a reduction smelting section II, and a fuming step carried out in a fuming furnace. The lead concentrate processing technology is high in raw material adaptability, and simple in material preparation process; after the mixture is pelletized and fed into the furnace, the quantity of powder dust taken away by the fume discharged from the furnace can be obviously decreased, and as a result, the fume dust rate can be reduced; a traditional lead sintering process is removed, so that the low-level pollution caused by powder dust and SO2 fume can be removed, and as a result, the operation environment can be effectively improved; the Ausmelt furnace used for lead smelting and fuming furnace for fuming are combined, so that the technological processes are reduced; the equipment investment is saved; the energy consumption is low; and the lead recovery rate is high; in addition, furnace bodies used in the technology are sealed, so that the fume leakage is small, and as a result, the working environment is optimized; the fume produced in the smelting step and the fuming step can be effectively separated; as the fume in the Ausmelt furnace and the fume in the fuming furnace are mixed, and the SO2 content can reach the acid making requirement, and thus a good condition is provided to the acid making technology.

Owner:呼伦贝尔驰宏矿业有限公司

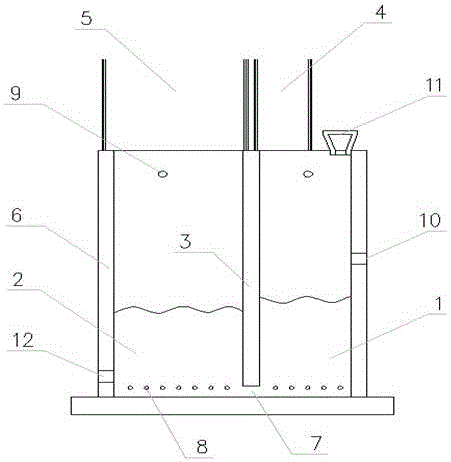

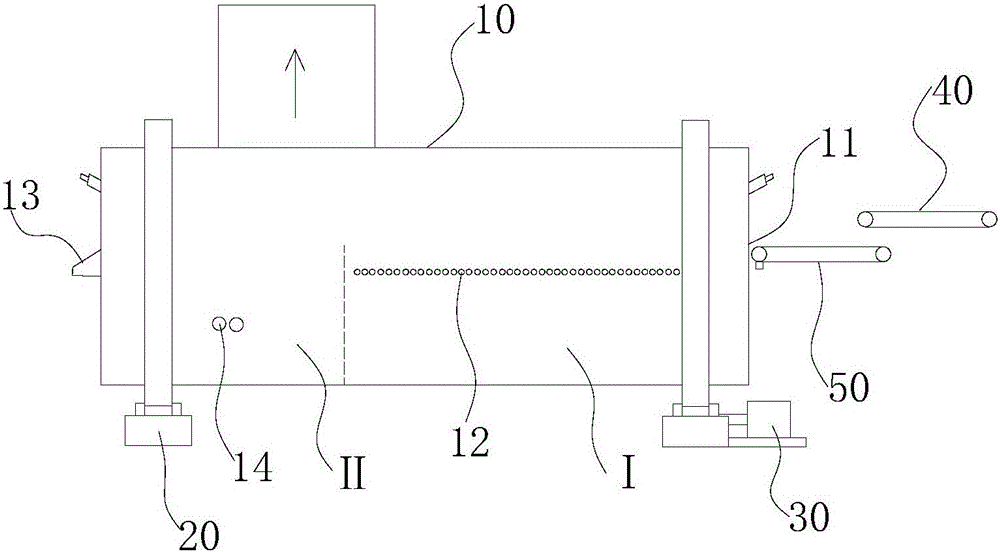

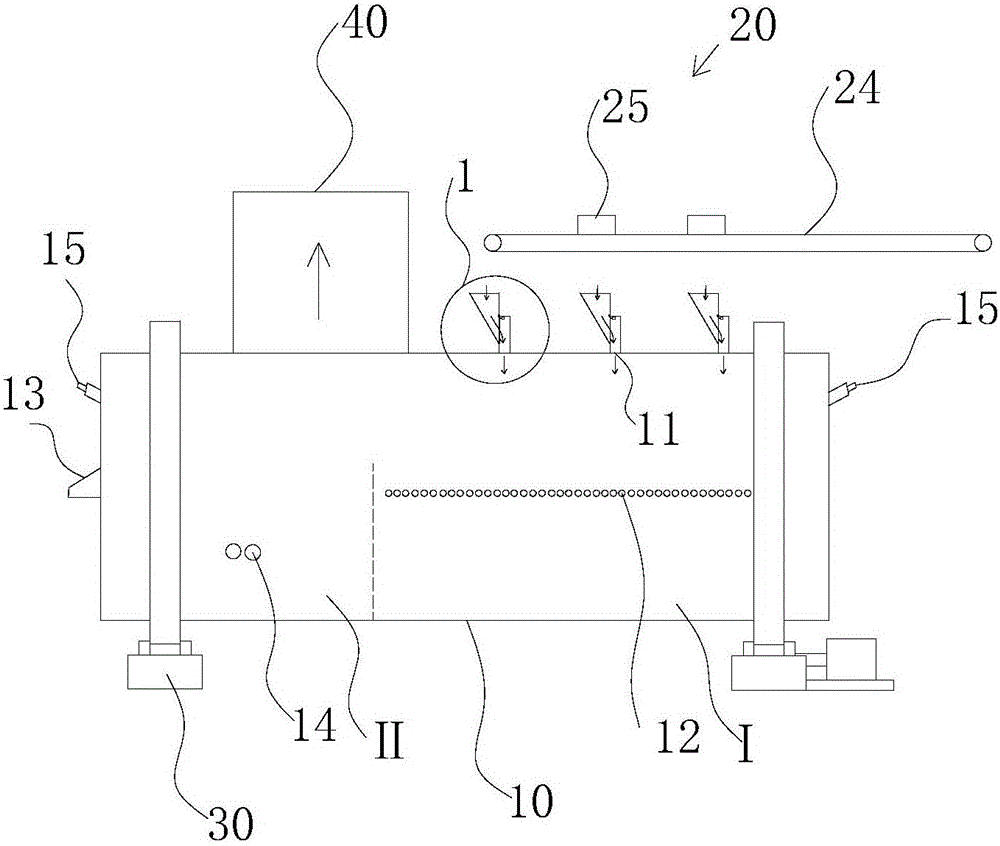

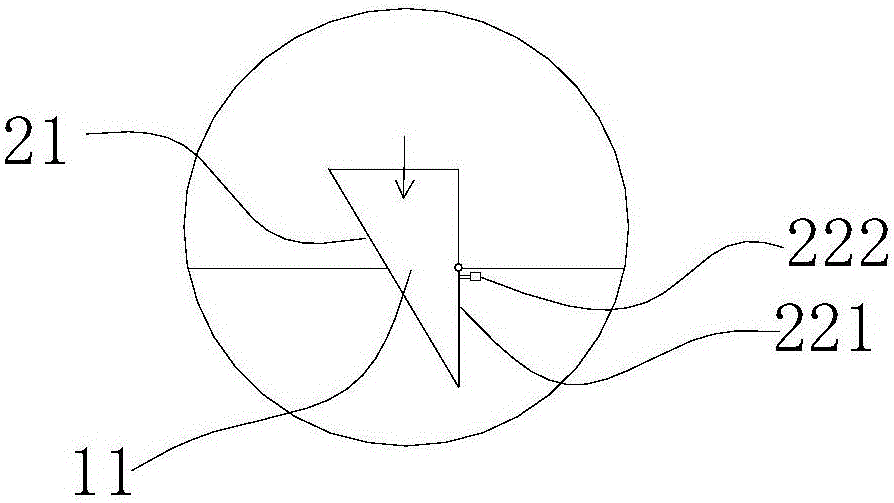

Drying device for metallurgical raw materials and drying method applying drying device

InactiveCN106705621AKeep dryExtended service lifeDrying gas arrangementsIncreasing energy efficiencyGas solidProcess engineering

The invention provides a drying device for metallurgical raw materials. The drying device comprises a separator and a vertical drying furnace, wherein a feeding device is mounted at a first feed opening of the vertical drying furnace; a gas inlet of the vertical drying furnace is connected with an external hot gas source; a gas outlet of the vertical drying furnace communicates with a gas inlet of the separator through a pipeline; a gas outlet in the top of the separator is connected with a flue; and a discharge opening in the bottom end of the separator communicates with a second feed opening in the lower part of the vertical drying furnace through a pipeline. According to the drying device for the metallurgical raw materials, the metallurgical raw materials are subjected to drying treatment in the vertical drying furnace through the hot air source and then are subjected to gas-solid two-phase separation in the separator, separated gas is discharged through the flue, and solid materials are discharged into the vertical drying furnace. The drying device is simple in design and convenient to operate and control, the drying effect of the metallurgical raw materials is very good, and metallurgical raw materials that are carried in the gas after drying are recycled to prolong the service life of follow-up dust removal equipment.

