Medium phase-change energy-storage thermoelectric power generating system

A technology of thermoelectric power generation and medium phase change, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems that the temperature of the cold end cannot be effectively lowered, cannot be widely popularized and applied, and the power generation efficiency is not high, so as to improve energy utilization efficiency and structure Compact size and long power generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below.

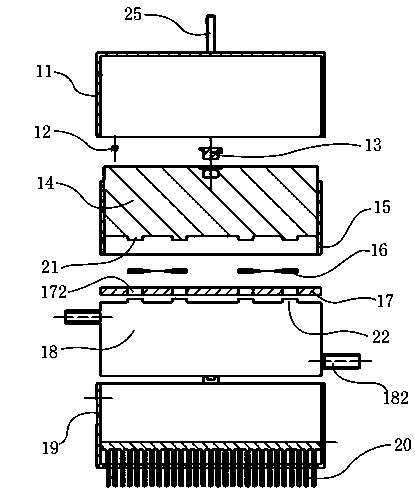

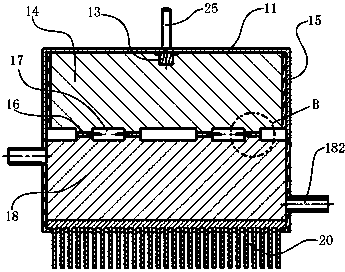

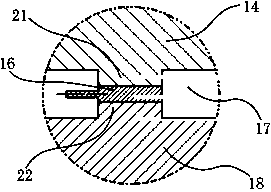

[0018] like Figure 1 to Figure 5 As shown, a medium phase change energy storage thermoelectric power generation system of the present invention uses molten salt as the phase change medium. The heat preservation cover 15 between the hood 11 and the molten salt energy storage device 14, the casing 19 that is connected to the hood 11 to form a chassis, the heat exchange tank 18 located in the casing 19, The fin radiator 20 located at the bottom of the casing 11 and partially protruding from the casing 11, the heat insulation layer 17 between the molten salt energy storage device 14 and the heat exchange tank 18, and the heat insulation layer embedded 17 and placed between the molten salt energy storage device 14 and the heat exchange tank 18, the temperature difference power generation chip 16, the insulation cover 15 is made of insulation materials surrounding the molten salt energy storage device 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com