Associated melamine from carbon ammonium through technique of two-step method under normal pressure

A technology of melamine and step method, which is applied in the field of two-step ammonium bicarbonate co-production process of melamine under normal pressure, can solve problems such as complex operation process, and achieve good economic benefits, low production cost, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

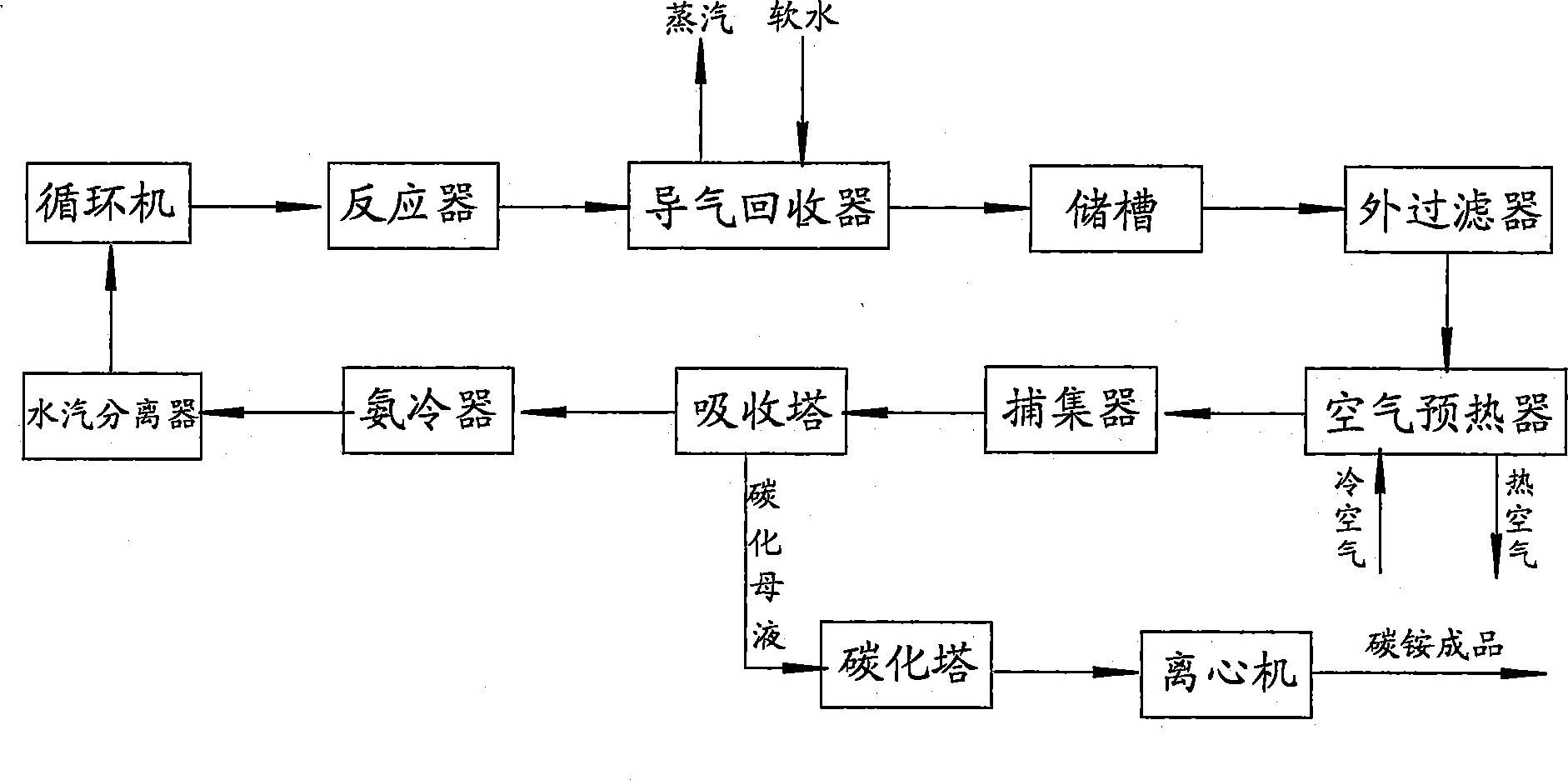

[0020] The process flow of the present invention is as follows: the raw material urea is blown into the reactor by gas ammonia, and the gas ammonia sent from the circulator is preheated to 350-400 ° C, and then the catalyst is blown to fluidize from the bottom of the reactor, and the catalyst is blown into a fluidized state at 385-400 ° C. At 395°C, urea reacts in the reactor to generate melamine. The reactant comes out from the top of the reactor and enters the air guide absorber with the circulating gas to exchange heat with softened water to generate steam. After the catalyst dust is removed by the external filter, it enters the air for preheating The collector further exchanges heat with the cold air to generate hot air at 130-135°C and sends it to the finished product process as one of the heat sources for drying melamine. The reactants enter the collector to cool down and desublimate naturally, and settle the captured melamine to be refined; The circulating gas from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com