Patents

Literature

42results about How to "Full use of waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

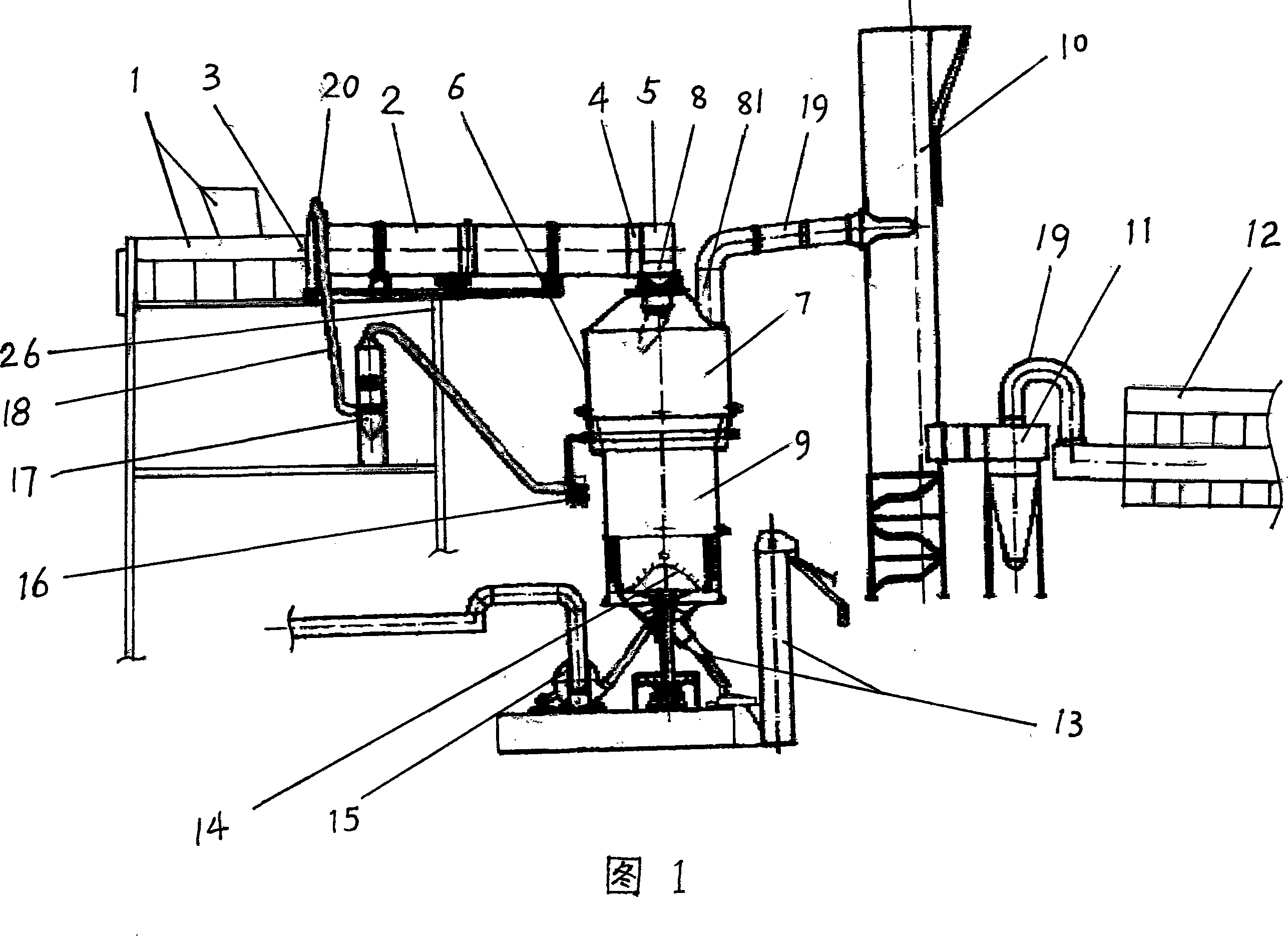

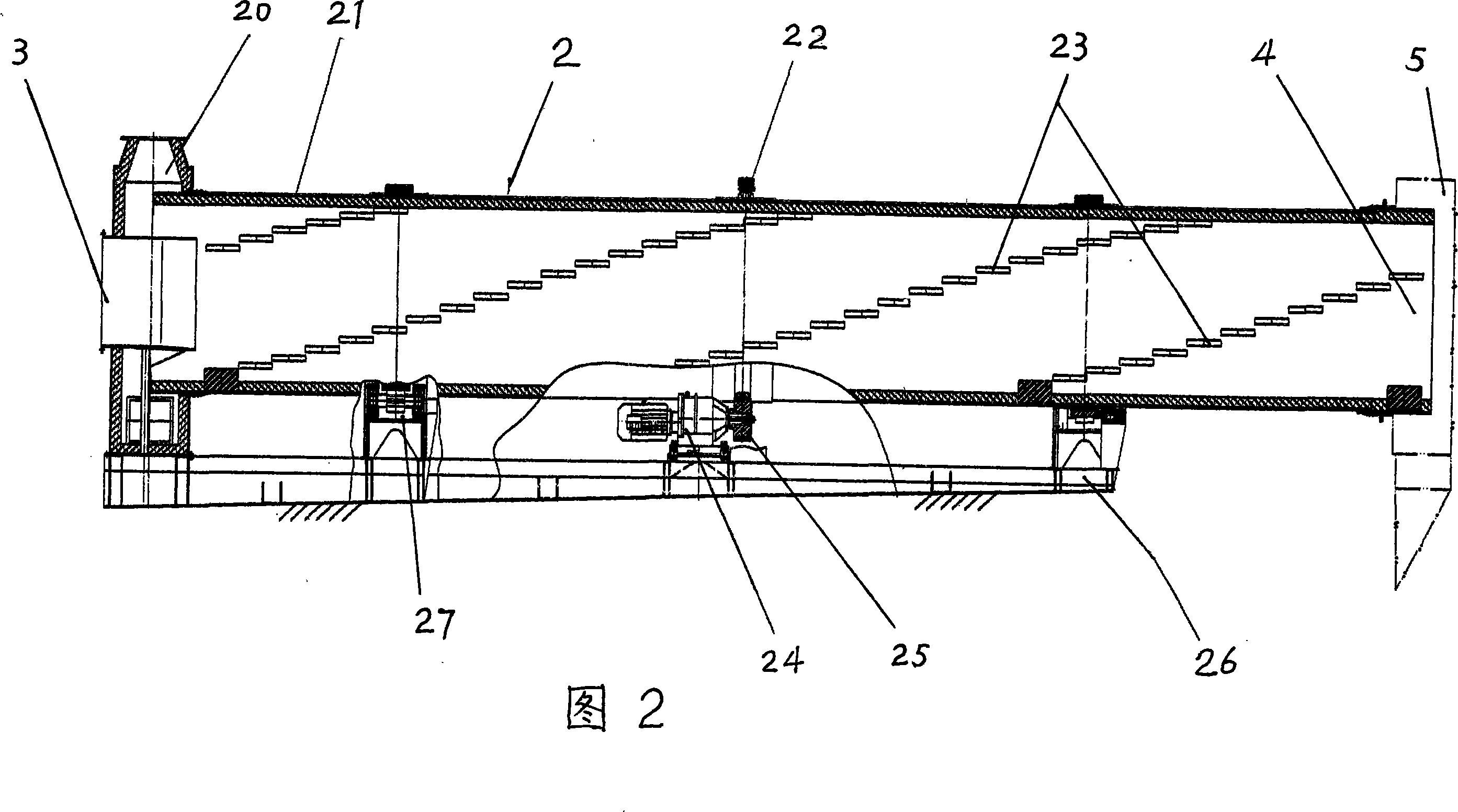

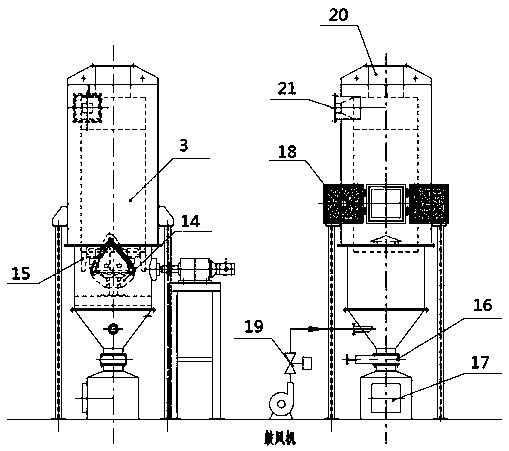

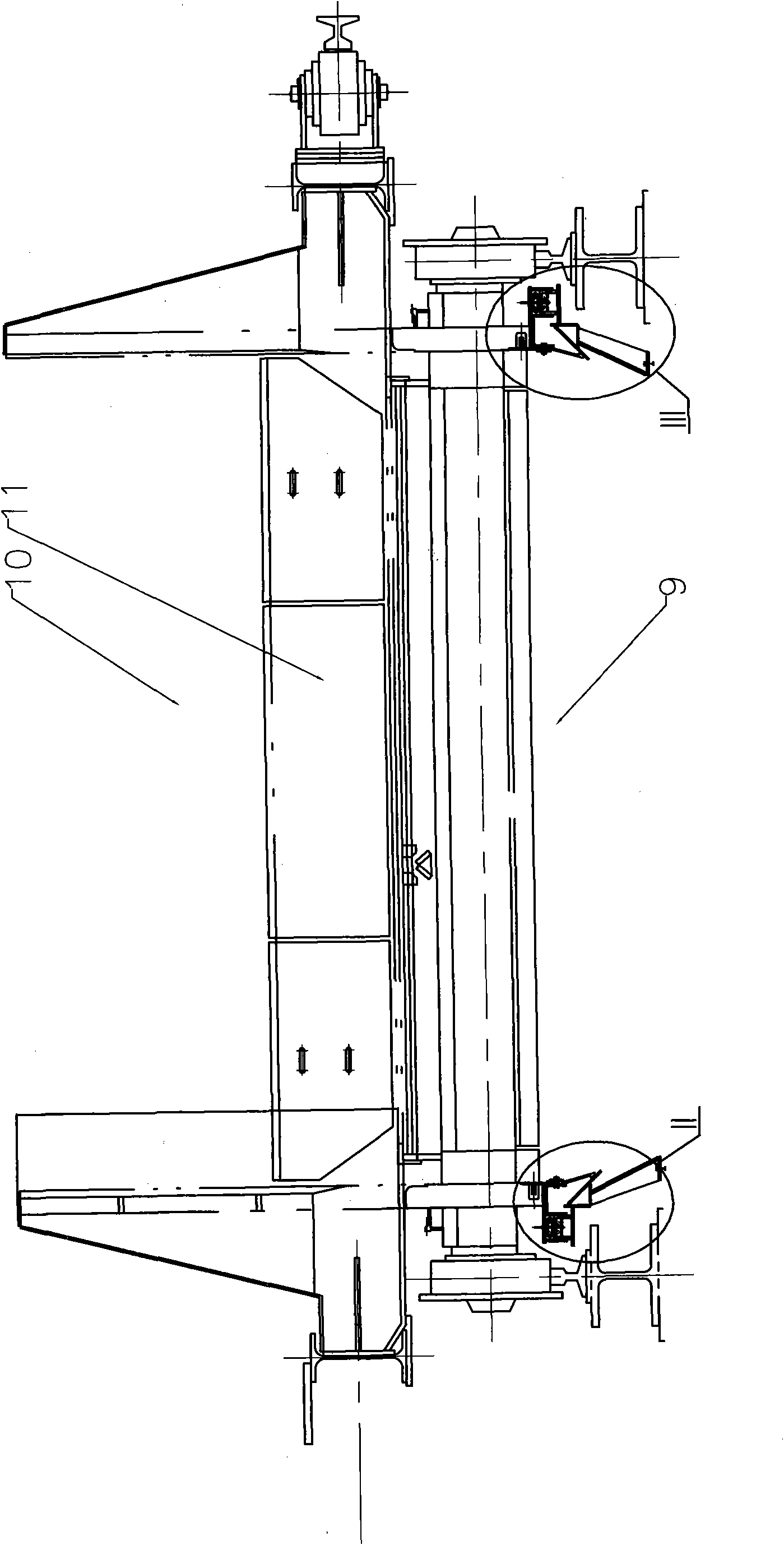

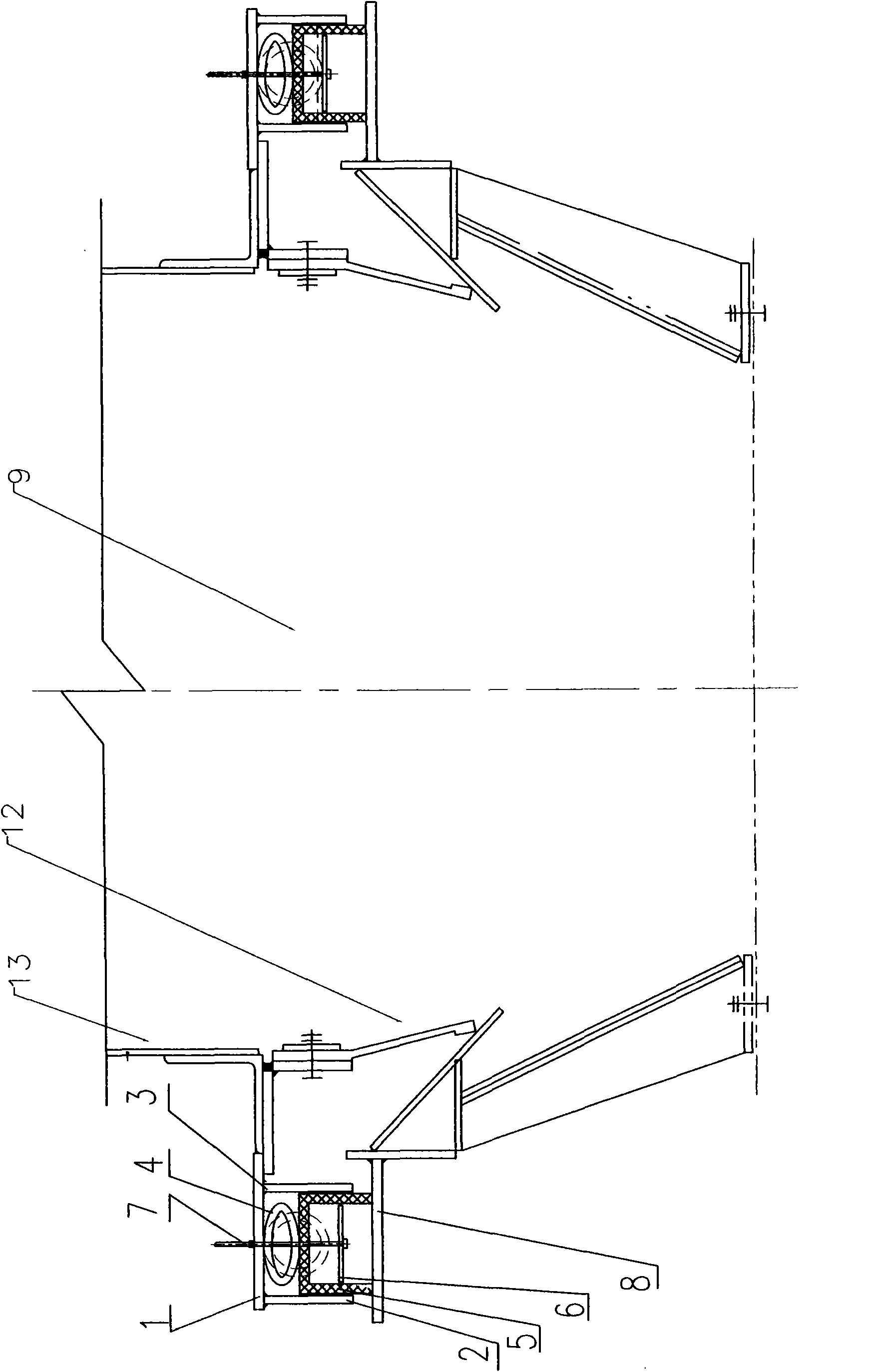

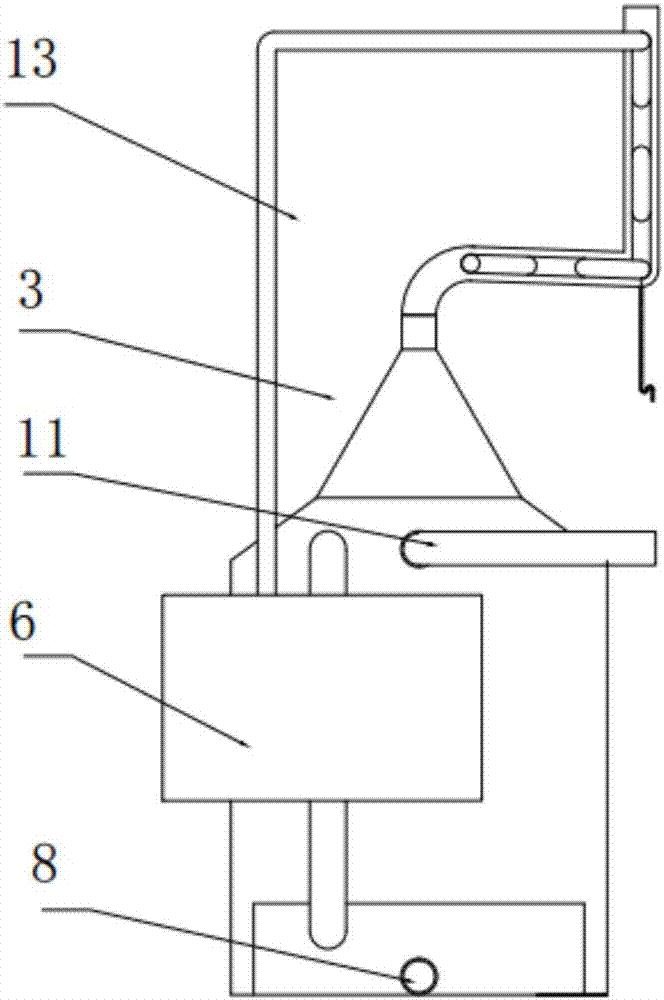

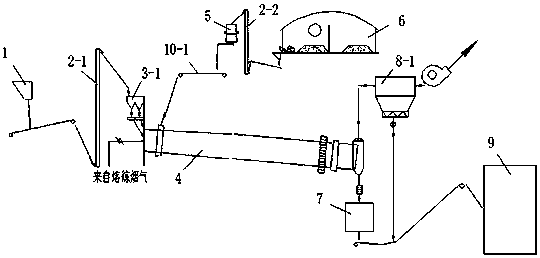

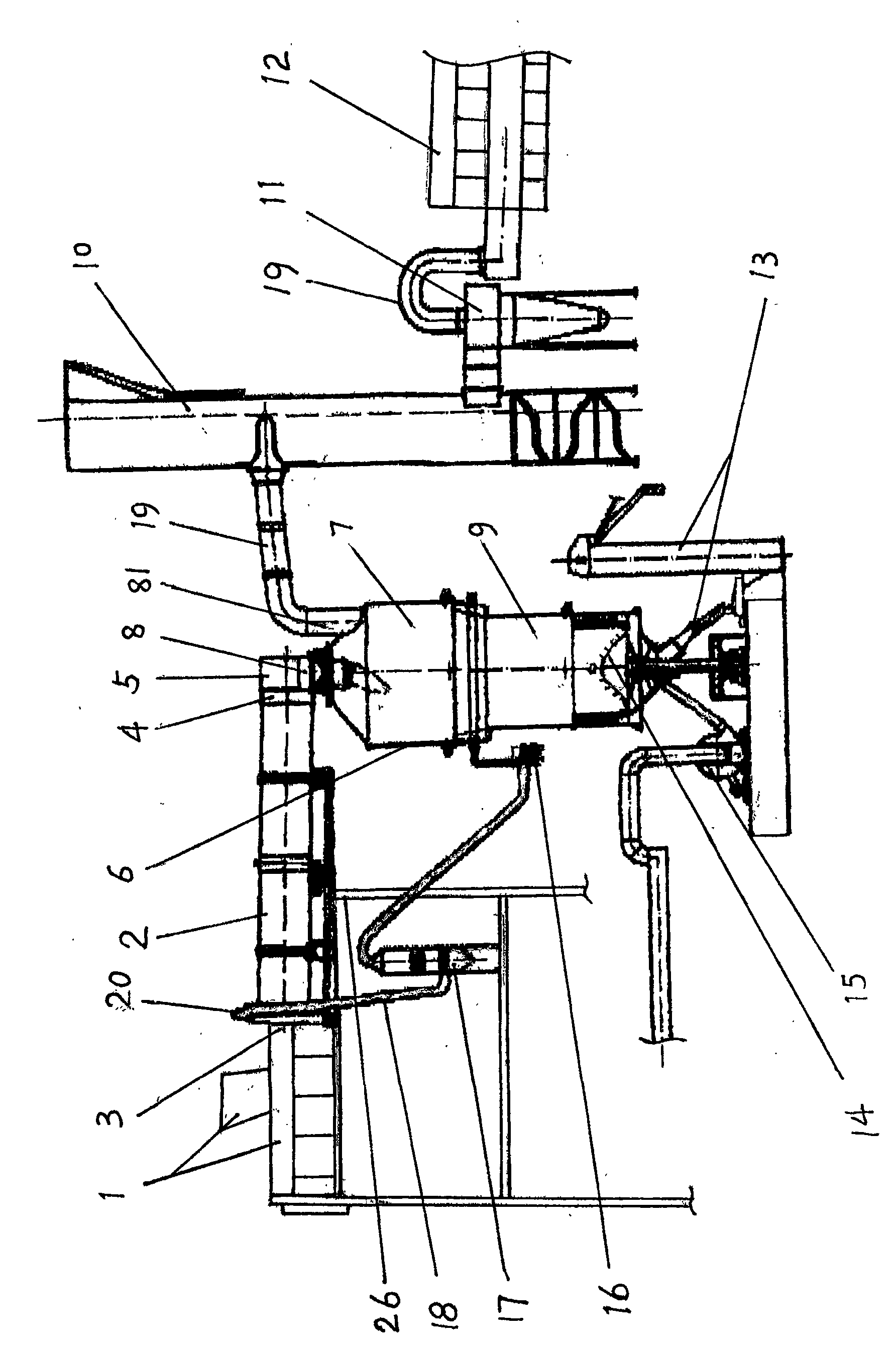

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

InactiveCN101101120APrevent external consumptionPlay the role of thermal insulationIncinerator apparatusRefluxCombustion chamber

