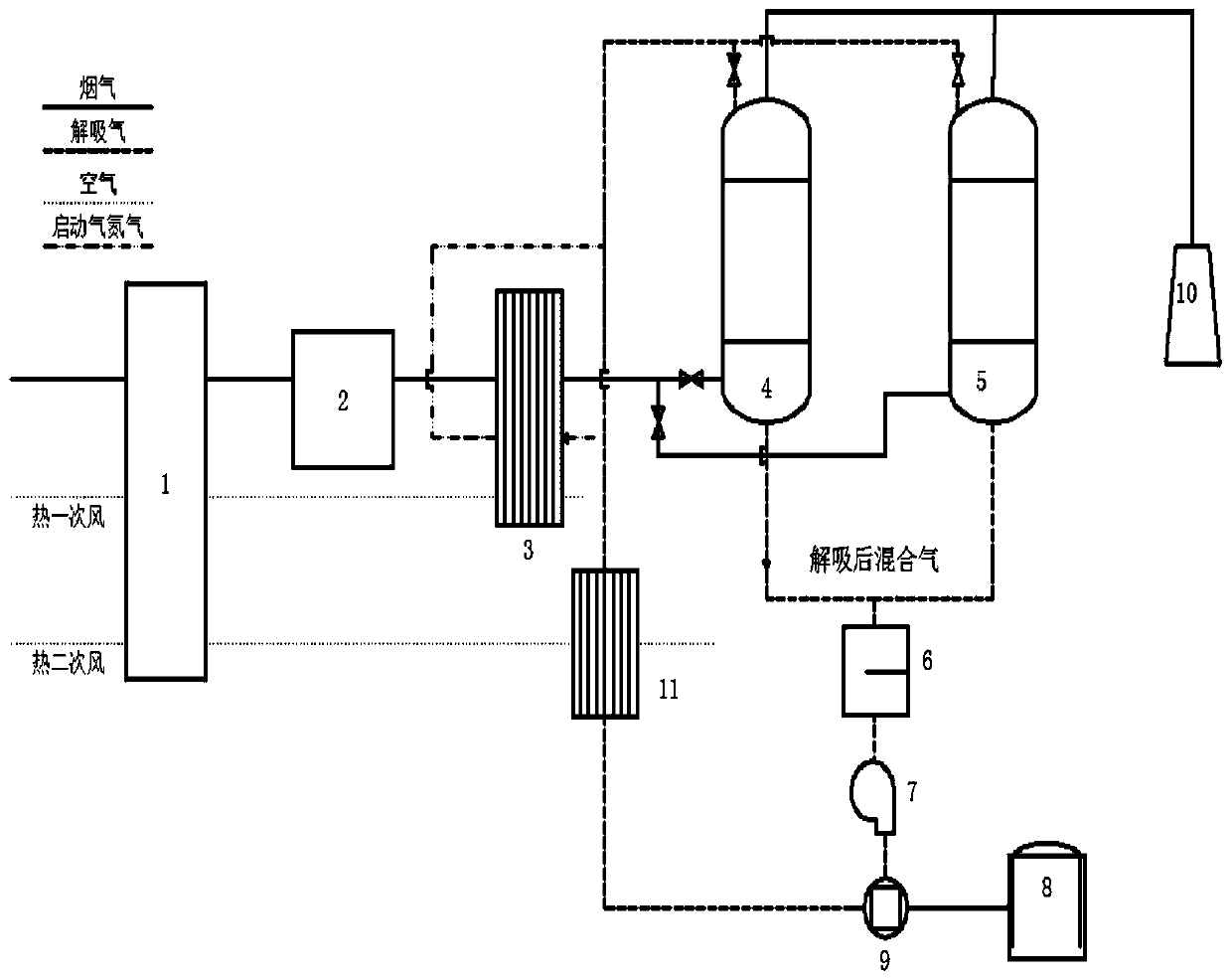

A flue gas carbon-based loaded ionic liquid flue gas desulfurization method

An ionic liquid and flue gas technology, applied in combustion methods, greenhouse gas reduction, climate sustainability, etc., can solve the problems of high regeneration and replacement costs of desulfurizers, low volatility electrochemical windows, and increased desulfurization operating costs, etc. Achieve stable and economical, fast gas absorption rate, and strengthen the effect of dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0053] Example 1: The ionic liquid used was synthesized under the action of microwaves. The ratio of triethanolamine and acetic acid was 1.2:1. After synthesis, activated carbon or silica gel was used for loading by impregnation. The loading ratio was 0.75:1, and then the ionic liquid was realized by evaporation and drying. load;

example 2

[0054] Example 2: The ionic liquid used was synthesized under the action of microwaves, the ratio of triethanolamine and acetic acid was 1.2:1, and after synthesis, 80-120 mesh activated carbon was used for loading by impregnation. The load ratio is 0.75:1, accurately weigh 7.5g of ionic liquid and dissolve it in 30ml of absolute ethanol, put 10g of 80-100 mesh activated carbon into it, keep stirring and gradually raise the temperature to 90°C, when most of the solvent is evaporated , put the loaded activated carbon into a drying oven at 50°C and dry until particles appear.

[0055] Take 2g of loaded activated carbon and place it in the reactor, pass through the simulated flue gas, and carry out the adsorption experiment at 40°C, and the loaded activated carbon is penetrated for about 7 hours.

example 3

[0056] Example 3: The ionic liquid used was synthesized under the action of microwaves, the ratio of triethanolamine and acetic acid was 1.2:1, and after synthesis, 60-80 mesh was used for loading by impregnation. The loading ratio is 0.75:1. Accurately weigh 7.5g of ionic liquid and dissolve it in 30ml of absolute ethanol. Put 10g of activated carbon into it, stir continuously and gradually raise the temperature to 90°C. When most of the solvent is evaporated, put the loaded The silica gel was dried in a drying oven at 50°C until particles appeared.

[0057] Take 2g of loaded activated carbon and place it in the reactor, pass through the simulated flue gas, and conduct the adsorption experiment at 40°C. The adsorption is complete in about 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com