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

Zinc leaching slag treatment method

ActiveCN103421955BShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Method for smelting lead-containing material

InactiveCN101768670BNo explosion hazardAdaptableProcess efficiency improvementLead smeltingSmelting process

The invention discloses a method for smelting a lead-containing material, relating to the technological process for processing complex lead materials by utilizing a smelting method. The method is characterized in that a flash furnace and a depletion furnace are combined for smelting during the smelting process. The method of the invention has the advantages of short and continuous flow, energy saving, large capacity, efficient source utilization, environment protection, good safety and good industrial hygiene, no danger of foam slag exploration and safe production. The lead smelting process with high smelting strength and various advantages realizes single-step lead smelting, and has stronger adaptability on materials. The process is not only suitable for treating lead ore with complex components, but also suitable for treating wet smelting zinc slag, wet smelting copper slag and lead noble metal system slag, can do complementation of lead, zinc and copper and has more advantages overlead, zinc and copper jointed enterprises. The recovery rates of lead and concomitant valuable metals of copper, zinc and noble metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

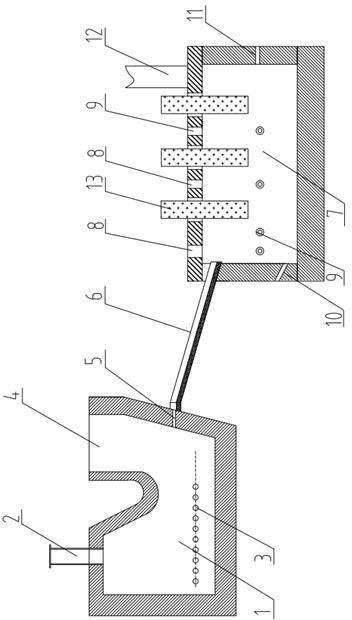

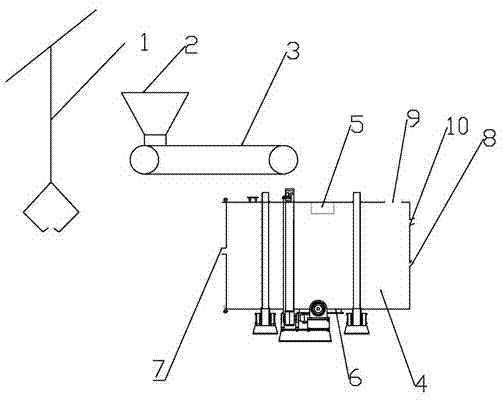

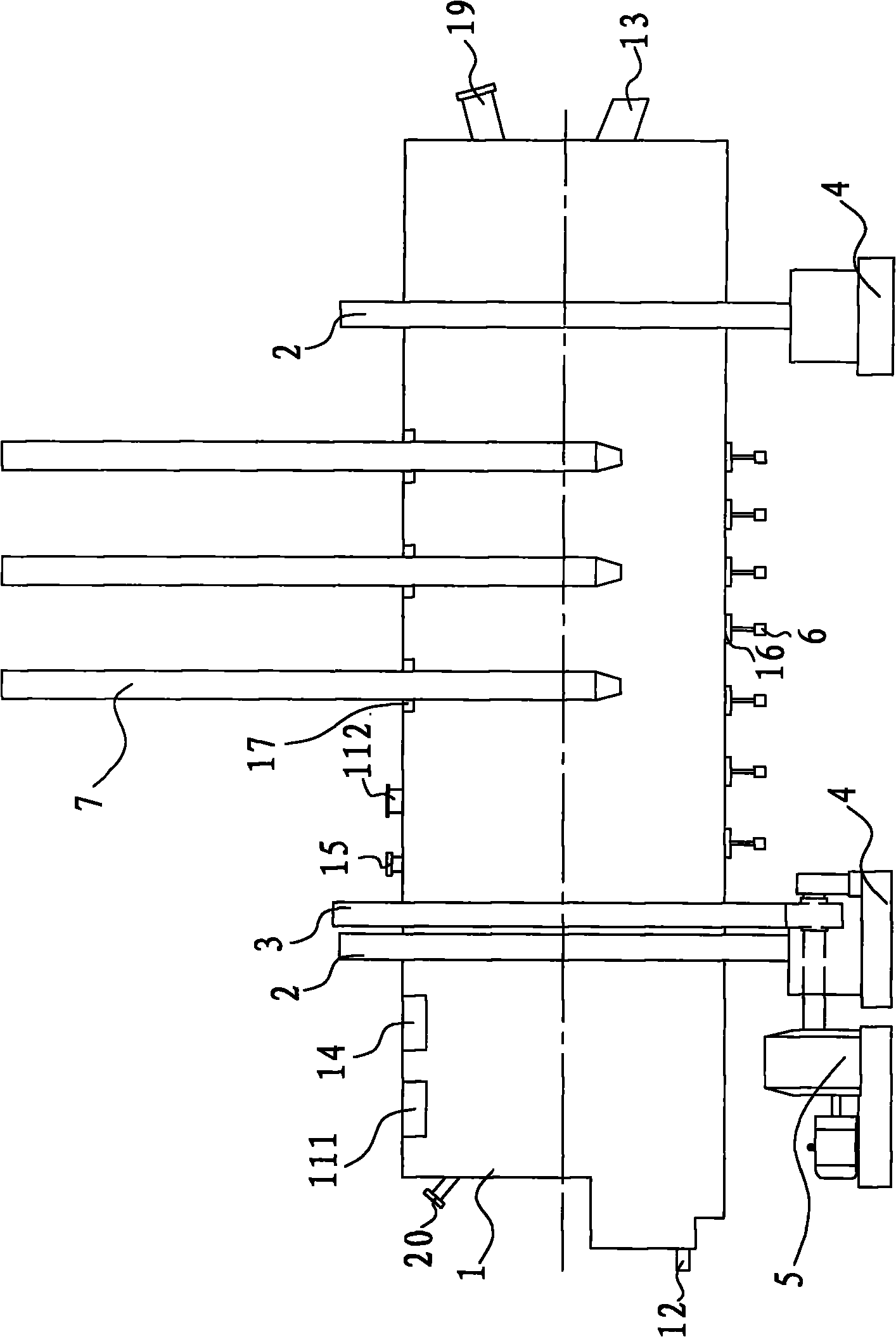

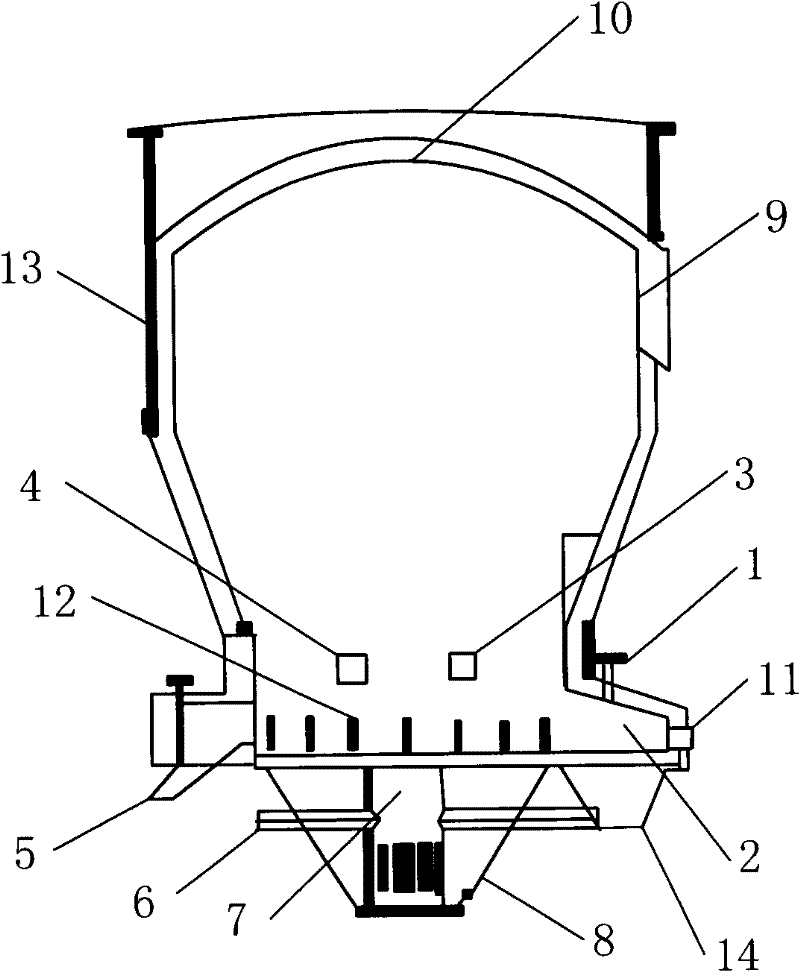

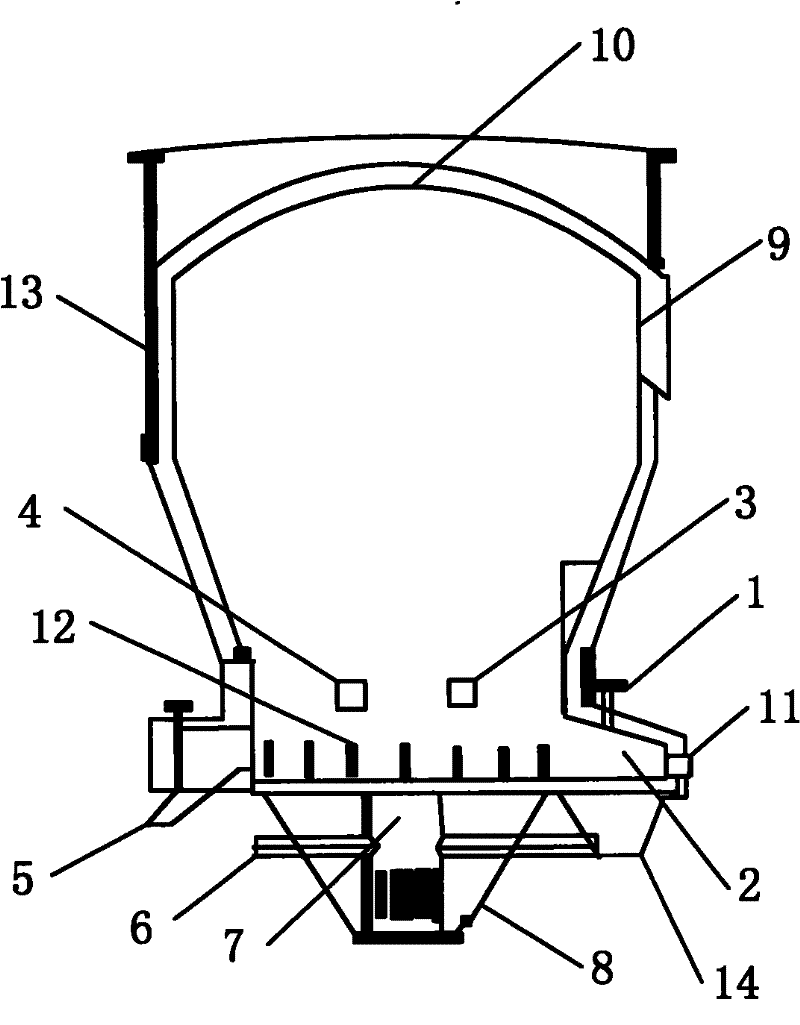

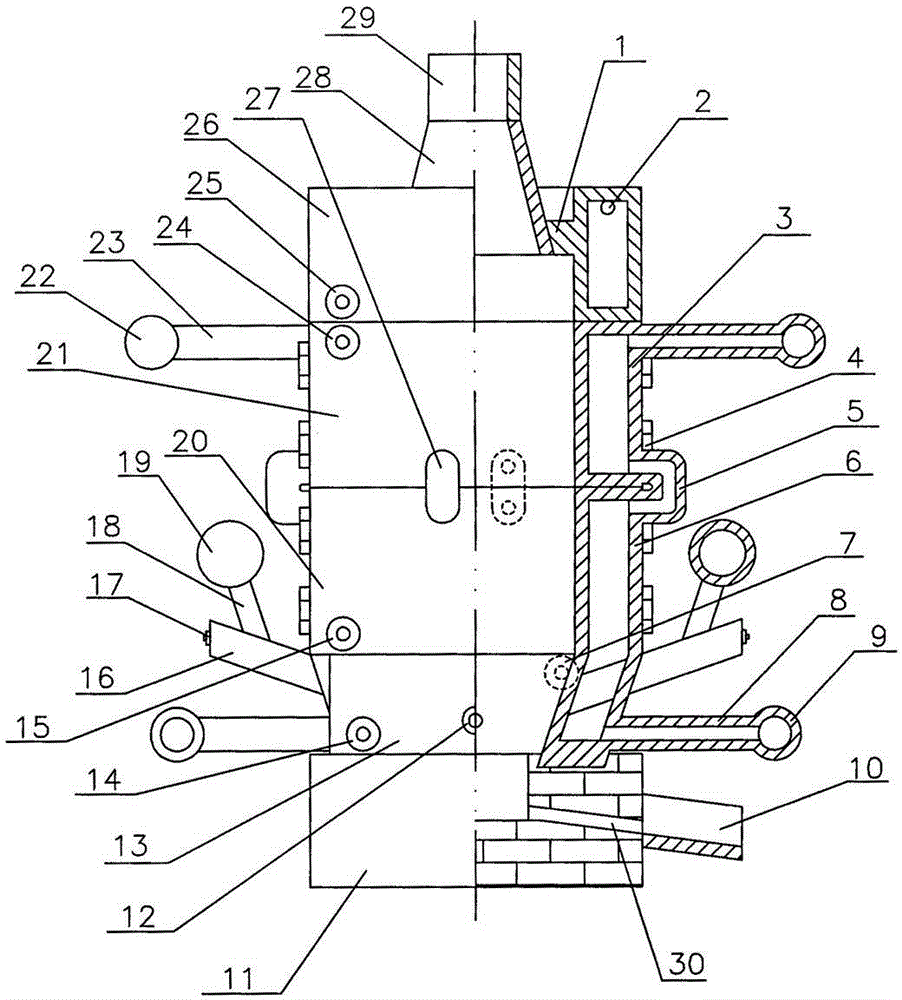

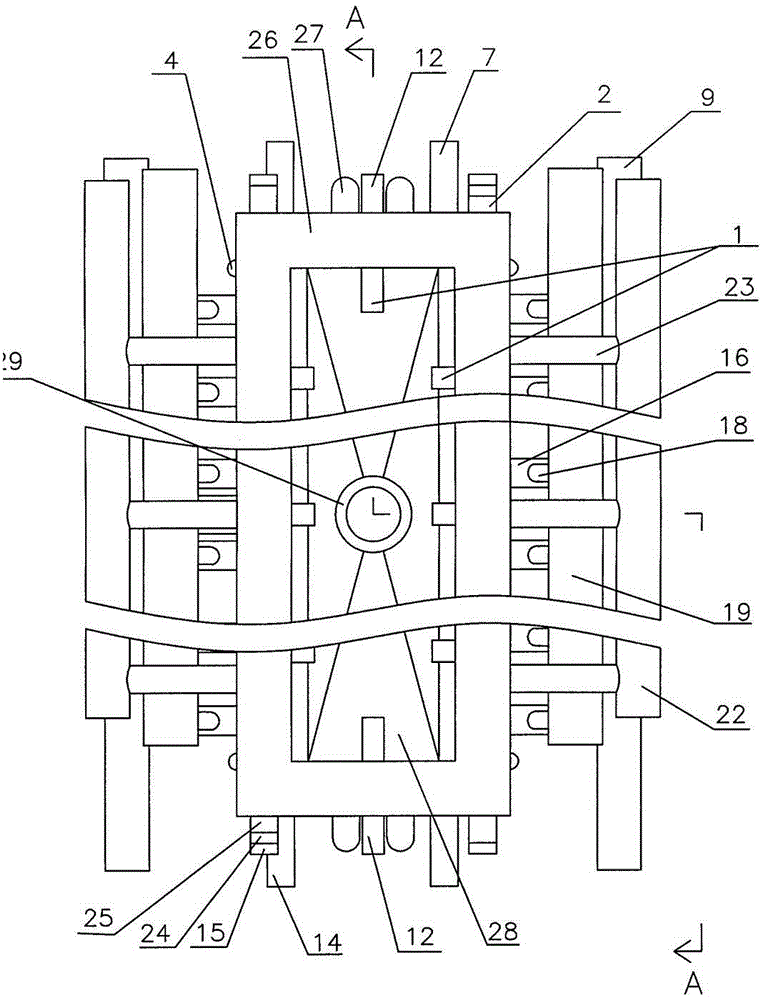

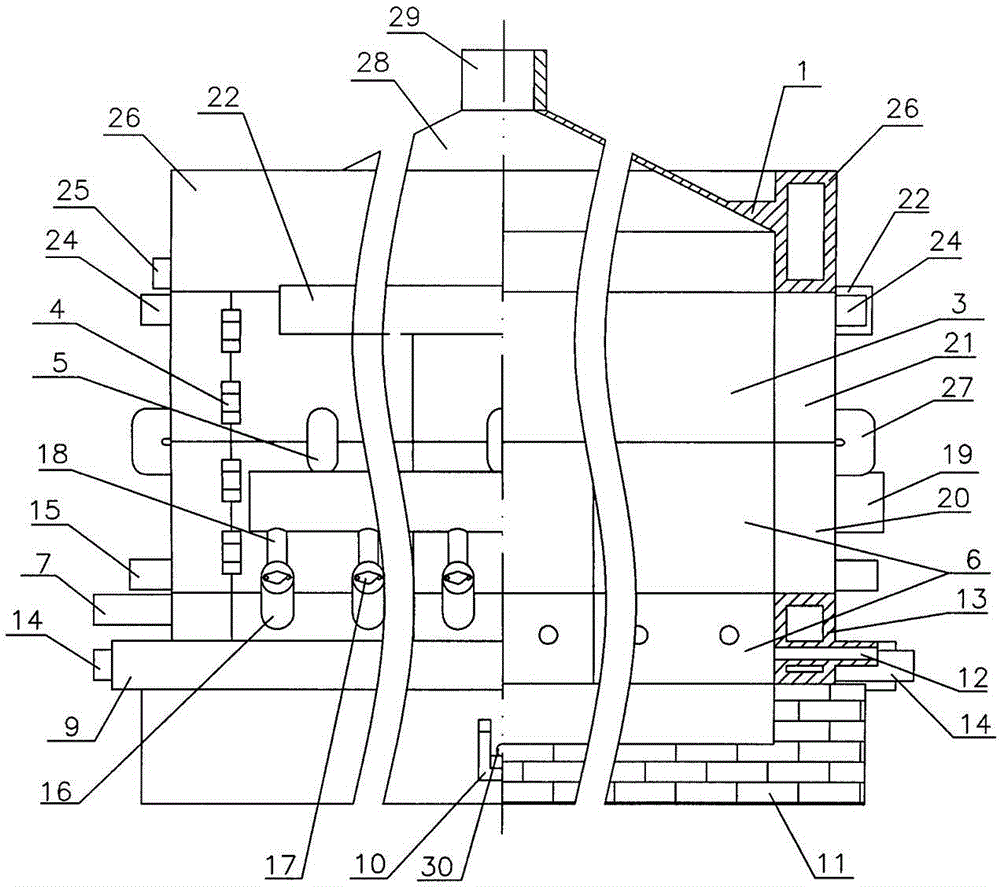

Lead skim reducing furnace

ActiveCN101839625AReduce energy consumptionLow costLighting and heating apparatusProcess efficiency improvementSlagSoot

The invention discloses a lead skim reducing furnace. The lead skim reducing furnace comprises a furnace body, a support for supporting the furnace body, a powder coal spray gun and an electrode, wherein the furnace body confines a hearth and is provided with a charging hole, a lead discharging hole, a slag tap, a vent nozzle, an electrode jack, a smoke outlet and a powder coal spray gun jack, the electrode jack and the flue outlet are arranged on the top of the furnace body, and the powder coal spray gun jack is arranged on the bottom of the furnace body; the powder coal spray gun is inserted into the powder coal spray gun jack for injecting power coal into the hearth; and the electrode is inserted into the hearth through the electrode jack to heat materials in the hearth. The reducing furnace of the invention has small needed powder coal amount, small smoke amount, low soot rate, high lead recovery rate and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