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

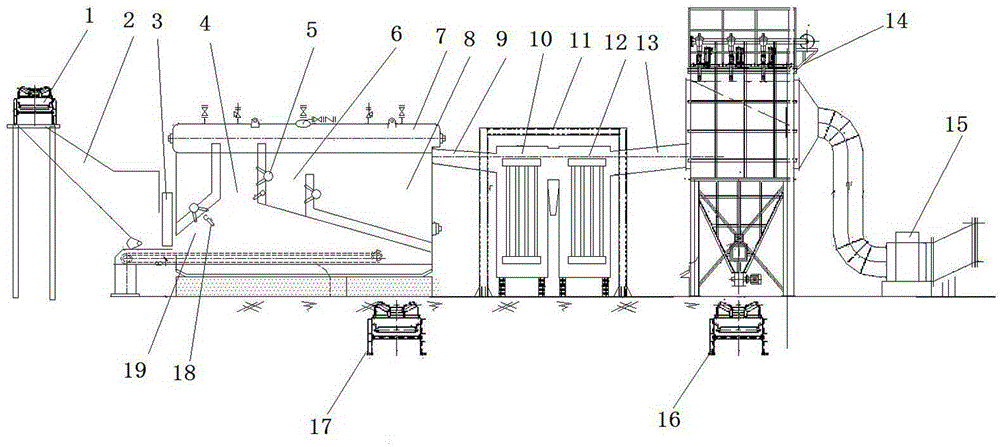

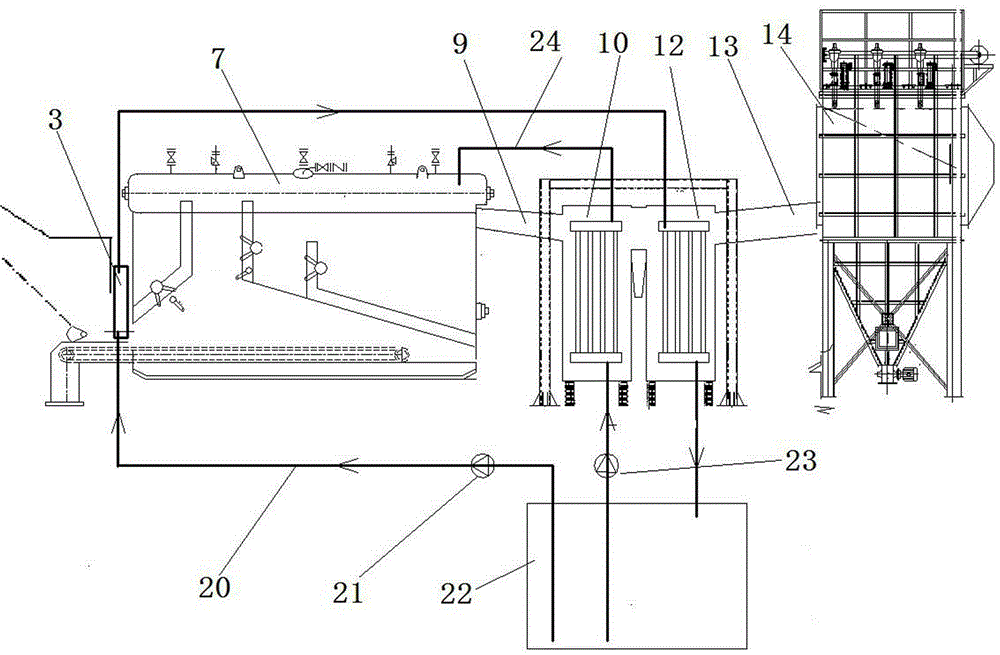

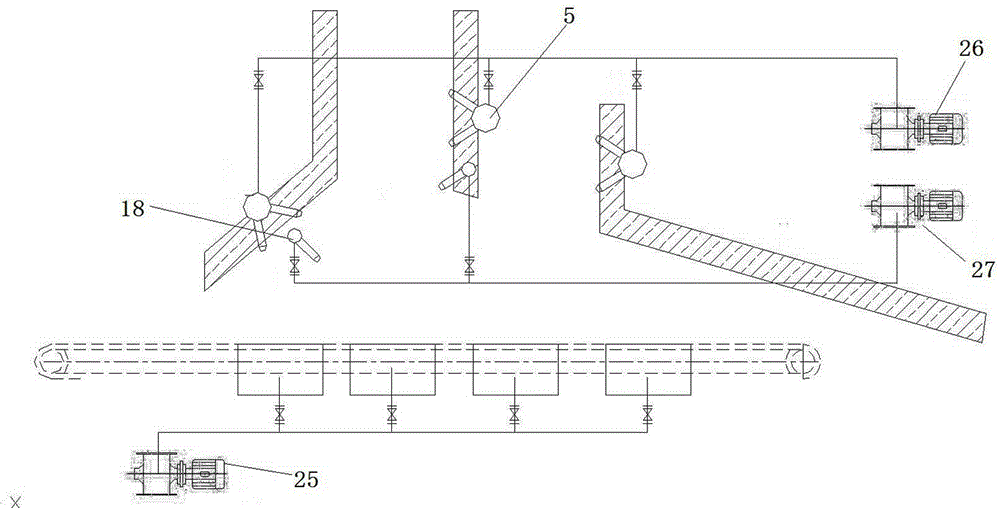

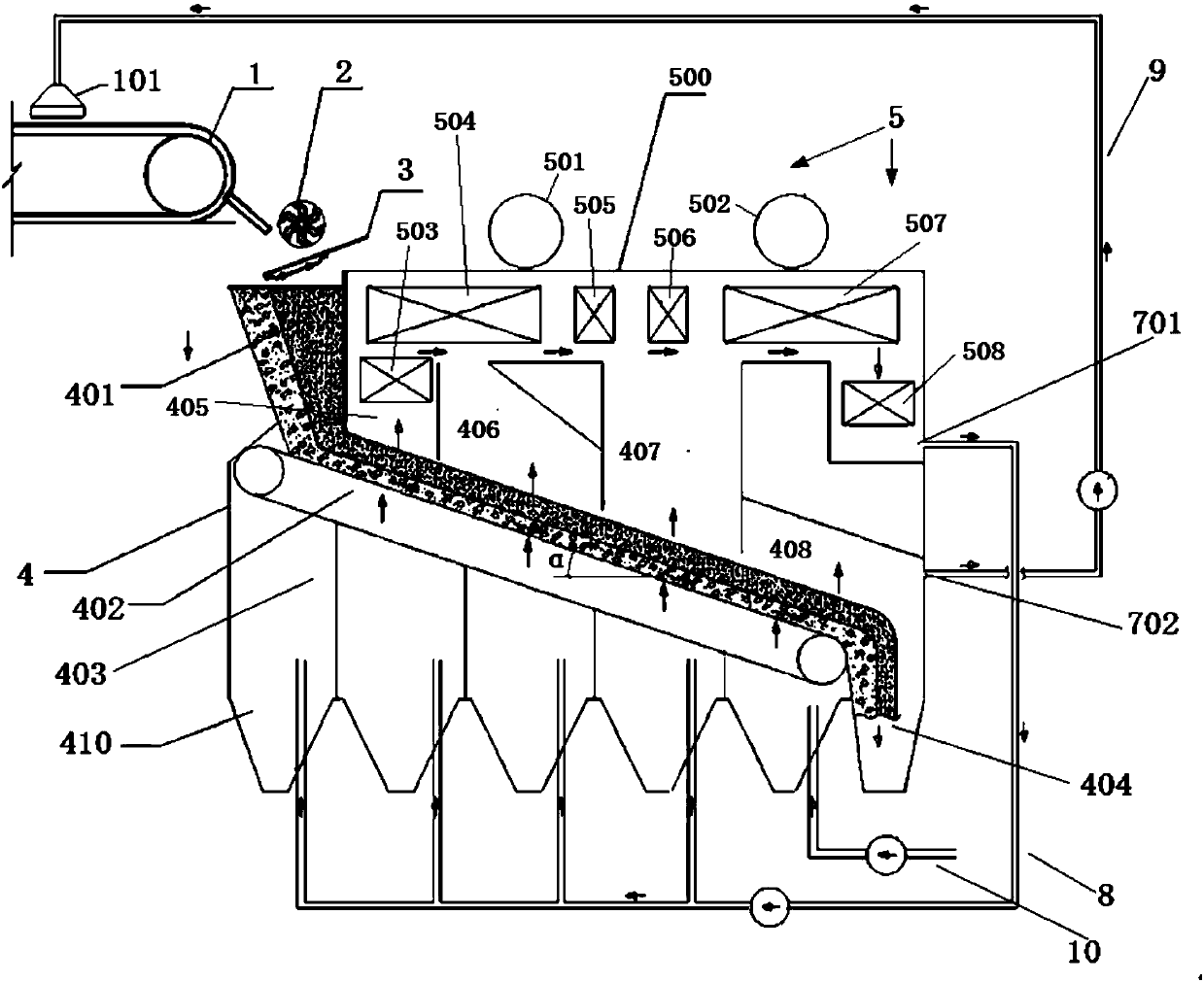

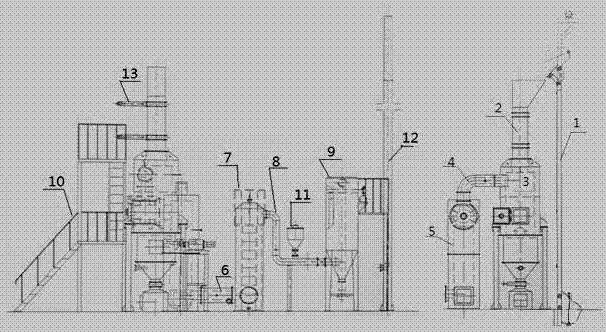

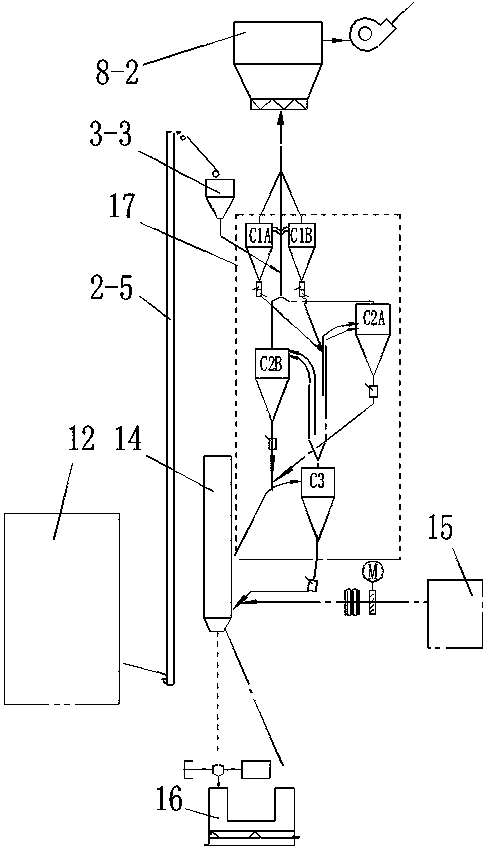

Continuous pyrolysis incineration device for full-scale electronic and electrical product waste

ActiveCN105509062AGuaranteed incineration temperatureGuaranteed incineration efficiencyEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING UNIV OF TECH

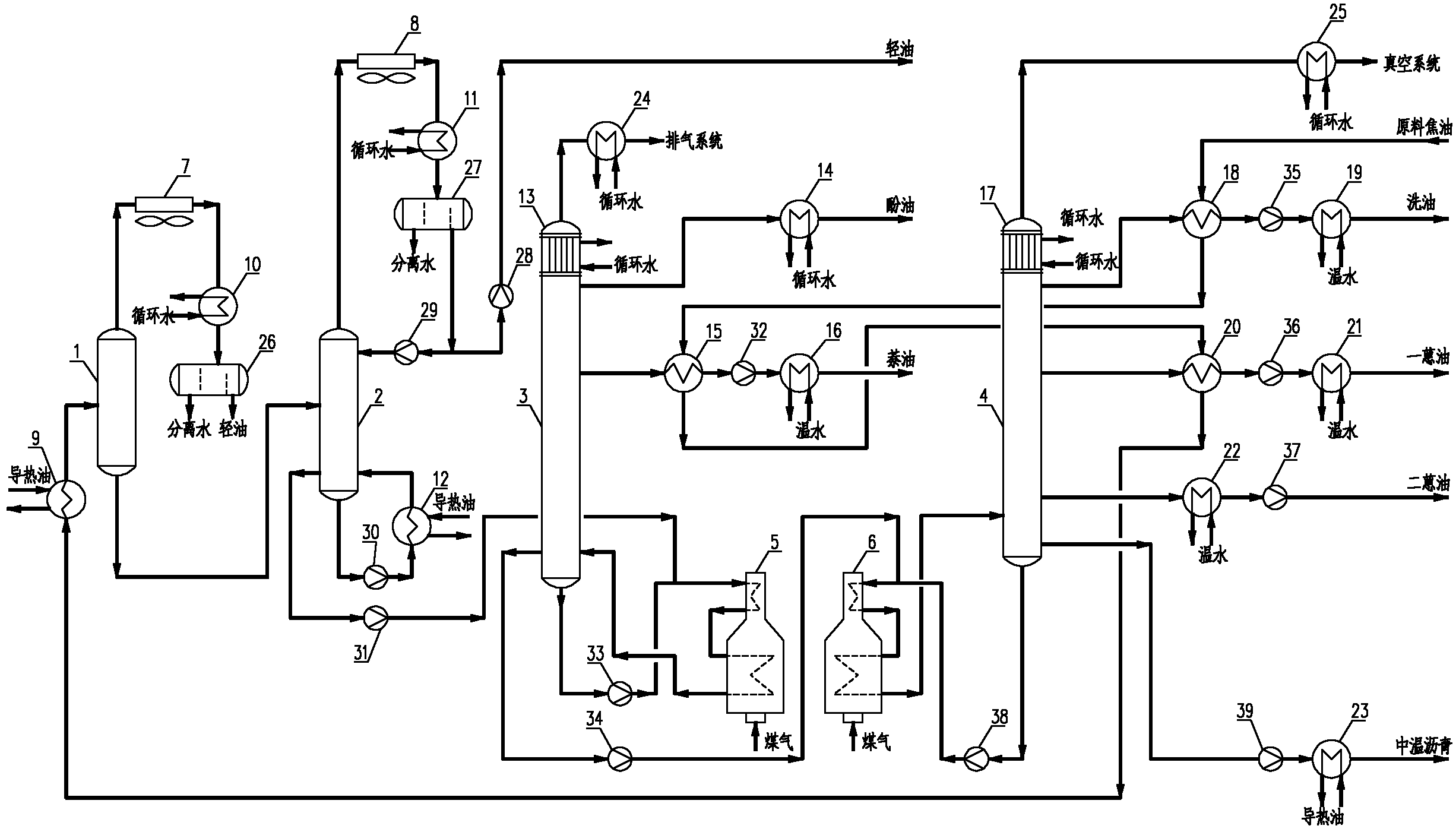

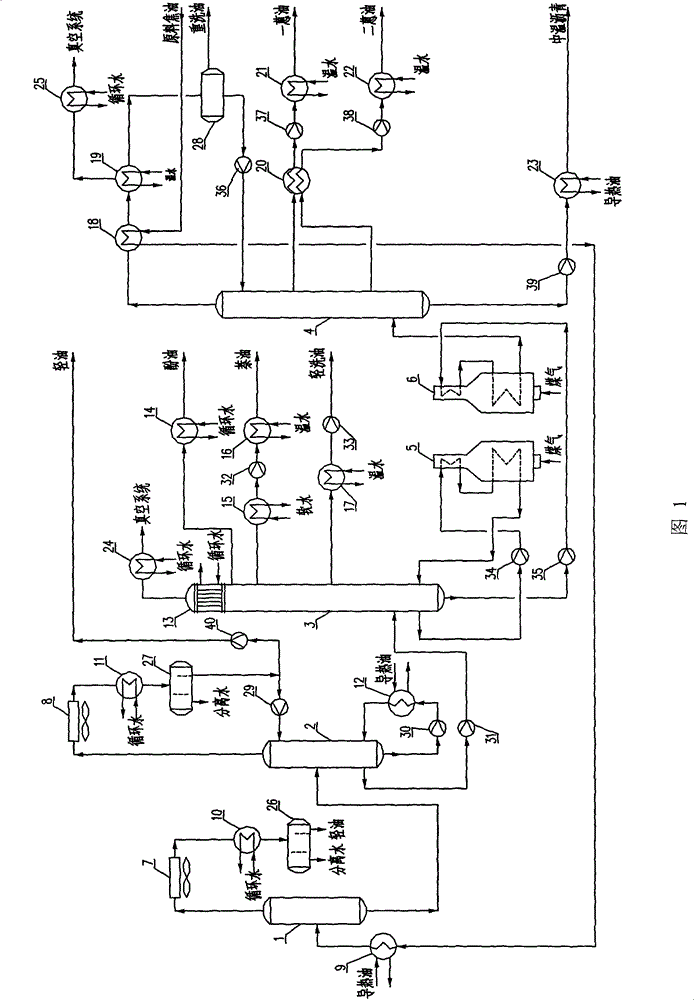

Three-tower type atmospheric-vacuum tar distillation process

InactiveCN102634363AReasonable distributionReduce consumptionTar working-up by distillationReboilerTar

The invention relates to a three-tower type atmospheric-vacuum tar distillation process. A raw material tar is dehydrated to obtain light oil fractions under constant pressure in a pre-dehydrating tower and a dehydrating tower, carrying out constant pressure operation in a No. 1 distillation tower to obtain carbolic oil and naphthalene oil fractions, and carrying out reduced pressure operation in a No. 2 distillation tower to obtain washing oil, primary anthracene oil, secondary anthracene oil and medium-temperature asphalt under or obtain the washing oil, the primary anthracene oil and maltha products. Heats of the pre-dehydrating tower and the dehydrating tower are provided by heat-conduction oil or steam; the heat of the No. 1 distillation tower is circularly provided by tower bottom mixing oil in a No. 1 tube-type heating furnace; and the heat of the No. 2 distillation tower is circularly provided by tower bottom asphalt in a No. 2 tube-type heating furnace. A main device comprises the dehydrating tower, the No. 1 distillation tower, the No. 2 distillation tower, a dehydrating tower reboiler, the No. 1 tube-type heating furnace, the No. 2 tube-type heating furnace, each fraction heat exchanger, a cooler, a pump and the like. The three-tower type atmospheric-vacuum tar distillation process disclosed by the invention has the advantages of being simple and quick in process flow, simple and convenient in operation, low in capital construction investment, energy-saving and environment-friendly, and is suitable for coal tar processing engineering capable of annularly processing anhydrous tar in the scale of more than 2,000,000 tons.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

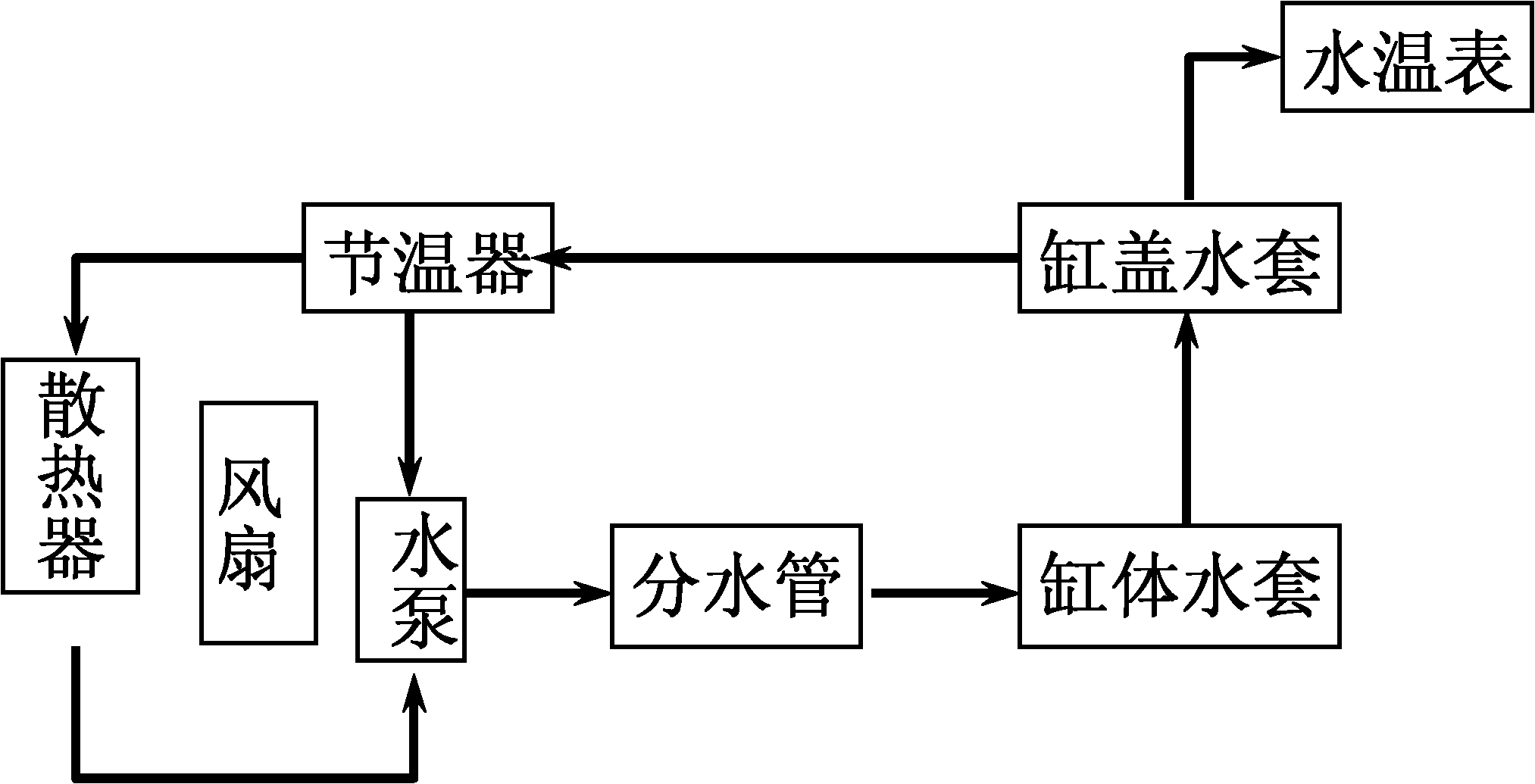

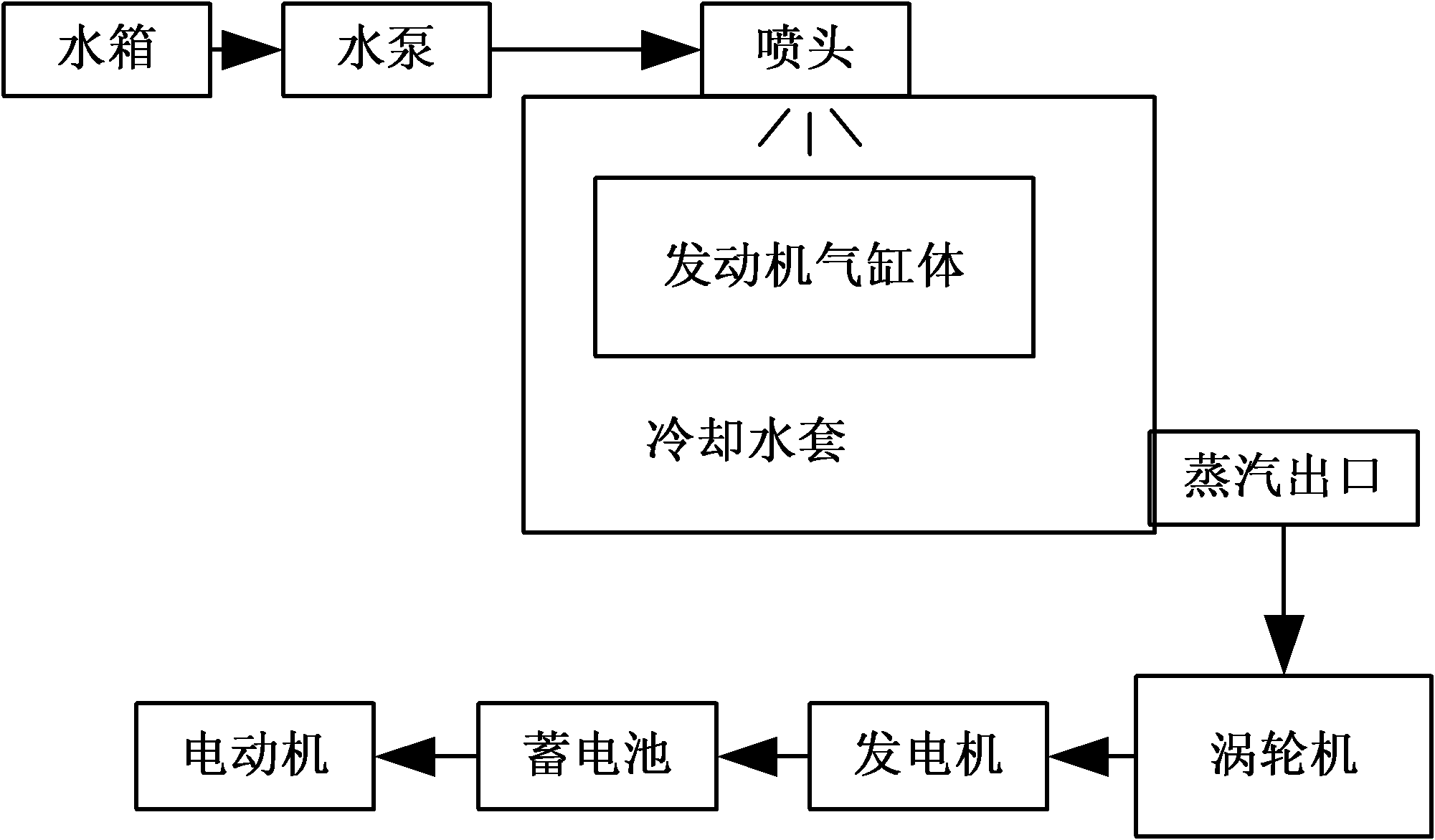

Method and system for utilizing engine waste heat

InactiveCN101979861AOverall small sizeReduce resource inputBatteries circuit arrangementsInternal combustion piston enginesCharging stationElectric generator

The invention discloses a method and a system for utilizing engine waste heat. The system comprises an engine cylinder body and a cooling water jacket outside the engine cylinder body, wherein the cooling water jacket is provided with a plurality of spray heads; each spray head is connected with a water tank through a water pump; the cooling water jacket is provided with a steam outlet; the steam outlet is connected with a steam driving device; the steam driving device is connected with an electric generator; and the electric generator is connected with a storage battery. The method and the system provided by the invention are particularly suitable for gasoline-electric hybrid automobiles. Steam kinetic energy produced by cooling an automobile engine is continuously and dynamically converted into electric energy, so that an automobile storage battery is charged continuously, the construction of a special charging station for hybrid electric vehicles can be avoided, resource investment can be saved greatly, the rapid development of the gasoline-electric hybrid automobiles is promoted and the international development trends of energy conservation and emission reduction are conformed.

