Method for smelting lead-containing material

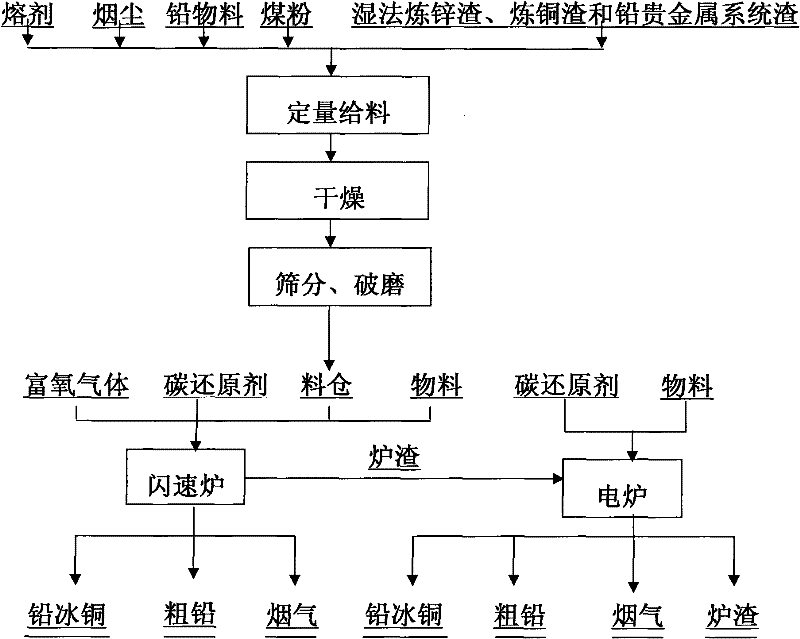

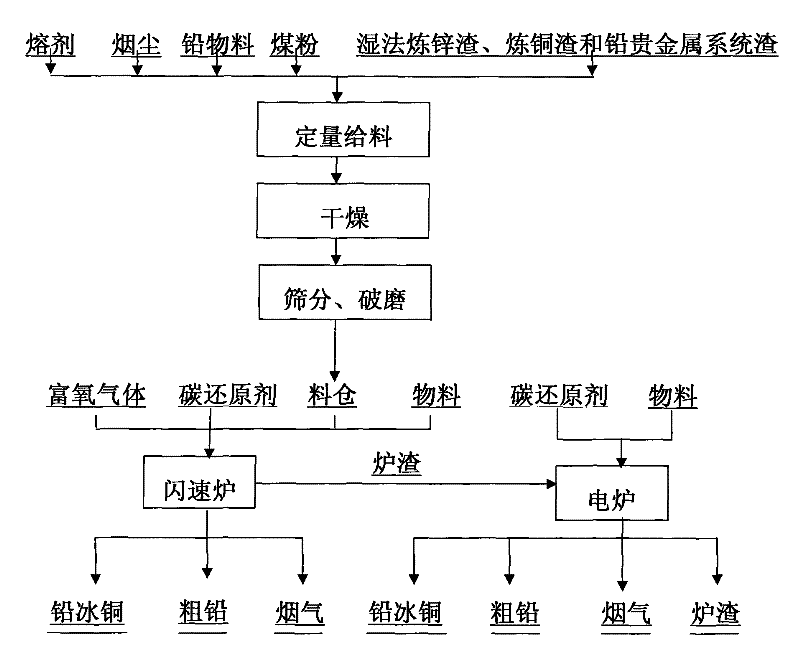

A material and melt technology, applied in the smelting field of lead-containing materials, can solve the problems of high precision operation technology, poor adaptability of raw materials, and high production cost, and achieve the effect of full utilization of waste heat, large production capacity and small heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