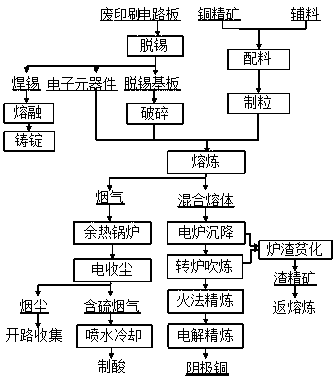

Oxygen-enriched top-blown copper smelting combined with a method for treating waste printed circuit boards

The invention provides a method for treating waste printed circuit boards with combination of oxygen-enriched top-blown copper smelting. The method comprises the following steps: (1) heating and removing tin; (2) crushing; (3) mixing and smelting; (4) treating melts; (5) treating smoke in a furnace; and (6) treating the smoke out of the furnace. According to the method, copper concentrates are used as the main raw materials and cooperate with part of waste printed circuit boards; the treatment of the waste circuit boards is combined with oxygen-enriched top-blown copper smelting; organic matters are effectively decomposed in a high-temperature smelting tank; the organic matters and sulphide ore are oxidized to generate heat and achieve self-heating smelting; high-concentration SO2 smoke is used for inhibiting generation of dioxin; secondary air is blown for decomposing residual compounds; the smoke enters an acid production system after being subjected to waste heat recovery, electric dust collection and water-injection cooling. The method is low in energy consumption and high in comprehensive recovery rate of valuable metals, is capable of recycling the waste circuit boards and can solve the problems of serious pollution, generation of hypertoxic dioxin and low metal recovery rate of the existing waste circuit board treatment process.