Owner:石金成

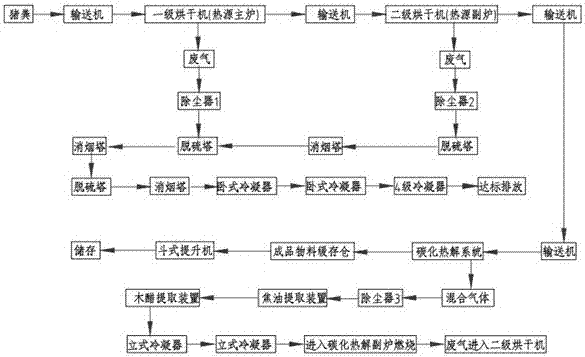

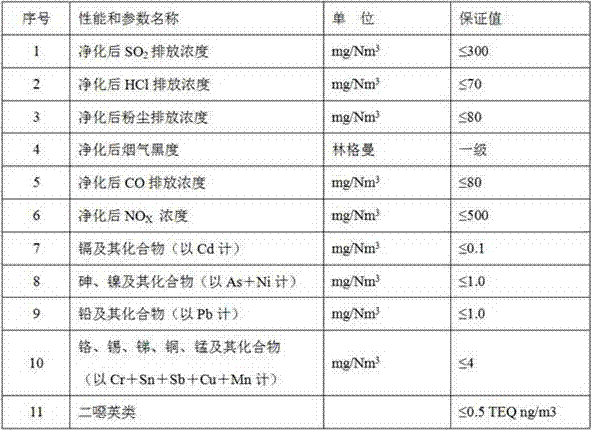

Comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology

InactiveCN107162373ARealize "three modernizations" processingImprove thermal efficiencySludge treatment by pyrolysisByproduct vaporizationHazardous substanceRetention time

The invention provides a comprehensive utilization method of pig manure on the basis of carbonization pyrolysis technology. Through steps including multi-stage drying to the pig manure, carbonization pyrolysis to the pig manure, flue gas treatment and the like, the pig manure is subjected to dry pyrolysis in a furnace, high-temperature pyrolysis gasification, and re-pyrolysis gasification to flue gas (outlet flue gas temperature is higher than 850 DEG C), wherein retention time of flue gas in the furnace is prolonged to more than 2 sec. In the whole pyrolysis process, generation of PCDDs / PCDFs harmful substances is effectively inhibited. Through quenching cooling to high-temperature flue gas, re-synthesis of dioxin is effectively avoided. Main measurements, such as a desulfurization column, adsorption in a smoke removal column, liquefaction in a condenser and the like, are all employed in the technology, so that national smoke and dust discharge standard at present can be satisfied.

Owner:FUJIAN YUYI ENVIRONMENT TECH CO LTD

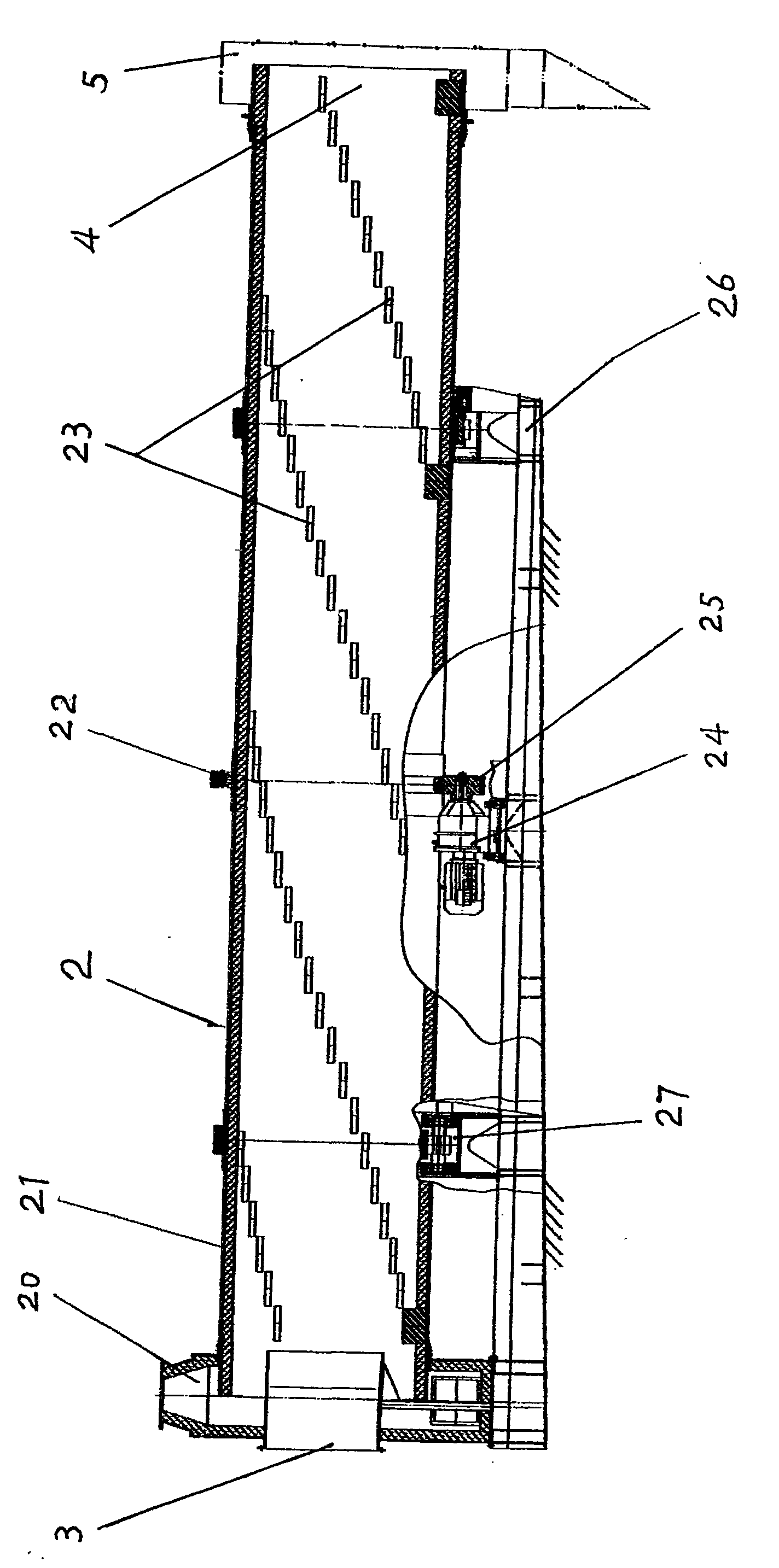

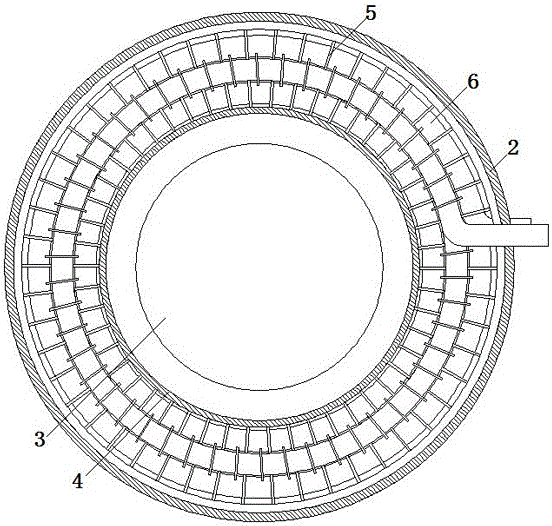

Seal structure between wind chamber and the lower part of sintering ring cold machine trolley of steel and iron plant

ActiveCN101655316AImprove the quality of useLow maintenanceFurnace typesHandling discharged materialIron plantEngineering

The invention discloses a seal structure between a wind chamber and the lower part of a sintering ring cold machine trolley of a steel and iron plant, which mainly comprises an outer seal piece, a seal contact plate and inner-side seal rubber, wherein the outer seal piece consists of a seal piece strut member, an outer limit plate, an inner limit plate, an elastic rubber cylinder, rubber in the shape of a seal groove, a support plate and an adjustable connection screw rod, the support plate is arranged in the rubber in the shape of a seal groove and is connected with the seal piece strut member through the adjustable connection screw rod in an adjustable way, outer seal is realized through the rubber in the shape of a seal groove and the seal contact plate, and inner seal is realized through the inner-side seal rubber. The invention improves the efficiency of smoke recycle and the quality of smoke utilization, fully recycles smoke, effeciently uses cold residual heat of sintering rings, decreases maintenance cost of the seal piece and shortens service life.

Owner:ZHEJIANG XIZI UNITED ENG

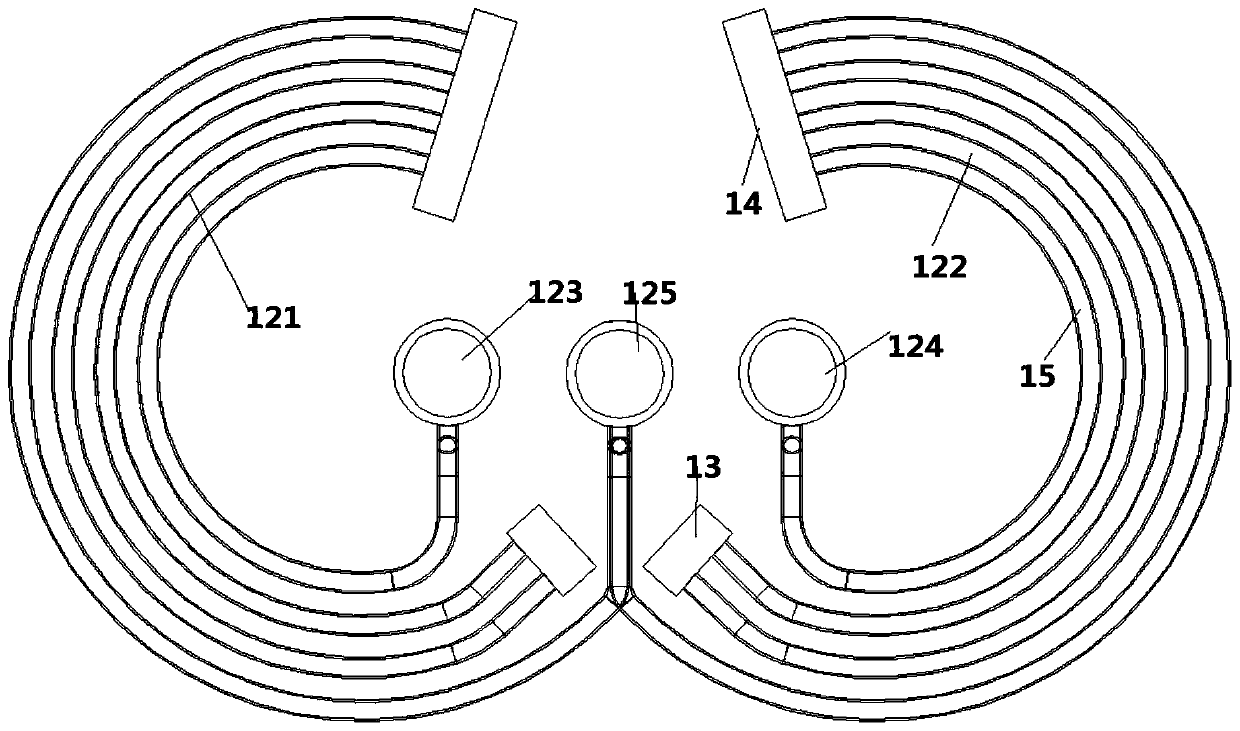

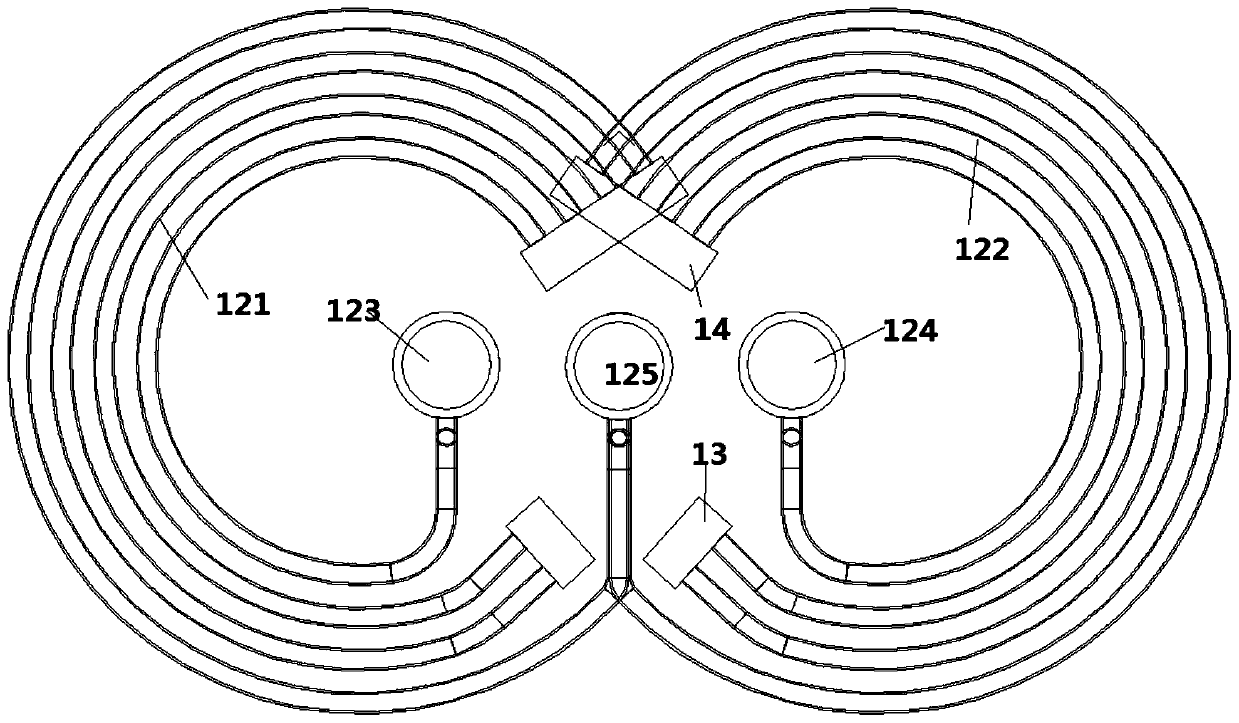

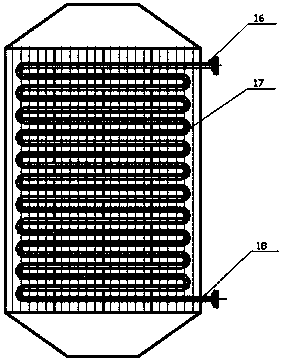

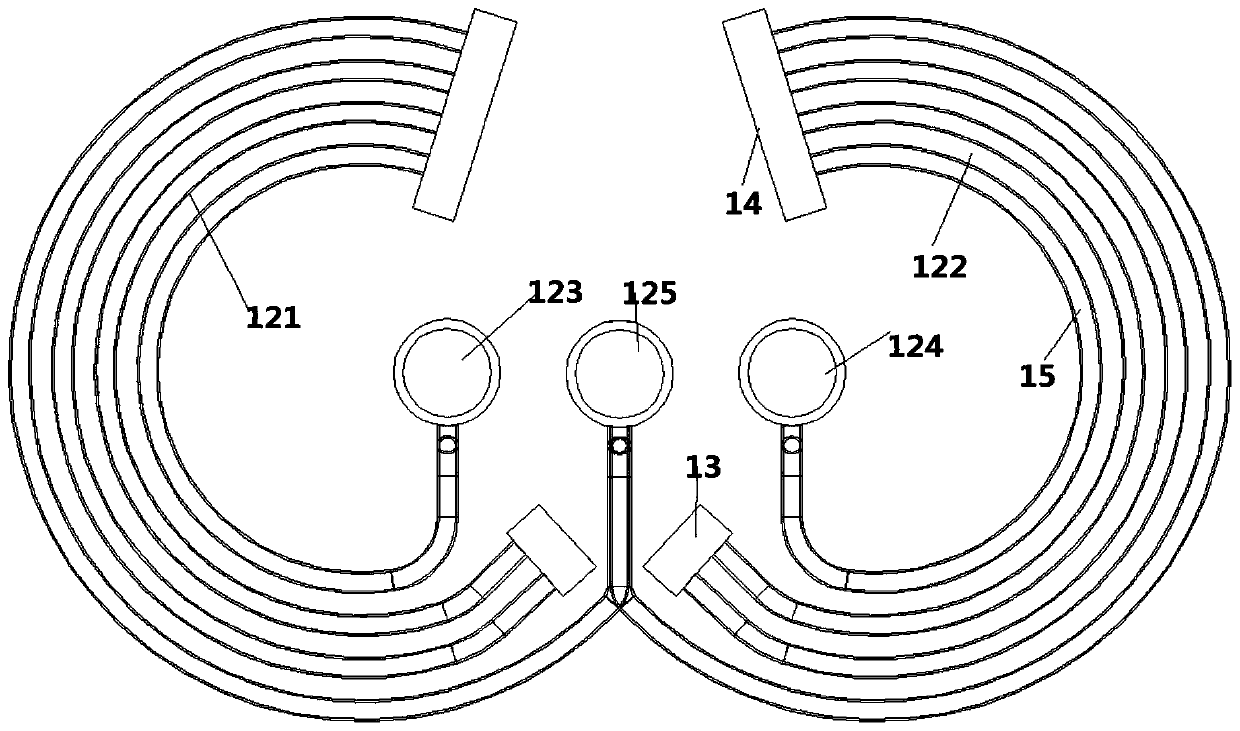

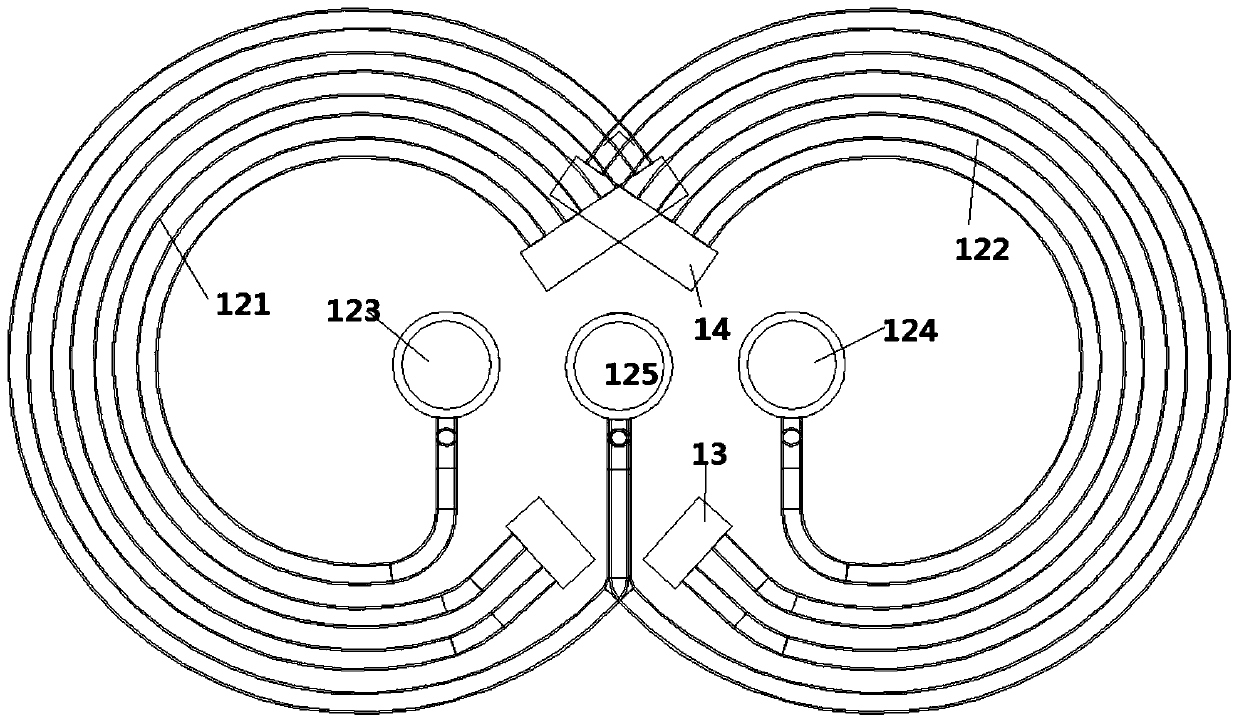

Asymmetrically-arranged heat exchanger

ActiveCN110174020AEnhanced heat transferStrengthen the dust removal effectEmission preventionIndirect heat exchangersEngineeringPlate heat exchanger

The invention provides an asymmetrically-arranged heat exchanger. The heat exchanger comprises a collecting pipe, left coil pipes and right coil pipes are distributed on the left side and the right side of the collecting pipe respectively; the heat exchanger is characterized in that the left coil pipes and the right coil pipes are arranged at intervals, one right coil pipe is arranged between every two adjacent left coil pipes, and one left coil pipe is arranged between every two adjacent right coil pipes. The heat exchanger can be used for carrying out reinforcing heat exchange and soot removal at different heights, and the effects of reinforcing heat exchange and removing accumulated dust are achieved.

Owner:SHANDONG UNIV

Steam generator for kitchen

PendingCN106871093AImprove production efficiencySimple structureSteam generation using hot heat carriersEngineeringSteam generation

The invention relates to a cooking utensil, in particular to a steam generator for a kitchen. The steam generator for the kitchen comprises a shell and is characterized in that the shell is provided with a steam generation cavity, a smoke collecting cavity and a smoke exhausting cavity sequentially from bottom to top; a tube plate is arranged between the steam generation cavity and the smoke collecting cavity; a gas stove installing cavity is arranged outside a bottom plate; the steam generation cavity comprises a plurality of smoke tubes installed in the vertical direction; the lower ends of the smoke tubes penetrate through the bottom plate and extend to the outside of the shell, and the upper ends of the smoke tubes penetrate through the tube plate to extend to the smoke collecting cavity; a steam output pipe is arranged on the steam generation cavity; and a smoke exhausting outlet is formed in the top of the smoke exhausting cavity. The smoke exhausting cavity is further provided with a heat exchange tube set, the two ends of the heat exchange tube set are provided with a water injection port and a water outlet correspondingly, and the water outlet is supplemented to the steam generation cavity through a pipeline. The steam generator for the kitchen has the beneficial effects that the steam generation efficiency is high, the structure is simple, maintenance is convenient, and the steam generator can be conveniently connected with other steaming utensils through pipelines and is clean and hygienic.