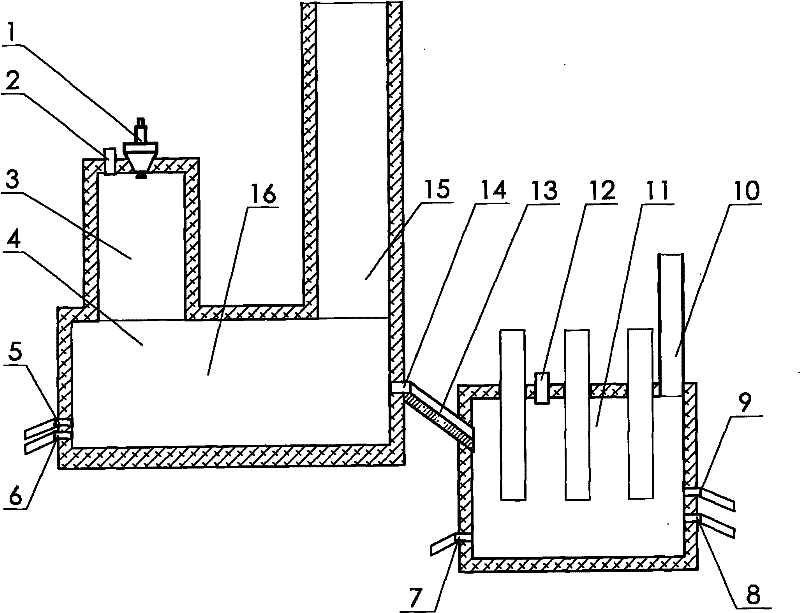

[0054] The treatment consists of low-grade lead oxide ore containing 16% Pb and high-grade lead sulfide ore containing about 70% Pb as the main ore, mixed with hydrometallurgy slag, lead precious metal system slag, pyrite and flux, after drying and crushing The powdery mixed lead material into the furnace contains about 40% of Pb, about 4% of Zn, about 1.5% of Cu, about 18% of S, and about 2500g / t of Ag. The powdery mixed lead material goes through the flash furnace ( 16) The central spray gun (1) is provided at the throat, and the oxygen-enriched gas with an oxygen volume ratio of 60% to 100% forms a high-speed jet at the throat, and the charge is introduced and dispersed into a mist through the bell mouth and sent to the reaction tower . 5-30mm carbon reducing agent is fed into the reaction tower (3) through the feeding device (2). According to the amount of pure oxygen fed per ton of mixed material into the furnace, the gas volume is 160-200Nm 3 According to calculation, ...

Embodiment 2

[0056]The treatment consists of low-grade lead oxide ore containing 30% Pb and low-grade lead sulfide ore containing about 35% Pb as the main ore, mixed with hydro-method zinc smelting slag, hydro-method copper smelting slag, pyrite and flux, and dried and crushed The powdery mixed lead material into the furnace contains about 25% of Pb, about 9% of Zn, about 0.8% of Cu, about 15% of S, and about 1100g / t of Ag, and the powdery mixed lead material goes through the flash furnace The central spray gun (1) of (16) is provided at the throat, and the oxygen-rich gas with a volume ratio of 60% to 100% forms a high-speed jet at the throat, and the charge is introduced and dispersed into a mist through the bell mouth and sent to the reaction. tower. 20-50mm carbon reducing agent is fed into the reaction tower (3) through the feeding device (2). According to the amount of pure oxygen fed per ton of mixed material into the furnace, the gas volume is 120-180Nm 3 According to the calcula...

Embodiment 3

[0058] The treatment consists of high-grade lead oxide ore containing 75% Pb and low-grade lead sulfide ore containing about 30% Pb as the main ore, mixed with hydro-method zinc smelting slag, hydro-method copper smelting slag, pyrite and flux, after drying and crushing The powdery mixed lead material into the furnace contains about 55% of Pb, about 6% of Zn, about 1.0% of Cu, about 12% of S, and about 1500g / t of Ag. The powdery mixed lead material goes through the flash furnace ( 16) The central spray gun (1) is provided at the throat, and the oxygen-enriched gas with an oxygen volume ratio of 60% to 100% forms a high-speed jet at the throat, and the charge is introduced and dispersed into a mist through the bell mouth and sent to the reaction tower . 5-20mm carbon reducing agent is fed into the reaction tower (3) through the feeding device (2). According to each ton of mixed material into the furnace, the amount of pure oxygen gas is 120-220Nm 3 According to calculation, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com