Owner:CENT SOUTH UNIV +1

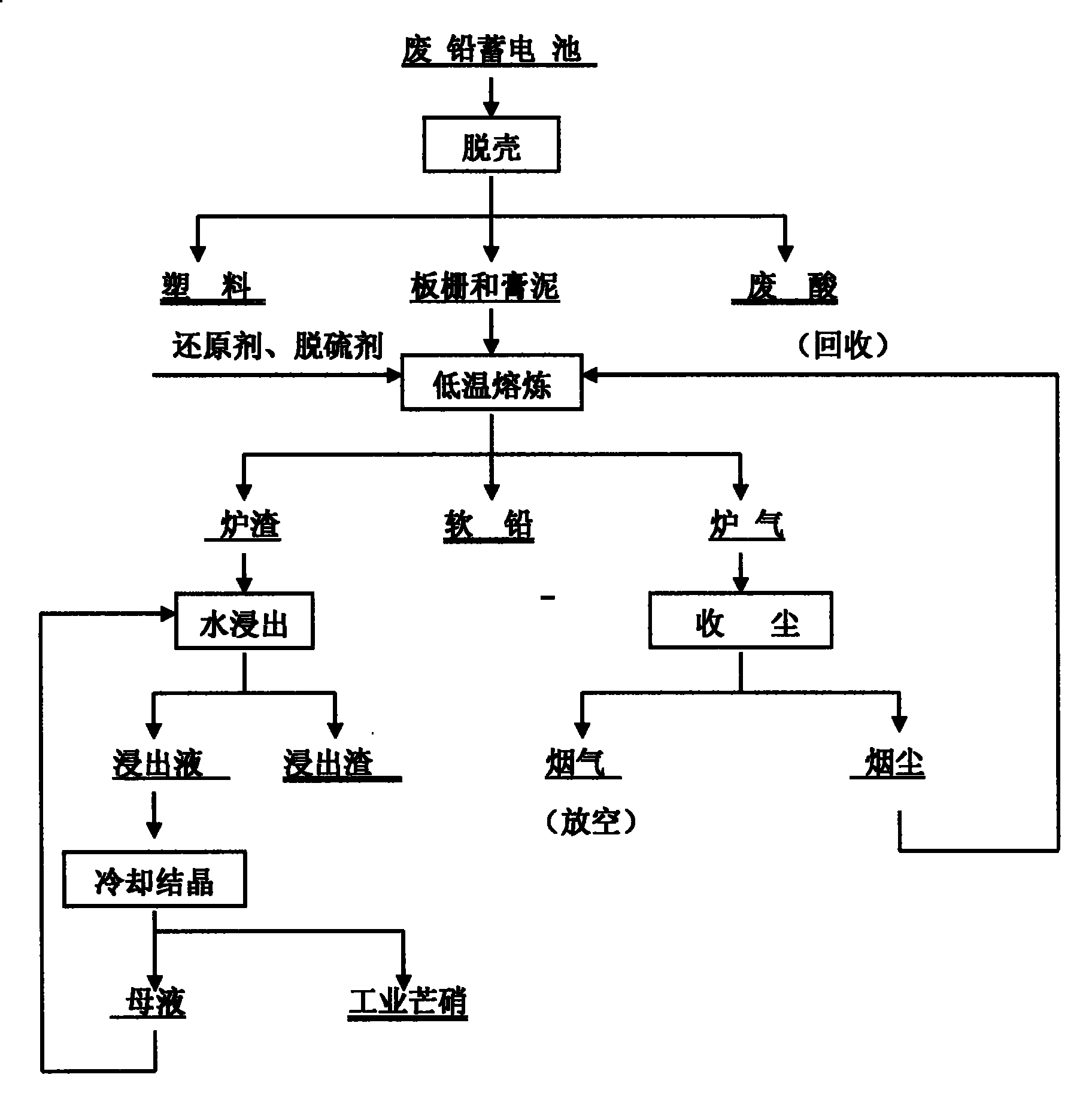

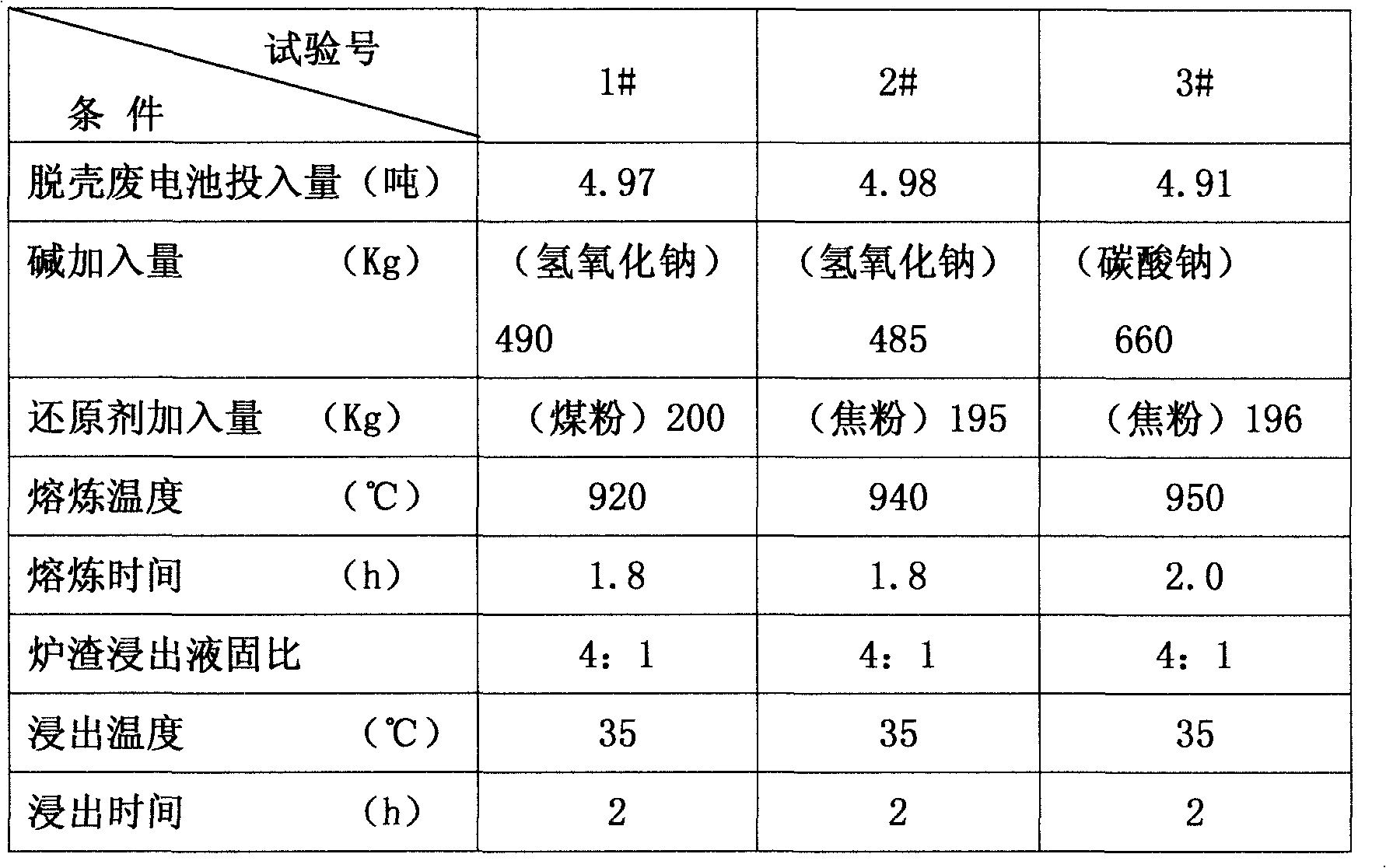

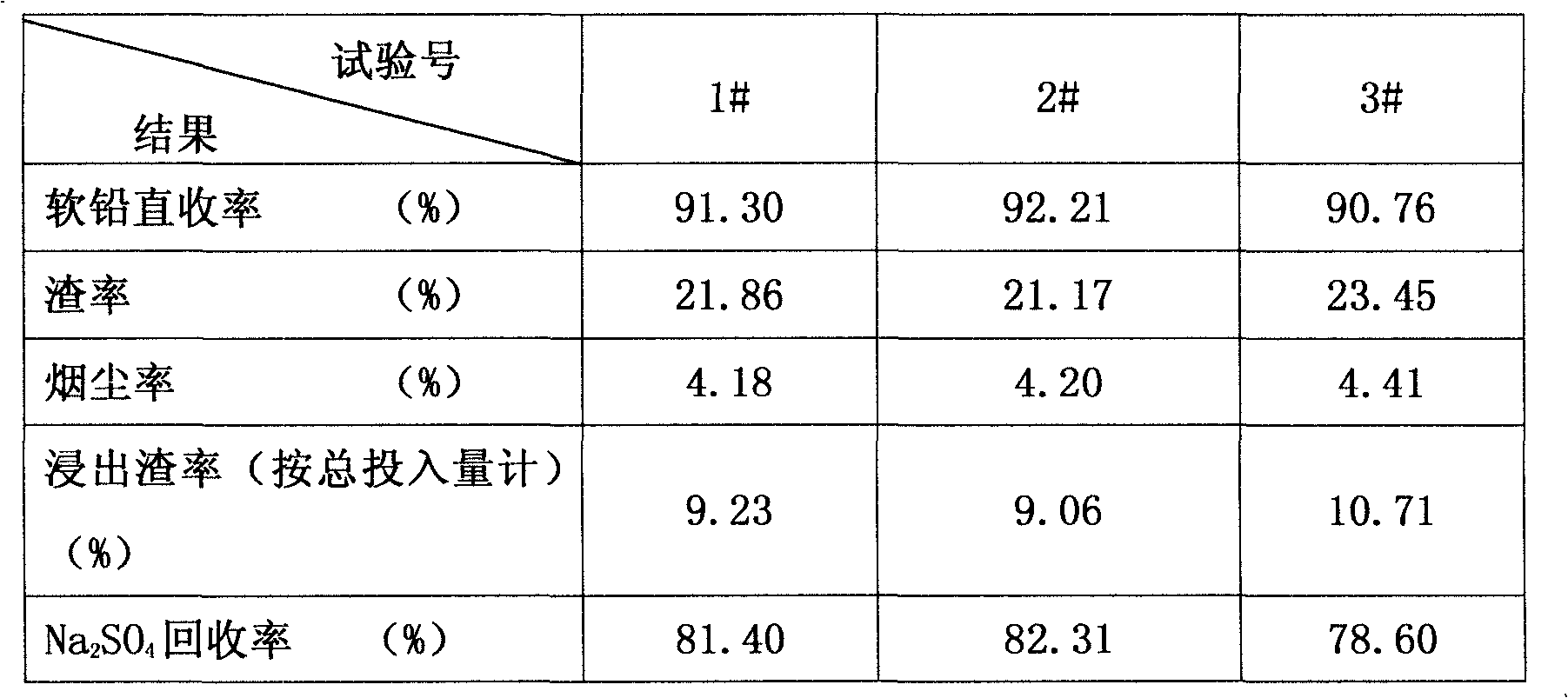

Method for direct low-temperature smelting of waste lead accumulator

InactiveCN101404348BReduce volumeReduce energy consumptionWaste accumulators reclaimingBattery recyclingSlagSodium sulfate