Owner:YANTAI ZHONGDE ENVIRONMENTAL PROTECTION EQUIPTECH

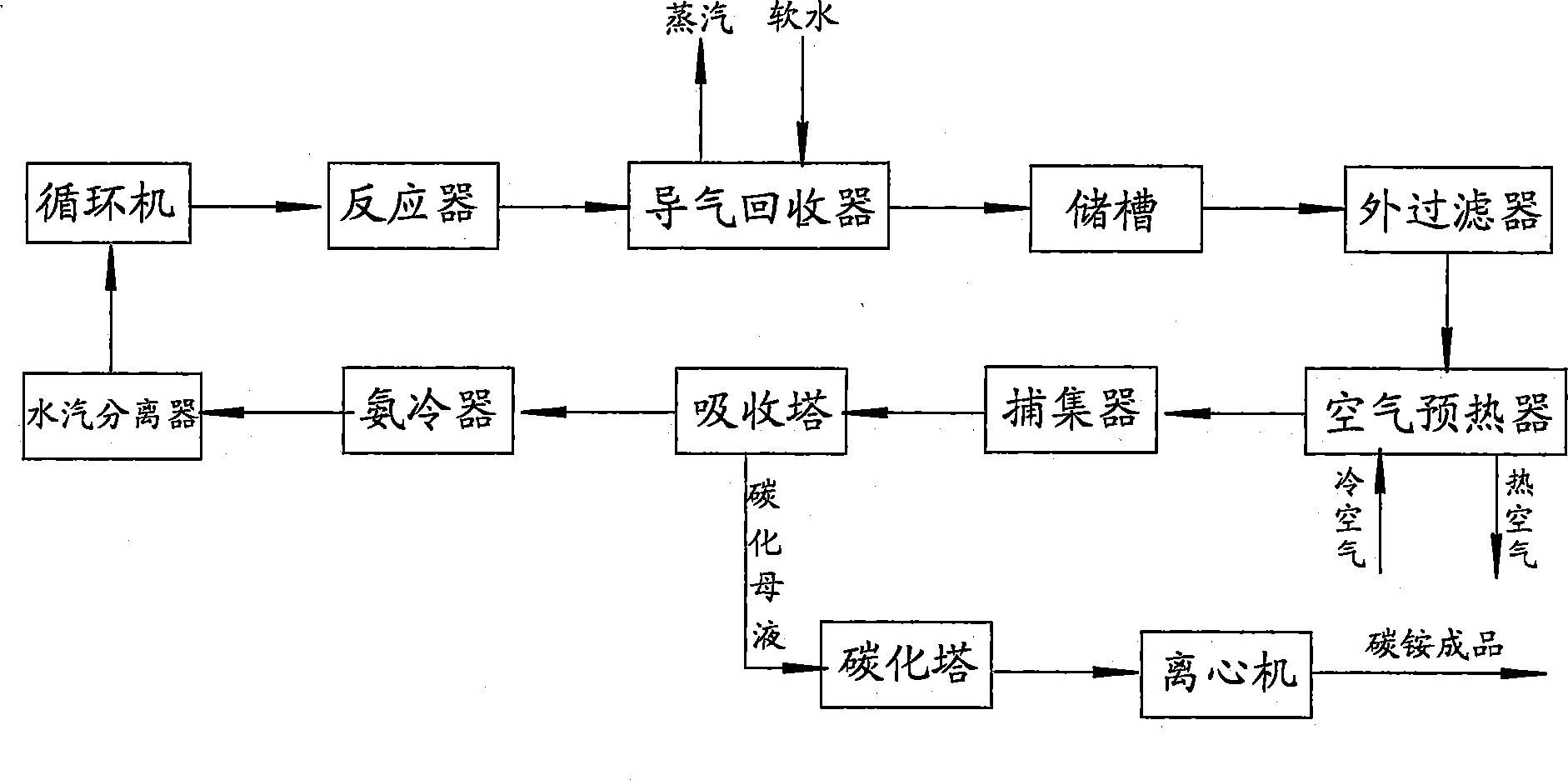

Associated melamine from carbon ammonium through technique of two-step method under normal pressure

InactiveCN1872842AThe process is simple and easy to controlStable circulationOrganic chemistryAmmoniaMelamine

This invention discloses a two-step process for producing melamine from urea under normal pressure. The method comprises: (1) blowing urea with ammonia into a reactor, mixing with ammonia from a circulation machine, preheating and blowing the catalyst from the bottom of the reactor to fluidize; (2) discharging the reactant from the top of the reactor, removing the catalyst dust by an outer filter, introducing into a collector, cooling naturally and condensing to obtain melamine; (3) purifying the circulation gas from the collector with an absorbing column to absorb carbon dioxide; (4) reacting the mother liquor obtained in step 3 and carbon dioxide obtained by the decarbonization of ammonium bicarbonate to obtain ammonium carbonate; (5) cooling the purified circulation gas, introducing into the circulation machine, concentrating, and passing into the reactor. Compared with present techniques, the method has such advantages as low raw material cost, high profit, easy control, simple process and reliable operation.

Owner:HOLITECH TECH CO LTD

Method for retrofitting coal-fired boiler into biomass boiler

ActiveCN105276566AImprove heat exchange efficiencySave fuelSolid fuel combustionSolid removalFlueDecomposition

The invention discloses a method for retrofitting a coal-fired boiler into a biomass boiler. The method comprises the following steps that firstly, a splitting decomposition combustion chamber is arranged behind a front arch and in front of a primary combustion chamber; secondly, a secondary combustion chamber is arranged behind the primary combustion chamber; thirdly, a smoke waste heat utilization device is arranged behind a boiler body, and a first water pipeline used for injecting water in a boiler barrel penetrates the smoke waste heat utilization device, so that water in the first water pipeline is preheated by smoke exhausted out of flues; and fourthly, a dust removal device is connected to the smoke waste heat utilization device. The existing coal-fired boiler is retrofitted and changed into the biomass boiler for burning biomass fuel, and biomass fuel is adopted, is low in carbon and environment-friendly and saves energy; the smoke waste heat utilization device is arranged to preheat the first water pipeline, heat exchange efficiency is high, smoke waste heat is fully utilized, and fuel can be saved; and the overall existing coal-fired boiler does not need to be replaced, and the investment cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for recycling hot waste gas generated in production process of -2-aminobutyric acid salt ammonium salt and using method thereof

InactiveCN107606962AIncrease the areaImprove drying rateIncreasing energy efficiencyHeating arrangementBrickTower

The invention disclose a device for recycling hot waste gas generated in the production process of -2- aminobutyric salt ammonium salt and a using method thereof. The device comprises a drying chamber, a hot waste gas pipe, a brick baking chamber, an exhaust pipe, a purification tower, gas inlets, a conveyor belt, rotating shafts, a first gas inlet pipe, a second gas inlet pipe, a spiral pipe, a water tank, a water pumping port and a partition plate. The device has the beneficial effects that the drying chamber and the brick baking chamber are connected together through the hot waste gas pipeso that the hot waste gas generated through baking the bricks can be recycled to dry green bricks; the gas inlets of the hot waste gas pipe are formed in the two sides of the drying chamber, the convection of the hot waste gas can be realized through the two gas inlets, the hot waste gas can be uniformly mixed, so that the contact area between the green bricks and the hot waste gas is increased, and the drying speed is accelerated; and the water tank is arrange on the partition plate, the circle of spiral pipe is arranged on the outer wall of the periphery of the water tank, and therefore theused hot waste gas passes through the spiral pipe to heat the water tank, and the waste heat of the hot waste gas is fully utilized. The device has the characteristics of being high in drying speed and capable of better utilizing the waste heat.

Owner:浙江双鸿新能源科技有限公司

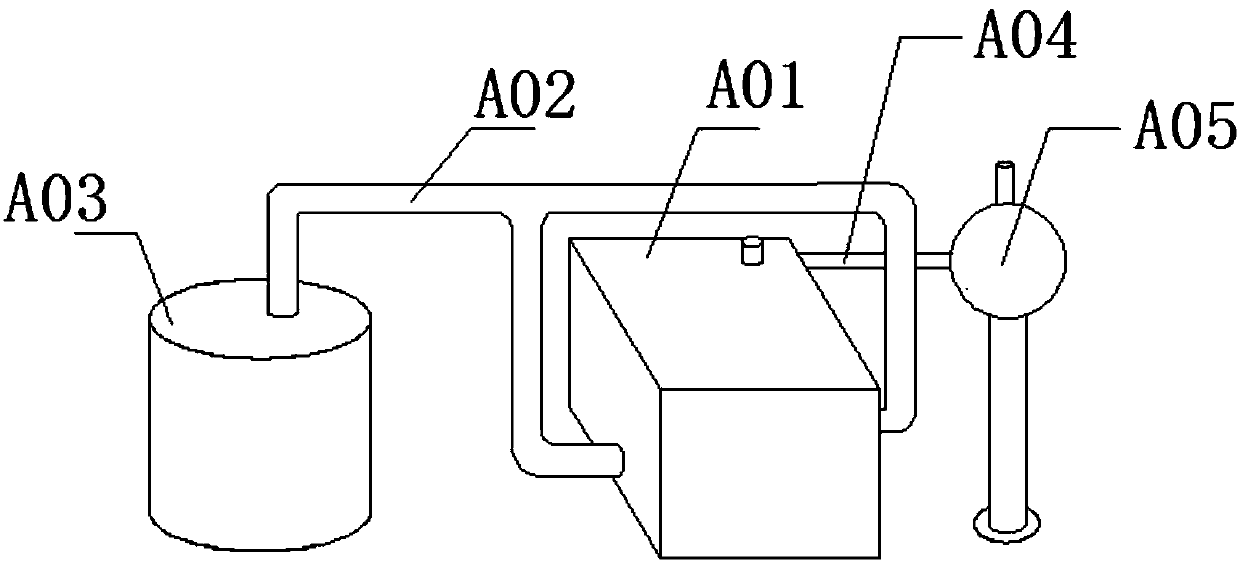

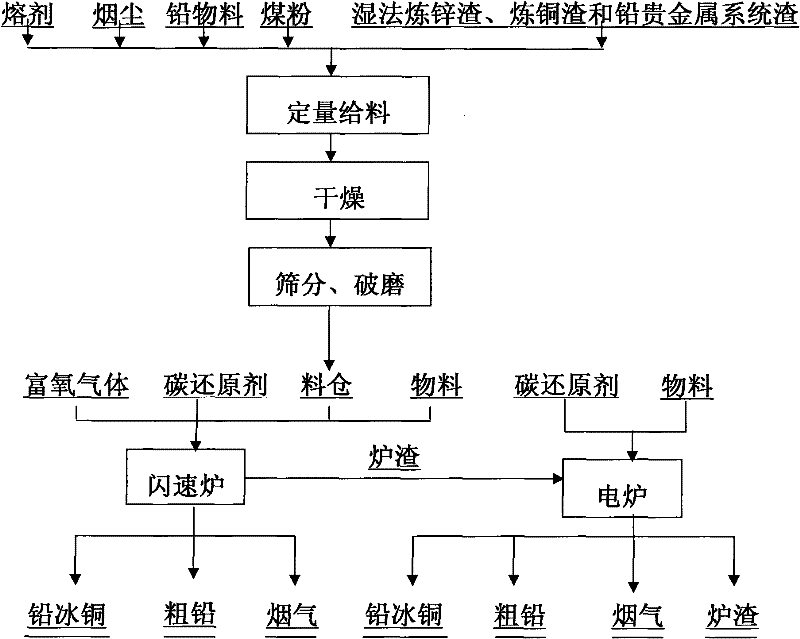

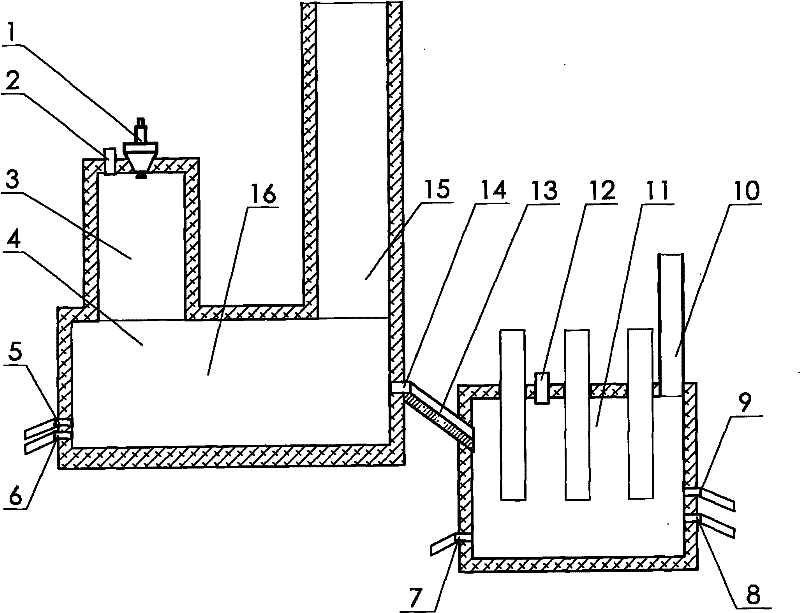

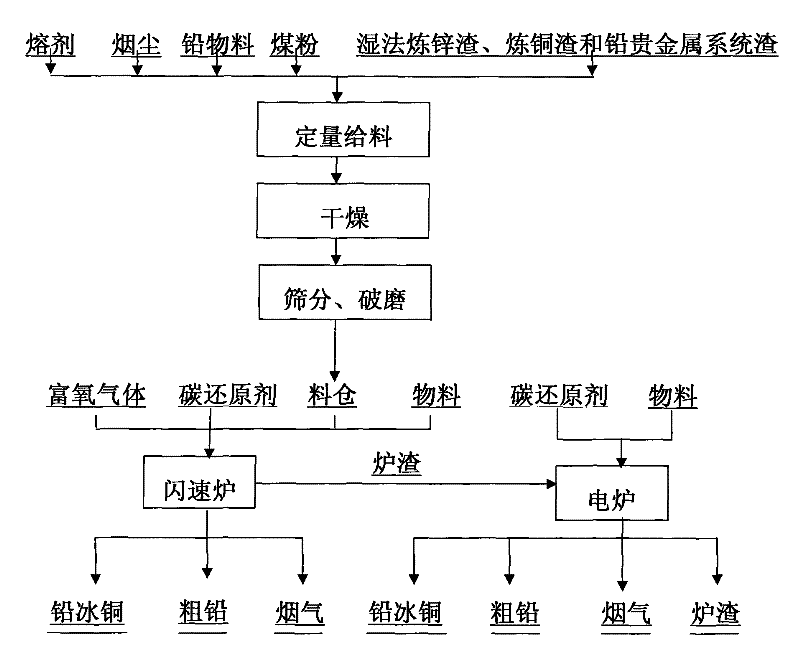

Method for smelting lead-containing material

InactiveCN101768670BNo explosion hazardAdaptableProcess efficiency improvementLead smeltingSmelting process

The invention discloses a method for smelting a lead-containing material, relating to the technological process for processing complex lead materials by utilizing a smelting method. The method is characterized in that a flash furnace and a depletion furnace are combined for smelting during the smelting process. The method of the invention has the advantages of short and continuous flow, energy saving, large capacity, efficient source utilization, environment protection, good safety and good industrial hygiene, no danger of foam slag exploration and safe production. The lead smelting process with high smelting strength and various advantages realizes single-step lead smelting, and has stronger adaptability on materials. The process is not only suitable for treating lead ore with complex components, but also suitable for treating wet smelting zinc slag, wet smelting copper slag and lead noble metal system slag, can do complementation of lead, zinc and copper and has more advantages overlead, zinc and copper jointed enterprises. The recovery rates of lead and concomitant valuable metals of copper, zinc and noble metals are higher.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