A method for directly smelting a scrap lead storage battery at low temperature is characterized by comprising the following steps: (1) firstly, the shell of the scrap lead storage battery is removed and plastic, waste acid, slab lattice and gypsum mud are obtained; (2) then, the slab lattice and the gypsum mud with the shell being removed as well as desulfurizer and reducing agent are added into a metallurgical furnace together for low smelting heat, so that soft lead, slag and flue gas are produced; (3) at last, the slag produced by low smelting heat is leached, and leaching dregs and leaching liquid are output by liquid solid separation; the leaching dregs wait to be treated, and the leaching liquid is evaporated and concentrated, so that industrial sodium sulfate is produced. The method does not need the complicated used battery resolving device, a sweetener has small volume, and the course of crystallization of the industrial sodium sulfate has low energy consumption; the method is characterized by low smelting temperature, little lead volatilization, low smoke dust rate, high direct lead yield coefficient, low energy consumption, no sulfur dioxide pollution, etc.

Owner:SHENYANG RES INST OF NONFERROUS METALS +1

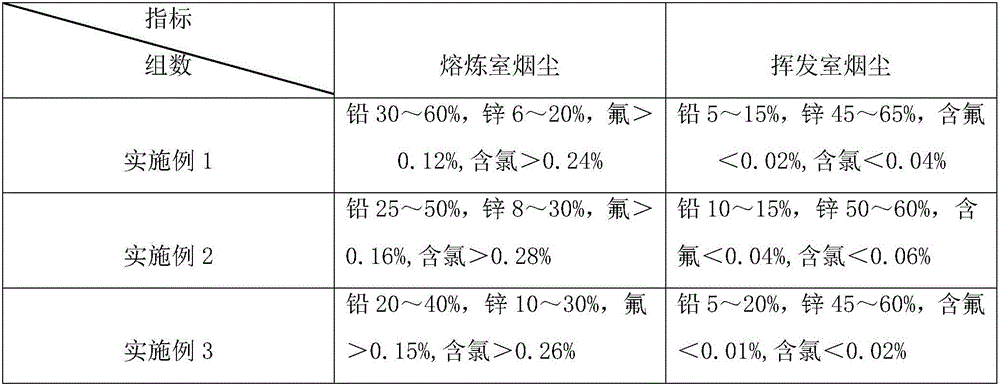

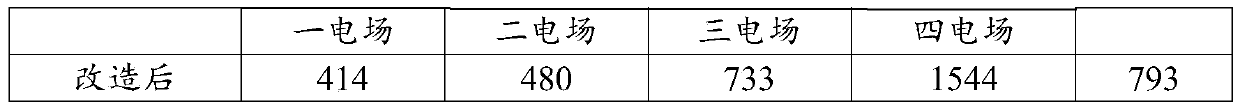

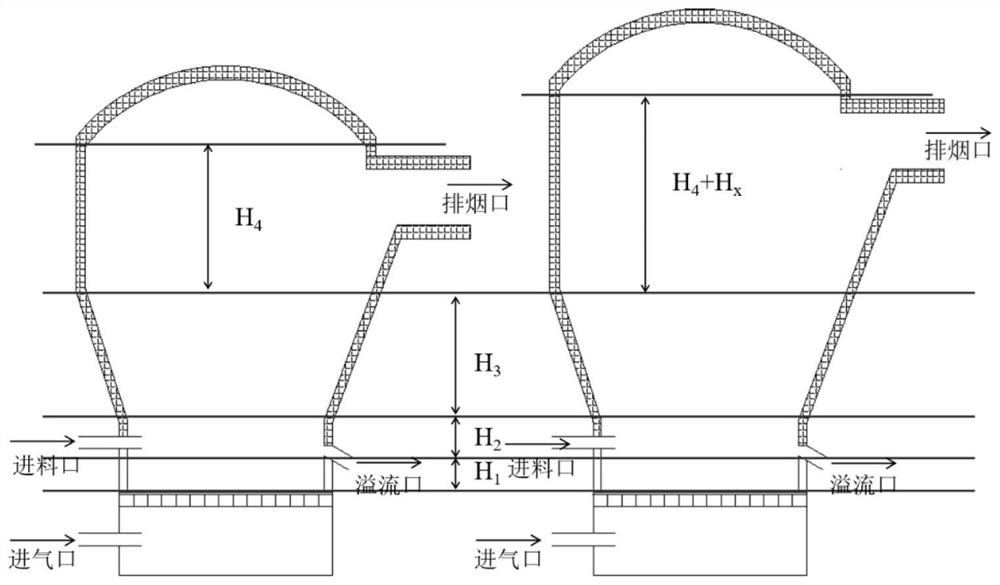

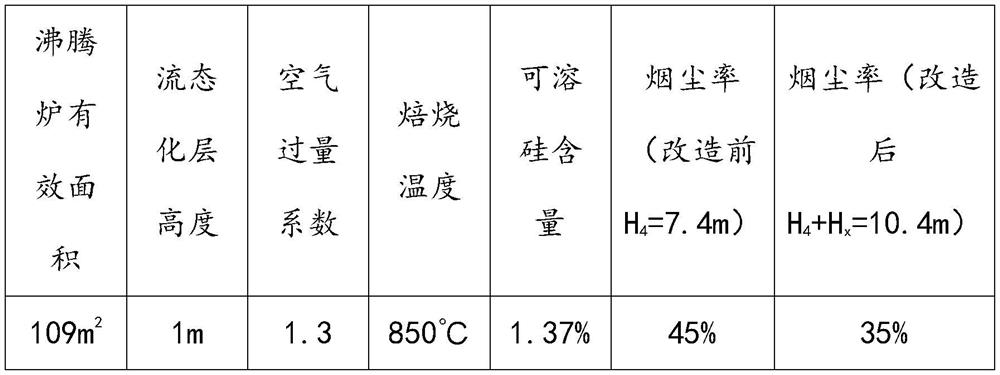

Oxidizing roasting process by blending high fluorine chlorine zinc oxide complex material

ActiveCN102021317BIncrease the effective heightTemperature controlEffective heightNon-ferrous extractive metallurgy

Owner:HULUDAO ZINC IND CO LTD

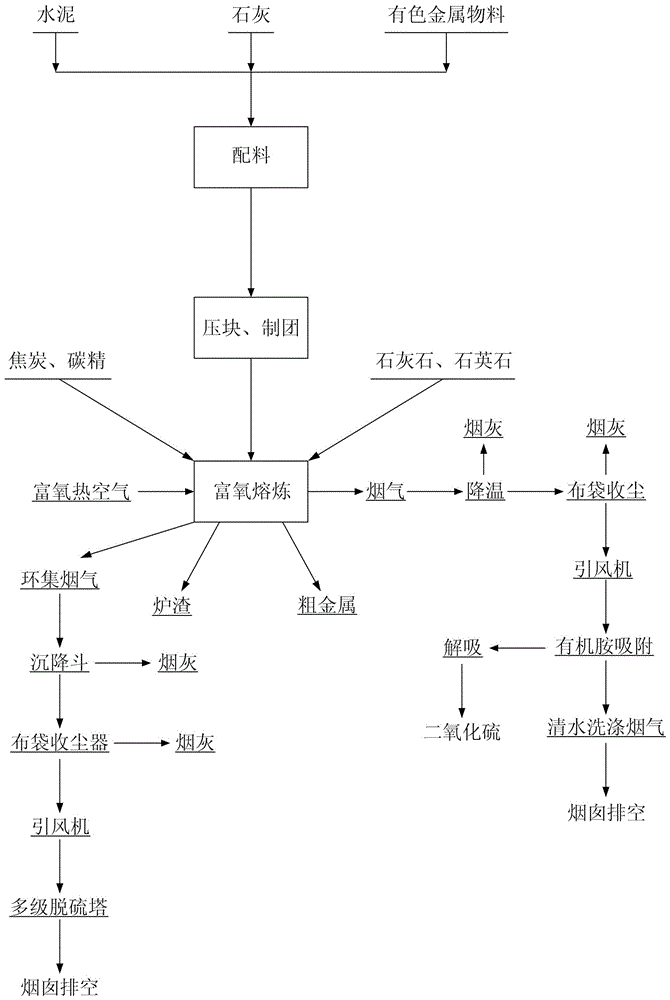

Process method for treatment of nonferrous metal material through energy-saving and environmental protection-type oxygen-rich smelting furnace