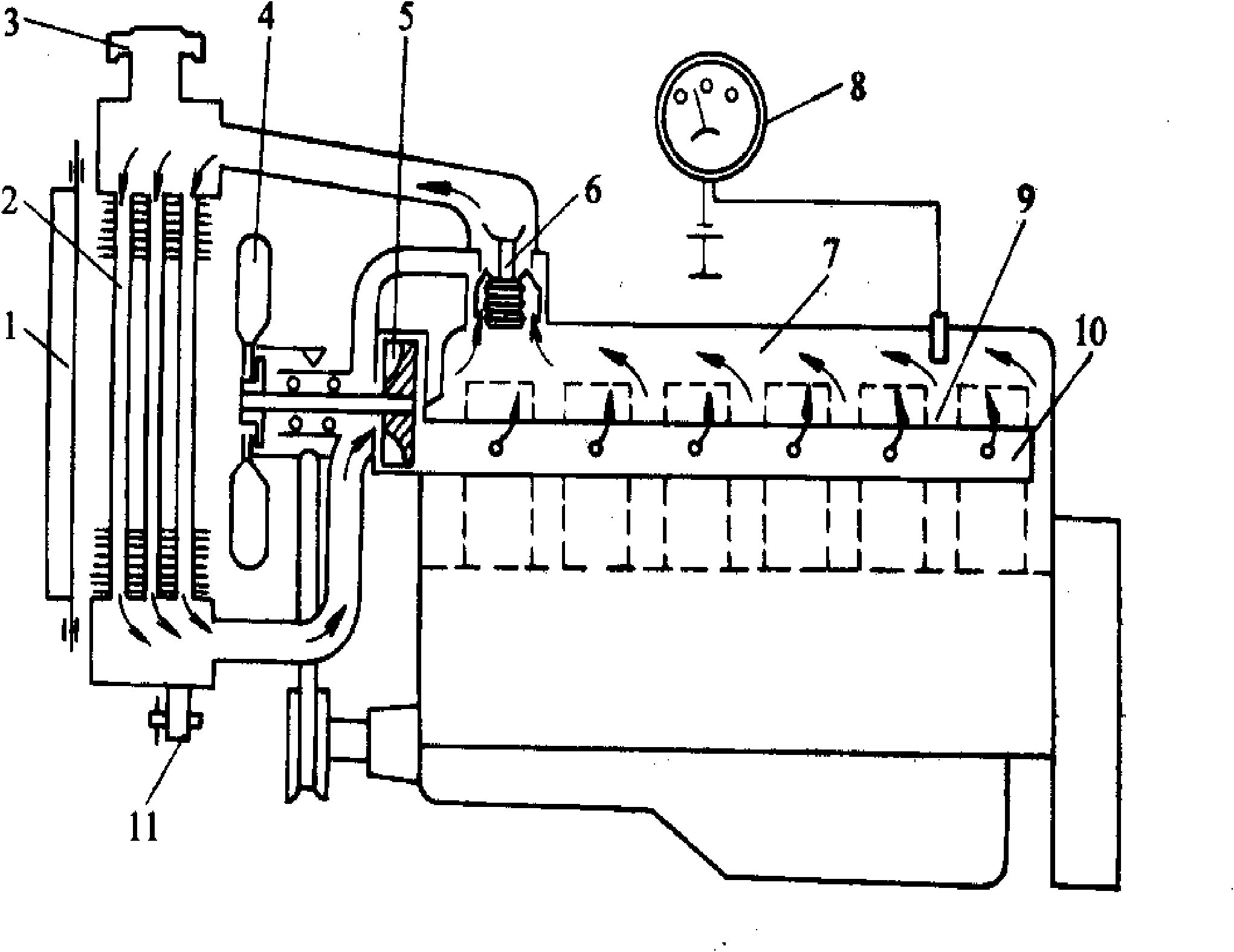

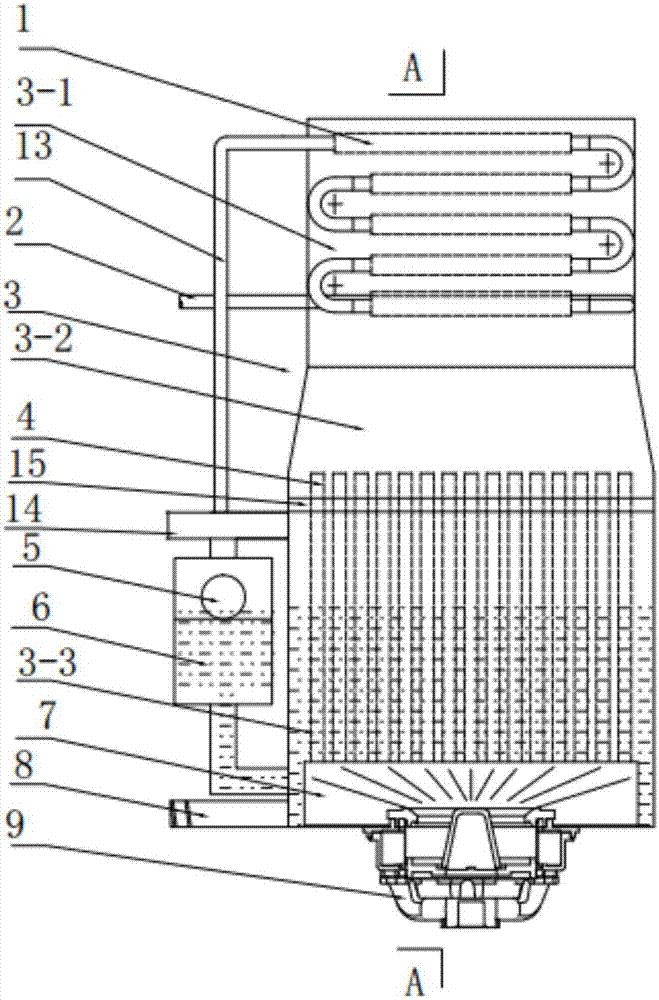

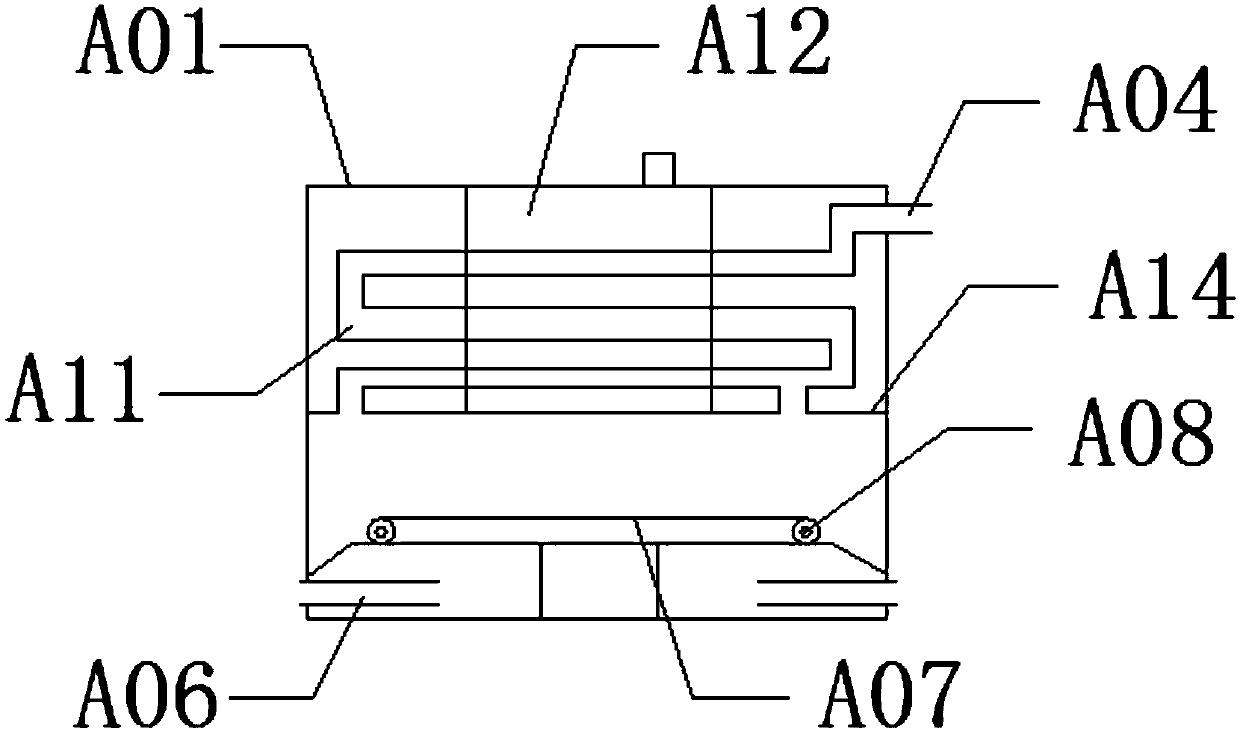

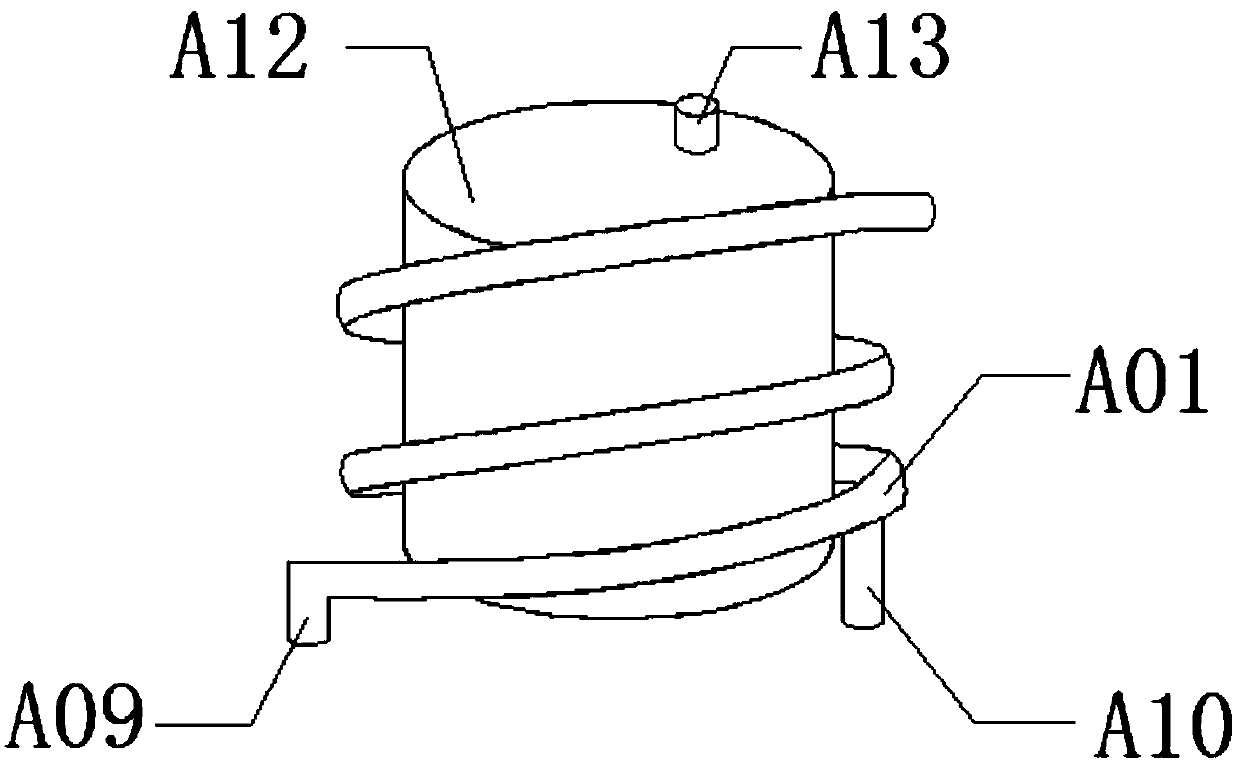

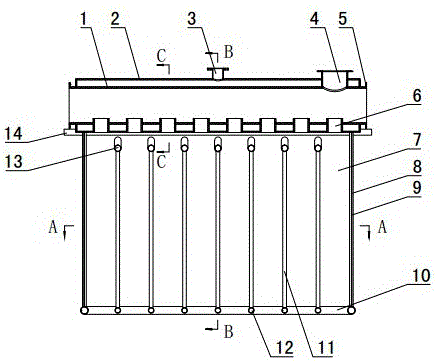

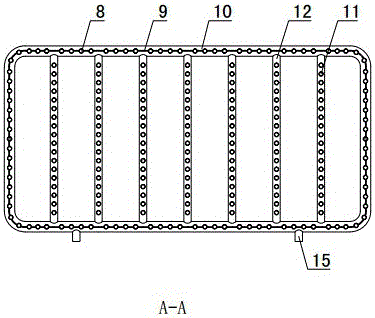

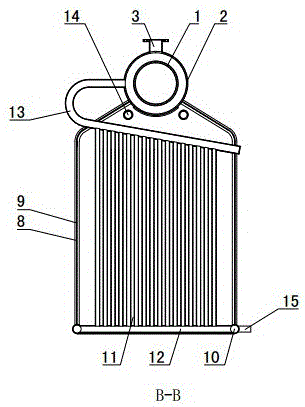

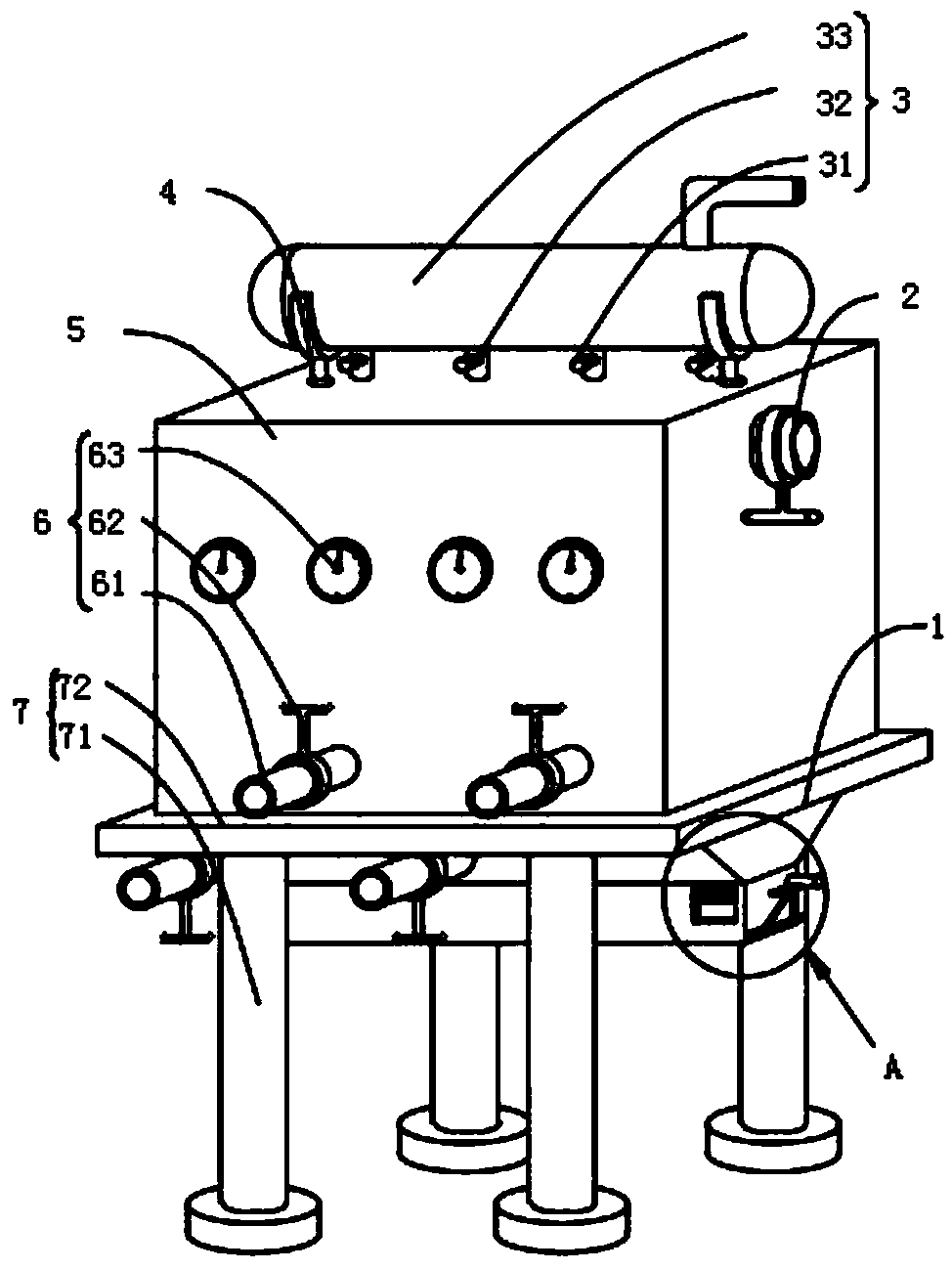

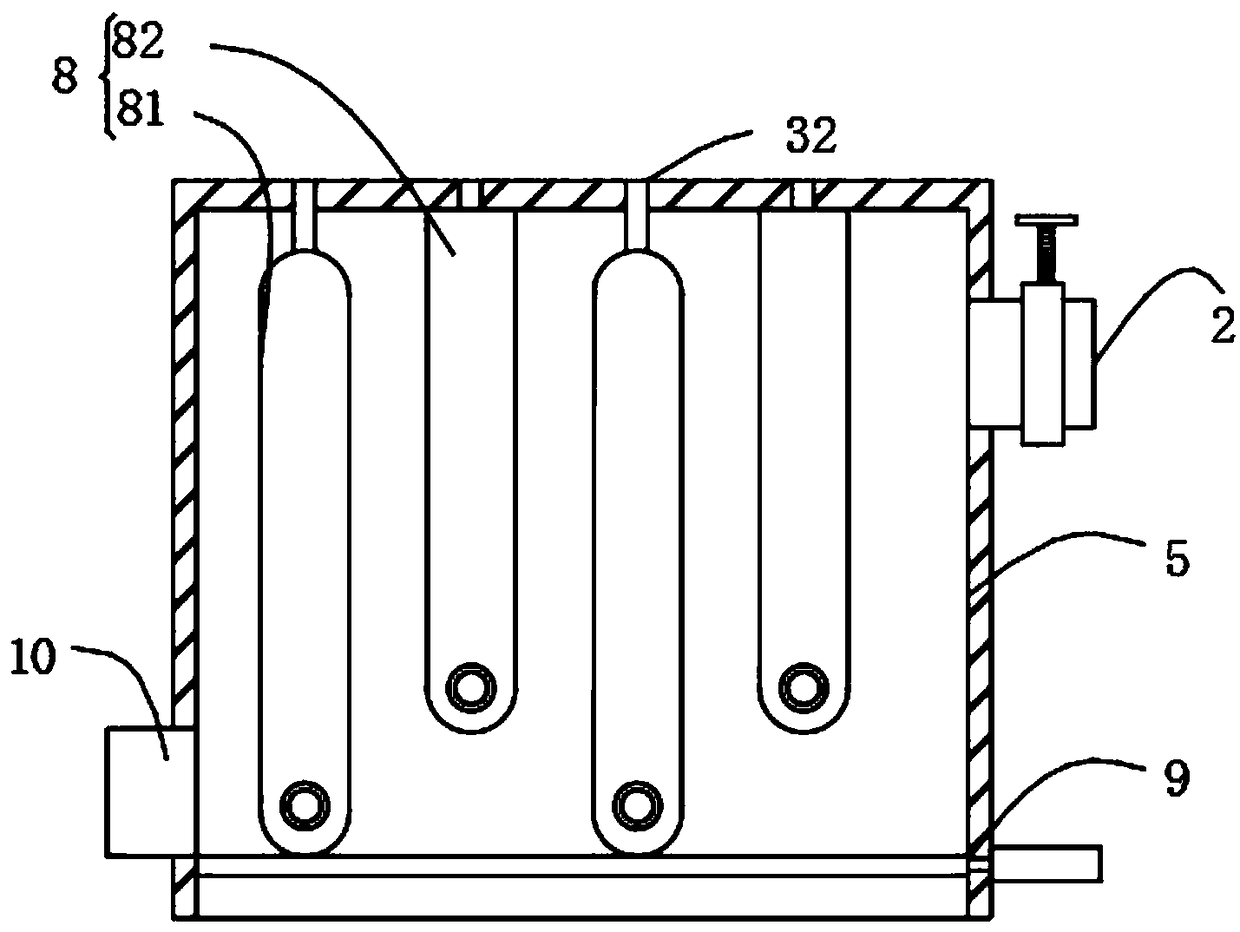

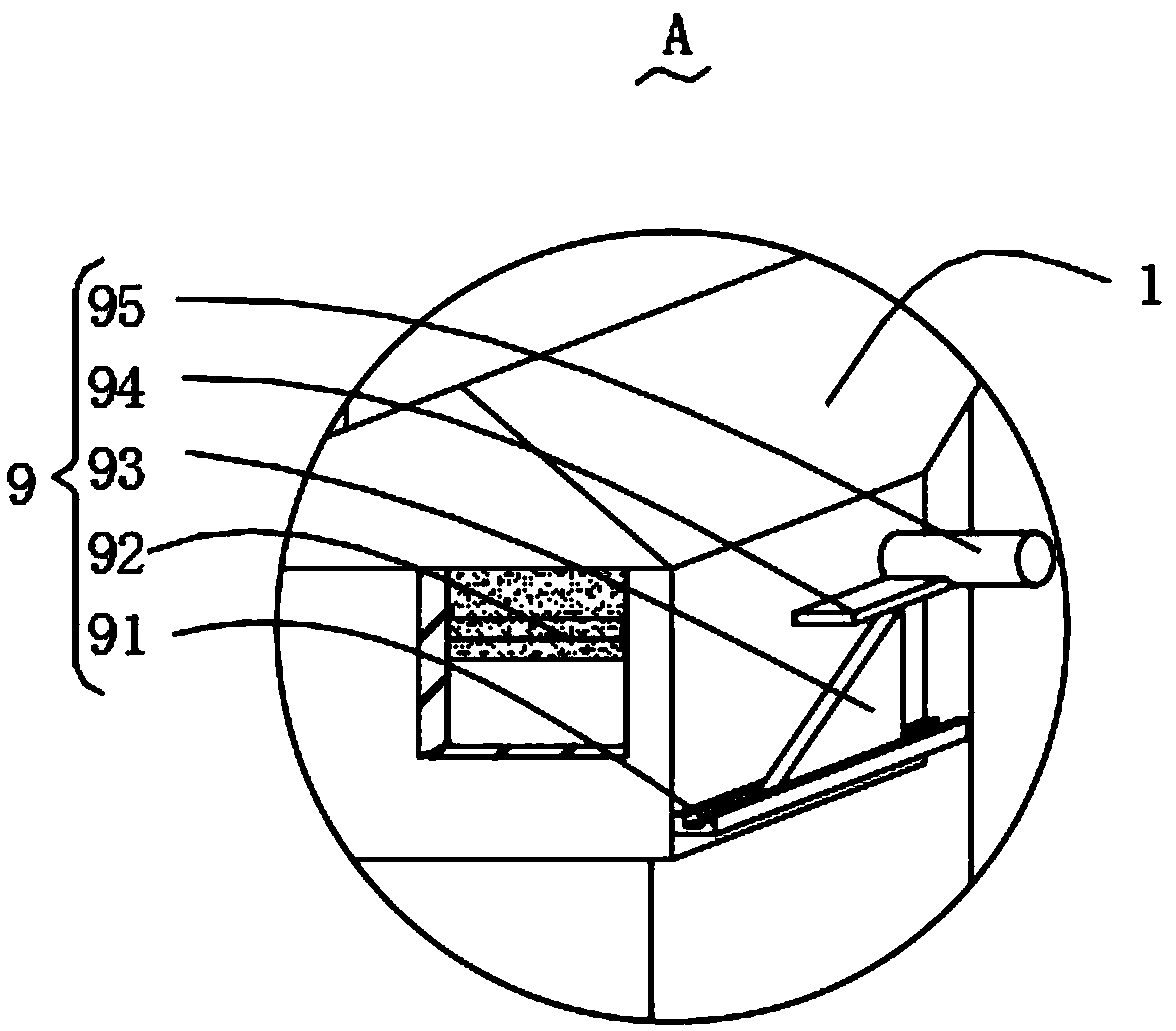

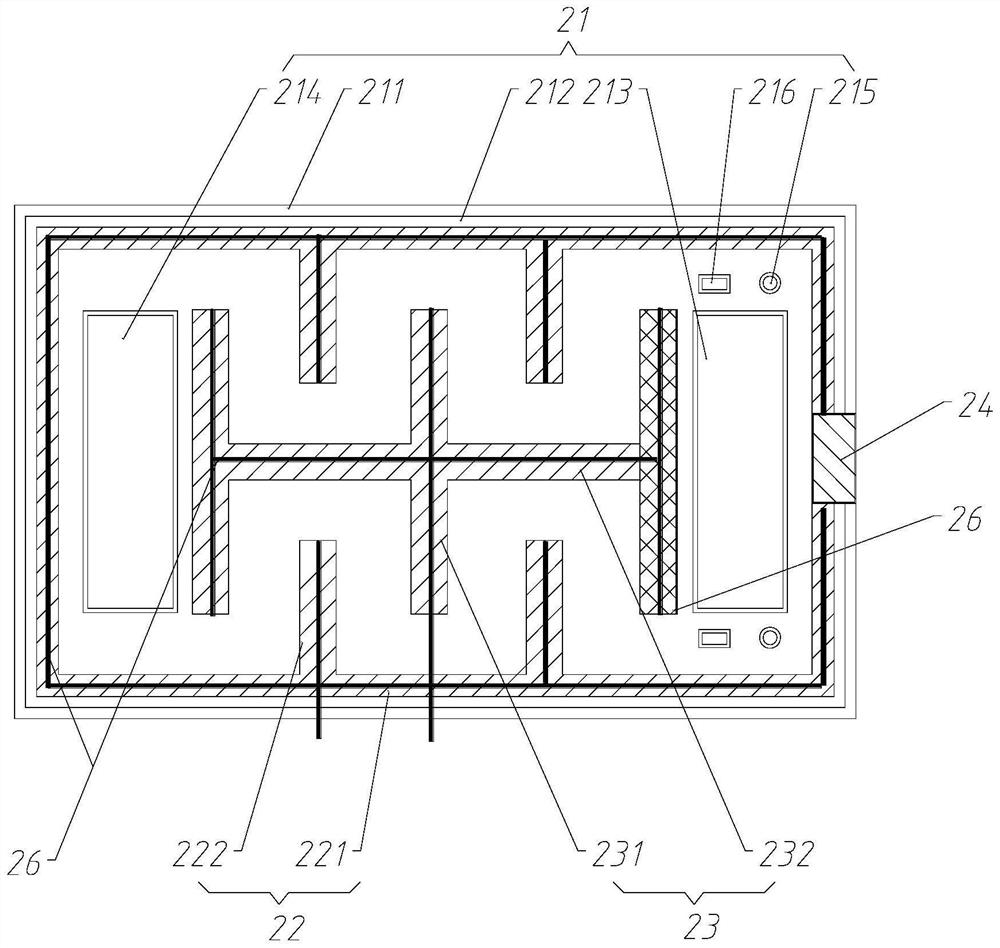

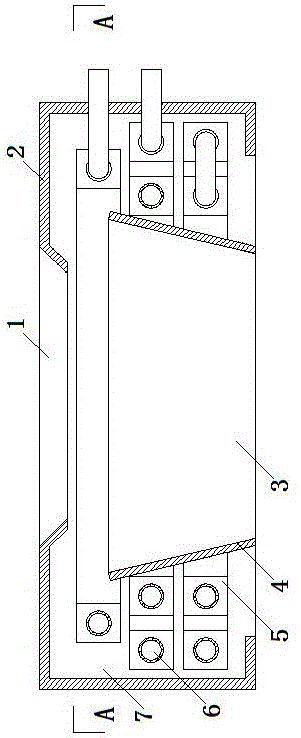

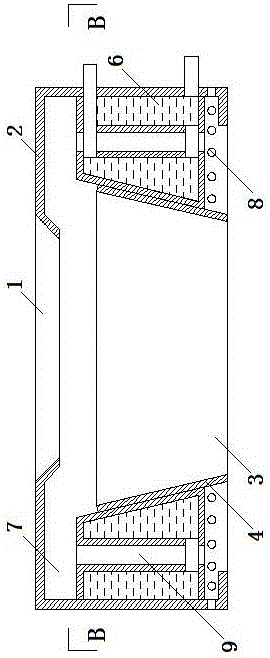

Box type evaporator for waste heat utilization of high-temperature solid materials

ActiveCN105953199ACompact structureEfficient waste heatEnergy industrySteam superheatersIsolating mechanismsEngineering

The invention discloses a box type evaporator for waste heat utilization of high-temperature solid materials and belongs to the field of cooling equipment for the high-temperature solid materials. The box type evaporator is characterized in that an outer cylinderl (2) and an inner cylinder (1) are combined to form a sleeve type header; the lower end of a heat exchange box (7) is open; the sleeve type header seals the upper end of the heat exchange box (7); a feeding port (4) communicated with the inner cylinder (1) is arranged at the upper part of the sleeve type header; a water-cooled spiral distributor for conveying and cooling the materials is arranged inside the inner cylinder (1); a heat exchange cavity is arranged on the side wall of the heat exchange box (7) ad is communicated with an inner cavity of the outer cylinder (2); multiple isolating mechanisms are arranged inside the heat exchange box (7) in parallel and divide the heat exchange box (7) into multiple material channels; and the materials in the inner cylinder (1) fall into the material channels via discharge ports (6). Both the sleeve type header and the heat exchange box of the box type evaporator for waste heat utilization of the high-temperature solid materials can bear pressure, so that the evaporator can be directly applied to production of steam, and waste heat of the high-temperature materials is efficiently utilized.

Owner:SHANDONG LIANXING ENERGY SAVING SERVICE

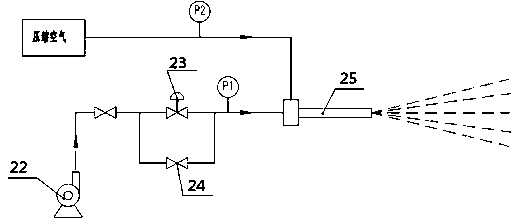

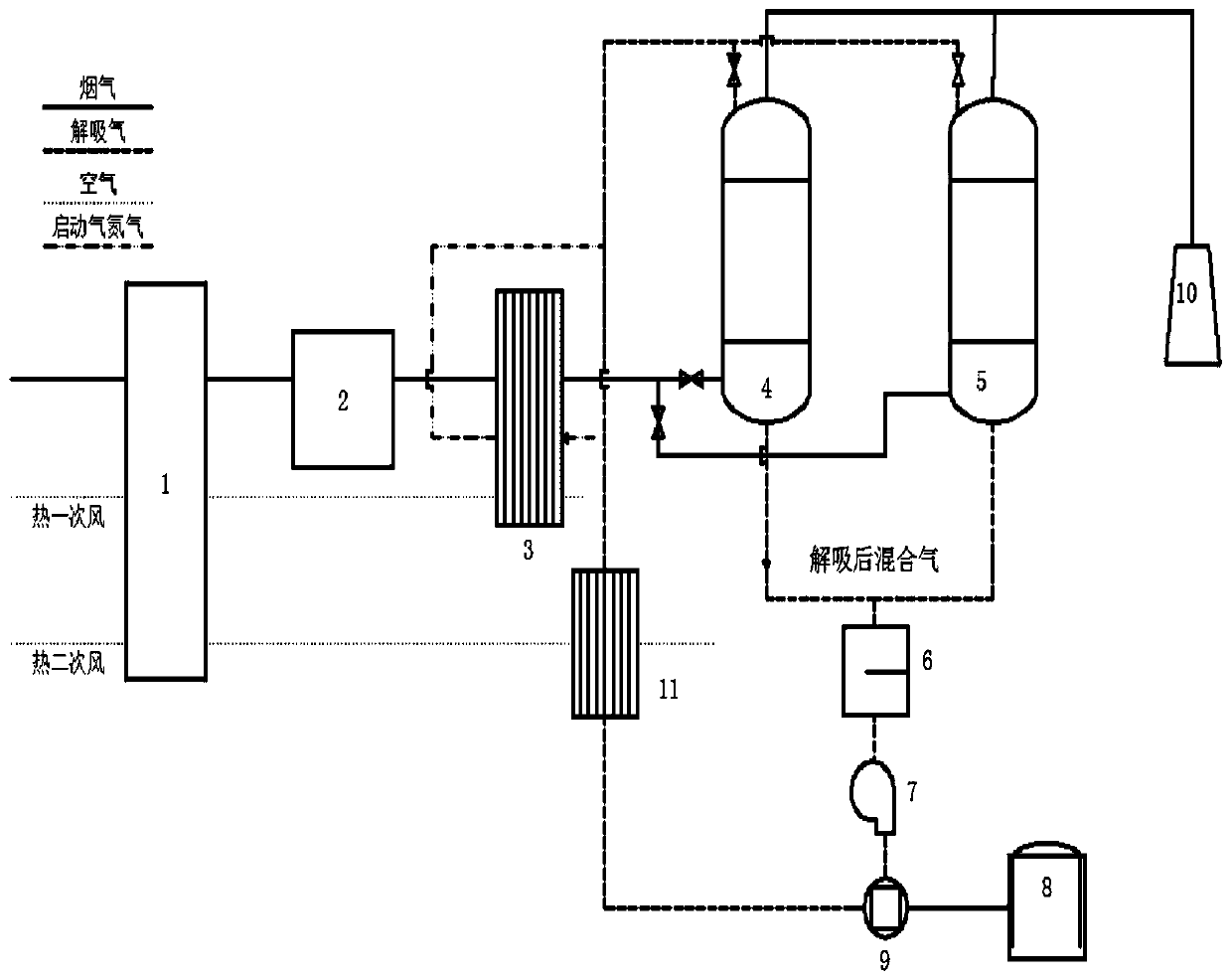

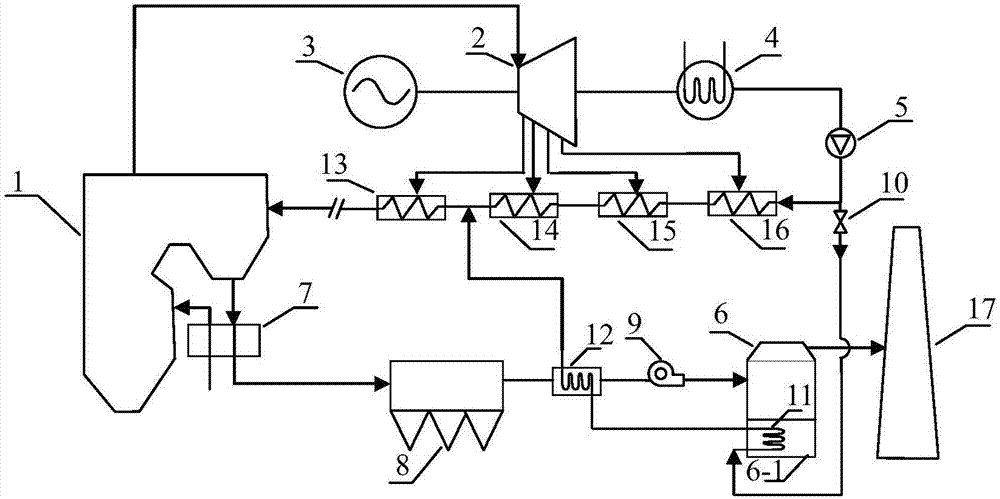

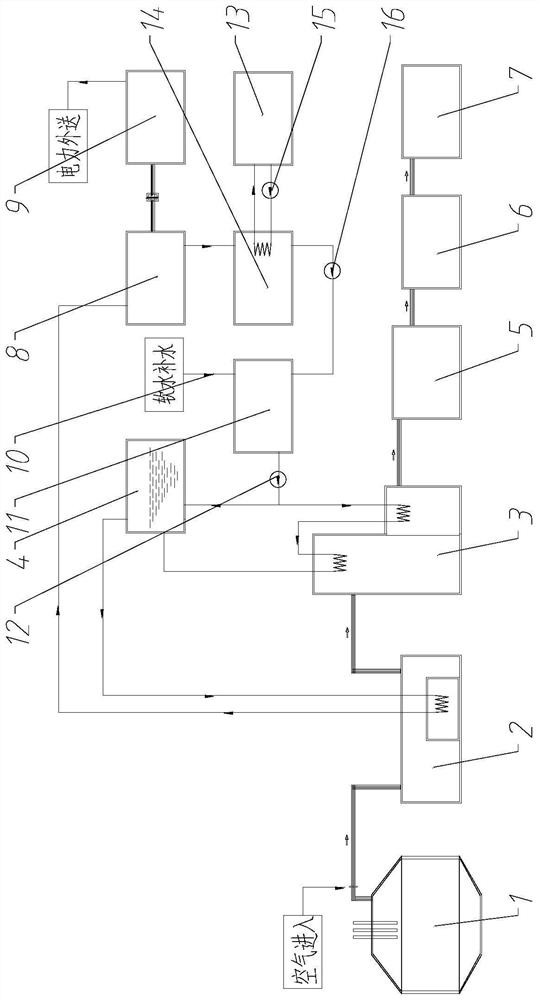

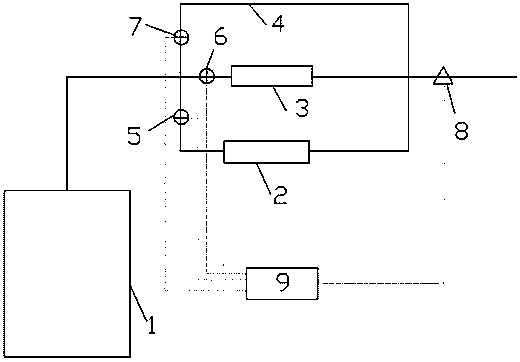

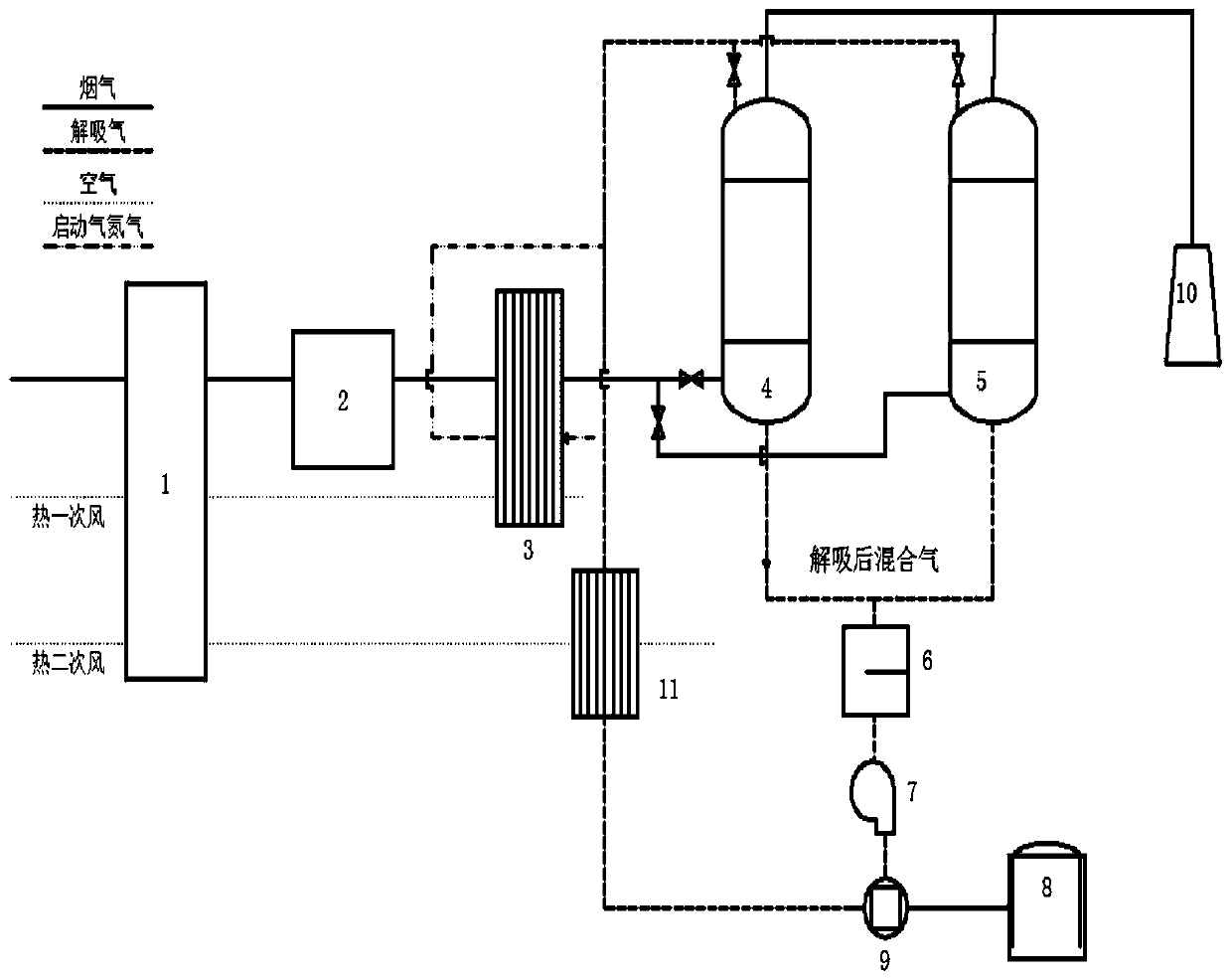

System used for coal-fired power plant waste-heat utilization and desulfuration water saving

PendingCN107062193ADoes not increase flow resistanceFull use of waste heatGas treatmentDispersed particle separationWater savingAir preheater

The invention discloses a system used for coal-fired power plant waste-heat utilization and desulfuration water saving. The system comprises a steam turbine, a first-level heat exchanger, a second-level heat exchanger, a condensate pump and an air pre-heater. The air inlet end of the steam turbine is connected with a boiler, and the exhaust air output end of the steam turbine is connected with the air inlet end of a condenser. The first-level heat exchanger is arranged in an absorption tower slurry pond at the bottom of a desulfuration absorption tower. The second-level heat exchanger is arranged between the desulfuration absorption tower and a dust remover, and the liquid inlet end of the second-level heat exchanger is connected with the liquid outlet end of the first-level heat exchanger. The liquid outlet end of the second-level heat exchanger is connected with an inlet pipeline of a fifth-level low-pressure heater. The air outlet end of the dust remover is connected with the air inlet end of the second-level heat exchanger. An outlet pipeline of the fifth-level low-pressure heater is connected with the boiler. The liquid inlet end of the condensate pump is connected with the liquid outlet end of the condenser, and the liquid outlet end of the condensate pump is connected with the first-level heat exchanger. The air inlet end of the air pre-heater is connected with the boiler, and the air outlet end of the air pre-heater is connected with the air inlet end of the dust remover.

Owner:DATANG ENVIRONMENT IND GRP

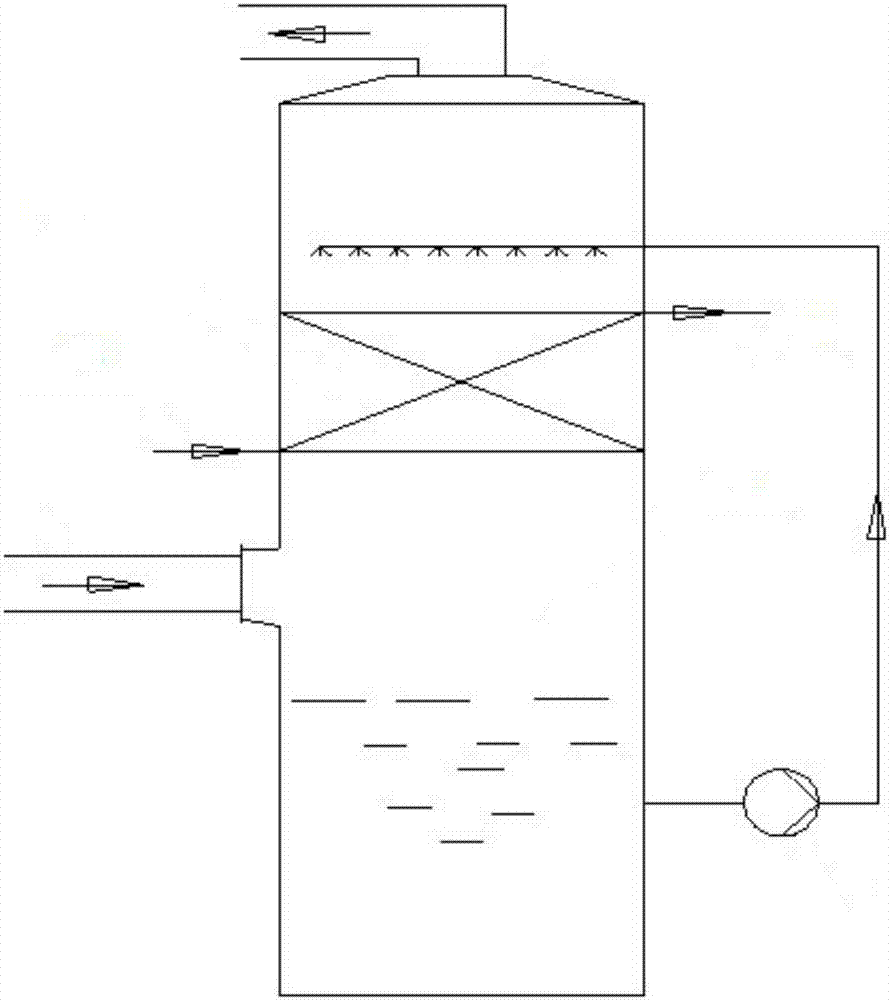

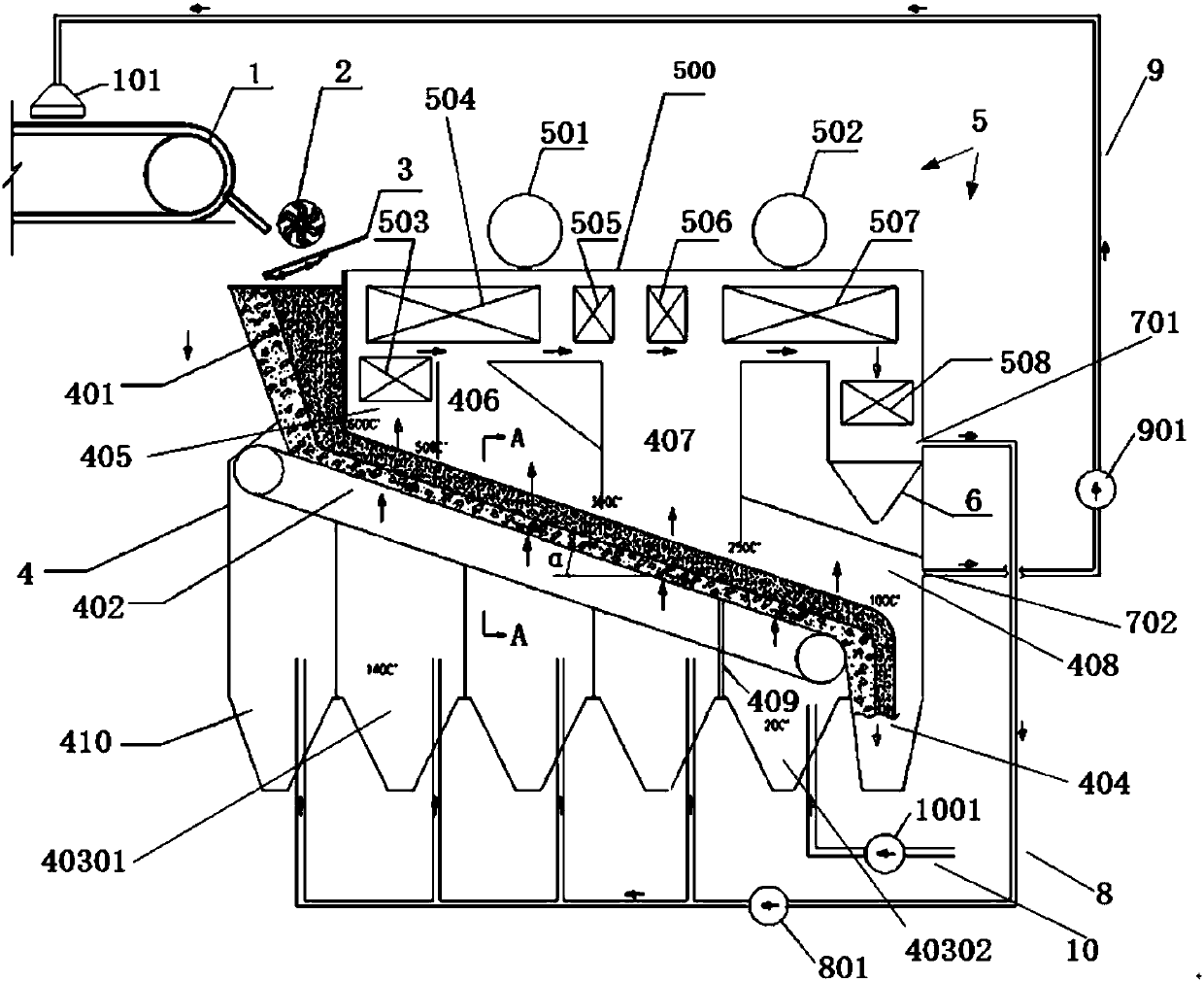

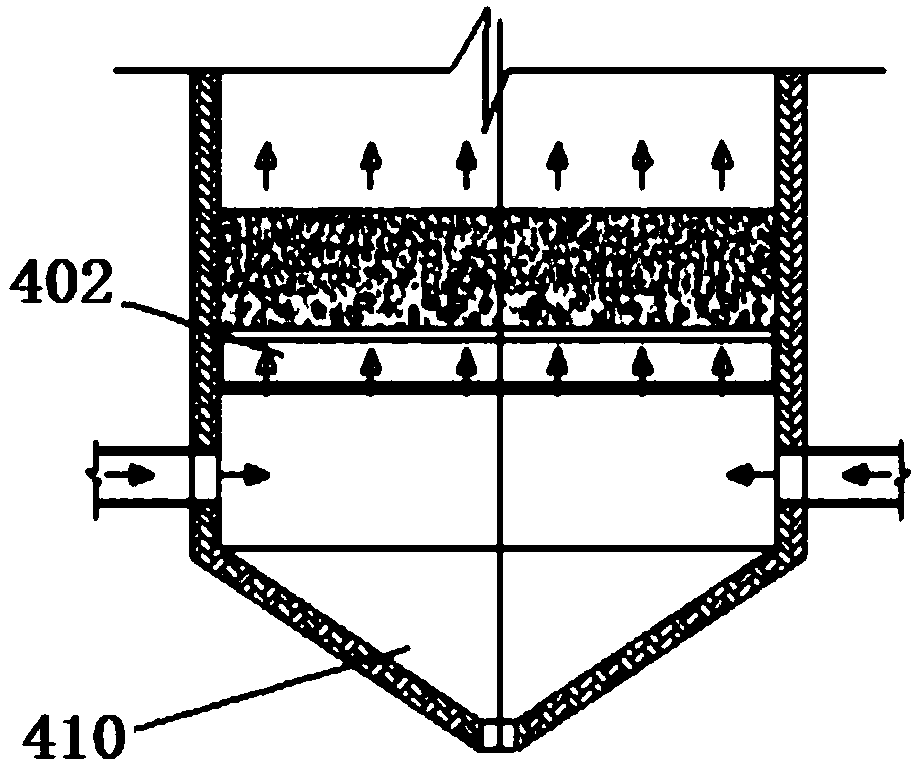

Sintering ore grate furnace cooling and waste heat utilization device and waste heat utilization method

PendingCN107796226ANo pollution in the processOvercome congenital deficienciesHandling discharged materialWaste heat treatmentEngineeringAir blower

The invention relates to a sintering ore grate furnace cooling and waste heat utilization device and waste heat utilization method. The device is sequentially provided with a sintering machine (1), acrusher (2), a hot screen (3) and a grate furnace (4). The grate furnace (4) comprises a feeding opening (401), a fire grate (402), air inlet cavities (403) and a discharging opening (404). High-temperature waste gas above the fire grate is recycled to be utilized through the waste heat utilization device, the utilized waste gas enters the air inlet cavities below the fire grate or an air cover ofthe sintering machine, and a cycle is formed. According to the device and waste heat utilization method, the problems of cooling machine air leaking, waste gas waste heat resource waste and environment pollution in the prior art can be solved, the problem of high power consumption of a vertical tank type cooling air blower can be reduced, and total utilization of sintering ore waste gas waste heat resources can be achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Full-scale electronic and electrical waste continuous pyrolysis incineration device

ActiveCN105509062BInhibitionTo achieve the purpose of volume reductionEmission preventionCombustion technology mitigationEnergy recoverySolvent

The invention relates to a continuous pyrolysis incineration device for full-scale electronic and electrical product waste. The continuous pyrolysis incineration device structurally comprises a feeder, a pulley feed hopper, a pyrolysis gasifier, a pyrolysis gas flue, a combustion furnace, a G-L air heat exchanger, a quenching absorption tower, a bypass flue, a chimney exhaust port, a cat ladder, an activated carbon storage tank and a chimney. The continuous pyrolysis incineration device has the advantages that dangerous electronic and electrical product waste, medical waste, organic waste and other kinds of dangerous combustible solid waste with a certain heat value are treated through a pyrolysis incineration technology, pyrolysis and high-temperature incineration technologies are combined in an optimized mode, low-temperature gas and high-temperature melt are combined together, waste incineration is conducted in the steps of pyrolysis, premixing and incineration, the synthetic technological process and technological conditions of pyrolysis incineration, energy recovery and flue gas cleaning are achieved and have perspectiveness, the overall technology has the outstanding harmless characteristic, compatibility and resourcezation are remarkable, material applicability is high, no hazardous reaction medium or poisonous and harmful solvent is involved in the process, and nature greenization can be achieved.

Owner:NANJING TECH UNIV

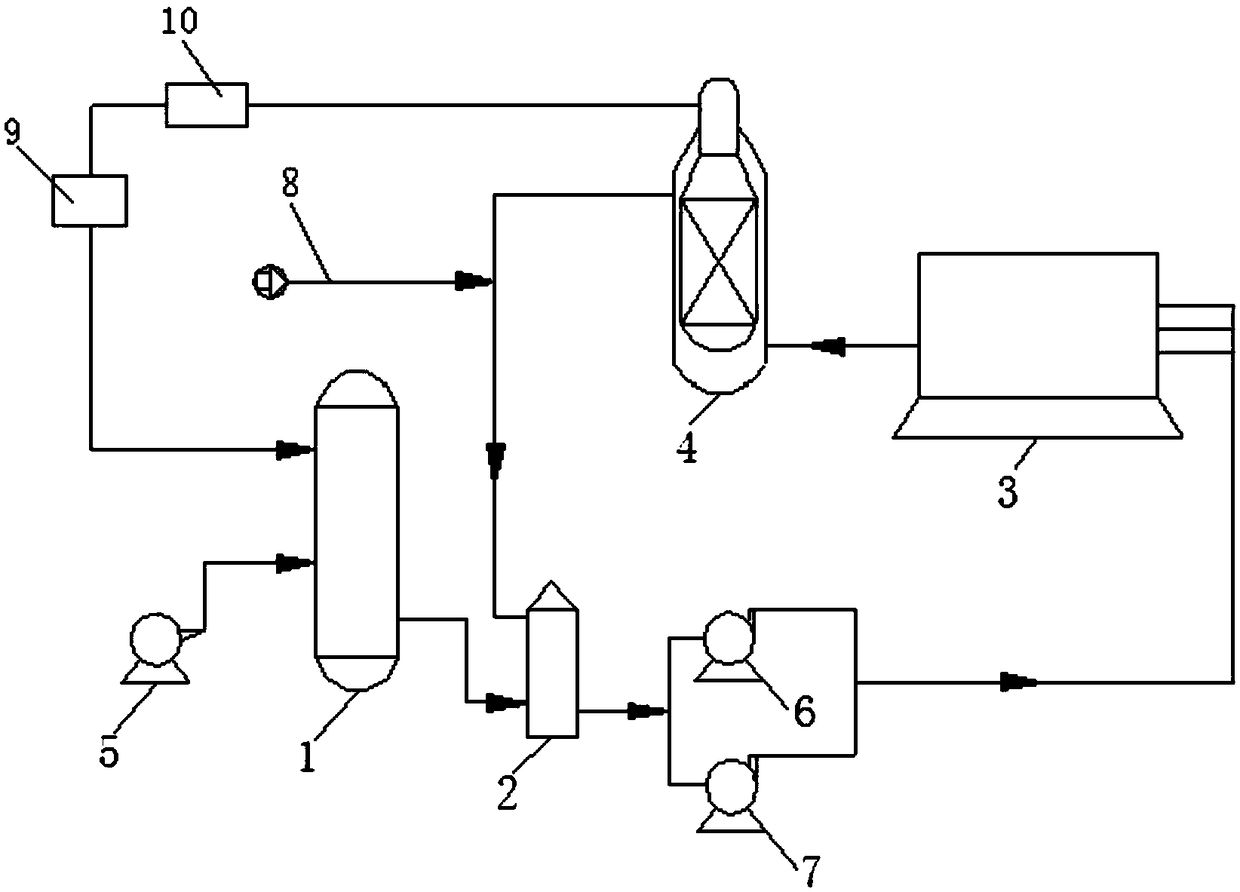

Recycling system for condensate after reforming of methane steam in coke oven gas

PendingCN108854167AEfficient use ofConserve waterLiquid degasification with auxillary substancesOrganic compound preparationVapor–liquid separatorCoke oven

The invention discloses a recycling system for condensate after reforming of methane steam in coke oven gas. The recycling system comprises a reforming furnace, wherein a gas outlet of the reforming furnace is connected to a gas inlet of a gas-liquid separator through a heat exchange unit; a gaseous phase outlet of the gas-liquid separator is used for delivering the coke oven gas to a methanol synthesis workshop through a pipeline; a liquid phase outlet of the gas-liquid separator is connected to a raw material inlet of a stripping tower through a pipeline; a stripping agent inlet of the stripping tower is connected with an air blower through a pipeline; a liquid outlet of the stripping tower is connected to a circulating water system of the reforming furnace so as to provide desalted water for the circulating water system. By combining the stripping tower with the circulating water system, the condensate drained from the gas-liquid separator can be effectively utilized, CO and CO2 inthe condensate are removed, and the condensate is reformed into up-to-standard reforming furnace jacket water; the up-to-standard reforming furnace jacket water enters the circulating water system forrecycling.