InactiveCN106498164AHigh strengthImprove melting efficiencyTransportation and packagingSolid waste disposalMixed materialsWater jacket

The invention discloses a process method for treatment of a nonferrous metal material through an energy-saving and environmental protection-type oxygen-rich smelting furnace. The method includes the following steps that (1) cement, lime and the nonferrous metal material are mixed to be blended, and then the mixed material is made to be in a block shape or pellet shape to obtain a block-shaped or pellet-shaped material; and (2) the obtained block-shaped or pellet-shaped material, limestone, quartz stone and coke or carbon buttons are added into the oxygen-rich smelting furnace to be smelted, oxygen-rich hot air is connected into the oxygen-rich smelting furnace in the smelting process, oxygen-rich concentration of the connected-in oxygen-rich hot air is adjusted through a distributed control system, a shell of the oxygen-rich smelting furnace is provided with a water jacket, the inner side of the water jacket is provided with a refractory concrete protecting layer, most rare and noble metals are gathered into crude metal after smelting is completed, and flue gas, cyclic collection flue gas, crude metal, soot and slag are obtained after smelting is over. By the adoption of the process method, smelting strength and smelting efficiency are high, the amount of flue gas is small, and energy saving and environmental protection can be realized.

Owner:HUNAN ZHONGDA JOINT INNOVATION & TECH DEV CO LTD

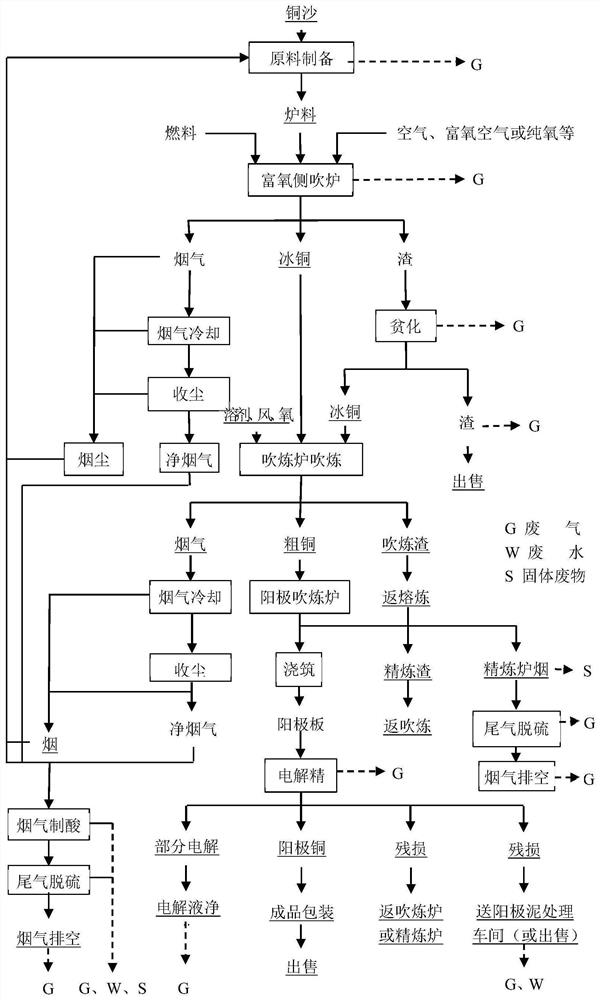

Treatment device and treatment process applied to slag recycling

ActiveCN113699382AAdaptableHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisSmelting process

The invention discloses a treatment device and a treatment process applied to furnace slag recycling. The treatment device is applied to treatment of copper sand. The treatment process mainly comprises the steps of 1, a smelting raw material preparation process, 2, a smelting process of copper matte and crude copper, 3, an acid-making process, and 4, an anode copper refining and electrolysis process. In the step 1, according to the requirement of furnace components, copper sand is mixed with limestone and fluorite solvents in a certain proportion to prepare a smelting raw material; in the step 2, the smelting raw material is smelted into the copper matte and the crude copper in sequence through a crude smelting furnace of an oxygen-enriched side-blown smelting furnace; in the step 3, heat exchange cooling, dust removal and pressurization are performed on flue gas generated by the oxygen-enriched side-blown smelting furnace by an acid-making system to prepare an acid product; and in the step 4, the crude copper is refined into anode copper through a refining furnace, and precious metal is electrolyzed and separated out through an electrolysis system. Therefore, the treatment process can be used for extracting high-purity precious metals such as copper, gold and silver from furnace slag generated after incineration of municipal solid waste so as to realize resourceful treatment of the furnace slag.

Owner:上海中川国宇环境有限公司

Modification method for top-blowing smelting facility as well as continuous copper smelting facility and method

The invention discloses a modification method for a top-blowing smelting facility as well as a continuous copper smelting facility and method. The modification method for the top-blowing smelting facility comprises the following steps of removing a converter or a converting furnace of a top-blowing converting facility; reducing the hearth height of a top-blowing smelting furnace of the top-blowingsmelting facility; removing a single immersed top-blowing main spray gun of the top-blowing smelting furnace; arranging at least three top-blowing smelting spray guns on the top of the top-blowing smelting furnace at intervals; forming a copper matte draining hole in the top-blowing smelting furnace; removing an electrode and an electrode matching device of a settling electric furnace of the top-blowing smelting facility, and arranging at least three top-blowing smelting spray guns on the top of the settling instrument at intervals in order to modify the settling electric furnace into a top-blowing converting furnace; and connecting the copper matte draining hole of the top-blowing converting furnace with the copper matte inlet of the top-blowing converting furnace through a launder. Through adoption of the modification method for the top-blowing smelting facility, the existing top-blowing smelting facility can be utilized fully; the production of high-grade copper matte can be facilitated; conditions are created for continuous converting; and the investment cost of continuous copper smelting can be lowered.

Owner:CHINA ENFI ENGINEERING CORPORATION

An Improved Blast Furnace

ActiveCN104329935BLong working hoursReduce maintenance timesFurnace componentsVertical furnacesBrickSlag

The invention relates to an improved novel blast furnace. A base is built by heat resistant bricks, coarse lead discharging holes are formed in the base, the left side wall and the right side wall of the base are respectively formed by one group of upper water sleeves and one group of lower water sleeves, the adjacent upper water sleeves and lower water sleeves are communicated by water sleeve communicating pipes, two air inlet inclined pipes penetrate through each lower water sleeve, and each air inlet inclined pipe is communicated with an air inlet main pipe through one air inlet branch pipe. The front and back walls are respectively formed by two upper water sleeve doors, two middle water sleeve doors and a lower water sleeve door, an upper water sleeve door water outlet pipe is arranged on each upper water sleeve door, a middle water sleeve door water inlet pipe is arranged on each middle water sleeve door, the adjacent upper water sleeve doors and middle water sleeve doors are communicated through water sleeve doors, and each lower water sleeve door is provided with a lower water sleeve door water outlet pipe, a slag discharge pipe and a lower water sleeve door water inlet pipe. The upper part of the novel blast furnace is provided with a water sleeve frame, a water sleeve frame water outlet pipe and a water sleeve frame water inlet pipe are arranged on the water sleeve frame, a gas collecting cover is connected with the water sleeve frame through a connecting frame, and the upper end of the gas collecting cover is provided with an exhaust pipe.