Owner:SHANXI HEIMAO JIAOHUA CO LTD

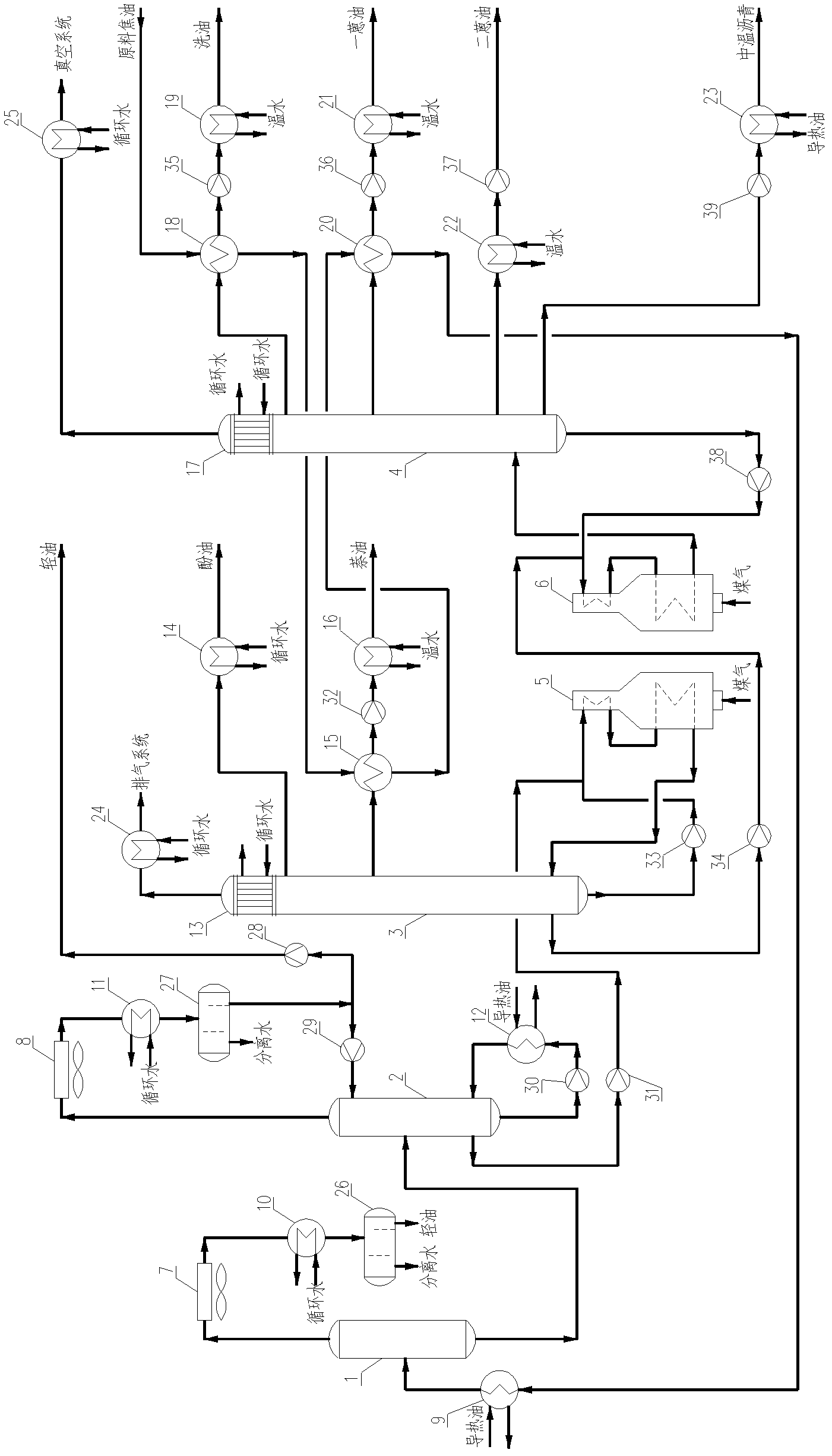

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

ActiveCN101475819BSolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationHeat conductingReboiler

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in aNo.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and thenperforming flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

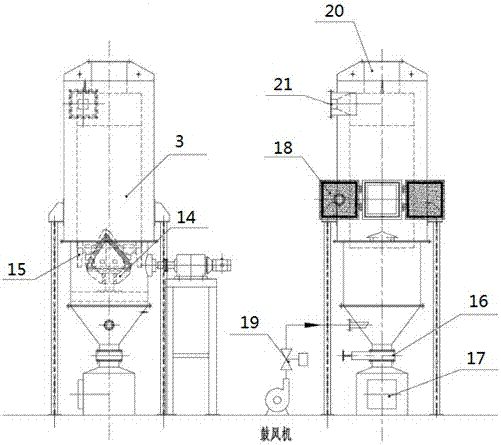

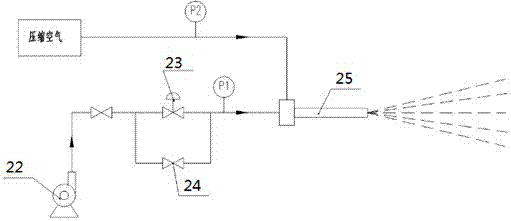

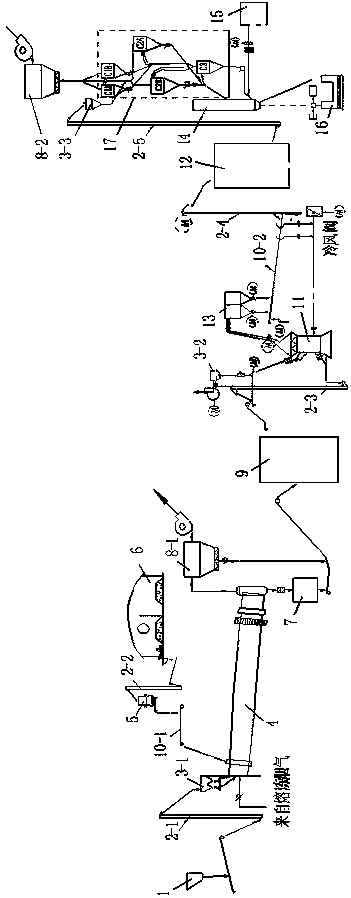

Process and apparatus for dry suspension sintering flash smelting of ferronickel

PendingCN108239708AReduce energy costsImprove production efficiency and social benefitsProcess efficiency improvementFlue gasPower consumption

The invention relates to a process and apparatus for dry suspension sintering flash smelting of ferronickel, belonging to the field of ferronickel production processes and apparatuses. The process comprises the following steps: 1) drying; 2) grinding; 3) multi-stage suspension pre-reduction; 4) sintering reduction; and 5) flash furnace smelting. Flue gas with waste heat from flash furnace successively enters a sintering furnace and a multi-stage suspension pre-reduction system; the heat and a reducing agent in the flue gas act on the links of pre-reduction and sintering reduction, so the wasteheat is utilized, and energy consumption is reduced; and mineral materials in the flue gas settle down in a preheating system and then return to a melting system, so productivity is enhanced and theemissions of pollutants are lowered. Material flow in the whole system operates in a closed loop, and exhaust gas is purified and then discharged after reaching the standard. The apparatus comprises adrying device, a grinding device and a dry suspension sintering device, wherein the drying device, the grinding device and the dry suspension sintering device are sequentially connected. The processand apparatus of the invention has the advantages of low investment cost, obvious energy saving effect, no consumption of electricity and coke, greatly-reduced power consumption, substantially-loweredcost for reducing agents, full utilization of exhaust gas and waste heat and high automation degree.

Owner:徐州贝克福尔节能环保技术有限公司

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

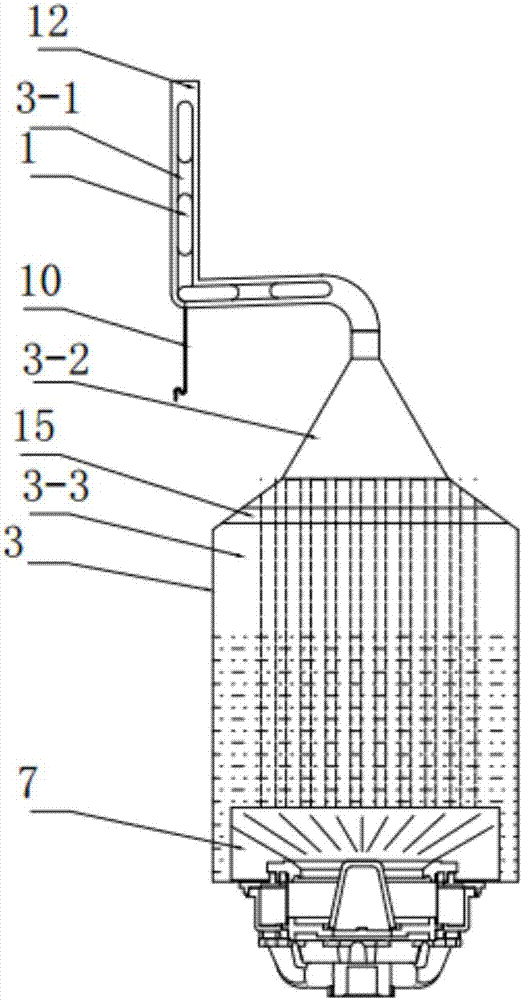

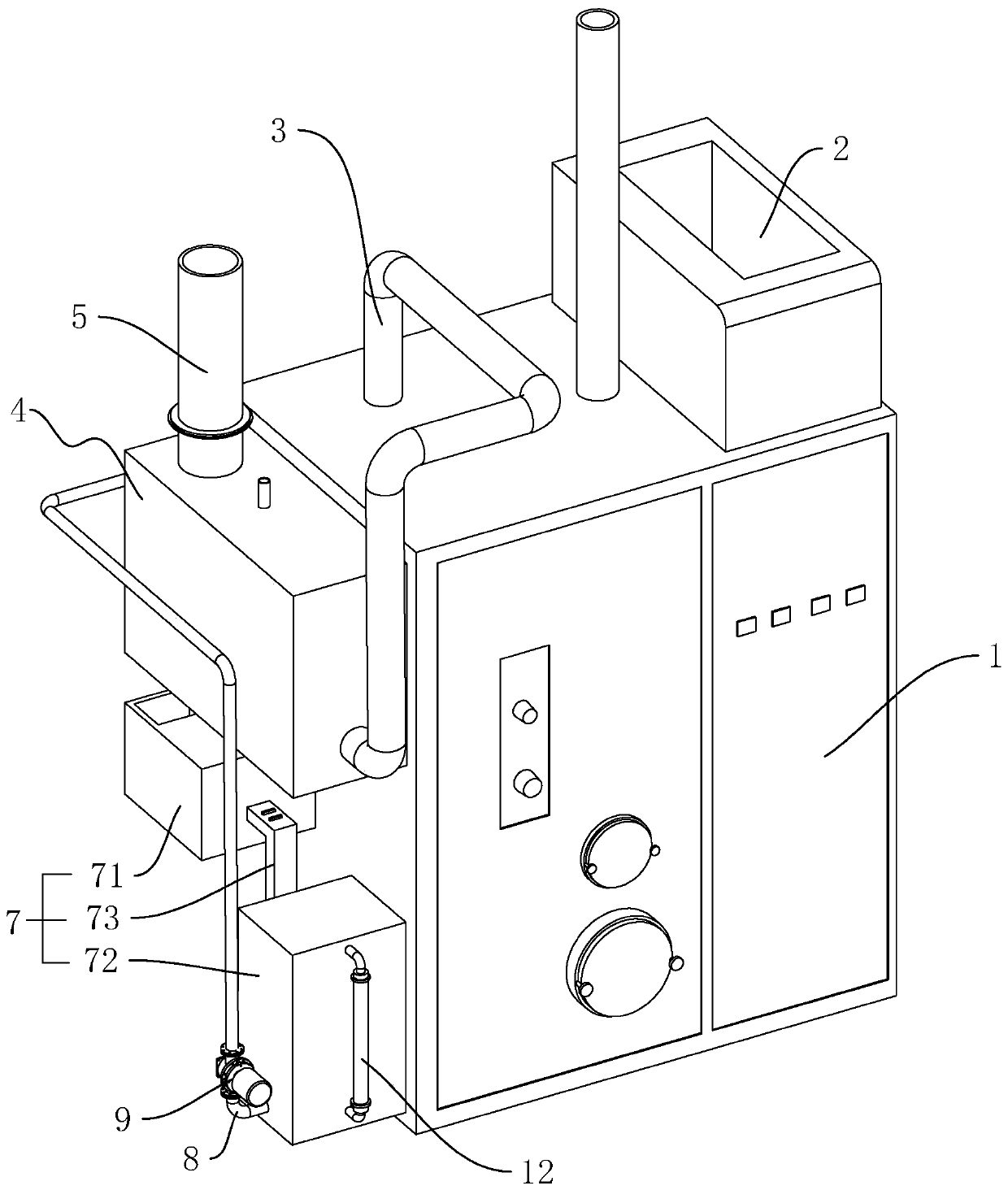

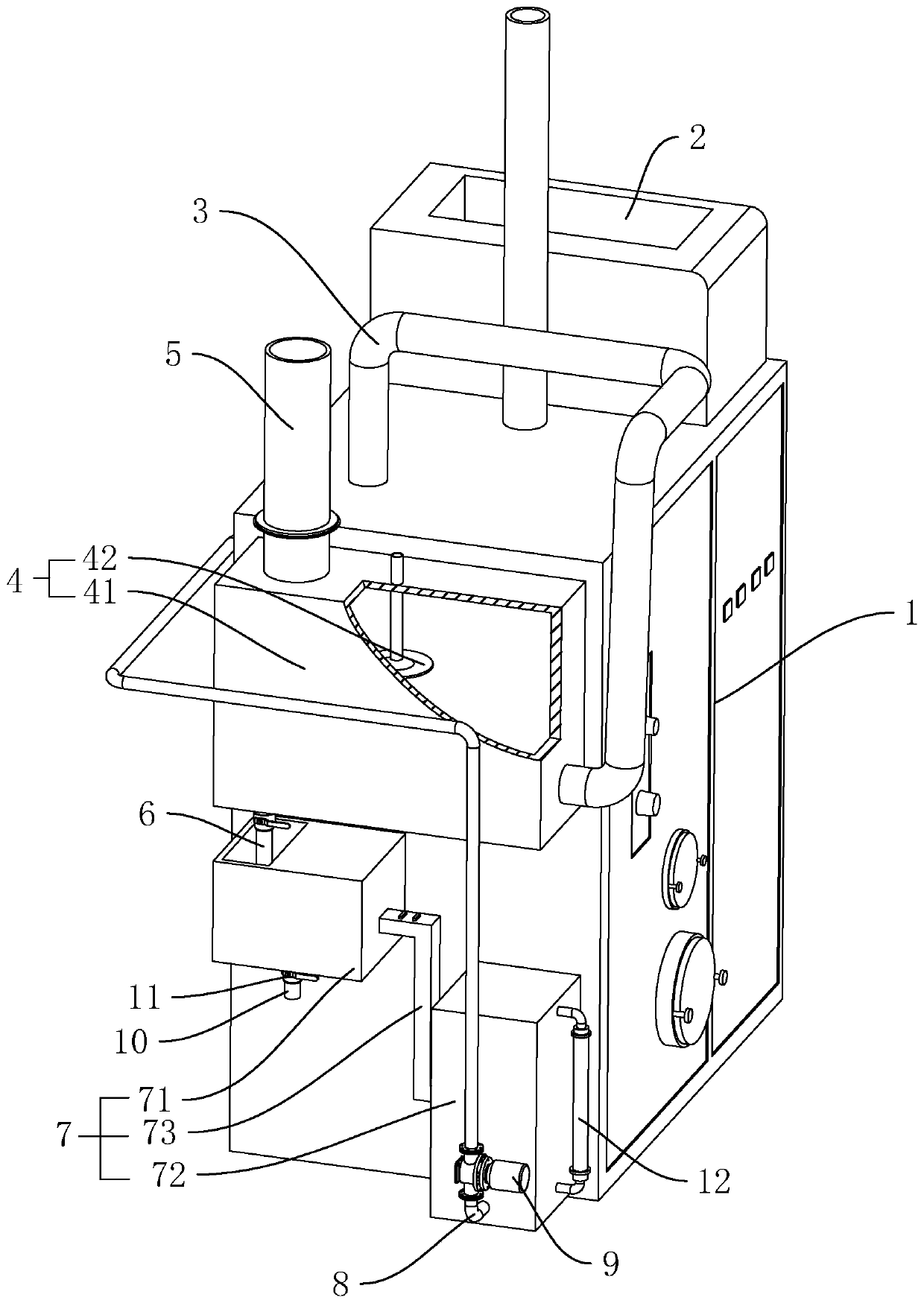

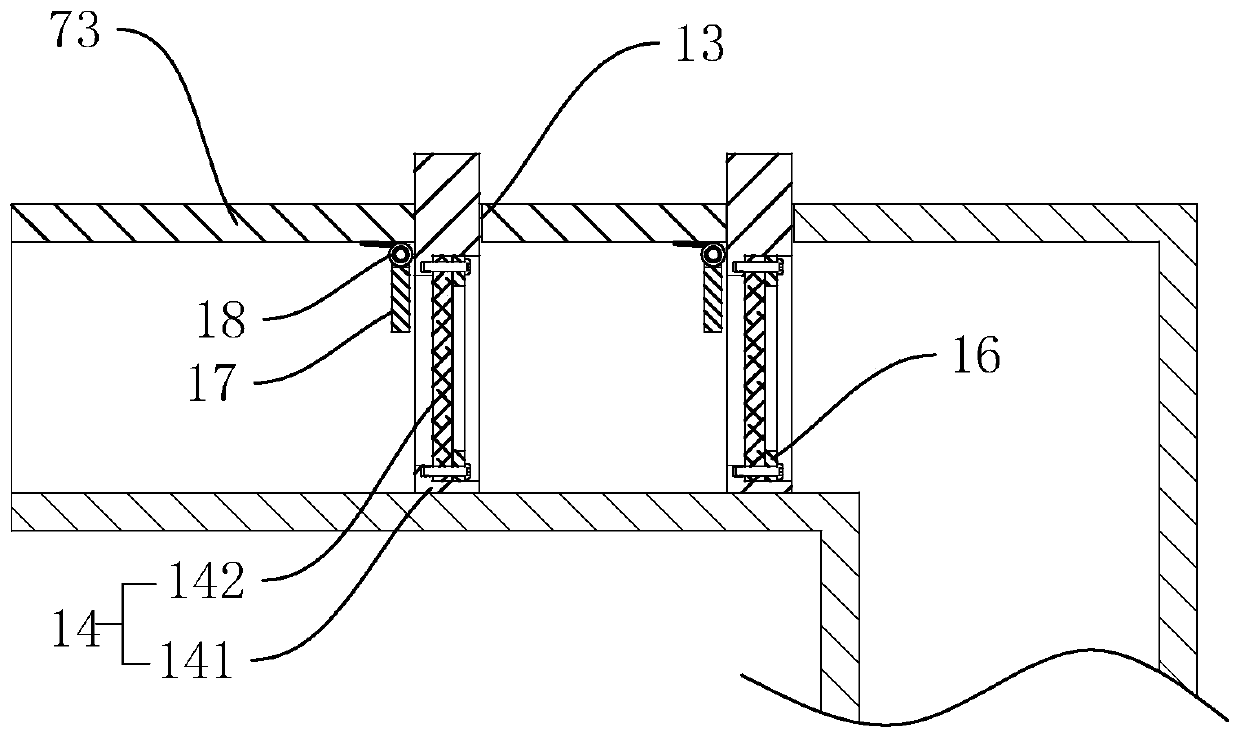

Boiler waste heat utilization water heater

ActiveCN109140480AEasy accessFull use of waste heatCombustion technology mitigationStationary tubular conduit assembliesExhaust fumesEngineering

The invention relates to the field of waste heat utilization, in particular to a boiler waste heat utilization water heater. The boiler waste heat utilization water heater comprises a hopper, a smokeinlet, a water feeding mechanism, first water valves, water pipes, a water box, supporting frames, a box body, a water drainage mechanism, water drainage pipes, second water valves, temperature gauges, a supporting mechanism, supporting rods, a supporting plate, heating mechanisms, first water heating boxes, second water heating boxes, a blocking mechanism, a first fixing plate, a baffle, a secondfixing plate, a smoke outlet and a sealing mechanism. According to the boiler waste heat utilization water heater, the side walls of the two ends of the box body are provided with the smoke inlet andthe smoke outlet correspondingly, the heating mechanisms distributed in a staggered mode are installed in the box body, waste gas enters the box body to make sufficient contact with the heating mechanisms, and thus, heat in the waste gas enters the heating mechanisms; and the side wall of the box body is rotationally connected with the sealing mechanism, the sealing mechanism is rotated so that the interior of the box body can be opened, the hopper is installed at the bottom end of the box body, dust inside the box body is removed through a shovel, and accordingly, dust in the box body and dust on the side walls of the heating mechanisms are discharged from the hopper.

Owner:安徽原上草节能环保科技有限公司

Electric furnace steelmaking flue gas efficient power generation system

PendingCN114777510AIncrease temperatureTemperature balanceLiquid degasificationSteam generation using hot heat carriersSteelmakingFlue gas

The invention relates to the technical field of electric furnace steelmaking, and provides an electric furnace steelmaking flue gas efficient power generation system which comprises a steelmaking electric furnace, a combustion settling chamber, a waste heat boiler, a pressure stabilizing energy accumulator, a flue gas treatment system and a power generation system. The heat accumulator is arranged in the combustion settling chamber, the superheater is arranged in the heat accumulator, the steelmaking electric furnace, the combustion settling chamber, the waste heat boiler and the flue gas treatment system are sequentially connected, the input end of the pressure stabilizing energy accumulator is connected with the steam output end of the waste heat boiler, and the output end of the pressure stabilizing energy accumulator is connected with the input end of the superheater. The output end of the superheater is connected with the power generation system. By means of the technical scheme, the problem that in the electric furnace steelmaking process in the prior art, due to the characteristic of periodical fluctuation of flue gas, flue gas waste heat cannot be recycled and reused is solved.

Owner:河北煜剑节能技术有限公司

Biomass steam generator

InactiveCN110793008AReduce entryFull use of waste heatUsing liquid separation agentSteam generation using pressureWater storageCombustion chamber

The invention discloses a biomass steam generator, and relates to the field of boilers. The biomass steam generator comprises a rack, a furnace body of a biomass combustion chamber arranged in the rack, a boiler body heated on the furnace body and a steam chamber, wherein the steam chamber is positioned at the top end of the boiler body and communicates with the boiler body; a feeding port and a smoke discharging pipe further communicate with the furnace body and are arranged on the furnace body; a dust removing and filtering device is arranged on the side wall of the rack, and the dust removing and filtering device comprises a filtering box fixedly connected to the rack and a water spraying assembly arranged in the filtering box; the water spraying assembly communicates with a water source through a water inlet pipe; the smoke discharging pipe communicates with the position, close to the bottom, of the filtering box; a water storage box is arranged below the filtering box; the bottomof the filtering box is connected with a water discharging pipe for discharging water to the water storage box; and an air outlet pipe is arranged at the top of the filtering box. Through the arrangement of the dust removing and filtering device, the situation that dust enters the outside air is reduced through the water spraying assembly, so that the influence of the dust in the smoke on the environment is reduced.

Owner:ZHEJIANG RUYI IND

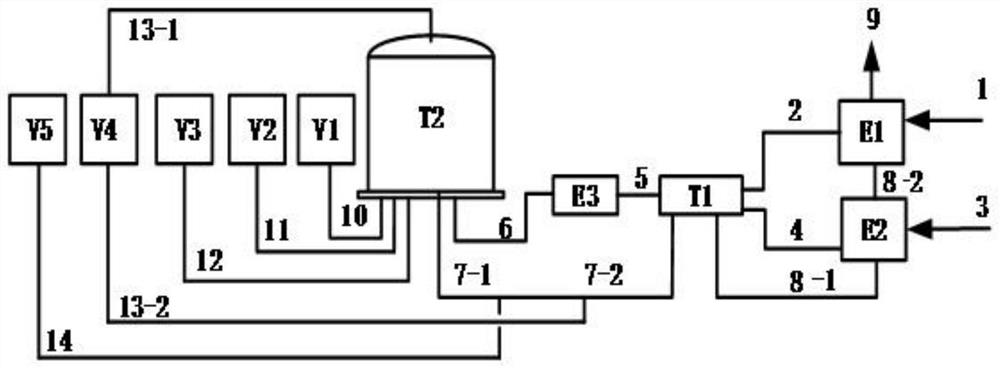

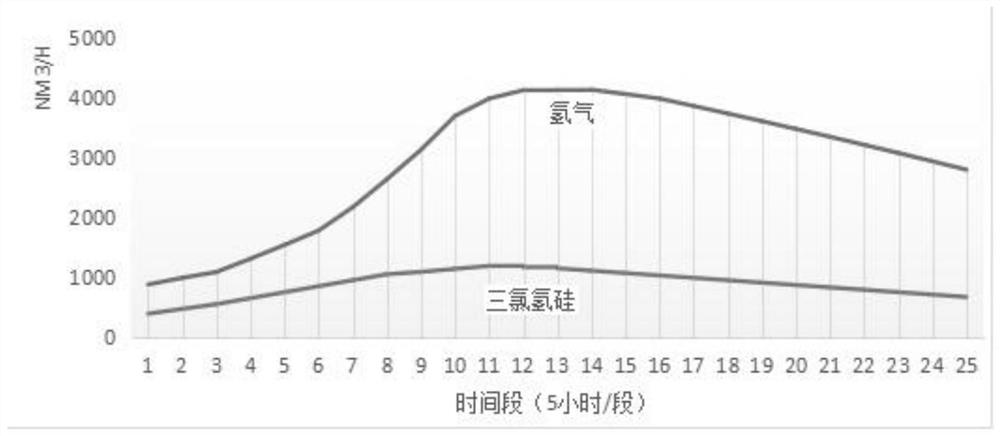

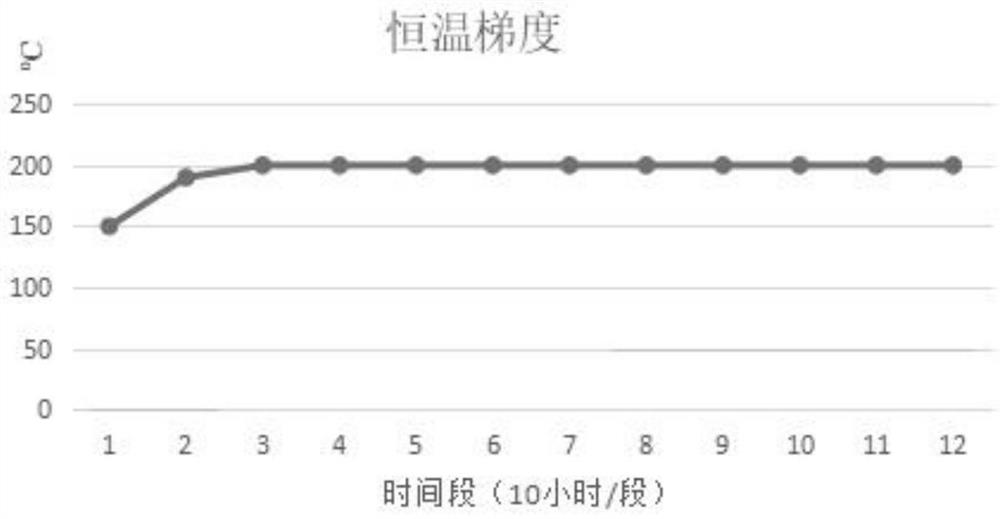

Production and reduction process of polycrystalline silicon

PendingCN114735706AImprove deposition efficiencyImprove heat recovery efficiencyEnergy inputSilicon compoundsPhysical chemistryProcess engineering

The invention relates to a production and reduction process of polycrystalline silicon. A production reduction process of polycrystalline silicon comprises the following steps: (1) conveying trichlorosilane to an E1 module through a pipeline 1, heating the trichlorosilane to 60-100 DEG C, and conveying the trichlorosilane to a T1 module through a pipeline 2; hydrogen is conveyed to the E2 module through a pipeline 3, and is conveyed to the T1 module through a pipeline 4 after being heated to 100-180 DEG C; and (2) mixing the trichlorosilane and the hydrogen in the module T1, conveying the trichlorosilane and the hydrogen to a module E3 through a pipeline 5, conveying the trichlorosilane and the hydrogen to a module T2 through a pipeline 6 for thermal deposition, and recycling waste heat. According to the production reduction process of the polycrystalline silicon, heat is utilized through continuous coupling, heat energy of the polycrystalline silicon is utilized to the maximum extent, a whole set of process system with the lowest energy consumption is provided in the efficient reduction production link of the polycrystalline silicon, and a whole set of complete circulating energy-saving control scheme is provided.

Owner:XINJIANG DAQO NEW ENERGY

Waste heat collecting cover of cooking range

InactiveCN105910145APrevent overheatingIncrease profitLighting and heating apparatusWater heating stoves/rangesWater sourceIsolation layer

The invention discloses a waste heat collecting cover of a cooking range. The waste heat collecting cover comprises a collecting cover body, an isolation layer and a heat exchange water pipe; the top and the bottom of the collecting cover body are each provided with an opening, and the opening in the top of the collecting cover body is sealed through a heating body; the opening in the bottom of the collecting cover body, and the collecting cover body is placed on the cooking range; the isolation layer is arranged in the collecting cover body to separate space in the collection cover body into a heating area and a waste heat collecting area, and a fire spraying opening of the cooking range is placed in the heating area; the top of the heating area and the top of the waste heat collecting area are communicated, and waste heat for the heating area enters the waste heat collecting area from the top of the heating area; the heat exchange water pipe is arranged in the waste heat collecting area; and the heat exchange water pipe is arranged around the isolation layer, one end of the heat exchange water pipe stretches out of the collecting cover body to be communicated with a water source, and a discharging opening controlled by a valve is formed in the position, arranged on the collecting cover body, of the other end of the heat exchange water pipe.

Owner:马志强

Rotary cement kiln waste heat utilization system with multistage heat accumulation system

InactiveCN104266481AAvoid Low Temperature CorrosionMeet heat storage needsRotary drum furnacesIncreasing energy efficiencyThermodynamicsProcess engineering

Owner:山东省能源与环境研究院

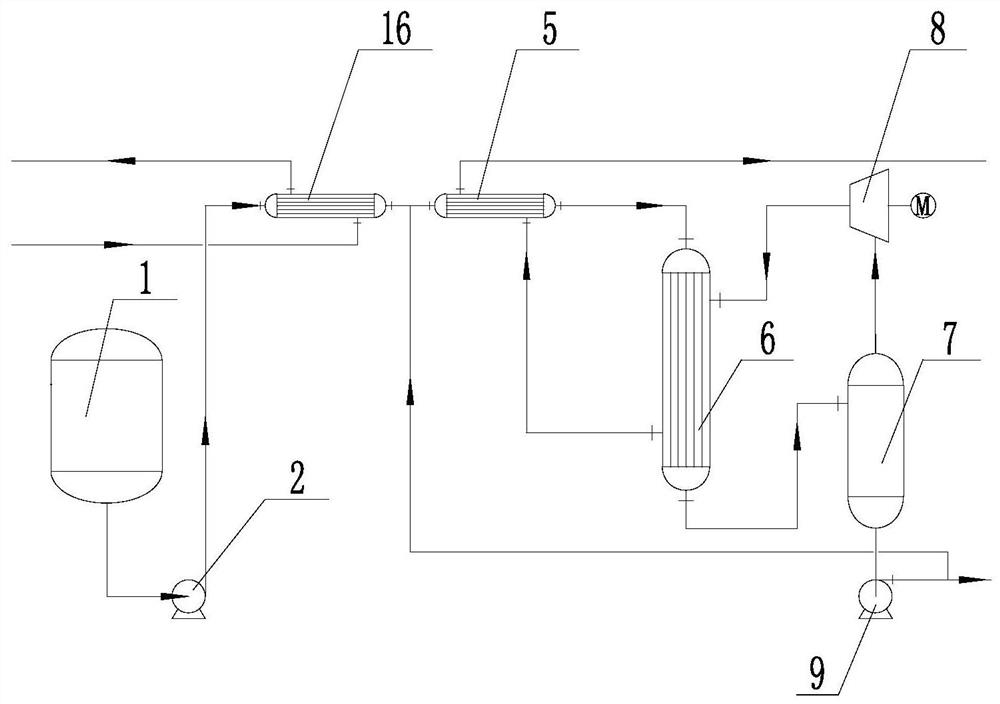

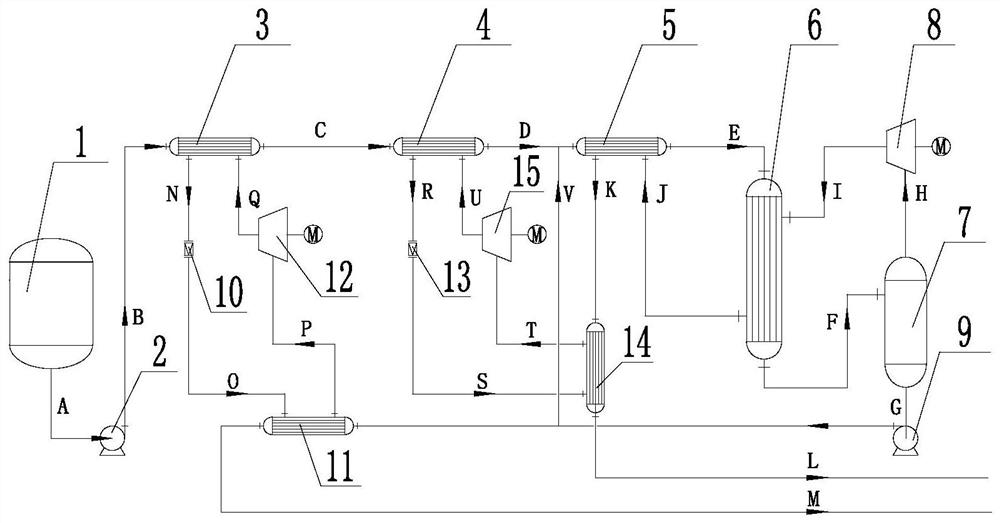

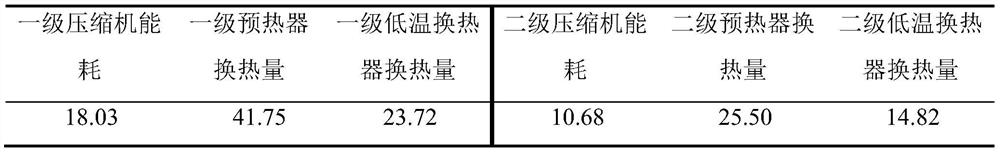

MVR coupled heat pump evaporative concentration system and evaporative concentration method

ActiveCN110193211BImprove energy utilizationRealize cascade utilizationHeat pumpsEvaporation with vapour compressionHeat pumpWaste management

The invention belongs to the technical field of energy saving and environmental protection, and in particular relates to an MVR coupling heat pump evaporation concentration system and an evaporation concentration method. The MVR coupling heat pump evaporation and concentration system includes the MVR system. The MVR system includes the raw material tank, the raw material preheater, the MVR waste heat recovery device, the MVR evaporator and the MVR two-phase separator. The heat pump system is used instead of the raw material preheater. The heat pump system Coupling between raw material tank and MVR waste heat recovery device. In the present invention, the logistics leaving the system undergoes sufficient heat exchange, recovering waste heat in the logistics as much as possible, and improving the energy utilization rate of the coupling system.

Owner:SHANDONG UNIV OF TECH

A flue gas carbon-based loaded ionic liquid flue gas desulfurization method

ActiveCN110174020BMake full use of waste heatFull use of waste heatEmission preventionIndirect heat exchangersThermodynamicsFlue gas

The invention provides an asymmetrically arranged heat exchanger, the heat exchanger includes a header, and left and right coils are distributed on the left and right sides of the header. The coils are arranged at intervals, a right coil is arranged between two adjacent left coils, and a left coil is arranged between two adjacent right coils. The heat exchanger designed in the present invention can enhance heat exchange and remove dust deposits at different heights, and enhance the effects of heat exchange and dust removal.

Owner:SHANDONG UNIV

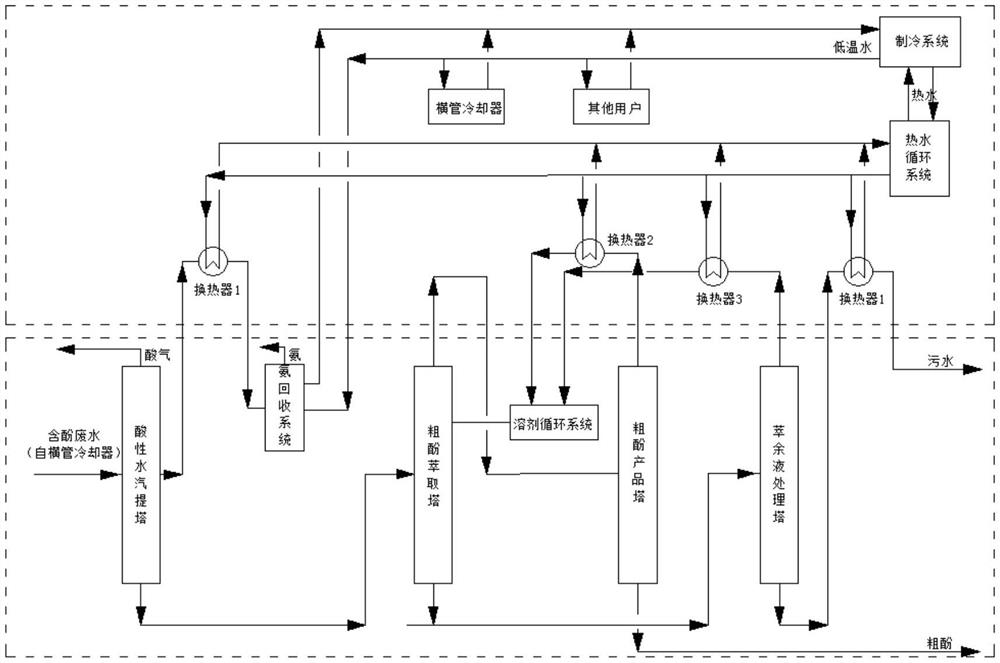

Waste heat utilization device of phenol ammonia recovery system

PendingCN111811163ACompact structureReasonable workmanshipClimate change adaptationEnergy inputProcess engineeringEnvironmental engineering

The invention relates to a waste heat utilization device of a phenol ammonia recovery system. The waste heat utilization device of the phenol ammonia recovery system comprises a phenol ammonia recovery device and a waste heat utilization device body, wherein the phenol ammonia recovery device comprises a horizontal pipe cooler, a sour water stripping tower, an ammonia recovery system, a crude phenol extraction tower, a solvent circulation system, a crude phenol product tower and a raffinate treatment tower, and the waste heat utilization device body comprises a hot water circulation system, afirst heat exchanger, a second heat exchanger, a third heat exchanger, a fourth heat exchanger and a refrigerating system. The waste heat utilization device of the phenol ammonia recovery system is compact in structure, reasonable in process and sufficient in waste heat utilization, can achieve the purposes of energy conservation and efficiency improvement, can be transformed on similar devices, reduces the operating cost of the devices and improves economic benefits.

Owner:查都(海南)科技有限公司

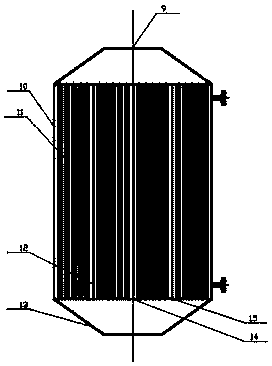

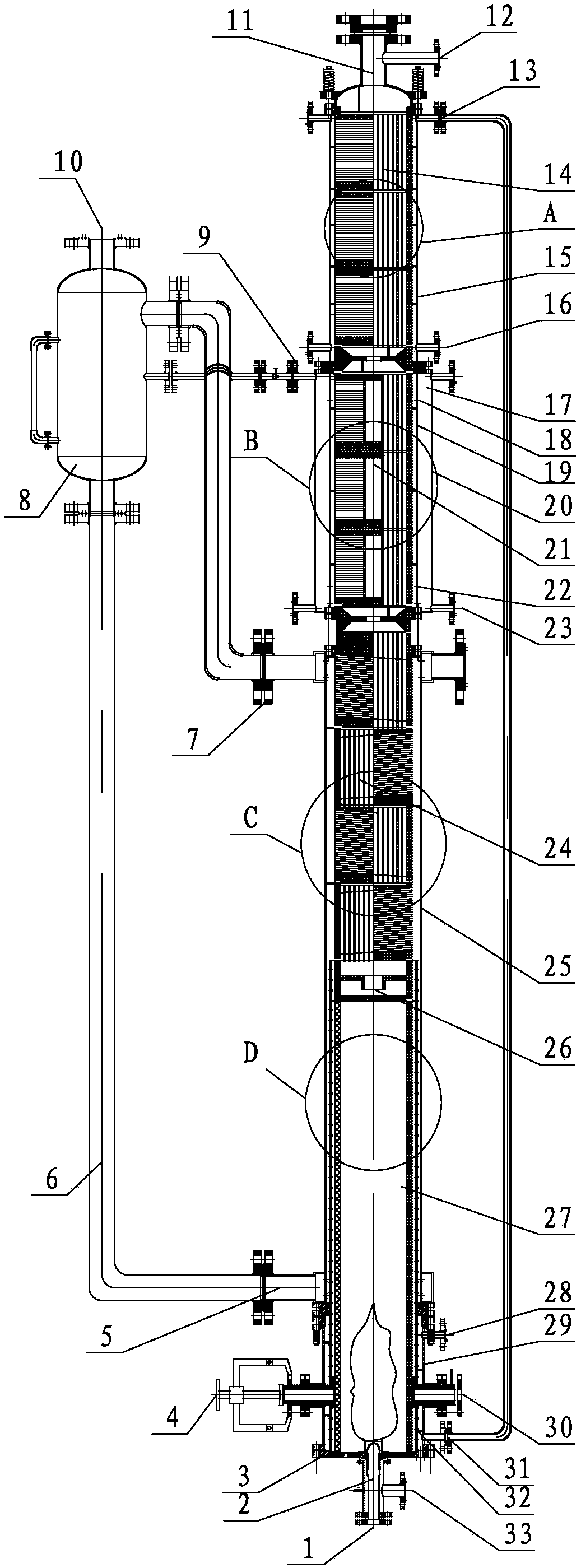

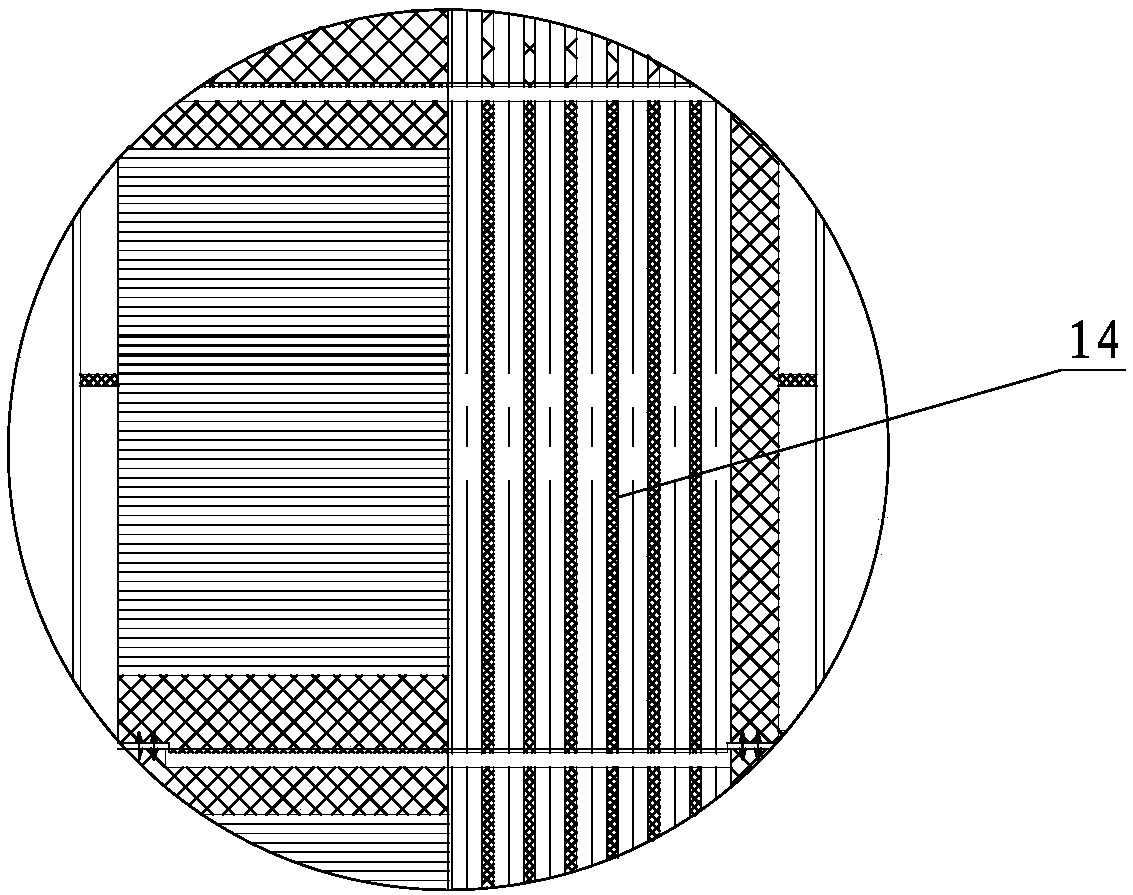

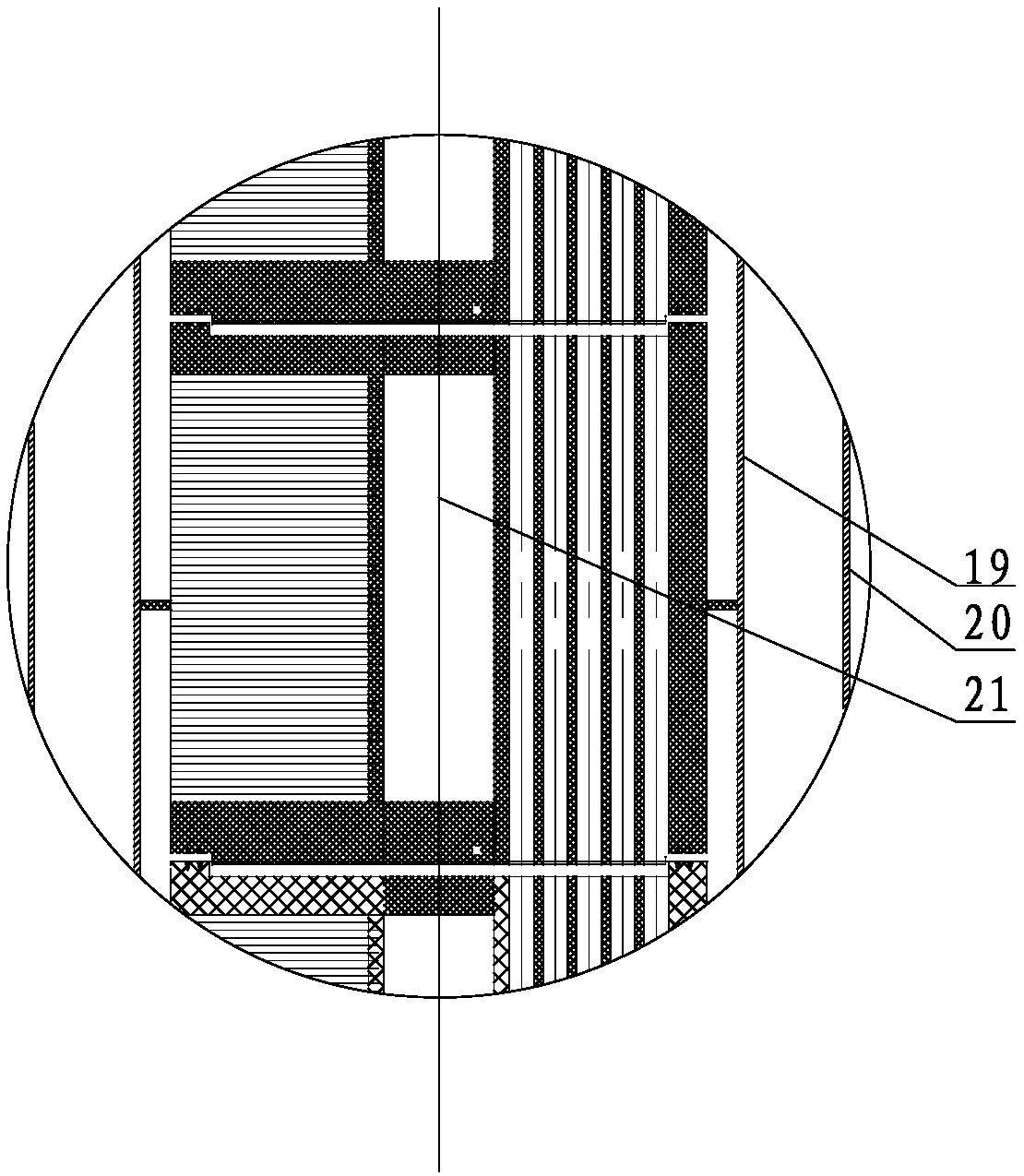

By-product steam hydrogen chloride graphite synthesis furnace with economizer

The invention is mainly applied in the technical field of hydrogen chloride synthesis, and in particular relates to a byproduct steam hydrogen chloride graphite synthetic furnace provided with a coal economizer. The byproduct steam hydrogen chloride graphite synthetic furnace provided with the coal economizer comprises a graphite furnace cylinder and a steam pocket, wherein a gas remixer is arranged in the top of the graphite furnace cylinder; an evaporation structure section, a coal economizer section and a cooling structure section which are hermetically connected are arranged at the top of the gas remixer sequentially from bottom to top; the upper part and the lower part of an evaporation section metal structure cylinder body are connected in series with the steam pocket through circulating pipelines; an integrated furnace bottom seal head is arranged at the bottom of the graphite furnace cylinder; a premixing type synthetic furnace lamp holder is arranged on the integrated furnace bottom seal head; an integrated furnace top seal head is arranged at the top of the cooling structure section; and a hydrogen chloride outlet is formed in the integrated furnace top seal head. According to the byproduct steam hydrogen chloride graphite synthetic furnace with the coal economizer, heat energy carried by the hydrogen chloride can be recovered to be used for preheating deionized water of the byproduct steam, the waste heat is utilized more completely and the heat utilization rate is increased; meanwhile, the hydrogen chloride is further cooled, the cooling load is reduced, and the advantages of energy conservation, consumption reduction, complete utilization of the waste heat and high heat utilization rate.

Owner:山东赫达集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com