Owner:永兴县荣鹏金属有限公司

Method for efficiently removing fluorine-chlorine impurities in zinc oxide smoke

InactiveCN106676272AReduce processing costsEfficient removalProcess efficiency improvementSlagImpurity

The invention belongs to the technical field of metallurgy, and particularly relates to a method for efficiently removing fluorine-chlorine impurities in zinc oxide smoke. The method for efficiently removing the fluorine-chlorine impurities in the zinc oxide smoke comprises the following steps of (1) oxidization smelting, (2) reductive volatilization, and (3) furnace slag discharging. According to the method for efficiently removing the fluorine-chlorine impurities in the zinc oxide smoke, after acid-leached slag is subjected to oxidization smelting, the impurities such as fluorine, chlorine and sulfur in the zinc oxide smoke can be removed in the smelting stage, fluorine and chlorine in the zinc oxide smoke can be effectively removed, the treatment cost of the zinc oxide smoke is reduced, energy is saved, the purposes of environmental friendliness and comprehensive utilization of resources are achieved, and melting of the acid-leached slag is accelerated in the smelting stage; volatilization of valuable metal such as zinc is reduced while the impurities such as fluorine and chlorine are effectively removed; and the interior of a volatilization chamber is in a reducing atmosphere, a large amount of CO is generated, high reducibility is kept, the volatilization efficiency for lead and zinc is improved easily, and the recovery rate of the valuable metal is increased.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

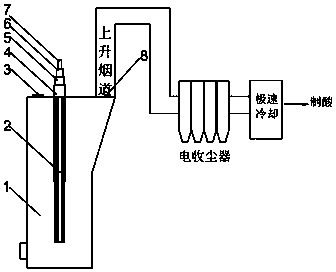

Copper smelting method capable of reducing dust content of flue gas by using molten bath of isa furnace

InactiveCN110423897AReduce air leakage rateReduce corrosionRotary drum furnacesCrucible furnacesSmelting processFlue gas

The invention discloses a copper smelting method capable of reducing dust content of flue gas by using a molten bath of an isa furnace. The method comprises the following steps: granulating a raw material, controlling the water content of granules at 8-9%, and feeding the granules, the water content of which is 8-9%, into the isa furnace to be smelted through a material guide pipe, wherein the material guide pipe enters from the top of a furnace body of the isa furnace, a discharge port of the material guide pipe is located in the middle of the furnace body, and a feed inlet of the material guide pipe is larger than the discharge port; inserting a spray gun into the isa furnace, blowing oxygen-enriched air into the molten bath in the isa furnace in a forced manner through the spray gun, and controlling the flow of the spray gun at 24000-25000 Nm<3> / h, wherein the spray gun is inserted to a position, 0.3-0.4 m, from the bottom end of the spray gun to a top opening of the furnace body ofthe isa furnace; and controlling the temperature of a melt in the isa furnace at 1140-1180 DEG C, wherein in the whole process, flue gas enters into an external flue gas system through a flue gas exhausting pipeline connected to the top of the furnace body of the isa furnace. Preferably, the material guide pipe comprises a feeding hopper and a discharging pipe, and the discharge port of the discharging pipe is located in the middle of the furnace body. The method has the advantage of being low in dust content of flue gas in a copper smelting process.

Owner:LIANGSHAN MINING CO LTD

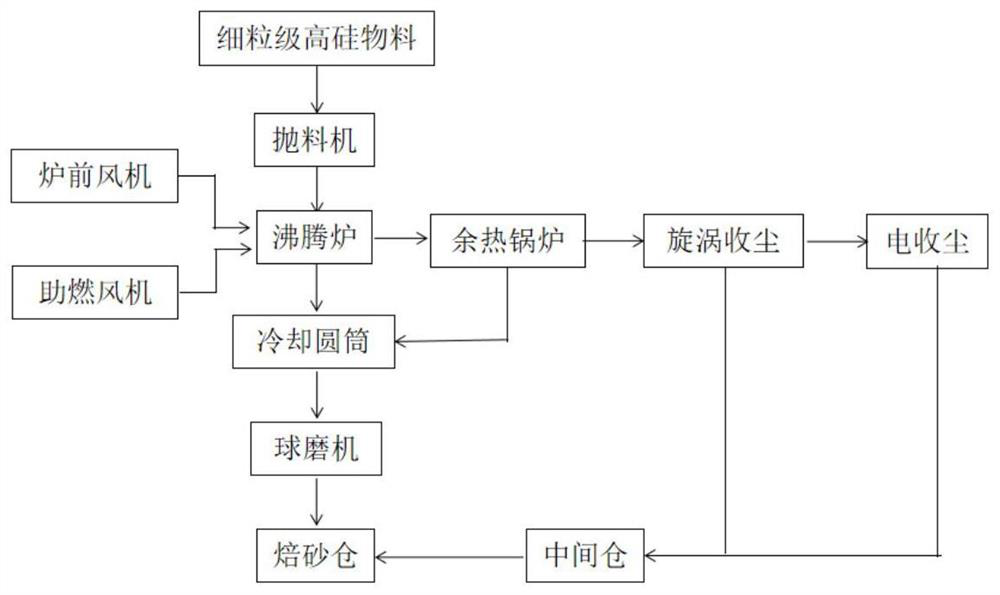

Fine-fraction high-silicon low-iron zinc concentrate fluidized bed roaster roasting treatment method

The invention discloses a fine-fraction high-silicon low-iron zinc concentrate fluidized bed roaster roasting treatment method. The roasting treatment method comprises the following steps of (1) feeding fine-fraction high-silicon low-iron zinc concentrate into a fluidized bed roaster through a thrower; (2) controlling roasting parameters of the fluidized bed roaster by controlling a fan in front of the roaster and a combustion fan, so that the zinc concentrate is subjected to low-temperature oxidizing roasting at the temperature of 850-920 DEG C on a fluidized bed layer, and products being roasted sand, smoke dust and flue gas; and (3) discharging the roasted sand from an overflow port of the fluidized bed roaster, cooling and ball-milling the roasted sand, then feeding the roasted sand into a roasted sand bin, enabling smoke dust and flue gas to sequentially pass through a waste heat boiler, vortex dust collection equipment and electric dust collection equipment for waste heat recovery and smoke dust collection, enabling the generated waste heat to enter a steam pocket, and enabling the collected smoke dust to enter the roasted sand bin. The content of soluble silicon in the roasted product can be effectively reduced, the smoke dust rate is effectively reduced, the burden of equipment such as the waste heat boiler, vortex dust collection and electric dust collection is reduced, and the labor intensity of workers is reduced.

Owner:新疆紫金有色金属有限公司

Copper smelting furnace

InactiveCN105002369ANot easy to coke and deformReduce flyingRotary drum furnacesCrucible furnacesCopperSmoke

The invention provides a copper smelting furnace. Smoke generated by feeding is effectively restrained by a furnace body, meanwhile, feeding openings are not prone to being caked or deformed, and reaction efficiency is improved. To achieve the aim, according to the technical scheme, the copper smelting furnace comprises the furnace body, and is characterized in that the feeding openings in the furnace body are located on the upper portion of the furnace body. According to the technical scheme, the feeding openings are formed on the upper portion of the furnace body, so that materials freely fall into the furnace through the feeding openings, the situations of material flying are reduced, materials capable of generating smoke can be reduced, and correspondingly the smoke rate is lowered; in addition, due to the fact that the temperature of smoke on the upper portion of the furnace body is high, the feeding openings are not prone to being caked or deformed after being formed on the upper portion of the furnace body.

Owner:铜陵有色金属集团股份有限公司

Lead skim reducing furnace

ActiveCN101839625BReduce energy consumptionLow costLighting and heating apparatusProcess efficiency improvementSlagSoot

The invention discloses a lead skim reducing furnace. The lead skim reducing furnace comprises a furnace body, a support for supporting the furnace body, a powder coal spray gun and an electrode, wherein the furnace body confines a hearth and is provided with a charging hole, a lead discharging hole, a slag tap, a vent nozzle, an electrode jack, a smoke outlet and a powder coal spray gun jack, the electrode jack and the flue outlet are arranged on the top of the furnace body, and the powder coal spray gun jack is arranged on the bottom of the furnace body; the powder coal spray gun is inserted into the powder coal spray gun jack for injecting power coal into the hearth; and the electrode is inserted into the hearth through the electrode jack to heat materials in the hearth. The reducing furnace of the invention has small needed powder coal amount, small smoke amount, low soot rate, high lead recovery rate and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com